Q5001 Valve Linkage

for Modutrol IV Motor

APPLICATION

The Q5001 Valve Linkage connects a Modutrol Motor to a 2or 3-way valve. It is used primarily on steam and water valves

such as the V5011 or V5013.

PRODUCT DATA

FEATURES

• Q5001 Valve Linkage is applicable to 2-way or 3-way

valves in modulating or two position service.

• Linkage requires no adjustment when used with

Honeywell valves and Modutrol IV Motors (can also be

used with Modutrol III motors).

• Q5001 Valve Linkage replaces Q601 and Q618 Valve

Linkages.

• Linkage mounts directly to the valve bonnet; motor

mounts on linkage bracket.

• Easy-to-read position indicator.

• Valve stem lift height cam selectable.

• Overtravel permits tight closeoff without excessive

motor strain.

• Easy mounting and valve connection.

• Available brackets make linkages adaptable to many

valve bodies.

• 80 lb, 160 lb, and 320 lb stem force models available.

Contents

Application ........................................................................ 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 4

Operation and Checkout .................................................. 8

Replacement .................................................................... 9

63-2425-01

Q5001 VALVE LINKAGE FOR MODUTROL IV MOTOR

SPECIFICATIONS

IMPORTANT:

The specifications given in this publication do not

include normal manufacturing tolerances.Therefore,

an individual unit may not exactly match the listed

specifications. Also, this product is tested and calibrated under closely controlled conditions and some

minor differences in performance can be expected if

those conditions are changed.

TRADELINE MODELS

TRADELINE MODELS are selected and packaged to provide

ease of stocking, ease of handling and maximum replacement value. TRADELINE model specifications are the

same as those of standard models unless specified otherwise.

Table 3 on page 4

TRADELINE MODELS AVAILABLE:

Q5001D1000 Valve Linkage: 3/4 in. lift, 80/160 lb force.

Q5001D1018 Valve Linkage: 3/4 in. lift, 160/320 lb force.

Q5001D1026 Valve Linkage: 1-1/2 in. lift, 160/320 lb force.

TRADELINE FEATURES:

• Selectable close-off force to meet application

requirements.Table 1 on page 3

• Special pack with Tradeline Cross Reference on label.

• Q5001A is shipped with 3/4 in. lift cam, part number

220861A.

• Q5001B is shipped with 1-1/2 in. lift cam, part

number 220867A.

CLOSE-OFF FORCE:

See Table 2 on page 4 for motor/valve/linkage selection.

VALVE BONNET SIZE:

See Table 2 on page 4 for bonnet size.

TEMPERATURE RATINGS:

°

-40

to 150° F [-40° to 66° C] ambient air temperature.

°

-40

to 337° F [-40° to 169° C] valve bonnet temperature.

MOTOR REQUIRED:

See Table 3 on page 4.

MOTOR STROKE:

160 degree rotation, mechanically normally open or nor-

mally closed.

VALVE ACTION:

Determined by motor rotation, cam orientation and valve

type. Cam mounting option (up or down) allows proper

control action with normally open or normally closed

motors and valves.

