Page 1

Perfect Climate Comfort Center™

PC8900A

W8900A-C

GENERAL

This document contains information on the Perfect Climate

Comfort Center™ Control System including components and

accessories. Some components and accessories include the

PC8900A Control Panel, W8900A-C Remote Module,

C7189A Remote Indoor Sensor, C7089A Outdoor Sensor,

C7100A Discharge Air Sensor, CO2 Monitor, CM8900A

Communication Module, and W8735B Telephone Access

Module.

The Comfort Center control system provides 24 Vac energy

saving control for a heating and cooling system, while

providing reliable and precise temperature, ventilation and

humidity control.

Control System

PRODUCT DATA

FEATURES

The PC8900A mounts in the living space and accurately

measures and controls room temperature and humidity.

• Only four wires required for installation.

• Large, continuously lit LCD.

• Seven-day (auto copy) programming.

• Simultaneous display of heat and cool setpoints.

• Keyboard lockout protection available.

• No batteries required, indefinite program retention.

• Circulation fan setting improves indoor air quality.

• Field configurable for:

— Automatic or manual changeover.

— °F or °C display.

— 12- or 24-hour clock.

— Adaptive Intelligent Recovery™ control or conven-

tional recovery.

— Humidity control in heating or cooling.

— Outdoor, remote, and discharge temperature sen-

sors available.

— Fan overrun in cooling.

— Ventilation control.

The W8900A-C mounts near the equipment. The

PC8900A, heating, cooling, ventilation and

dehumidification equipment and all additional sensors

are wired to the W8900A-C.

• Compatible with most 24 Vac Systems.

• Remote sensor, discharge sensor, outdoor sensor and

CO

monitor available.

2

• Optional remote communications available.

Contents

General ............................................................................. 1

Features ........................................................................... 1

Specifications .................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 5

Wiring Diagrams ............................................................... 9

W8900A,C Hookup Diagrams ....................................... 9

W8900B Hookup Diagrams ........................................... 14

W8900A,B,C Humidity Control Hookup Diagrams ........ 18

Installer Setup ................................................................... 24

Programming PC8900A .................................................... 27

Checkout .......................................................................... 33

Operation .......................................................................... 34

Troubleshooting ................................................................ 40

Glossary ........................................................................... 44

® U.S. Registered Trademark

Copyright © 2001 Honeywell • All Rights Reserved

68- 0173- 3

Page 2

SPECIFICATIONS

IMPORTANT

The specifications given in this publication do not

include normal manufacturing tolerances; therefore,

an individual unit might not exactly match the listed

specifications. Also, this product is tested and calibrated under closely controlled conditions, and some

minor differences in performance can be expected if

those conditions are changed.

Models:

The PC8900A Comfort Center™ Control Panel mounts in the

living space and accurately measures and controls room

temperature and humidity. The W8900A-C Remote Module

provides a wiring panel and switching for the Perfect Climate

Comfort Center™ Control System. See Table 1.

System Components and Accessories (See Fig. 1):

C7089A1002 Outdoor Sensor: Used to measure outdoor tem-

perature.

C7100A1015 Discharge Air Sensor: Used to sense tempera-

ture in discharge or return air.

C7189A1001 Remote Indoor Sensor: Used for remote sensor

applications.

CM8900A1009 Communication Module: Used for remote

communication.

W8735B1003 Telephone Access Module: Used for remote

communication.

202689A Mounting Plate Accessory: Used when C7189A

Remote Indoor Sensor cannot cover wall marks from old

thermostat.

205224A Wall Cover Plate: Used when PC8900A Control

Panel cannot cover wall marks from old thermostat.

32007496-001 Replacement Door: Used for PC8900A Control

Panel.

Dimensions:

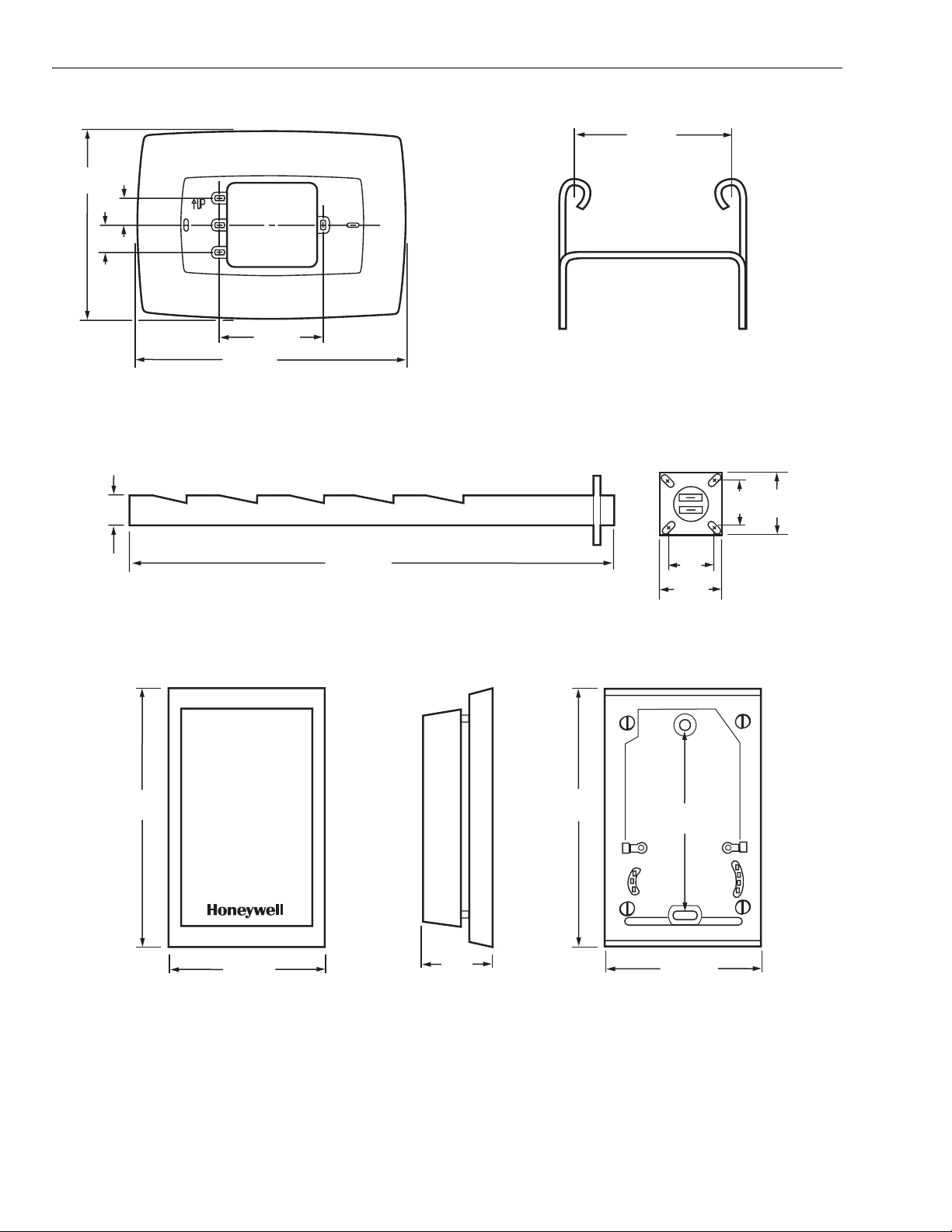

205224A: See Fig. 2.

C7089A: See Fig. 3.

C7100A: See Fig. 4.

C7189A: See Fig. 5.

PC8900A: See Fig. 6.

W8900A-C: See Fig. 7.

Operating Ambient Temperature Range:

NOTES: System is capable of turning on heat at 0°F (-18°C).

C7089A: -40° to 128°F (-40° to 53°C).

C7100A: 40° to 150°F (4° to 66°C).

C7189A: 40° to 95°F (4° to 35°C).

PC8900A: 40° to 110°F (4° to 43°C).

W8900A-C: -40° to 150°F (-40° to 66°C).

Shipping Temperature Range (All Components): -20° to

150°F (-29° to 66°C).

Operating Relative Humidity Range (All Components):

5 percent RH to 90 percent RH, noncondensing.

Mounting Means:

C7089A Outdoor Sensor: Mounts outside of living space using

locally obtained mounting hardware.

C7100A Discharge Air Sensor: Mounts in discharge air duct,

near air exchanger in a 2 x 4 in. outlet box or on a flat duct

or plenum surface. The temperature sensor probe passes

through a 7/8 in. knockout in the 2 x 4 in. outlet box.

C7189A Remote Indoor Sensor: Mounts directly on the wall

using mounting screws and anchors provided.

PC8900A Control Panel:

Without Remote Sensor: Mounts directly on the wall in liv-

ing space using mounting screws and anchors provided.

With Remote Sensor: Mounts directly on the wall in a

closet or other convenient location using mounting

screws and anchors provided.

W8900A-C Remote Module: Mounts directly on the wall, near

HVAC equipment or cold air return, using mounting screws

and anchors provided.

Table 1. W8900A-C Models.

Model

System Type

W8900A Conventional 2

Use with

Heat

Stages

Cool

Stages

a

2

Ven t

Adjustment

Humidity

Adjustment Heat

Humidity

Adjustment Cool Use with

yes yes yes PC8900A

W8900B Heat pump 3 2 yes yes yes PC8900A

W8900C Conventional 2 2 yes yes

a

Models with O and B terminals have single stage cooling.

b

Uses reheat. See Operation section.

yes

b

PC8900A

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Home and Building Control Sales Office (check white pages of your phone directory).

2. Home and Building Control Customer Relations

Honeywell, 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386 (800) 328-5111

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

68-0173—3 2

Page 3

Finish:

C7189A Wall Mount Remote Indoor Sensor: Premier White®

color.

PC8900A Control Panel: Premier White® color.

W8900A-C Remote Module: Charcoal gray color.

Clock Accuracy: ± 1 minute per month.

Approvals:

FCC Class B: Pending.

NEMA DC-3: Not required.

Batteries: No batteries required. During power outages, time

is retained for six hours. All programmed setpoints and

times are retained indefinitely.

Resistance Characteristics of Sensors:

C7089A Outdoor Sensor: PTC Sensor. See Fig. 39 in the

Operation section for sensor resistance characteristics.

C7100A Discharge Air Sensor: See Fig. 39 in the Operation

section for sensor resistance characteristics.

C7189A Remote Indoor Sensor: NTC Sensor. See Fig. 40 in

the Operation section for sensor resistance characteristics.

Auxiliary Heat and Emergency Heat Indication: PC8900A

display indicates when auxiliary heat and emergency heat

are activated.

Input Ratings:

20 to 30 Vac, 50/60 Hz.

Heat Pump Failure Input (L Terminal on W8900B Models):

24 Vac load, 50/60 Hz, 0.3 VA load.

CO2 Monitor Input (CO

els): 24 Vac load, 50/60 Hz, 0.3 VA load.

Terminal on all W8900A-C Mod-

2

Output Ratings:

Humidity Control Output Relay: 50 VA at 24 Vac.

Ventilation, W1, W2, Y1, Y2, E, G, O, B, AUX, Y1/W1:

a. 1.5A running, 3.5A inrush at 200,000 cycles

(30 Vac).

b. 1.5A running, 7.5A inrush at 100,000 cycles

(30 Vac).

Run: 40% power factor minimum.

Inrush: 50% power factor minimum.

Temperature Setting Range: PC8900A: 45° to 88°F

(7° to 31°C).

Humidity Setting Range:

PC8900A: 10 to 80% RH.

Cooling: 40 to 80% RH.

Heating: 10 to 80% RH.

Calibration: C7089A, C7100A, C7189A, and PC8900A are

factory calibrated and require no field calibration.

Monitors: The W8900A-C allows for connection of a

CO

2

Monitor with uncommitted contacts.

CO

2

PC8900A

Comfort Center™

Control Panel

C7189A

Remote Indoor Sensor

C7089A

Outdoor Sensor

W8735B

Telephone Access

Module

CM8900A

Communication Module

Fig. 1. System components and accessories.

W8900A-C

Remote Module

C7100A

C7100A

Discharge Air Sensor

Discharge Air Sensor

3 68-0173—3

Page 4

6

(152)

7/8

(22)

7/8

(22)

1-1/2 (38)

3-1/4 (83)

8-1/2 (216)

M7513

Fig. 2. Dimensions for 205224A Wall Cover

Plate in in. (mm).

3/4

(19)

13-1/4 (336)

Fig. 4. Dimensions for C7100A Discharge Air Sensor in in. (mm).

M4488

Fig. 3. Dimensions for C7089A Outdoor Sensor

Mounting Clip in in. (mm).

1-3/16

1-13/16

(30)

(46)

1-3/16

(30)

1-13/16

(46)

M4461

4-5/8

(117)

2-3/4 (70)

M4465

FRONT VIEW SIDE VIEW FRONT VIEW (COVER OFF)

Fig. 5. Dimensions for C7189A Remote Indoor Sensor in in. (mm).

