Page 1

Honeywell

THE Q539 SUBBASES PROVIDE COOLING ANTICI

PATORS. WIRING TERMINALS. AND MOUNTING

BASES FOR T87F THERMOSTATS. MOST ALSO

PROVIDE SYSTEM AND FAN SWITCHING FOR

HEATING. COOLING. AND HEATING-COOLING

THERMOSTATS.

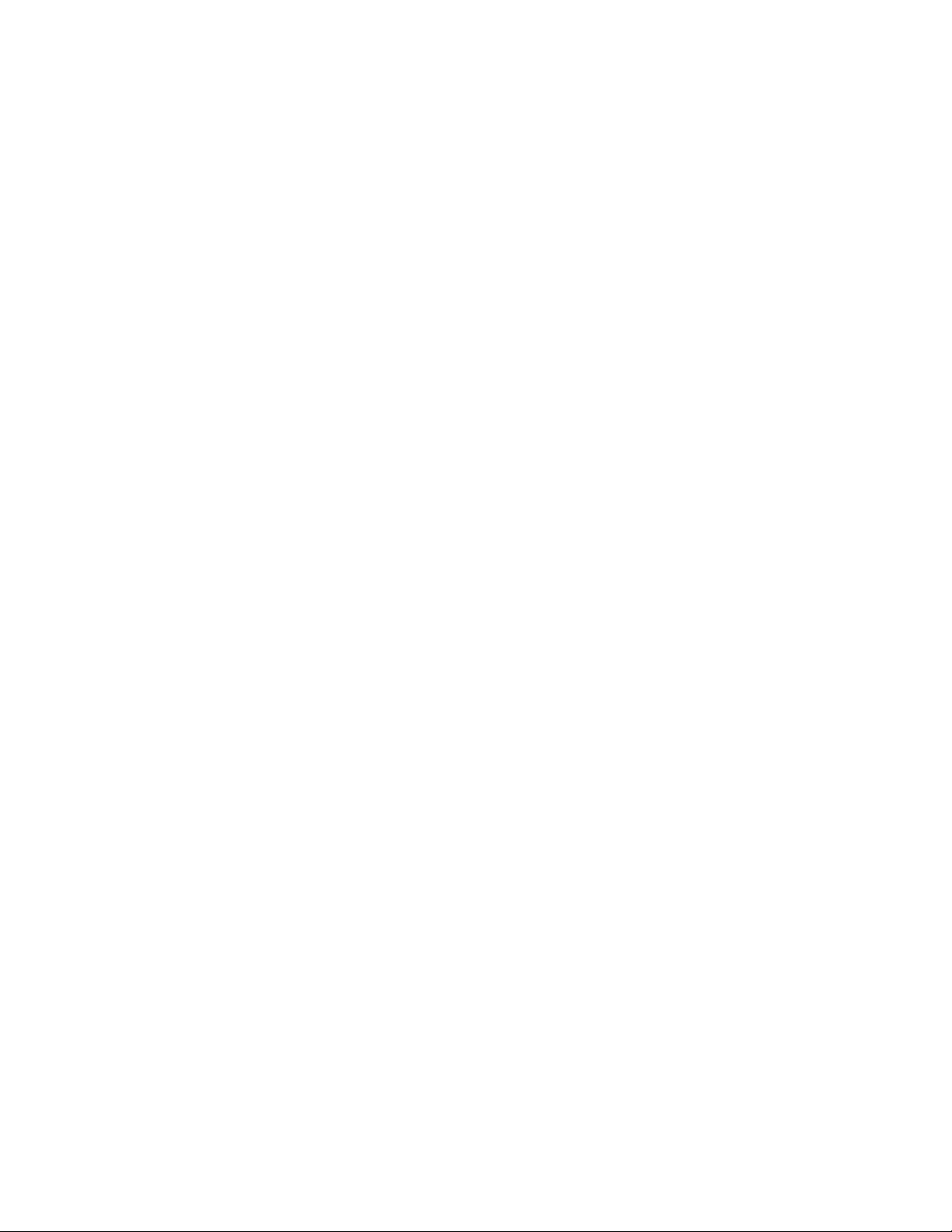

□ Screw terminals for electrical connections are lettercoded for quick, accurate installation.

