Page 1

APPLICATION

The Q7100 Thermostat Subbases provide electronic

control of commercial 24 Vac single or multistage heat

pump or conventional heating and cooling systems.

Select models have terminals for light emitting diodes

LEDs, remote temperature sensors and remote setback

timer. The LED models have up to two field configurable

LEDs and up to two factory assigned LEDs. Refer to

Table 1. All Q7100 Thermostat Subbases require a

common wire to the supply power.

Table 1. Description of Q7100 Subbases.

a

Use

T7100

Q7100

AD or F Conventional 1 or 2 1 or 2 8-9

CE or F Heat pump 1, 2 or 3 1 or 2 10-14

DE or F Heat pump 1 or 2 1 or 2 15

a

Depends on the model.

System Heat Cool Figs.

Stages

Q7100A,C,D

Thermostat Subbases

INSTALLATION INSTRUCTIONS

3. Installer must be a trained, experienced service

technician.

4. After completing installation, use these instructions

to check out the product operation.

CAUTION

Disconnect power supply to prevent electrical

shock or equipment damage.

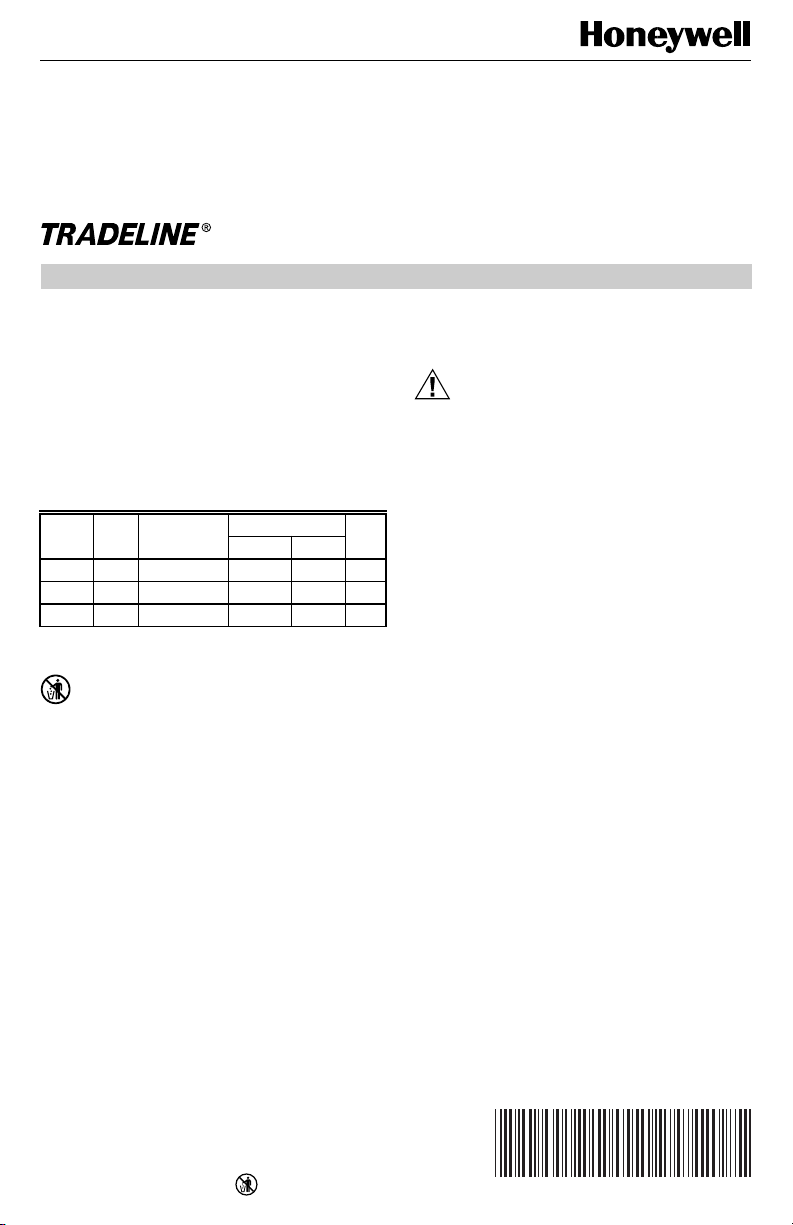

Location

Subbase without Remote-Mounted Temperature Sensor

Install the subbase about 5 ft (1.5m) above the floor in an

area with good air circulation at average temperature.

See Fig. 1.

Do not install the subbase where it can be affected by:

— drafts, or dead spots behind doors and in corners.

— hot or cold air from ducts.

— radiant heat from sun or appliances.

— concealed pipes and chimneys.

— unheated (uncooled) areas such as an outside wall

behind the thermostat.