68-0173—3 4

1-1/8

(29)

4-5/8

(117)

3-1/4

(83)

2-3/4 (70)

Page 5

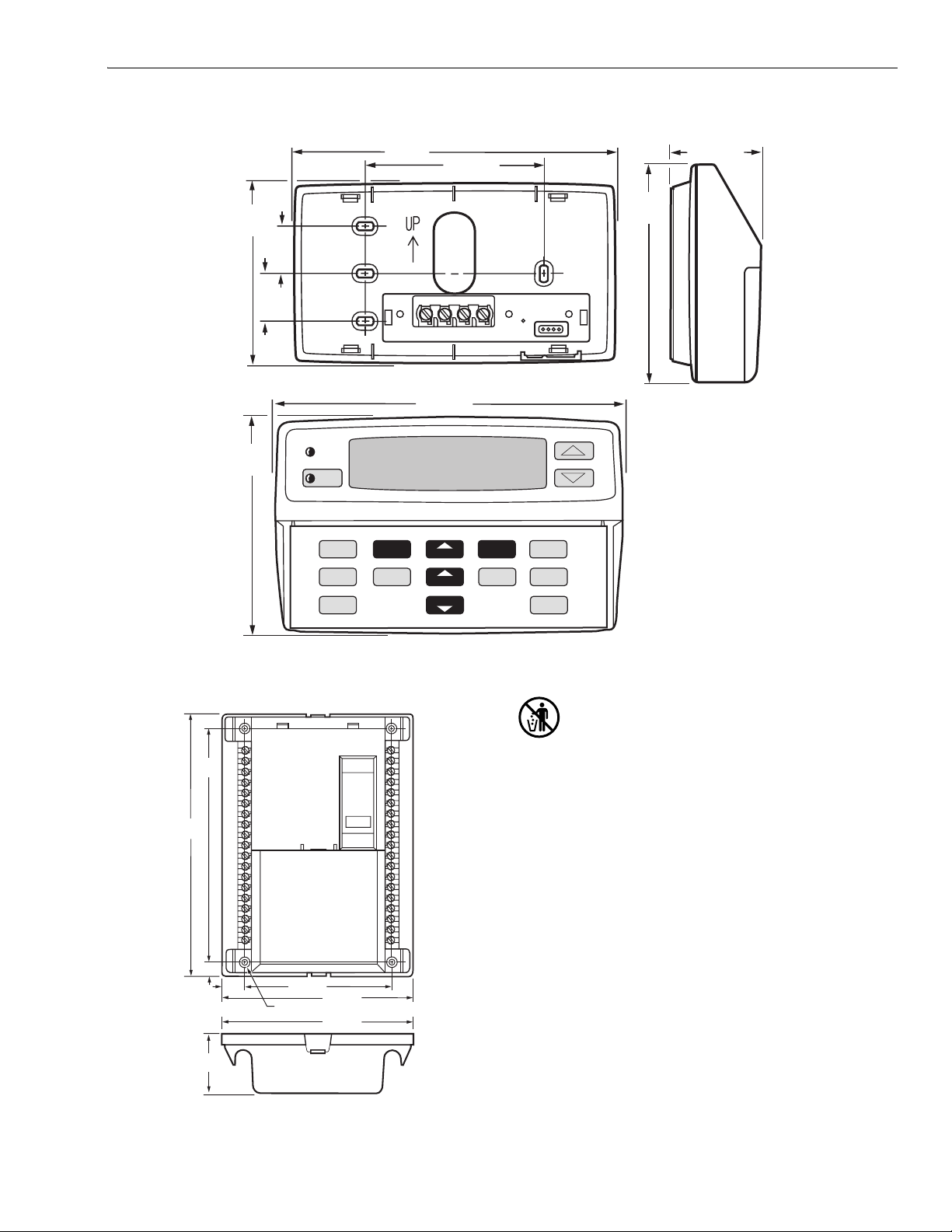

3-3/8

(86)

7/8

(22)

7/8

(22)

6 (152)

3-1/4 (83)

6-3/8 (162)

4

(102)

1-5/8 (41)

8-3/4

(222)

7-13/16

(197)

4

(102)

SYSTEM

CHECK

SET

CLOCK

SELECT

PERIOD

CANCEL

SYSTEM

HEAT OFF COOL

HUMIDITY

DAY

TIME

TIME

FAN

AUTO ON CIRC

VENTILATE

HEAT/COOL

SETPOINTS

HOLD

RUN

NOTE:

PC8900 SHOWN WITH

COVER REMOVED.

Fig. 6. Dimensions for PC8900A Control Panel in in. (mm).

MERCURY NOTICE

If this control is replacing a control that contains

mercury in a sealed tube, do not place your old control

in the trash.

Contact your local waste management authority for

instructions regarding recycling and the proper

disposal of this control or of an old control containing

mercury in a sealed tube.

If you have questions, call Honeywell Inc. at

1-800-468-1502, Monday through Friday, 7:00 a.m. to

5:30 p.m., Central time.

M6356

1/2 (12)

3/4

(19)

2

(51)

NOTE: W8900 SHOWN WITH COVER REMOVED.

4-7/8 (124)

(4) 3/8 (5)

6-3/8 (163)

6-3/8 (163)

M6355

Fig. 7. Dimensions for W8900A-C Remote

Module in in. (mm).

INSTALLATION

When Installing this Product…

1. Read these instructions carefully. Failure to follow

instructions can damage the product or cause a

hazardous condition.

2. Check the ratings on the product to make sure the

product is suitable for your application.

3. Installer must be a trained, experienced service

technician.

4. After completing installation, use these instructions to

check out product operation.

5 68-0173—3

Page 6

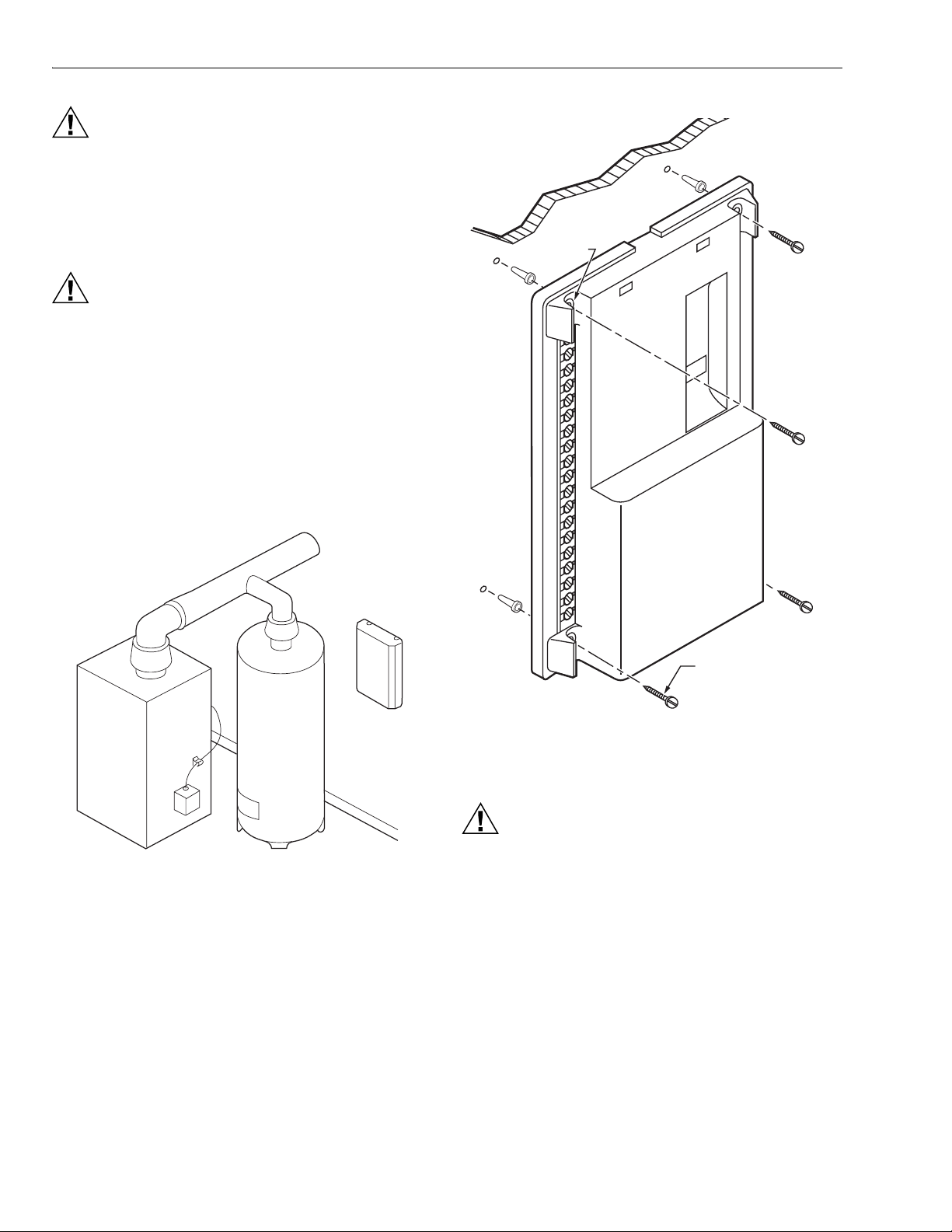

CAUTION

Disconnect power supply before wiring to prevent

electrical shock or equipment damage.

Mounting the W8900A-C Remote Module

Locate the W8900A-C in the equipment room near the HVAC

equipment. See Fig. 8.

CAUTION

Do not mount the W8900A-C inside any HVAC

equipment. Mounting the W8900A-C inside HVAC

equipment can cause damage to the W8900A-C.

1. Grasp the top edge of the W8900A-C cover, either at

the center or both corners, and pull it off fro m t h e b a s e .

2. Locate the four mounting holes. See Fig. 9.

3. Position the W8900A-C on wall or cold air return. Level

the W8900A-C for appearance only; the device will

function properly even when not level. Use a pencil to

mark the mounting holes on the wall.

WALL

MOUNTING

HOLES (4)

W8900

W8900

FURNACE OR BOILER

WATER HEATER

M4459

Fig. 8. W8900A-C location example.

4. Remove the W8900A-C from the wall, and drill 3/16 in.

holes in the wall (if drywall) as marked. For firmer material such as plaster or wood, drill 7/32 in. holes. Gently

tap anchors (provided) into drilled holes until flush with

the wall.

5. Reposition the W8900A-C over the holes. Loosely insert

the four mounting screws (included) into the holes.

MOUNTING

SCREWS (4)

M4463

Fig. 9. Mounting W8900A-C Remote Module.

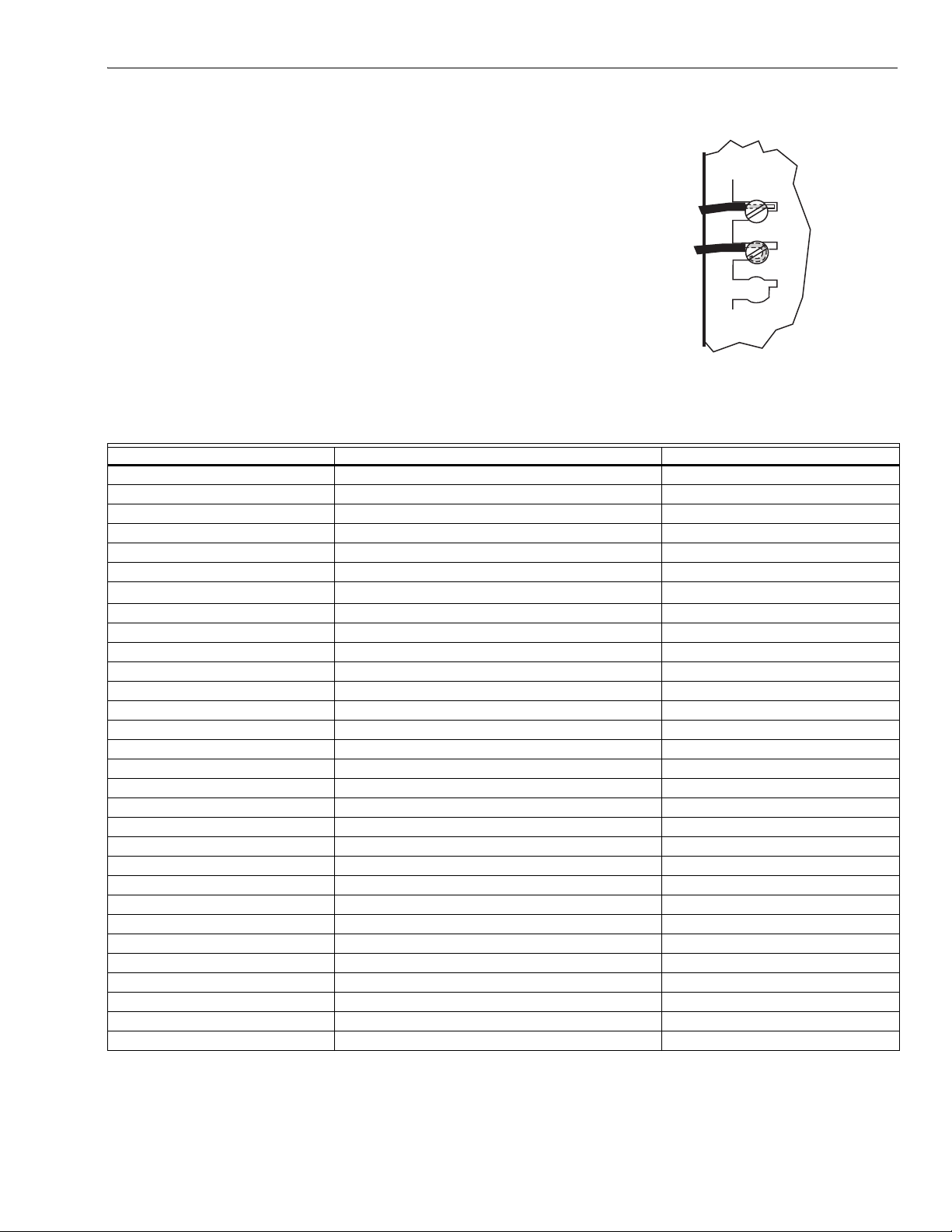

Wiring the W8900A-C to the HVAC Equipment

CAUTION

Disconnect power supply before connecting

wiring to prevent electrical shock or equipment

damage.

Wiring must comply with applicable codes, ordinances, and

regulations.

IN REPLACEMENT INSTALLATION:

1. Locate the terminal wiring strip on the old thermostat.

2. Note the wire color for each wiring terminal used.

3. Remove the wires connected to the old thermostat and

other controls. Tape off unused wires.