□ Shunt type carbon heater provides cooling anticipa

tion for close temperature control.

THERMOSTAT

SUBBASES

□ Guide posts assure mounting and leveling necessary

to maintain thermostat calibration.

□ Fan and system switch levers (available on most

models) located at top edge for convenient control.

□ Indicator LED available on most models.

□ Mount directly on wall or on standard outlet box with

accessory wallplate. i

□ Q539P with indicator LED for oil primary systems

(HEAT-only).

Q539A,B,C,F,

D.T.

Rev. 10-89

Form Number 60-2246—4

© Honeywell Inc. 1989

Page 2

SPECIFICATIONS

IMPORTANT

THE SPECIFICATIONS GIVEN IN THIS PUBLICATION DO NOT INCLUDE NORMAL MANUFACTURING TOL

ERANCES. THEREFORE, THIS UNIT MAY NOT MATCH THE LISTED SPECIFICATIONS EXACTLY. ALSO,

THIS PRODUCT IS TESTED AND CALIBRATED UNDER CLOSELY CONTROLLED CONDITIONS, AND SOME

MINOR DIFFERENCES IN PERFORMANCE CAN BE EXPECTED IF THOSE CONDITIONS ARE CHANGED.

TRADELINE MODELS

TRADELINE models are selected and packaged to provide ease of stocking, ease of handling, and maximum

replacement value. Specifications of TRADELINE models are the same as those of standard models except as noted

below.

Q539A,J Thermostat Subbases—provide COOL-OFF-

HEAT system and AUTO-ON fan switching.

0539C Thermostat Subbase—provides COOL-OFF

system and AUTO-ON fan switching.

0539P Thermostat Subbases—provide HEAT-only

and indicator LED for oil primary systems.

FEATURES:

• TRADELINE package with cross reference label

and special instruction sheet.

• Textured beige finish designer models (available

on some TRADELINE models).

STANDARD MODELS

Refer to Table 1 for the general specif ications for 0539

Thermostat Subbases.

ELECTRICAL RATINGS:

Subbase Switches:

Resistive: 2A at 30 Vac maximum.

Inductive: 1.5 AFL, 7.5 ALR at 30 Vac maximum.

Cooling Anticipator—24 to 30 Vac.

Optional Indicator LED—30 Vac.

Terminal Designations: Refer to Table 2.

MOUNTING MEANS: Two screws provided for wall

mounting through holes and slots in subbase. Use Part

No. 127293 Wallplate for mounting on an outlet box or

for covering old thermostat marks.

DIMENSIONS: Diameter—3-11/16 in. [94 mm]; depth with

T87F—1-3/4 in. [45 mm).

OPTIONAL SPECIFICATIONS:

1. Indicator LED available on most models.

2. 0539A available with system switches marked

COOL-OFF-RESET-HEAT.

3. Models available with isolated heat-codi circuits for

--------------------------

installations with separate heating and cooling

transformers or for systems requiring thermostat

control of FAN operation.

ACCESSORIES:

1. Part No. 129044A Wallplate includes 6 in. [152 mm]

wall ring for mounting Q539 Subbase on outlet box

or for covering old thermostat mounting marks.

2. TG587F Thermostat guard protects T87F thermo

stats and Q539 subbases against tampering, dam

age and unauthorized adjustment of settings.

THERMOSTAT:

T87F Round Thermostat provides temperature control

for 24 to 30 V heating, cooling, or heating-cooling

systems.

T87F Designer Round Thermostat provides tempera

ture control for 24 to 30 V heating, cooling, or heating

cooling systems; textured beige finish.

(continued on page 3)

ORDERING INFORMATION

WHEN PURCHASING REPLACEMENT AND MODERNIZATION PRODUCTS FROM YOUR TRADELINE

WHOLESALER OR YOUR DISTRIBUTOR, REFER TO THE TRADELINE CATALOG OR PRICE SHEETS FOR

COMPLETE ORDERING NUMBER, OR SPECIFY—

1. Order number.

— Q539 Subbase, TRADELINE, If desired.

