Page 1

PX940

High Performance Industrial Printer

User Guide

Page 2

Disclaimer

Honeywell International Inc. (“HII”) reserves the right to make changes in specifications and other information contained in

this document without prior notice, and the reader should in all cases consult HII to determine whether any such changes

have been made. The information in this publication does not represent a commitment on the part of HII.

HII shall not be liable for technical or editorial errors or omissions contained herein; nor for incidental or consequential

damages resulting from the furnishing, performance, or use of this material. HII disclaims all responsibility for the

selection and use of software and/or hardware to achieve intended results.

This document contains proprietary information that is protected by copyright. All rights are reserved. No part of this

document may be photocopied, reproduced, or translated into another language without the prior written consent of HII.

Copyright 2019 Honeywell International Inc. All rights reserved.

Web Address:

www.honeywellaidc.com

Trademarks

Microsoft® Windows®, Windows NT®, Windows 2000, Windows ME, Windows XP, and the Windows logo are trademarks or

registered trademarks of Microsoft Corporation.

Wi-Fee is a registered certification mark of the Wi-Fee Alliance.

Bluetooth is a trademark of Bluetooth SIG, Inc., U.S.A.

Apple® and App Store® are registered trademarks of Apple Inc., registered in the U.S. and other countries.

Google™, Android™ and Google Play Store™ are registered trademarks of Google, LLC.

Zebra is a trademark or registered trademark of Zebra Corporation.

Other product names or marks mentioned in this document may be trademarks or registered trademarks of other

companies and are the property of their respective owners.

For patent information, refer to www.hsmpats.com.

Page 3

TABLE OF CONTENTS

Customer Support ........................................................................................................................ xi

Technical Assistance ............................................................................................................. xi

Product Service and Repair ................................................................................................ xi

Limited Warranty .................................................................................................................... xi

Safety Warnings ..................................................................................................................... xii

Caution Statements..............................................................................................................xii

Shipping the Printer ............................................................................................................xiii

Chapter 1 - Get Started ....................................................................................1

Features ............................................................................................................................................. 1

About the Display..................................................................................................................... 1

Back View (Ports and Power)............................................................................................... 2

Print Button................................................................................................................................ 2

Ready Screen............................................................................................................................. 2

Main Menu ................................................................................................................................. 4

Navigate the Main Menu ...................................................................................................... 5

Wizards............................................................................................................................................... 5

Printing Wizard......................................................................................................................... 6

Communications Wizard ...................................................................................................... 6

Calibration Wizard................................................................................................................... 6

Printer Command Languages and Simulator Support Options .................................6

Autosense .................................................................................................................................. 7

Direct Protocol ..........................................................................................................................7

Fingerprint.................................................................................................................................. 7

IPL..................................................................................................................................................7

PX900/PX900V User Guide iii

Page 4

ZSim...............................................................................................................................................7

DPL ................................................................................................................................................8

Smart Printing ...........................................................................................................................8

Access the Printer Web Page......................................................................................................8

Set the Printer Command Language......................................................................................8

From the Printer Web Page ..................................................................................................8

From the Main Menu ..............................................................................................................9

Chapter 2 - Set Up the Printer ..................................................................... 11

Power Up the Printer...................................................................................................................11

Calibrate the Touch Screen......................................................................................................12

To calibrate the screen from the website:....................................................................12

About the Media ........................................................................................................................... 12

Load Media for Tear-Off Printing ...................................................................................12

Load Media for Rewind Printing .....................................................................................16

Load Media for Peel-Off Printing ...................................................................................17

Load Fanfold Media ............................................................................................................. 18

About the Ribbon .........................................................................................................................19

Load Ribbon ............................................................................................................................ 19

Ribbon Removal..................................................................................................................... 20

Print a Test Label .........................................................................................................................21

Printhead Pressure and Toggle Position............................................................................22

Pressure Adjustment ...........................................................................................................22

Toggle Position Adjustment..............................................................................................22

Toggle Settings .....................................................................................................................23

Chapter 3 - Connect the Printer.................................................................. 25

Connect the Printer to Your PC ..............................................................................................25

Connect the Printer Using a Serial Cable....................................................................25

Connect the Printer Using a USB Cable.......................................................................25

Connect the Printer to Your Network ...................................................................................25

Connect the Printer to an Ethernet Network..............................................................26

Configure Bluetooth Communications from the Web Page ................................ 26

iv PX900/PX900V User Guide

Page 5

Configure Bluetooth Communications from the Main Menu .............................27

Connect the Printer via Wi-Fi............................................................................................27

Configure Wi-Fi Communications from the Web Page ...................................27

Configure Wi-Fi Communications from the Main Menu ................................28

Install Authentication Certificates ...........................................................................28

Printer Drivers................................................................................................................................29

Install Honeywell Windows Driver ..................................................................................29

USB Host Port................................................................................................................................29

Connect a USB Device .........................................................................................................30

Chapter 4 - Configure the Printer................................................................31

Printer Configuration Menus ..................................................................................................31

Printer Configuration...........................................................................................................32

Restrict Access to the Main Menu ..................................................................................32

Access the Printer Web Page ............................................................................................32

Printer Webpage User Name and Password...............................................................33

Configure the Printer from the Web Page..........................................................................33

Configure the Printer with PrintSet 5 or Print Set MC...................................................34

Configure the Printer with Programming Commands..................................................34

Uploading from the Web Page .........................................................................................34

Uploading from a USB Storage Device .........................................................................35

Change Background Image for the Ready Screen..........................................................35

Printer Profiles...............................................................................................................................36

Save a Printer Profile from the Web Page....................................................................36

Load a Printer Profile from the Web Page ...................................................................36

Save a Printer Profile from the Main Menu.................................................................37

Load a Printer Profile from the Main Menu ................................................................37

Load a Printer Profile Using Programming Commands........................................37

Install a Configuration File from a USB Storage Device........................................38

Export a Configuration File to a USB Storage Device.............................................38

Menu Shortcuts ............................................................................................................................39

Create Menu Shortcuts .......................................................................................................39

Customize the Printer Web Page...........................................................................................40

PX900/PX900V User Guide v

Page 6

Chapter 5 - About the Verifier...................................................................... 41

Setting up the Verifier ................................................................................................................41

Webpage ................................................................................................................................... 42

Front Panel...............................................................................................................................42

Calibration......................................................................................................................................42

Verifier Calibration Card.....................................................................................................42

Handling Instructions...................................................................................................42

Calibrating the Printer.........................................................................................................43

Verifier Settings ............................................................................................................................ 44

Verification Type ....................................................................................................................44

Passing Grade.........................................................................................................................44

Aperture ....................................................................................................................................44

Maximum Consecutive Failures......................................................................................44

Verification Failure Action .................................................................................................44

Save Failed Label Images ..................................................................................................44

Void Pattern.............................................................................................................................45

Print Modes and Speed.......................................................................................................45

Barcode Symbologies Supported ...................................................................................45

Barcode Orientations...........................................................................................................45

Barcode Size Supported .....................................................................................................45

Verification Length...............................................................................................................46

Maximum Number of Barcodes per Label..................................................................46

Printing Behavior after Error Recovery.........................................................................46

Printing Behavior after Recovered from error above: .............................................46

Printing Errors........................................................................................................................48

Unsupported Barcode Behavior......................................................................................48

Example:.............................................................................................................................48

Verification Failed Error Handling..................................................................................48

Failed Label Image File ...............................................................................................49

USB Thumbdrive............................................................................................................. 49

Reporting and Statistics.....................................................................................................50

Report Formats ......................................................................................................................50

Individual Report ................................................................................................................... 50

vi PX900/PX900V User Guide

Page 7

Report Header .................................................................................................................51

Barcode Information ............................................................................................................53

All Supported 1D Barcodes Overall Parameters .......................................................54

2D Barcode, DataMatrix Overall Parameters .............................................................55

1D barcode 10 line Profile Grading Parameters.......................................................57

Summary Report....................................................................................................................58

Restore Default Verification Files....................................................................................58

Fingerprint Command.........................................................................................................59

Chapter 6 - Troubleshooting.........................................................................61

System Information.....................................................................................................................61

Statistics....................................................................................................................................61

Printer Odometer .........................................................................................................................62

Maintenance Alerts .....................................................................................................................62

Set Alerts ...................................................................................................................................62

Alert Notifications .................................................................................................................63

Error Alerts and Solutions ..................................................................................................64

Verifier Error Alerts and Solutions ..................................................................................65

Troubleshoot Printer Problems and Find Solutions.......................................................65

Print Problems........................................................................................................................65

Verifier Problems ...................................................................................................................67

Networking Problems ..........................................................................................................68

Restore Printer Defaults............................................................................................................68

Restore Defaults from the Printer Web Page..............................................................68

Restore Defaults from the Main Menu .........................................................................68

Restore Defaults with a Hardware-Based Reset .......................................................69

Upgrade the Printer Firmware ................................................................................................69

Upgrade Firmware from the Printer Web Page..........................................................70

Upgrade Firmware from a USB Storage Device ........................................................70

Chapter 7 - Maintenance...............................................................................71

Clean the Printer...........................................................................................................................71

Clean the Printhead..............................................................................................................72

Clean the Front Sensor (PX940A) ...................................................................................72

PX900/PX900V User Guide vii

Page 8

Clean the Verifier (PX940V)...............................................................................................73

Clean the Media Path ..........................................................................................................73

Clean the Exterior of the Printer...................................................................................... 73

Replace the Printhead ...............................................................................................................73

Replace the Platen Roller .........................................................................................................74

Label Taken Sensor Calibration.......................................................................................76

Label Gap and Black Mark Sensor Adjustments ......................................................76

Chapter 8 - Product Specifications............................................................. 79

Printer and Environmental Specifications ........................................................................79

Command Languages and Simulator Support Features ............................................79

Print Sensors .................................................................................................................................79

Network Services.......................................................................................................................... 80

Fonts ................................................................................................................................................. 80

Resident Fonts........................................................................................................................80

Downloadable Fonts ............................................................................................................81

Supported Font Types .........................................................................................................82

Printed Barcode Symbologies..........................................................................................82

1D Barcode Symbologies ............................................................................................82

2D Barcode Symbologies ............................................................................................82

Graphic File Types.................................................................................................................83

Appendix A - Default Settings...................................................................... 85

Communications Settings .......................................................................................................85

Serial Port.................................................................................................................................85

Ethernet ....................................................................................................................................86

Bluetooth Settings ......................................................................................................................86

Media Settings..............................................................................................................................86

Print Quality Settings.................................................................................................................89

System Settings............................................................................................................................90

General System ......................................................................................................................90

Display and Audio Settings ...............................................................................................91

System I/O ...............................................................................................................................91

viii PX900/PX900V User Guide

Page 9

System Network Services ...................................................................................................92

Verifier Settings ............................................................................................................................93

Maintenance Alerts ....................................................................................................................94

Appendix B - Print Labels with INPrint.......................................................95

The INPrint Page ..........................................................................................................................95

Print INPrint Labels..............................................................................................................95

Appendix C - Accessories and Options........................................................97

Printer Accessories and Options............................................................................................97

PX900/PX900V User Guide ix

Page 10

x PX900/PX900V User Guide

Page 11

Customer Support

Technical Assistance

To search our knowledge base for a solution or to log in to the Technical Support

portal and report a problem, go to www.hsmcontactsupport.com.

