Page 1

Applicator Interface Board

For PX940

Installation Instructions

50158270-001 Rev B

03/20

Page 2

Introduction

This guide describes the Applicator Interface kit for PX940 Industrial Series

printers.

Description

The installation instructions describe how to physically install and configure

the applicator board in the printer.

Printer Firmware

The printer must be fitted with Honeywell Fingerprint v8.60 (or later).

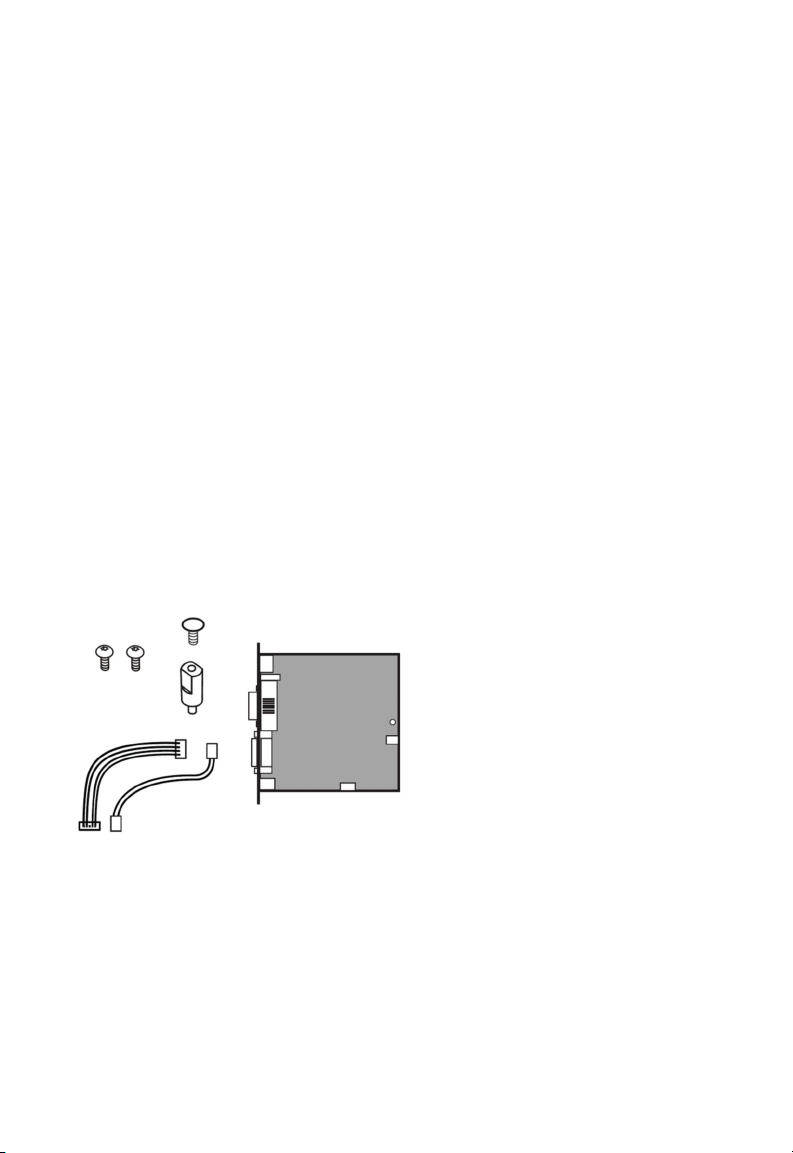

Installation Kit

The Applicator Interface Board installation kit includes:

• One Applicator Interface Board

• One power cable

• One USB cable

• One spacer screw

• One 3X8mm Torx screw

• Two 4X8mm Torx screws

The only tools required for installation are the #T10 and #T20 Torx

screwdrivers.