4. Use Table 2 or 3 to identify the W8900A-C terminal

labels. Connect the same loads that were connected to

the old thermostat to the W8900A-C Remote Module

with a new bundle of 18-gauge color-coded thermostat

wire; see Fig. 10. See Fig. 11 through 20 for wiring diagrams for specific equipment applications.

68-0173—3 6

Page 7

IMPORTANT

Be sure to connect the C terminal to transformer

common.

W8900

IN NEW INSTALLATION:

1. Locate the terminal strip(s) on the HVAC equipment.

2. Refer to Fig. 11 through 20 for wiring diagrams for spe-

cific equipment applications.

FOR STRAIGHT

CONNECTION—

STRIP 5/16 IN. (8 MM)

3. Connect all loads to the appropriate W8900A-C wiring

terminal using 18-gauge, color-coded thermostat wire;

see Fig. 10.

4. Use a small screwdriver to connect the loads. Do not

FOR WRAPAROUND

CONNECTION—

STRIP 7/16 IN. (11 MM)

overtighten; device can be damaged.

M4464

Fig. 10. Proper wiring technique for

W8900A-C and PC8900A.

Table 2. Conventional Applications (W8900A or C).

W8900A, C Terminal Designation Function Existing Thermostat Designation

1 PC8900A Control Panel —

2 PC8900A Control Panel —

3 PC8900A Control Panel —

4 PC8900A Control Panel —

B Heating, changeover valve B

C 24 Vac Transformer Common C

CO

2

Carbon Dioxide Monitor —

VNT VNT Relay —

G Fan Relay G

GND Ground —

HUM Humidity Relay —

OUT Outdoor Air Temperature Sensor —

O Cooling, Changeover Valve O

R 24 Vac System Transformer R

RC 24 Vac Cooling Transformer RC

RH 24 Vac Heating Transformer RH

S, S1 Remote Air Temperature Sensor —

See note a Fan Control—Evaporative Cooling F

See note b Heat Pump Contactor P

T, T1 Discharge Air Temperature Sensor —

W1 Heating Relay W

W1 Stage 1 Heat Relay W1

W2 Stage 2 Heat Relay W2

Y1 Cooling Relay Y

Y1 Stage 1 Cool Relay Y1

Y2 Stage 2 Cool Relay Y2

See note c Fan Control (Honeywell dual fuel thermostat [T834]) 1

See note c Fan Control (Honeywell dual fuel thermostat [T834]) 2

See note d Filter Light X

none Remote Timer Contacts Z

a

PC8900A/W8900A,C are not compatible with evaporative cooling equipment.

b

In single stage heat pump applications, jumper W1 and Y1 and connect to Y. Configure the system for Auto Fan in Heat.

c

Dual fuel fan feature configured in installer setup.

d

Filter light feature available in PC8900A fan accumulation timer feature.

7 68-0173—3

Page 8

Table 3. Heat Pump Applications (W8900B).

Existing Thermostat

Designations

(Customer Specials)

W8900B Terminal

Designations

Function

Existing Thermostat

Designations

(Standard)

1 PC8900A Control Panel — —

2 PC8900A Control Panel — —

3 PC8900A Control Panel — —

4 PC8900A Control Panel — —

AUX

a

Stage-3 heat control (strip heat) W3 —

B Heating, changeover valve B —

C 24 Vac transformer common C X,B

CO

2

Carbon dioxide monitor — —

E Emergency heat relay E K

VNT VNT relay — —

G Fan relay G F

GND Ground — —

L System monitor L L

O Cooling, changeover valve O R

R 24 Vac system transformer R V

S, S1 Remote Air Temperature Sensor — —

T, T1 Discharge Air Temperature Sensor — —

W2

Y1/W1

Y1/W1

Y1/W1

Y1/W1

b

c

c

c

c

Stage-2 heat control (compressor) W2 H2,Y,R4

Compressor contactor — RS

Compressor contactor Y M

Stage-1 cool control Y1 C1,M

Stage-1 heat control W1 H1,R3

Y2 Stage-2 cool control Y2 C2

None Clogged filter switch or common connection X X1,X2,C

None Defrost — P

None HSII Control Panel — L,C,H

None LEDs — A,A1,A2,Z,C,L

None LO and HI speed fan relays — R1,R2

None Momentary circuit, changeover — O

None Outdoor thermistor T A

d

Out

a

AUX controls the auxiliary heat like W2, and allows additional stages of auxiliary heat with outdoor thermostats while maintaining the proper second stage anticipation.

b

For systems without 2nd stage heat, configure W2 to No.

c

For systems requiring separate W1 and Y1 terminals for proper heat pump operation, refer to Fig. 18 and 19.

d

Replace existing sensor with C7089A Outdoor Sensor.

External temperature readout, T relay — —

68-0173—3 8

Page 9

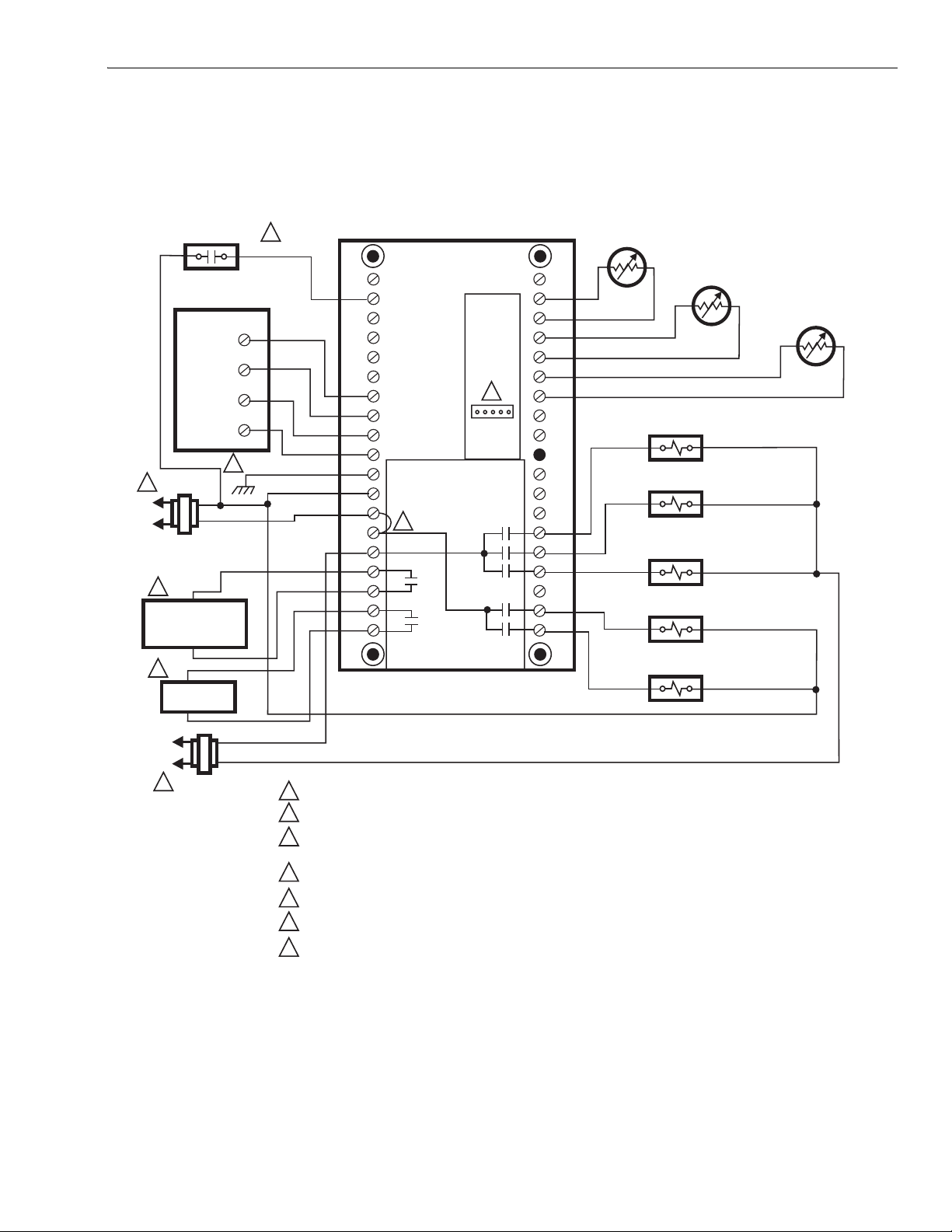

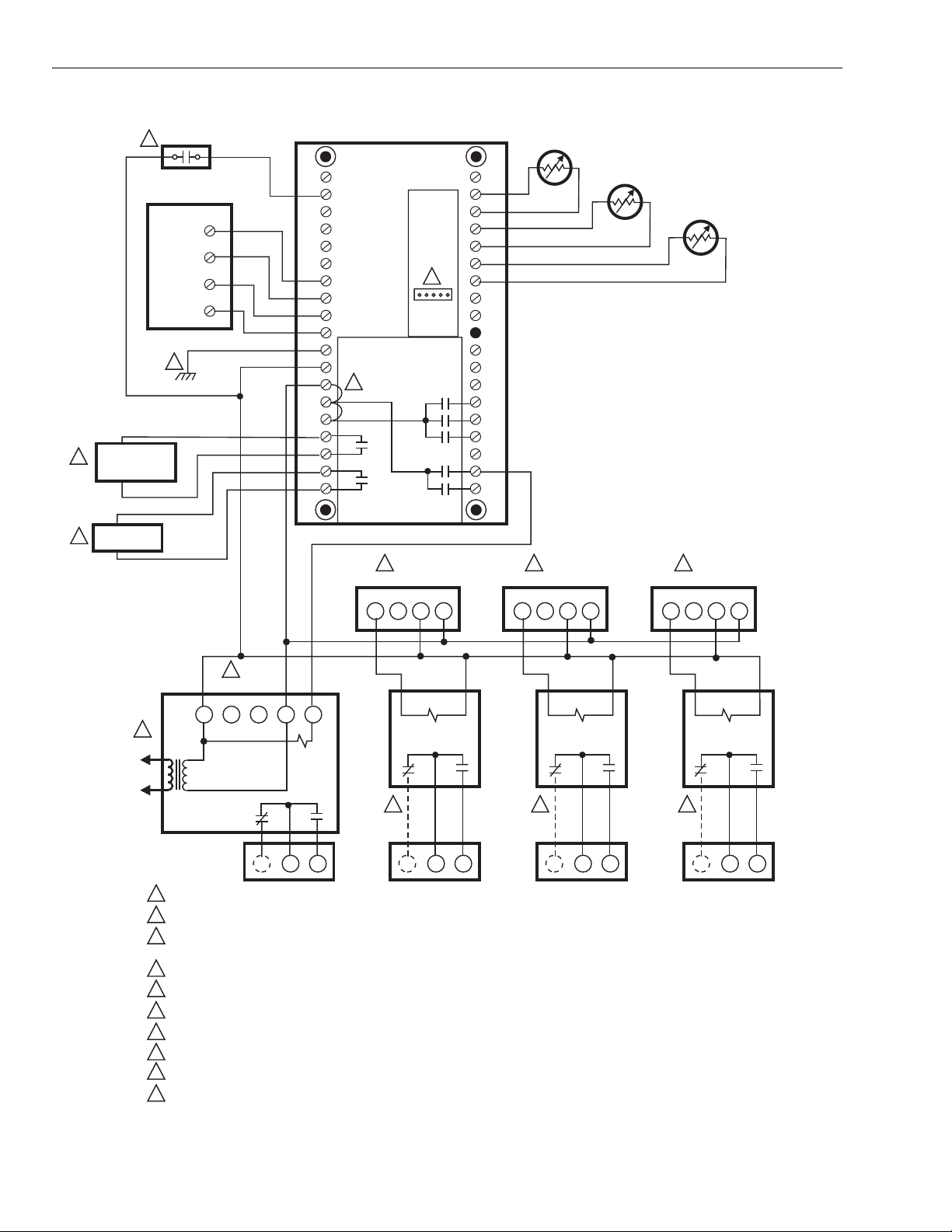

WIRING DIAGRAMS

W8900A,C Hookup Diagrams

CO2 MONITOR

1

L2

L1

(HOT)

HEATING

TRANSFORMER

3

HUMIDIFIER

OR DEHUMIDIFIER

EQUIPMENT

5

VENTILATION

EQUIPMENT

PC8900

1

2

3

4

6

4

CO

2

1

2

3

4

GND

C

R

RH

RC

HUM

HUM

VNT

VNT

W8900A,C

7

2

C7189A REMOTE AIR

TEMPERATURE SENSOR

S1

S

T1

T

OUT

OUT

LED

G

Y2

Y1

W1

W2

C7100 DISCHARGE AIR

TEMPERATURE SENSOR

FAN RELAY

STAGE 2

COOL RELAY

STAGE 1

COOL RELAY

STAGE 1

HEAT RELAY

STAGE 2

HEAT RELAY

C7089A OUTDOOR AIR

TEMPERATURE SENSOR

L1

(HOT)

L2

1

COOLING

TRANSFORMER

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

2

JUMPER R TO RH FOR SINGLE HEAT TRANSFORMER APPLICATIONS.

3

CONFIGURE PC8900 FOR HUMIDITY CONTROL IN HEATING MODE

(HUMIDIFIER) OR COOLING MODE (DEHUMIDIFIER) DURING INSTALLER SETUP .

4

W8900 ALLOWS CONNECTION OF A CO MONITOR WITH UNCOMMITTED CONTACTS.

5

SEE VENTILATION INSTRUCTIONS FOR WIRING.

6

GROUNDING THE GND TERMINAL IS NOT RECOMMENDED.

CONNECTION FOR CM8900A REMOTE COMMUNICATIONS MODULE.

7

2

Fig. 11. Hookup diagram for heating/cooling system in conventional system with multiple transformers.