For our latest contact information, see www.honeywellaidc.com/locations.

Product Service and Repair

Honeywell International Inc. provides service for all of its products through service

centers throughout the world. To obtain warranty or non-warranty service, return

your product to Honeywell (postage paid) with a copy of the dated purchase record.

To learn more, go to www.honeywellaidc.com and select Service & Repair at the

bottom of the page.

Limited Warranty

For warranty information, go to www.honeywellaidc.com and click Get Resources >

Product Warranty.

PX940 User Guide xi

Page 12

Safety Warnings

Warning: Moving parts are exposed when the cover is open. Make sure

Warning: The printhead/motor may be hot. Allow the printhead/motor to

Warning: Do not put your fingers inside the print mechanism when the

Warning: The tear bar contains sharp edges. Keep fingers and other body

Warning: Installing the printer requires a power cord connected to a

Warning: Disconnect the power cord from the socket-outlet before

Warning: This printer contains a coin battery and is NOT user

the cover is closed before operating the printer.

cool.

power is on.

parts away from the tear bar.

socket-outlet with an earthing connection.

installing user-service parts in the printer.

replaceable. Keep children away from the printer when the

printer is in service.

Caution Statements

Caution: Read and review the warnings in this manual carefully before

Caution: Observe all safety and accident prevention regulations

Caution: Do not spray the printer with water. If you are using a hose to

Caution: You must implement both hardware and software safety

Caution: You must make sure that dangerous conditions cannot occur

Caution: Carefully read the warning text on the envelope before using a

Never put batteries in your mouth as swallowing may lead to

serious injury or death. If swallowed, seek medical attention

immediately from a physician or local poison control center.

connecting the printer.

applicable to your specific region and application.

clean the premises in an industrial environment, remove the

printer or protect it carefully from spray and moisture.

precautions to prevent the possibility of undefined system

states.

under any circumstances, even for a brief period of time.

cleaning card.

xii PX940 User Guide

Page 13

Caution: To reduce the risk of electric shock or fire, keep the cover closed

and turn off the printer when not in use. There are no userserviceable parts inside the power supply unit.

Shipping the Printer

To avoid printer damage during transit:

1. Power off the printer and remove all cables.

2. Remove media and ribbon (if installed) from the printer.

3. Lower the printhead and front arm.

4. Pack the printer in the original container.

Note: Honeywell is not responsible for any damage caused during shipment/transit.

PX940 User Guide xiii

Page 14

xiv PX940 User Guide

Page 15

CHAPTER

1

GET STARTED

The PX940 industrial printer series includes:

• PX940 productivity version (PX940A)

• PX940 Verifier version (PX940V) with an integrated barcode verification

module.

Both PX940A and PX940V printers are rugged label printers that include

integrated USB, RS-232, Ethernet, and Bluetooth LE interfaces. You can connect

the printers to a single PC, a wired network, or a wireless (optional) network.

Note: Bluetooth LE is only used with Print Set MC to configure the printer on Android and

iOS devices.

Features

• USB host port for connecting storage devices, scanners, or keyboards.

• USB device port to connect to a PC.

• Support for printer command languages including Fingerprint (FP), Direct

Protocol (DP), Intermec Printer Language (IPL), Zebra Simulation (ZSim),

Datamax Printer Language (DPL), and Smart Printing.

About the Display

The front panel has a 3.5 inch full-touch screen that supports touch input with

fingers, gloved hands, or a stylus.

PX940 User Guide 1

Page 16

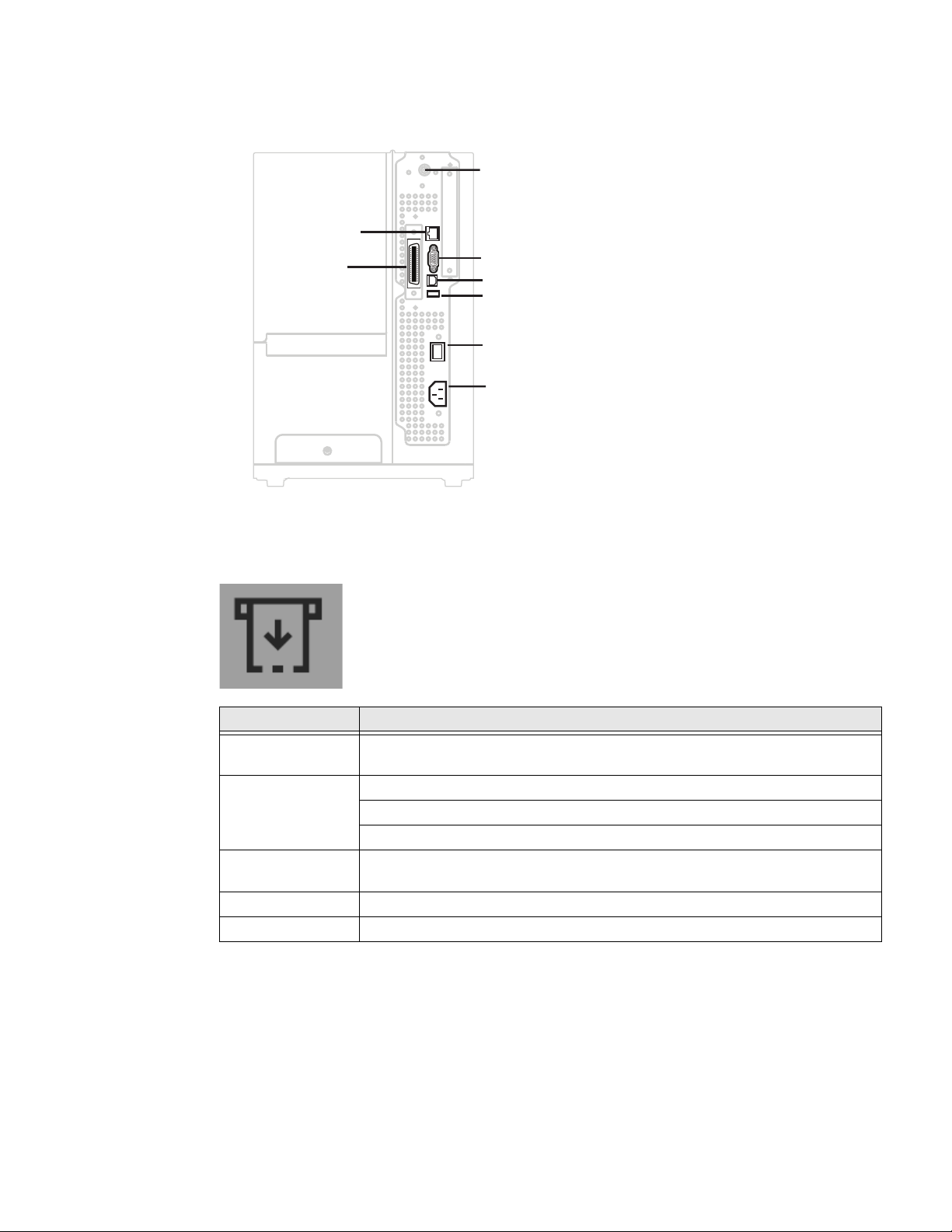

Back View (Ports and Power)

Ethernet Port

IEEE 1284 Port

(Optional)

RS232 Serial Port

On/Off Switch

USB Host Port

USB Device Port

AC Power

IEEE 802.11 Port

(Optional)

Print Button

Ready Screen

Use the Print button to feed media, pause print jobs, calibrate, test feed, and print.

Printer State Print Button Action

Startup Press the Print button during startup to enter Calibration mode or to restore

defaults if the printhead is lifted.

Ready Press the Print button to advance the media.

If the print key feature is on, press the Print button to reprint the last job.

Press and hold the Print button to calibrate the media sensors.

Printing Press the Print button to stop or pause printing. The printer stops after

completing the current label.

Paused Press the Print button to resume printing.

Error Press the Print button to advance the media.

The Ready Screen appears when the printer is powered on and has completed its

startup process.

Note: The icon for Wi-Fi status appears only when the optional Wi-Fi module is installed.

2 PX940 User Guide

Page 17

By default, the information bar at the bottom of the screen shows the printer command language and the printer IP address. You will see the time and current date

only if the real time clock (RTC) is installed. You can customize the screen to show

different types of information.

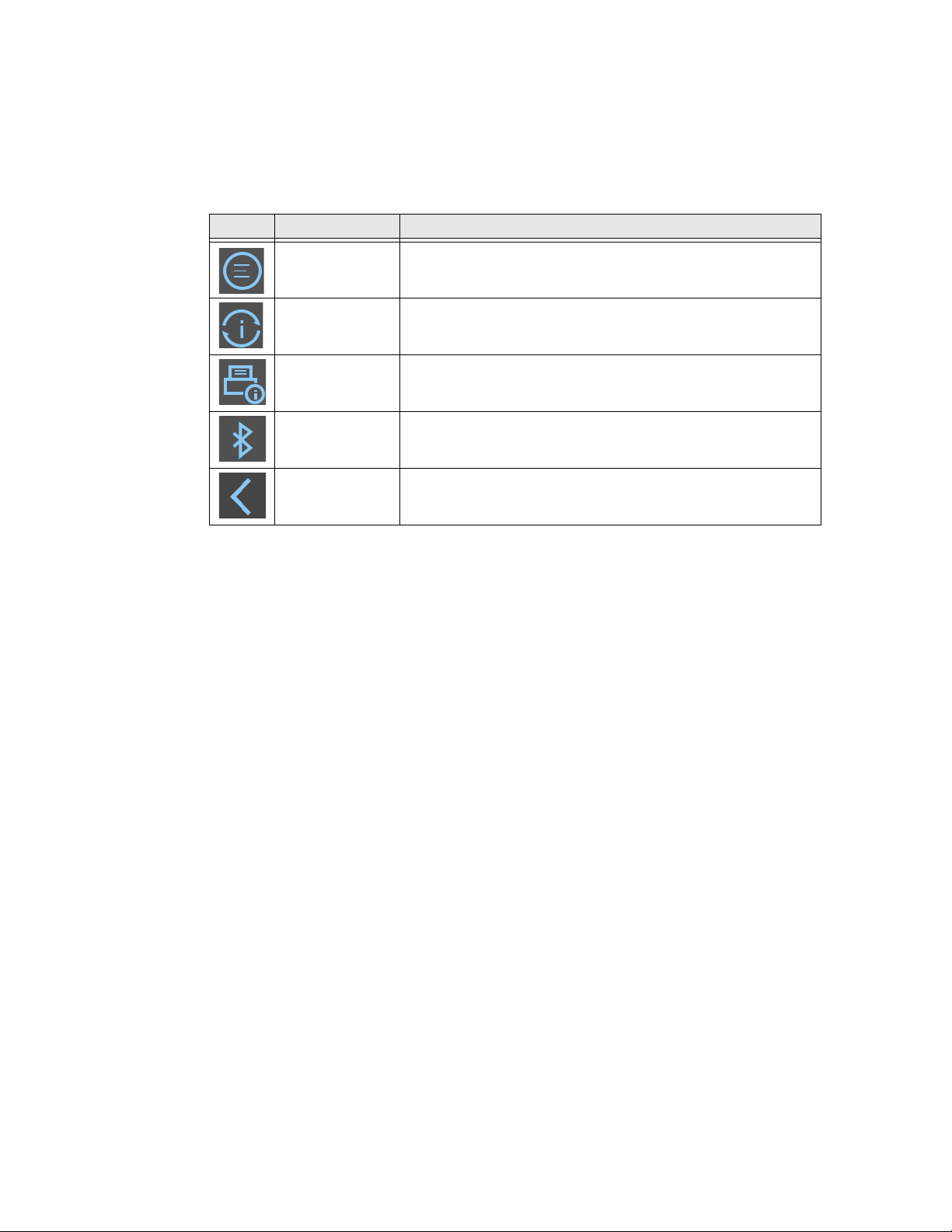

The status bar at the top of the screen includes these icons:

Icon Name Description

Main Menu Press the icon to view the main menu for your printer.

