Honeywell NFXI-ASD11, NFXI-ASD12, NFXI-ASD22 Wiring Diagram

E N G L I S H

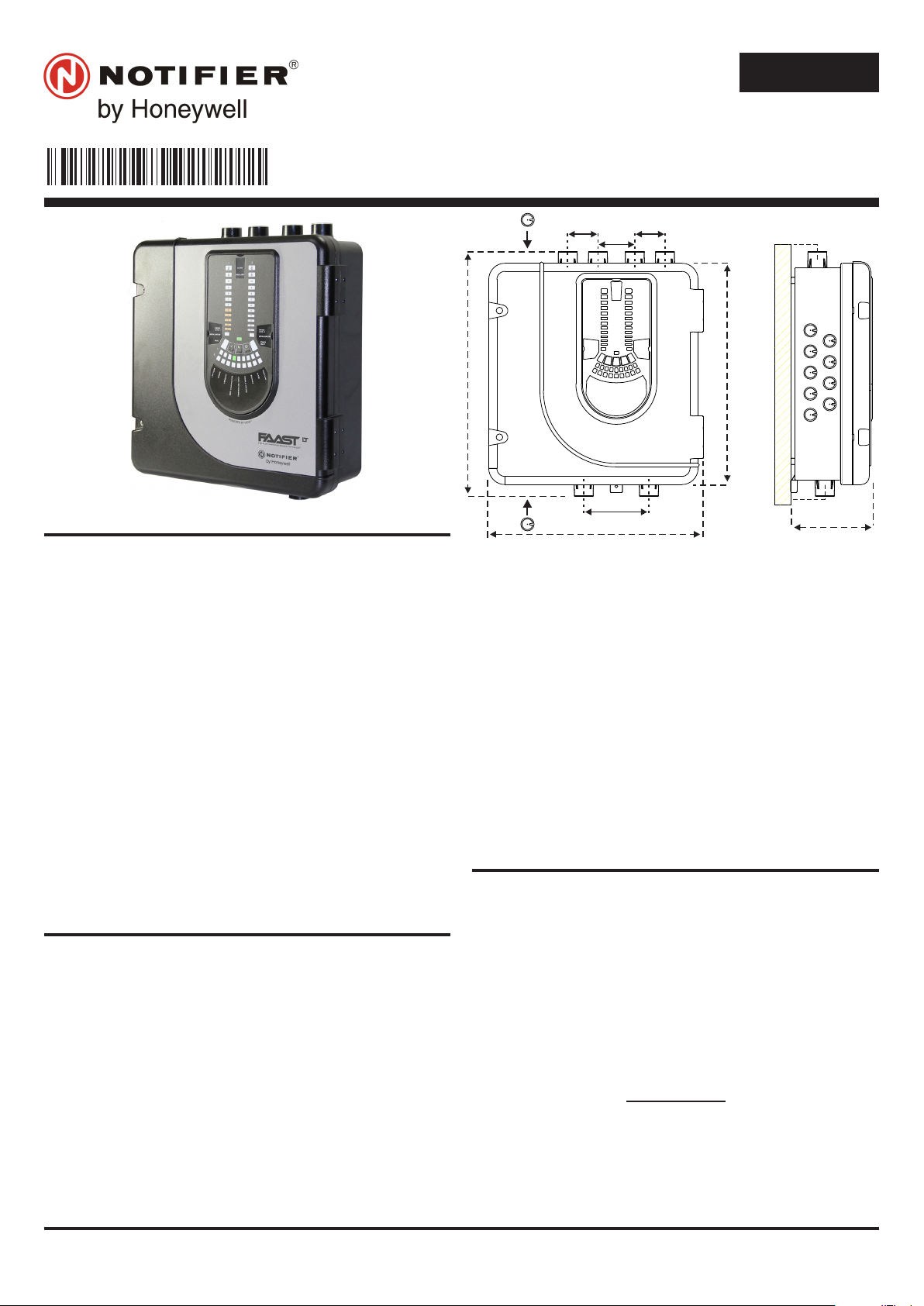

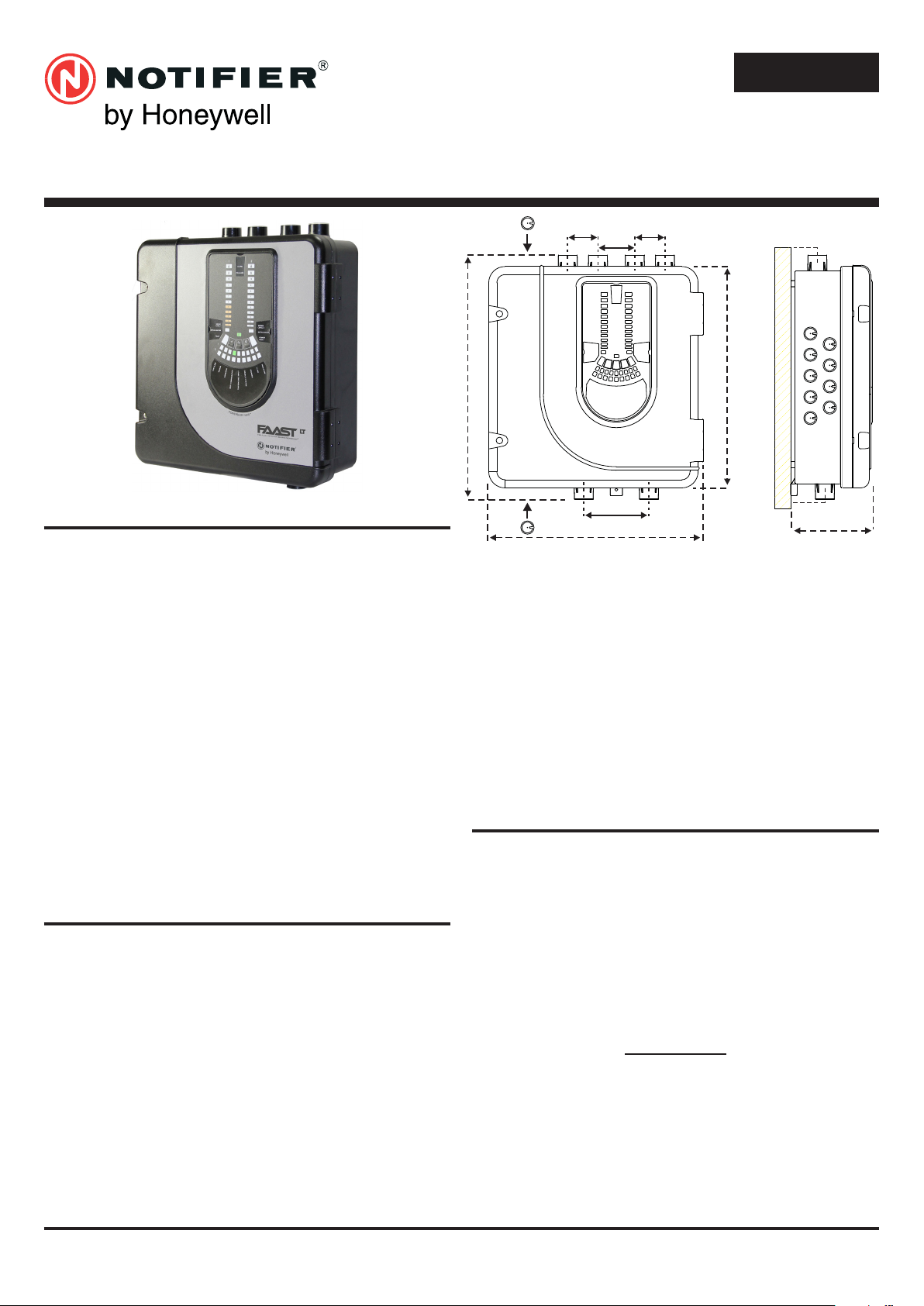

367 mm

135 mm

56 mm

44 mm

403 mm

356 mm

50 mm 50 mm

60 mm

110 mm

®

I 56- 3947- 2 02

FIRE ALARM ASPIRATION SENSING TECHNOLOGY

QUICK INSTALLATION GUIDE ADDRESSABLE FAAST LT

MODELS NFXI-ASD11, NFXI-ASD12, NFXI-ASD22

DESCRIPTION

The LT NFXI-ASD Series is part of the Fire Alarm Aspiration

Sensing Technology® (FAAST) family. FAAST is an advanced

re detection system for use where early warning and very early

warning are a requirement. The system continuously draws air

from the controlled environment through a series of sampling holes

to monitor the environment for smoke particulate.

The NFXI-ASD is the addressable version of the FAAST LT range,

communicating with the CIE (Fire Panel) via a proprietary loop

protocol. It is available in 3 different models:

NFXI-ASD11 - Has single channel capability with one laser smoke

sensor.

NFXI-ASD12 - Has single channel capability with two laser smoke

sensors in a common chamber for coincidence

detection.

NFXI-ASD22 - Has two channel capability with two laser smoke

sensors in separate chambers. (one sensor for

each channel).

This guide provides information for mounting and basic installation

using the unit’s default factory settings. For more advanced information

please see the FAAST LT Advanced Setup and Control Guide.

SPECIFICATIONS

Electrical Characteristics

Voltage Range: 18.5 - 31.5 VDC

Supply Current: 1 Channel: 170mA (typical); 360mA (max) @

2 Channel: 270mA (typical); 570mA (max) @

Communication Loop Supply Voltage: 15 – 29 VDC (Loop current ≤

Communication Loop Standby Current: @ 24V: 900 µA max. (poll once

Module Isolator Characteristics

Maximum rated switching current

(under short circuit, Is max): 0.9A @ ≤ 29V

Maximum leakage current (IL max)

with the switch open (isolated state): 15mA

Maximum series impedance with

the switch closed (Zc max): 190 m ohm at 15Vdc; 1A

24 VDC 25oC (excluding sounders)

24 VDC 25oC (excluding sounders)

900mA)

every 5s)

Power Reset: 0.5s

Congurable Input: Activation Time: 2s (min)

Relay Contact Ratings: 2.0 A @ 30 VDC, 0.5A @ 30 VAC

Environmental Ratings

Temperature: -10°C to 55°C

Relative Humidity: 10% to 93% (non-condensing)