2. Optional Q539 Subbase specifications. If desired.

3. Accessories, If desired.

IF YOU HAVE ADDITIONAL QUESTIONS, NEED FURTHER INFORMATION, OR WOULD LIKE TO COMMENT

ON OUR PRODUCTS OR SERVICES, PLEASE WRITE OR PHONE:

1. YOUR LOCAL HONEYWELL RESIDENTIAL SALES OFFICE (CHECK WHITE PAGES OF PHONE

DIRECTORY).

2. RESIDENTIAL DIVISION CUSTOMER SERVICE

HONEYWELL INC., 1885 DOUGLAS DRIVE NORTH

MINNEAPOLIS, MINNESOTA 55422-4386 (612) 542-7500

IN CANADA—HONEYWELL CONTROLS LIMITED/HONEYWELL LIMITEE, 740 ELLESMERE ROAD,

SCARBOROUGH, ONTARIO M1P 2V9, INTERNATIONAL SALES AND SERVICE OFFICES IN ALL

PRINCIPAL CITIES OF THE WORL

Page 3

TABLE 1—MODEL SPECIFICATIONS

MODEL AND DESCRIPTION

Q539A Subbases provide system

and fan switching and cooiing

anticipation to controi heating and

cooiing appiications.

Q539A1014, Q539A4026' for

single heating and cooling

transformer applications.

Q539A1022 with impedance

relay reset switch.

Q539A1022 with indicator LED

for impedance relay reset

switch.

Q539A1022 with impedance

relay reset switch for heat

pump applications.

Q539A1121 with special

resistor for gas air conditioning

applications.

Q539A1147, Q539A4000‘ for

applications with isolated heating

and cooling circuits.

Q539A1162 used with W884

Comfort Control Center only.

SYSTEM

SWITCHING

(dpst and dp3t)

COOL-OFF-HEAT ON-AUTO

COOL-OFF-

HEAT-RESET

COOL-OFF-

RESET-HEAT

COOL-OFF-

RESET-HEAT

COOL-OFF-HEAT

COOL-OFF-HEAT ON-AUTO

COOL-OFF-HEAT

FAN

SWITCHING

(spdt)

ON-AUTO

ON-AUTO X X

ON-AUTO

ON-AUTO X X X

ON-AUTO X X X

X X X

X X X

X X X

X

SUBBASE TERMINALS WIRING

X X X

X

X X X X

X

X X

X*

X X

X

G

o X p z

X X

X Fig. 3

X X

X X

Rc R»

X X

DIAGRAMR W Y B

Fig. 1

Fig. 2

Fig.1

Fig. 2

Fig. 1

Fig. 2

Fig. 1

Fig. 2

Fig. 4

Fig. 5

Fig. 1

Fig. 2

Q539A1196 with “G” terminal

isolated on heating for external

low voltage fan switch.

Q539A1394 with indicator LED

for oil burner applications"

Q539B1005 with system

switching and cooling

anticipation for heating and

cooling applications. No fan

switching.

Q539C1020, Q539C4008’' with

system and fan switching and

cooling anticipation for coolingonly applications.

Q539G1000 with system and fan

switching for control of heatingonly system. No cooling

anticipator. Summer fan operation

available.

Q539H1009 with fan switching,

cooling anticipation, and "Z”

terminal for remote AUTO FAN

switching. No system switching.

Q539J1006, Q539J400(y= with

system switching and cooling

antidpation for electric heat and

heat pump applications. Fan

relay controls AUTO FAN

operation.

COOL-OFF-HEAT ON-AUTO

COOL-OFF-HEAT ON-AUTO

COOL-OFF-HEAT

COOL-OFF ON-AUTO

HEAT-OFF ON-AUTO

NONE ON-AUTO X

COOL-OFF-HEAT ON-AUTO

NONE X X X X X

X X X

X X

X X

X X

X X

X X X

X Fig. 6

X

X

X Fig. 8

X X

X

X X X

X X

x“ Fig. 9

X Fig. 10

X

Fig. 7

Fig. 1

Fig. 2

Fig. 11

(continued on next page)

