Page 1

GENERAL

R8182D,E,F,H,J Combination

Protectorelay™ and Hydronic

Heating Controls

PRODUCT DATA

FEATURES

• Depending on model, these single unit devices provide

combinations of high limit, low limit, and circulator

control.

• All models use a 24V thermostat and C554A Cadmium

Sulfide Flame Detector.

• R8182D,E,H and J have auxiliary terminals ZC and ZR

for circulator zone control. Additional zones require a

separate 24V thermostat and R845 Relay.

• All models have capability for zone control with zone

valves. Each additional zone requires a separate 24V

thermostat and a V8043 or V8044 Zone Valve.

• Ideal for packaged boiler systems requiring compact,

multipurpose controls.

• R8182D,E,F mode

• R8182H,J models mount on a 4 x 4 inch junction box,

and have a 5 ft (1.5m) armored capillary for remote

sensor location.

• Aquastat® Controller section is field replaceable.

• Oil burner circuit includes an improved safety shutoff

in the event the burner fails to start.

• Flame failure during the running cycle results in a

45 second attempt to restart. If unsuccessful, safety

shutoff occurs, requiring manual reset before burner

can be restarted.

The R8182 is a combination Protectorelay™ intermittent

ignition oil burner primary and immersion type Aquastat®

controller for oil-fired, hydronic heating systems.

® U.S. Registered Trademark

Copyright © 2002 Honeywell • All Rights Reserved

Contents

General ............................................................................. 1

Features ........................................................................... 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 5

Wiring ............................................................................... 7

Operation .......................................................................... 12

Startup and Checkout ....................................................... 14

68- 0105- 2

Page 2

R8182D,E,F,H,J COMBINATION PROTECTORELAY™ AND HYDRONIC HEATING CONTROLS

SPECIFICATIONS

IMPORTANT

The specifications given in this publication do not

include normal manufacturing tolerances. Therefore,

this unit may not exactly match the listed

specifications. Also, this product is tested and

calibrated under closely controlled conditions, and

some minor differences in performance can be

expected if those conditions are changed.

TRADELINE® Models: TRADELINE® models are selected

and packaged for ease of handling, ease of stocking, and

maximum replacement value. TRADELINE® model

specifications are the same as those of standard models

except as noted below.

TRADELINE® Models Available:

R8182D Combination Protectorelay™ Primary Control and

Aquastat® Controller.

Table 1. Standard Models:

Model Switching

R8182D

R8182E

R8182F High Limit, Spst 130 to 240 54 to 116 10 Fixed 6 Fixed

R8182Ha Remote Bulb

R8182J

a

a

a

a

Remote Bulb

Auxiliary ZC and ZR terminals can be used to provide circulator zone control through an R845A Switching Relay.

High Limit, Spst 130 to 240 54 to 116 10 Fixed 6 Fixed

High Limit/Circulator, Spdt 110 to 220 43 to 104 10 to 25 Adj 6 to 14 Adj

High Limit, Spst 180 to 240 82 to 116 15 Fixed 8 Fixed

Circulator, Spst 110 to 220 43 to 104 10 Fixed 6 Fixed

High Limit, Spst 130 to 240 54 to 116 10 Fixed 6 Fixed

Low Limit/Circulator, Spdt 110 to 220 43 to 104 10 to 25 Adj 6 to 14 Adj

High Limit, Spst 180 to 240 82 to 116 15 Fixed 8 Fixed

R8182H Combination Protectorelay™ Primary Control and

Aquastat® Controller.

Additional Features:

• Well not included. To order wells or well adapters, refer to

form 68-0040, Wells and Fittings for Temperature

Controllers, for part numbers and descriptions.

• Heat-conductive compound supplied for better bulb

response in oversized well.

• Field addable stops for Aquastat® Controller.

• Conversion to R8182E or F.

• TRADELINE® pack with special instructions.

•Wire nut.

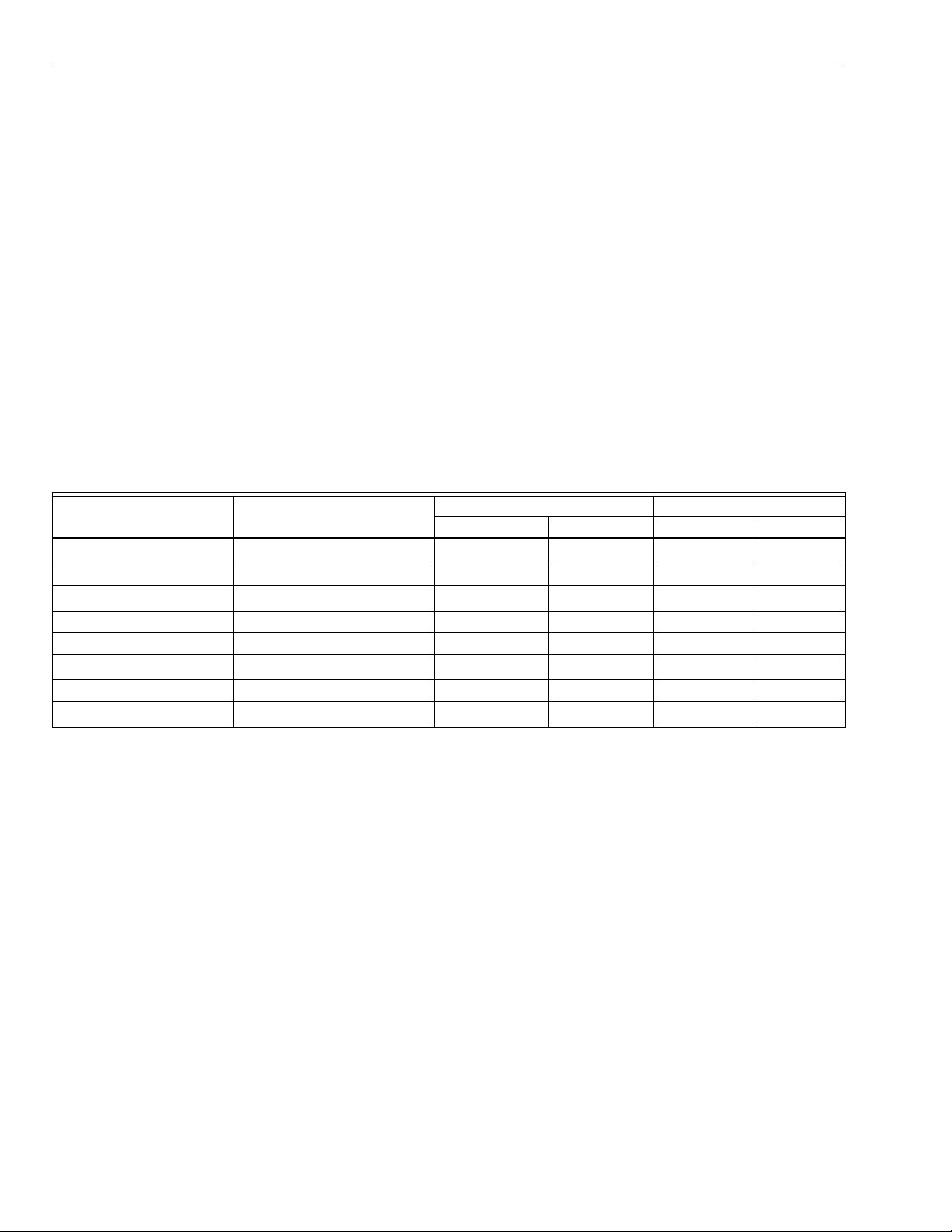

Mounting Means:

R8182D,E,F: Case clamps to horizontal immersion well

installed through boiler wall.