PX940 Applicator Interface Installation Instructions 1

Page 3

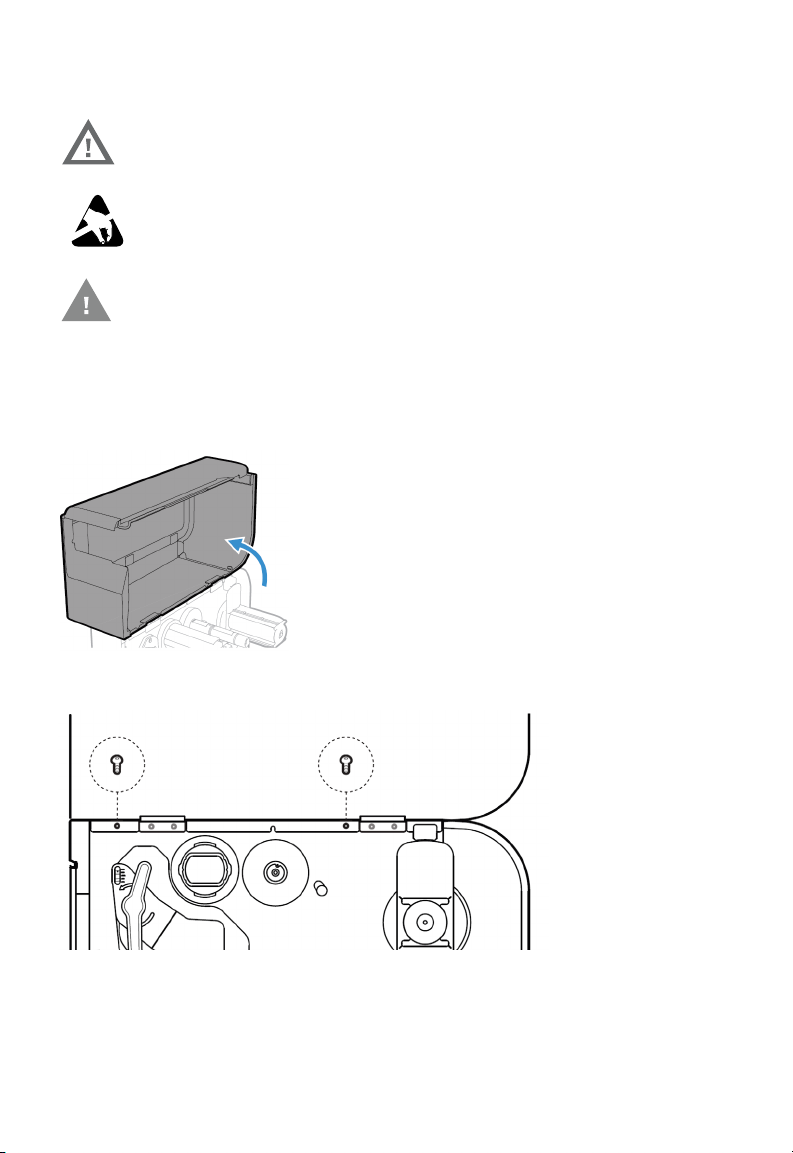

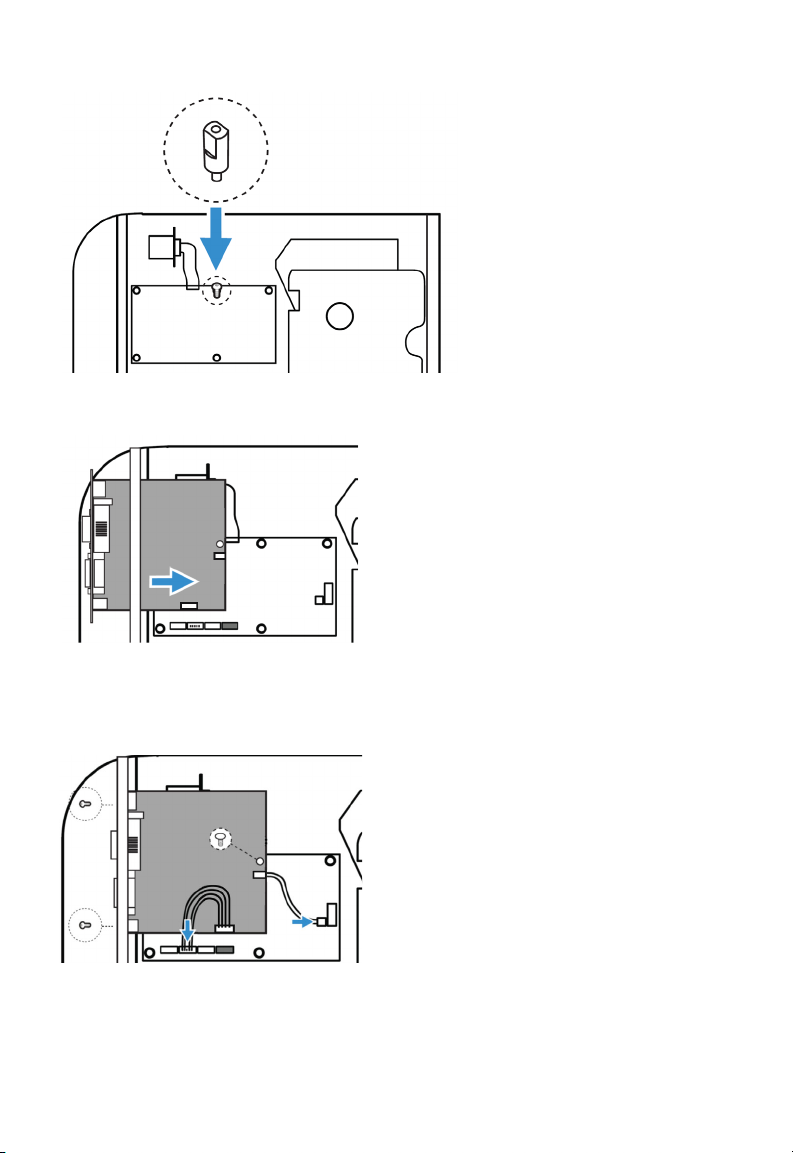

Installing the Applicator Interface Board

Warning: The installation described in this section must only be

performed by an authorized service technician.

Honeywell assumes no responsibility for personal injury

or damage to the equipment if the installation is

performed by an unauthorized person.

Caution: Follow standard ESD guidelines to avoid damaging the

equipment.

Follow ESD

Procedures

Caution: Before you begin, turn off the printer and disconnect the

power cord and communication cables.

Follow the procedure to physically install Applicator Interface Board in the

PX940 printer.

1. Turn off the printer and disconnect the power cord.

2. Open the media cover.

3. Use the T20 screwdriver to remove the two screws securing the electronics

cover to the inside of the printer base.