IP Rating: 65

Mechanical

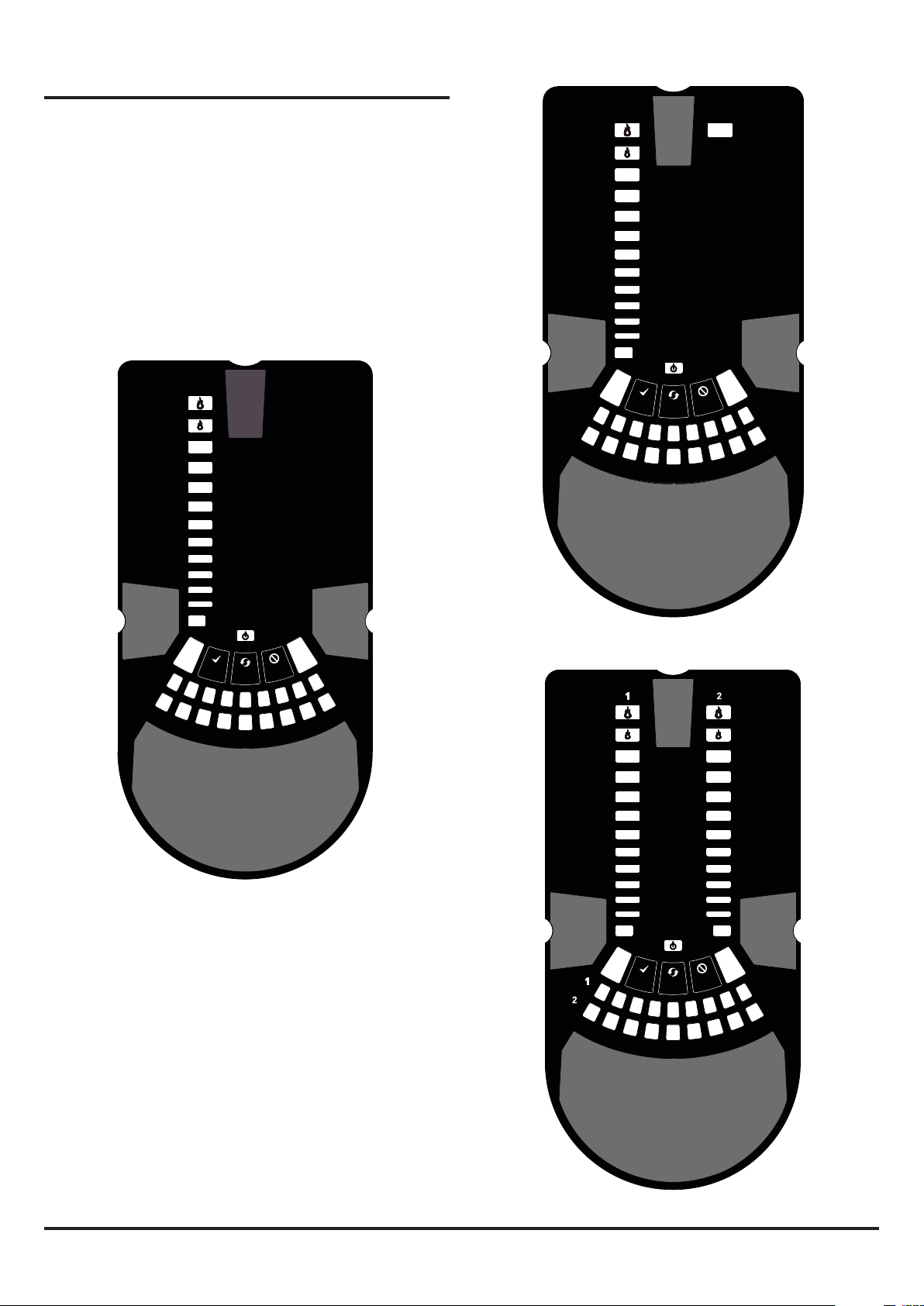

Exterior Dimensions: See Figure 1

Wiring: 0.5 mm² to 2 mm² max

Maximum Single Pipe Length: 100m (Classes B & C) 80m (A)

Maximum Branched Pipe Length: 160m (2 x 80m, Class C)

Maximum Number of Holes See Table 1A

Pipe Spec (EN54-20 Compliance): to EN 61386

(Crush 1, Impact 1, Temp 31)

Outside Pipe Diameter: 25mm (nom) or 27mm (nom)

Shipping Weight: 6.5kg (inc sensors)

PARTS LIST

Description Quantity

FAAST LT unit 1

Mounting bracket 1

3-pin Terminal block 6

4-pin Terminal block 1

2-pin Terminal block 3

47 k-ohm EOL Resistor 2

USB Cable 1

Front Panel Labelling Pack 1

Wiring Diagram Label 1

Installation Kit CD 1

Quick Installation Guide 1

Aspirating Smoke Detectors supplied and installed within the

EU must conform to the EU Construction Products Regulation

(CPR) 305/2011 and the related European Product Standard EN

54-20. FAAST LT has been tested and certied to ensure that it

conforms to the necessary Standards, but strict adherence to this

instruction guide is advised to ensure that the installation meets

the requirements of the CPR.

N200-102-00 1 I56-3947-202

Figure 1: Dimensions and Knock-Outs

Important Note

Warning

1 2 3 4 5 6 7 8 9101112131415161718

90 mm

The performance of this system is dependent upon the pipe

network. Any extension or modication to the designed

installation may cause improper operation. The operational

effects of such changes need to be veried using the PipeIQ

2 design software.

This equipment and all associated pipe work must be installed in

accordance with all relevant codes and regulations.

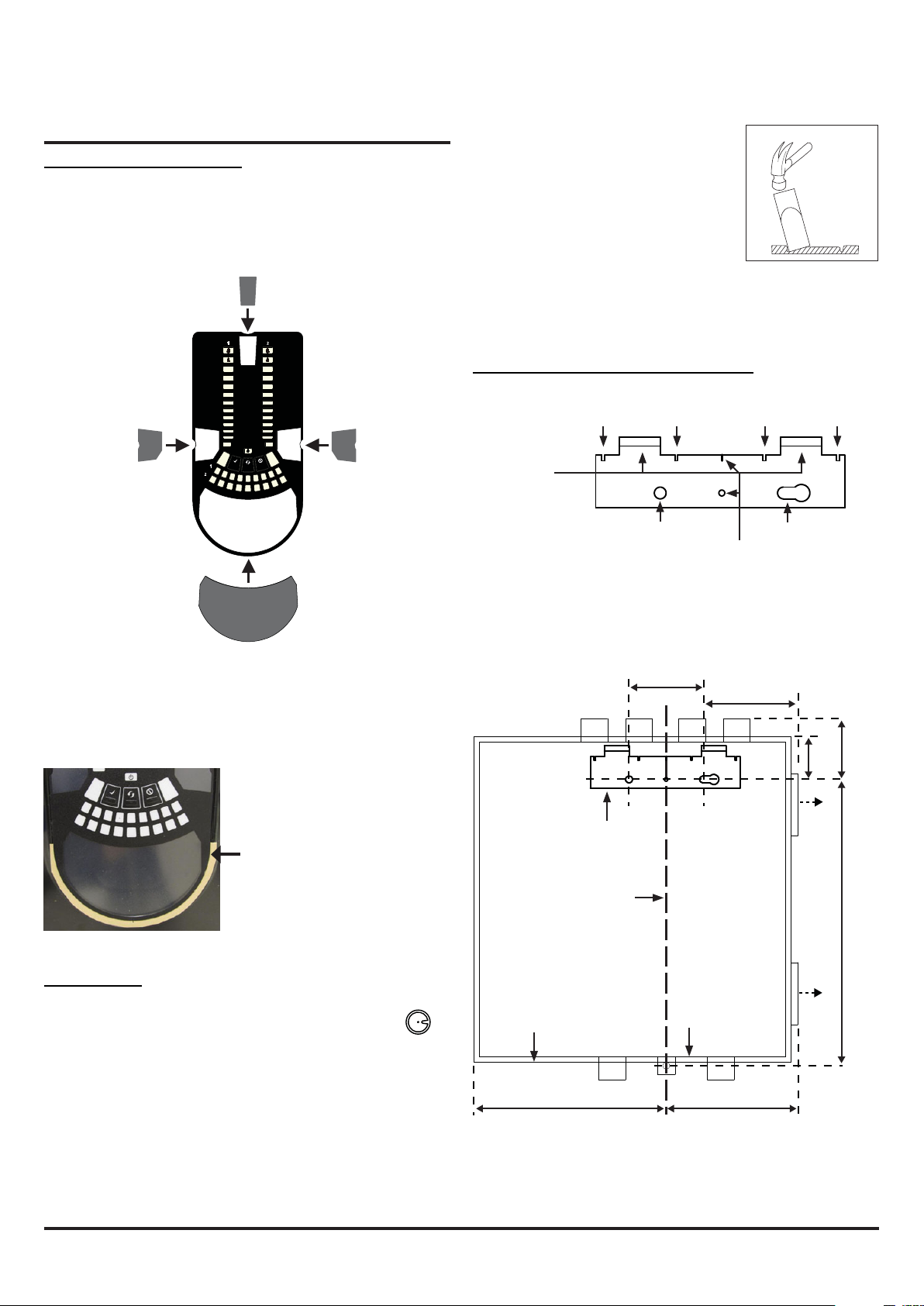

PHYSICAL INSTALLATION

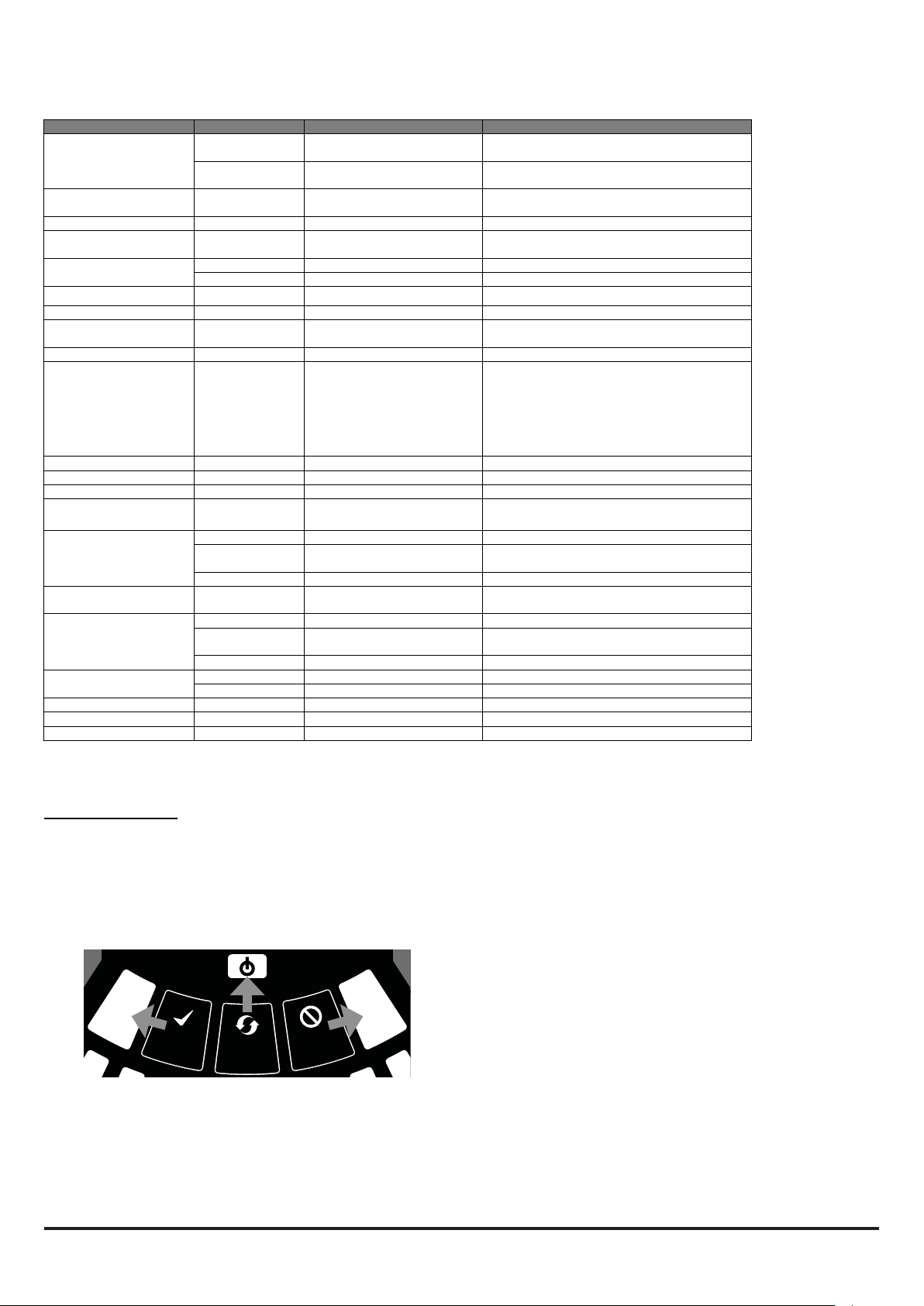

Front Panel Labels

The LT NFXI-ASD is shipped without the front panel labels

xed in place. This allows the installer to choose the language

required for the installation from the Front Panel Labelling Pack.

