Page 1

Installation Instructions for the

5

ISSUE 2

4AV Series Vane Sensors

PERSONAL INJURY

DO NOT USE these products as safety or

emergency stop devices or in any other application

where failure of the product could result in personal

injury.

Failure to comply with these instructions could

result in death or serious injury.

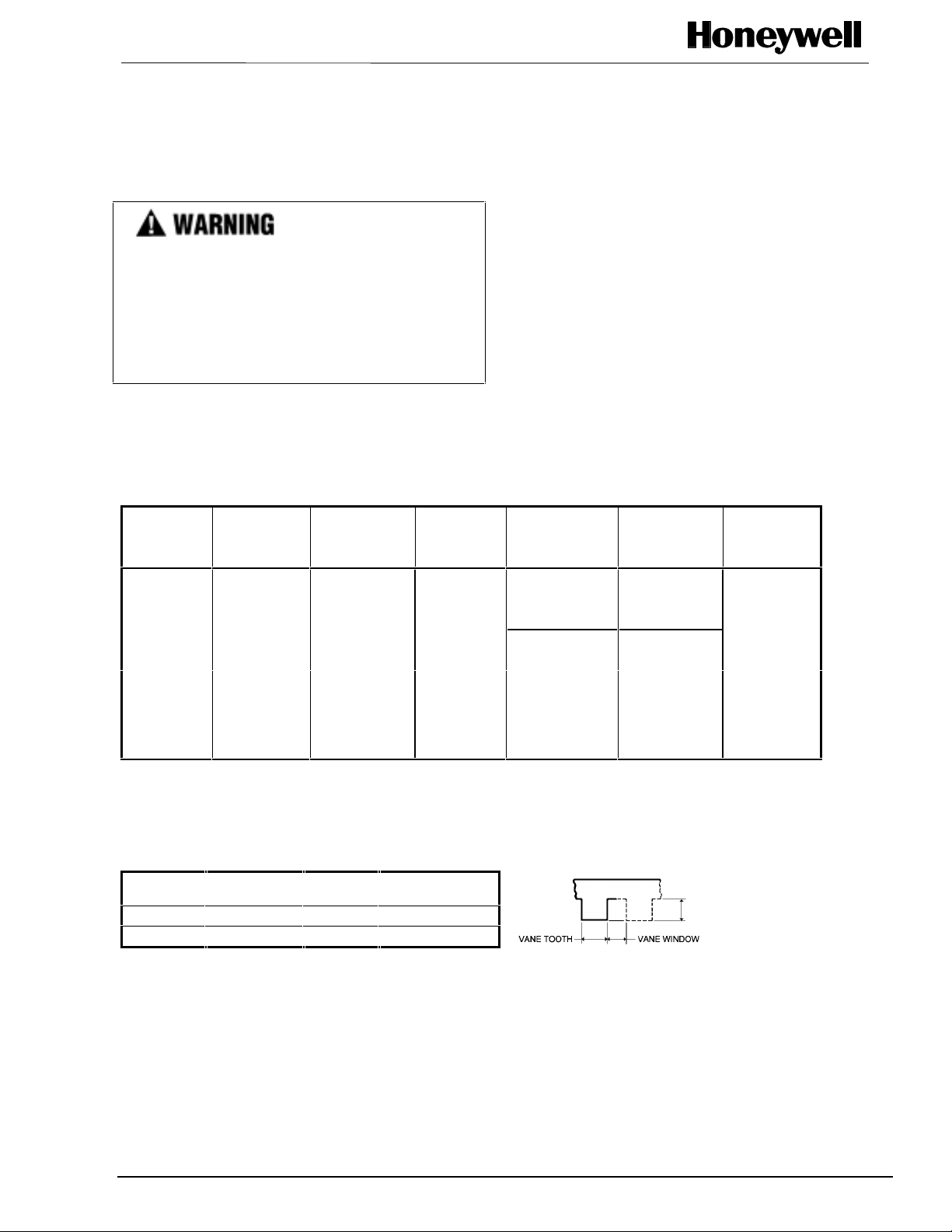

ELECTRICAL CHARACTERISTICS

Catalog

Listing

4AV15F 24 AWG Wire 5.50 ± 0.25

4AV16F 24 AWG Wire 7.45 ± 0.25

4AV17F 24 AWG Wire 13.15 ± 0.50

4AV18F 24 AWG Wire 18.15 ± 0.50

4AV19F 24 AWG Wire 22.00 ± 0.50

4AV20F . 015 X . 025 PCB 0.140

4AV20F-T1* .025 X .025

4AV20F-T2**

*Will mate with AMP Connector Housing 87499-8, not supplied

**Will mate with Molex Connector Housing 2695/6471, not supplied

Termination

Connector

.025 X .025

Connector

Lead

Length

AMP Terminal

Block 103323-4

Molex Terminal

Block 22-05-3041

Supply

Voltage

All Listings

4.5 VDC

through

26.5 VDC

PK 8760

GENERAL INFORMATION

4AV Hall effect vane sensor s in cl ude a Hal l effec t

sensor and a magnet in a common package. They

are operated by passing a ferrous vane through the

gap between the magnet and the sensor.

With no vane in the gap, the output is Operated

(conducting). With the vane in the gap, the output is

Released (non-conducting). The vane actuator is

annealed low carbon cold roll ed ste el , type AI SI

1018 or lower in carbon. Minimum recomm end ed

vane dimensions are required to ensure operating

characteristics will be met.

Supply

Current

All Listings

18.5 mA Max

@ -40 °C

15.25 mA typical

11.75 mA

@25 °C

typical

Output

Voltage

All listings

0.4 V Max

@125 °C

0.1 typical

0.075 V

@25 °C typical

Output

Sink Current

All listings

40 mA Max

Dual output

sink currents

are summed

to reach total.

VANE DIMENSIONS (mm/in)

Thickness Min.

Window

1,0/0.4 10,2/.40 10,2/.40 9,27/.365

1,6/.06 10,2/.40 6,3/.25 9,27/.365

Min.