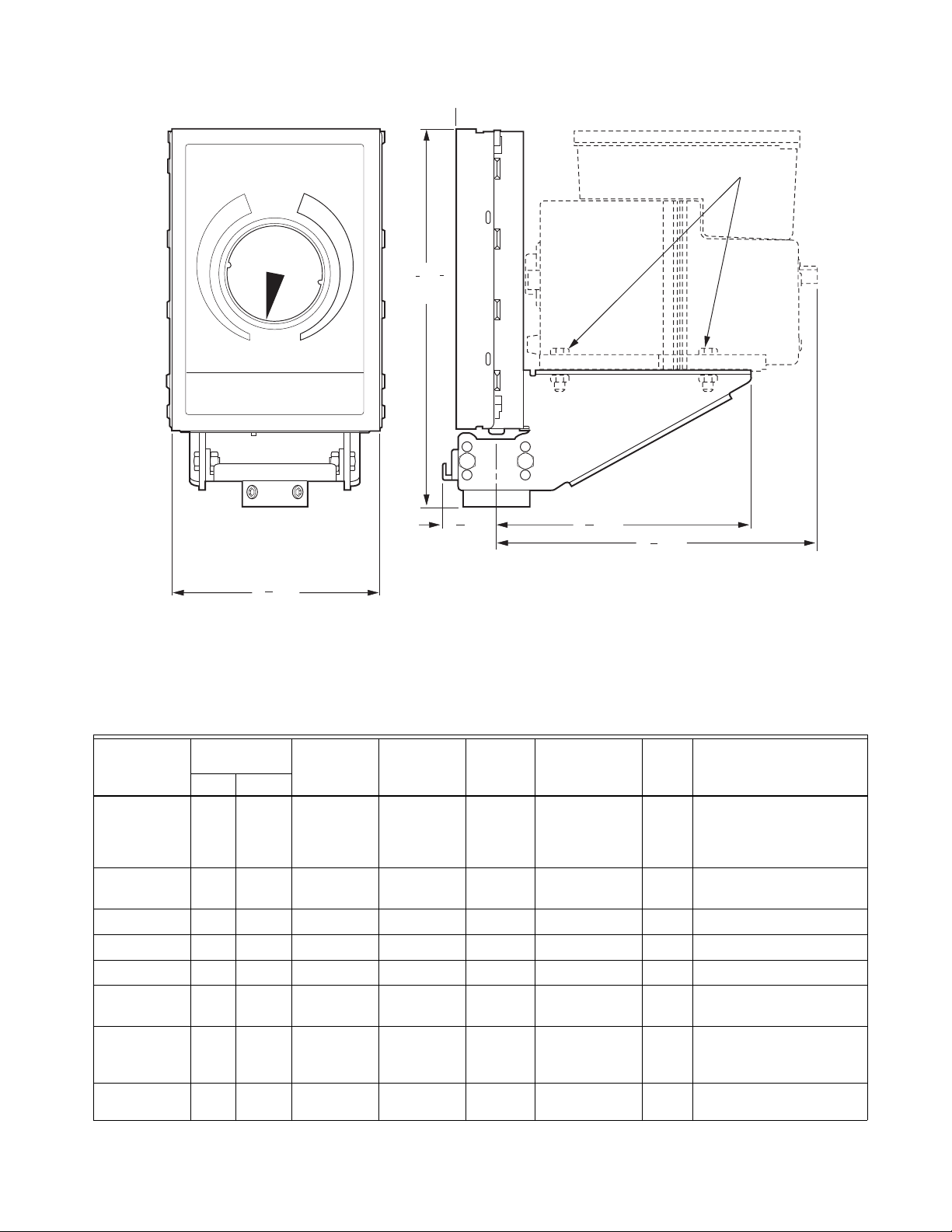

DIMENSIONS: See Fig. 1.

STANDARD MODELS

Q5001A,B Valve Linkage for Modutrol IV Motors.

See Table 1 on page 3 for model specifications. (Can also

be used with Modutrol III motors.)

LIFT: Selectable based on cam selection. See Table 3 on

page 4 for part numbers of alternate cams.

WEIGHT: 6.2 pounds.

ACCESSORIES:

4074ETB: Anti-spin clip, valve button and set screws for

1/4 in. [6 mm] valve stem.

Cams: See Table 3 on page 4 for merchandise cam part

numbers.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée,

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

63-2425—01 2

Q5001 VALVE LINKAGE FOR MODUTROL IV MOTOR

OPEN

C

LOSE

13

5 [148]

16

MOTOR NOT INCLUDED

IN LINKAGE

1

1

-10

10

2

4

-[267]

[260]

D

27

1 [36]

64

(POWER END

OF MOTOR)

29

6 [176]

32

25

8 [223]

32

1/4 X 20 X 1

MOUNTING

BOLTS

M3443A

Fig. 1. Approximate Q5001 Valve Linkage dimensions in in. [mm].

NOTE: High torque spring return motor shown. Medium torque spring return and nonspring return motors require less clearance

on auxiliary end of motor. Linkage for 3/4 in. stroke and 1-3/8 in. valve bonnet shown. Linkage for large valve bonnet and

larger stroke maximum 12 in. of clearance is required.