R8182H,J: Mounts on standard 4 x 4 inch junction box.

Dimensions: Refer to Fig. 1 and 2.

Adjustable Control Range Differential

°F °C °F °C

Electrical Ratings:

Power Supply: 120 Vac, 60 Hz.

Ignition: 360 VA in addition to motor load rating.

Maximum Power Consumption:

R8182D,E,H and J: 9W.

R89182F: 5.5W.

Burner Circulator Contact Rating: 4.4A full load; 26.4A locked

rotor at 120 Vac.

Safety Switch Timing: Approximately 45 seconds.

Flame Detector Required: C554A Cadmium Sulfide Flame

Detector (ordered separately).

Thermostat Required: 24V, 2-wire thermostat such as the

T87F.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Home and Building Control Sales Office (check white pages of your phone directory).

2. Home and Building Control Customer Relations

Honeywell, 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

68-0105—2 2

Page 3

7

-1/8

(

)

E

181)

3-9/16

(91)

1-5/16

(33)

KNOCKOUTS

FOR 1/2 IN.

(13 MM)

CONDUIT (5)

2-7/16

(62)

R8182D,E,F,H,J COMBINATION PROTECTORELAY™ AND HYDRONIC HEATING CONTROLS

KNOCKOUTS

FOR 1/2 IN. (13 MM

CONDUIT (5)

3-3/8 (86)

VERTICAL

MOUNT

ONLY

HORIZONTIAL

MOUNT ONLY

1

1/2 (13)

7-1/8

(181)

7/8

(22)

3-7/16

(87)

1

3/16

(5)

1 VERTICAL MOUNT SHOWN.

5-1/4 (133)

3-1/4 (83)

M4517

Fig. 1. R8182D,E,F installation dimensions in in. (mm).

Thermostat Anticipator Setting: 0.2A for R8182, 0.4A for

each R845A Switching Relay used.

Maximum Ambient Temperature (at Element): 250°F

(121°C).

Maximum Pressure Rating:

200 psi (1379 kPa) on immersion well.

100 psi (689.5 kPa) direct immersion.

Internal Views: Refer to Fig. 4 through 8.

Well Insertion Length: 3-3/8 in. (86 mm).

Immersion Well Dimensions (Order Well Separately):

Refer to Fig. 3.

Aquastat® Assembly Repair Parts: 125026AAE Aquastat®

Assembly: Replaces R8182D,F Sensing Bulb.

Replacement Well Assemblies: Refer to form 68-0040,

Wells and Fittings for Temperature Controllers, for part

numbers and descriptions.

5-1/4 (133)

1 SIDE MOUNTED HINGE SHOWN.

3-7/16 (87)

M4518

Fig. 2. R8182H,J installation dimensions in in. (mm).

R8182D,E,F

CONTROL MOUNT

INSULATION LENGTH

1-1/2 OR 3 IN.

(38 OR 76 MM)

R8182H,J

SETSCREW

INSULATION LENGTH

1-1/2 IN. (38 MM)

FITS BOILER TAPPED HOLE

1/2 OR 3/4 NPT

INSERTION LENGTH

3-3/8 IN. (86 MM)

FITS BOILER TAPPED HOL

1/2 OR 3/4 NPT

INSERTION LENGTH

3-3/8 IN. (86 MM)

M4530

Fig. 3. Approximate immersion well dimensions.

Device Description Part Number

R8182D 1-1/2 in. (38 mm) insulation, horizontal or vertical; 3 in. (76 mm) insulation horizontal. 125026AAD

3 in. (76 mm) insulation, vertical. 1250266AAE

R8182E 1-1/2 in. (38 mm) insulation, horizontal or vertical; 3 in. (76 mm) insulation horizontal. 123726AV

3 in. (76 mm) insulation, vertical. 123726AW

3 68-0105—2

Page 4

R8182D,E,F,H,J COMBINATION PROTECTORELAY™ AND HYDRONIC HEATING CONTROLS

R

T

H

R

Device Description Part Number

R8182F 1-1/2 in. (38 mm) insulation, horizontal or vertical; 3 in. (76 mm) insulation horizontal. 125017AAB

3 in. (76 mm) insulation, vertical. 125017AAC

R8182H 1-1/2 in. (38 mm) insulation. 125026AAJ

R8182J 123726AT

Dial Stop: For restricting range, part no. 4074BRR for

R8182D,F,H.