Communications

Printing

Bluetooth

Back

Press the icon to view communications information for your

printer.

Press the icon to view specific printer information.

Press the icon to view Bluetooth LE information for your

printer.

Press this icon to navigate back through the printer menus.

PX940 User Guide 3

Page 18

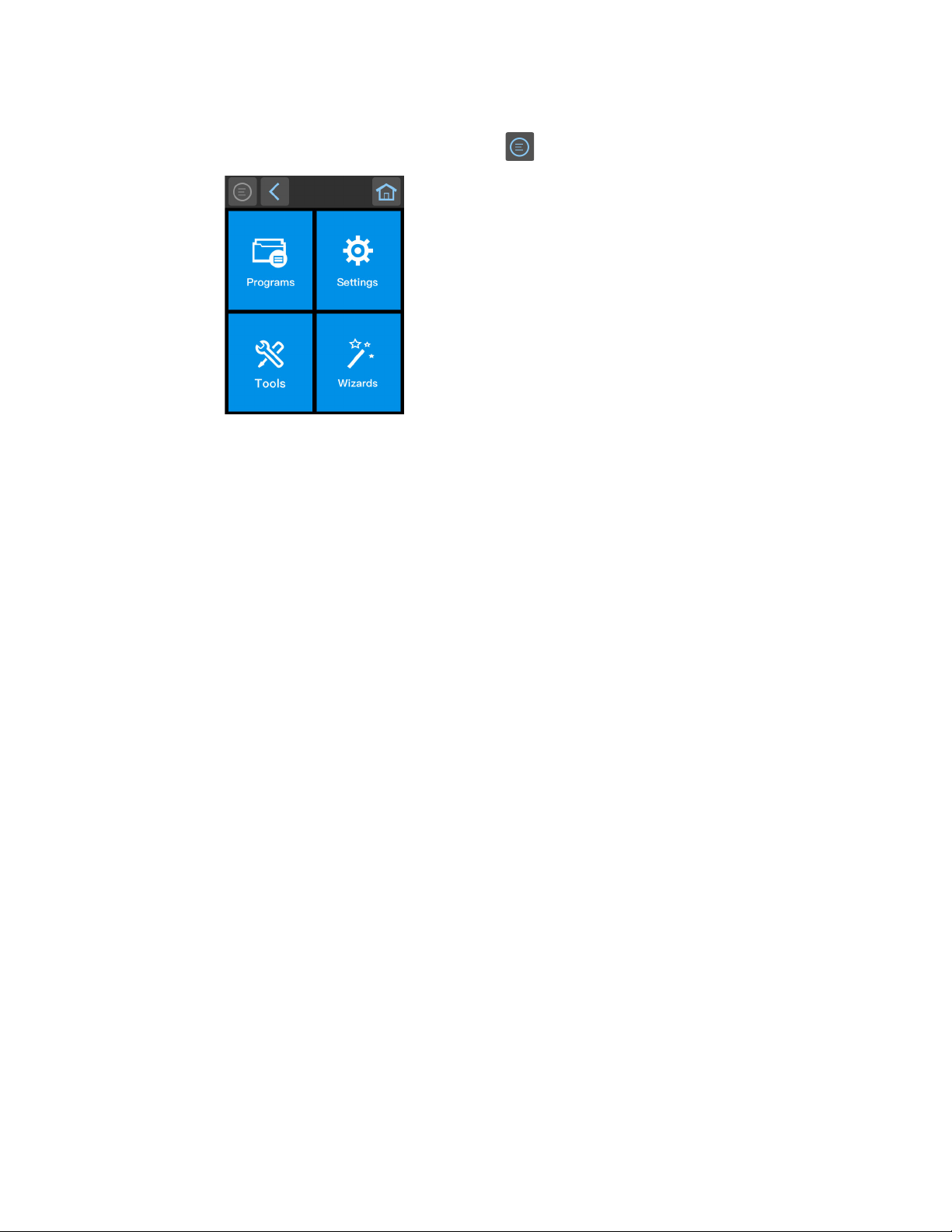

Main Menu

Note: If you create menu shortcuts, the Main Menu is replaced by the Quick Choices menu.

On the printer Ready screen, press to view the Main Menu.

Press a button to select the Programs, Settings, Tools, or Wizards menu.

• Programs displays a list of programs installed on the printer. This list includes

utility programs provided as part of the firmware and programs you have

installed. Programs appears in the Main Menu only if the printer is using

Fingerprint or Direct Protocol as the command language.

• Select Settings to view and change printer settings.

• Select Tools to print test labels, manage a connected USB storage device,

restore printer default settings, or save and load printer profiles.

• Select Wizards to see a list of wizards that help you configure printing or

communication settings, or calibrate the media sensors.

Note: The printer cannot print while the Main Menu is showing. Exit the Main Menu and

return to the Ready screen to begin printing.

4 PX940 User Guide

Page 19

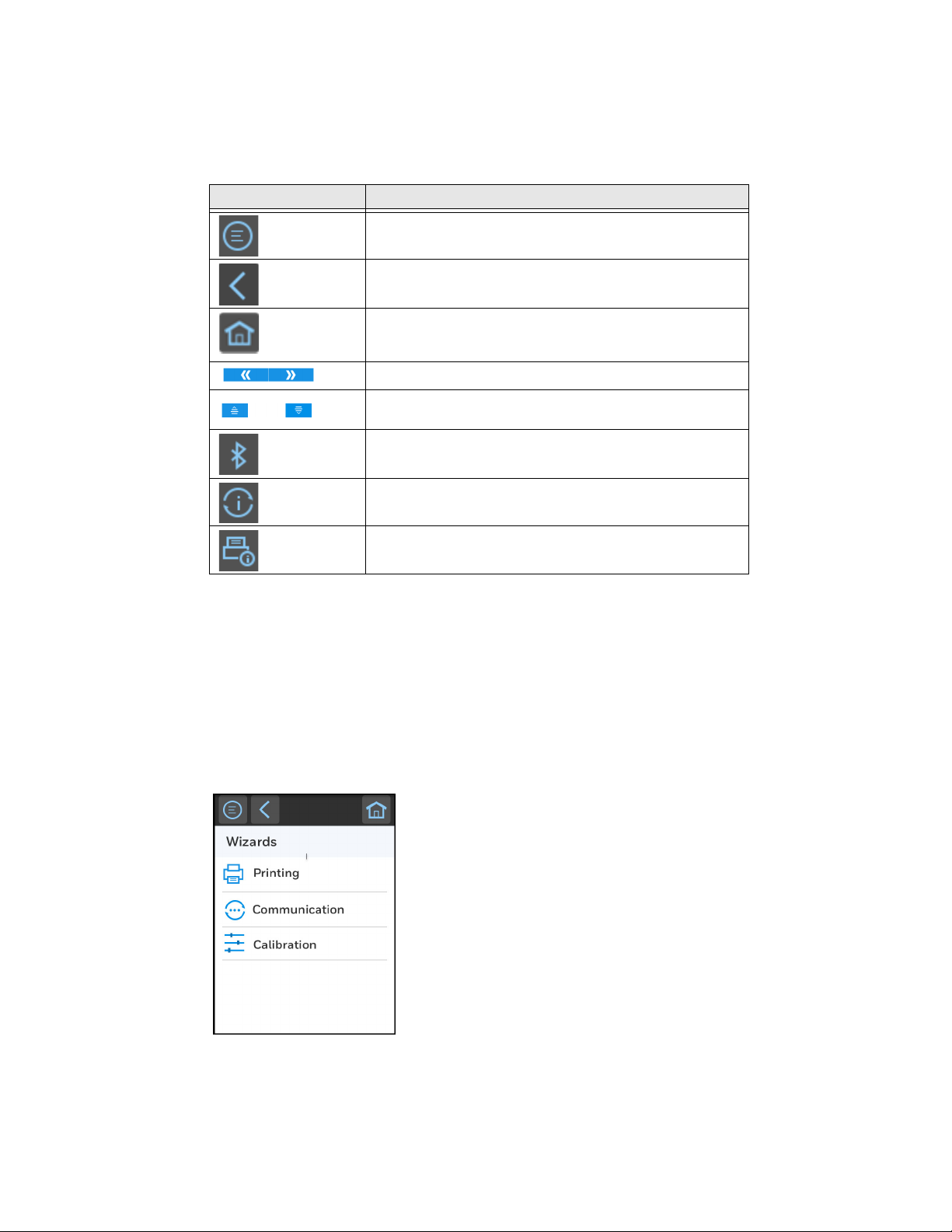

Navigate the Main Menu

Use the status bar buttons to navigate between menus in the Main menu and save

changes.

Button Description

Returns to the Main menu

Goes back one level in the menu

Returns to the Ready screen

Moves between options in a settings menu

Moves to additional options not viewable in the menu

Bluetooth: Gives the device name and device address

Information: Gives Communications information such as

Ethernet, Serial, and USB.

Printer Information

Note: Use the horizontal scroll bar for settings with additional options.

Wizards

The printer includes several wizards you can use to quickly set up your printer. You

can start all of the wizards from the Main menu except for the startup wizard. The

startup wizard appears the first time you turn on the printer and after the printer

has been reset to the factory default state.