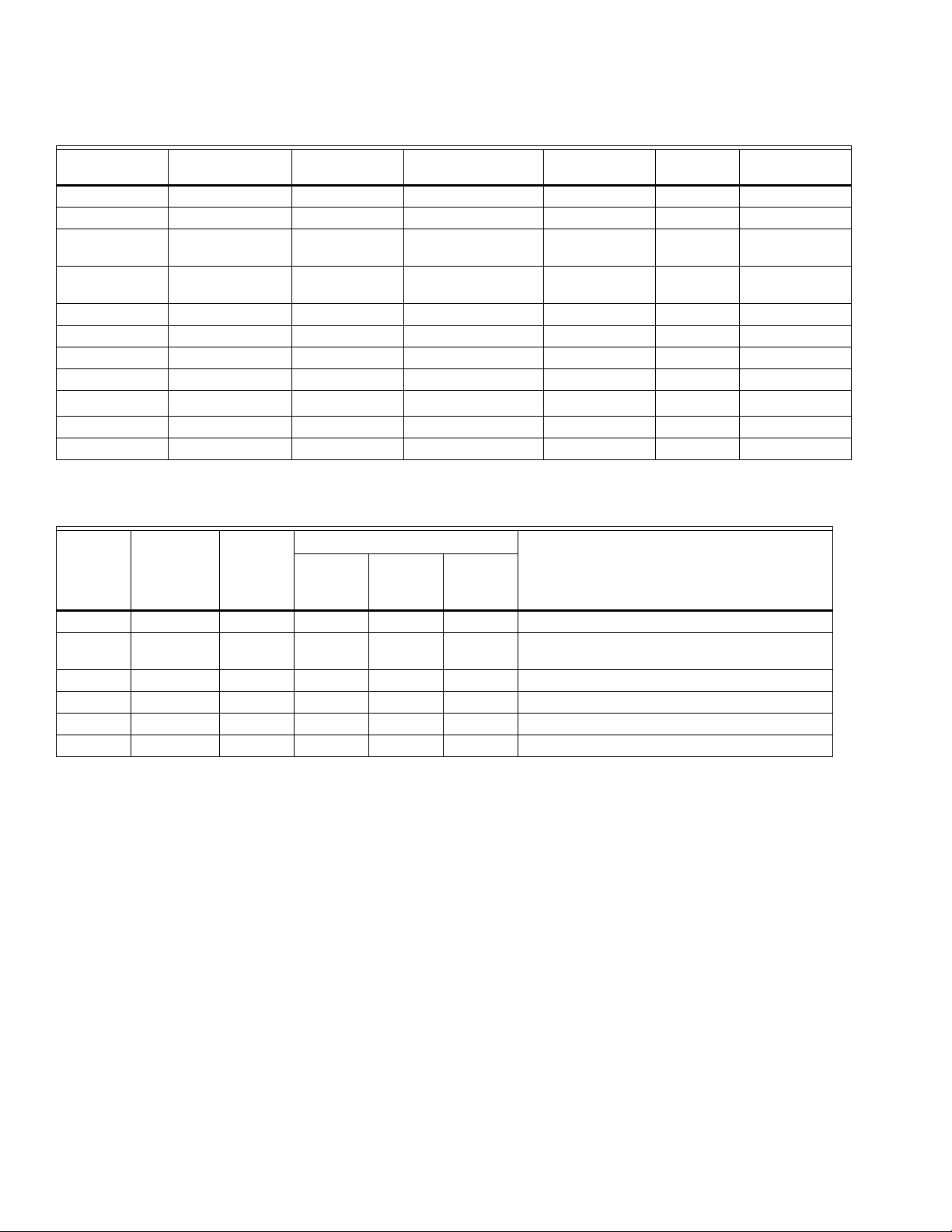

Table 1. Standard Models.

Model

Valve Ste m

Force

Lift Adjust-

ment

Bonnet

Connect

Bonnet

Size

(O.D.) Stem Connect

AntiSpin Linkage Replaced(lb) N

Q5001A1006 80 355.9 3/4 fixed Setscrew 1-3/8 Button and clip No Q618A1016,

Q618A1032,

Q618A1040,

Q618A1014, Q601L, M

Q5001A1014 160 711.7 3/4 fixed Setscrew 1-3/8 Button and clip No Q618A1008,

Q618A1024, Q601J, K

Q5001A1022 320 1355 3/4 fixed Setscrew 1-3/8 Button and clip No

Q5001B1004 160 711.7 1-1/2 fixed Setscrew 1-7/8 Button and clip Yes

Q5001B1012 320 1355 1-1/2 fixed Setscrew 1-7/8 Button and clip Yes

Q5001D1000

Tradeline

Q5001D1018

Tradeline

80,

160

160,

320

355.9-

711.7

711.71355

3/4 fixed Setscrew 1-3/8 Button and clip Yes

3/4 fixed Setscrew 1-3/8 Button and clip Yes Q601J, K, Q

a

Q601Q

b

Q601E

b

Q601P

Q601J, K, L, M

Q618A

Q618A1008

Q618A1024

Q5001D1026

Tradeline

a

If valve stroke is not 3/4 in. [19 mm], a merchandise cam must be purchased.

b

If valve stroke is not 1-1/2 in. [38 mm], a merchandise cam must be purchased.

160,

320

711.71355

1-1/2 fixed Setscrew 1-7/8 Button and clip Yes

Q601E, P

a

a

a

a

,

b

3 63-2425—01

Q5001 VALVE LINKAGE FOR MODUTROL IV MOTOR

Table 2. Valve-Linkage Selection Guide.

Honeywell

Valve Type

Valve

Body Style

Pipe

Size (in.) Linkage

Bonnet

Size (O.D.)

Lift

(in.)

V5011A 2-way Flanged 2-1/2, 3 Q5001A, D 1-3/8 3/4

V5011A, B 2-way Flanged 4, 5, 6 Q5001B, D 1-7/8 1-1/2

V5011F 2-way Screwed 1/2, 3/4, 1, 1-1/4, 1-1/

Q5001A, D 1-3/8 3/4

2, 2, 2-1/2, 3

V5011G 2-way Screwed 1/2, 3/4, 1, 1-1/4,

Q5001A, D 1-3/8 3/4

1-1/2, 2, 3

V5013B 3-way mixing Flanged 2-1/2, 3 Q5001A, D 1-3/8 3/4

V5013B 3-way mixing Flanged 4, 5, 6 Q5001B, D 1-7/8 1-1/2

V5013C 3-way diverting Flanged 2-1/2, 3 Q5001A, D 1-3/8 3/4

V5013C 3-way diverting Flanged 4, 5, 6 Q5001B, D 1-7/8 1-1/2

V5047A 2-way Screwed 1, 1-1/4, 1-1/2 Q5001A, D 1-3/8

9/16

a

V5047A 2-way Screwed 2 Q5001A, D 1-3/8 3/4

V5051A 2-way Flanged 2-1/2, 3, 4, 5, 6 Q5001B, D 1-3/8 1-1/2

a

Merchandise cam required.