9 68-0173—3

M4479D

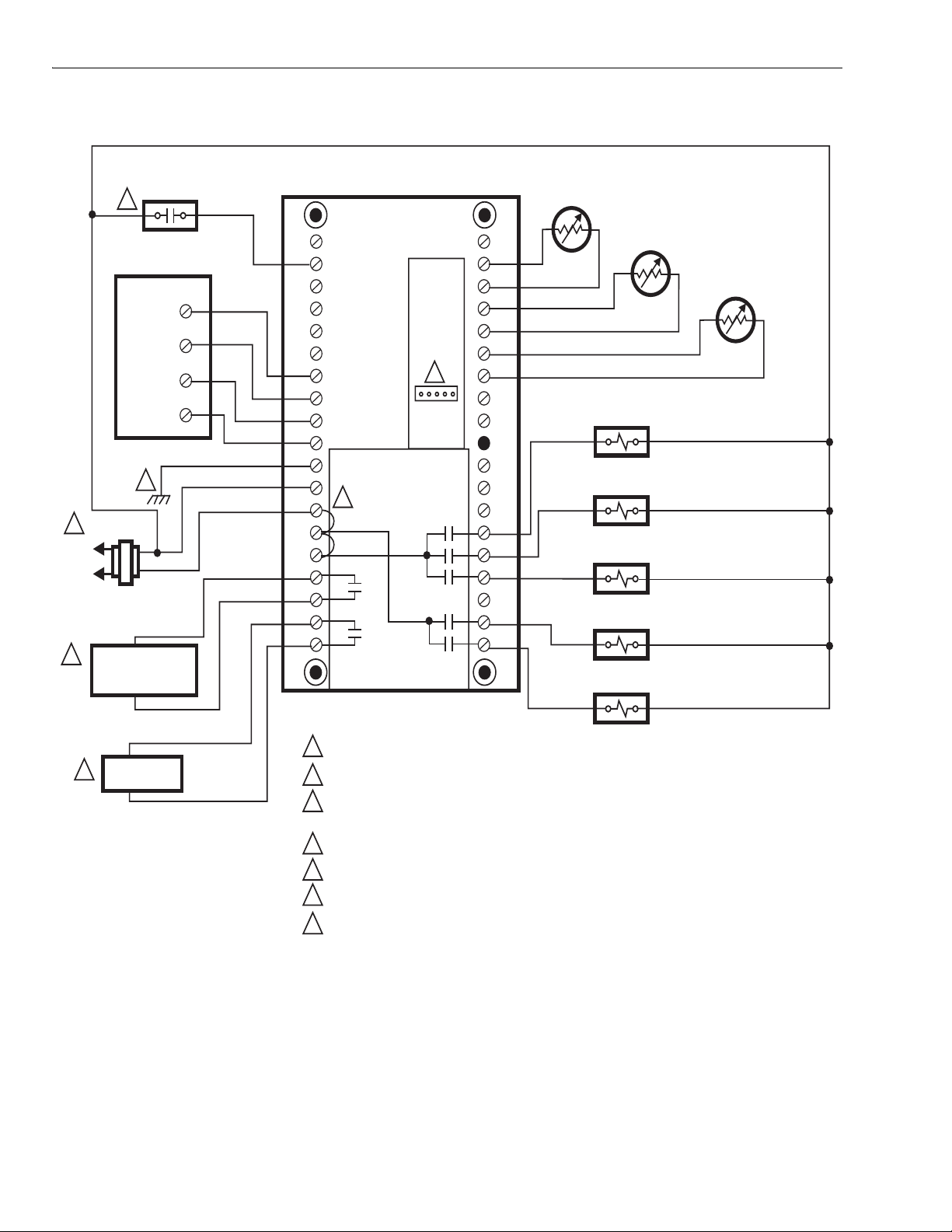

Page 10

1

L2

L1

(HOT)

SYSTEM

TRANSFORMER

3

HUMIDIFIER

OR DEHUMIDIFIER

EQUIPMENT

CO2 MONITOR

4

PC8900

1

2

3

4

6

CO

1

2

3

4

GND

C

R

RH

RC

HUM

HUM

VNT

VNT

W8900A,C

2

7

2

C7189A REMOTE AIR

TEMPERATURE SENSOR

S1

S

T1

T

OUT

OUT

LED

G

Y2

Y1

W1

W2

C7100 DISCHARGE AIR

TEMPERATURE SENSOR

C7089A OUTDOOR AIR

TEMPERATURE SENSOR

FAN RELAY

STAGE 2

COOL RELAY

STAGE 1

COOL RELAY

STAGE 1

HEAT RELAY

STAGE 2

HEAT RELAY

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

VENTILATION

5

EQUIPMENT

2

JUMPER R TO RH TO RC FOR SINGLE TRANSFORMER APPLICATIONS.

3

DURING INSTALLER SETUP, CONFIGURE PC8900 FOR HUMIDITY CONTROL IN HEATING MODE

(HUMIDIFIER) OR COOLING MODE (DEHUMIDIFIER).

4

W8900 ALLOWS CONNECTION OF A CO MONITOR WITH UNCOMMITTED CONTACTS.

5

SEE VENTILATION INSTRUCTIONS FOR WIRING.

6

GROUNDING THE GND TERMINAL IS NOT RECOMMENDED.

7

CONNECTION FOR CM8900A REMOTE COMMUNICATIONS MODULE.

2

M4478D

Fig. 12. Hookup diagram for 1-stage or 2-stage heating and cooling in conventional system with single transformer.

68-0173—3 10

Page 11

L2

L1

(HOT)

SYSTEM

TRANSFORMER

3

HUMIDIFIER OR

DEHUMIDIFIER

EQUIPMENT

4

PC8900

1

CO2 MONITOR

1

2

3

4

6

CO

1

2

3

4

GND

C

R

RH

RC

HUM

HUM

VNT

VNT

W8900A,C

2

7

2

C7189A REMOTE AIR

TEMPERATURE SENSOR

S1

S

T1

T

OUT

OUT

LED

G

Y2

Y1

W1

W2

C7100 DISCHARGE AIR

TEMPERATURE SENSOR

FAN RELAY

STAGE 1

COOL RELAY

C7089A OUTDOOR AIR

TEMPERATURE SENSOR

VENTILATION

5

EQUIPMENT

PILOT

1ST

OPERATOR

DUAL VALVE COMBINATION

GAS CONTROL

POWER SUPPLY. PROVIDE DISCONNECT

1

MEANS AND OVERLOAD PROTECTION

AS REQUIRED.

2

JUMPER R TO RH TO RC FOR SINGLE

TRANSFORMER APPLICATIONS.

3

DURING INSTALLER SETUP, CONFIGURE PC8900 FOR HUMIDITY CONTROL IN HEATING MODE

(HUMIDIFIER) OR COOLING MODE (DEHUMIDIFIER).

4

W8900 ALLOWS CONNECTION OF A CO MONITOR WITH UNCOMMITTED CONTACTS.

5

SEE VENTILATION INSTRUCTIONS FOR WIRING.

6

GROUNDING THE GND TERMINAL IS NOT RECOMMENDED.

7

CONNECTION FOR CM8900A REMOTE COMMUNICATIONS MODULE.

COM

2ND

OPERATOR

MAIN

VALVE

2

IGNITER

MV

MV/PV

PILOT GAS

SUPPLY

PV

SENSOR

GND

(BURNER)

PILOT

BURNER

GROUND

24V

GND

S8610U

24V

TH-W

VENT

DAMPER

PLUG

LIMIT

CONTROLLER

SENSE

D892 VENT

DAMPER

SPARK

M4489D

Fig. 13. Hookup diagram for heating/cooling intermittent pilot gas burning ignition system.

11 68-0173—3

Page 12

HUMIDIFIER OR

3

DEHUMIDIFIER

EQUIPMENT

VENTILATION

8

EQUIPMENT

CO2 MONITOR

4

PC8900

9

W8900A,C

CO

2

1

2

3

4

1

2

3

4

GND

C

R

RH

RC

HUM

HUM

VNT

VNT

2

ZONE 2 THERMOSTAT

10

7

C7189A REMOTE AIR

TEMPERATURE SENSOR

S1

S

T1

T

OUT

OUT

LED

G

Y2

Y1

W1

W2

7

ZONE 3 THERMOSTAT

C7100 DISCHARGE AIR

TEMPERATURE SENSOR

C7089A OUTDOOR AIR

TEMPERATURE SENSOR

7

ZONE 4 THERMOSTAT

L2

L1

(HOT)

GC

W

5

R8239A1052

CYRG

24V

W

6

ZONE 1

VALVE

2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

JUMPER R TO RH TO RC FOR SINGLE TRANSFORMER APPLICATIONS.

2

DURING INSTALLER SETUP, CONFIGURE PC8900 FOR HUMIDITY CONTROL IN HEATING MODE

3

(HUMIDIFIER) OR COOLING MODE (DEHUMIDIFIER).

W8900 ALLOWS CONNECTION OF A CO MONITOR WITH UNCOMMITTED CONTACTS.

4

5

USE ONE R8239 FOR EVERY FOUR ZONES.

6

USE FOR 3-WIRE ZONE VALVE OR DAMPERS.

ZONES 2, 3, 4 CAN BE CONTROLLED BY ADDITIONAL PC8900/W8900 OR OTHER THERMOSTATS.

7

8

SEE VENTILATION INSTRUCTIONS FOR WIRING.

9

GROUNDING THE GND TERMINAL IS NOT RECOMMENDED.

10

CONNECTION FOR CM8900A REMOTE COMMUNICATIONS MODULE.

RW

R8222B1067

ZONE 2

VALVE

GC

R8222B1067

6

RW

ZONE 3

VALVE

GC

R8222B1067

6

R

ZONE 4

VALVE

M4491D

Fig. 14. Hookup diagram for 3-wire zone valves in Series 20 heating system with zone controls.

68-0173—3 12

Page 13

CO2 MONITOR

PC8900

L2

1

L1

(HOT)

SYSTEM

TRANSFORMER

HUMIDIFIER OR

2

DEHUMIDIFIER

EQUIPMENT

3

CO

2

1

2

3

4

5

1

2

3

4

GND

C

R

RH

RC

HUM

HUM

VNT

VNT

W8900A,C

6

C7189A REMOTE AIR

TEMPERATURE SENSOR

S1

S

T1

T

OUT

OUT

LED

G

Y2

Y1

W1

W2

C7100 DISCHARGE AIR

TEMPERATURE SENSOR

FAN RELAY

STAGE 1

COOL RELAY

C7089A OUTDOOR AIR

TEMPERATURE SENSOR

4

VENTILATION

EQUIPMENT

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

DURING INSTALLER SETUP, CONFIGURE PC8900 FOR HUMIDITY CONTROL IN HEATING MODE

2

(HUMIDIFIER) OR COOLING MODE (DEHUMIDIFIER).

3

W8900 ALLOWS CONNECTION OF A CO MONITOR WITH UNCOMMITTED CONTACTS.

4

SEE VENTILATION INSTRUCTIONS FOR WIRING.

5

GROUNDING THE GND TERMINAL IS NOT RECOMMENDED.

6

CONNECTION FOR CM8900A REMOTE COMMUNICATIONS MODULE.

2

L1

(HOT)

L2

1

OIL PRIMARY

Fig. 15. Hookup diagram in oil heating/electric cooling system (oil primary has its own transformer).