Tooth

Min. Tooth

Depth

Sensing and Control

Page 2

4AV Series Vane Sensors

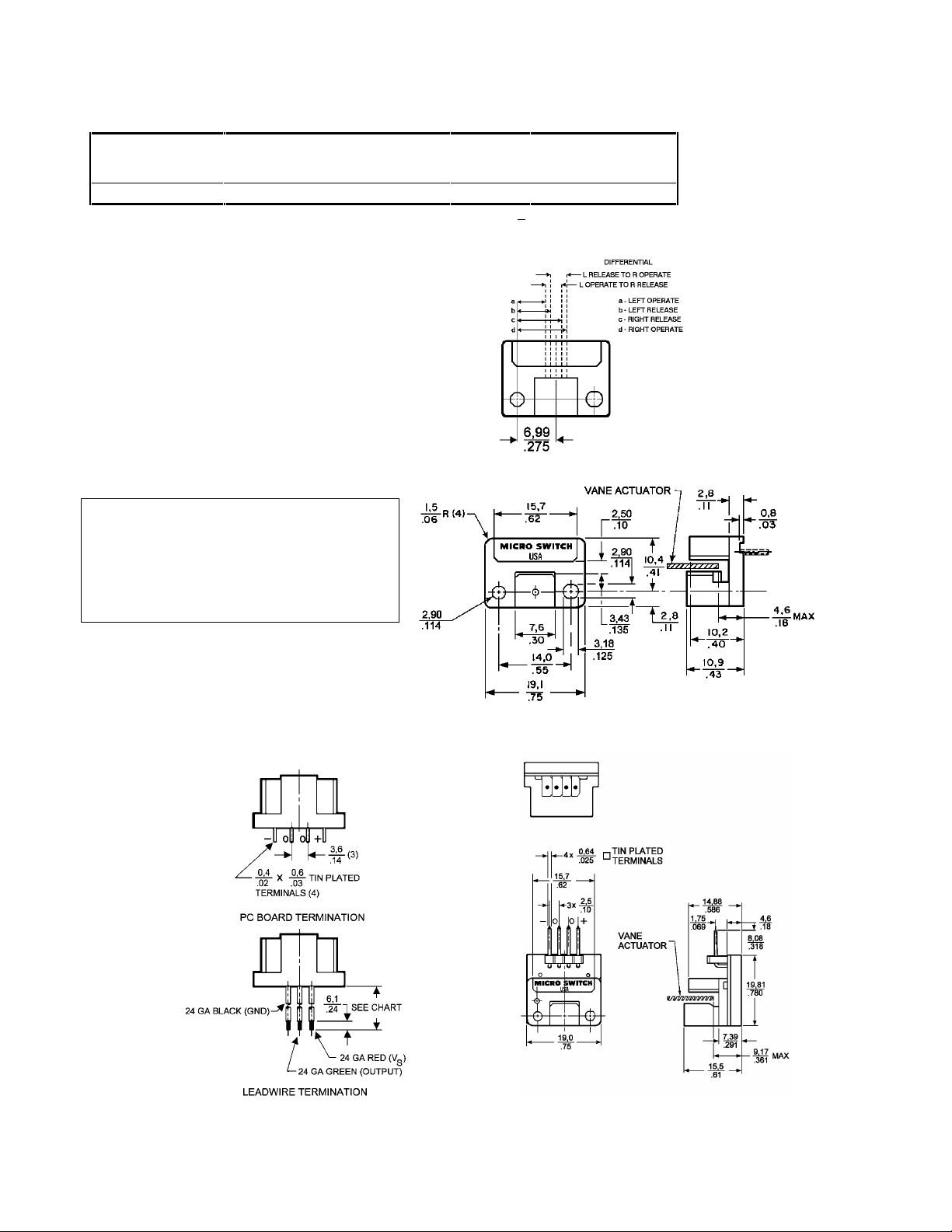

MECHANICAL CHARACTERISTICS (mm/in)

Series Left Left Left Right Right Right L-R

Operate Release Diff. Operate Release Diff Diff.

a b d c

4AV* 5,4/.213 6,0/.237 0,6/.024 8,6/.337 7,9/.313 0,6/.024 2,5/.100

*Operating characteristics of the 4AV are adjusted to produce a .100 + .010 dimension between

the Operate point on one side of the package to the Release point on the other side. The actuator

can be designed to produce a specific pulse width for timing or sequencing operations.

MOUNTING DIMENSIONS (for reference only)

ISSUE 2 PK 87605

CAUTION

PRODUCT DAMAGE

• Do not exceed electrical specifications.

• Do not mis-wire the output connection.

• Do not reverse supply voltage polarity.

• Handle terminals with care.

Failure to comply with these instructions may

result in product damage.

Mates with AMP housing 87499-8

2 Honeywell • Sensing and Control For application help: call 1-800-537-6945

Page 3

4AV Series Vane Sensors

ISSUE 2 PK 87605

SOLDERING

CAUTION

PRODUCT DAMAGE

• Ensure iron tip is clean when soldering.

Failure to comply with these instructions may result in

product damage.

Hand Soldering

The following is recommended:

Flux: Rosin Base

1.

Solder: Kester #44 60-40 rosin core, or

2.

equivalent.

Soldering Iron: Type; Weller, Model TC-552, 55

3.

watt or equivalent.

Tip Size: 3mm (.118 in.) Diameter x 30mm

4.

(1.182 in.) long

Tip Temperature: 288°C (550°F) max

5.

Terminal Contact Time: 6 second s max.

6.