4. Close the media cover.

5. Remove the two screws located on the outside of the electronics cover.

2 PX940 Applicator Interface Installation Instructions

Page 4

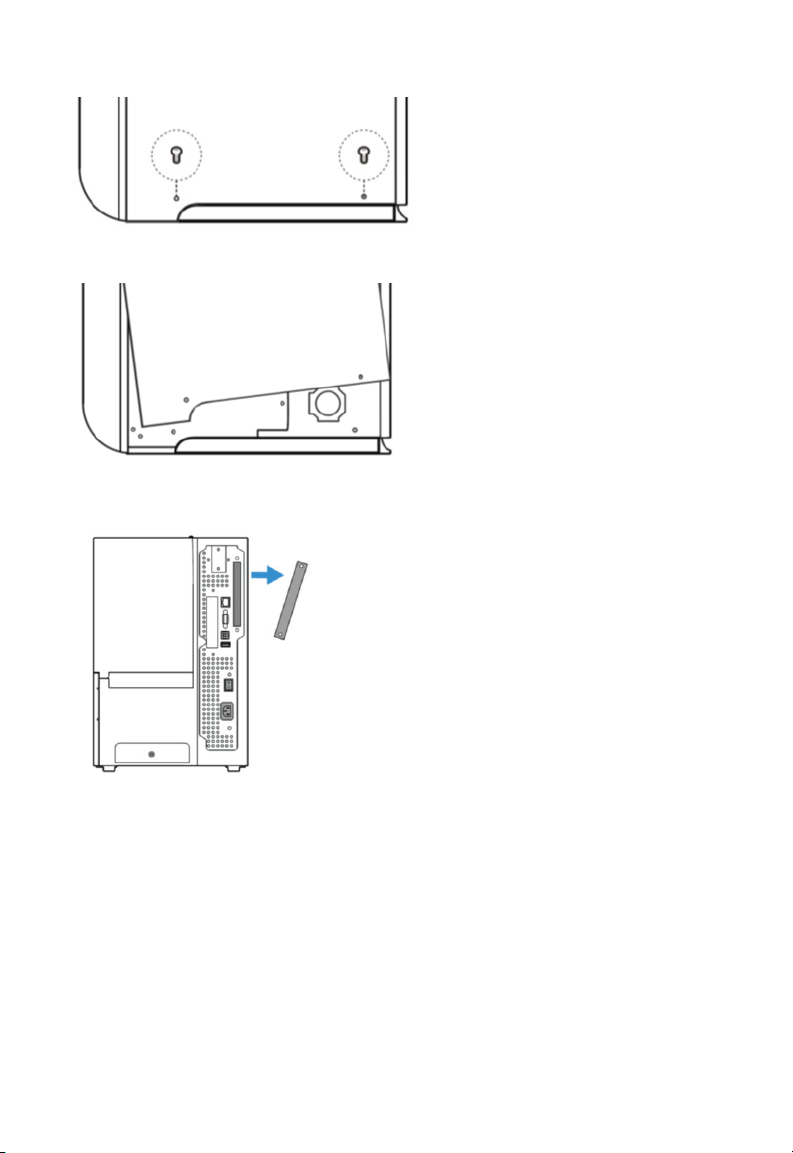

6. Remove the electronics cover.

7. Remove the two screws on the back of the printer securing the cover plate

and remove the cover plate.

8. Use the T10 screwdriver to remove the screw located on the top of the

printer main board and replace with spacer screw.

PX940 Applicator Interface Installation Instructions 3

Page 5

9. Insert the Applicator Interface Board into the printer and secure the board

assembly to the printer with two torx screws.

10. Secure the interface board assembly to the spacer screw with a Torx screw.

11. Insert the USB cable and power cable into the J37 and J33 connectors on

the printer main board. Then insert the other ends into the J1 and J2

connectors on the Applicator Interface Board.