T

M4490D

T

13 68-0173—3

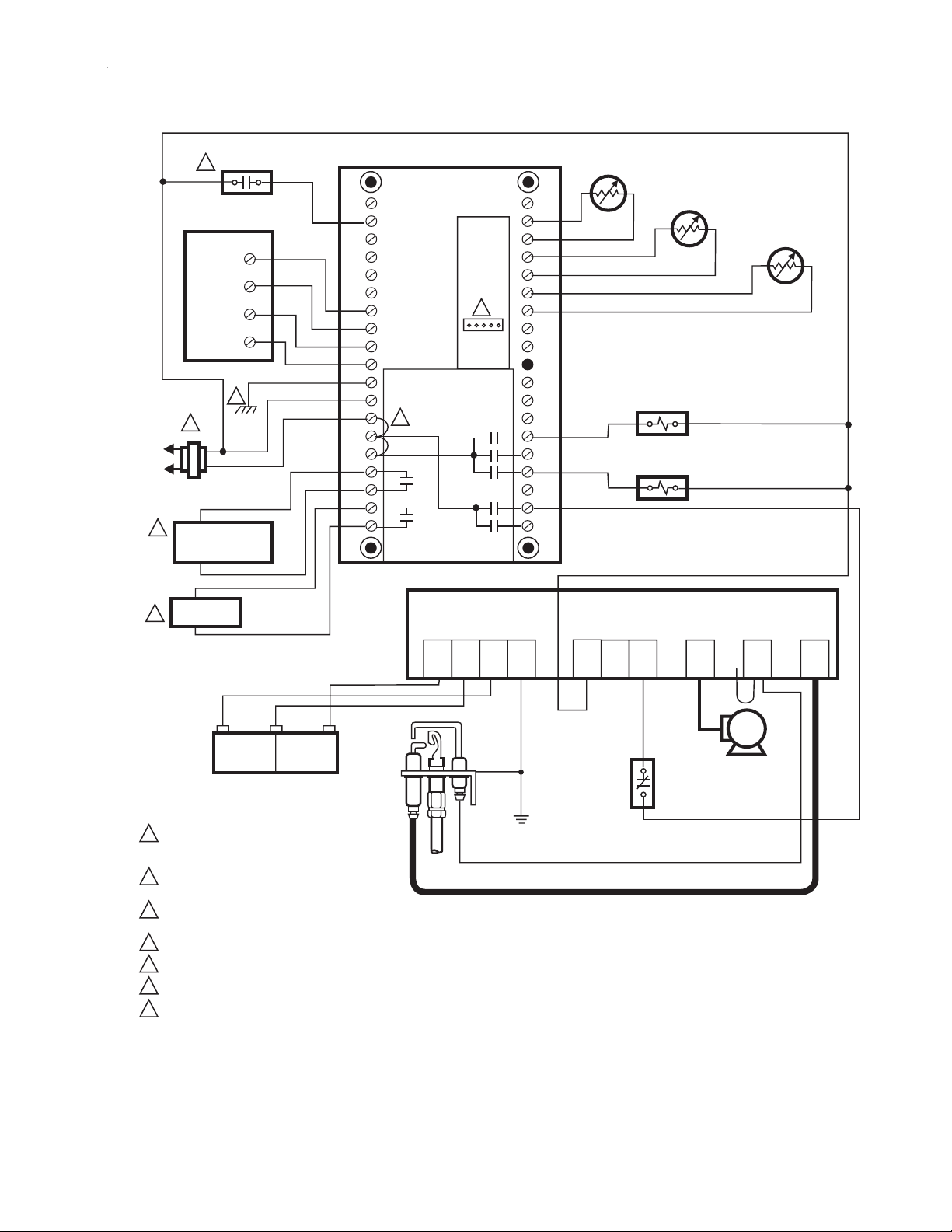

Page 14

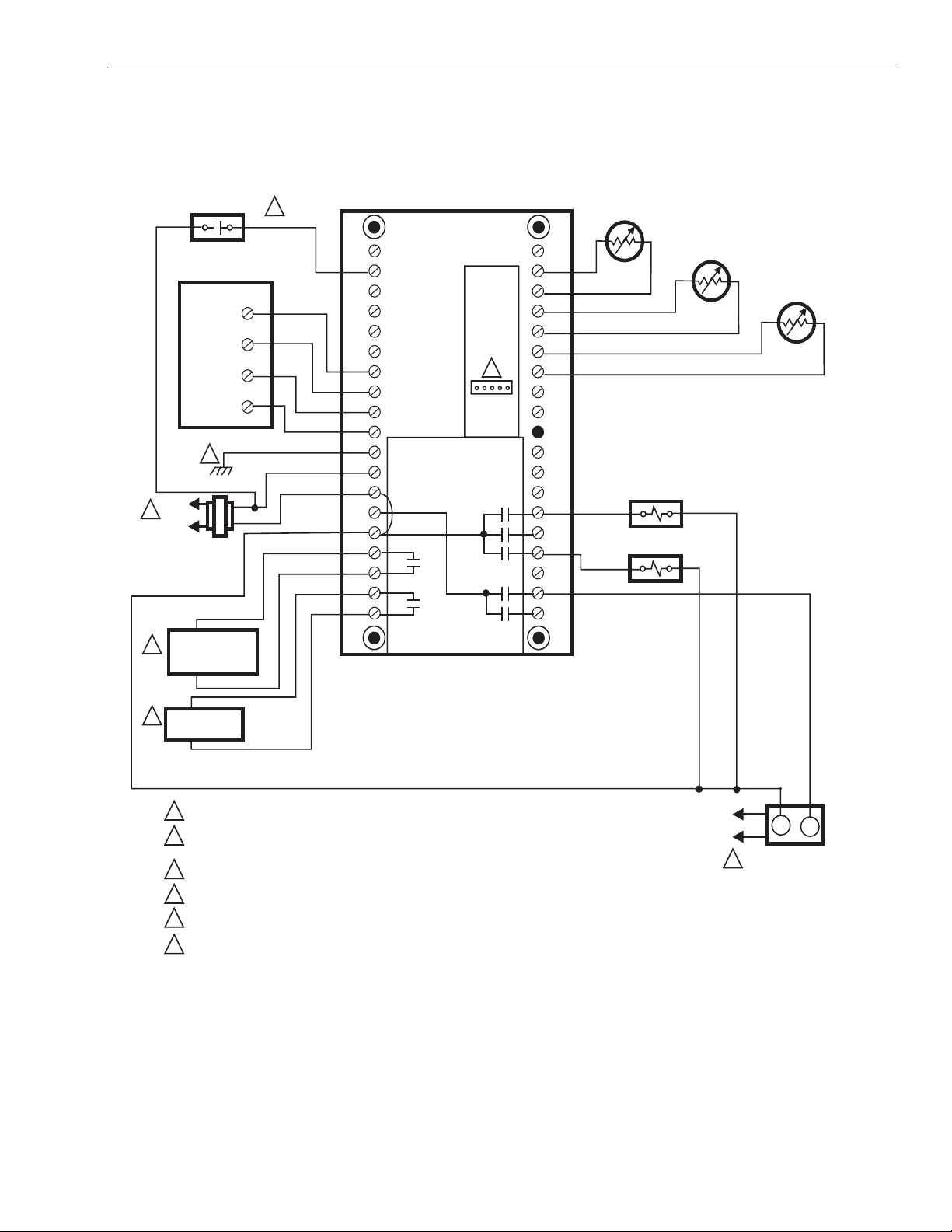

W8900B Hookup Diagrams

1

L2

L1

(HOT)

3

7

VENTILATION

EQUIPMENT

CO2 MONITOR

COMPRESSOR

MONITOR

PC8900

1

2

3

4

8

SYSTEM

TRANSFORMER

HUMIDIFIER OR

DEHUMIDIFIER

EQUIPMENT

4

W8900B

CO

2

L

1

2

3

4

GND

C

R

RH

HUM

HUM

VNT

VNT

2

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

JUMPER R TO RH.

2

3

DURING INSTALLER SETUP, CONFIGURE PC8900 FOR HUMIDITY CONTROL IN HEATING MODE

(HUMIDIFIER) OR COOLING MODE (DEHUMIDIFIER).

4

W8900 ALLOWS CONNECTION OF A CO MONITOR WITH UNCOMMITTED CONTACTS.

CONFIGURE PC8900 FOR CHANGEOVER IN HEATING MODE OR COOLING MODE.

5

IF SEPARATE Y1 AND W1 TERMINALS ARE REQUIRED, REFER TO FIGURES 18 AND 19.

6

SEE VENTILATION INSTRUCTIONS FOR WIRING.

7

GROUNDING THE GND TERMINAL IS NOT RECOMMENDED.

8

CONNECTION FOR CM8900A REMOTE COMMUNICATIONS MODULE.

9

CONFIGURE PC8900 FOR NO CONNECTION TO TERMINALS Y2, E, AUX AND W2 FOR

10

SINGLE-STAGE HEAT PUMP SYSTEM.

9

C7189A REMOTE AIR

TEMPERATURE SENSOR

S1

S

T1

T

OUT

OUT

LED

O/B

G

Y2

Y1/W1

E

AUX

W2

10

2

C7100 DISCHARGE AIR

TEMPERATURE SENSOR

CHANGEOVER

5

RELAY

FAN RELAY

COMPRESSOR

CONTACTOR

EMERGENCY

HEAT RELAY

AUXILIARY

HEAT RELAY

C7089A OUTDOOR AIR

TEMPERATURE SENSOR

6

M4483D

Fig. 16. Hookup diagram for 2-stage heat/1-stage cool in heat pump system.

68-0173—3 14

Page 15

CO2 MONITOR

4

1

L2

L1

(HOT)

3

COMPRESSOR

MONITOR

PC8900

1

2

3

4

9

SYSTEM

TRANSFORMER

HUMIDIFIER OR

DEHUMIDIFIER

EQUIPMENT

CO

L

1

2

3

4

GND

C

R

RH

HUM

HUM

VNT

VNT

W8900B

2

10

2

Y1/W1

6

C7189A REMOTE AIR

TEMPERATURE SENSOR

S1

S

T1

T

OUT

OUT

LED

O/B

G

Y2

E

AUX

W2

C7100 DISCHARGE AIR

TEMPERATURE SENSOR

CHANGEOVER

RELAY

FAN RELAY

STAGE 2

COMPRESSOR

STAGE 1

COMPRESSOR

EMERGENCY

HEAT RELAY

5

7

C7089A OUTDOOR AIR

TEMPERATURE SENSOR

VENTILATION

8

EQUIPMENT

AUXILIARY

HEAT RELAY

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQUIRED.

JUMPER R TO RH.

2

DURING INSTALLER SETUP, CONFIGURE PC8900 FOR HUMIDITY CONTROL IN HEATING MODE

3

(HUMIDIFIER) OR COOLING MODE (DEHUMIDIFIER).

W8900 ALLOWS CONNECTION OF A CO MONITOR WITH UNCOMMITTED CONTACTS.

4

5

CONFIGURE PC8900 FOR CHANGEOVER IN HEATING MODE OR COOLING MODE.

6

JUMPER Y2 AND W2 TERMINALS.

7

IF NO EMERGENCY HEAT RELAY, FIELD INSTALL JUMPER E TO AUX.

SEE VENTILATION INSTRUCTIONS FOR WIRING.

8

9

GROUNDING THE GND TERMINAL IS NOT RECOMMENDED.

CONNECTION FOR CM8900A REMOTE COMMUNICATIONS MODULE.

10

2

Fig. 17. Hookup diagram of 3-stage heat/2-stage cool heat pump system.

M4485D

15 68-0173—3

Page 16

1

L2

L1

(HOT)

SYSTEM

TRANSFORMER

3

HUMIDIFIER OR

DEHUMIDIFIER

EQUIPMENT

CO2 MONITOR

COMPRESSOR

MONITOR

PC8900

1

2

3

4

8

4

C7189A REMOTE AIR

TEMPERATURE SENSOR

S1

S

T1

T

OUT

OUT

LED

R8222N1011

5

O/B

G

Y2

Y1/W1

E

AUX

W2

1

6

4

C7100 DISCHARGE AIR

TEMPERATURE SENSOR

3

2

6

STAGE 1 HEAT RELAY

STAGE 1 COOL RELAY

HEAT

CHANGEOVER VALVE

C7089A OUTDOOR AIR

TEMPERATURE SENSOR

CO

L

1

2

3

4

GND

C

R

RH

HUM

HUM

VNT

VNT

W8900B

2

9

2

VENTILATION

7

EQUIPMENT

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

2

JUMPER R TO RH.

3

DURING INSTALLER SETUP, CONFIGURE PC8900 FOR HUMIDITY CONTROL IN HEATING MODE

(HUMIDIFIER) OR COOLING MODE (DEHUMIDIFIER).

4

W8900 ALLOWS CONNECTION OF A CO MONITOR WITH UNCOMMITTED CONTACTS.

5

CONNECT HEATING CHANGEOVER VALVE TO R8222N1011 AND CONFIGURE PC8900 FOR

CHANGEOVER IN HEATING MODE.

6

CONNECT G, Y2, E, AUX, AND W2 TERMINALS AS REQUIRED.

7

SEE VENTILATION INSTRUCTIONS FOR WIRING.

8

GROUNDING THE GND TERMINAL IS NOT RECOMMENDED.

9

CONNECTION FOR CM8900A REMOTE COMMUNICATIONS MODULE.

2

M4486D

Fig. 18. Hookup diagram for heat pump application requiring separate W1 and Y1 terminals with heating changeover.

68-0173—3 16

Page 17

1

L2

L1

(HOT)

HUMIDIFIER OR

3

DEHUMIDIFIER

EQUIPMENT

CO2 MONITOR

COMPRESSOR

MONITOR

PC8900

1

2

3

4

8

SYSTEM

TRANSFORMER

4

C7189A REMOTE AIR

TEMPERATURE SENSOR

S1

S

T1

T

OUT

OUT

LED

R8222N1011

5

O/B

G

Y2

Y1/W1

E

AUX

W2

1

6

4

C7100 DISCHARGE AIR

TEMPERATURE SENSOR

C7089A OUTDOOR AIR

TEMPERATURE SENSOR

3

2

6

STAGE 1 COOL RELAY

STAGE 1 HEAT RELAY

COOL

CHANGEOVER VALVE

CO

L

1

2

3

4

GND

C

R

RH

HUM

HUM

VNT

VNT

W8900B

2

9

2

VENTILATION

7

EQUIPMENT

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

2

JUMPER R TO RH.

3

DURING INSTALLER SETUP, CONFIGURE PC8900 FOR HUMIDITY CONTROL IN HEATING MODE

(HUMIDIFIER) OR COOLING MODE (DEHUMIDIFIER).

4

W8900 ALLOWS CONNECTION OF A CO MONITOR WITH UNCOMMITTED CONTACTS.

5

CONNECT COOLING CHANGEOVER VALVE TO R8222N1011 AND CONFIGURE PC8900 FOR

CHANGEOVER IN COOLING MODE.

6

CONNECT G, Y2, E, AUX, AND W2 TERMINALS AS REQUIRED.

SEE VENTILATION INSTRUCTIONS FOR WIRING.

7

GROUNDING THE GND TERMINAL IS NOT RECOMMENDED.

8

CONNECTION FOR CM8900A REMOTE COMMUNICATIONS MODULE.

9

2

M4487D

Fig. 19. Hookup diagram for heat pump application requiring separate Y1 and W1 terminals with cooling changeover.