Figure 2 shows where the labels need to be placed:

Figure 4: How to Knock Out Cable

Gland Holes

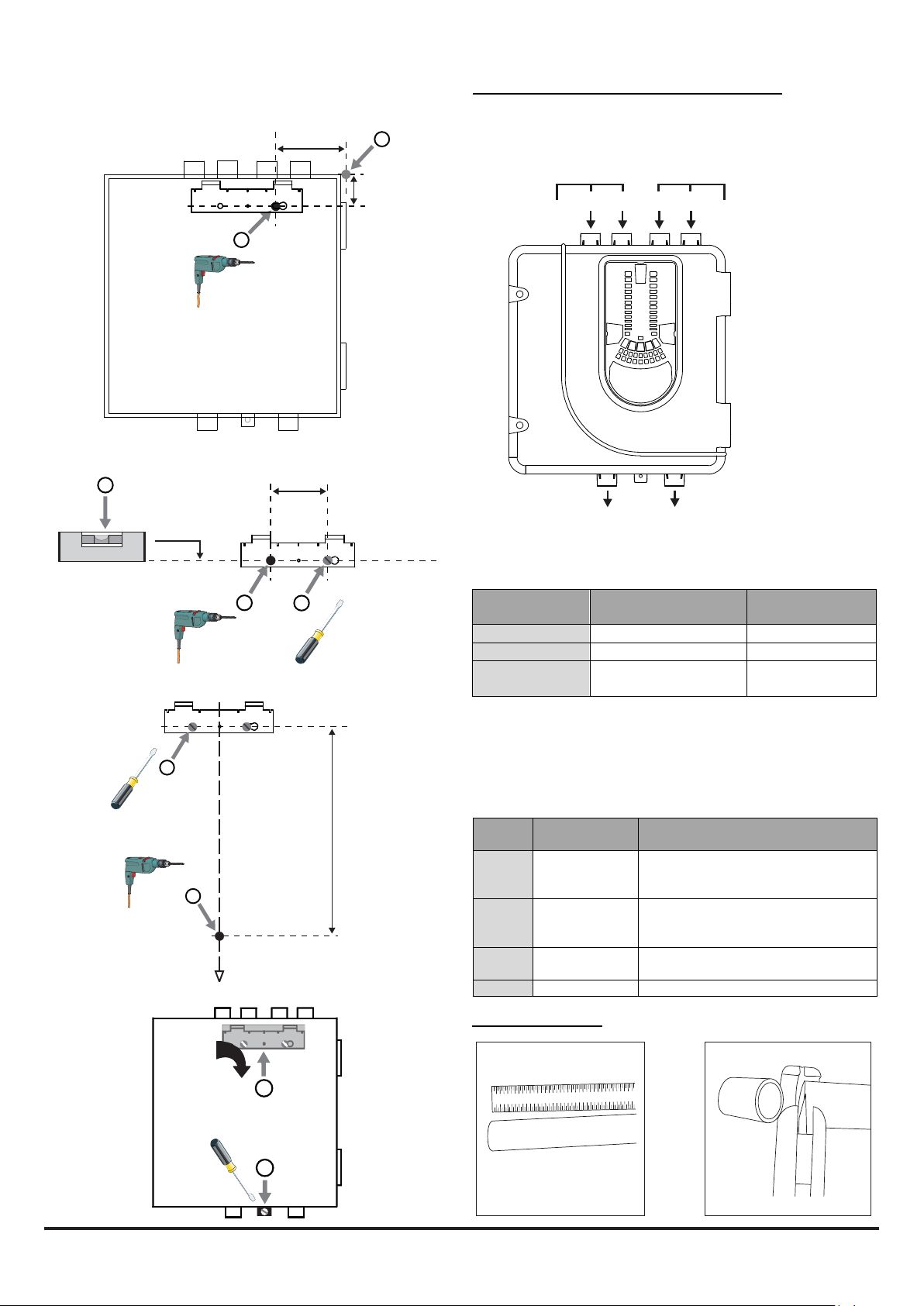

Mounting the LT NFXI-ASD to the Wall

ALARM

PREALARM

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

MODULE1

SMOKE

LEVEL1

FAULT

2

1

1

SMOKE

LEVEL2

MODULE2

POWER

FAULT

A

HIGHFLOW

FILTER

SOUNDER

TEMPERATURE

ELBASID/MESY

INPUT

LOWFLOW

SENSOR

ASPIRATOR

T

S

Figure 2: Placing the Front Panel Labels

When label A is in place, remove the protector from the bottom of

the clear cover to stick the cover down, as shown in Figure 3:

FAAST LT

HANGING LUGS

POSITION OF BRACKET

INDICATES CENTRE OF ASPIRATING PIPES

FIXING HOLE FIXING HOLE

USE FOR PLUMB-LINE

Figure 5: Mounting Bracket

99 mm

41

mm

59

mm

*

PLUMB LINE

329

mm

Figure 3: Remove Backing to

Stick Cover Down

Cable Access

Knock out cable gland holes where required. The

location of the cable gland holes is shown in Figure 1,

represented by the icon:

OUTER DIMENSION OF UNIT

212 mm

BASE OUTLINE

144 mm

* Minimum clearance required from hinges to open door = 35 mm.

Figure 6: Fasten the mounting bracket to the wall

*

N200-102-00 2 I56-3947-202

Figure 7: Sequence (1 to 9) to Mount the Detector on the Bracket

1 2 3 4 5 6 7 8 9 101112131415161718

7a

41

mm

1

99 mm

2

Pipe Hole Conguration

Figure 8 below shows the pipe holes available on the unit. Each

unit has 2 pipe holes per channel connected together like a T-Piece.

If using a 1 channel unit, holes 3 and 4 do not function. Use Table

1 to locate the holes required for the installation:

3

1

CHANNEL 1 CHANNEL 2 (ONLY FUNCTION

2

4

ON 2 CHANNEL UNITS)

Figure 8: Pipe Holes

7b

7c

7d

4

o

0.00

90 mm

CHANNEL 1 (NOT

USED FOR COMMON

CHAMBER UNIT)

5

3

Table 1: Pipe Holes Used for Each FAAST LT Model

5

CHANNEL 2 (ONLY FUNCTIONS

6

ON 2 CHANNEL AND COMMON

CHAMBER UNITS)

FAASTLTMODEL INLETPIPEHOLE OUTLETPIPEHOLE

NFXI‐ASD11 1and/or2 5

NFXI‐ASD12 1and/or2 6

NFXI‐ASD22 Channel1‐1and/or2

Channel2–3and/or456

Note 1: Pipe holes not used should be kept sealed.

Note 2: Do NOT glue pipes into the pipe holes.

6

Table 1a: Maximum Number of Pipe Holes Allowed Per Channel

for EN54-20 Compliance

329 mm

All gures quoted using highest (level 1) sensitivity.

CLASS PIPELENGTH

(m)

MAXNUMBEROFHOLESPER

CHANNEL

C 100 18(5x2mm,6x2.5mm,3x3mm,

7

3x3.5mmand1x4mm)+4mm

nonsensingendhole

C 160(2x80)

UsingT‐Piece

9holesperbranch(3x2.5mm,6x

3mm)+3mmnonsensingendhole

B 100 6(2x3.5mm,2x4mm,2x5mm

incendhole)

A 80 3(1x5mm,2x6mmincendhole)