PX940 User Guide 5

Page 20

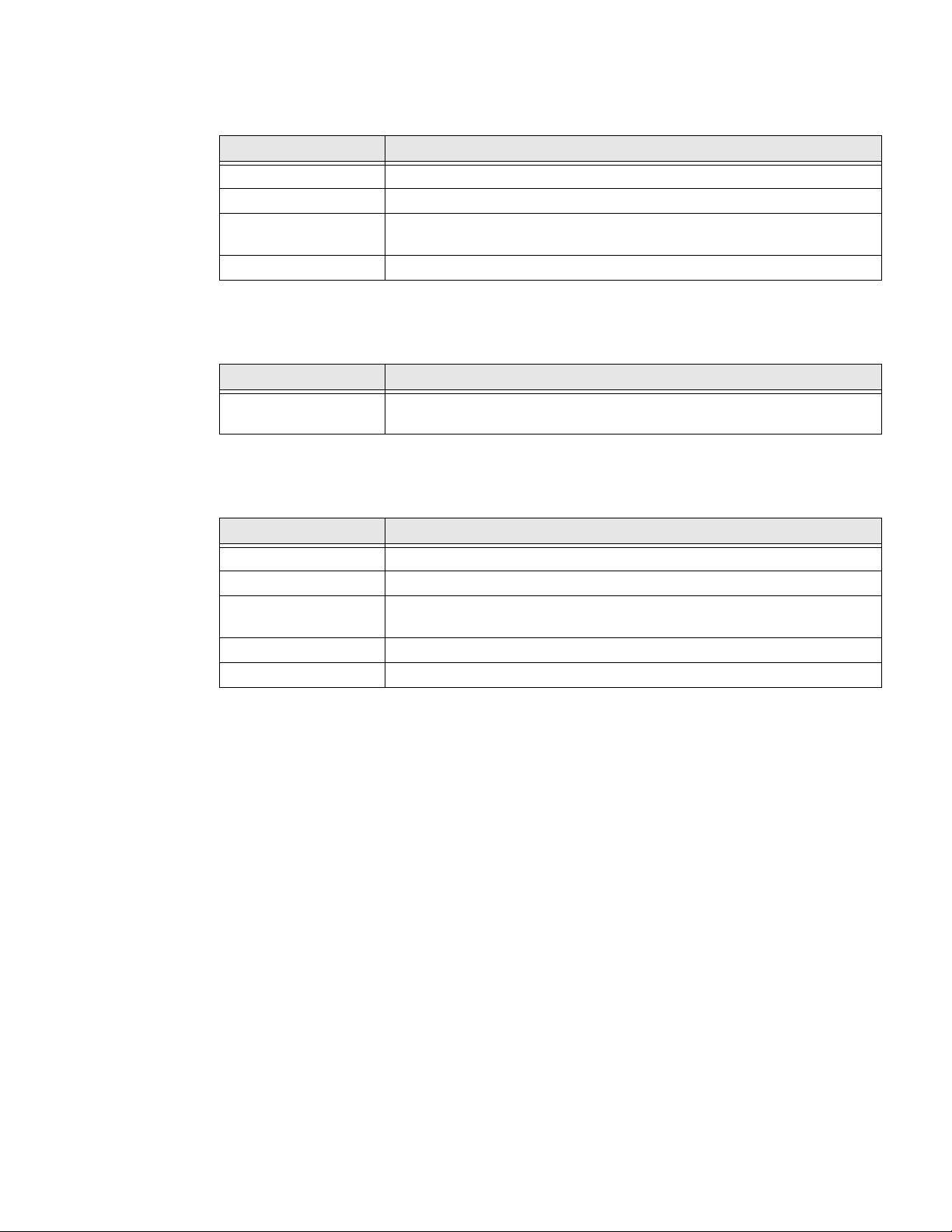

Printing Wizard

Wizard Description

Media Loading Guide Shows how to load media.

Ribbon Loading Guide Shows how to load ribbon.

Media Setup Select media and printing type (DT or TTR), media width, length, and X-

Print Quality Prints a series of labels to determine the best print quality setting.

Communications Wizard

Wizard Description

Line Analyzer Logs all incoming data on all communications channels and saves the

Calibration Wizard

Wizard Description

margin, Label Reset and Label Top Adjust values, and print speed.

data to a log file. For advanced users.

Media Calibrates all media sensors and shows current print settings.

Verifier Calibrates the Verifier. (for PX940V only)

Label Taken Sensor Calibrates the label taken sensor used with the label dispenser. Available

when the label taken sensor is installed.

Date and Time Calibrates the date and time.

Screen Calibrates the touch screen.

Printer Command Languages and Simulator Support Options

A printer command language is a set of instructions that controls printer functions:

• Configure the printer.

• Return the status of the printer.

• Control peripheral devices.

• Format a label or receipt for printing.

The printer supports these command languages and language simulator support

options:

• Autosense

• Direct Protocol

• Fingerprint

• IPL

6 PX940 User Guide

Page 21

• ZSim

• DPL

• Smart Printing

Autosense

Autosense allows the printer to automatically sense from label to label, the incoming data stream and its language, and print each label accordingly.

Note: Autosense is the default printer configuration and does not support an IPL data

stream.

Direct Protocol

Direct Protocol (DP) uses a more intuitive English-like syntax. Direct Protocol lets

you combine predefined layouts and variable data to create labels, tickets, and

tags. If you are using barcode software, select Direct Protocol as your printer

command language.

Fingerprint

IPL

ZSim

Fingerprint is a BASIC-inspired general purpose printer language. Use Fingerprint

to design custom label formats and write printer application software. If you plan

to run Smart Printing applications directly on the printer, without connecting to a

PC, select Fingerprint as your printer command language.

IPL is a host-based printer command language. Use IPL to design, modify, and

download label formats, write printer application software, and configure the

printer. If you are sending IPL label files to the printer, select IPL as your printer

command language.

Note: IPL can be supported on 200dpi and 300dpi printers only.

The ZSim (Zebra Printer Language Simulator) interprets Zebra™ programs (ZPL II

or later) without requiring any host programming changes. If you are sending ZPL

label files to the printer, select ZSim as your printer command language.

PX940 User Guide 7

Page 22

DPL

The DPL command language interprets Datamax™ data streams without requiring

any host programming changes. If you are sending DPL label files to the printer,

select DPL as your printer command language.

Smart Printing

Smart Printing refers to the ability of the printer to independently run printing

operations without being connected to a host computer. If you are running

printer-based applications written in C#, select Smart Printing as your printer

command language.

Access the Printer Web Page

1. Open a browser window on your PC.

2. In the location or address bar, type the printer IP address and press Enter.

3. Click Login. The Login page appears.

You will be prompted for a user name and password. The defaults are:

•User Name: itadmin

•Password: pass

After logging in, you will be prompted to change your password.

Set the Printer Command Language

You can use one of these methods to change the printer command language:

• From the printer web page

• From the Main Menu

• PrintSet 5

• Print Set MC

From the Printer Web Page

To set the command language from the printer web page, you need to turn on the

printer and connect to your network.

1. Make sure that the printer has media and ribbon installed (if necessary).

2. Follow the directions to Access the Printer Web Page.

3. Once you are logged in to the printer web page, click the Configure tab.

8 PX940 User Guide

Page 23

4. Click System Settings > General.

5. select the printer command language you want to used from the Command

Language list, and then click Save. A restart button will appear at the top of the

page.

6. Click Restart.

From the Main Menu

You can use this procedure to change the printer command language from the

main menu on the printer.

1. From the Ready screen, press the Main Menu button.

2. From the Main Menu, press Settings > System Settings > General.

3. Scroll down until you reach Command Language, and make your selection.

4. Restart the printer: the printer starts up in the command language that you

selected.

PX940 User Guide 9

Page 24

10 PX940 User Guide

Page 25

CHAPTER

2

SET UP THE PRINTER

This section contains information about loading media and ribbon, printing a test

label, calibrating the screen, and adjusting the printer.

Power Up the Printer

The printer goes through a startup wizard the first time you turn on the power.

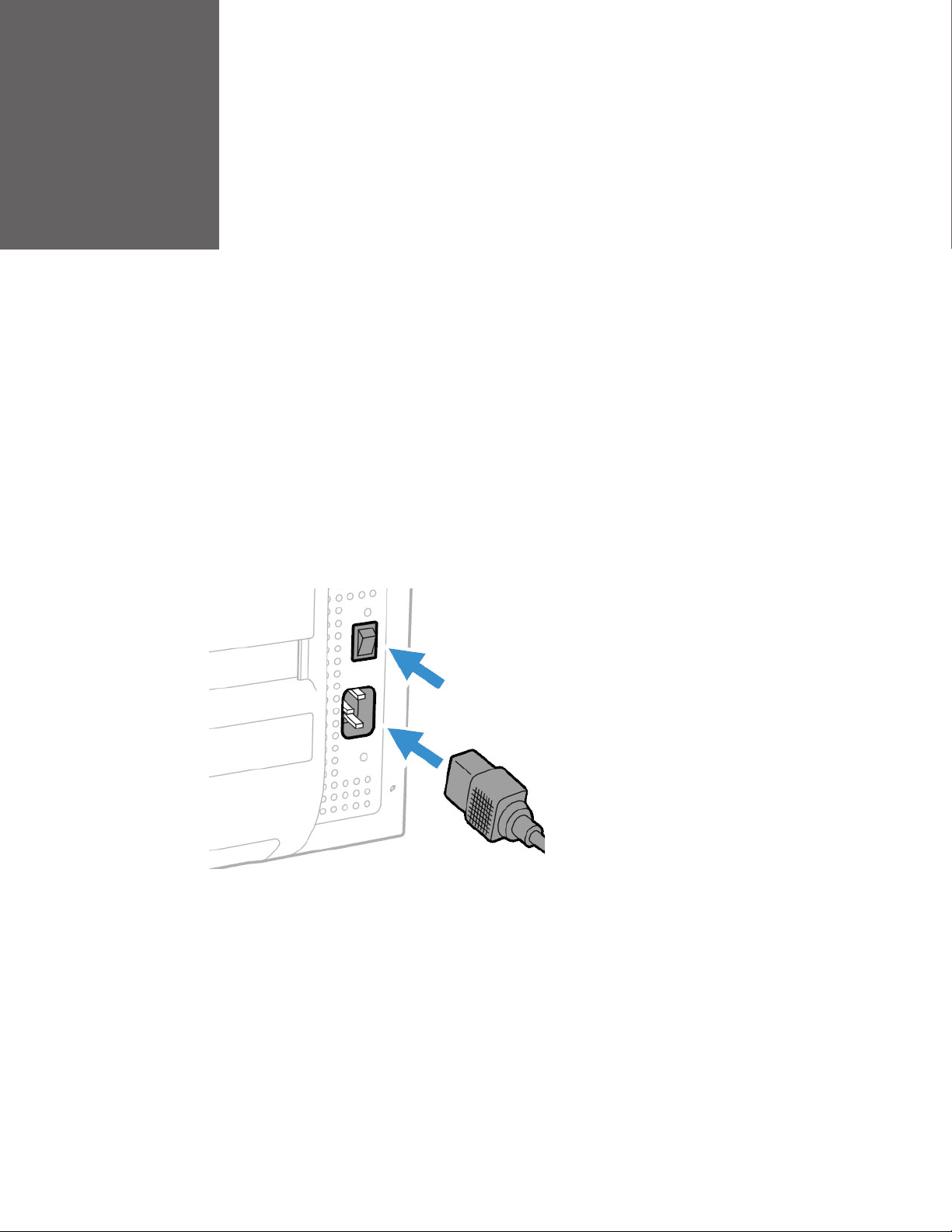

1. Connect one end of the power cord to the back of the printer and plug the other

end to AC power.