60-2246—4

Page 4

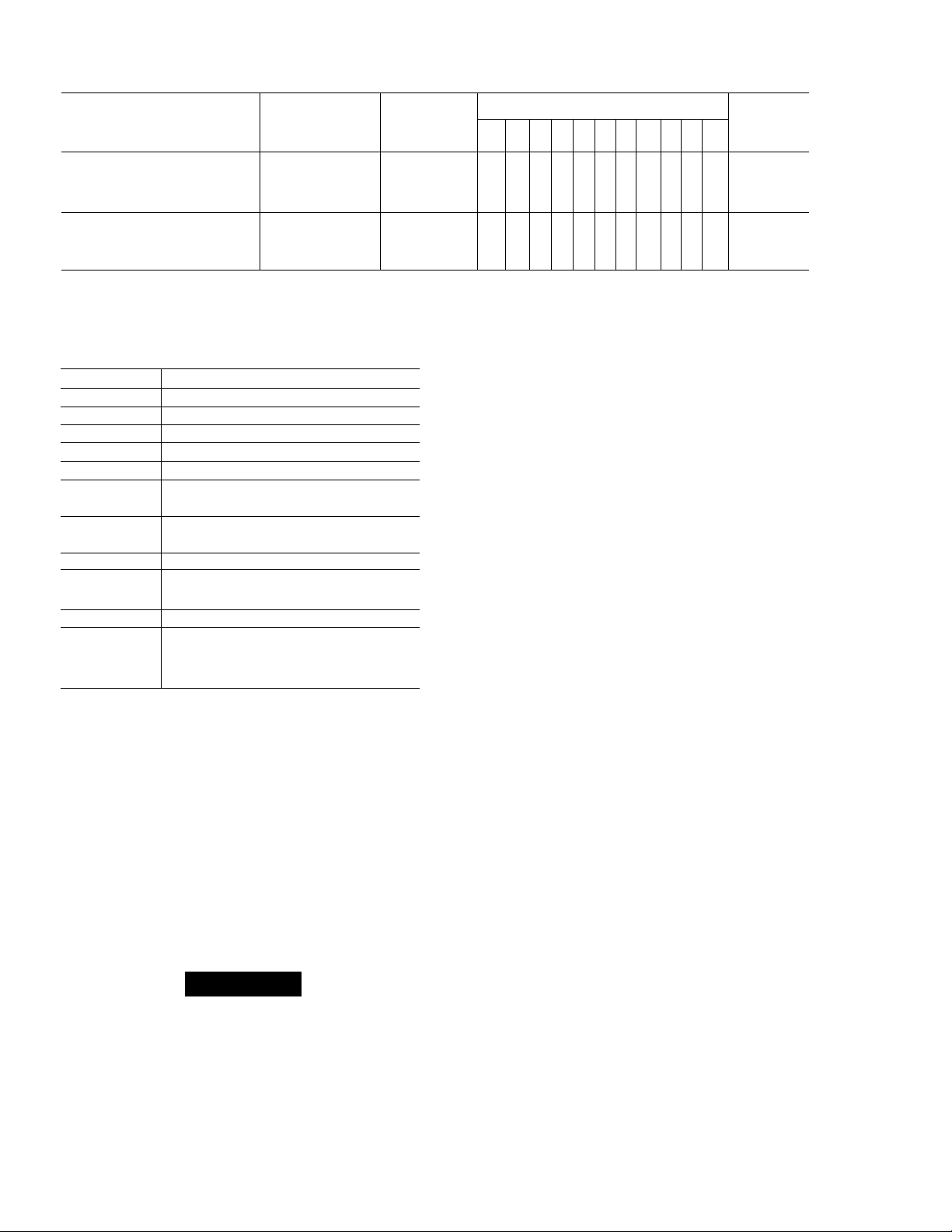

Table 1 (continued)

SYSTEM

MODEL AND DESCRIPTION

Q539J1022 is the same as

Q539J1006 for use in W884E

Comfort Control Center only.

Q539P1018 with wiring terminals

and indicator LED for heatingonly oil burner applications.

“Subbase has “4" terminal which is same as “B" terminal.

’’Rj,terminal for cooling transformer.

“Designer model with textured beige finish.

‘‘Subbase has "1" terminal in place of "Z" terminal.

TABLE 2—TERMINAL DESIGNATIONS“.

TERMINAL

R Transformer.

w

Y Cooling Contactor.

B9(4)«

O®

G

X'

P Heat Pump Contactor Coil.

Z

CONNECTION

Cooling transformer.

Heating transformer.