Table 3. Cam Selections Available.

Cam

Number Type Lift

Required Torque

160 lb

80 lb stem

force

stem

force

a

(lb-in.)

320 lb

force

stem

b

Application

220858A Custom 9/16 in. 25 50 100 V5047A, 1 in. to 1-1/2 in.

220861A Standard 3/4 in. 25 50 100 V5011/V5013, 1/2 in. to 3 in.;

V5047A, 2 in.

220863A Custom 1 in. 30 60 120

220864A Custom 1-1/8 in. 30 60 120

220865A Custom 1-1/4 in. 50 100 200

220867A Standard 1-1/2 in. 50 100 200 V5011/V5013, 4 in. to 6 in.

a

Refer to Modutrol Motor specifications to select motor with equal or greater torque. Modutrol IV Motors are available with 25 and

60 lb-in. outputs (spring return); 35, 75, 150 and 300 lb-in. (nonspring return).

b

The 320 lb stem force linkage must be used with a 300 lb-in. motor.

INSTALLATION

WHEN INSTALLING THIS PRODUCT…

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous condition.

2. Check the ratings and description given on the product

to make sure the product is suitable for your application.

3. Installer must be a trained, experienced service technician.

4. After installation is complete, check out product operation as provided in these instructions.

5. Refer to the instruction sheet packed with the valve body

for information on installing the valve.

63-2425—01 4

6. Refer to the instruction sheet packed with the Modutrol

IV Motor for wiring diagrams and additional installation

information for the motor.

Location

Select a location that allows ample clearance for adjustment

and maintenance. Allow at least 4 in. [102 mm] above the

linkage to remove the valve assembly for maintenance.

Linkages may be mounted in a variety of positions. The 320 lb

stem force linkage must be assembled to a 300 lb-in. Modutrol

IV Motor. The linkage and motor may be rotated 360 degrees

around the valve stem. However, in all installations, the motor

shaft must be horizontal to ensure proper gear train lubrication

and the valve stem must be above horizontal.