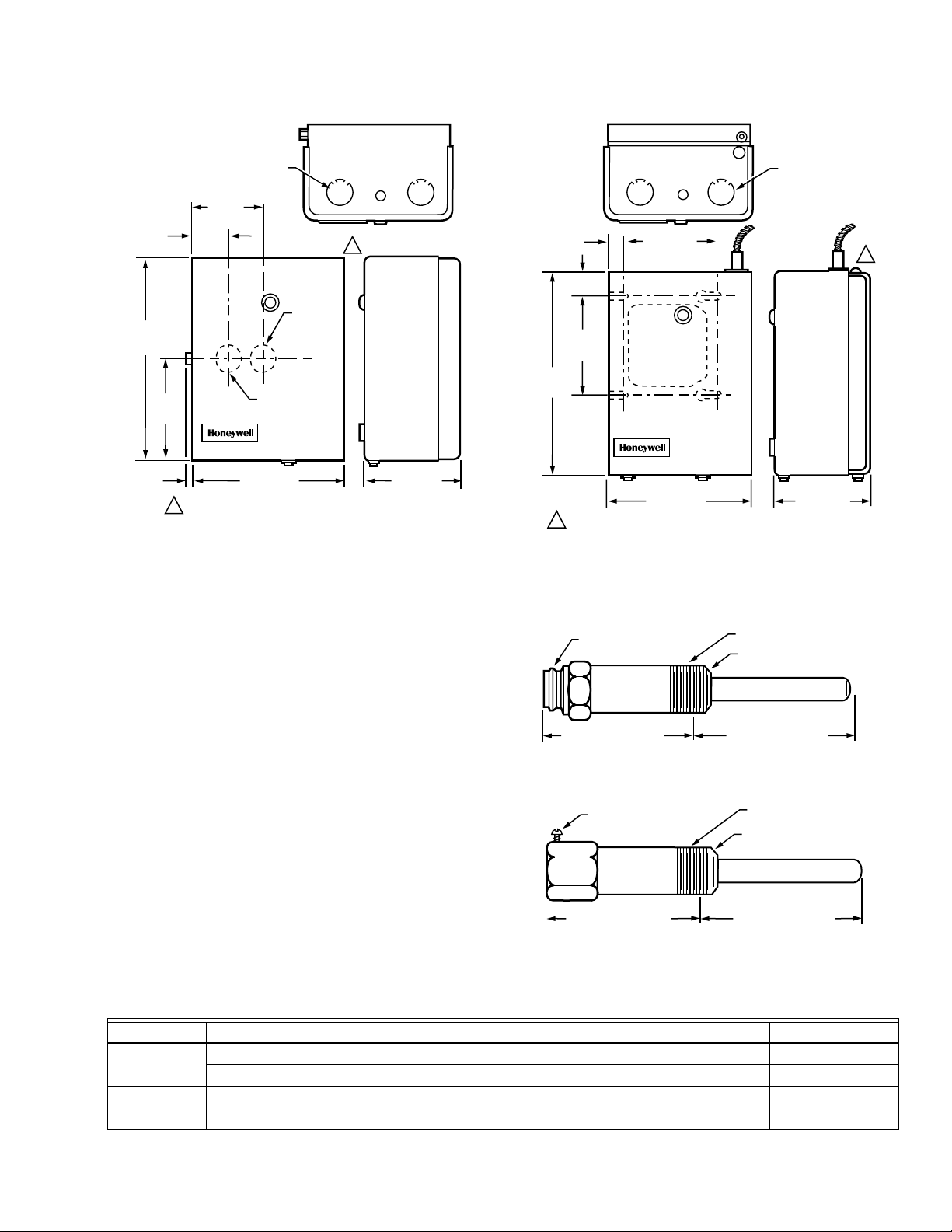

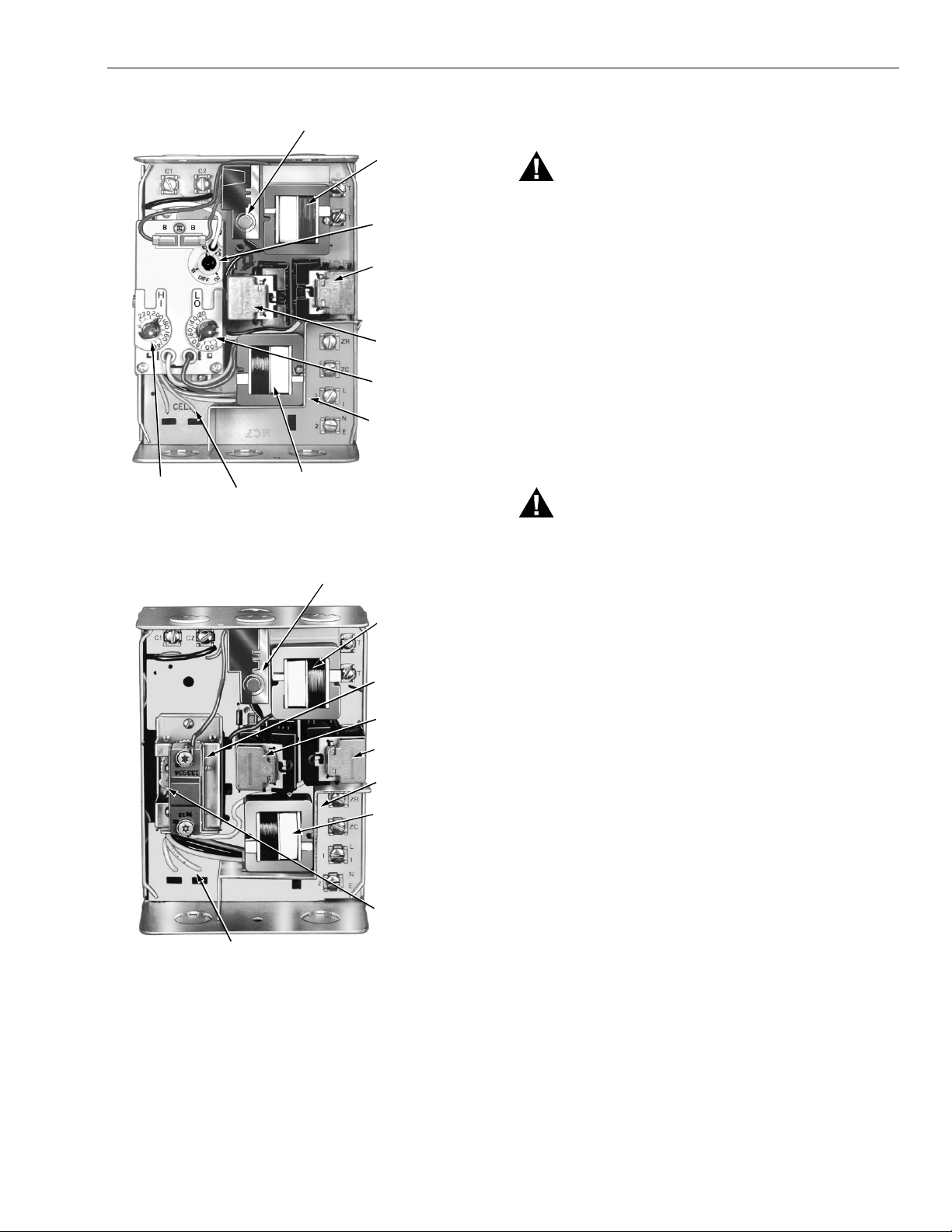

GROUNDING SCREW

SAFETY SWITCH

RESET BUTTON

Optional Specifications:

R8182D,E,F: Case with long dimension horizontal.

R8182H,J: End mounted hinge.

SAFETY SWITCH

GROUNDING SCREW

RESET BUTTON

TRANSFORMER

FOR THERMOSTA

CIRCUIT

DIFFERENTIAL

SETTING

CIRCULATOR

RELAY (1K)

TRANSFORMER

FOR THERMOSTAT

CIRCUIT

AQUASTAT SWITC

CIRCULATOR

RELAY (1K)

BURNER MOTOR

AND IGNITION

RELAY (2K)

BURNER MOTOR

AND IGNITION

RELAY (2K)

LOW LIMIT

SETTING

VOLTAGE BARRIE

HIGH LIMIT

SETTING

TRANSFORMER FOR

CAD CELL CIRCUIT

Fig. 4. Internal view of R8182D.

M4525

HIGH LIMIT

SETTING

TRANSFORMER FOR

CAD CELL CIRCUIT

Fig. 5. Internal view of R8182E.

GROUNDING SCREW

BURNER MOTOR

AND IGNITION

RELAY (2K)

LOW LIMIT

SETTING

TRANSFORMER FOR

CAD CELL CIRCUIT

VOLTAGE BARRIER

M4532

SAFETY SWITCH

RESET BUTTON

HIGH LIMIT

SETTING

VOLTAGE BARRIE

M4515

68-0105—2 4

Fig. 6. Internal view of R8182F.