17 68-0173—3

Page 18

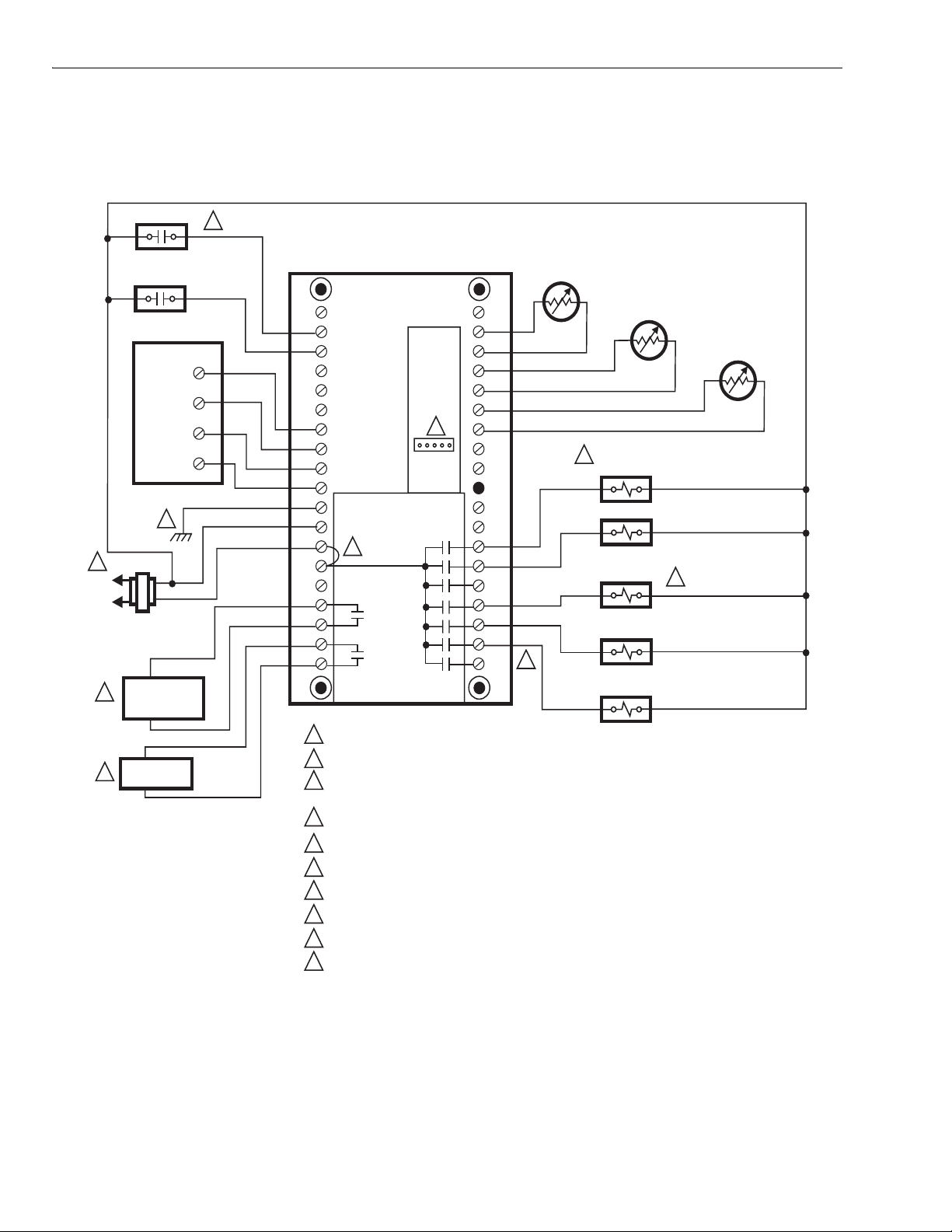

W8900A,B,C Humidity Control Hookup Diagrams

W8900A,B,C

lines applying to the location of the sensor. If a

remote sensor is used, humidity is only measured at

the PC8900A location.

SYSTEM

TRANSFORMER

L2

L1

(HOT)

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQUIRED.

JUMPER R TO RH TO RC FOR SINGLE TRANSFORMER APPLICATIONS.

2

3

CONFIGURE PC8900 FOR HUMIDITY CONTROL IN HEATING MODE.

3

R8222N1011

1

4

C

2

R

RH

RC

HUM

HUM

VNT

VNT

3

6

G

Y2

W1

W2

FAN

Y1

COMP

M18588

Fig. 20. Hookup diagram connecting cooling humidity

control in parallel with temperature control.

W8900A,B,C

SYSTEM

TRANSFORMER

L2

L1

(HOT)

1

L2

L1

(HOT)

1

HUMIDIFIER

3

4

RH

RC

HUM

HUM

VNT

VNT

C

2

R

G

Y2

Y1

W1

W2

Location Guidelines

• Choose a location for the PC8900A where it is safe from

tampering.

• Locate the PC8900A on an inside wall, about 5 ft (1.5m)

above the floor. The PC8900A can also be mounted

horizontally on a standard 2 x 4 in. (51 x 102 mm) outlet

box.

• The wire distance between the PC8900A and W8900A-C

should not exceed 200 ft.

• Install the PC8900A in an area with good air circulation at

average temperature. Avoid the following locations

because they can introduce errors in temperature

measurements:

— Hot or cold areas caused by concealed pipes or ducts.

— Drafts from windows, doors, fireplaces or other heat/

cool sources.

— Convection or radiant heat from the sun or electrical

equipment.

— Unheated areas on the other side of the wall location.

— Dead air areas behind doors, furniture, curtains or in

corners and alcoves.

Mounting

1. Mark the mounting location on the wall for the PC8900A

or outlet box.

2. Run cable from the unit to a hole at the selected wall

location. Pull approximately three inches of wire through

the hole. Color-coded 18-gauge thermostat wire is recommended. See Fig. 22.

NOTE: If the old thermostat leaves marks on the wall that

the PC8900A does not cover, order part no.

205224A Wall Cover Plate to mount between the

PC8900A and the wall. See Fig. 23. Use the following instructions and at step 7, put the wall cover plate

between the wall and wiring plate.

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQUIRED.

JUMPER R TO RH TO RC FOR SINGLE TRANSFORMER APPLICATIONS.

2

3

CONFIGURE PC8900 FOR HUMIDITY CONTROL IN HEATING MODE.

4

USE OF A SEPARATE POWER SUPPLY TO RUN THE HUMIDIFIER

IS RECOMMENDED.

M4997

Fig. 21. Hookup diagram connecting humidifier

using separate transformers for humidity

control in the heating mode.

Mounting the PC8900A Control Panel

NOTE: The following location guidelines apply only if a

remote sensor is not part of the installation. If a

remote sensor is installed, the PC8900A can be

installed in any convenient location, with these guide-

68-0173—3 18

WIRES

THROUGH WALL

WALL

ANCHORS

(3)

1

USE THREE MOUNTING HOLES THAT BEST

FIT APPLICATION

WALL

MOUNTING

HOLES (4)

MOUNTING

SCREWS (3)

M4466

Fig. 22. Mounting PC8900A Wiring Plate.

1

Page 19

3. Remove the PC8900A from the wiring wallplate by pulling the PC8900A straight off the wallplate.

4. Position the PC8900A Wiring Plate on the wall.

5. Level the wiring plate (for appearance only) using the

posts on top of the wiring plate; device functions properly even when not level.

6. Remove wiring plate from wall and drill 3/16 in. holes in

wall (if drywall) as marked. For firmer material such as

plaster or wood, drill 7/32 in. holes. Gently tap anchors

(provided) into drilled holes until flush with the wall.

NOTE: When using a wall cover plate, be sure to

place the wall cover plate between the wall

and the wiring plate.

7. Position wiring plate over holes in wall or outlet box,

pulling wires through wiring opening. Loosely insert

three mounting screws into holes that best fit the application.

8. Tighten the mounting screws.

9. Reinstall the PC8900A on the wallplate by pressing the

PC8900A directly onto the wallplate.

WALL

ANCHORS

(3)

WIRES THROUGH

WALL OPENING

CHOOSE THREE MOUNTING HOLES

1

THAT BEST FIT APPLICATION.

1

PC8900

COMFORT

CENTER

CONTROL

PANEL

205224A

WALL COVER PLATE

M

E

SYST

CHECK

PC8900 WIRING

PLATE

MOUNTING

SCREWS (3)

M7512A

Fig. 23. Mounting PC8900A Wiring Plate and 205224A Wall Cover Plate to wall.

Wiring the PC8900A

CAUTION

Keep wiring at least one foot away from large

inductive loads such as motors, line starters,

lightning ballasts and large power distribution

panels. Failure to follow these wiring practices can

introduce electrical interference (noise), which can

cause erratic system operation. Use shielded

cable to reduce interference if rerouting of wiring

is not possible. Ground the shielded cable only to

GND terminal on W8900A-C.

IMPORTANT

Erratic temperature readings can occur as a result of

any of the wiring practices described below. These

practices must be avoided to assure proper operation. Use shielded cable to reduce interference if

rerouting of wiring is not possible.

— Do not route thermostat wiring with building power

wiring, next to control contactors or near light dim-

ming circuits, electric motors or welding equipment.

— Avoid poor wiring connections.

— Avoid intermittent or missing building earth ground.

19 68-0173—3

Page 20

CAUTION

Disconnect the power supply before connecting

wiring to prevent electrical shock or equipment

damage.

All wiring must comply with all applicable electrical codes,

ordinances and regulations.

1. Loosen the PC8900A terminal screws and insert one

wire beneath each terminal (1, 2, 3, 4). Four wires are

required at the PC8900A to assure operation. Note the

color of the wire that is attached to each terminal number to later match the colors with the terminals on the

W8900A-C Remote Module. See Fig. 10 and 24 for wiring technique and wiring diagram.

2. Tighten screw terminals securely.

3. Push the excess wire back into the hole. Plug the hole

with nonhardening caulk, putty or insulation to prevent

drafts from affecting PC8900A operation.

IMPORTANT

In replacement applications, more than four wires can be available. In these applications, tape off the unused wires at the PC8900A location and the W8900A-C location.

Mounting the C7189A Remote Sensor (if needed)

2. Run cable from the W8900A-C Remote Module to a

hole at the selected wall location. Pull approximately

three inches of wire through the opening. Color-coded,

18-gauge thermostat wire is recommended.

W8900

1

2

1

3

2

4

GND

Location Guidelines

• Choose a location where the C7189A is safe from

tampering.

• Locate the C7189A on an inside wall, about 5 ft (1.5m)

above the floor. The C7189A can also be mounted

vertically on a standard 2 x 4 in. (51 x 102 mm) outlet box.

• The wire distance between the C7189A and W8900A-C

should not exceed 200 ft.

• Install the C7189A in an area with good air circulation at

average temperature. Avoid the following locations

because they can introduce errors in sensor

measurements (see Fig. 25):

— Hot or cold areas caused by concealed pipes or ducts.

— Drafts from windows, doors, fireplaces or other heat/

cool sources.

— Convection or radiant heat from the sun or electrical

equipment.

— Unheated areas on the other side of the wall location.

— Dead air areas behind doors, furniture, curtains or in

corners and alcoves.

Mounting

1. Mark the mounting location on the wall for the C7189A

Remote Indoor Sensor or junction box.

NOTE: Order 202689A Coverplate when C7189A can-

not cover wall marks from old thermostat.

3

1

1234

1

NOTE WHICH COLOR WIRE IS ATTACHED TO EACH TERMINAL.

2

FOUR WIRES ARE REQUIRED FOR PROPER OPERATION.

IF FEWER THAN FOUR ARE AVAILABLE, ADDITIONAL WIRES

MUST BE RUN TO PC8900 LOCATION. IF MORE THAN FOUR

ARE AVAILABLE, TAPE OFF UNUSED WIRES.

3

IF SHIELDED CABLE IS REQUIRED, GROUND TO GND

TERMINAL ON W8900.

IN REPLACEMENT APPLICATIONS, PC8900 REPLACES OLD

4

THERMOSTATS, HUMIDISTATS, VENTILATION CONTROLS,

AND AIR CLEANER INDICATORS. BE SURE TO REMOVE

OLD DEVICES AND TAPE OFF UNUSED WIRES.

4

2

M7519

Fig. 24. Wiring diagram for PC8900A Control Panel to

W8900A-C Remote Module.

68-0173—3 20

Page 21

NO

NO

YES

5 FEET

(1.5 METERS)

NO

M4476

Fig. 25. Typical location for C7189A Remote Sensor (C7189A must be

mounted in living space and not in return air duct).

Wiring the C7189A Remote Sensor (if needed)

CAUTION

Failure to follow these wiring practices can

introduce electrical interference (noise), which can

cause erratic system operation.

Keep wiring at least one foot away from large inductive

loads such as motors, line starters, lightning ballasts,

and large power distribution panels. Use shielded

cable to reduce interference if rerouting wire is not

possible. Ground the shielded cable to the ground

terminal on the W8900A-C.

IMPORTANT

Erratic temperature readings from a sensor can

occur as a result of any of the wiring practices

described below. These practices must be avoided to

assure proper operation. Use shielded cable to

reduce interference if rerouting of sensor wiring is

not possible.

— Do not route temperature sensor wiring with building

power wiring, next to control contactors or near light

dimming circuits, electric motors or welding equip-

ment.

— Avoid poor wiring connections.

— Avoid intermittent or missing building earth ground.

CAUTION

Disconnect power supply before connecting to

wiring to prevent electrical shock or equipment

damage.

Wiring must comply with applicable codes, ordinances and

regulations.

1. Wire the C7189A Remote Indoor Sensor to the

W8900A-C Remote Module terminals S1 and S. For an

example of general wiring of the C7189A, see Fig. 26.

2. Push excess wire back into the hole. Plug the hole with

nonhardening caulk, putty or insulation to prevent drafts

from affecting the C7189A and PC8900A performance.

3. Remove the C7189A Cover.

4. Mount the C7189A on the wall or junction box using the

screws and anchors provided.

5. Level the C7189A for appearance only. The device

functions properly even when not level.

6. Install the C7189A Cover.

21 68-0173—3

Page 22

W8900

W8900

S1

S

GND

C

R

RH

RC

L1

(HOT)

L2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

IF MORE THAN ONE C7189 REMOTE SENSOR IS REQUIRED, REFER TO DIAGRAM BELOW.

2

IF SHIELDED CABLE IS REQUIRED, GROUND TO GND TERMINAL ON W8900.

3

LED

W8900

3

2

C7189

S1

S

C7189 C7189

C7189 C7189

4

SENSORS MUST BE ARRANGED IN THIS NUMBER AND CONFIGURATION FOR PROPER OPERATION.

4

Fig. 26. Wiring diagram for C7189A Remote Sensor to W8900A-C Remote Module.