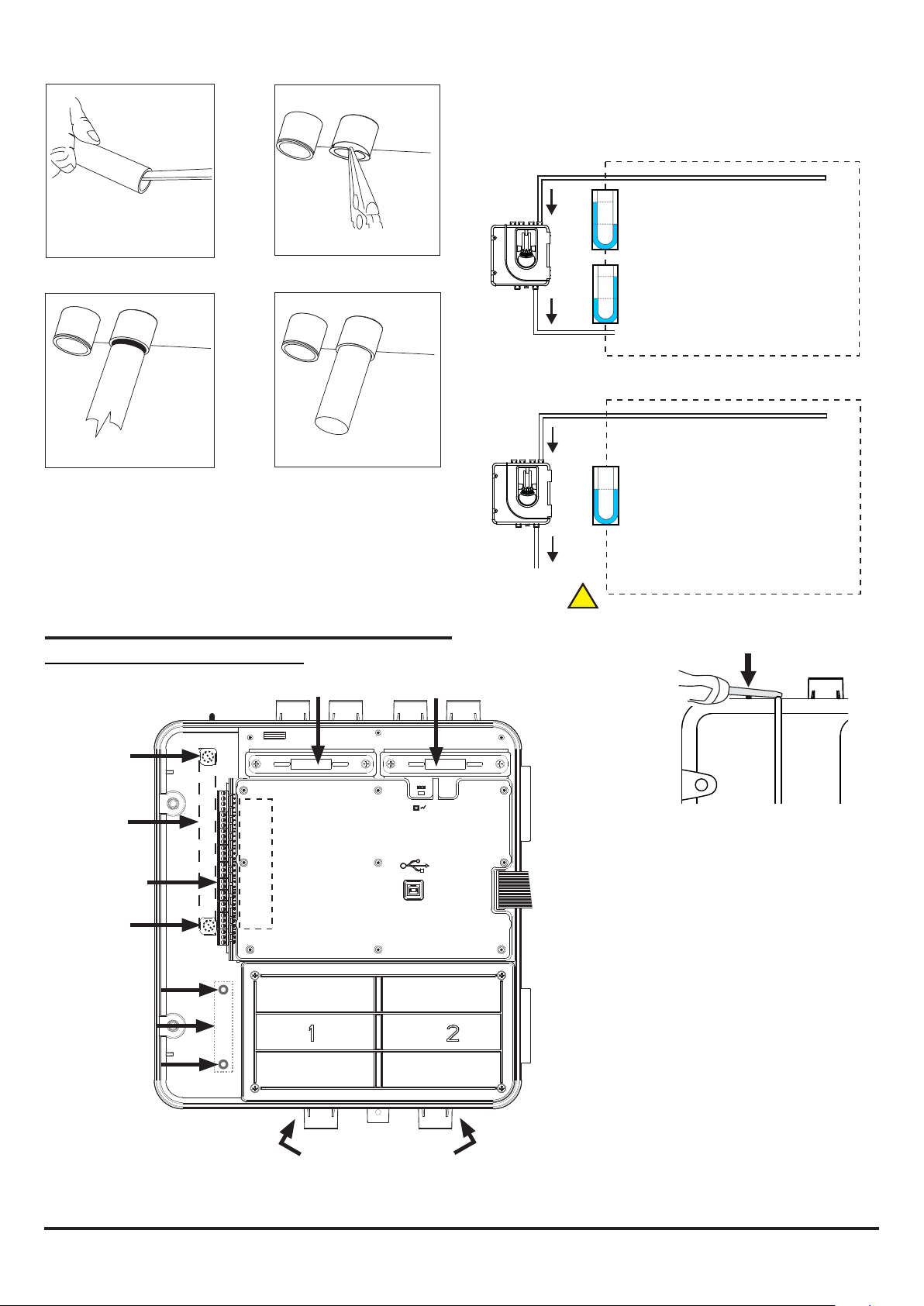

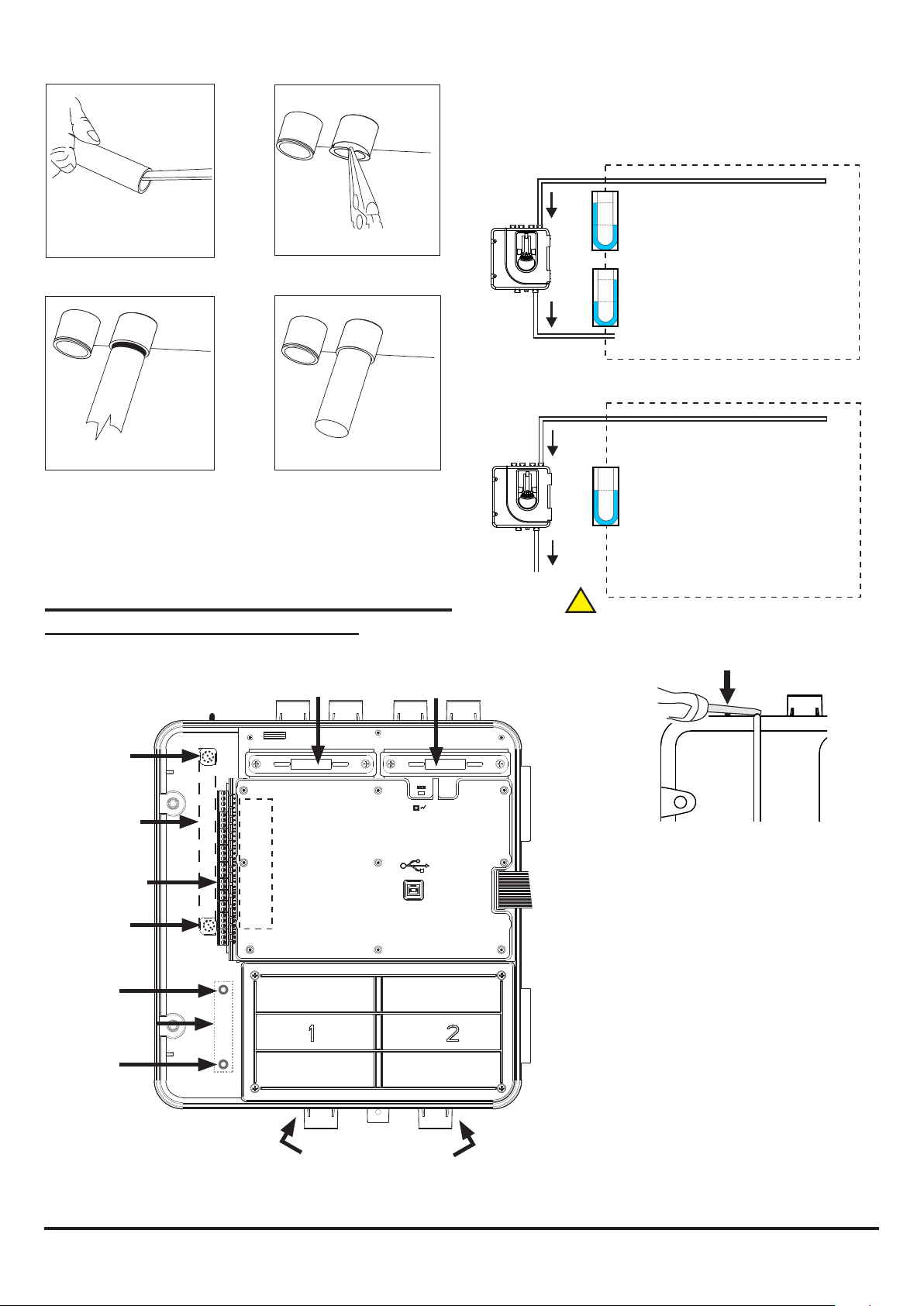

Pipe Installation

8

1 2 3 4 5 6 7 8 9 10111213141516

1718

9

1 2

N200-102-00 3 I56-3947-202

Exhaust Pipe

1 2 3 4 5 6 7 8 9 10111213141516 1718

1 2 3 4 5 6 7 8 9 1011121314 15161718

1 2 3 4 5 6 7 8 9 101112131415161718

1 2 3 4 5 6 7 8 9 10 1112 131415161718

Whenever the FAAST LT is installed outside the risk area, return of

the exhaust air back into the protected area can reduce ow faults

due to pressure difference.

3 4

5 6

WIRING INSTALLATION

Power, Alarm and Control Connections

CHANNEL 1 FILTER

CHANNEL 2 FILTER

SAMPLING AREA

SAMPLING AREA

!

EARTH BAR

MOUNT

F-LT-EB

EARTH BAR

(OPTIONAL)

POWER AND

ALARM

CONNECTIONS

EARTH BAR

MOUNT

MODULE MOUNT

F-LT-PMB

MODULE MOUNT

KIT (OPTIONAL)*

MODULE MOUNT

*If required, an input/output module

can be installed into the FAAST LT

unit. The optional module mount kit

(F-LT-PMB) will be needed for this.

PLACE

WIRING

LABEL

HERE

SENSOR COVER

POSITION FOR

TEST MAGNET

If the FAAST LT door is closed for a long time

(especially at high temperatures) it may be

necessary to use a at-bladed screwdriver

between the two tabs at the top of the unit to

lever open the door (as shown above).

USB PORT

Figure 9: Inside the Detector

Note 1: All wiring should comply with local

requirements and regulations.

Note 2: Loop wiring must observe the

recommendations of the panel manufacturer

N200-102-00 4 I56-3947-202

Fitting the Terminal Blocks

To insert the terminal blocks into the unit use the following method:

1 Insert a corner of the block into the slot (see a).

2 Push the length of the block into the slot until the block ‘clicks’

into place, the 2 upper hooks on the block should be visible

(see c).

a

b c

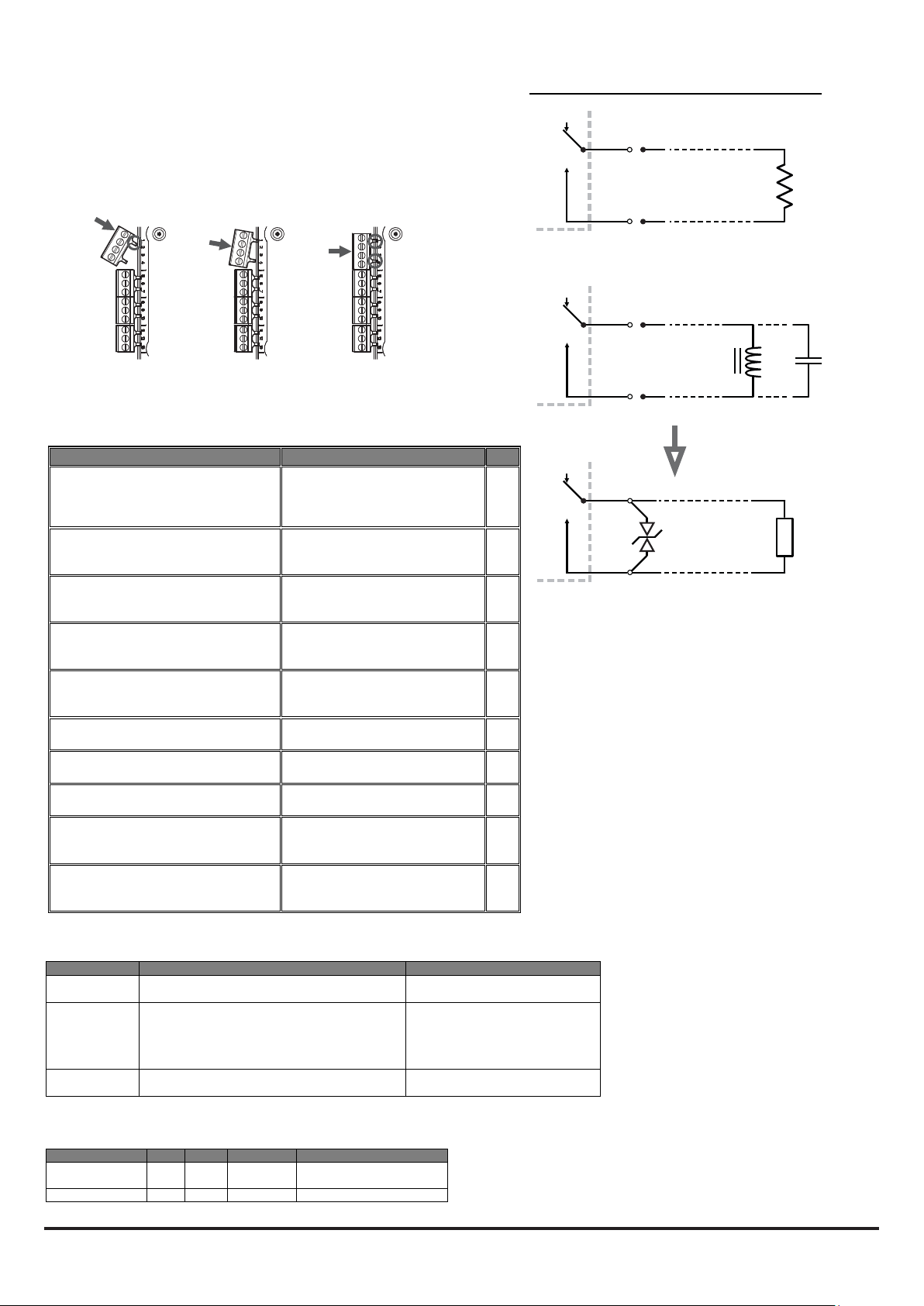

WARNING: Switching Inductive Loads

FAAST LT

FAAST LT

R

Table 2: Wiring Terminal Designations

(Note - Terminals marked CH2 will only be available on 2 channel

models)

No. Function

1 Ext Power In +

2 Ext Power In 3 Aux Power In +

4 Aux Power In -

5 NC Alarm Relay

6 C Alarm Relay

7 NO Alarm Relay

8 NC Alarm Relay

9 C Alarm Relay

10 NO Alarm Relay

11 NC Fault Relay

12 C Fault Relay

13 NO Fault Relay

14 NC Fault Relay (AUX)

15 C Fault Relay (AUX)

16 NO Fault Relay (AUX)

17 Sounder Output 1 18 Sounder Output 1 +

19 Sounder Output 2 20 Sounder Output 2 +

21 Configurable Input +

22 Configurable Input -

23 Not Used

24 Loop out 25 Loop switched out +

26 Loop in 27 Loop in +

28 Loop not switched out +

Primary PSU

Primary PSU

Not used in default

Not used in default

CH1

CH1

CH1

CH2

CH2

CH2

CH1

CH1

CH1

CH2

CH2

CH2

47 k-ohm EOL Resistor

47 k-ohm EOL Resistor

(Reset)

(Reset)

To use isolator

Internally connected to 27

Default is active = short circuit

(unsupervised)

T1

T2

T3

T4

T5

T6

T7

T8

T9

T10

FAAST LT

1N6284CA

Inductive loads can cause switching surges, which may

damage the module relay contacts (see above).