Page 5

R8182D,E,F,H,J COMBINATION PROTECTORELAY™ AND HYDRONIC HEATING CONTROLS

T

H

R

T

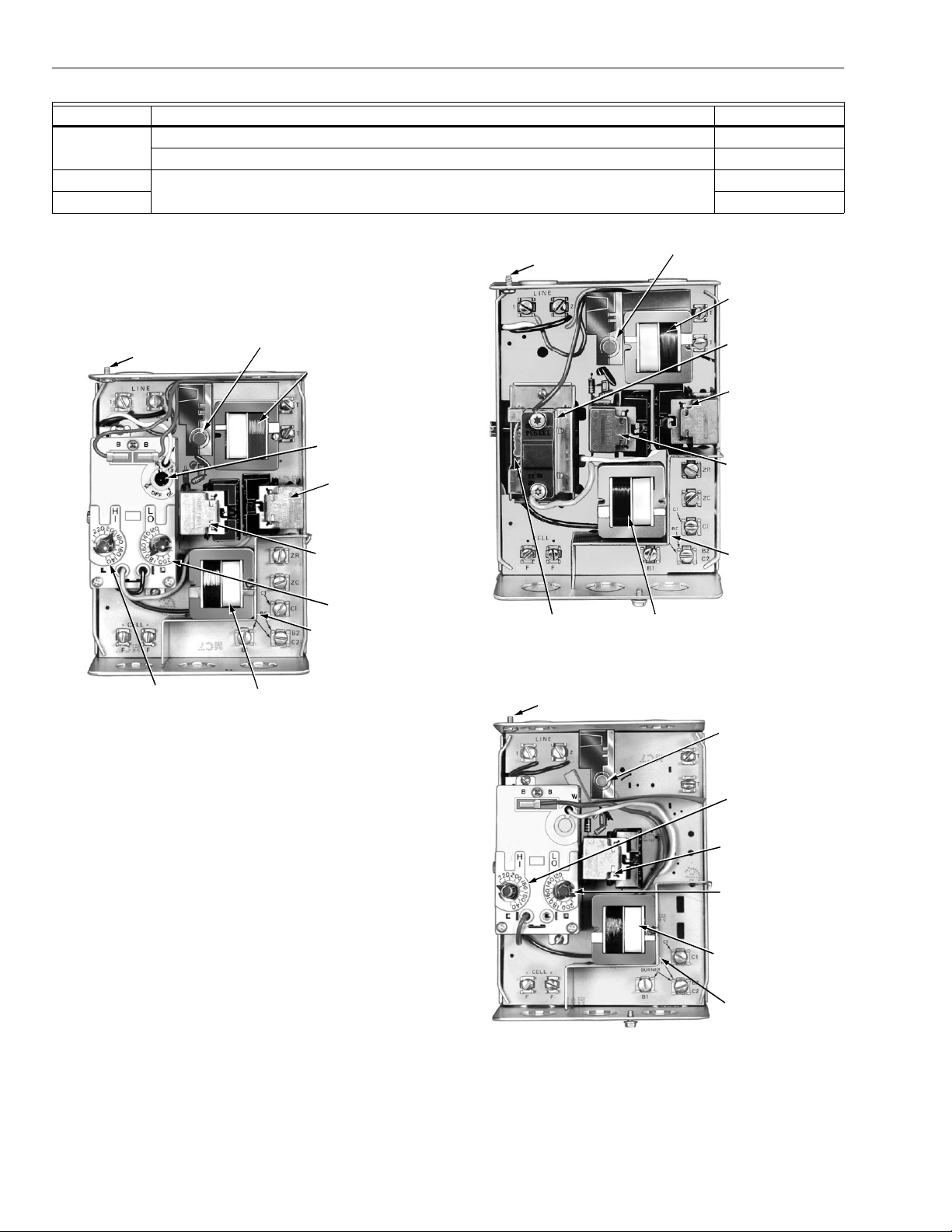

SAFETY SWITCH

RESET BUTTON

HIGH LIMIT

SETTING

CAD CELL

LEADS (YELLOW)

TRANSFORMER FOR

CAD CELL CIRCUIT

Fig. 7. Internal view of R8182H.

TRANSFORMER

FOR THERMOSTA

CIRCUIT

DIFFERENTIAL

SETTING

CIRCULATOR

RELAY (1K)

BURNER MOTOR

AND IGNITION

RELAY (2K)

LOW LIMIT

SETTING

VOLTAGE BARRIER

SAFETY SWITCH

RESET BUTTON

TRANSFORMER

FOR THERMOSTA

CIRCUIT

AQUASTAT SWITC

M4524

INSTALLATION

WARNING

Explosion Hazard.

Can cause severe injury, death or property

damage.

This product is intended for use only in systems with a

pressure relief valve.

When Installing this Product…

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check the ratings given in these instructions and on the

product to be sure the product is suitable for your

application.

3. The installer must be a trained, experienced service

technician.

4. After completing installation, use these instructions to

check product operation.

WARNING

Explosion or Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

1. Disconnect the power supply before beginning

installation to prevent electrical shock or equipment

damage.

2. Be sure that combustion chamber is clear of oil or

oil vapor before starting burner.

3. Be sure that the ambient temperature at the

element will not exceed 250°F (121°C).

2K RELAY

1K RELAY

VOLTAGE BARRIE

TRANSFORMER

FOR CAD CELL

CIRCUIT

CAD CELL LEADS (YELLOW)

HIGH LIMIT

SETTING

Fig. 8. Internal view of R8182J.

M4531

IMPORTANT

Be sure that the sensing bulb fits snugly inside the

immersion well and that the sensing bulb rests

against the bottom of the immersion well. Refer to

Fig. 9.

Mounting the R8182

1. Disconnect the power supply.

2. Drain all water from the boiler.

3. Generally, boilers are equipped with a tapping that

allows horizontal mounting of the immersion well where

average temperature boiler water circulates freely. If no

tapping is provided, prepare one.

4. Install the immersion well or compression fitting

(ordered separately) by threading the immersion well

into the tapped hole.

5. For R8182D,E,F models:

a. Loosen the immersion well clamp screw on the side

of the R8182 case.

b. Insert the bulb into the immersion well until it

bottoms.

c. If necessary, bend the capillary tube to hold the bulb

against the bottom of the immersion well.

5 68-0105—2

Page 6

R8182D,E,F,H,J COMBINATION PROTECTORELAY™ AND HYDRONIC HEATING CONTROLS

NOTE: Do not make sharp bends in the tubing. A sharp

bend can break the tubing and cause a loss of fill. In

models with an adjustable tubing length, pull the

extra tubing out of the controller case.

d. Fit the controller case onto the immersion well so

that the immersion well clamp slides over the flange

of the immersion well.

e. Securely tighten the immersion well clamp screw.

6. For R8182H,J models:

a. Loosen the screw holding the hinged backplate to

the controller case and swing the backplate away

from the controller case.

b. Screw the backplate to a 4 by 4 inch junction box.

c. Insert the bulb into the immersion well until it

bottoms.

d. If necessary, bend the capillary tube to hold the bulb

against the bottom of the immersion well.

NOTE: Do not make sharp bends in the tubing. A sharp

bend can break the tubing and cause a loss of fill. In

models with an adjustable tubing length, pull the

extra tubing out of the controller case.

e. Tighten the immersion well screw over the brass

collar.

f. After wiring, swing control against the backplate and

refasten with the screw.

7. Refill the boiler and check for water leakage.

Mounting the R8182D TRADELINE®

If the existing immersion well does not fit the R8182D

immersion well clamp, use a 1249094 immersion well adapter

(order separately; see form 68-0040, Wells and Fittings for

Temperature Controllers).

1. Disconnect the power supply.

2. Drain all water from the boiler.

3. Fasten the R8182D immersion well clamp to the flange

on the immersion well adapter. Refer to Fig. 9.

4. Place the adapter on the capillary tube.

5. Put the adapter end into the hole in the controller case

and tighten the clamp screw.

6. Insert the sensing bulb into the immersion well and

bend the capillary tubing, if necessary, to hold the

sensing bulb against the bottom of the immersion well.

NOTE: Do not make sharp turns while bending the capillary

tubing. In models with an adjustable tubing length,

pull the extra tubing out of the controller case.

7. Apply the heat-conductive compound into the

immersion well (if necessary).

a. Fold the plastic bag of heat-conductive compound

lengthwise and twist it gently.

b. Cut off the end of the plastic bag and work the open

end of the bag all the way into the immersion well.

c. Slowly pull the bag out of the immersion well while

squeezing it firmly to evenly distribute the

heat-conductive compound.

8. Wipe off any excess grease and tighten the set screw

against the adapter.

If the existing immersion well is not usable, remove the

existing immersion well and order a new one using form

68-0040, Wells and Fittings for Temperature Controllers.

1. Disconnect the power supply.

2. Drain all water from the boiler.

3. Install the new immersion well by threading it into the

threaded hole.

4. Loosen the immersion well clamp screw. See Fig. 9.

5. Insert the sensing bulb into the immersion well and

bend the capillary tubing, if necessary, to hold the

sensing bulb against the bottom of the immersion well.

NOTE: Do not make sharp turns while bending the capillary

tubing. In models with an adjustable tubing length,

pull the extra tubing out of the controller case.