Mounting the C7089A Outdoor Sensor (if needed)

Location Guidelines

• Locate the C7089A Outdoor Sensor where it will be safe

from tampering.

S1

S

C7189 C7189

C7189 C7189

C7189 C7189 C7189

4

C7189

C7189

M4456A

• Choose an outdoor location for the sensor where there is

good air circulation at average outdoor temperature. See

Fig. 27. Locate the sensor where it can measure the true

outdoor ambient temperature:

— On a flat surface is best.

— Avoid locations that can introduce errors in sensor

measurements such as areas of direct sunlight or high

temperature, or areas where hot or cold air is blowing

out of a fan or vent such as next to the compressor

discharge line in the outdoor unit.

68-0173—3 22

Page 23

— Mount it high enough to prevent tampering or coverage

by snow, ice or debris.

• The wire distance between the C7089A and W8900A-C

should not exceed 200 ft.

Mounting

1. Remove the sensor from the mounting clip.

2. Mark the area on the surface where the C7089A mount-

ing clip will be mounted.

3. Mount the clip.

GND

C7089

1

W8900

OUT

OUT

LED

WIRING HOLE

THROUGH

2

STRUCTURE

3

Fig. 27. Typical locations for C7089A

Outdoor Sensor.

Wiring the C7089A Outdoor Sensor (if needed)

CAUTION

Failure to use the following wiring practices can

introduce electrical interference (noise), which can

cause erratic system operation.

Keep wiring at least one foot away from large inductive

loads such as motors, line starters, lightning ballasts,

and large power distribution panels. Use shielded

cable to reduce interference when rerouting wires is

not possible. Ground the shielded cable to the ground

terminal on the W8900A-C.

M7514

1

USE APPROPRIATE MOUNTING MEANS FOR THE TYPE

OF STRUCTURE.

2

PLUG WIRING HOLE WITH NONHARDENING CAULK OR PUTTY.

IF SHIELDED CABLE IS REQUIRED, GROUND TO GND TERMINAL

3

ON W8900.

Fig. 28. Wiring diagram for C7089A Outdoor Sensor

to W8900A-C Remote Module.

IMPORTANT

Erratic temperature readings from a sensor can

occur as a result of any of the wiring practices

described below. Use shielded cable to reduce interference if rerouting of sensor wiring is not possible.

These practices must be avoided to assure proper

operation:

— Do not route temperature sensor wiring with building

power wiring, next to control contactors or near light

dimming circuits, electric motors or welding

equipment.

— Avoid poor wiring connections.

— Avoid intermittent or missing building earth ground.

M4457

23 68-0173—3

Page 24

CAUTION

Disconnect power supply before connecting the

wiring to prevent electrical shock or equipment

damage.

Wiring must comply with applicable codes, ordinances and

regulations.

1. Wire the C7089A Outdoor Sensor to the terminals

marked OUT on the W8900A-C Remote Module. If the

leadwire provided with the C7089A is not long enough,

run cable to a hole at the selected C7089A location.

Color-coded, 18-gauge thermostat wire is recommended. Refer to Fig. 28 for an example of general wiring for the C7089A. Pigtail wiring can be used.

2. Mount the C7089A in its mounting clip.

3. Plug wiring hole using nonhardening caulk or putty.

Mounting the C7100A Discharge Air Sensor (if needed)

Location Guidelines

• Locate the C7100A Discharge Air Sensor in the air duct or

plenum where it can sample an average air temperature.

• Avoid locations where air stratification can cause sensor

errors.

• The distance between the C7100A and W8900A-C should

not exceed 200 ft.

Mounting

Wiring the C7100A Discharge Air Sensor (if needed)

CAUTION

Failure to use the following wiring practices can

introduce electrical interference (noise), which can

cause erratic system operation.

Keep wiring at least one foot away from large inductive

loads such as motors, line starters, lightning ballasts,

and large power distribution panels. Use shielded

cable to reduce interference when rerouting wires is

not possible. Ground the shielded cable to the ground

terminal on the W8900A-C.

IMPORTANT

Erratic temperature readings from a sensor can

occur as a result of any of the wiring practices

described below. Use shielded cable to reduce interference if rerouting sensor wiring is not possible.

These practices must be avoided to assure proper

operation:

— Do not route temperature sensor wiring with building

power wiring, next to control contactors or near light

dimming circuits, electric motors or welding equip-

ment.

— Avoid poor wiring connections.

— Avoid intermittent or missing building earth ground.

— If the discharge air temperature fails to display when

the check key is pressed, see the Troubleshooting

Section.

TO MOUNT ON A FLAT DUCT OR PLENUM SURFACE:

1. Cut a 7/8 in. (22 mm) hole in the duct or plenum surface

at the desired location.

2. Insert the sensor probe into the duct or plenum with inlet

holes facing the air stream.

3. If necessary, use the flange provided as a template to

mark and drill four holes for 8-32 mounting screws.

4. Fasten the sensor to the duct or plenum surface with

the four 8-32 sheetmetal screws provided.

TO MOUNT IN A 2 X 4 IN. JUNCTION BOX:

1. Cut a 7/8 in. (22 mm) hole in the duct or plenum surface

at the desired location.

2. Remove the center rear knockout from the 2 x 4 in. junction box and insert the sensing probe through the

knockout with the flange flat against the junction box.

3. Using the flange (provided) as a template, mark and drill

four holes in the junction box and the duct or plenum

surface for 8-32 mounting screws.

4. Insert sensor probe through both the junction box

knockout and the 7/8 in. (22 mm) hole drilled in the duct

or plenum and fasten the junction box and sensor to the

duct or plenum surface.

CAUTION

Disconnect power supply before connecting the

wiring to prevent electrical shock or equipment

damage.

Wiring must comply with applicable codes, ordinances and

regulations.

Wire the C7100A Discharge Air Sensor to the terminals

marked T and T1 on the W8900A-C Remote Module. Use 1/4

in. female quick connects on the C7100A.

INSTALLER SETUP

IMPORTANT

Installer setup must be done for the HVAC equipment and the PC8900A/W8900A-C to operate

properly.

The installer setup mode is used by the installer to configure

the PC8900A/W8900A-C for the HVAC equipment used at the

installation (heating, cooling, ventilation, humidification, air

cleaning) and to configure the PC8900A operation

(changeover mode, remote sensors, and outdoor sensors).

68-0173—3 24

Page 25

TO ENTER THE INSTALLER SETUP MODE:

638

1. Hold the PC8900A CHECK key until all display segments are displayed (approximately three seconds).

See Fig. 29.

2. Press the up and down arrowhead keys at the same

time. The display goes blank, except for up to four segments (SYSTEM, HEAT, COOL, FAN) as shown in

Fig. 30. One of these segments flashes. The flashing

segment indicates the current menu selection.

TO CHANGE TO ANOTHER SELECTION:

1. Press the up or down arrowhead key until the desired

segment is flashing.

2. Once the desired segment is flashing, press the

CHECK key for options within that segment. The

options are SYSTEM, HEAT, COOL and FAN.

3. Press RUN to exit the installer setup.

Table 4. System Setting Options

Factory-Setting Description

System switch is configured for

manual changeover HEAT-OFFCOOL or EM HT-HEAT-OFF-COOL.

M6361

Five-minute compressor protection is

on; calls for cooling (heat pump) are

followed by a five-minute enforced

M6362

shutdown.

System does not have a C7189A

Remote Indoor Sensor.

M6363

System does not have a C7100A

Discharge Air Sensor.

M6364

System uses PC8900A temperature

only. If the system is configured for a

remote sensor (SENS REM Y),

M6365

temperature control is averaged

between C7189A Remote Indoor

Sensor and PC8900A Control Panel.

System does not have a C7089A

Outdoor Sensor.

M6366

System has an Energy Recovery

Ventilator (for example, Honeywell

ER90). Calls for ventilation, close

M6367

Communications should always be

configured to N. If CM8900A

Communication Module is present, it

M6368

changes to Yes automatically.

W8900B model only. O/B terminal

energized in heating only. Use this

setting for heat pumps with heating

M6369

changeover.

System has a humidifier that is used

in the heating mode.

M6370

a

System Options

When SYSTEM is flashing, the following list of options

pertaining to the equipment and sensors connected to the

system appears on the PC8900A display. To make each

selection, press the CHECK key. See Table 4 for setting

options.

SYSTEM OFF AUTO

SUN MON TUE WED THU FRI SAT WAKELEAVERETURNSLEEP TEMPORARY VENT

Fig. 29. All segments on display.

Other Choices (Press

Up or Down Arrowhead

Keys to Change) Description

M6375

M6376

M6377

M6378

M6379

M6380

M6381

M6382

M6383

M

4

M6385

AUX HEAT SET PT COOL SET PT

AM

PM

FAN

AUTO

ON

CIRC

M6360

System switch is configured for automatic

changeover HEAT-OFF-COOL-AUTO or

EM HT-HEAT-OFF-COOL-AUTO.

No compressor protection exists. Calls for

cooling (heat pump) can occur

immediately.

System does have a C7189A Remote

Indoor Sensor.

System does have a C7100A Discharge

Air Sensor.

System uses C7189A Remote Indoor

Sensor only. Be sure the system is

configured for remote sensor

(SENS REM Y).

System does have a C7089A Outdoor

Sensor.

System has an outside air damper. Calls

for ventilation close VNT contacts and

activate system fan.

System has no ventilation equipment. A

call for ventilation activates the system fan.

Communication module is activated.

W8900A-C automatically changes to this

setting when communication is received.

W8900B model only. O/B terminal

energized in cooling only. Use this setting

for heat pumps with cooling changeover.

System has no humidifier.

25 68-0173—3

Page 26

Table 4. System Setting Options

Other Choices (Press

Up or Down Arrowhead

Factory-Setting Description

System set to control humidity in

cooling.

M6371

(W8900C only).

PC8900A displays temperature

settings and readings in °F.

M6372

PC8900A displays setpoint times and

clock times (12-hour clock) with AM

and PM.

M6373

System is set for Adaptive Intelligent

Recovery™. When recovering from

setback modes, programmed times

M6374

indicate when recovery ends. (See

Operation section for description).

a

The humidity option can only be set for heat or cool. If both are set to Y, it will not honor either one.

a

Can also have reheat

Keys to Change) Description

System does not control high humidity in

cooling.

M6386

PC8900A displays temperature settings

and readings in °C.

M6387

PC8900A displays setpoint times and clock

times (24-hour clock) with military time.

M6388

System is set for conventional recovery.

When recovering from setback modes,

programmed times indicate when recovery

M6389

begins.(See Operation section for

description.)

Heat Options

When HEAT is flashing, refer to Table 5 for the options

pertaining to the heat equipment that appear in the PC8900A

display after each press of the CHECK key. HEAT and its list

of options appear only when the system allows field selection

of cycle rates, and only stages present in the remote module

hardware are shown.

SYSTEM

CHECK

SYSTEM

HEAT COOL

1

FAN

1

ONE OF THESE SEGMENTS WILL BE FLASHING.

M6401

Fig. 30. Initial display for installer setup.

Table 5. Heating Cycle Rates.

Display Shows

a

b

AUX HT CPH 6bEM. HT. CPH 6

AUX HT EM. HT.

System

Gas or Oil Forced Air 6

Cycles per

Hour Setting

Stage 1 Stage 2

W1 CPH 6

b

W2 CPH 6

Electric Heat 9 W1 CPH 9 W2 CPH 9 AUX HT CPH 9 EM. HT. CPH 9

Single Stage Heat Pump,

3 W1 CPH 3 W2 CPH 3 AUX HT CPH 3 EM. HT. CPH 3

Hydronic Heat, Condensing

Gas Furnaces

Radiant Floor Heat, Gravity 1 W1 CPH 1 W2 CPH 1 AUX HT CPH 1 EM. HT. CPH 1

Cooling-only Application; no

Not connected W1 CPH NC W2 CPH NC AUX HT CPH NC EM. HT. CPH NC

heat sources connected

N/A

c

4.5 W1 CPH 4.5 W2 CPH 4.5 AUX HT CPH 4.5 EM. HT. CPH 4.5

2.5 W1 CPH 2.5 W2 CPH 2.5 AUX HT CPH 2.5 EM. HT. CPH 2.5

2 W1 CPH 2 W2 CPH 2 AUX HT CPH 2 EM. HT. CPH 2

1.5 W1 CPH 1.5 W2 CPH 1.5 AUX HT CPH 1.5 EM. HT. CPH 1.5

a

When W2 is not used, configure W2 cycle rate to NC (not connected).

b

Factory setting.

c

Use these cycle rate settings if faster or slower cycling is required.

b

68-0173—3 26

Page 27

Press the up or down arrowhead key until the word HEAT is

flashing on the PC8900A display.

The PC8900A/W8900A-C is designed to be used on most

types of heating systems. Initially, the PC8900A/W8900A-C

are factory-set to be used on the following systems:

PC8900A/W8900A,C models: Stage 1 and 2 heat:

Conventional noncondensing gas or oil fired furnace (six

cycles per hour at 50 percent load).

PC8900A/W8900B models: Stage 1, 2 and 3 heat: Heat

pump (three cycles per hour at 50 percent load).

The cycle requirements for each stage of heat can be

changed to match the type of heating system used. See Table

5 for the cycle rate options available and the equipment that

corresponds with each cycle rate.

Cool Options

When COOL is flashing, see Table 6 for options for the cooling

equipment stages that appear in the display in the following

order after each press of the CHECK key.

Table 6. Cooling Cycle Rates.