To protect the relay contacts, connect a suitable Transient

Voltage Suppressor (for example 1N6284CA ) across the

load as shown.

Alternatively, for unsupervised DC applications, t a diode

with a reverse breakdown voltage greater than 10 times the

circuit voltage.

L/C

CL

Table 3: Relays

RELAY ACTION: NOTES

ALARM 1 or 2 Controlled by panel when it determines

FAULT 1 or 2 When FAULT CONDITION on Ch1 or Ch2

SOUNDER 1 or 2 Set ON when a channel is in ALARM.

alarm condition has been met.

or a common FAULT occurs. Fault is also

signalled when in Service Mode and when

the device is unpowered.

Sounder 1 corresponds to Ch1 and

Sounder 2 corresponds to Ch2

Set ON and OFF by panel; not latched

Fault state is not latched.

Default condition = set on in ALARM.

Table 3a: Relay Electrical Specication

SPECIFICATION MIN MAX UNITS COMMENTS

Contact Rating 2

0.5

Life Time 105 Operations

A

A

30 VDC resistive load

30 VAC resistive load

N200-102-00 5 I56-3947-202

X 10 X 1

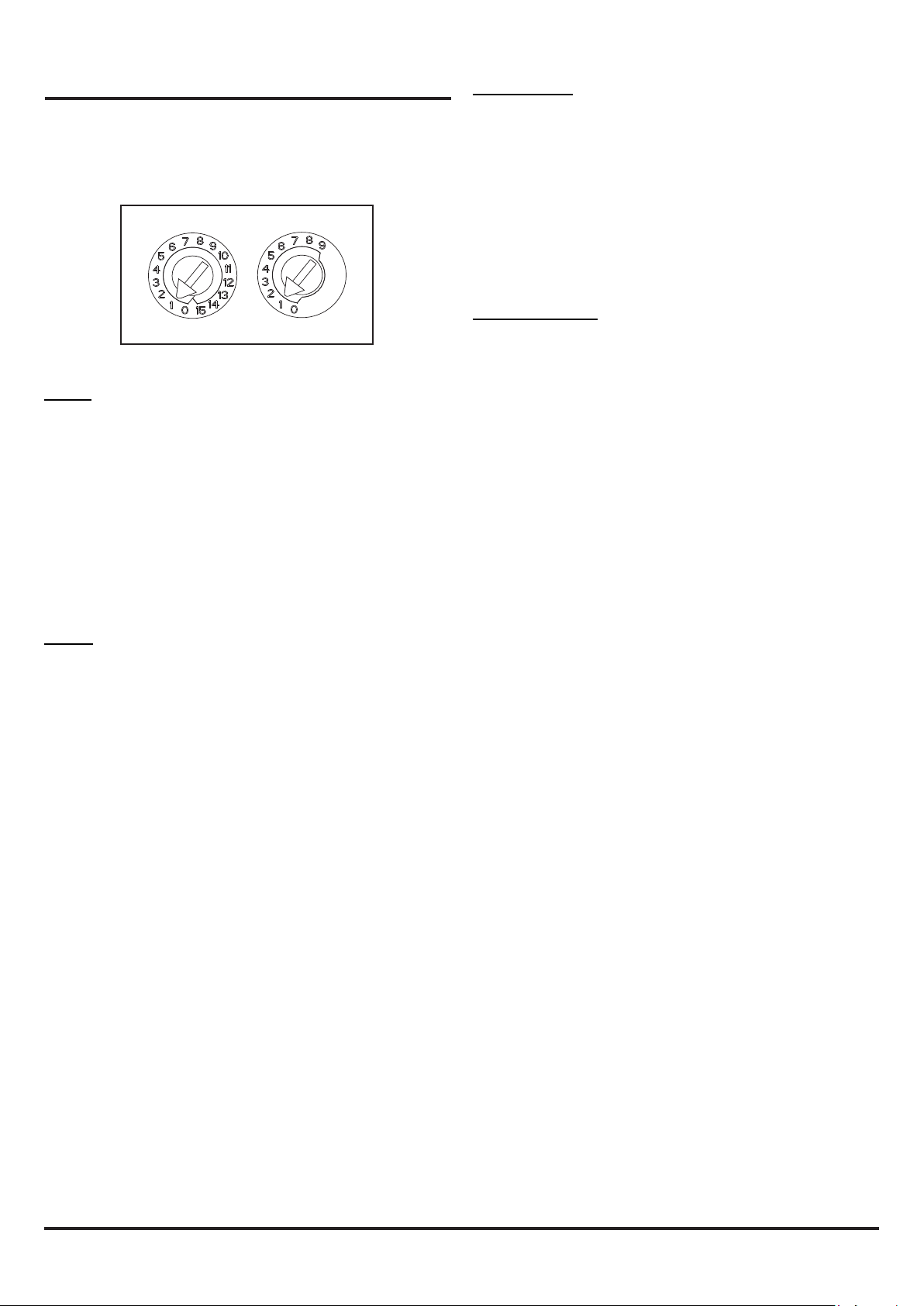

SETTING THE ADDRESSES POWERING UP

Each aspiration channel uses loop communications to report its

status information to the CIE (Fire Panel). As a factory default,

the unit will report smoke alarm and sensor information at an

associated sensor address and general alerts and faults on a

different module address.

Figure 10: Address Switches

Sensor

The sensor address is set on rotary decade switches on the back

of the smoke sensing devices. The smoke sensors are located

under the sensor cover inside the unit (see Figure 9). The Smoke

Sensors section of Service - later in the manual - shows how

to remove the sensors. As supplied, the default for channel 1 is

Address 1; in 2 channel units (or when two sensors are tted) the

second device is set to Address 2.

Any sensor address may be used except 0, whilst respecting the

panel’s rules on co-operative Multi-Sensing* (see below) between

the VIEW™ smoke sensors.

Note: The sensors communicate with the re panel through the

loop connection whether the 24VDC power supply is on or not.

Module

The module address is set by means of rotary decade address

switches located behind the door of the unit. Use a screwdriver to

rotate the wheels to the desired address. The selected address

refers to channel 1; on 2 channel units the device assigns the next

(+1) module address to channel 2 automatically. Hence, address

159 is not valid for channel 1. (Note: for control panels that use

only 99 addresses, 99 is invalid for channel 1.)

Note: The module address will only respond to a panel poll when

in Normal mode with the 24VDC power supply on.

* Co-Operative Multi-Sensing

Depending upon the panel used, the rules to dene the co-operative

Multi-Sensing between the VIEW™ smoke sensors differs. This

mode will allow an even higher sensitivity, but is only to be used for

the sensors within a single NFXI-ASD12.

How to Set this up for the NF300, NF3000, NF500, NF5000 and

ID3000 Panels

The co-operative Multi-Sensing is automatically activated if the

VIEW™ sensors on a loop are set to adjacent sensor addresses

and if they are also put into the same zone. Additionally, if cells

are being used, the cell numbers for the co-operative sensors must

also be the same.

How to Set this up for the NF50-A, NF50, NF50-S, ID60 and

Pearl Panels

The co-operative Multi-Sensing is automatically activated if the

VIEW™ sensors on a loop are put into the same AWACS group.

Setting an AWACS group to 0 will disable co-operative Multi-

Sensing for that sensor.

Using Default Settings

1. Connect a suitable 24VDC supply (complying with European

Standard EN 54-4) to pins 1 and 2 on terminal block T1 (See

Table 2)

2. Check the voltage at the connector. Make sure it is within the

required voltage range.

3. If the voltage is within the specied range, connect the power

connector to the unit.

4. Close and secure the housing door; verify the fan starts up and

air ows out of the exhaust port. The unit takes 1-3 minutes to

initialise and stabilise in normal mode.

EXTERNAL RESET

The default setting for the congurable external input is Device

Reset (terminal block T8). A short circuit connection between these

terminals will cause the FAAST LT unit to perform a reset.