RECYCLING NOTICE

If this control is replacing a control that contains

mercury in a sealed tube, do

control in the trash.

Contact your local waste management authority

for instructions regarding recycling and the proper

disposal of the old thermostat.

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow

the instructions can damage the product or cause

a hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

®U.S. Registered Trademark

Copyright © 1996 Honeywell Inc. • • All Rights Reserved

not

place your old

Subbase with Remote-Mounted Temperature Sensor(s)

Install the subbase in an area that is accessible for

setting and adjusting the temperature and settings.

Install the remote-mounted sensor(s) about 5 ft (1.5m)

above the floor in an area with good air circulation at

average temperature. See Fig. 1.

Do not mount the sensor(s) where it can be affected by:

— drafts, or dead spots behind doors and in corners.

— hot or cold air from ducts.

— radiant heat from sun or appliances.

— concealed pipes and chimneys.

— unheated (uncooled) areas such as an outside wall

behind the thermostat.

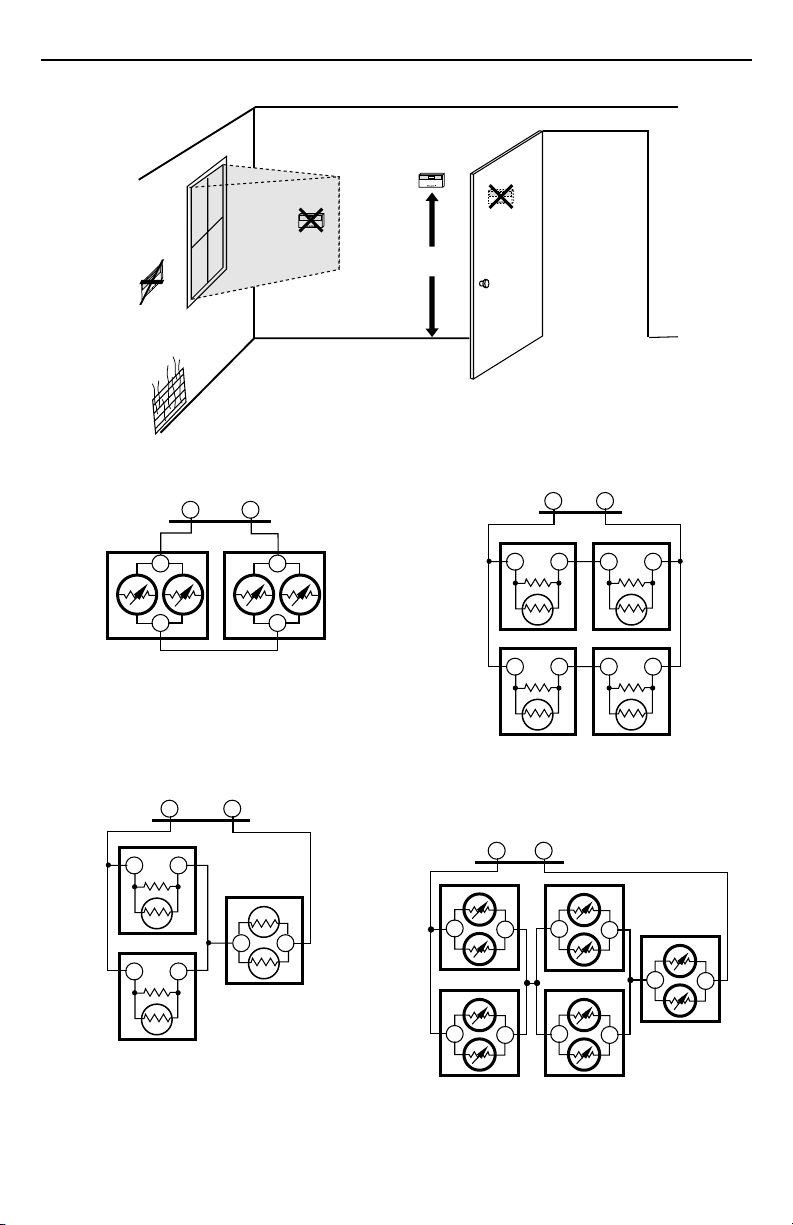

If more than one remote sensor is required, they must be

arranged in a temperature averaging network consisting

of two, three, four, five or nine sensors. See Fig. 2

through 6.

X-XX UL

69-0931-3

Page 2

Q7100A,C,D THERMOSTAT SUBBASES

NO

NO

Fig. 1. Typical location of thermostat or remote-mounted sensor.

SUBBASE

TT

T7047GT7047G

T

T

Fig. 2. Two T7047G Sensors providing a

temperature averaging network for a

T7100/Q7100 Thermostat/Subbase.