Q5001 VALVE LINKAGE FOR MODUTROL IV MOTOR

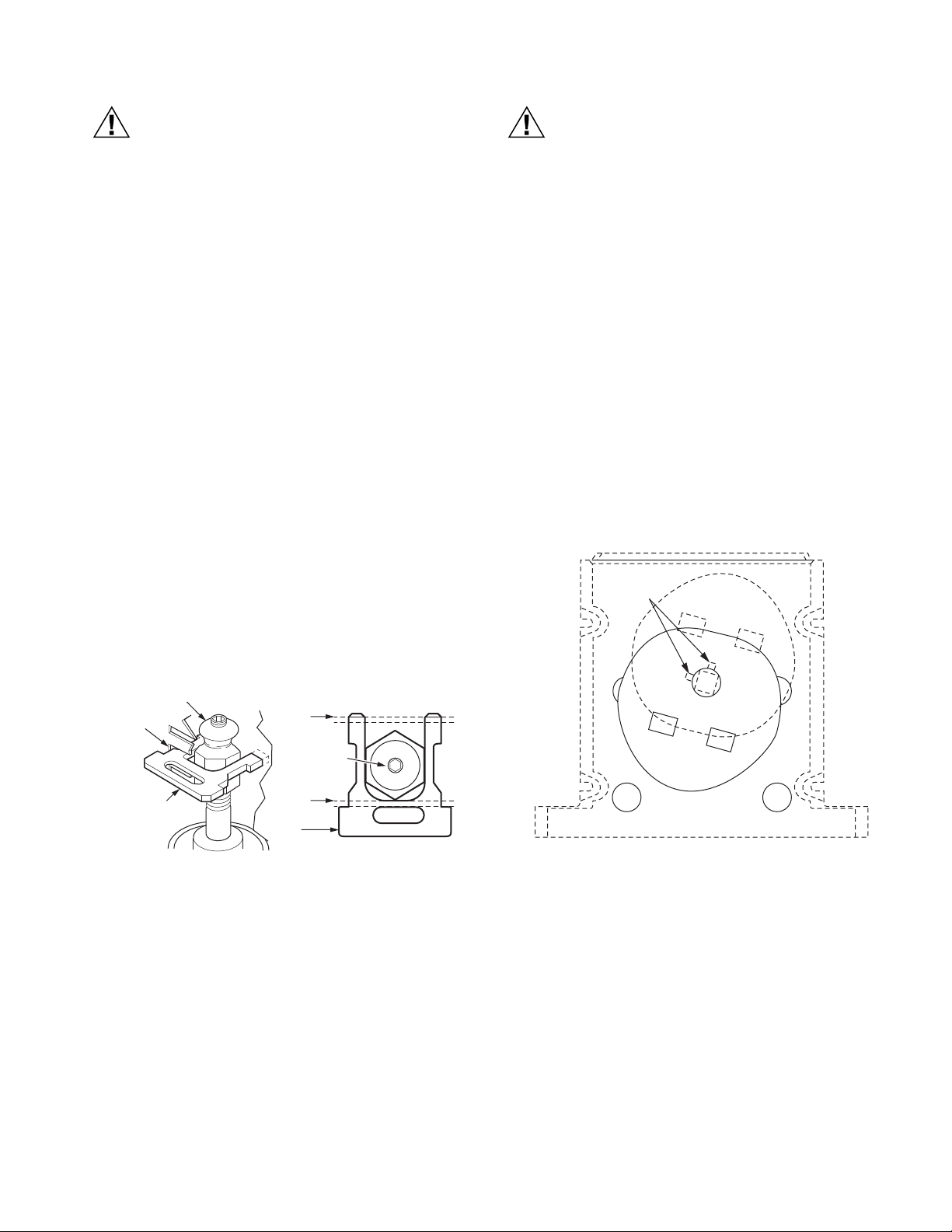

CAUTION

CAUTION

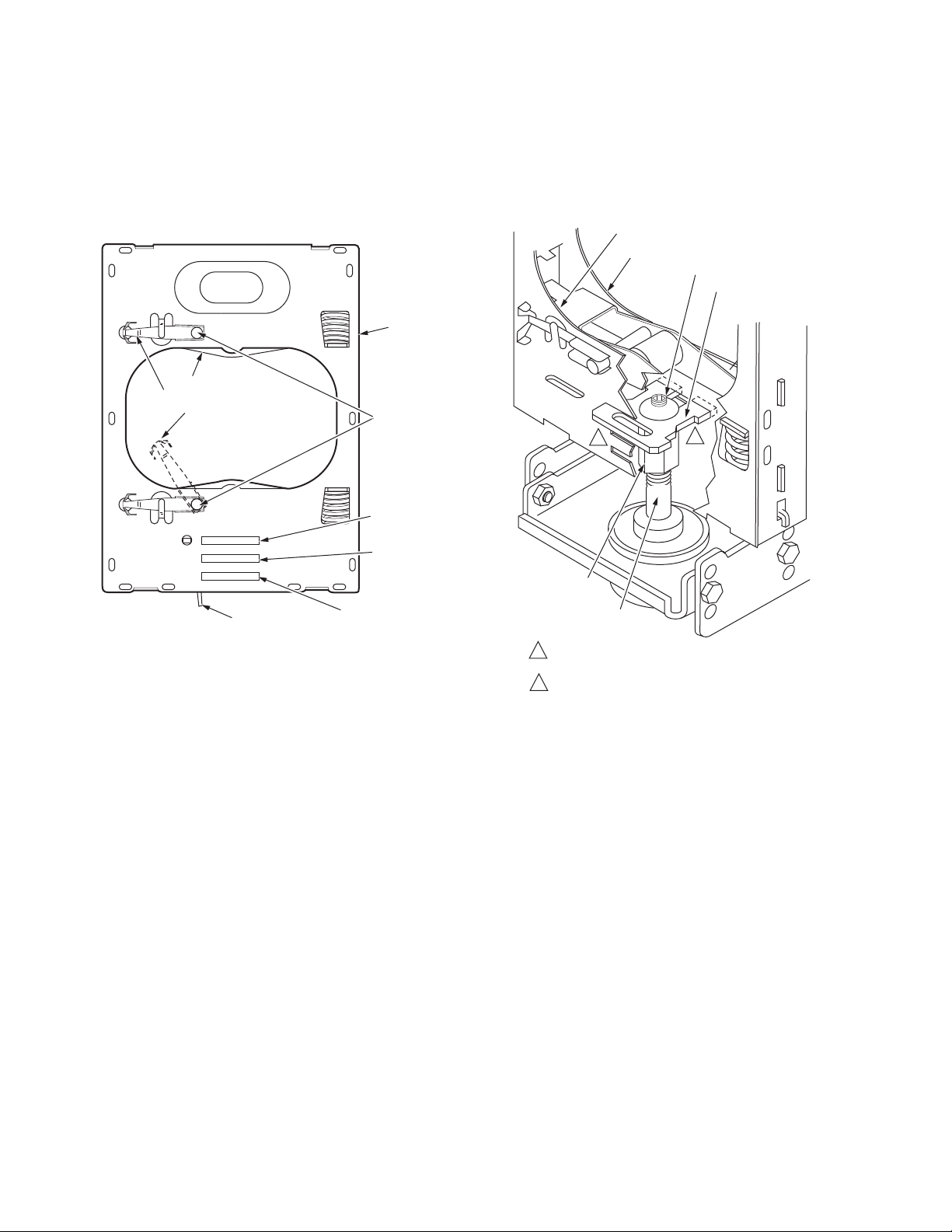

STEM BUTTON

MIDDLE

SLOT

ANTI

SPIN CLIP

M3480

REAR SLIDE

PLATE

FRONT SLIDE

PLATE

STEM BUTTON

ANTISPIN

CLIP

TOP VIEW

When mounting the linkage to the valve, make sure

that the set screws holding the valve linkage to the

valve body are properly tightened to prevent

improper operation or damage to the equipment.

The torque for tightening these screws should be

in the range of 72 to 120 lb-in.

Mounting

Tools

Tools required for installing the linkage are:

• 5/32 in. hex wrench.

• 7/16 in. open end or box end wrench.