12. Put the electronics cover back on and secure it with the 4 screws.

4 PX940 Applicator Interface Installation Instructions

Page 6

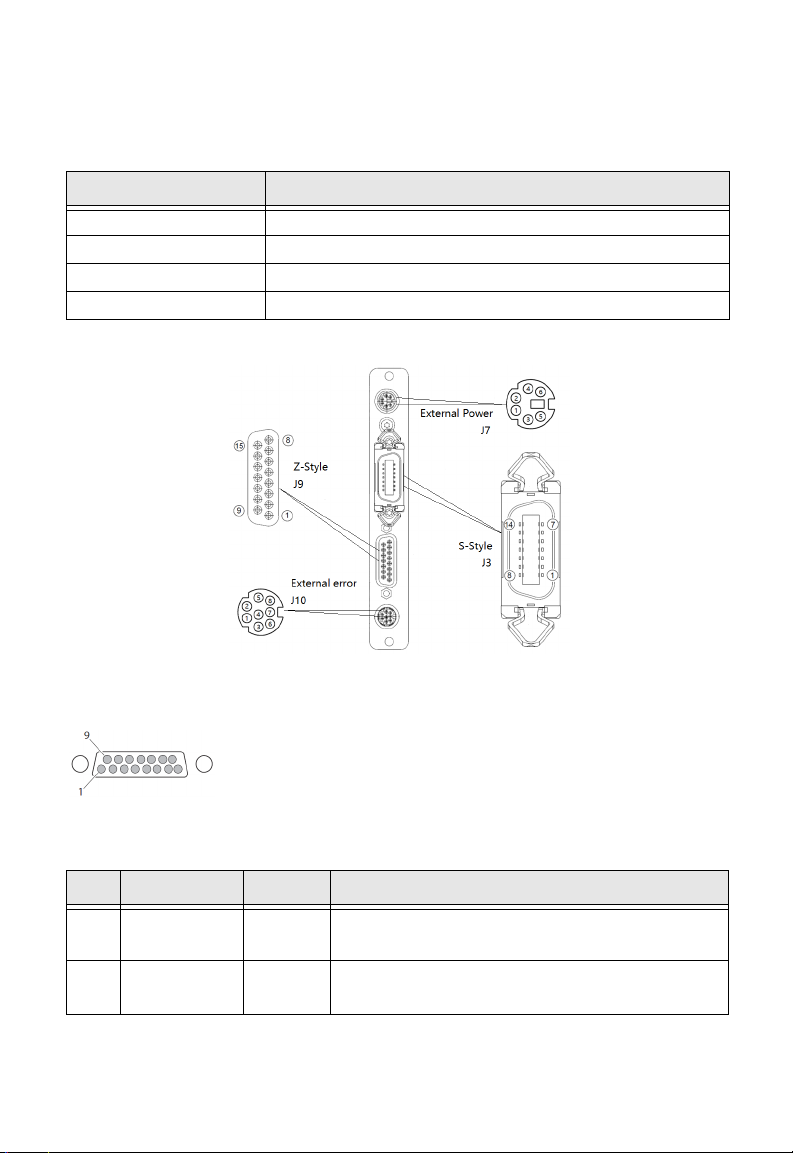

Interfacing

This option board contains 4 connectors for a Z-Style Port, a S-Style Port, an

External Power Port, and an External Error Port.

Port Description

Z-Style A D-Sub 15Pin receptacle connector.

S-Style A D Shaped SCSI 14Pin connector.

External Power A Mini-DIN 6Pin receptacle connector.

External Error A Mini-DIN 8Pin receptacle connector.

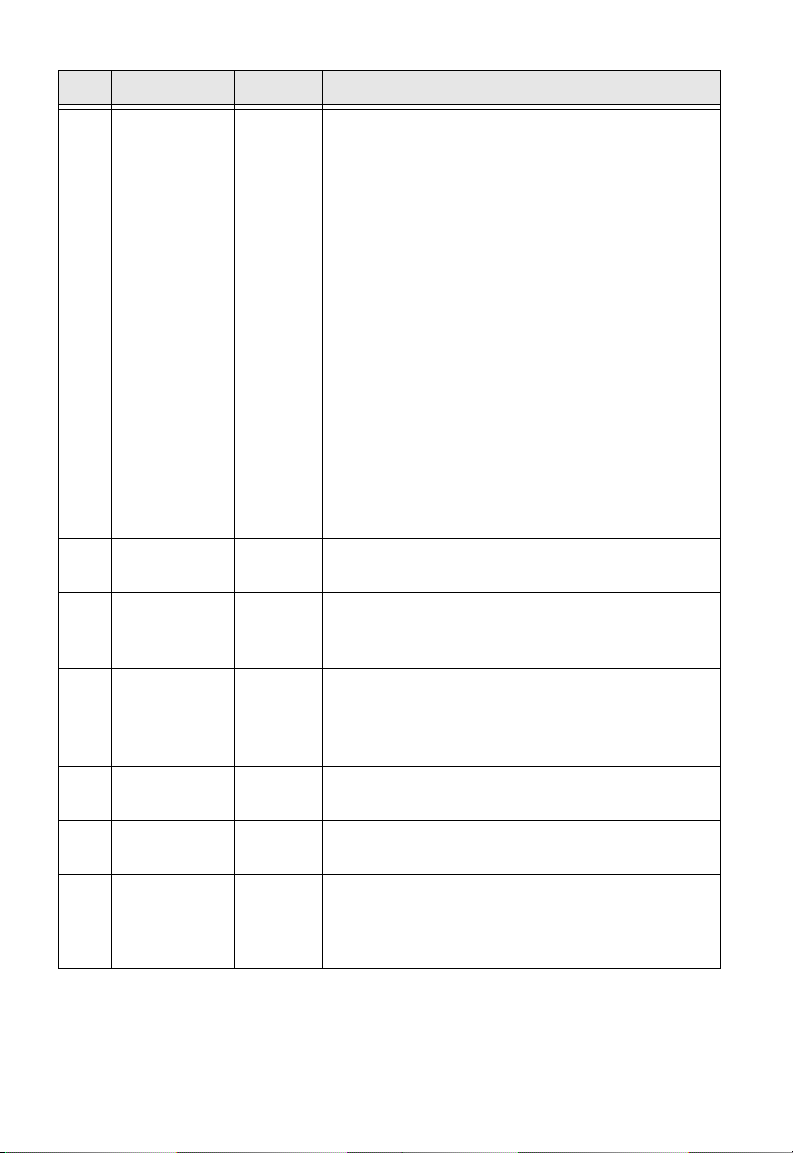

Z-Style Port

Z-Style Port Pinouts

Pin Signal Type Description

1Signal

groud

2 +5VDC Power Voltage supply for external sensors.

PX940 Applicator Interface Installation Instructions 5

Ground configurable for internal or external source

Configurable for internal or external source.

Page 7

Pin Signal Type Description

3 Start print Input Pulse Mode - prints one and only one label

whenever this pin is pulled to ground. Signal

must be de-asserted and reasserted to print

another label.

• Printing starts on HIGH to LOW transition if

format is ready.

• De-assert this signal to HIGH to inhibit

printing.

Level Mode - prints labels continuously when

this pin is pulled to ground. Printing is

disabled when signal is de-asserted. If a label

is printing when de-asserted, printing stops

after the label is complete.

• Assert LOW to start printing if format is

ready.

• De-assert HIGH when current label has

finished printing. Remains de-asserted

while waiting for the next label to be ready to

print.

4 Feed Input Assert LOW to feed label stock. De-assert

HIGH to stop feeding labels.

5 Pause Input Assert LOW for 200ms and then de-assert

HIGH to toggle between pause and un-pause

states.

6 Reprint Input Enables Reprint mode via software. When

this mode in enabled, assert LOW to reprint

last label. This input is ignored when reprint

mode is disabled.

7 +24VDC Output Power for external devices: +24VDC (±10%)

@ 2A.