6. Apply heat-conductive compound into the immersion

well (if necessary).

a. Fold the plastic bag of heat-conductive compound

lengthwise and twist it gently.

b. Cut off the end of the plastic bag and work the open

end of the bag all the way into the immersion well.

c. Slowly pull the bag out of the immersion well while

squeezing it firmly to evenly distribute the

heat-conductive compound.

7. Be sure the immersion well fits the hole in the controller

case.

8. Position the immersion well clamp snugly over the

immersion well flange. Securely tighten the clamp

screw.

9. Refill the boiler and check for water leakage.

68-0105—2 6

Page 7

R8182D,E,F,H,J COMBINATION PROTECTORELAY™ AND HYDRONIC HEATING CONTROLS

(

).

0

C)

2

WIRING

IMPORTANT

Use Underwriters Laboratories Inc. listed connectors

when making external circuit connections to the

orange and white line voltage burner and ignition

leadwires of the R8182H,J.

CONTROLLER

CASE

IMMERSION

WELL CLAMP

ADAPTER

CAPILLARY

TUBE

SETSCREW

IMMERSION

WELL CLAMP SCREW

BACK OF

CONTROLLER

CASE

IMMERSION

OLD IMMERSION

WELL ASSEMBLY

HEAT-CONDUCTIVE COMPOUND

1

BEND THE CAPILLARY TUBE TO HOLD THE SENSING BULB IN GOOD

THERMAL CONTACT WITH THE IMMERSION WELL AT POINTS (A) AND (B).

2

ASSURE THAT CAPILLARY TUBE FITS FREELY IN THE ADAPTER SO THE

TENSION OF THE CAPILLARY TUBE AT POINT (C) HOLDS THE SENSING

BULB IN GOOD THERMAL CONTACT WITH THE IMMERSION WELL AT POINT (D

WELL CLAMP

SCREW

IMMERSION

WELL SPUD

BOILER

1

SHORT TUBE

FITS IN CENTRAL

RECESS OF ADAPTER

(A)

Fig. 9. Positioning the sensing bulb in the immersion well.

Method 1

1. Strip 7/16 in. of insulation from the wire end.

2. Wrap the wire 3/4 of the distance around the screw as

shown in method 1.

3. Using a standard, flat-headed screwdriver, tighten the

screw until the wipe is snugly in contact with the screw

and contact plate.

4. Tighten the screw pin an additional one-half turn.

ADAPTER

IMMERSION

WELL CLAMP

SENSING

BULB

(D)

(B)

M883

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect power supply before wiring to prevent

electrical shock or equipment damage.

Method 2

1. Strip 5/16 in. of insulation from the wire end.

2. Insert wire beneath the screw as shown in method 2.

3. Using a standard, flat-heat screwdriver, tighten the

screw until the wire is snugly in contact with the screw

and contact plate.

4. Tighten the screw an additional one-half turn.

All wiring must comply with local codes, regulations, and

ordinances.

IMPORTANT

Terminals on the R8182 are approved for copper

wire only.

NOTE: Do not use a push-type ratchet screwdriver.

The TRADELINE® R8182D,H can be converted to replace an

R8182B,C,E,F or a White Rodgers 6C92-2 or 6C92-3. When

replacing a White Rodgers model, the immersion well must

also be replaced. Refer to Fig. 10 for Aquastat® limit

Follow the wiring instructions furnished by the appliance

connections necessary for each R8182D conversion.

manufacturer, if available, or refer to Fig. 11 through 17. For

wiring multiple zoning systems, refer to Fig. 16 and 17.

To release the wires from the R8182, insert a screwdriver into

the rectangular hole adjacent to the wire, push inward to

The R8182 is equipped with special wiring terminals. Wires

can be wrapped around the terminal screw or inserted from

release the locking-grip on the wire, and pull the wire out of

the terminal hole.

the side.

To reinsert the wire into a new terminal hole, simply push the

wire into the new slot.

7 68-0105—2

Page 8

R8182D,E,F,H,J COMBINATION PROTECTORELAY™ AND HYDRONIC HEATING CONTROLS

2

C

W

R

R

USING THE TRADELINE® R8182D

TO REPLACE R8182F:

1. REMOVE BLUE WIRE FROM

THIS TERMINAL AND INSULATE

END TO PREVENT CONTACT.

2. REMOVE OTHER BLUE WIRE

FROM THIS TERMINAL AND

CONNECT AS SHOWN BELOW.

3. CONNECT CIRCULATOR TO

ZC AND C2.

BLUE

OMPLETED

IRING TO

EPLACE

8182C,F

YELLOW

H

I

Fig. 10. Converting TRADELINE® R8182D,H to replace other controls.

L

O

BLACK

WHITE

USING THE TRADELINE® R8182D

TO REPLACE R8182B,E OR

WHITE RODGERS 6C92:

1. REMOVE WHITE ABD BLACK

LEADS FROM THEIR TERMINAL

AND CONNECT WITH A

SODDERLESS CONNECTOR.

TO USE TRADELINE® R8182H

TO REPLACE R8182J:

1. REMOVE RED AND WHITE

LEADS FROM THEIR TERMINALS

AND CONNECT WITH A

SOLDERLESS CONNECTOR.

L

H

O

I

YELLOW

BLUEBLUE

COMPLETED WIRING

TO REPLACE

R8182B,E AND

WHITE RODGERS 6C9

BLACK

OR RED

M4526

68-0105—2 8

Page 9

R8182D,E,F,H,J COMBINATION PROTECTORELAY™ AND HYDRONIC HEATING CONTROLS

R

R

1

L1

L2

(HOT)

R8182D

4

1

G

24 VOLT

THERMOSTAT

120 VAC POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQUIRED.

WHEN THE BLACK AND WHITE WIRES ON THE TRADELINE® R8182D

2

AQUASTAT® CONTROLLER ASSEMBLY ARE DISCONNECTED FROM

THE CIRCULATOR SWITCH AND ARE INTERCONNECTED, LOW LIMIT

AND CIRCULATOR CONTROL ARE BYPASSED. CIRCULATOR

OPERATES WITHY THEROMSTAT ONLY.

3

TO REPLACE R8182C,F, REMOVE BLUE WIRE AND INSULATE END.

DISCONNECT THE THE OTHER BLUE WIRE AT 4 AND WIRE TO

AT 3. WHEN CIRCULATOR IS CONNECTED BETWEEN ZC AND C2,

LOW LIMIT FUNCTION IS REMOVED AND CIRCULATOR OPERATES

WITH CIRCULATOR CONTROL (R TO W) ONLY.

4

CONTROL CASE MUST BE CONNECTED TO EARTH GROUND.

USE GROUNDING SCREW PROVIDED.

Fig. 11. R8182D internal schematic and wiring diagram.

2

3

BLUE

ZR

1K2

BLUE

BLACK

4

B

LOW

LIMIT

R

W

CIRCULATOR

1K

BILATERAL

SWITCH

T T F F

C1

3

WHITE

SAFETY

SWITCH

HEATER

TRIAC

R2

C554A

HIGH LIMIT

B

ZC

2

2K2

1K1

2K1

B2

C2

C1

S.SW

CONTACTS

2K

TO OIL

B1R

BURNER

AND

IGNITION

TO WATER

CIRCULATO

R1

B

M4519

1

L1

L2

(HOT)

HIGH LIMIT

2K1

R8182E

2K2

B2

C2

C1

S.SW

CONTACTS

2K

R1

M4527

B1R

TO OIL

BURNER

AND

IGNITION

TO WATER

CIRCULATO

2

1

2

1

G

24 VOLT

THERMOSTAT

120 VAC POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

CONTROL CASE MUST BE CONNECTED TO EARTH GROUND.