Mount Linkage to Valve

1. Loosen the two valve bracket set screws, if necessary,

and slide the linkage over the valve stem and bonnet

until the valve bracket rests on the shoulder of the valve

bonnet.

2. Tighten the two valve bracket set screws to secure the

linkage to the valve. Make sure that the set screws holding the valve linkage to the valve body are properly tightened to prevent damage to the equipment. The torque

for tightening these screws should be in the range of 72

to 120 lb-in.

Connect Valve Stem to Linkage Slide (Modutrol IV)

1. Position the stem and stem button so that the sides are

parallel to the entry of the anti-spin clip (Fig. 2). This will

allow using the clip without disassembling and turning

the stem and button as described in step 5.

When mounting the cam to the motor, make sure

that the set screws holding the cam to the motor

shaft are properly tightened to prevent damage to

the equipment. The torque for tightening these

screws should be in the range of 72 to 120 lb-in.

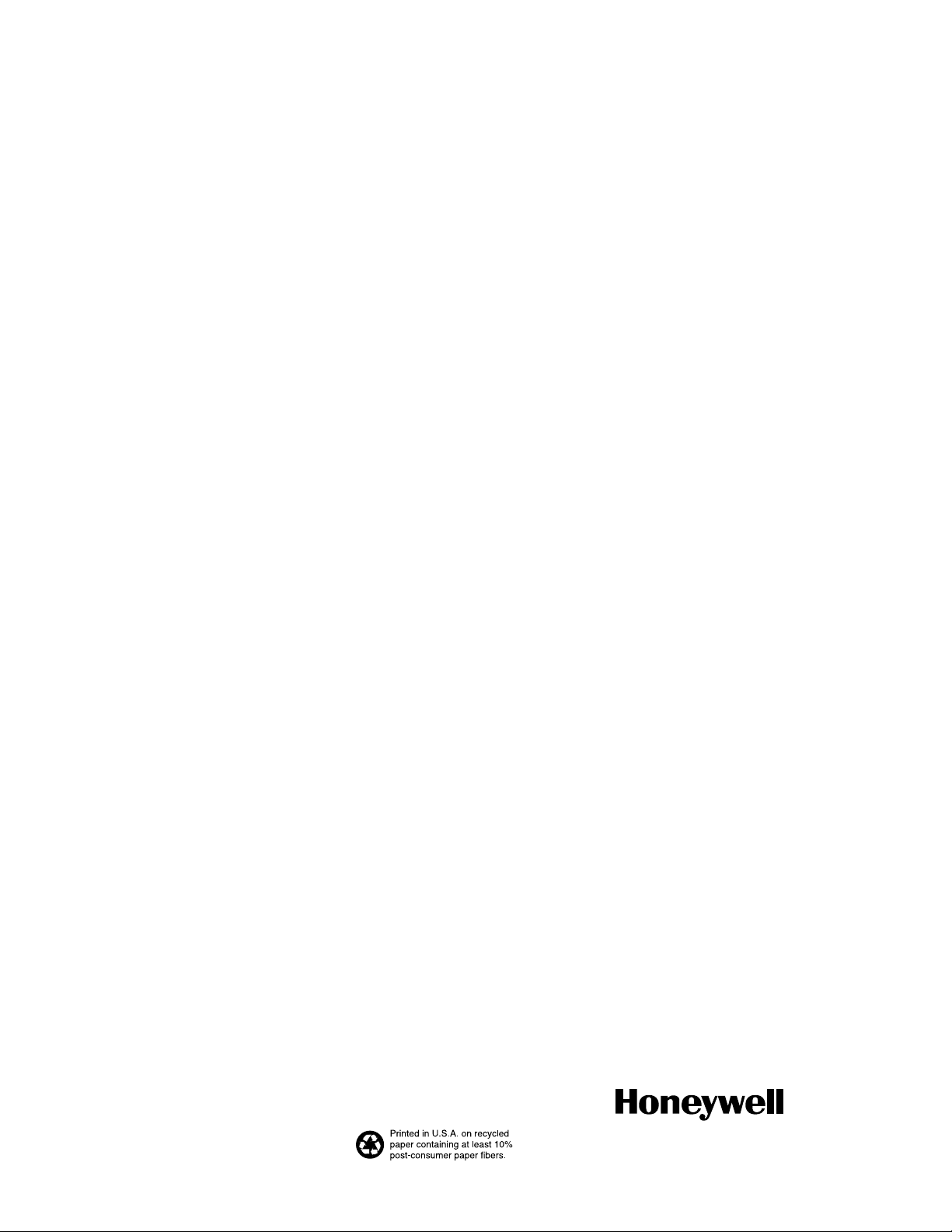

Mount Cam to Motor

1. Place 1/2 in. diameter plastic washer on motor shaft.

2. Select cam appropriate to linkage and valve combination

(standard model Q5001 Linkages include only one cam).

Refer to Table 3 on page 4 for alternate cam selections.

3. Determine correct position of the cam to provide proper

valve operation. To achieve normally closed operation

(stem down to close valve), the cam must be mounted

on the power end of the motor as shown in Fig. 3. For a

normally closed motor, the shaft rotates clockwise on an

increase in signal, lifting the valve stem. If normally open

operation is desired, install the cam rotated 180 degrees.