N200-102-00 6 I56-3947-202

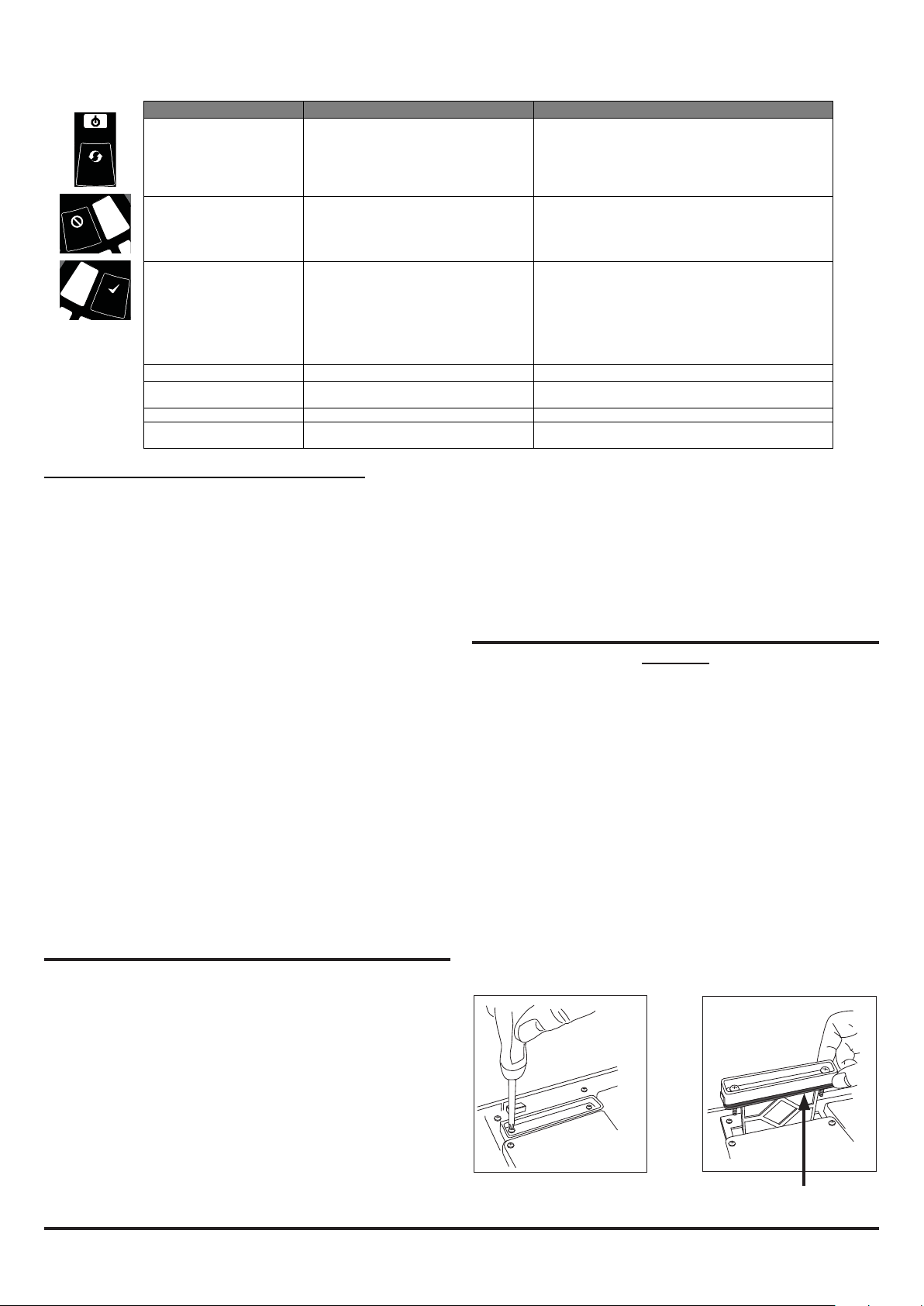

FRONT PANEL

The front panel will be different depending on which of the 3 NFXIASD models is being installed, and each is shown below.

The following information is displayed:

• Detector Status: Normal, Alarm, Fault or Isolate

• Alarm Level; Alarm, Pre-Alarm - only available with panels

using Advanced Protocol

• Particulate Levels; 1-9 - only available with panels using

Advanced Protocol

• Flow Level

• Test, Reset and Disable Buttons

Figure 11: Front Panel Display

ALARM

PREALARM

10

9

8

7

6

5

4

3

LEVEL

2

1

POWER

FAULT

SMOKE

MODULE

FAULT

ALARM

PREALARM

10

9

8

7

6

5

4

3

INPUT

2

1

SENSOR

ASPIRATOR

POWER

FAULT

HIGH FLOW

FILTER

SOUNDER

TEMPERATURE

ELBASID/METSYS

SMOKE

LEVEL

MODULE

FAULT

LOW FLOW

11b: NFXI-ASD12 1 Channel Detector (2 Sensors)

HIGH FLOW

FILTER

SOUNDER

TEMPERATURE

LOW FLOW

INPUT

SENSOR

ELBASID/METSYS

ASPIRATOR

11a: NFXI-ASD11 1 Channel Detector (1 Sensor)

SMOKE

LEVEL 1

MODULE 1

FAULT

LOW FLOW

INPUT

10

9

8

7

6

5

4

3

2

1

SENSOR

ASPIRATOR

ALARM

PREALARM

ELBASID/MESY

T

S

TEMPERATURE

10

9

8

7

6

5

4

3

2

1

SOUNDER

SMOKE

LEVEL 2

MODULE 2

POWER

FAULT

FILTER

HIGH FLOW

11c: NFXI-ASD22 2 Channel Detector

N200-102-00 7 I56-3947-202

Table 4: Front Panel Indicators and Fault Descriptions

FAULT

POWER

LEVEL 2

SMOKE

INITIALIZATION

ALARM

PREALARM

2

10

3

1

4

5

6

7

8

9

2

10

3

1

4

5

6

7

8

9

INDICATOR ACTION WARNING OR TROUBLE COMMENT / ACTION

CHANNEL 1/2 ALARM ON Red

CHANNEL 1/2 PRE-

ALARM

SMOKE LEVEL 1/2 ON Yellow

CHANNEL 1/2 MODULE ON Green Controlled by panel

FAULT ON Yellow Common or multiple faults

POWER ON Green FAAST LT is powered Displays Yellow when initialising

POWER FAULT ON Yellow Low power alert / high power

CHANNEL FLOW

INDICATORS 1/2

LOW FLOW ON Yellow Low flow fault Check filter; check pipe network for blockages.

INPUT 1 BLINK Yellow External input fault Not used with default settings

SENSOR 2 BLINKS Yellow Sensor communication fault Check sensor addresses and installation;

ASPIRATOR ON Yellow Air flow sensor fault Try to restart device.

DISABLE 1 BLINK Yellow Alarms & alerts not reported Returns to Maintenance then Normal operation

SYSTEM 1 BLINK Yellow Wrong configuration Flashes all FAULT LEDs; try to restart device.

TEMPERATURE 1 BLINK Yellow Low temperature alert Check the air flow temperature

SOUNDER 1 BLINK Yellow Sounder fault Check the sounder circuit and the EOL

FILTER 1 BLINK Yellow Filter alert at set date No date set as default

HIGH FLOW ON Yellow High flow fault Check pipe network for breaks or leaks.

In case of simultaneous alerts/faults on the same LED, priority order is: ON (Highest), 1 blink, 2 blinks, 3 blinks (Lowest)

Note: The channel alarm and smoke level LEDs are under the

(Set by panel)

1 BLINK Green

(Polled by panel)

ON Yellow Channel is in pre-alarm Only with panels using Advanced Protocol

(Set by panel)

BLINK Green Module communication Controlled by panel

ON Green The LED indicates the air flow

1 BLINK Yellow Flow initialization fault Check filter; check pipe network for blockages;

2 BLINKS Yellow Fan fault Try to restart device.

2 BLINKS Yellow EEPROM fault Check power supply voltage. Try to restart

3 BLINKS Yellow Real time clock fault RTC is corrupted or time reading failed.

2 BLINKS Yellow High temperature alert Check the air flow temperature

Channel is in alarm (relay is

set ON with no delay)

When sensor is polled Not when in alarm

Led number indicates sensor

alarm level reached

fault

for a channel:

- Centre = normal flow

- Left = flow low;

(-20% at extreme)

- Right = flow high;

(+20% at extreme)

Default setting

Only numbers 1 – 9 used - only with panels

using Advanced Protocol

Check the power supply voltage.

On 2 channel unit:

Upper row = Ch1

Lower row = Ch2

replace sensor.

try to restart device.

after 60min (default)

device

control of the CIE (Fire Panel).

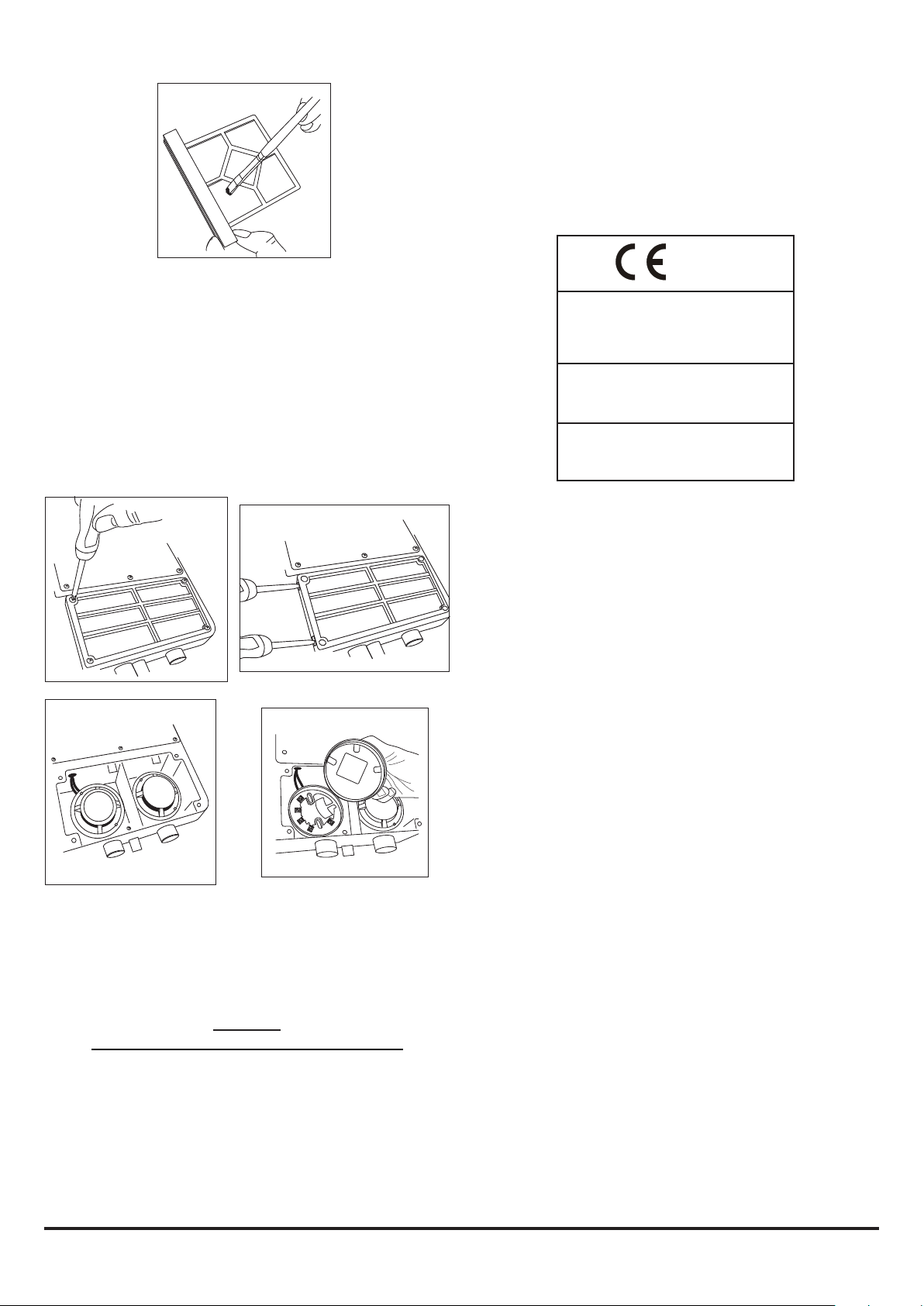

Front Panel Buttons

The front panel has 3 user buttons: TEST, RESET and DISABLE.

These buttons are used to enter the pass-code which then allows

the user to carry out simple test functions.