2. Press the power switch to turn on the printer.

3. As the printer starts up, a progress bar appears, then the startup wizard

appears.

4. Follow the steps on the touch screen to complete the startup wizard.

PX940 User Guide 11

Page 26

Calibrate the Touch Screen

You can calibrate the screen from the printer website or from the touch panel on

the printer.

To calibrate the screen from the website:

To access the website, make sure your printer is connected to the same network as

your computer.

1. Open your browser and type the printer IP address into the web address bar.

2. In the menu section, click on Services > Screen Calibration. If you are

prompted to login, the temporary username is itadmin and the password is

pass.

3. Click on the blue Screen Calibration button, this will engage the touch panel

to start screen calibration.

• When the small square appears on the front touch panel of the printer, touch

the square and continue to touch the square until the printer beeps.

4. Once calibration is complete, your touch screen will automatically return to the

Ready screen.

Note: Typical screen calibration consists of five touches (one in each corner and one in the

middle of the screen)

About the Media

The printers can print on labels, tickets, tags, and continuous stock. The procedure

you use to load media depends on how you are operating the printer and the

options you have installed.

Note: The PX940 series printers only support out-wound media.

Load Media for Tear-Off Printing

Tear-off printing is applicable to media with perforation. Printed labels, tickets, and

other printed media are manually torn from the front of the printer. These of media

can be used for tear-off printing:

• Non-adhesive continuous stock.

• Self-adhesive continuous stock with liner.

• Self-adhesive labels with liner.

• Tickets with gaps, with or without perforations.

• Tickets with black marks, with or without perforations.

12 PX940 User Guide

Page 27

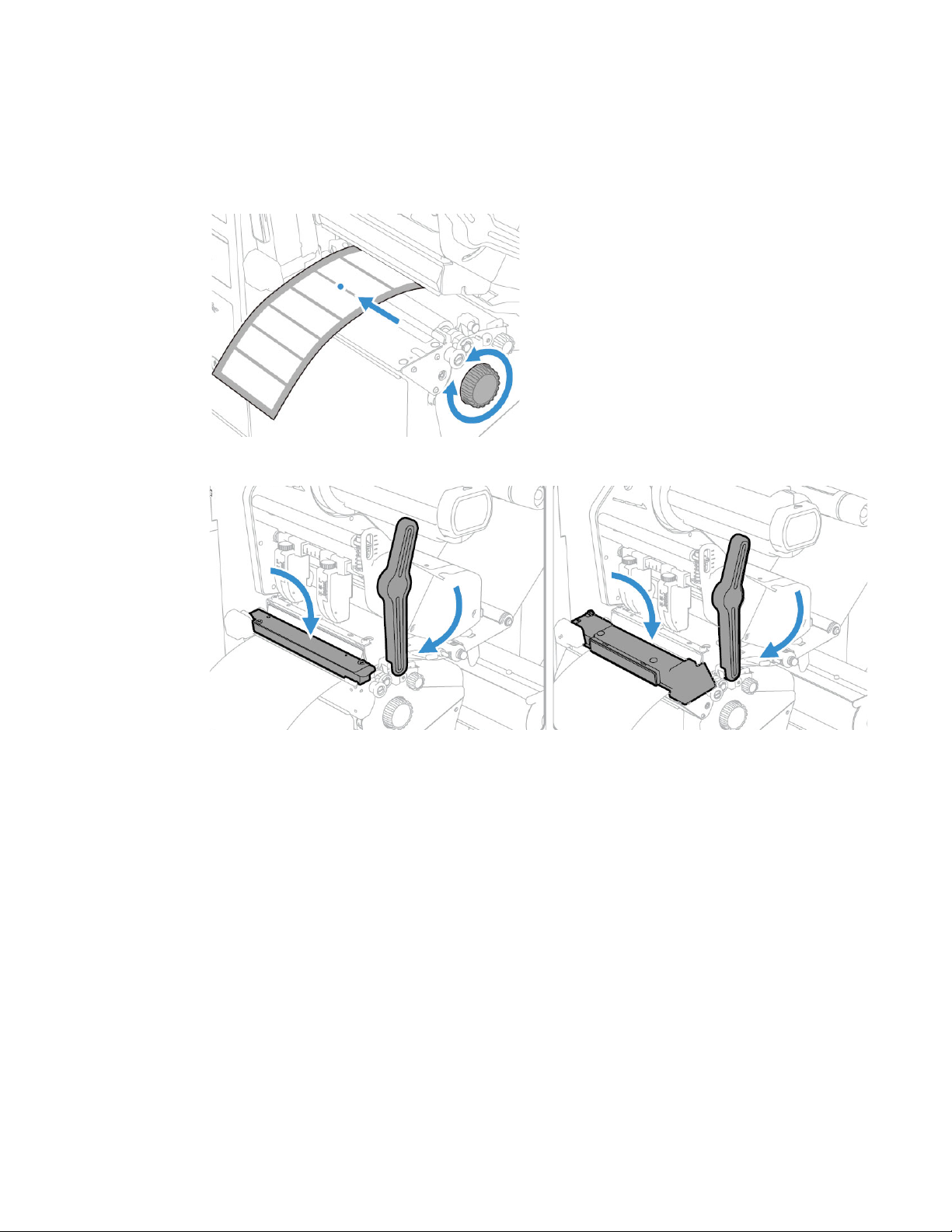

To load media for tear off printing:

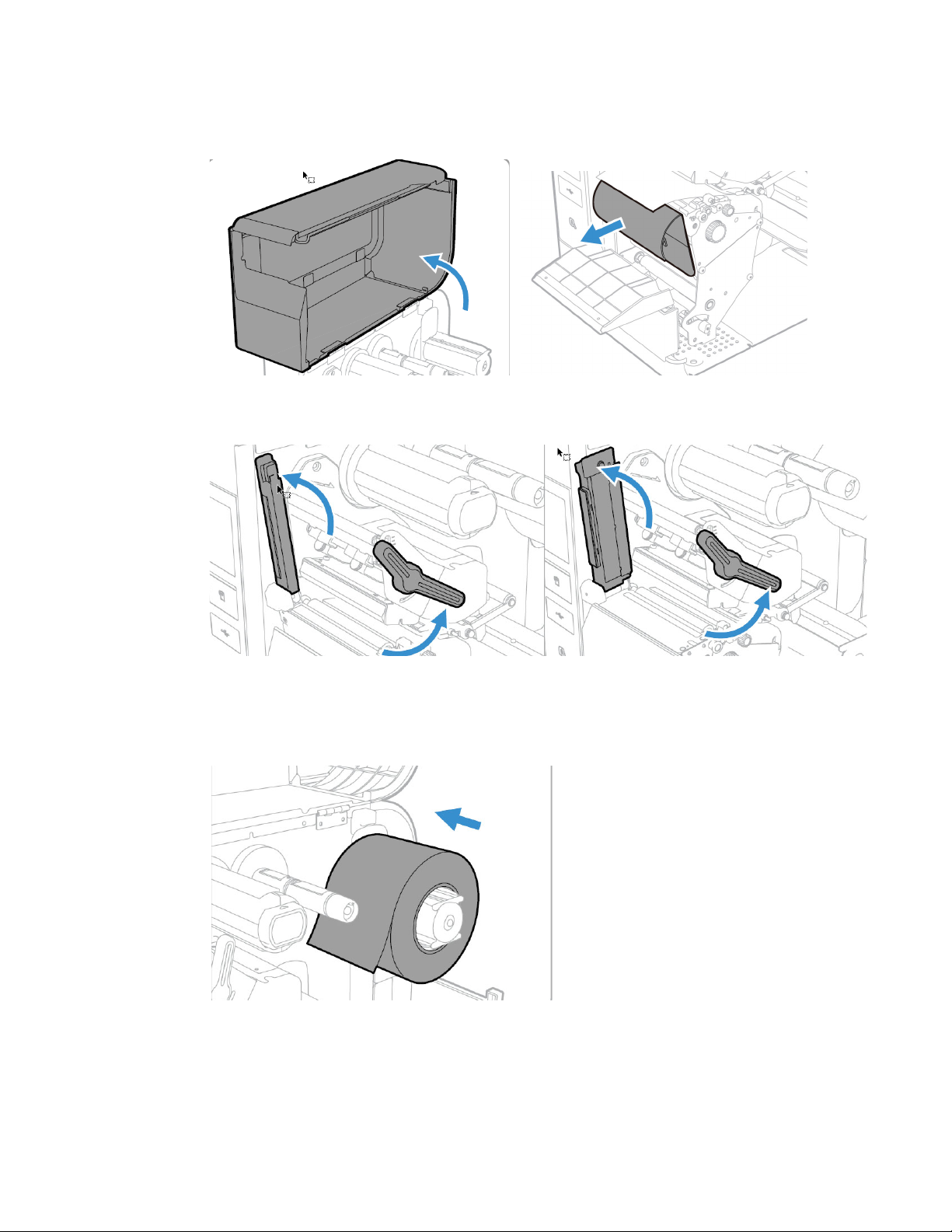

1. Open the media cover and remove the rewinder plate (if installed).

2. Turn the printhead lift lever counterclockwise to raise the printhead and lift the

front arm or verifier arm.

printhead and front arm lifted (PX940A) printhead and front arm lifted (PX940V)

3. Load a media roll onto the media supply hub.

Note: Make sure you push the roll all the way against the inner wall of the printer.

PX940 User Guide 13

Page 28

4. Insert the media roll holder and tighten the screw.

5. Route the media through the print mechanism, through the front arm.

6. Adjust the media and dancer guides to hold the media in place.

14 PX940 User Guide

Page 29

Note: There is a media guide that is located near the printhead. It is recommended to adjust

the media guide all the way to the right in order to insert the media. If not, it can be

difficult to load the media.

7. Adjust the label gap and black mark sensor. The sensor blue LED should line

up with the center of the media.

8. Turn the printhead lift lever clockwise to close the printhead and lower the

front arm and click into place.

front arm in place (PX940A) front arm in place (PX940V)

9. Press the Print button to advance the media.

10. Close the media cover.

PX940 User Guide 15

Page 30

Load Media for Rewind Printing

Follow steps 1-9 from Load Media for Tear-Off Printing, then:

1. Place the rewinder batch plate back on the printer.

2. Insert an empty media core onto the rewinder take-up hub.

3. Round the media through the rewinder batch plate and tape leading edge of

label to the empty media core to secure position.