4. Loosen the two cam set screws, if necessary, and slide

the cam over the motor shaft to the stops and tighten the

set screws. Make sure the set screws holding the cam to

the motor shaft are properly tightened to prevent damage to the equipment. The torque for tightening these

screws should be in the range of 72 to 120 lb-in.

SET

SCREWS

Fig. 2. Installing anti-spin clip

2. Move the slide up or down until the top slot matches the

slot in the stem button as indicated in Fig. 4.

3. Push clip retainer lever to the left.

4. Insert clip into upper slot until clip stops reach linkage

slide front plate. The clip must engage the slot on the

stem button and rear slide plate slot for proper valve

operation.

5. OPTIONAL: To insert the anti-spin clip, push clip retainer

lever to the left, and insert the anti-spin clip in the middle

slot. Insert until clip contacts linkage slide front plate. If

clip will not fully insert, remove anti-spin clip and stem

button clip. Turn stem and button until the button sides

are parallel to the entry of the anti-spin clip. Replace

stem button clip and anti-spin clip.

6. Release clip retainer lever. When slide is moved, entire

slide and valve stem should move up and down together.

5 63-2425—01

POWER END

VIEW IS FROM POWER END, NORMALLY CLOSED

1.

SPRING RETURN MOTOR.

CAM IS IN NORMAL ORIENTATION FOR NORMALLY

2.

CLOSED (STEM DOWN TO CLOSE VALVE) OPERATION.

DOTTED LINES SHOW INSTALLATION FOR NORMALLY

3.

OPEN OPERATION.

M3445A

Fig. 3. Mounting the cam on the Modutrol Motor

Mounting the Motor Without Power

1. On Tradeline selectable stem force models, select the

proper hole for the pin to obtain the desired closeoff

force needed for your application. The stem force holes

are labeled on the slide.

2. If the cam is pointing upward, go to Step 5. If the cam is

pointing downward, slide motor and cam assembly into

the linkage, aligning the motor mounting holes with the

linkage mounting holes and mount the motor on the linkage bracket using the enclosed 1/4-20 x 1 in. bolts. The

linkage will raise the motor power end off the linkage

Q5001 VALVE LINKAGE FOR MODUTROL IV MOTOR

motor bracket. It may be necessary to squeeze the

motor auxiliary end of the linkage bracket slightly to align

the mounting holes.

3. Start all four motor bolts, then tighten the bolts on the

power end first, pulling the motor snugly to the linkage

motor bracket and compressing the linkage springs.

4. Tighten the auxiliary end mounting bolts.

SLIDE

PUSH HERE

PIN LOCKED POSITION

PIN REMOVAL POSITION

STEM FORCE PINS

MODUTROL IV

MOTOR CLIP SLOT

MODUTROL IV

ANTI-SPIN

CLIP SLOT

5. If the cam is pointing upward, remove motor wiring cover

(on nonspring return motors) and raise the linkage slide.

6. Tilt the motor power end face down about 30° and slide

motor and cam assembly into linkage opening at an

angle to align one power end bolt hole. Make sure that

the cam is between the linkage rollers. See Fig. 5(A).

FRONT SLIDE PLATE

REAR SLIDE PLATE

SET SCREW

CLIP IN SLOT

2

STEM BUTTON

1

M2774

CLIP RETAINING

LEVER

MODUTROL III MOTOR

CLIP SLOT

VALVE STEM

CLIP MUST ENGAGE SLOTS ON STEM BUTTON AND

1

REAR SLIDE PLATE.

2

CHOOSE TOP SLOT IN SLIDE FOR MODUTROL IV OR

BOTTOM SLOT FOR MODUTROL III

Fig. 4. Stem force pin position selection.

63-2425—01 6

Q5001 VALVE LINKAGE FOR MODUTROL IV MOTOR

A

B

C

M2773

Fig. 5. Mounting Modutrol Motor to Q5001 Valve Linkage with cam pointing up.

7. Install bolt but do not tighten.

8. Rotate motor to align the other power end bolt hole (B)

and install second bolt, but do not tighten at this time.

9. Install auxiliary end mounting bolts and tighten (C), pulling auxiliary end of motor snugly to linkage motor

bracket. It may be necessary to squeeze the motor auxiliary end of the linkage bracket slightly to align the mounting holes.

10. Tighten power end mounting bolts.

NOTE: If motor and linkage are assembled without power,

the operation and checkout must be performed to

guarantee proper performance.

Mounting the Motor With Power Available

(Optional Means)

1. For easier assembly, run the motor to mid-stroke. Refer

to Modutrol Motor Specification for instructions on operating the motor.

2. OPTIONAL: Remove the upper force pin, push up the

lever arm as indicated in Fig. 4 and replace pin in position to hold the lever arm away from the opening to allow

the cam and motor assembly to slide into position easily.

Repeat for the lower force pin. The lower force pin must

be placed in the outer hole, because the valve stem button limits the lever movement, preventing inner hole

alignment. Refer to Fig. 4.