Note: In Remote Maintenance and Service Mode, these buttons

are always disabled.

Figure 12: User Interface Buttons

N200-102-00 8 I56-3947-202

Table 5: Front Panel Buttons

FAULT

POWER

LEVEL 2

SMOKE

INITIALIZATION

ALARM

PREALARM

2

10

3

1

4

5

6

7

8

9

FAULT

POWER

LEVEL 2

SMOKE

INITIALIZATION

2

10

3

1

4

5

6

7

8

9

FAULT

POWER

LEVEL 2

SMOKE

INITIALIZATION

ALARM

PREALARM

2

10

3

1

4

5

6

7

8

9

2

10

3

1

4

5

6

7

8

9

BUTTON NORMAL Mode MAINTENANCE Mode

RESET When pressed for 2 s, starts PASSWORD

PROCEDURE to enter Maintenance

mode.

DISABLE Used to increment Password digits in

PASSWORD PROCEDURE

TEST Used to confirm password in PASSWORD

PROCEDURE. Default Password = 3111

When pressed for 2 s latched alarms, faults and

sounders (relays) are reset. Alarm controlled by panel. If

alarm persists, set again immediately after the reset

In DISABLE Mode, if pressed for 2 s unit will exit from

DISABLE Mode (but remains in MAINTENANCE Mode)

When pressed for 2 s, device enters DISABLE Mode for

60 minutes (default). Alarm and fault relays reset .

Smoke sensors continue to report alarm and their faults

to the panel.

(To exit DISABLE Mode see RESET)

When pressed for 2 s and released, both sensor will

simulate alarm

When pressed for 4 s and released, sensor #1 will

simulate alarm

When pressed for 6 s and released, sensor #2 will

simulate alarm

Warning: Outputs will be activated by test

COMBINATIONS

RESET + DISABLE When pressed for 2 s, shows fan speed

(on smoke level scales) for a preset time.

RESET + TEST No action When pressed for 2 s, turns off sounders

RESET + TEST + DISABLE No action When pressed for 2 s, unit exits from MAINTENANCE

When pressed for 2 s, shows fan speed (on smoke level

scales) for preset time.

Mode

Password Sequence to Enter Maintenance Mode

Press and hold RESET; Left ow indicator will turn yellow, then

green.

Release RESET and FAULT indicator will switch on green. The

left ow indicator will blink green indicating the device is ready for

the rst digit.

Press DISABLE to increment the LEDs 1…9; press TEST to select

a digit.

The ashing airow segment will turn solid green and the next

segment will begin to ash indicating set the next digit. When the

4th digit is selected, all 4 airow segments are turned off. If the

password is accepted the FAULT indicator will remain green and

the unit enters Maintenance mode. If the password is incorrect

the FAULT indicator ashes yellow and the unit remains in Normal

mode. The Default password in 3111.

If no button is pressed for 10s during the password sequence, the

unit returns to Normal mode.

Exit from Maintenance Mode

To exit from the Maintenance mode, press the three front panel

user interface buttons TEST, RESET and DISABLE simultaneously

for 2 seconds. Alternatively, reset the unit using the Remote Input

(when set to default value) or power the device off and on again.

If there is no activity in Maintenance mode for 5 minutes (default),

the FAULT indicator blinks green for 15s and then the unit

automatically returns to the Normal state.

TESTING

Note that the sensor LEDs, which are under the control of the CIE

(Fire Panel), must be turned on to activate the front panel alarm

indicators.

Magnet Test

The alarm signalling can be tested for functionality by placing a

test magnet in the position shown in Figure 9 (displayed earlier in

the guide). This method does not test the air ow in the pipe-work.

Smoke Testing

The system alarm response can be tested for functionality

using smoke. The choice of smoke source is dependant on the

installation but in all cases the smoke must be present for the

duration of the test. Smoke pellets or matches can be used close

to the sampling point to introduce smoke particulates into the

N200-102-00 9 I56-3947-202

system. It is recommended that smoke with a particulate life cycle

of greater than 120s should be used – standard aerosol sprays for

point detector testing do not work well on aspirated systems.

Fault Testing

Simulate a fault on the detector (for example, block the outlet pipe)

and check that a fault is signalled on both the front panel of the unit

and at the CIE (Fire Panel).

SERVICE

WARNING

Isolate the aspirating detector from the re alarm system to prevent

any unwanted alarms when opening the front door of the unit.

Make sure all power is removed from the system before removing

any covers.

Service Mode

Opening the cabinet door during normal operation will cause the

unit to enter Service Mode. The FILTER LEDs will blink, the unit will

switch off power to the fans and stops communicating with the re

panel (the smoke sensors continue to communicate with the panel).

When the cabinet door is closed, the unit restarts automatically.

Filters

Periodic cleaning or replacement of the lters will be required.

The lters are located inside the cabinet at the top of the unit (see

Figure 9 displayed earlier in the guide) and are removed as shown

in the sequence below:

1 2

FOAM GASKET

3

Either replace the lter assembly or carefully brush off the

accumulated dust.

Note: If replacing the lter, remove the foam gasket from the old

lter and place onto the new lter. When placing the new lter into

the slot, ensure that the gasket is correctly aligned.

Ret the lter, close and secure the cabinet door. The unit will

initialise and restart.

Smoke Sensors

The smoke sensors are located under the sensor cover (see Figure

8 displayed earlier in the guide). To access the sensors, follow the

sequence below:

2

Conguring Other Options

To change any of the default options, it will be necessary to connect

the detector to a PC/laptop with the PipeIQ 2 software installed;

see the FAAST LT Advanced Setup and Control Guide for further

information.

Note: The USB connecting cable should be removed during

normal operation.

0832 12

Declaration of Performance Ref:

NFXI-ASD11: DOP-ASP012

NFXI-ASD12: DOP-ASP013

NFXI-ASD22: DOP-ASP014

EN54-20 : 2006 Class C

Aspirating Smoke Detectors

EN54-17: 2005 Short Circuit Isolators

System Sensor Europe

Pittway Tecnologica S.r.l.

Via Caboto 19/3, 34147 Trieste, Italy

1

4

3

If replacing a sensor, ensure that the address set on the new

sensor is the same as on the sensor being replaced.

LASER SAFETY INFORMATION

The detector contains a Class 1 laser product. Radiation emitted

inside the smoke sensor is completely contained within its housings

and protective covers during all phases of operation.

WARNING

Using compressed air to clean the pipe system

High pressure air ushed through the system could damage

the fan, ensure that the FAAST LT unit is sealed or detached

from the system before commencing this procedure.

USB CONNECTION

PC connectivity is provided by an on board USB B socket located

centrally between the lter and the sensor cover (see Figure 9

displayed earlier in the guide). The USB interface allows access to

a range of additional options via the PipeIQ 2 application software

running on a PC.

Notier by Honeywell

Brooks Road

Lewes

East Sussex

BN7 2BY

United Kingdom

www.notierresystems.co.uk

N200-102-00 10 I56-3947-202

I T A L I A N O

367 mm

135 mm

56 mm

44 mm

403 mm

356 mm

50 mm 50 mm

60 mm

110 mm

GUIDA DI INSTALLAZIONE RAPIDA FAAST LT INDIRIZZABILE

DESCRIZIONE

La serie LT NFXI-ASD fa parte della famiglia FAAST (Fire Alarm

Aspiration Sensing Technology®). FAAST è un sistema di rilevamento

di incendi avanzato da utilizzare dove sono richieste rilevazioni

di tipo “early warning” e “very early warning”. Il sistema aspira

continuamente l'aria dall'ambiente controllato attraverso una serie di

fori di campionamento per monitorare se nell'ambiente sono presenti

particelle di fumo.

Il modello NFXI-ASD è la versione indirizzabile della gamma FAAST LT,

che comunica con il CIE (pannello antincendio) tramite un protocollo

proprietario. È disponibile in 3 diversi modelli:

NFXI-ASD11 - Ha un singolo canale a disposizione con un rivelatore

laser di fumo.

NFXI-ASD12 - Ha un singolo canale a disposizione con due rivelatori

laser di fumo in una camera comune per il rilevamento

combinato.

NFXI-ASD22 - Ha due canali a disposizione con due rivelatori laser di

fumo in camere separate. (Un sensore per ogni canale.)

Questa guida fornisce informazioni per il montaggio e l'installazione di

base utilizzando le impostazioni di fabbrica predenite dell'unità. Per

informazioni più dettagliate consultare FAAST LT Advanced Setup and

Control Guide - riferimento D200-100-00.

SPECIFICHE

Caratteristiche elettriche

Intervallo di tensione: 18,5 - 31,5 VDC

Corrente di alimentazione: 1 Canale: 170 mA (tipico); 360 mA (max) a 24

2 Canali: 270 mA (tipico); 570 mA (max) a 24

Tensione di alimentazione del loop 15 - 29 VDC (corrente dei loop ≤ di

comunicazione: 900 mA)

Corrente a riposo del loop di comunicazione: A 24 V: 900 μA max. (un polling

Caratteristiche dell'isolatore del modulo

Corrente nominale massima di commutazione

(in condizioni di corto circuito, Is max): 0,9 A a ≤ 29 V

Corrente di dispersione massima (IL max)

con il selettore aperto (stato isolato): 15 mA

Massima impedenza in serie con

il selettore chiuso (Zc max): 190 m ohm a 15 Vcc; 1 A

Reset dell'alimentazione: 0,5 secondi

Input congurabile: Tempo di attivazione: 2 secondi (min)

Dati dei contatti relè: 2,0 A a 30 VDC, 0,5 A a 30 VAC

VDC 25 oC (escluse le sirene)

VDC 25 oC (escluse le sirene)

ogni 5 secondi)

FIRE ALARM ASPIRATION SENSING TECHNOLOGY

MODELLI NFXI-ASD11, NFXI-ASD12 E NFXI-ASD22

Figura 1: dimensioni e prefori

Dati ambientali

Temperatura: da -10 oC a 55 oC

Umidità relativa: dal 10% al 93% (senza condensa)

Classicazione IP: 65

Meccanica

Dimensioni esterne: Vedere Figura 1

Cablaggio: da 0,5 mm² a 2 mm² max

Lunghezza massima tubo singolo: 100 m (Classi B e C) 80 m (Classe A)

Lunghezza massima tubo collegato: 160 m (2 x 80 m, Classe C)

Numero massimo di fori: Vedere tabella 1A

Speciche tubi (conformità a EN54-20): secondo EN 61386

(urto 1, impatto 1, temperatura 31)

Diametro esterno tubo: 25 mm (nom.) o 27 mm (nom.)

Peso di spedizione: 6,5 kg (sensori inclusi)

ELENCO DELLE PARTI

Descrizione Quantità

Unità FAAST LT 1

Staffa di montaggio 1

Morsettiera a 3 posizioni 6

Morsettiera a 4 posizioni 1

Morsettiera a 2 posizioni 3

Resistenza di ne linea 47 KOhm 2

Cavo USB 1

Confezione di etichette per pannello anteriore 1

Etichetta schema di cablaggio 1

CD con kit di installazione 1

Guida di installazione rapida 1

Nota importante

I rivelatori di fumo ad aspirazione forniti e installati all'interno dell'UE

devono essere conformi alla direttiva dell'UE sui prodotti da costruzione

(CPR) 305/2011 e alla norma europea sui prodotti EN 54-20 correlata.