8Power

Ground +24VDC return.

ground

9 Ribbon/

Media low

Output

Goes LOW when the ribbon/media roll

diameter drops below a predefined level,

otherwise Goes HIGH.

Media low is supported only by I-Style.

6 PX940 Applicator Interface Installation Instructions

Page 8

Pin Signal Type Description

10 Service

required

Output Goes LOW during every status that keeps the

printer from printing:

• Printhead lifted

•Ribbon out

•Media out

• General print engine fault

• Front arm lifted

• Verifier calibration required

• Verifier calibration expired

• Exceed maximum barcodes

• Verifier hardware error

• Verifier failure action prompt

11 End print Output Drives an applicator or other external device

requiring synchronization with the print

cycle. Choose between five types of output

signals:

• Mode 0: Applicator port is OFF.

• Mode 1: Asserted LOW only when media is

moving, otherwise de-asserted HIGH.

• Mode 2: Asserted HIGH only when media is

moving, otherwise de-asserted LOW.

• Mode3 (Default): Asserted LOW for 20ms

when label has finished printing and

positioned. Not asserted during continuous

printing.

• Mode 4: Asserted HIGH for 20 ms when label

has finished printing and positioned. Not

asserted during continuous printing.

12 Media out Output Goes LOW when the printer is out of media.

13 Ribbon out Output Goes LOW when the printer is out of ribbon.

14 Data ready Output Goes LOW when ready to print. De-asserted

HIGH when printing stops after the current

label.

15 Verification

failed

Output

Goes LOW when the printer encounters

Verification failed error.

Goes HIGH when the error is cleared.

PX940 Applicator Interface Installation Instructions 7

Page 9

S-Style Port

S-Style Port Pinouts

Pin Signal Type Description

1 Media out Output Goes LOW when the printer is out of media.

2Signal

ground

3 Ribbon out Output

4 Error Output Goes LOW during every status that keeps the

Ground Configurable for internal or external source.

Goes LOW when the printer is out of ribbon.

printer from printing:

• Printhead lifted

• Ribbon out

•Media out

• General print engine fault

•Front arm lifted

• Verifier calibration required

• Verifier calibration expired

• Exceed maximum barcodes

• Verifier hardware error

• Verifier failure action prompt

8 PX940 Applicator Interface Installation Instructions

Page 10

Pin Signal Type Description

5 Start print Input

Pulse mode - prints one and only one label

whenever this pin is pulled to ground. Signal

must be de-asserted and re-asserted to print

another label.

• Printing starts on HIGH to LOW transition if

format is ready.

• De-assert this signal to HIGH to inhibit

printing.

Level mode - prints labels continuously

when this pin is pulled to ground. Printing is

disabled when signal is de-asserted. If a label

is printing when de-asserted, printing stops

after that label is complete.

• Assert LOW to start printing if format is

ready.

• De-asserted HIGH when current label

has finished printing. Remains

de-asserted while waiting for next label

to be ready to print.

6 End print Output Drives an applicator or other external device

requiring synchronization with the print

cycle. Choose between four types of output

signals:

• Type 1 (Default): Asserted LOW for 20ms

when label has finished printing and

positioned. Not asserted during continuous

printing.

• Type 2: Asserted HIGH for 20ms when label

has finished printing and positioned. Not

asserted during continuous printing.

• Type 3: Asserted LOW only when media is

moving, otherwise de-asserted HIGH.

• Type 4: Asserted HIGH only when media is

moving, otherwise de-asserted LOW.

7 Reprint Input Enables Reprint mode via software. When

this mode in enabled, assert LOW to reprint

last label. This input is ignored when Reprint

mode is disabled.

8 Reserved

PX940 Applicator Interface Installation Instructions 9

Page 11

Pin Signal Type Description

9 Reserved

10 Ribbon/

Media low

11 Verification

failed

12 +24VDC Output Power for external devices: +24VDC (±10%)

13 +5VDC Power Voltage supply for external sensors.

14 Power

ground

Output Goes LOW when the ribbon/media roll

diameter drops below a predefined level,

otherwise Goes HIGH.

Media low is supported only by I-Style.

Output

Ground +24VDC return.

Goes LOW when the printer encounters

Verification failed error.

Goes HIGH when the error is cleared.

@2A.

Configurable for internal or external source.

External Power Port

External Power Port Pinouts

Pin Signal Type Description

1 +5VDC Input +5VDc input for distribution through Applicator

Port connector (Z-Style pin 2, S-Style pin 13)

2Signal

ground

3 +24VDC Input

4Power

ground

5 +24VDC Input

10 PX940 Applicator Interface Installation Instructions

Input Signal return for +5VDC supply (Z-Style pin 1,

S-Style pin 2)

+24VDC input for distribution through Applicator

Port connector (Z-Style pin 7, S-Style pin 12)

Input

Power return for input (Z-Style pin 8, S-Style pin 2)

+24VDC input for distribution through Applicator

Port connector (Z-Style pin 7, S-Style pin 12)

Page 12

Pin Signal Type Description

6Power

ground

Input

Power return for input (Z-Style pin 8, S-Style pin 2)

External Error Port

PX940 Applicator Interface Installation Instructions 11

Page 13

External Error Port Pinouts

Pin Signal Type Description

1 AppErr_1 Input

Applicator error #1,

applicator device to signal error for

printer to receive status of applicator.

2 AppErr_2 Input

Applicator error #2,

applicator device to signal error for

printer to receive status of applicator.

3 AppErr_3 Input

Applicator error #3,

applicator device to signal error for

printer to receive status of applicator.