Wave Soldering

The following is recommended:

Flux: London Chemical Co. Loncoflux - 106A35

1.

or equivalent

Preheat: Preheaters should be set to give 95 °C

2.

(200 °F) on the top (component side) of printed

circuit board just prior to board entering the

wave. (May have to be adjusted depending

upon board thickness.)

Solder Temperature: 260 °C (500 °F) max.;

3.

preferably 252 °C to 260 °C (485 °F to 500 °F).

Speed: Set conveyor speed to approximately

4.

4.5 feet/minute (1,37 meters/minute).

Printed circuit board requires rigid support

5.

during wave soldering.

CLEANING

Hand Cleaning

Clean areas with a 50-50 mixture of isopropyl

alcohol and clean tap water. Dry in a 71 °C (160 °F)

oven for 10-15 minutes, preferably in a noncirculating oven. This will remove all moisture from

the assembly, which must be done before electrical

testing, or application.

Machine Cleaning *

Detergent: London Chemical Company

Loncoterge 444-NRT6 or equivalent. Equipment:

Dee Electric Aqueous Cleaner or equivalent. The

following is reccommend ed:

Wash Section: 55 °C (130 °F) maxim um water

1.

temperature, 5 to 10% maximum solution soft

water, low pressure nozzles (60 psi) on top

spray and high pressure nozzles ( 120 psi) on

bottom spray, conveyor sp eed 3 feet/mi nute

minimum. Recirculating tank.

Rinse Section #1: Clean tap water up to 25

2.

grains hard, salt free (to minimize possibility of

corrosion), unheated, non-recirculating, with

high press ure nozzles (120 psi).

Rinse Section #2: Clean deion iz ed water onl y,

3.

high pressure nozzles (120 psi), unheated and

non-recirculating.

Air Knife Section: To remove excessive amounts

4.

of water.

Drying Section: 71°C (160 °F) drying for 10-15

5.

minutes, preferably in a non-circulating conveyor

oven.

* In this cleaning system, the detergent in the wash

section removes the non-polar contaminants, the first rinse

removes the detergent solution, and the deionized water

rinse removes the polar contaminants. The air knife and

dryer remove all the moisture from the assembly, which

must be done before electrical testing or application.

CAUTION

PRODUCT DAMAGE

• Ensure cleaner does not come in contact with sensor If

other cleaning methods are selected for removal of flux

residue.

Failure to comply with these instructions may result in

product damage.

For application help: call 1-800-537-6945 Honeywell • Sensing and Control 3

Page 4

4AV Series Vane Sensors

EXAMPLE WIRING DIAGRAMS

ISSUE 2 PK 87605

WARRANTY/REMEDY

Honeywell warrants goods of its manufacture as

being free of defective materials and fault y

workmanship. Contact your local sales office for

warranty information. If warranted goods are

returned to Honeywell during the period of coverage,

Honeywell will repair or replace without charge those

items it finds defective. The foregoing is Buyer’s sole

remedy and is in lieu of all other warranties,

expressed or implied, including those of

merchantability and fitness for a particular

purpose.

Specifications may change without notice. The

information we supply is believed to be accurate and

reliable as of this printing. However, we assume no

responsi bility for its use.

While we provide application assistance

personally, through our literature and the Honeywell

web site, it is up to the customer to determine the

suitability of the product in the application.

For application assistance, current specifications,

or name of the nearest Authorized Distributor,

contact a nearby sales office. Or call:

1-800-537-6945 USA

1-800-737-3360 Canada

1-815-235-6847 International

FAX

1-815-235-6545 USA

INTERNET

www.honeywell.com/sensing

info.sc@honeywell.com

Sensing and Control

Honeywell Inc.

11 West Spring Street

Freeport, Illinois 61032

Printed w ith S o y In k

on 50% Recycled Paper

PK 87605-2-EN IL50 GLO 0303 Printed in USA

www.honeywell.com/sensing

Loading...

Loading...