4. Route the media around the media rewinder.

16 PX940 User Guide

Page 31

5. Lock the Rewind/Liner Take-Up knob into closed position.

6. Put media roll holder in place.

7. Go to Main Menu > Setting > Printing > Media > Printing Mode, select

Rewind from the list.

Note: Honeywell recommends using non-perforated labels when using rewinder mode.

Load Media for Peel-Off Printing

Follow steps 1-9 from Load Media for Tear-Off Printing, then:

1. Insert the media in the opening between the label dispenser and the platen

roller.

2. Insert an empty media core onto the rewinder take-up hub.

3. Round the liner through the media rewinder and tape leading edge of label to

the empty media core to secure position.

4. Pull the liner tight and lock the Rewind/Liner Take-Up knob into closed

position.

PX940 User Guide 17

Page 32

5. Put media roll holder in place.

6. Go to Main Menu > Setting > Printing > Media > Printing Mode, select

Peel-Off from the list.

Note: Honeywell recommends using non-perforated labels when using peel-off mode.

Load Fanfold Media

Note: Before loading fanfold media, insert an empty media core onto the rewinder take-up

hub.

To load Fanfold Media from behind the printer:

18 PX940 User Guide

Page 33

To load Fanfold media from bottom access slot:

= Ink out

About the Ribbon

Thermal transfer printing provides a durable printout that is less vulnerable to

chemicals, heat, and sunlight than direct thermal printing. Select a ribbon type

that matches the media you are using and configure the printer for thermal

transfer media.

The printer supports thermal transfer ribbon rolls with the ink-coated side facing

either inward or outward. To determine which type of ribbon you have, place the

ribbon on a piece of paper as shown, and use a pen or other sharp object to scratch

the ribbon. If you see a mark on the paper, your ribbon is wound ink out.

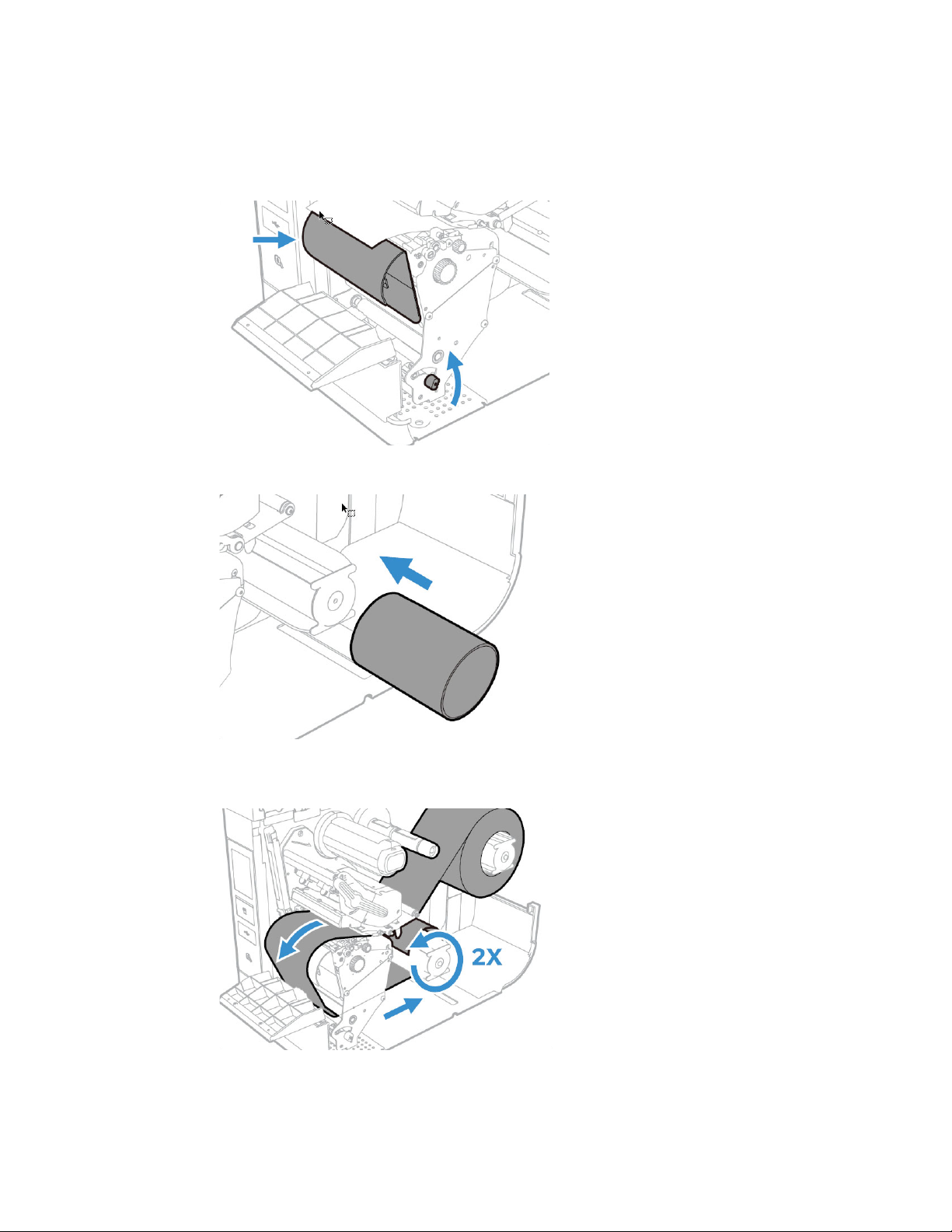

Load Ribbon

= Ink in

1. Open the media cover.

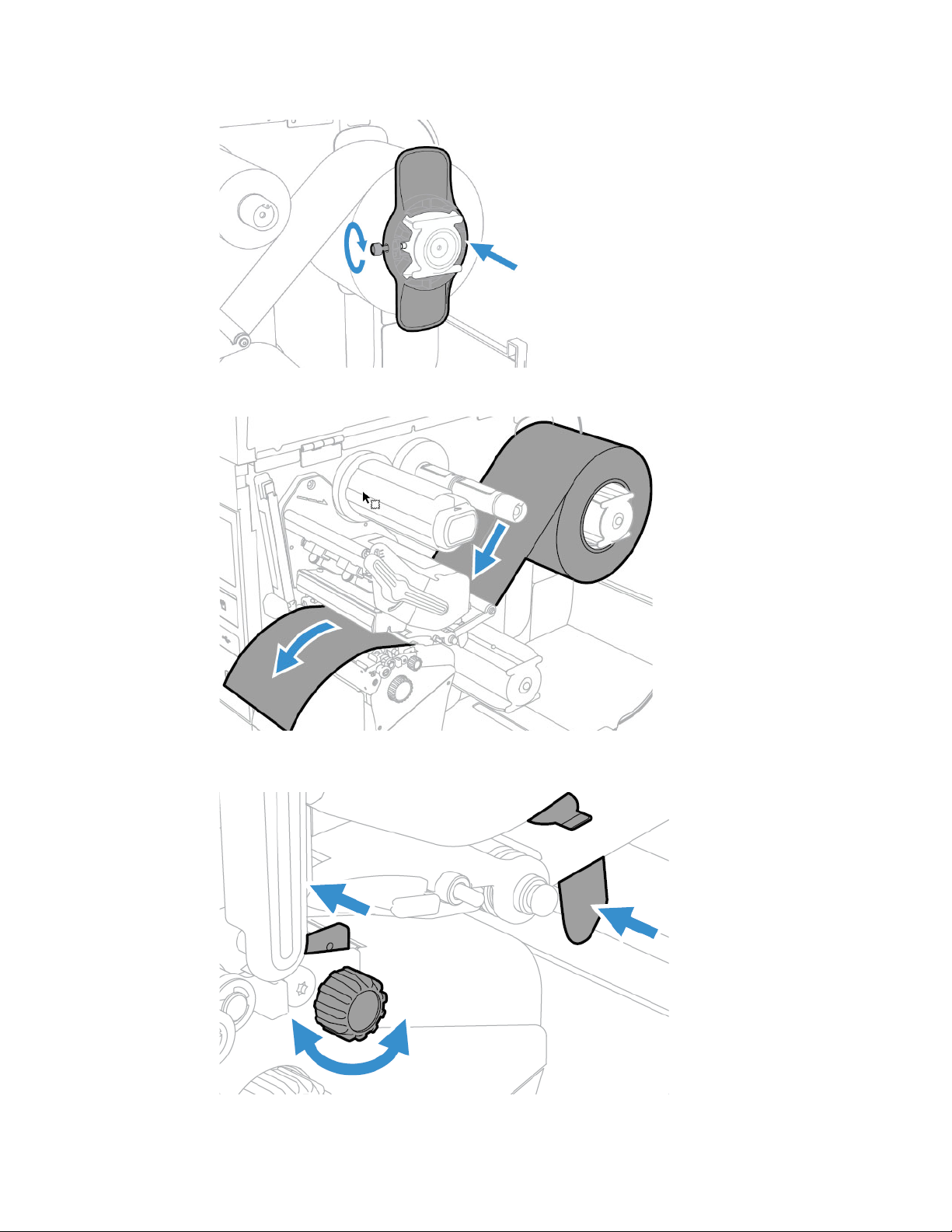

2. Turn the printhead lift lever counterclockwise to raise the printhead and lift the

front arm.

3. Slide the ribbon roll onto the ribbon supply hub.

PX940 User Guide 19

Page 34

Note: For ribbon that has the ink wound out, place the ribbon on the ribbon supply hub with

the ribbon wound clockwise. For ribbon that has the ink wound in, place the ribbon on

the ribbon supply hub with the ribbon wound counterclockwise.

4. Route the ribbon through the print mechanism and pull out approximately 8

inches (20cm) of ribbon leader.

The dotted line in this illustration shows how to load ribbon with the ink wound in.

5. Turn the ribbon take-up hub counterclockwise until the ribbon becomes tight

and runs wrinkle-free through the print mechanism.

6. Set the Ribbon Selector switch to Ink In or Ink Out.

7. Close the media cover.

Note: Ensure that the knob at the take up is not pushed in during rewinding. This can cause

difficulty removing the ribbon when full.

Ribbon Removal

Remove used ribbon from the ribbon take-up hub when you change the roll of

ribbon. Remove the used ribbon each time you change a new roll of media if the

ribbon is less than the width of the printhead.

To remove the used ribbon:

20 PX940 User Guide

Page 35

1. Break/tear the ribbon before the ribbon take-up hub.

Note: Do not cut the ribbon on the ribbon take-up hub; doing so may result in damage to

the take-up hub.

2. Push and hold the ribbon release knob until it stops.

Note: Do not push the ribbon release knob in if you do not want to remove the used ribbon

as this will cause difficulty to remove ribbon when full.

3. Push the two ribbon release plates and slide the used ribbon from the ribbon

take-up hub.

Print a Test Label

The first time you turn on the printer or reset to factory defaults, the printer runs a

startup wizard to let you enter basic setup information. After the startup wizard finishes, the printer enters Ready mode where you can access the Main Menu and

print a test label.