Heating Relay or Valve.

Heating Damper Motor or Changeover

Valve (if used).

Cooling Damper Motor or Changeover

Valve.

Fan Relay Coil.

Clogged Filter Switch or Lockout Switch

(primary control).

Q539H low voltage fan switch for

control of fan relay in AUTO position for

both heating and cooling control.

SWITCHING

(dpst and dp3t)

COOL-OFF-HEAT ON-AUTO X

NONE NONE X X

FAN

SWITCHING

(spdt)

R W Y B G

SUBBASE TERMINALS

X X

R1, W1, Y1, (or B1) are not marked on thermostat

subbase. They are mounting posts and electrical con

nections for thermostat.

Cooling transformer in systems with isolated heating

and cooling circuits.

Heating transformer in systems with isolated heating

and cooling circuits.

Circuit only completed between "R” and "B” with system

switch in HEAT position: “4” terminal is the same as

Honeywell “B” terminal.

Circuit only completed between “R” and “O” with system

switch in COOL position.

Only available on subbases with indicator lights.

Jumpered to humidity controller in Q539K/T87F

hookup.

X X X

X

O X p z

X Fig. 12

Rc R-

WIRING

DIAGRAM

Fig. 11

INSTALLATION

WHEN INSTALLING THIS PRODUCT...

1. Read these instructions carefully. Failure to follow

instructions can damage product or cause a hazardous

condition.

2. Check ratings given in instructions and on product to

make sure product is suitable for your application.

3. Make sure installer is a trained, experienced service

technician.

4. After completing installation, use these instructions

to check out product operation.

CAUTION

1. Disconnect power supply before beginning in

stallation to prevent electrical shock or equip

ment damage.

2. On systems using a low voltage gas control,

never apply a jumper across the control coil

terminals. This may burn out the thermostat heat

anticipator.

LOCATION

Locate the subbase about 5 ft [1.5 m] above the floor in

an area with good air circulation at average temperature.

Do not mount the subbase where it may be affected

by—

— drafts or dead spots behind doors or in corners.

— hot or cold air from ducts.

— radiant heat from the sun, fireplaces, or appliances.

— concealed pipes and chimneys.

— unheated (uncooled) areas behind the subbase,

such as an outside wall.

MOUNTING AND WIRING

Disconnect power supply before beginning installation

to prevent electrical shock or equipment damage.

All wiring must comply with local codes and ordinances.

1. In replacement applications, check the existing sub

base wires for cracked or frayed insulation. Replace any

wires in poor condition. If the wire is plastered into the wall,

make a hole next to the wires and loosen the wires so that

Page 5

they can be pushed back into the wall later.

2. In new installations, run wiring (if necessary) to the

subbase location.

3. Connect the wires to the terminals inside the sub

base. Refer to equipment manufacturer's instructions for

Q539 wiring diagrams. If not available, refer to Figs. 1

through 12.

4. Push excess wire back through the hole and plug any

opening with insulation to prevent drafts that may affect

performance.

5. Loosely fasten the thermostat subbase to the wall

with a screw through the left mounting hole. Adjust the

subbase so that it is approximately level and start the

second screw through the right mounting slot. Do not

tighten.

6. Level the thermostat subbase using a plumb line or

spirit level as shown in Fig. 13.

7. Tighten mounting screws.

IMPORTANT

This thermostat is calibrated at the factory while

mounted at true level. Any inaccuracy in leveling

during mounting causes control point deviation.

8. Mount and wire the thermostat to the thermostat

subbase by tightening three captive mounting screws on

thermostat. Tightening the three captive mounting screws

completes all electrical connections.

Q539Arr87F

A POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

A NO. 4 TERMINAL IS SAME AS B TERMINAL.

M310B

A X TERMINAL USED ON 0539 MODELS WITH FACTORY-INSTALLED

INDICATOR LED.

FIG. 1—Q539A,B,C IN HEATING-COOUNG APPUCATION USING COMMON POWER SUPPLY.

60-2246—4

Page 6

Q539An'87F

HEATING

DAMPER

WITCH

MOTOR

(IF USED)

COOLING

DAMPER

MOTOR

(IF USED)

“1“

A

_C “

■^T

<i) I

-0^1

A

A X TERMINAL IS USED ON 0539 MODELS WITH FACTORY-

INSTALLED INDICATOR LED,

A POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

A ISOLATING RELAY.