SUBBASE

TT

T7047C

TT

T

T

M4838

T7047G

YES

5 FEET

[1.5 METERS]

NO

SUBBASE

TT

T7047C

TT

T7047C

TT

Fig. 4. Four T7047C Sensors providing a

temperature averaging network for a

T7100/Q7100 Thermostat Subbase.

SUBBASE

TT

T7047G

T7047G

M10074

T7047C

TT

T7047C

TT

M4840

T7047C

TT

Fig. 3. Two T7047C Sensors and one T7047G Sensor

providing a temperature averaging network

for a T7100/Q7100 Thermostat/Subbase.

TT

M4839

69-0931—3

T

T7047G

T

Fig. 5. Five T7047G Sensors providing a

temperature averaging network for a

T7100/Q7100 Thermostat/Subbase.

T

T

T7047G

T

T

2

T

T7047G

T

T

T

M4841

Page 3

Q7100A,C,D THERMOSTAT SUBBASES

M4826

FOR WRAPAROUND

INSERTION STRIP

7/16 IN. (11 MM).

FOR STRAIGHT

INSERTION STRIP

5/16 IN. (8 MM).

SUBBASE

TT

T7047C

TT

T7047C

TT

T7047C

TT

Fig. 6. Nine T7047C Sensors providing a

temperature averaging network for a

T7100/Q7100 Thermostat/Subbase.

T7047C

TT

T7047C

TT

T7047C

TT

T7047C

TT

T7047C

TT

T7047C

TT

M4842

Subbase Installation

The subbase can be mounted horizontally on the wall or

a 2 in. x 4 in. wiring box. Position the subbase horizontally on the wall or on a 2 in. x 4 in. wiring box.

1. Position and level the subbase (for appearance

only). The thermostat will function properly even

when not level.

2. Use a pencil to mark the mounting holes. See Fig. 7.

3. Remove the subbase from the wall and drill two

3/16 inch holes in the wall (if drywall) as marked. For

firmer material such as plaster or wood, drill two

7/32 inch holes. Gently tap anchors (provided) into

the drilled holes until flush with the wall.

4. Position the subbase over the holes, pulling wires

through the wiring opening.

5. Loosely insert the mounting screws into the holes.

6. Tighten mounting screws.

WIRING

All wiring must comply with local electrical codes and

ordinances. Refer to Fig. 9 through 15 for typical

hookups. A letter code is located near each terminal for

identification.

CAUTION

Disconnect power before wiring to prevent

electrical shock or equipment damage.

1. Loosen the terminal screws on the back of the

thermostat and connect the system wires. See

Fig. 8.

IMPORTANT

Use 18 gauge, color-coded thermostat cable for

proper wiring.

2. Securely tighten each terminal screw.

3. Push excess wire back into the hole.

4. Plug the hole with nonflammable insulation to

prevent drafts from affecting the thermostat.

WALL

ANCHORS

(2)

WALL

WIRES

THROUGH WALL

LEDS

Fig. 7. Mounting the subbase.

MOUNTING

HOLES

MOUNTING

SCREWS

Fig. 8. Proper wiring technique.

SUBBASE

B

COOL

DAMPER

M6531

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

Fig. 9. Typical hookup of Q7100A1044 in a one-stage

heat and one-stage cool conventional system.

COMPRESSOR

CONTACTOR

FAN

RELAY

HEAT

DAMPER

Y

3

X

W

HEAT

RELAY OR

VALVE COIL

RH

RCOG

1

L1

(HOT)

L2

M4831A

69-0931—3

Page 4

Q7100A,C,D THERMOSTAT SUBBASES

RC

3

COOL

DAMPER

COMPRESSOR

CONTACTOR 1

2

L1

(HOT)

L2

1

CAUTION:

EQUIPMENT DAMAGE WILL OCCUR IF POWER IS CONNECTED TO THE D TERMINALS.

2

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

3

JUMPER RC TERMINAL TO RH TERMINAL WHEN INSTALLED ON A SYSTEM WITH ONE TRANSFORMER

Fig. 10. Typical hookup of Q7100A1010 in a two-stage heat and two-stage cool

SUBBASE

B

COOL

CHANGEOVER

VALVE

Fig. 11. Typical hookup of Q7100C1024 in a one-stage

heat and one-stage cool heat pump system.

FAN

RELAY

HEAT

RELAY

HEAT

CHANGEOVER

VALVE

G

Y2 RH T D

COMPRESSOR

CONTACTOR 2

FAN

RELAY

conventional system with two transformers.

X1

ROW X Y

COMPRESSOR

CONTACTOR

EQUIPMENT

MONITOR

L1

(HOT)

L2

M11088

SUBBASE

W1 B T

HEAT

RELAY 2

HEAT

HEAT

DAMPER

RELAY 1

HEAT

RELAY

Fig. 12. Typical hookup of Q7100D in a one-stage

REMOTE

TEMPERATURE

SENSOR

2

L1

(HOT)

L2

EM. HT.