1. Connect the printer to power and turn on the printer.

2. After the startup sequence finishes, the startup wizard begins. Enter all the

information on the wizard screens then tap No when prompted to run other

wizards.

3. From the Ready screen, press to view the Main Menu.

4. From the Main Menu, tap Tools > Test Labels.

5. Select the test label you want to print and tap it.

Your test label prints. If print quality is low, go to Wizards > Printing > Print Quality.

Note: You can use command languages, like Direct Protocol, and language simulators, like

ZSim, to create and print labels. For more information, see the command reference

manual for the language.

PX940 User Guide 21

Page 36

Printhead Pressure and Toggle Position

Pressure Adjustment

You may need to adjust the printhead pressure on the printer if:

• You are using thicker or thinner media than previously.

• Your thermal transfer ribbon starts to crease.

Do not use a higher printhead pressure than necessary. It may increase the wear on

the printhead and shorten its life.

1. Use your finger to turn the wheel to adjust pressure.

• Rotate the wheel clockwise to increase the pressure resulting in darker print.

• Rotate the wheel counterclockwise to decrease the pressure resulting in

lighter print.

2. Test for Print Quality

Note: Marking on the toggle, “L”: Light pressure; “M”: Middle pressure; “H”: High pressure.

Toggle Position Adjustment

If the toggles are not adjusted in the correct position or do not apply the correct

pressure, the following issues may occur:

• Labels print lighter on one side than the other

• Media and ribbon may slip

• Ribbon may wrinkle

• Media may move from side to side during printing

If any of these things occur, you probably have an unbalanced printhead. The

printer is adjusted at the factory for full-width media.

If you are using media that is less than full-width (4 inches or 102mm), adjust the

position of the toggle as necessary to provide the even pressure on the media.

22 PX940 User Guide

Page 37

Toggle Settings

Item Scenario Printhead Toggle Setting

1 Thin media or the media and ribbon

requires lower pressure to print well or

DT media

2 Thick media or the media requires

high pressure to print well

3 Light Printing on the left side of the

label

4 Light Printing on the right side of the

label

5 Media moves from left side to right

side during printing

6 Media moves from right side to left

side during the printing

7 Media and ribbon slippage during

printing at retract mode

8 Narrow media (less than 2inch) Move the left toggle to the center of the media

Decrease the pressure on both left and right

toggles.

Increase the pressure on both left and right

toggles.

Increase the pressure on the left toggle.

Increase the pressure on the right toggle.

Increase the pressure on the left toggle or

decrease the pressure on the right toggle.

Increase the pressure on the right toggle or

decrease the pressure on the left toggle.

Increase the pressure on both left and right

toggles.

and decrease the pressure on the right toggle.

PX940 User Guide 23

Page 38

24 PX940 User Guide

Page 39

CHAPTER

3

CONNECT THE PRINTER

This section contains information about connecting the printer to a PC or to a network. Use the From the Printer Web Page or the Main Menu to configure settings.

Connect the Printer to Your PC

You can connect the printer to your PC using one of the following methods.

Connect the Printer Using a Serial Cable

You can use a serial connection to communicate with your PC and send commands

directly to the printer through a terminal connection.

1. Connect one end of the DB9 to DB9 RS-232 cable to the back of your printer

and connect the other end to a serial COM port on your PC.

Connect the Printer Using a USB Cable

Connect only one printer to your PC, either directly or through a hub. You do not

need to set up any parameters for USB communications.

1. Download and install the InterDriver software on your PC (see Install

Honeywell Windows Driver).

2. When prompted, connect one end of the USB Type A cable to the back of the

printer and connect the other end to your PC.

Connect the Printer to Your Network

These network interfaces provide features such as security, FTP server, web page,

and Alert handling.

PX940 User Guide 25

Page 40

Connect the Printer to an Ethernet Network

Use the Ethernet port to set up your printer as a network printer. The printer is set

to automatically retrieve an IP address from the network (DHCP) when you turn the

printer. You can use the network connection with InterDriver. You can also use it to

send commands directly to the printer through a terminal connection (Telnet), or

through FTP.

Note: To enable the FTP from the webpage, go to Configure > System Settings > Manage

Services

1. Turn the printer off.

2. Connect the Ethernet cable to the Ethernet port in the rear of the printer and

connect the other end of the cable to your network.

3. Turn the printer on.

4. If your printer uses a DHCP server to assign IP addresses, the IP address

appears in the lower left corner of the screen.

5. If you are not using a DHCP server to automatically assign IP addresses to

devices in your network, you must set a static IP address and other network

information manually. Continue with the next step.

6. For a non-DHCP network:

• From the Main Menu select Settings > Communications > Ethernet > IPv4

or IPv6 and change the settings as needed.

Setting Default

(IPv4) IP Assignment Method DHCP

(IPv4) IP Address 0.0.0.0

Subnet Mask 0.0.0.0

Default Router 0.0.0.0

DHCP Response Broadcast

(IPv6) IP Assignment Method Automatic

(IPv6) IP Address Automatic

Configure Bluetooth Communications from the Web Page

The printer must be connected to an Ethernet or wireless network and you must

know the printer IP address.

1. Open a web browser on your PC and click Login

2. Type your Username and Password and click Login.

3. Click the Configure tab. The Configuration Summary page appears.

4. Click Communications > Bluetooth. The Bluetooth settings page appears.

26 PX940 User Guide

Page 41

5. Change Bluetooth settings as needed. You can also click Default Settings to

restore all default Bluetooth settings.

6. Click Save.

Configure Bluetooth Communications from the Main Menu

Use this procedure to configure Bluetooth settings from the printer Main Menu.

You may need to configure these settings if you want to connect to a mobile

computer through Bluetooth.

1. Press the Main Menu button.

2. Select Settings > Communications > Bluetooth.

3. Change settings as needed for your Bluetooth device.

4. Tap Save.

Connect the Printer via Wi-Fi

The printer supports wireless communications when the optional Wi-Fi module is

installed.

You can configure wireless communications:

• From the printer web page.

• From the printer Main Menu.

By default, the printer supports DHCP networks.

Note: If you are not using a DHCP network, Wi-Fi settings must be configured by using

Honeywell PrintSet 5 through a USB connection to the printer. Send commands

through a serial connection, or use the wizards and settings menus on the printer.

Configure Wi-Fi Communications from the Web Page

Use this procedure to configure wireless communications from the printer web

page.

Note: The printer must be turned on and connected to your Wi-Fi or Ethernet network to

configure the printer from the web page.

1. Open a web browser on your PC.

2. In the address bar, type the IP address of your printer and press Enter. The

printer web page appears.

3. Click Login.

4. Type your Username and Password and then click Login. The default value for

Username is itadmin and the default value for Password is pass.

5. Click the Configure tab. The Configuration Summary page appears.

6. Click Communications > Wireless 802.11. The Wireless 802.11 settings page

appears.

PX940 User Guide 27

Page 42

7. Change wireless settings as needed. You can also click Default Settings to

restore all default Wireless 802.11 settings.

8. Click Save when you are finished.

Configure Wi-Fi Communications from the Main Menu

You can configure wireless communications using the Wireless 802.11 wizard or

from the Main Menu.

1. Press the Main Menu button.

2. Select Settings > Communications > Wireless 802.11.

3. Change settings as needed for your wireless connection.

4. Tap Save when you are finished.

Install Authentication Certificates

If you are using Wireless 802.11 security, you may need to install authentication

certificates in the printer for the highest level of security.

1. Configure the printer for the correct date and time.

2. On your PC, open an FTP connection to the IP address of the printer.

3. Transfer your certificate to /home/user/certificates/public.

4. On your PC, open a Telnet session to the printer.

5. Change the directory to: /home/user/certificates/public.

6. Type the command: ls -la.

7. You should see the certificate that you transferred in step 3.

8. Use the certinstall script to install the certificate using this format:

<prompt> certinstall.sh <certificate name>

Example: itadmin@PX940-00000000073 /home/user/certificates/

public$certinstall.sh entrust.cer

9. When you receive confirmation that the certificate was installed, type this

command to make sure you see a.pem file and another soft link to the same

file: ls -la.

Note: Use the printer web page the Main Menu, or Honeywell PrintSet 5 to specify the

certificate .pem file to use for security.

28 PX940 User Guide

Page 43

Printer Drivers

Before you can use the printer with Microsoft® Windows® printing applications,

you must install printer driver software on the PC. Drivers enable the printer to

communicate with your PC and with printer software applications.

You can access the Honeywell Technical Support Downloads portal at:

https://hsmftp.honeywell.com. Click on Software > Printers > Printer Software

and Drivers)

Note: Although Windows may auto-detect the printer when you connect it to a PC through

a USB port, you still need to install printer drivers on the PC for the printer to operate

correctly.

Install Honeywell Windows Driver

Use InterDriver to install printer driver software on your PC.

Note: Although Windows may auto-detect the printer when you connect it to a PC through

a USB port, you must still install printer drivers on the PC for correct printer operation.

1. Access the Honeywell Technical Support Downloads portal at https://

hsmftp.honeywell.com.

2. Download Honeywell Software Download Manager by clicking here in the web

page. Install the Download Manager.

3. Click on the (+) to expand the list. Then go to Software > Printers > Printer

Drivers > Honeywell Windows Driver.

4. Open the Honeywell Software Download Manager and follow the instructions

to download the file.

5. Extract the driver files to a location on your PC.

6. Double-click the.exe file to install InterDriver and follow the prompts to

complete the installation.

USB Host Port

Use the USB host interface port on the printer to connect these peripheral devices:

Device Description

Keyboard Use a standard USB keyboard to send Fingerprint printer language commands

Barcode scanner Use USB barcode scanners for data input with a Smart Printing application. The

directly to the printer or to enter information if you are running a Smart Printing

application.

printer also supports other USB scanners that use a generic keyboard driver.

PX940 User Guide 29

Page 44

Device Description

USB storage

device

You can also connect a peripheral device through the USB-to-Serial or USB-toParallel adapter cable accessories. Contact your local sales representative for

information.

Connect a USB Device

A USB storage device can be inserted into the USB host port on the front of

printer or into the USB host port on the back of the printer.

1. If you are connecting a USB storage device, make sure the device has a single

partition and is formatted as FAT16 or FAT32.

2. Connect the device to one of the USB host ports.

3. If you connected a USB storage device to an LCD printer, select Tools > USB

Menu for more options.

Use a USB storage device to load applications, configuration files, fonts, and

images into the printer memory, or to perform firmware upgrades. You can also

save configuration files to a USB storage device for upload to a printer. The USB

storage device must have a single partition and be formatted as FAT16 or

FAT32.

30 PX940 User Guide

Page 45

CHAPTER

4

CONFIGURE THE PRINTER

Use one of these methods to view and change printer settings:

•Printer web page

• Main Menu

• PrintSet 5

• Print Set MC

• Programming commands

Printer Configuration Menus

The structure of the printer configuration menus is consistent among the different

interfaces. The same organization appears whether you are accessing the menus

through the web page or the printer Main Menu. There are four main printer

configuration menus for each interface:

•Printing

• System Settings

• Verification Settings (PX940V only)

•Alert

Use the following table to understand where information is located in the printer

configuration menus. Not all configuration items appear in each type of interface.