USE GROUNDING SCREW PROVIDED.

2

1K2

ZR

ZC

1K

T T F F

C1

1K1

SAFETY

SWITCH

HEATER

TRIAC

BILATERAL

SWITCH

R2

C554A

B

Fig. 12. R8182E internal schematic and wiring diagram.

9 68-0105—2

Page 10

R8182D,E,F,H,J COMBINATION PROTECTORELAY™ AND HYDRONIC HEATING CONTROLS

2

T

R

R

1

L1

L2

(HOT)

2

SAFETY

SWITCH

CONTACTS

4 VOLT

HERMOSTAT

1

2

1

G

T

T

120 VAC POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

CONTROL CASE MUST BE CONNECTED TO EARTH GROUND.

USE GROUNDING SCREW PROVIDED.

2

JUMPER

R

HIGH

LIMIT

B

2K2

2K1

SAFETY

SWITCH

HEATER

2K

R1

BILATERAL

SWITCH

F F

C554A

R

CIRCULATOR

CONTROL

TRIAC

R2 C1

R8182F

W

C1

C2

B2

B1

TO WATER

CIRCULATO

TO

BURNER

AND

IGNITION

M4528

Fig. 13. R8182F internal schematic and wiring diagram.

1

L1

L2

(HOT)

R8182H

1

2

1K2

1K

T T

24 VOLT

THERMOSTAT

120 VAC POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQUIRED.

ZR

B

LOW

LIMIT

R

CIRCULATOR

C1

YELLOW

W

BILATERAL

SWITCH

SAFETY

SWITCH

HEATER

TRIAC

R2

C554A

HIGH LIMIT

B

ZC

2K2

R

1K1

S.SW

CONTACTS

2K

2K1

ORANGE

WHITE

C1

C2

R1

YELLOW

M4520

TO OIL

BURNER

AND

IGNITION

TO WATER

CIRCULATO

Fig. 14. R8182H internal schematic and wiring diagram.

68-0105—2 10

Page 11

R8182D,E,F,H,J COMBINATION PROTECTORELAY™ AND HYDRONIC HEATING CONTROLS

R

N

1

L1

L2

(HOT)

R8182J

1

2

1K2

1K

T T F F

24 VOLT

THERMOSTAT

120 VAC POWER SUPPLY. PROVIDE DISCONNECT MEANS

1

AND OVERLOAD PROTECTION AS REQUIRED.

ZR

ZC

C1

YELLOW

HIGH LIMIT

B

SAFETY

SWITCH

HEATER

TRIAC

BILATERAL

SWITCH

R

R2

C554A

2K1

2K2

1K1

ORANGE

WHITE

C1

C2

S.SW

CONTACTS

2K

R1

YELLOW

M4529

TO OIL

BURNER

AND

IGNITION

TO WATER

CIRCULATO

Fig. 15. R8182J internal schematic and wiring diagram.

24 VOLT

THERMOSTAT

YELLOW

5 5 5

RED

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

2

R8182H AND J HAVE WHITE AND ORANGE LEADWIRES FOR OIL

BURNER AND IGNITION CONNECTIONS.

3

RED LEADWIRES PROVIDED ONLY ON MODLES WITH END SWITCH.

CHOOSE AT72, AT87, OR AT88 TRANSFORMER TO MATCH

4

MAXIMUM SYSTEM LOAD.

5

USE V8043 OR V8044 ZONE VALVES WITH AUXILIARY END

SWITCH ONLY.

YELLOW

RED

24 VOLT

THERMOSTAT

YELLOW

YELLOW

RED

RED

24 VOLT

THERMOSTAT

YELLOW

YELLOW

RED

333

RED

4

L1 L2

T

B1

T

B2

C2

C1

CIRCULATOR

Fig. 16. R8182D,E,F,H and J in a typical zoning

application using zone valves.

L1

(HOT)

L2

2

1

TO OIL

BURNER

AND

IGNITIO

M4522

11 68-0105—2

Page 12

R8182D,E,F,H,J COMBINATION PROTECTORELAY™ AND HYDRONIC HEATING CONTROLS

R

L1

L2

6

ZONE 2

THERMOSTAT

3

120 VAC POWER SUPPLY. PROVIDE DISCONNECT

1

MEANS AND OVERLOAD PROTECTION AS REQUIRED.

THERMOSTAT HEAT ANTICIPATOR SETTING, 0.2 AMP FOR R8182D.

2

THERMOSTAT HEAT ANTICIPATOR SETTING, 0.4 AMP FOR R845A.

3

4

CONTROL CASE MUST BE CONNECTED TO EARTH

GROUND. USE GROUNDING SCREW PROVIDED.

R8182E,H,J CONNECTIONS FROM ZC AND ZR ARE IDENTICAL

5

FOR MULTIPLE CIRULATOR ZONING APPLICAITON.

EACH ADDITIONAL ZONE REQUIRES A SEPARATE,

6

FIELD-ADDED 24V THERMOSTAT AND R845 RELAY.

R845A

SWITCHING

RELAY ZONE 2

1K

T

T

1

5 3

1K1

2

6 4

ZONE 2

CIRCULATOR

1K2

TO ADDITIONAL

ZONES 3, 4, ETC.

24 VOLT

THERMOSTAT

(HOT)

1

G

4

T T F F

2

1

2

1K2

1K

BLUE

ZR

B

LOW

LIMIT

R

CIRCULATOR

BILATERAL

SWITCH

C1

HIGH LIMIT

B

W

SAFETY

SWITCH

HEATER

TRIAC

R2

ZC

5

2K2

C554A

R8182D

2K1

B2

C2

1K1

S.SW

CONTACTS

2K

R1

B1R

C1

TO OIL

BURNER

AND

IGNITION

TO WATER

CIRCULATO

M4521

Fig. 17. R8182D and R845A in a typical multiple circulator zoning application.

OPERATION

R8182D

A call for heat by the thermostat pulls in relay 1K, which

energizes the safety switch circuit and relay 2K to turn on the

burner. Safety switch starts to heat. If burner ignites within

safety switch timing, the cadmium sulfide flame detector sees

flame and the safety switch heater circuit is bypassed. The

burner operates until the call for heat is satisfied. The

circulator operates when relay 1K pulls in only if R to W is

made in the Aquastat¨ limit.

When R to B (low limit) is made by a drop in water

temperature, it acts as a call for heat, pulling in relay 2K to

turn on the burner. The circulator cannot operate. See Fig. 11,

16, 17 and 19.

R8182E

The burner and circulator operate whenever the thermostat

calls for heat. Relay 2K pulls in. When the cadmium sulfide

flame detector sees flame, the safety switch heater circuit is

bypassed, and 2K is held in through 2K1. If temperature rises

to a high limit setpoint, R to B breaks, shutting off the burner.

The circulator continues operation under the thermostat

direction. See Fig. 12, 16, 17 and 20.

R8182F

The thermostat call for heat pulls in relay 2K to turn on the

burner. When the cadmium sulfide the flame detector sees

flame, safety switch the heater circuit is bypassed. The

circulator is independent of the thermostat circuit, being

controlled only by the Aquastat¨ limit switch. See Fig. 13, 17

and 20.

R8182H

A call for heat by the thermostat pulls in relay 1K, which

energizes the safety switch circuit and relay 2K to turn on the

burner. The safety switch starts to heat. If the burner ignites

within the safety switch timing, the cadmium sulfide flame

detector sees the flame and the safety switch heater circuit is

bypassed. The burner shuts Off when a call for heat is

satisfied. The circulator operates when relay 1K pulls in only if

R to W in the Aquastat¨ limit is made.