A VALVE OR RELAY WITH SEPARATE POWER SUPPLY MAY BE USED

IN PLACE OF OIL PRIMARY AS SHOWN BY BROKEN LINE.

FIG. 2—Q539A,B IN HEATING-COOLING APPLICA

TION WITH DAMPER MOTORS AND

ISOLATION RELAY.

Q539ATr87F

A POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

A CONNECT VALVE OR RELAY TO O FOR CHANGEOVER IN COOLING

OR B FOR CHANGEOVER IN HEATING.

A X TERMINAL IS USED ON Q539 MODELS WITH FACTORY-INSTALLED

INDICATOR LED.

A RECOMMENDED HEAT ANTICIPATOR SETTING ON HEAT PUMPS IS

140% OF THE TOTAL COMBINED CURRENT DRAW OF THE FAN AND

COMPRESSOR RELAYS. STANDARD HEATING SYSTEMS CYCLE AT

5 TO 6 CPH AND HEAT PUMP SYSTEMS CYCLE AT 2.5 TO 3 CPH ON

EITHER HEATING OR COOLING. ^

FIG. 3—Q539A IN HEAT PUMP APPLICATION.

/K POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

Ak valve or relay with separate power supply may BE USED

IN PLACE OF OIL PRIMARY AS SHOWN BY BROKEN LINE.

A\ THIS SUBBASEH-HERMOSTAT COMBINATION IS ALSO USED WITH

ELECTRIC HEATING COMPONENTS OR PANELS USING BOTH AC

AND DC CONTROL CIRCUITS.

FIG. 4—Q539A1147 IN HEATING-COOLING APPLICATION WITH ISOLATED CIRCUITS.

Page 7

-EXAMPLE;FOR Rc TO Rh JUMPER.

STRIP WIRE END LONG ENOUGH

TO JOIN BOTH TERMINALS.

FIG. 5-JUMPER "R^" AND "R„" TERMINALS FOR

COMMON HEATING-COOLING TRANS

FORMER IN Q539A1147.

Q538WTe7F

A POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

LOW VOLTAGE EXTERNAL FAN SWITCH FOR CONTROL OF AUTO

A

FAN DURING HEATING. u,™

FIG. 6—Q539A IN TYPICAL HOOKUP.

a539A/T87F

A POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

FIG. 7—Q539A IN HEATING-COOLING APPLICATION

WITH INDICATOR LED.

A POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

A X TERMINAL USED ON 0539 MODELS WITH FACTORY-INSTALLED

INDICATOR LED. .....

FIG. 8—Q539C IN COOLING-ONLY APPLICATION.

7 60-2246-4

Page 8

PROTECTION AS REQUIRED.

^JUMPER FOR AUTO FAN IN ELECTRIC HEAT APPLICATIONS. IF

És

JUMPER IS USED. MEASURE COMBINED “HEAT RELAY" AND

"FAN RELAY" CURRENT RATINGS.

A

3\ RECOMMENDED HEAT ANTICIPATOR SETTING IS THE COMBINED

CURRENT DRAW OF THE FAN RELAY AND HEAT RELAY AS THE FAN

RELAY CURRENT PASSES THROUGH THE HEAT ANTICIPATOR.

M2162

FAN

RELAY

HEATING

RELAY OR

VALVE

SWITCH

I______________________

A X TERMINAL IS USED ON 0539 MODELS WITH FACTORY-!NSTAUED

INDICATOR LED.

A POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

COOLING

CONTACTOR

EXTERNAL

SWITCHING

FOR

AUTO FAN

Fig. 9—Q539G IN HEATING APPLICATION

AUTOMATIC FAN OPERATION.

WITH

Fig. 10—Q539H IN HEATING-COOLING APPLICATION

AND AUTOMATIC FAN OPERATION

SWITCHING.

^1\ X TERMINAL IS USED ON Q539 MODELS WITH FACTORY-INSTALLED

A

INDICATOR LED.