FAAST LT è stato sottoposto a veriche e certicazione per garantirne

la conformità agli standard necessari, ma si consiglia di attenersi

scrupolosamente a questa guida di istruzioni afnché l'installazione

soddis i requisiti CPR.

®

N200-102-00 1 I56-3947-202

Questa apparecchiatura e tutte le tubazioni associate devono essere

1 2 3 4 5 6 7 8 9101112131415161718

90 mm

installate in conformità a tutti i codici e alle normative pertinenti.

INSTALLAZIONE FISICA

Etichette per pannello anteriore

Il modello LT NFXI-ASD viene spedito senza etichette applicate sul

pannello anteriore. Ciò consente all'installatore di scegliere la lingua

richiesta per l'installazione dalla confezione di etichette per pannello

anteriore.

In Figura 2 viene mostrato dove devono essere applicate le etichette:

ALARM

PREALARM

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

MODULE1

SMOKE

LEVEL1

FAULT

2

1

1

SMOKE

LEVEL2

MODULE2

POWER

FAULT

Figura 4: come praticare i fori serracavo

Montaggio dell'unità LT NFXI-ASD alla parete

INDICA IL CENTRO DEI TUBI DI ASPIRAZIONE

FAAST LT

ALETTE

DI SUPPORTO

A

HIGHFLOW

FILTER

SOUNDER

TEMPERATURE

ELBASID/MESY

INPUT

LOWFLOW

SENSOR

ASPIRATOR

T

S

Figura 2: posizionamento delle etichette per pannello anteriore

Quando l'etichetta A è in posizione, rimuovere la protezione dalla

parte inferiore della copertura trasparente per incollare la copertura,

come mostrato in Figura 3:

Figura 3: Rimozione del

rivestimento per

incollare la copertura

FORO DI FISSAGGIO FORO DI FISSAGGIO

Figura 5: staffa di montaggio

POSIZIONE DELLA STAFFA

FILO A PIOMBO

USO DI FILO A PIOMBO

99 mm

41

mm

59

mm

*

329

mm

Accesso ai cavi

Praticare i fori serracavo dove necessario. La posizione

dei fori serracavo è mostrata in Figura 1, rappresentata

DIMENSIONE ESTERNA

DELL'UNITÀ

CONTORNO BASE

*

dall'icona:

212 mm

144 mm

* Spazio minimo necessario dai cardini per aprire lo sportello = 35 mm.

Figura 6: ssaggio della staffa di montaggio alla parete

N200-102-00 2 I56-3947-202

Figura 7: sequenza (da 1 a 9) per il montaggio del rivelatore

1 2 3 4 5 6 7 8 9 10111213 14 1516 1718

FAAST LT

ASPIRAZIONE

SCARICO

alla staffa

7a

41

mm

1

99 mm

2

Congurazione dei fori di entrata e uscita dei tubi

Figura 8 di seguito sono mostrati i fori di entrata e uscita dei tubi

disponibili sull'unità. Ogni unità dispone di 2 fori per tubi per canale

collegati insieme a T. Se si utilizza un'unità a 1 canale, i fori 3 e 4 non

funzionano. Utilizzare la Tabella 1 per localizzare i fori necessari per

l'installazione:

3

CANALE 1

1

2

4

CANALE 2 (FUNZIONA SOLO

SU UNITÀ A 2 CANALI)

Figura 8: fori di

entrata e uscita dei

7b

7c

7d

4

o

0.00

90 mm

CANALE 1 (NON

UTILIZZATO PER

L'UNITÀ A CAMERA

COMUNE)

CANALE 2 (FUNZIONA SOLO SU

5

UNITÀ A 2 CANALI E CAMERA

6

COMUNE)

Tabella 1: fori sui tubi utilizzati per ogni modello FAAST LT

5

3

MODELLO

FORO SU TUBO DI

FORO SU TUBO DI

NFXI-ASD11 1 e/o 2 5

NFXI-ASD12 1 e/o 2 6

6

7

329 mm

NFXI-ASD22 Canale 1 - 1 e/o 2

Canale 2 – 3 e/o 4

Nota 1: i fori sui tubi non utilizzati devono essere tenuti sigillati.

Nota 2: NON incollare i tubi nei relativi fori.

Tabella 1a: Numero massimo di fori per tubi consentito per canale

Tutte le cifre sono stimate usando il livello più elevato di sensibilità

(livello 1)

CLASSE LUNGHEZZADEL

TUBO(m)

C 100 18(5x2mm,6x2,5mm,3x3mm,3x

C 160(2x80)

Utilizzodel

raccordoaT

B 100 6(2x3,5mm,2x4mm,2x5mmincluso

A 80 3(1x5mm,2x6 mminclusoforofinale)

Installazione dei tubi

NUMEROMASSIMODIFORIPERCANALE

3,5mme1x4mm)+4mmforofinale

nonsensibile

9foriperraccordo(3x2,5mm,6x3mm)

+3mmforofinalenonsensibile

forofinale)

5

6

8

1 2 3 4 5 6 7 8 9 10111213141516

1718

9

1 2

N200-102-00 3 I56-3947-202

Tubo di scarico

1 2 3 4 5 6 7 8 9 10111213 14 1516 1718

1 2 3 4 5 6 7 8 9 10111213 1415161718

1 2 3 4 5 6 7 8 9 10111213 141516 1718

1 2 3 4 5 6 7 8 9 10 11 12131415161718

Ogni volta che FAAST LT viene installato al di fuori della zona a rischio,

il ritorno dell'aria di scarico nella zona protetta può ridurre i guasti di

usso dovuti alla differenza di pressione.

3 4

5

6

INSTALLAZIONE DEL CABLAGGIO

Collegamenti di alimentazione, allarme e controllo

FILTRO CANALE 1

FILTRO CANALE 2

AREA DI CAMPIONAMENTO

AREA DI CAMPIONAMENTO

!

MONTAGGIO

DELLA BARRA DI

TERRA

BARRA DI

TERRA F-LT-EB

(OPZIONALE)

COLLEGAMENTI

DI

ALIMENTAZIONE

E ALLARME

MONTAGGIO

DELLA BARRA

DI TERRA

MONTAGGIO

MODULO

KIT MONTAGGIO

MODULO F-LT-PMB

(OPZIONALE)*

MONTAGGIO

MODULO

*Se necessario, è possibile installare

un modulo di ingresso/uscita nell’unità

FAAST LT. Sarà necessario il kit opzionale

di montaggio modulo (F-LT-PMB).

POSIZIONARE

L'ETICHETTA DI

CABLAGGIO QUI

PORTA USB

COPERCHIO DEI SENSORI

POSIZIONE DEL

MAGNETE DI PROVA

Se la porta FAAST LT viene chiusa per un

lungo periodo (soprattutto ad alte temperature),

può essere necessario utilizzare un cacciavite

a lama piatta tra le due linguette nella parte

superiore dell'unità per mantenere aperta la

porta (come mostrato sopra).

Figura 9: interno del rivelatore

Nota 1: L'intero cablaggio deve rispettare i

requisiti e le norme locali.

Nota 2: Il cablaggio del circuito deve rispettare

le raccomandazioni del fabbricante del pannello

N200-102-00 4 I56-3947-202

N.

Funzione

1

Ingresso alimentazione est. +

PSU principale

T1

2

Ingresso alimentazione est. -

PSU principale

3

Ingresso alimentazione aus. +

Non in uso in impostazione predefinita

4

Ingresso alimentazione aus. -

Non in uso in impostazione predefinita

5

Relè di allarme NC

CH1

T2

6

Relè di allarme C

CH1

7

Relè di allarme NO

CH1

8

Relè di allarme NC

CH2

T3

9

Relè di allarme C

CH2

10

Relè di allarme NO

CH2

11

Relè di guasto NC

CH1

T4

12

Relè di guasto C

CH1

13

Relè di guasto NO

CH1

14

Relè di guasto NC (AUS.)

CH2

T5

15

Relè di guasto C (AUS.)

CH2

16

Relè di guasto NO (AUS.)

CH2

17

Uscita sirena 1 -

Resistenza di fine linea 47 KOhm

T6

18

Uscita sirena 1 +

19

Uscita sirena 2 -

Resistenza di fine linea 47 KOhm

T7

20

Uscita sirena 2 +

21

Input configurabile +

(Reset)

Valore predefinito attivo = corto circuito

(senza supervisione)

T8

22

Input configurabile -

(Reset)

23

Non in uso

T9

24

Uscita loop -

25

Uscita loop + 'isolatori'

Utilizzo isolatore

26

Ingresso loop -

T10

27

Ingresso loop +

28

Uscita loop + (no isolatori)

Collegato internamente al terminale 27

RELÈ

AZIONE:

NOTE

ALLARME 1 o 2

Attivato dal pannello quando rileva che è soddisfatta

la condizione di allarme.

Impostato ON e OFF dal pannello;

senza memoria

GUASTO 1 o 2

Attivato quando si verifica una CONDIZIONE DI

GUASTO sul Ch1 o sul Ch2 o un GUASTO generico.

Un guasto viene segnalato anche quando il dispositivo

è in modalità di Assistenza o non è alimentato.

Stato di guasto senza memoria.

SIRENA 1 o 2

Attivato quando un canale è in ALLARME.

La Sirena 1 corrisponde a Ch1 e la Sirena 2 a Ch2

Condizione predefinita = impostata su

ON in ALLARME.

Fissaggio morsettiere

Per inserire le morsettiere nell’unità utilizzare il seguente metodo:

1 Inserire un angolo della morsettiera nella fessura (vedere a).

2 Premere tutta la lunghezza della morsettiera nella fessura nché

non scatta in posizione, i due ganci superiori sulla morsettiera

devono essere visibili (vedere c).

a b c

AVVERTENZA: Commutazione carichi induttivi

FAAST LT

R

FAAST LT

Tabella 2: Descrizioni dei morsetti del cablaggio

(Nota: i morsetti contrassegnati con CH2 sono disponibili solo su

modelli a 2 canali)

L/C

CL

FAAST LT

1N6284CA

I carichi induttivi possono causare sovratensioni da

commutazione che potrebbero danneggiare i contatti del

relè del modulo (vedere sopra).

Per proteggere i contatti del relè, collegare un soppressore

di tensione transitoria (ad esempio 1N6284CA) al carico,

come indicato.

In alternativa, per applicazioni CC non controllate, inserire

un diodo con una tensione di scarica contraria 10 volte

superiore alla tensione del circuito.

Tabella 3: Relè

Tabella 3a: Speciche elettriche del relè

SPECIFICHE MIN. MAX. UNITÀ COMMENTI

Portata contatto 2

Durata 105 Operazioni

N200-102-00 5 I56-3947-202

0,5

A

Carico resistivo da 30 VCC

A

Carico resistivo da 30 VCA

Loading...

Loading...