When R to B (low limit) is made by a drop in water

temperature, it acts as a call for heat, pulling in relay 2K to

turn on the burner. The circulator cannot operate. See Fig. 14,

16, 17 and 18.

68-0105—2 12

Page 13

R8182D,E,F,H,J COMBINATION PROTECTORELAY™ AND HYDRONIC HEATING CONTROLS

H

S

A

S

H

S

R8182J

The burner and circulator operate whenever the thermostat

calls for heat. Relay 2K pulls in. When the cadmium sulfide

flame detector sees flame, the safety switch heater circuit is

bypassed, and 2K is held in through 2K1. If temperature rises

to a high limit setpoint, R to B breaks, shutting off the burner.

The circulator continues operation under direction of the

thermostat. See Fig. 15, 16, 17 and 19.

Multizone Control

In all multizone applications, a call for heat in any zone

energizes the safety switch circuit and relay 2K pulls in. If the

burner ignites within the safety switch timing, the cadmium

sulfide flame detector sees flame and the safety switch heater

is bypassed.

In all multizone applications with R8182D and H, the low limit

control in the Aquastat® limit acts independently to turn on the

main burner on a drop in water temperature. When R to B (low

limit) is made, relay 2K pulls in to turn on the main burner, the

same as for single-zone application.

Zone Circulator Control with R8182D,H

The relay for each zone is connected to the Aquastat® limit

through terminals ZC and ZR. The R845 Relay and

thermostat for each zone can energize the zone circulator

through ZC only if R to W in the Aquastat® limit is made. If

R to B (high limit) is made, the zone thermostat energizes the

burner through ZR.

Zone Circulator Control with R8182E,J

The relay for each zone is connected to the Aquastat® limit

through terminals ZC and ZR. The R845A Relay and

thermostat in each zone can energize the zone circulator

through ZC on a call for heat. If R to B (high limit) is made, the

zone thermostat energizes the burner through ZR.

Zone Valve Control with R8182

The valve for each zone is connected to the Aquastat® limit

by wiring end switches on the zone valve to T-T on the R8182.

On a call for heat from any zone, the R8182 operates the

same as for single zone applications.

SWITCH BREAKS ON

TEMPERATURE RISE.

BURNER TURNS OFF.

IGH LIMIT

ETTING

LOW LIMIT

AND

CIRCULATOR

SETTING

1

WHEN WATER REACHES PROPER TEMPERATURE, THE BURNER

SHUTS OFF OR THE CIRCULATOR PUMP STARTS (WHEN CALLING

FOR HEAT).

CIRCULATOR OPERATES

ON A CALL FOR HEAT.

SWITCH MAKES ON

TEMPERATURE FALL.

BURNER OPERATES ON

CALL FOR HEAT.

SWITCH MAKES R-W

AND BREAKS R-B ON

TEMPERATURE RISE.

SWITCH MAKES R-W

AND BREAKS R-B ON

TEMPERATURE RISE.

SWITCH MAKES R-B AND

BREAKS R-W ON

TEMPERATURE FALL.

BURNER IS ON TO

MAINTAIN MINIMUM

WATER TEMPERATURE.

CIRCULATOR IS OFF.

Fig. 18. R8182D,H Aquastat® limit switching.

240°F (116°C)

R-B BREAKS ON

TEMPERATURE RISE.

IGH LIMIT

ETTING

15°F (8°C)

DIFFERENTIAL

180°F (82°C)

BURNER TURNS OFF.

CIRCULATOR OPERATE

ON A CALL FOR HEAT.

R-B MAKES ON

TEMPERATURE FALL.

BURNER AND

CIRCULATOR OPERATE

ON A CALL FOR HEAT.

Fig. 19. R8182E,J Aquastat® limit switching.

1

M1523

M1510

13 68-0105—2

Page 14

R8182D,E,F,H,J COMBINATION PROTECTORELAY™ AND HYDRONIC HEATING CONTROLS

C

S

H

S

.

.

Low Limit/Circulator Setting—D And H

240°F (116°C)

IGH LIMIT

ETTING

IRCULATOR

ETTING

10°F (6°C)

DIFFERENTIAL

10°F (6°C)

DIFFERENTIAL

110°F (43°C)

R-B BREAKS ON

TEMPERATURE RISE.

BURNER TURNS OFF.

R-B MAKES ON

TEMPERATURE FALL.

BURNER OPERATES

ON CALL FOR HEAT.

R-W MAKES ON

TEMPERATURE RISE.

CIRCULATOR TURNS ON

R-B BREAKS ON

TEMPERATURE FALL.

CIRCULATOR TURNS OFF

Fig. 20. R8182F Aquastat® limit switching.

M1509

Models

On a temperature rise, with the adjustable differential at the

minimum setting of 10°F (6°C), the burner circuit (R-B) breaks

and the circulator circuit (R-W) makes at the low limit setpoint.

See Fig. 19. On a temperature drop of 10°F (6°C) below the

setpoint, the R-B circuit makes and the R-W circuit breaks.

At any differential setting greater than 10°F (6°C), the R-B

make temperature and R-W break temperature remains the

same— setting minus 10°F (6°C). The R-B break and R-W

make temperature are the setpoint temperature plus the

difference between the differential setting and 10°F (6°C).

EXAMPLE: Setpoint of 140°F (60°C); differential set at 25°F

(14°C). On a temperature rise, R-B breaks and R-W makes at

155°F (68°C). On a temperature fall, R-B makes and R-W

breaks at 130°F (54°C).

Set the low limit indicator at the minimum temperature

recommended for domestic hot water supply. This setting

must be at least 20°F (11°C) below the high limit setting to

prevent one switch from locking out the other.

Set the differential the desired number of degrees.

STARTUP AND CHECKOUT

Circulator Setting—F Models

Set the circulator indicator at the minimum water temperature

recommended for hydronic heating comfort.

WARNING

Explosion Hazard.

Can cause severe injury, death or property

damage.

This product is intended for use only in systems with a

pressure relief valve.

Because heating systems differ, the correct temperature

setting for one system may not be correct for another. Follow

the boiler manufacturers recommendations for proper

selection of settings.

High Limit Setting—All Models

The high limit opens and turns off the burner when the water

temperature reaches the setpoint. The high limit automatically

resets after the water temperature drops past the setpoint and

through the 10°F (6°C) [15°F (8°C) with R8182E,J] differential.

Set the indicator at the desired shutoff temperature.

Setting Stops (R8182D,H TRADELINE®)

Part no. 126580 Setting Stops can be installed on the low and

high limit adjusting knobs to prevent turning the knobs beyond

a predetermined point. To install the setting stops, proceed as

follows:

IMPORTANT

Once the setting stops are in place, they cannot be

replaced. If they must be removed, cut off with

cutters—do not twist off.

1. On low limit knob, turn the knob to the setting that is to

be established as the limit.

2. Place the setting stop over the knob so that the arm of

the setting stop (after the stop is pressed into place)

strikes projection A and prevents turning the knob

beyond the chosen limit setting. See Fig. 21.

3. Press the setting stop tightly onto the knob so its inner

teeth securely engage the knob.

4. Turn knob back and forth several times to make sure

stop functions properly.

5. Repeat steps 1 to 4 for the high limit knob.

After settings are made, replace the cover.

68-0105—2 14

Page 15

"

120

140

160

KNOB SET AT 140°F (60°C)

R8182D,E,F,H,J COMBINATION PROTECTORELAY™ AND HYDRONIC HEATING CONTROLS

Make certain the system operates as described in the

OPERATION section. Use the following procedure to verify

that the Protectorelay™ burner sequencing relay is controlling

properly.