RELAY

G

FAN

RELAY

W1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

heat and one-stage cool heat pump system.

1

REMOTE

SETBACK

TIMER

SUBBASE

COMPRESSOR

CONTACTOR

DOY1 GX W2

M4837A

.

EQUIPMENT

MONITOR

L1

(HOT)

L2

REXY1X1

1

M4843A

SUBBASE

W2

X

Fig. 13. Typical hookup of Q7100C1016 in a two-stage heat and one-stage cool heat pump system.

Includes remote temperature sensor and remote setback timer.

69-0931—3

OGY1

W1 R

HEAT

RELAY

FAN

RELAY

AUX.

HEAT

RELAY

HEAT

CHANGEOVER

VALVE

COOL

CHANGEOVER

VALVE

EB

EM. HT.

RELAY

EQUIPMENT

MONITOR

COMPRESSOR

CONTACTOR

4

X1

SENSOR

DD

TT

TIMER

L1

(HOT)

L2

M11089

Page 5

Q7100A,C,D THERMOSTAT SUBBASES

SUBBASE

REMOTE

SETBACK

TIMER

D

1

REMOTE

SETBACK

TIMER

M4834B

D

1

M4835A

D

OE BW2 Y2

X

COOL

CHANGEOVER

VALVE

1

CAUTION: EQUIPMENT DAMAGE WILL OCCUR IF POWER IS CONNECTED TO THE D TERMINALS.

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

2

EM. HEAT RELAY DOES NOT CYCLE. TO TURN OFF THE EM. HEAT, GO TO SYSTEM SELECTION AND CHOOSE HEAT.

3

SELECT MODELS HAVE LEDS.

4

X2 AND X4 NEED TO BE JUMPERED TO TERMINAL X.

5

Fig. 14. Typical hookup of Q7100C1008 in a two-stage heat and two-stage cool heat pump system.

HEAT

CHANGEOVER

VALVE

1

CAUTION: EQUIPMENT DAMAGE WILL OCCUR IF POWER IS CONNECTED TO THE D TERMINALS.

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

2

SELECT MODELS HAVE LEDS.

3

X4 NEEDS TO BE JUMPERED TO TERMINAL X.

4

Fig. 15. Typical hookup of Q7100C1073 in a three-stage heat and one-stage cool heat pump system.

EM. HT.

RELAY

FAN

RELAY

3

G

HEAT

CHANGEOVER

VALVE

HEAT

RELAY 2

W1 Y1

COMPRESSOR

CONTACTOR 2

HEAT

RELAY 1

5

COMPRESSOR

CONTACTOR 1

4

X3

X1X2 X4

EQUIPMENT

MONITOR 2

EQUIPMENT

MONITOR 1

Includes remote temperature sensor and remote setback timer.

SUBBASE

OE W3Y2

XB G

COOL

CHANGEOVER

VALVE

EM. HT.

RELAY

FAN

RELAY

AUX. HT.

RELAY

Y1

COMPRESSOR

CONTACTOR 2

COMPRESSOR

CONTACTOR 1

X3

X1X4

4

EQUIPMENT

MONITOR 2

EQUIPMENT

MONITOR 1

3

Includes remote temperature sensor and remote setback timer.

R

R

REMOTE

TEMPERATURE

SENSOR

T

REMOTE

TEMPERATURE

SENSOR

T

T

L1

(HOT)

L2

2

2

L1

(HOT)

L2

TD

Mounting Thermostat on Subbase

Mount the thermostat on the subbase after the subbase

is installed.

1. Engage tabs at the top of thermostat and subbase.

See Fig. 16.

2. Press lower edge of case to close and latch.

NOTE: To remove the thermostat from the wall, first pull

out at the bottom of the thermostat; remove top

last.

IMPORTANT

Refer to the thermostat installation instructions

for Installer Setup, Settings, Installer Self-Test

and Troubleshooting information.

A. ENGAGE TABS AT TOP OF

THERMOSTAT AND SUBBASE.

B. PRESS LOWER

EDGE OF CASE

TO LATCH.

Fig. 16. Mounting thermostat on subbase.

5

M6799A

69-0931—3

Page 6

Q7100A,C,D THERMOSTAT SUBBASES

Home and Building Control

Honeywell Inc.

Honeywell Plaza

P.O. Box 524

Minneapolis, MN 55408-0524

69-0931—3

69-0931—3 Rev. 2-98 L. C.

Home and Building Control

Honeywell Limited-Honeywell Limitée

155 Gordon Baker Road

North York, Ontario

M2H 2C9

6

www.honeywell.com

Loading...

Loading...