4 RtW_in_Ext Input

5+5VDC Output

6 RtW_Out Output

7 Ground Ground

8 Ground Ground

External input signal from the applicator to

the printer, for the printer to switch to the

same state with the applicator, and behave in

sync as part of the entire system.

Available for applicator.

External output signal indicating the printer

is Ready to Work.

Signal may be asserted LOW when there are

no active events in the System Health

Monitor (SHM), when the printer motor is

idle, or both.

Available for applicator.

Available for applicator.

reserved for external

reserved for external

reserved for external

Applicator Signals

The diagrams below show how applicator signals function in each applicator

mode during the stages of printing labels.

12 PX940 Applicator Interface Installation Instructions

Page 14

End Print Mode 1/Type 3

PX940 Applicator Interface Installation Instructions 13

Page 15

End Print Mode 2/Type 4

End Print Mode 3/ Type 1

End Print Mode 4/ Type 2

Configuring Applicator Port Settings

The applicator interface supports three different applicator modes:

• Z-Style. Choose this mode for a Zebra-type applicator.

• S-Style. Choose this mode for a Sato-type applicator.

• I-Style. This mode combines Z-Style or S-Style settings with the ability to

trigger external I/O systems via the External Error port.

14 PX940 Applicator Interface Installation Instructions

Page 16

You can configure applicator port settings from the web browser interface or in

Setup Mode.

Web Browser Interface

1. From the menu, click System Settings > Manage I/O. The configuration

screen appears.

2. Chose Enable from the drop down list for the Applicator.

3. From the menu, click Configure > Printing > Applicator.

4. Choose desired settings from the drop down lists.

Setting Description

Style I-Style, Z-Style, S-Style

Startprint Level or Pulse

Endprint Mode 0, Mode 1/Type3, Mode2/Type4, Mode3/Type 1,

Mode 4/Type 2

Ribbon/Media Low Enables/disables the printer low ribbon alert message.

Enables/disables the printer low media alert message.

Reprint Enables/disables reprinting the last label sent to the

printer (by using the Reprint signal)

Error on Pause Enable this setting to set the ”Service Required” signal

when the printer is paused. This setting supported by

Z-Style only.

Error Port Enables/disables the printer external error port.

RTW Configures the Ready-to-Work output signal

(RTWOUTEXT). Choose from:

• Mode 1 - Signal is asserted low when no events are

active in the System Health Monitor (SHM).

• Mode 2 - Signal is asserted low when the printer motor

is idle.

• Mode 3 - Signal is asserted low when the printer motor

is idle and no events are active in the SHM.

DC 5V Configures the printer to use either its internal power

supply or an external supply (connected to the External

Power port) to provide +5VDC to the Z-Style and S-Style

ports.

PX940 Applicator Interface Installation Instructions 15

Page 17

Setting Description

DC 24V Configures the printer to use either its internal power

supply or an external supply (connected to the External

Power port) to provide +24VDC to the Z-Style and

S-Style ports.

5. Click Save. The settings are saved.

Setup Mode

Use the printer touch screen to view and change settings.

1. Press Menu > Settings > System Settings > Manage I/O.

2. Choose Enable from the drop-down list for the applicator.

3. From the menu, select Menu > Settings > Printing > Applicator.

About Applicator Input Signals

This section describes the INPUT signals.

Note: All IN signals are asserted low and de-asserted high.

Signal Description

Startprint

Feed

Pause

Reprint

Apperr1

Apperr2

Apperr3

RTWINEXT

Starts a print job. Choose either Level or Pulse.

• Level: The printer starts printing labels when the

startprint signal is asserted and continues printing

until the signal is de-asserted.

• Pulse: The printer prints one label when the startprint

signal is asserted. The startprint signal must be

de-asserted and then asserted to print the next label.

Feeds a single label. Not supported by S-Style.

Toggles between Pause mode and printing. Not

supported by S-Style.

Reprints the last valid label.

Applicator error 1.

Applicator error 2.

Applicator error 3.

External input signal, which you can use to monitor the

operational status of the entire system.

16 PX940 Applicator Interface Installation Instructions

Page 18

About Applicator OUT Signals

This section describes the Applicator OUT signals.

Note: Unless described otherwise, all OUT signals are asserted low and

de-asserted high.

Signal Description

Data Ready Asserted when the printer is ready to receive a startprint

signal and execute the current print job. De-asserted

when the print cycle ends. Not supported by S-Style.

Endprint Asserted during or after a print cycle. The endprint signal

also behaves differently depending on the applicator

port endprint mode. When the startprint signal is

received, the endprint signal may or may not be

asserted.

There are five options to choose from:

• Mode 0: Endprint signal is never asserted.

• Mode 1 (Z-Style)/Type 3 (S-Style): Asserted low during

print/feed cycle.

• Mode 2 (Z-Style)/Type 4 (S-Style): Asserted high during

print/feed cycle.

• Mode 3 (Z-Style)/Type 1 (S-Style): Asserted low for at

least 20 ms after print/feed cycle end.

• Mode 4 (Z-Style)/Type 2 (S-Style): Asserted high for at

least 20 ms after print/feed cycle end.

Media out Asserted when the printer is out of media. Activates an

SHM PaperOut event in the System Health Monitor

(SHM). De-asserted when the same event is deactivated.

Ribbon/Media

low

Ribbon out Asserted when the printer is out of ribbon. Activates an

Asserted when the ribbon/media roll diameter drops

below a predefined level. De-asserted while the roll

diameter remains above the predefined level.

Media low is supported only by I-Style.

SHM RibbonOut event in the System Health Monitor

(SHM). De-asserted when the same event is deactivated.