1

180

200

STOP ARM

SETTING

PROJECTION "A

SETTING STOP

Flame Failure Check

Shut off the oil supply hand valve while the burner is on. After

45 seconds, the safety switch locks out, the motor stops, and

the oil valve closes. Allow five minutes for the burner to cool,

then manually reset the safety switch.

Ignition Failure Check

Test by closing the oil supply while the burner is off. Run

through the starting procedure but do not open the oil supply

line hand valve. The safety switch locks out as in flame failure.

Then turn the oil back on, and reset the safety switch.

1

SCALE MARKINGS IN FAHRENHEIT ONLY.

Fig. 21. Setting stop in position to restrict low limit setting

to 180°F (82°C) or lower.

M4523

Startup

WARNING

Explosion Hazard.

Can cause severe injury, death or property

damage.

Be sure combustion chamber is free of oil or vapor.

1. Push red reset button and release.

2. Open hand valve on oil supply line.

3. Set thermostat to call for heat.

4. Close line switch; burner will start.

5. Under normal conditions, burner operates until

thermostat is satisfied or line switch is opened.

MATERIAL SAFETY DATA SHEET (MSDS)

Power Failure Check

Turn off the power supply while the burner is on. When the

burner goes out, restore power and the burner will restart.

NOTE: If operation is not as described, see cover insert for

additional information and check wiring.

Aquastat® Controller Replacement

The Aquastat® limit section of the Protectorelay™ control is

field replaceable. When ordering a replacement assembly,

specify the complete model number of the R8182.

Replace the Aquastat® Limit

1. Disconnect power supply.

2. On all models—Note the position of the connecting

wires.

3. Remove fastening screws and wires.

4. Remove Aquastat® limit and install the new assembly.

SECTION 1. PRODUCT AND COMPANY IDENTIFICATION.

Product Name: Heat conductive compound.

MSDS ID: DS9021.

Synonyms: MS1699.

Product Use: Heat conductive material used to enhance

contact and heat transfer in temperature sensor applications.

15 68-0105—2

Manufacturer: Honeywell Inc., 1985 Douglas Drive North,

Minneapolis, MN 55422.

Date Released: October 8, 1999.

Emergency Telephone Information: 1-888-809-3787.

NFPA Ratings:

Health 0; Flammability 1; Reactivity 0; Personal Protection

B.

Page 16

R8182D,E,F,H,J COMBINATION PROTECTORELAY™ AND HYDRONIC HEATING CONTROLS

Section 2. Composition, Information on Ingredients (Table 3).

Table 2. Ingredients of Heat Conductive Compounda.

Ingredients CAS Number Percent PEL TLV

No. 2 Lithium Complex Grease (70%):

Mineral Oil 64742-65-0 35-50

Mineral Oil 64742-62-7 20-25

Lithium Hydrostearate/Sebacate Complex 68815-49-6 4-9 — —

Zinc Alkyldithiophosphate 68649-42-3 0-2 — —

Aluminum Paste (30%):

Aluminum, as Al 7429-90-5 20-25

Aliphatic Petroleum Distillates 8052-41-3 10-15

Stearic Acid 57-11-4 1-2 — —

Aromatic Petroleum Distillates 64742-95-6 1-2

a

Additional Information: Part No. 120650 (0.5 oz. tube); Part No. 107408 (4 oz. can); Part number 197007 (5 gallon container).

May also contain minute amounts of lithium and molybdenum lubricant compounds.

5 mg/m

5 mg/m

15 mg/m

2900 mg/m

5 mg/m

3

3

3

3

3

3

5 mg/m

3

5 mg/m

10 mg/m

525 mg/m

3

5 mg/m

3

3

Section 3. Hazard Identification

Acute Health Effects:

Skin—Excessive contact can cause skin irritation and

dermatitis.

Eye—Direct contact with eye will cause irritation.

Inhalation—No adverse effects are expected.

Ingestion—Ingestion of product may cause nausea, vomiting

and diarrhea.

Chronic Health Effects:

Existing skin rash or dermatitis may be aggravated by

repeated contact.

OSHA Hazard Classifications:

None.

Carcinogenicity:

Not considered to be a carcinogen by either OSHA, NTP,

IARC, or ACGIH.

Target Organs:

None known.

Section 4. First Aid Measures

Skin Contact:

Remove excess with cloth or paper. Wash thoroughly with

mild soap and water. Obtain medical attention if irritation

develops and persists.

Ingestion:

Contact physician or local poison control center immediately.

Inhalation:

Remove patient to fresh air and obtain medical attention if

symptoms develop.

Section 5. Fire Fighting Measures

Flash Point:

>383°F (195°C). Will burn if exposed to flame.

Extinguishing Media:

Carbon dioxide, dry chemical or foam.

Special Fire Fighting Procedures:

None.

Explosion Hazards:

None. Aluminum powder can react with water to release

flammable hydrogen gas. In the form of this product, this

reaction is not expected.

Eye Contact:

Flush eyes with water for 15 minutes. Remove any contact

lenses and continue to flush. Obtain medical attention if

irritation develops and persists.

68-0105—2 16

Section 6. Accidental Release Measures

Scrape up and dispose as solid waste in accordance with

state and federal regulations.

Section 7. Handling and Storage

Store in dry place. Keep container closed when not in use.

Page 17

R8182D,E,F,H,J COMBINATION PROTECTORELAY™ AND HYDRONIC HEATING CONTROLS

Section 8. Exposure Controls and Personal Protection

Ventilation:

No special ventilation is required when working with this

product.

Respiratory Protection:

None required.

Eye Protection:

Not normally required. However, use chemical safety goggles

or faceshield if potential for eye contact exists, especially if

material is heated.

Hand/Clothing Protection:

Not normally required. Protective gloves and clothing are

recommended, as material is difficult to remove from skin and

clothing.

Other Protective Equipment:

None required.

Section 9. Physical and Chemical Properties

Incompatibilities:

Strong oxidizing agents and halogens.

Hazardous Decomposition Products:

Carbon dioxide, carbon monoxide.

Section 11. Toxicology Information

No data available.

Section 12. Ecological Information

Chemical Fate Information:

Hydrocarbon components will biodegrade in soil; relatively

persistent in water.

Section 13. Disposal Consideration

Dispose of as solid waste in accordance with Local, State and

Federal regulations.

Section 14. Transportation Information

DOT Classification:

Not classified as hazardous.

Appearance/Odor:

Aluminum color, semi-solid material, pleasant odor.

Solubility in Water:

Negligible.

Specific Gravity:

0.86.

Section 10. Stability and Reactivity

Stability:

Stable.

Reactivity:

Hazardous polymerization will not occur.

Section 15. Regulatory Information

SARA Title III Supplier Notification:

Include in Section 311/312 inventory reports if amounts

exceed 10,000 pounds. Aluminum compounds are subject to

the reporting requirements under Section 313 of Emergency

Planning and Community Right-to-Know Act of 1986 (40 CFR

372). Ingredients listed in TSCA Inventory.

Section 16. Other Information

This information is furnished without warranty, expressed or

implied, except that it is accurate to the best of our knowledge.

Prepared By:

PROSAR, 1295 Bandana Boulevard, Suite 335, St. Paul, MN

55108 (651-917-6100).

17 68-0105—2

Page 18

68-0105—2 18

Page 19

19 68-0105—2

Page 20

Automation and Control Solutions

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

Honeywell Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Scarborough, Ontario

M1V 4Z9

68-0105—2 G.R. Rev. 1-02 www.honeywell.com/building/components

Loading...

Loading...