3. Slide motor and cam assembly into opening, align the

motor mounting holes with the linkage mounting holes

and assemble the motor to the motor brackets using the

enclosed 1/4 - 20 x 1 in. bolts, but do not tighten. It may

be necessary to squeeze the motor auxiliary end of the

Q5001 Valve Linkage slightly to align the mounting

holes. See Fig. 1.

4. If levers were held out of the way in Step 2, remove the

force pins and allow levers to return to operating position. Insert pins in the proper hole for the pin to obtain the

desired closeoff force needed in your application and

rotate to the locked position as shown in Fig. 4.

5. Tighten the 1/4 x 20 x 1 in. motor bolts.

NOTE: Both upper and lower stem force pins must be in the

same force hole location to make sure that proper

seal off force for the valve is applied. Failure to lock

arms in location with stem force pins will prevent the

valve from closing.

Final Assembly

After checkout (see “Operation and Checkout” on page 8),

install the position indicator on the cam. The center of the

indicator should coincide with the center of the motor shaft, see

Fig. 3. This will allow the indicator to show position of the valve

through the cover of the motor.

The indicator is shipped with arrow label for normally closed

valve operation. On a normally open valve, install the spare

indicator label at 180° to the original label.

Place the cover on the linkage by positioning the cover with the

hole centered over the indicator, label oriented upwards. Press

the cover over the linkage frame until the indents snap into

place on the frame. Run the valve through two operating cycles

to make sure that no binding occurs during operation.

7 63-2425—01

Q5001 VALVE LINKAGE FOR MODUTROL IV MOTOR

OPERATION AND CHECKOUT

The Q5001 Valve Linkage operates the valve in a 160-degree

stroke. See Fig. 6. As shown, a normally closed spring return

motor will rotate the cam through the 160-degree stroke to lift

the stem the distance prescribed by the selected cam. On loss

of power, the spring will return the motor, linkage and valve to

the closed position.

For normally open spring return models, reverse the closed

and open captions in Fig. 6.

After installation and adjustment are completed, run valve/

linkage/motor combination through two or more full cycles to

make sure the combination operates properly.

Refer to the appropriate Modutrol IV Motor instruction sheet for

information on running the motor during checkout.

1. A 2-way valve should close off tightly at the closed end of

its stroke.

2. A 3-way valve should close off tightly at both ends of its

stroke. See Table 4 on page 8.

3. The motor should be free to run through its complete

stroke without stalling.

4. The linkage should operated freely without binding.

Lubrication

The Q5001 does not require any lubrication.

Spring Compression

Spring compression for the Q5001 is shown in Table 4 on

page 8.

If spring compression is less than minimum or more than

maximum, verify that the correct cam was used. If the correct

cam was used, remove valve stem clip and adjust valve stem

button after set screw has been loosened. See Table 4 on

page 8.

Measure spring compression by measuring the distance

between the lever end and the end of the spring slot. See Fig.

7.

Maximum spring compression = 11/32 in. [8.7 mm].

VALVE CENTER LINE

1

10˚

CW

MOTOR

LIMIT

OPEN

2-WAY

OR

160˚

3-WAY

VALVE

CLOSE

LINES REPRESENT POSITION OF CAMS (VIEWED FROM

1

POWER END OF MOTOR).

2

SPRING RETURN MODELS: SPRING DRIVES MOTOR AND

VALVE CLOSED IF POWER IS TURNED OFF.

2

CW

MOTOR

LIMIT

10˚

M5400

Fig. 6. Q5001 operation.

Table 4. Minimum Spring Compression in in. [mm] (See

Fig. 6.).

Stem Force Load

O.S. Number

80 lb 160 lb 320 lb

Q5001A1006 3/64 [1.2]

Q5001A1014 3/32 [2.4]

Q5001D1000 3/64 [1.2] 3/32 [2.4]

Q5001D1018 3/64 [1.2] 3/32 [2.4]

Q5001D1026 3/64 [1.2] 3/32 [2.4]

63-2425—01 8

Q5001 VALVE LINKAGE FOR MODUTROL IV MOTOR

SPRING

COMPRESSION

SPRING

SPRING

COMPRESSION

SPRING

M3444

REPLACEMENT

When replacing a motor or linkage in a valve application, make

sure that the motor stroke is 160° to operate Q5001 with

Honeywell V5011 two-way and V5013 threeway valves. Refer

to Installation section for further details. Refer to Mount Cam to

Motor and Mounting the Motor in the Installation section for

details on mounting and removing the Modutrol Motor from the

linkage.

Fig. 7. Spring compression.

9 63-2425—01

Q5001 VALVE LINKAGE FOR MODUTROL IV MOTOR

63-2425—01 10

Q5001 VALVE LINKAGE FOR MODUTROL IV MOTOR

11 63-2425—01

Q5001 VALVE LINKAGE FOR MODUTROL IV MOTOR

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your use or modification to,

the literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and against any liability, cost, or damages,

including attorneys’ fees, arising out of, or resulting from, any modification to the literature by you.

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

® U.S. Registered Trademark

© 2008 Honeywell International Inc.

63-2425—01 M.S. Rev. 12-08

Loading...

Loading...