PX940 Applicator Interface Installation Instructions 17

Page 19

Signal Description

RTWOUTEXT External output signal.

Behavior depends on the current setup. Signal may be

asserted when there are no active events in the System

Health Monitor (SHM), when the printer motor is idle, or

both.

This signal is inactive when the Error Port option is

disabled.

SERVICEREQ

(Service Required)

Asserted low when an event in the System Health

Monitor (SHM) is activated. De-asserted when no events

are active in the SHM.

A “service required” event is also activated when the

Error Port is enabled and any applicator errors is

detected. This signal is also asserted when the Error on

Pause option is enabled.

Programming Applications for the printer

The printer includes Honeywell Fingerprint, a programming language that

resides on the printer. Fingerprint is an easy-to-use programming tool for label

formatting and printer customization.

Fingerprint also includes a slave protocol, Honeywell Direct Protocol, which

allows layouts and variable data to be downloaded from a host and combined

into labels, tickets, and tags with a minimum of programming. Honeywell Direct

Protocol also includes a versatile error handler and a flexible counter function.

Fingerprint Commands for the printer

The ON PORTIN, PORTIN, PORTOUT, and ON PORTOUT Fingerprint commands

support applicator functionality for the printer. These commands are functional

when the printer applicator port status is enabled.

This section includes basic information for each of these commands. For more

information, see the Fingerprint Command reference manual.

ON PORTIN

This command allows a Fingerprint application to detect in signals. If a particular in signal is asserted, the application moves to the subroutine responsible for

carrying out tasks related to that in signal. One command is available for detection of each of the 8 in signals.

Note: This command is not supported by Honeywell Direct Protocol.

Example:

18 PX940 Applicator Interface Installation Instructions

Page 20

• ON PORTIN.STARTPRINT GOSUB nnn

PORTIN

This command is a version of the PORTIN(PORT) command and checks the

current state of a specified signal. This command returns -1 if the signal is

asserted, or 0 if the signal is de-asserted.

Note: This command is supported by Fingerprint and Direct Protocol.

Examples:

• PORTIN.STARTPRINT

or

• PORTIN.RIBBONLOW

PORTOUT

Supports manually modifying the dataready signal. PORTOUT is not allowed

when the applicator port style is set to S-Style.

Note: This command is not supported by Direct Protocol.

Example

• PORTOUT.DATAREADY ON

• PORTOUT DATAREADY OFF

where on asserts the dataready signal low and off de-asserts the dataready

signal high.

ON PORTOUT

This command allows a Fingerprint application to detect when out signals have

been reset to default values. The command moves to a specified subroutine

whenever the applicator port status is enabled, and whenever the applicator

port style is changed.

Example:

• ON PORTOUT.RESET GOSUB nnn

Using External Applicator Signals

The printer responds to external applicator port signals differently, depending

on whether your application is using Fingerprint or Honeywell Direct Protocol.

Fingerprint and Applicator Signals

When you use Fingerprint, all in signals and the Data-ready out signal are

handled by Fingerprint. Other out signals are handled by firmware.

PX940 Applicator Interface Installation Instructions 19

Page 21

Feed

When the Feed in signal is received, the application moves to a specified subroutine that feeds labels until the Feed in signal is de-asserted.

Example

• 10 ON PORTIN.FEED GOSUB 200

...

200 FORMFEED

210 RETURN

Pause

When the Pause in signal is received, the application moves to a specified subroutine that finishes the current print job and then places the printer in pause

mode.

Example

• 10 ON PORTIN.PAUSE GOSUB 90

...

90 pause printer

Startprint

When the Startprint signal is received, the application moves to a specified

subroutine that starts the print job. The Startprint signal must be preceded by

the dataready signal as seen in this example.

Example

• 10 PORTOUT.DATAREADY on

20 ON PORTIN.STARTPRINT GOSUB 60

...

60 my print routine

70 PRINTFEED

80 RETURN

Reprint

When the Reprint signal is received, the application moves to a specified subroutine that reprints the last valid label.

20 PX940 Applicator Interface Installation Instructions

Page 22

Example:

•...

100 ON PORTIN.REPRINT GOSUB 150

...

150 PRINTFEED -1,1

160 RETURN

Printfeed

The dataready signal must be set manually by the Fingerprint application

before a printfeed is issued when using with an applicator.

Handling External Applicator Errors

When an error signal (apperr1, apperr2, or apperr3) is received, the application

moves to a specified subroutine that takes action based on error severity.

Example

•...

60 ON PORTIN.APPERR1 GOSUB 100

...

100 perform error handling

110 RETURN

Handling Internal System Errors

For internal system errors, the system error signal status can be read at any

time within the application so appropriate measures can be taken. When any of

these errors occur, the appropriate out signal (including the error) is asserted:

• Printhead lifted

• Ribbon out

• Media out

• General print engine fault

•Front arm lifted

• Verifier calibration required

• Verifier calibration expired

• Exceed maximum barcodes

• Verifier hardware error

• Verifier failure action prompt

Example

• 10 IF PORTIN.RIBBONLOW GOTO 200

...

PX940 Applicator Interface Installation Instructions 21

Page 23

200 perform error handling

210 RETURN

Resetting Out Signals

Out signals are reset to their default values when certain options are changed

by using the SETUP menu. When the reset is detected, the application moves to

a specified subroutine and performs the tasks necessary to reinitialize the print

engine.

Example

• 10 ON PORTOUT.RESET GOSUB 150

...

150 perform initialization

160 RETURN

Direct Protocol and Applicator Signals

In Direct Protocol, all in and out signals are handled by the Direct Protocol firmware.