WITH NO O TERMINAL LOAD. THERMOSTAT CURRENT DURING HEATING

A

CYCLE VARIES DEPENDING ON WHETHER FAN SWITCH IS IN THE ON OR

AUTO POSITION. HEATER SHOULD BE SET FOR COMBINED CURRENT

LEVEL OF HEAT RELAY AND FAN RELAY COILS. WITH O TERMINAL

LOAD. SET THERMOSTAT HEAT ANTICIPATOR TO ITS MAXIMUM

SETTING AS COOLING ANTICIPATOR IN SERIES WITH 0 TERMINAL

LOAD PROVIDES HEAT ANTICIPATION IN THE HEATING CYCLE. (LIMIT

THE THERMOSTAT HEATING LOAD CURRENT TO 0.8 AMPS TO ASSURE

GOOD PERFORMANCE.)

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

A

PROTECTION AS REQUIRED.

Fig. 11—Q539J IN HEATING-COOLING APPLICATION WITH AUTO FAN OPERATION.

Page 9

Q539P/T87F

MOLDED

POST (2)

VERTICAL

PLUMP

I LINE

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

A

PROTECTION AS REQUIRED.

Fig. 12—Q539P IN HEATING-ONLY SYSTEM WITH

REMOTE LOCKOUT INDICATION.

M1029A

CHECKOUT

NOTE; When adding a subbase to a thermostat with

positive OFF, make certain the positive OFF switch on

the thermostat is in the ON position so the system can

be manually controlled from the subbase system

switch.

When installation is complete, turn on power supply and

check system operation as follows:

SUBBASES WITH SYSTEM OR FAN SWITCHING

1. With 0539 system switch (or remote system switch)

set at HEAT and fan switch set at AUTO, turn the thermo

stat dial at least 5° F [3° C] above room temperature.

Heating should start immediately; the fan should start after

a short delay (immediately with Q539G (with jumper) or

Q539J).

2. With 0539 system switch (or remote system switch)

set at COOL and fan switch set at AUTO, turn the thermo

stat dial at least 5° F [3° C] below room temperature.

Cooling and fan should start. (External switch must be

made in Q539H hookup.)

OPENING FOR

THERMOSTAT ,

WIRING

I ' VERTICAL

I GUIDE

0

Fig. 13—LEVEL 0539 USING A SPIRIT LEVEL OR

PLUM LINE (dimensions are In In. [mm]).

3. Set system switch at OFF and fan switch at FAN ON.

Fan should run continuously. Turn thermostat 5“ F [3® C]

below room temperature. Heating and cooling equipment

cannot be actuated by the thermostat (except in system

with dpst remote changeover switch.

4. Operate entire system at least one complete cycle

with switches in each position before leaving installation.

Turn thermostat dial to the desired setting and move the

system and fan switches to their desired positions.

SUBBASE WITHOUT MANUAL SWITCHES (Q539P)

1. On Q539P subbase, turn thermostat dial 5° F [3° C]

above room temperature to call for heat. Heating should

start immediately, the fan should start after a short delay.

2. Turn thermostat dial 5® F [3® C] below room tempera

ture. Heating and fan should shut off.

3. Operate the entire system at least one complete

cycle before leaving installation. Turn thermostat dial to the

desired setting.

60-2246—4

Page 10

OPERATION

The Q539 Subbase provides cooling anticipation, wir

ing terminals, mounting base, and system and fan switch

ing for the T87F Thermostat.

The Q539 Subbase mounts directly to the wall using

two mounting screws. The T87F Thermostat mounts to the

Q539 Subbase using three captive screws. Tightening

these screws into the subbase also completes all electrical

connections between the subbase and the thermostat.

The HEAT-OFF-COOL system switch selects either

heating or cooling or turns the system off. The FAN-ONAUTO fan switch either sets the fan to turn on automatically

during heating or cooling or allows the fan to run continu

ously.

10

Page 11

NOTES

—

11

60-2246—4

Page 12

Honeywell Inc.

1885 Douglas Drive N.

International Sales Offices in all principal cities of the world. Manufacturing in

Australia, Canada, Finland, France, Germany, Japan, Mexico, Netherlands,

Golden Valley, MN 55422-4386 Spain, Taiwan, United Kingdom, U.S.A.

PRINTED IN U S A.

QUALITY IS KEY

Loading...

Loading...