Cycles per

Display Shows

Hour

System

Recommended

setting

a

N/A

a

N/A

Natural gas air

Setting

3 Y1 CPH 3

9 Y1 CPH 9 Y2 CPH 9

6 Y1 CPH 6 Y2 CPH 6

1 Y1 CPH 1 Y2 CPH 1

Stage 1 Stage 2

Y2 CPH 3

(factory

setting)

(factory

setting)

conditioning

Heating-only

application

a

N/A

a

N/A

a

N/A

a

N/A

a

Use these cycle rate settings if faster or slower cycling is

Not

Y1 CPH NC Y2 CPH NC

connected

4.5 Y1 CPH 4.5 Y2 CPH 4.5

2.5 Y1 CPH 2.5 Y2 CPH 2.5

2 Y1 CPH 2 Y2 CPH 2

1.5 Y1 CPH 1.5 Y2 CPH 1.5

required.

Fan Options

When FAN is flashing, refer to Table 7 for the options

pertaining to the fan equipment that appear in the display in

the following order after each press of the CHECK key.

Table 7. Fan Setting Options.

Display Description

When PC8900A calls for heat,

a

PC8900A also calls for fan

M6390

(Electric Heat).

No fan overrun in cooling. 80-second fan overrun after PC8900A

M6392 M6393

a

Option not used on the W8900B model.

PROGRAMMING PC8900A

The Comfort Center™ control panel must have 24 Vac to

program.

The current day and time need to be set. This activates the

preprogram in the Comfort Center™ panel. See Table 8 for

the preprogram settings.

Table 8. PC8900A Preprogram.

Period Start Time

Te mp

Saturday

WAKE (6:00 AM) (70°F) (78°F) (AUTO) (OFF)

LEAVE (8:00 AM) (62°F) (85°F) (AUTO) (OFF)

RETURN (6:00 PM) (70°F) (78°F) (AUTO) (OFF)

SLEEP (10:00 PM) (62°F) (82°F) (AUTO) (OFF)

Heating

Cooling

Te mp

Fan

Setting

Vent

Setting

Other Choices (Press

Up or Down Arrowhead

Keys to Change) Description

When PC8900A calls for heat, fan is

energized by equipment

M6391

(Conventional).

ends call for cooling.

Setting the Current Day and Time

NOTES:

— Always press the keys with a fingertip or similar

blunt tool. Sharp instruments like a pen or pencil

point can damage the keyboard.

— Check the Glossary section for definitions of

unfamiliar words.

1. Press SET CLOCK. The display shows a time and day.

2. Press and hold DAY until the current day appears in the

display.

3. Press and hold a TIME key until the current time

appears in the display. Be sure AM or PM appear as

desired.

4. Press RUN to exit the SET CLOCK program mode.

27 68-0173—3

Page 28

The current day and time are now programmed. The

preprogrammed schedule is activated. The preprogrammed

settings can be customized or cleared. When using the

preprogrammed settings as is, programming is done. To

customize or create a new program, follow the steps in the

Setting a Customized Program section. Operating the Comfort

Center™ section shows how to make any temporary changes.

Setting a Customized Program

Planning your Program

Plan a schedule before programming. Leave any period blank

when no setting is required. When an outdoor sensor is part of

the system, enter a frost setting. The humidity and frost

settings are the same for the entire program.

Programming the First Day

When changing the existing program, go to step 7a. When

clearing the program and starting over, proceed as follows.

NOTE: Press the RUN key at any time to exit the program-

ming mode.

1. Clearing Current Program

a. Press SELECT PERIOD.

SYSTEM

SELECT

PERIOD

CHECK

SET

CLOCK

SELECT

PERIOD

CANCEL

HEAT/COOL

FAN

SYSTEM

SETPOINTS

HEAT OFF COOL

AUTO ON CIRC

DAY

HOLDHUMIDITY

VENTILATE

TIME

TIME

RUN

MON

b. Hold CANCEL until display shows PROG CLR.

SYSTEM

CHECK

CANCEL

SET

CLOCK

SELECT

PERIOD

CANCEL

HEAT/COOL

FAN

SYSTEM

SETPOINTS

HEAT OFF COOL

AUTO ON CIRC

DAY

HOLDHUMIDITY

VENTILATE

TIME

TIME

RUN

2. Setting Day, Time, and Setpoints

a. Press SELECT PERIOD until display shows WAKE.

SYSTEM

SELECT

PERIOD

b. Press DAY until display shows MON.

DAY

c. When display reads COOL SET PT, press HEAT/

COOL SETPOINTS to switch to HEAT SET PT.

HEAT/COOL

SETPOINTS

d. Press and hold a TIME key until the display shows

the desired starting time. The time changes in tenminute increments.

TIME

TIME

CHECK

SET

CLOCK

SELECT

PERIOD

CANCEL

SYSTEM

CHECK

SET

CLOCK

SELECT

PERIOD

CANCEL

SYSTEM

CHECK

HEAT/COOL

FAN

SYSTEM

SETPOINTS

HEAT OFF COOL

AUTO ON CIRC

DAY

HOLDHUMIDITY

VENTILATE

TIME

TIME

RUN

HEAT/COOL

FAN

SYSTEM

SETPOINTS

HEAT OFF COOL

AUTO ON CIRC

DAY

HOLDHUMIDITY

VENTILATE

TIME

TIME

RUN

MON

MON

HEAT SET PT COOL

SET

CLOCK

SELECT

PERIOD

CANCEL

HEAT/COOL

FAN

SYSTEM

SETPOINTS

HEAT OFF COOL

AUTO ON CIRC

DAY

HOLDHUMIDITY

VENTILATE

TIME

TIME

RUN

SYSTEM

CHECK

SET

CLOCK

SELECT

PERIOD

CANCEL

HEAT/COOL

FAN

SYSTEM

SETPOINTS

HEAT OFF COOL

AUTO ON CIRC

DAY

HOLDHUMIDITY

VENTILATE

TIME

TIME

RUN

MON

HEAT SET PT COOL

WAKE

M6206

M6205

HEAT SET PT COOL

WAKE

M6206

HEAT SET PT COOL

WAKE

M6207

M6209

AM

M6215

e. Press and hold the up or down arrowhead key until

the display shows the desired temperature.

SYSTEM

CHECK

SET

FAN

SYSTEM

CLOCK

HEAT OFF COOL

AUTO ON CIRC

DAY

SELECT

VENTILATE

PERIOD

TIME

TIME

CANCEL

HEAT/COOL

SETPOINTS

HOLDHUMIDITY

RUN

HEAT SET PT COOL

f. Press HEAT/COOL SETPOINTS to switch to COOL

SET PT.

HEAT/COOL

SETPOINTS

SYSTEM

CHECK

SET

CLOCK

SELECT

PERIOD

CANCEL

HEAT/COOL

FAN

SYSTEM

SETPOINTS

HEAT OFF COOL

AUTO ON CIRC

DAY

HOLDHUMIDITY

VENTILATE

TIME

TIME

RUN

HEAT COOL SET PT

WAKE

NOTE: The time is used for both heating and cooling.

When you change the time while setting the

cooling temperatures, the time is also changed

for heating.

g. Press and hold the up or down arrowhead key until

the display shows the desired temperature.

SYSTEM

CHECK

SET

FAN

SYSTEM

CLOCK

HEAT OFF COOL

AUTO ON CIRC

DAY

SELECT

VENTILATE

PERIOD

TIME

TIME

CANCEL

HEAT COOL SET PT

HEAT/COOL

SETPOINTS

HOLDHUMIDITY

RUN

NOTE:

— When the numbers do not move while you are

holding the up or down arrowhead key, the setting

limit (45°F and 88°F) is reached.

— When set for auto changeover, there must be 3°F

between the heating and cooling setpoints. When

setting the cooling setpoint with the heating setpoint

at 68°, the cooling setpoint can be no lower than 71°.

And when cooling is set for 70°, the heat setpoint

changes to 67°. The PC8900A automatically pushes

the alternate setpoint so you can adjust the setpoint

to its desired setting.

— When set for manual changeover, the 3° differential

between the heating and cooling setpoint does not

apply.

3. Setting Fan

IMPORTANT

The FAN and VENTILATOR settings are the same

for heating and cooling. The FAN setting for heating

cannot be set for AUTO and the cooling set for CIRC.

a. Press FAN until FAN AUTO, FAN ON or FAN CIRC

is displayed, as desired.

SYSTEM

FAN

AUTO ON CIRC

CHECK

SET

CLOCK

SELECT

PERIOD

CANCEL

HEAT/COOL

FAN

SYSTEM

SETPOINTS

HEAT OFF COOL

AUTO ON CIRC

DAY

VENTILATE

TIME

TIME

NOTES:

— AUTO means the fan only runs when heating or

cooling is running.

— ON means the fan runs during this entire period.

— CIRC means the fan runs at least 30 percent of the

time during this period, including when the heating or

cooling system is running.

HOLDHUMIDITY

RUN

HEAT COOL SET PT

WAKE

M6210

M6232

FAN

AUTO

FAN

AUTO

FAN

AUTO

FAN

AUTO

M6231

M6213

68-0173—3 28

Page 29

4. Setting Ventilator

a. Press VENTILATE to display VENT when increased

ventilation is desired during the WAKE period.

FAN

AUTO ON CIRC

SYSTEM

CHECK

SET

CLOCK

SELECT

PERIOD

CANCEL

HEAT/COOL

FAN

SYSTEM

SETPOINTS

HEAT OFF COOL

AUTO ON CIRC

DAY

HOLDHUMIDITY

VENTILATE

TIME

TIME

RUN

HEAT COOL SET PT

WAKE

FAN

AUTO

M6213

b. When normal ventilation is desired, press VENTI-

LATE until VENT is not displayed.

VENTILATE

SYSTEM

CHECK

SET

CLOCK

SELECT

PERIOD

CANCEL

HEAT/COOL

FAN

SYSTEM

SETPOINTS

HEAT OFF COOL

AUTO ON CIRC

DAY

HOLDHUMIDITY

VENTILATE

TIME

TIME

RUN

HEAT COOL SET PT

WAKE

FAN

AUTO

M6212

5. Programming LEAVE, RETURN and

SLEEP

a. Repeat steps 2a through 4b for each period to be

programmed on Monday.

The Comfort Center™ Monday program is now complete.

Programming The Remaining Days

6. Copying the First Day Program

a. Hold down the DAY key until all the days of the

week have appeared on the screen.

SYSTEM

CHECK

DAY

SET

CLOCK

SELECT

PERIOD

CANCEL

HEAT/COOL

FAN

SYSTEM

SETPOINTS

HEAT OFF COOL

AUTO ON CIRC

DAY

HOLDHUMIDITY

VENTILATE

TIME

TIME

SUN SLEEP

RUN

PM

M6233

b. Press RUN key to save and start the program.

SYSTEM

RUN

CHECK

SET

CLOCK

SELECT

PERIOD

CANCEL

HEAT/COOL

FAN

SYSTEM

SETPOINTS

HEAT OFF COOL

AUTO ON CIRC

DAY

HOLDHUMIDITY

VENTILATE

TIME

TIME

RUN

MON

AM

M6230

NOTE: The Monday program is now copied to all seven

days of the week. If copy fails, start over (see Programming the First Day section).

7. Changing the Program

a. Press SELECT PERIOD to enter the programming

mode.

SYSTEM

SELECT

PERIOD

CHECK

SET

CLOCK

SELECT

PERIOD

CANCEL

HEAT/COOL

FAN

SYSTEM

SETPOINTS

HEAT OFF COOL

AUTO ON CIRC

DAY

HOLDHUMIDITY

VENTILATE

TIME

TIME

MON

RUN

b. Press DAY until the desired day is displayed.

SYSTEM

CHECK

DAY

SET

CLOCK

SELECT

PERIOD

CANCEL

HEAT/COOL

FAN

SYSTEM

SETPOINTS

HEAT OFF COOL

AUTO ON CIRC

DAY

HOLDHUMIDITY

VENTILATE

TIME

TIME

RUN

HEAT SET PT COOL

AM

WAKE

HEAT SET PT COOL

AM

WAKE

SAT

M6234

M6235

c. Press and hold SELECT PERIOD until the desired

period is displayed.

SELECT

PERIOD

SYSTEM

CHECK

SET

CLOCK

SELECT

PERIOD

CANCEL

HEAT/COOL

FAN

SYSTEM

SETPOINTS

HEAT OFF COOL

AUTO ON CIRC

DAY

HOLDHUMIDITY

VENTILATE

TIME

TIME

RUN

HEAT SET PT COOL

AM

SAT

d. Press HEAT/COOL SETPOINTS to switch between

HEAT SET PT and COOL SET PT.

HEAT/COOL

SETPOINTS

SYSTEM

CHECK

SET

CLOCK

SELECT

PERIOD

CANCEL

HEAT/COOL

FAN

SYSTEM

SETPOINTS

HEAT OFF COOL

AUTO ON CIRC

DAY

HOLDHUMIDITY

VENTILATE

TIME

TIME

RUN

HEAT SET PT COOL

LEAVE

e. Press and hold a TIME key until the desired start

time is displayed.

TIME

TIME

CHECK

SET

CLOCK

SELECT

PERIOD

CANCEL

HEAT/COOL

FAN

SYSTEM

SETPOINTS

HEAT OFF COOL

AUTO ON CIRC

DAY

HOLDHUMIDITY

VENTILATE

TIME

TIME

RUN

AM

SYSTEM

f. Press and hold up or down arrowhead key until the

desired temperature is displayed.

SYSTEM

CHECK

SET

FAN

SYSTEM

CLOCK

HEAT OFF COOL

AUTO ON CIRC

DAY

SELECT

VENTILATE

PERIOD

TIME

TIME

CANCEL

HEAT/COOL

SETPOINTS

HOLDHUMIDITY

RUN

HEAT SET PT COOL

g. Follow steps 3a and 4a when changes to the fan

and ventilator settings are desired.

IMPORTANT

When in a program, pressing the CANCEL key until

PROGRAM CLR appears (approximately three seconds) cancels your entire program and you need to

start again with step 3.

8. Canceling One Program Period

a. Press CANCEL while you are in the period to be

cancelled. The programmed time, temperature, vent