Configuration Menu Description

Printing Media and Print Quality

System Settings General, Display, Audio, Manage I/O, Manage

Services, and Maintenance Alerts

Verification Settings Verification Settings

Alerts Error, Warning, and Information

Communications General, Security, and Network

PX940 User Guide 31

Page 46

Printer Configuration

Configure the Printer from the Main Menu

You can view or change the configuration settings by pressing the Settings button

from the Main Menu.

1. From the Ready screen, press the Main Menu button.

2. From the Main Menu, press the Settings button. The Settings menu appears.

3. Select the settings you want to configure and make your changes.

4. Save your changes when prompted.

Restrict Access to the Main Menu

By default, all menus are available from the Main Menu the first time you turn on

the printer. If necessary, you can require a PIN to restrict access to menus or you

can disable access to all menus.

Menu Access

Setting

Enable (default) All users can access the menus from the Main

Enable with PIN Users need to enter a PIN to access the Main

Disable Users cannot access the menus from the Main

1. Go to the Display menu for the printer:

• From the web page (see Smart Printing), select Configure > System Settings

> Display.

• From the Main Menu screen, select Settings > System Settings > Display.

2. Select a Menu Access setting and save your changes.

3. If you select Enable with PIN, you also need to type in a PIN and save your

changes.

Description

Menu and from the USB flash drive menu.

Menu or USB flash drive menu.

Menu or from the USB flash drive menu.

Access the Printer Web Page

4. Open a browser window on your PC.

5. In the location or address bar, type the printer IP address and press Enter.

The printer web page appears.

6. Click Login. The login page appears.

32 PX940 User Guide

Page 47

Printer Webpage User Name and Password

You will be prompted for a user name and password. The default username is

itadmin and the default password is pass. Once you login, you have the option to

change the user name and password.

Configure the Printer from the Web Page

If you are using Ethernet or Wi-Fi communications, you can change configuration

settings from the web page of the printer. Connect the printer to your network and

obtain an IP address.

1. Open a web browser on your PC.

2. In the address bar, type the IP address of your printer and press Enter. The

printer web page appears.

3. Click Login. The Login page appears.

4. Type your Username and Password and then click Login. The default value for

Username is itadmin and the default value for Password is pass.

5. Click Configure. The Configuration Summary page appears.

6. To see a complete list of printer settings, click Configuration Summary.

7. To configure printer settings, click an item in the navigation pane:

• For serial, Ethernet, Wireless 802.11, or Bluetooth LE settings, click

Communications.

• For media or print quality settings, click Printing.

• For display, audio, service, and general settings, or maintenance alert

message triggers click System Settings.

• To set conditions that trigger error, warning, and information alert

messages, click Alerts.

• For network-related settings (such as DNS, WINS, Net1), for web and email

server information, or if you are using a network management application,

click Network Services.

8. Make any changes to the settings you want to configure.

9. To save your changes, click Save.

10. To reset all parameters on the page to the default settings, click Default

Settings.

PX940 User Guide 33

Page 48

Configure the Printer with PrintSet 5 or Print Set MC

You can use PrintSet 5 or Print Set MC to change configuration settings on your

printer. Download the PrintSet 5 or Print Set MC from the App Store on iOS or

Google Play Store on Android devices.

You can download Honeywell applications to extend the capabilities of the printer.

You may need to purchase a license to run some applications. To learn more about,

licenses and other Honeywell software solutions, go to www.honeywellaidc.com >

Browse Products > Software.

Support for Honeywell Safety and Productivity Solutions products is available

online through the Technical Support Portal.

Configure the Printer with Programming Commands

You can change configuration settings by sending programming commands

directly from your PC to the printer through a terminal program (such as

HyperTerminal), a serial connection, or a network connection.

If your printer uses the Fingerprint programming language, use the SETUP

command followed by the node, subnode, and parameter setting.

You must log in as an itadmin to perform a SETUP operation, but you do not need

to log in to perform a SETUP GET operation.

Note: For more information on how to change configuration settings with a programming

language, see Printer Command Languages and Simulator Support Options,

beginning on page 6.

Uploading from the Web Page

You can use the printer web page to install fonts, images, applications, formats,

and web forms to the printer.

1. Open a web browser on your PC.

2. In the address bar, type the IP address of your printer and press Enter. The

printer web page appears.

3. Click Login. The Login page appears.

4. Type your Username and Password and then click Login. The default value for

Username is itadmin and the default value for Password is pass.

5. Click the Manage tab. The Overview page appears.

6. Click on the desired item in the Overview list. The upload page appears for the

option you selected.

7. To upload a file to the printer, click Browse to locate your file. Double-click the

file to select it, then click Upload. The file uploads to the printer.

8. Click Save when you are finished.

34 PX940 User Guide

Page 49

Uploading from a USB Storage Device

You can use a USB storage device to install fonts, images, applications, formats,

and web forms to the printer. Use this table to understand where your files need to

be located on the USB storage device for the printer to install them.

File Type

Application /apps /home/user/apps

Configuration /config

Configuration profile /profiles /home/user/profiles

Display images /display /home/user/display

Fingerprint script /scripts /home/user/scripts

Firmware /firmware

Font /fonts /home/user/fonts

Form/layout /forms /home/user/forms

Printed images /images /home/user/images

Installation package

(UFF file)

Start file Root of USB storage

Web Form /webforms /home/user/webforms

Directory to

Place the File

Root of USB storage

device

device

Installed in this

Printer Directory

1. Copy your files to a USB storage device using the directories in the table.

2. Insert the USB storage device into one of the USB host ports on the printer.

3. The USB Device menu automatically appears:

a. Select Install Resources.

b. Select the file you want to install and wait until the item turns gray and a

checkmark appears next to it. The file is now successfully installed in the

printer.

c. Continue to another file if you have more files to install.

Change Background Image for the Ready Screen

You may customize the Ready screen that appears on the printer. The background

image you create must be:

• 320 x 240 pixels.

•named background_idle.png.

1. Create a /display directory on your USB storage device.

2. Copy your background_idle.png file to the /dis play directory on the USB

storage device.

PX940 User Guide 35

Page 50

3. Insert the USB storage device into one of the USB host ports on the printer.

4. Use the USB Device menu to upload the file to the printer.

5. Restart the printer.

The new image file you uploaded appears in place of the original Ready screen.

Printer Profiles

You can save updated printer default settings as a printer profile. The printer

supports multiple profiles that can be saved and loaded at any time. For example,

you can create one profile to use when you are printing on continuous label stock,

and a different profile to use when you are printing on label stock with gaps.

The following printer settings are not saved in a profile:

• IP address for either IPv4 or IPv6 networks

• Media calibration settings for the label stop sensor

• Remote port or remote host values for a remote computer accessing the printer

through raw TCP

Save a Printer Profile from the Web Page

From the printer web page, you can save the current settings as a profile that you

can load from the printer memory at any time.

1. In the printer web page (see Access the Printer Web Page), click the Configure

tab.

2. Click System Settings > General.

3. Click Save As Profile. The Save As Profile screen appears.

4. Enter a name in the Profile field, and then click Save.

Load a Printer Profile from the Web Page

You can load a saved profile from the printer web page.

1. In the printer web page (see Smart Printing), click the Manage tab.

2. Click Profiles.

3. The Resident list includes profiles that are saved in the printer memory.

4. To load a profile from the printer memory, select the profile in the Resident list

and then click Activate. The profile is loaded.

5. To load a profile from another location, lick Browse and browse to the location

of the file. Double-click the file to select it, then click Upload. The profile is

uploaded to the printer.

36 PX940 User Guide

Page 51

Save a Printer Profile from the Main Menu

Use this procedure to save the current settings as a printer profile.

1. From the Ready screen, press the Main Menu button. The Main Menu appears.

2. Select Tools > Profiles. The Profiles menu appears.

3. Select Create. The Create Profile menu appears.

Note: selecting Create acts as the Save function

4. Select the Filename text box and type a name for the profile. The profiles can

have up to sixteen characters.

5. Press on the SIP to save your profile name and go back to the Save Profile

menu.

6. Press and wait until Complete appears on the screen.

7. Press to return to the Main Menu.

Load a Printer Profile from the Main Menu

Use this procedure to load a saved printer profile on the printer.

1. From the Ready screen, press the Main Menu button. The Main Menu appears.

2. Select Tools > Profiles. The Profiles menu appears.

3. Select Load. The Load Profile menu appears.

4. Select the profile you want to load on the printer and press .

5. When Complete appears on the screen, press to return to the Main

Menu.

Load a Printer Profile Using Programming Commands

You can load a saved printer profile to another printer by sending programming

commands directly from your PC to the printer through a terminal program (such

as HyperTerminal), a serial connection, or a network connection. All commands are

case-sensitive.

Note: To load printer profiles that modify communication settings that require itadmin

rights, you must log in as an itadmin: RUN “su- p pass itadmin” for FD/DP.

PX940 User Guide 37

Page 52

Connection Programming Commands

Printer running

Fingerprint

Printer running IPL <STX><ESC>.x,/system/usr/bin/cfg -o xmlimportset -k /home/user/

Telnet connection over

Port 23

RUN “/system/usr/bin/cfg -o xmlimportset -k /home/user/profiles/

myprofile”

profiles/myprofile<ETX>

/system/usr/bin/cfg -o xmlimportset -k /home/user/profiles/myprofile

Install a Configuration File from a USB Storage Device

After you save an .xml configuration file to a USB storage device, you can install it

on the printer at any time.

1. Insert the USB storage device in the printer USB host port.

2. From the Ready screen, press the Main Menu button. The Main Menu appears.

3. Select Tools > USB Menu.

4. Select Configuration.

5. Select Install Configuration. The printer imports the configuration file.

• For most printer languages, the configuration file is imported directly into

the working configuration and is not copied to the /config directory.

• An IPL configuration file is copied to /home/user/config/ipl.

6. Press OK when the confirmation message appears.

Export a Configuration File to a USB Storage Device

You can save an .xml configuration file to a USB storage device and install it on

other printers.

1. Make sure the USB storage device has a single partition and is formatted as

FAT16 or FAT32.

2. Insert the storage device into the printer USB host port.

3. From the Ready screen, press the Main Menu button. The Main Menu appears.

4. Select Tools > USB Menu.

5. Select Configuration.

6. Select Export Configuration. A list of the available files appears.

7. Select the file to export.

8. Press OK when the confirmation message appears.

38 PX940 User Guide

Page 53

Menu Shortcuts

You can create shortcuts to access frequently used menus or items, such as

profiles, applications, test labels, and wizards. These shortcuts are added to a

Quick Choices menu, which replaces the Main Menu.

The Main Menu appears as the first item in the Quick Choice menu. Items in the

Quick Choice menu appear in the order in which they are added. The Main Menu