Feed

There are two ways to trigger blank label feeding:

• by manually pressing Feed on the printer front panel. The printer feeds a

single blank label.

• by using the Feed in signal. When this signal is detected, the printer feeds

blank labels as long as internal applicator flag indicates that the Feed

signal is asserted.

Pause

The applicator can toggle the current pause state by using the pause in signal

to simulate pressing Pause on the printer front panel. When the printer is in

pause state, you can press Setup on the printer front panel and place the print

engine in Setup Mode for manual configuration.

Startprint

When the printfeed command is executed, the print process sets the dataready

signal and then waits for the startprint signal to be detected before proceeding

with the print job.

The print process will not set another dataready signal until the current print

job de-asserts the previous dataready signal. This prevents the printer from

printing a new label before the previous label is completed.

22 PX940 Applicator Interface Installation Instructions

Page 24

Reprint

This signal works much the same way as startprint. The reprint signal is

detected under two conditions:

• when the printer is idle.

• when the printer is waiting for a startprint signal during the execution of a

printfeed command.

The printer prints only one label at a time.

Handling External Applicator Errors

The external applicator error in signals (APPERR1, APPERR2, APPERR3,

RTWINEXT) should be asserted when external applicator errors occur. When

one of these signals is detected, an associated event is activated in the System

Health Monitor (SHM). When the issue causing the error has been resolved and

the error signals are de-asserted, the events are deactivated in the SHM.

Handling Internal System Errors

When a system error occurs that activates an event in the SHM, the “service

required” signal is asserted. The external RTW out signal can be de-asserted,

depending on the current print engine RTW setting.

When any of these errors occur, the appropriate out signal (including the error)

is asserted:

• Printhead lifted

• Ribbon out

• Media out

• General print engine fault

•Front arm lifted

• Verifier calibration required

• Verifier calibration expired

• Exceed maximum barcodes

• Verifier hardware error

• Verifier failure action prompt

PX940 Applicator Interface Installation Instructions 23

Page 25

Error Messages

Message:

Cause:

ERRNOAPP

Operation not allowed. Applicator Port disabled.

Application sent an applicator port command to the printer

and the applicator port is disabled.

Error Number:

Message:

Cause:

Error Number:

Message:

Cause:

Error Number:

Message:

Cause:

Result:

Error Number:

88

ERRAPP

Operation not allowed. Applicator Port enabled.

Application sent the Fingerprint command PORTOUT(PORT)

ON|OFF on a port used by the applicator port when the

applicator port is enabled.

89

ERRINPUTON

Operation not allowed in Direct Protocol.

Running the PORTOUT.DATAREADY ON|OFF or

PORTIN.<SIGNAL> GOSUB XXX commands when the printer

is using Direct Protocol.

90

EAPPERR1

Applicator Error 1.

AppErr1 in signal detected.

Activates event in System Health Monitor (SHM).

1340

EAPPERR2

Message:

Cause:

24 PX940 Applicator Interface Installation Instructions

Applicator Error 2.

AppErr2 in signal detected.

Page 26

Result:

Error Number:

Message:

Cause:

Result:

Error Number:

Message:

Cause:

Result:

Error Number:

Message:

Cause:

Activates event in System Health Monitor (SHM).

1341

EAPPERR3

Applicator Error 3.

AppErr3 in signal detected.

Activates event in System Health Monitor (SHM).

1342

ERTWINEXT

RTW Extenal Error.

RTWExternal in signal detected.

Activates event in System Health Monitor (SHM).

1343

ENODATAREADY

Dataready not enabled.

Application sent a PRINTFEED in Fingerprint when the

applicator port is enabled, the style is set to I-Style or Z-Style,

and the dataready signal is not enabled.

Result:

Error Number:

PX940 Applicator Interface Installation Instructions 25

Terminates the printfeed command without printing a label.

1344

Page 27

Display Messages

These messages appear in the printer display under certain conditions when a

PRINTFEED command is run.

Message:

Cause:

Message:

Cause:

APPLICATOR PORT: Wait for signal.

Running a PRINTFEED command blocks execution until a

startprint signal is received. The message appears when

execution has been blocked for a few seconds.

APPLICATOR PORT: Wait for reprint.

Running a PRINTFEED -1,1 command blocks execution until a

reprint signal is received. The message appears when execution

has been blocked for a few seconds.

26 PX940 Applicator Interface Installation Instructions

Page 28

Support

To search our knowledge base for a solution or to log into the Technical Support

portal and report a problem, go to www.hsmcontactsupport.com.

User Documentation

For the user guide and other documentation, go to www.honeywellaidc.com.

Limited Warranty

For warranty information, go to www.honeywellaidc.com and click Get

Resources > Product Warranty.

Patents

For patent information, see www.hsmpats.com.

Disclaimer

Honeywell International Inc. (“HII”) reserves the right to make changes in specifications and other information contained in this document without prior

notice, and the reader should in all cases consult HII to determine whether any

such changes have been made. The information in this publication does not

represent a commitment on the part of HII.

HII shall not be liable for technical or editorial errors or omissions contained

herein; nor for incidental or consequential damages resulting from the furnishing, performance, or use of this material. HII disclaims all responsibility for the

selection and use of software and/or hardware to achieve intended results.

This document contains proprietary information that is protected by copyright.

All rights are reserved. No part of this document may be photocopied, reproduced, or translated into another language without the prior written consent of

HII.

Copyright2009-2020 Honeywell International Inc. All rights reserved.

PX940 Applicator Interface Installation Instructions 27

Loading...

Loading...