Page 1

Fire Alarm Control Panel

NFS2-640/E

Programming Manual

Document 52742

7/17/14 Rev:

P/N 52742:L2 ECN 13-838

L2

Page 2

Fire Alarm & Emergency Communication System Limitations

While a life safety system may lower insurance rates, it is not a substitute for life and property insurance!

An automatic fire alarm system—typically made up of smoke

detectors, heat detectors, manual pull stations, audible warning

devices, and a fire alarm control panel (FACP) with remote notification capability—can provide early warning of a developing fire.

Such a system, however, does not assure protection against

property damage or loss of life resulting from a fire.

An emergency communication system—typically made up of

an automatic fire alarm system (as described above) and a life

safety communication system that may include an autonomous

control unit (ACU), local operating console (LOC), voice communication, and other various interoperable communication methods—can broadcast a mass notification message. Such a

system, however, does not assure protection against property

damage or loss of life resulting from a fire or life safety event.

The Manufacturer recommends that smoke and/or heat

detectors be located throughout a protected premises following

the recommendations of the current edition of the National Fire

Protection Association Standard 72 (NFPA 72), manufacturer's

recommendations, State and local codes, and the

recommendations contained in the Guide for Proper Use of

System Smoke Detectors, which is made available at no charge

to all installing dealers. This document can be found at http://

www.systemsensor.com/appguides/. A study by the Federal

Emergency Management Agency (an agency of the United

States government) indicated that smoke detectors may not go

off in as many as 35% of all fires. While fire alarm systems are

designed to provide early warning against fire, they do not

guarantee warning or protection against fire. A fire alarm system

may not provide timely or adequate warning, or simply may not

function, for a variety of reasons:

Smoke detectors may not sense fire where smoke cannot

reach the detectors such as in chimneys, in or behind walls, on

roofs, or on the other side of closed doors. Smoke detectors

also may not sense a fire on another level or floor of a building.

A second-floor detector, for example, may not sense a first-floor

or basement fire.

Particles of combustion or “smoke” from a developing fire

may not reach the sensing chambers of smoke detectors

because:

• Barriers such as closed or partially closed doors, walls, chimneys, even wet or humid areas may inhibit particle or smoke

flow.

• Smoke particles may become “cold,” stratify, and not reach

the ceiling or upper walls where detectors are located.

• Smoke particles may be blown away from detectors by air

outlets, such as air conditioning vents.

• Smoke particles may be drawn into air returns before reaching the detector.

The amount of “smoke” present may be insufficient to alarm

smoke detectors. Smoke detectors are designed to alarm at various levels of smoke density. If such density levels are not created by a developing fire at the location of detectors, the

detectors will not go into alarm.

Smoke detectors, even when working properly, have sensing

limitations. Detectors that have photoelectronic sensing chambers tend to detect smoldering fires better than flaming fires,

which have little visible smoke. Detectors that have ionizing-type

sensing chambers tend to detect fast-flaming fires better than

smoldering fires. Because fires develop in different ways and

are often unpredictable in their growth, neither type of detector is

necessarily best and a given type of detector may not provide

adequate warning of a fire.

Smoke detectors cannot be expected to provide adequate warning of fires caused by arson, children playing with matches

(especially in bedrooms), smoking in bed, and violent explosions

(caused by escaping gas, improper storage of flammable materials, etc.).

Heat detectors do not sense particles of combustion and alarm

only when heat on their sensors increases at a predetermined

rate or reaches a predetermined level. Rate-of-rise heat detectors may be subject to reduced sensitivity over time. For this

reason, the rate-of-rise feature of each detector should be tested

at least once per year by a qualified fire protection specialist.

Heat detectors are designed to protect property, not life.

IMPORTANT! Smoke detectors must be installed in the same

room as the control panel and in rooms used by the system for

the connection of alarm transmission wiring, communications,

signaling, and/or power. If detectors are not so located, a developing fire may damage the alarm system, compromising its ability to report a fire.

Audible warning devices such as bells, horns, strobes,

speakers and displays may not alert people if these devices

are located on the other side of closed or partly open doors or

are located on another floor of a building. Any warning device

may fail to alert people with a disability or those who have

recently consumed drugs, alcohol, or medication. Please note

that:

• An emergency communication system may take priority over

a fire alarm system in the event of a life safety emergency.

• Voice messaging systems must be designed to meet intelligibility requirements as defined by NFPA, local codes, and

Authorities Having Jurisdiction (AHJ).

• Language and instructional requirements must be clearly disseminated on any local displays.

• Strobes can, under certain circumstances, cause seizures in

people with conditions such as epilepsy.

• Studies have shown that certain people, even when they hear

a fire alarm signal, do not respond to or comprehend the

meaning of the signal. Audible devices, such as horns and

bells, can have different tonal patterns and frequencies. It is

the property owner's responsibility to conduct fire drills and

other training exercises to make people aware of fire alarm

signals and instruct them on the proper reaction to alarm signals.

• In rare instances, the sounding of a warning device can cause

temporary or permanent hearing loss.

A life safety system will not operate without any electrical

power. If AC power fails, the system will operate from standby

batteries only for a specified time and only if the batteries have

been properly maintained and replaced regularly.

Equipment used in the system may not be technically compatible with the control panel. It is essential to use only equipment

listed for service with your control panel.

Telephone lines needed to transmit alarm signals from a premises to a central monitoring station may be out of service or temporarily disabled. For added protection against telephone line

failure, backup radio transmission systems are recommended.

The most common cause of life safety system malfunction is

inadequate maintenance. To keep the entire life safety system in

excellent working order, ongoing maintenance is required per the

manufacturer's recommendations, and UL and NFPA standards. At a minimum, the requirements of NFPA 72 shall be followed. Environments with large amounts of dust, dirt, or high air

velocity require more frequent maintenance. A maintenance

agreement should be arranged through the local manufacturer's

representative. Maintenance should be scheduled monthly or as

required by National and/or local fire codes and should be performed by authorized professional life safety system installers

only. Adequate written records of all inspections should be kept.

Limit-D-1-2013

2 NFS2-640/E Programming Manual — P/N 52742:L2 7/17/14

Page 3

Installation Precautions

Adherence to the following will aid in problem-free installation with long-term reliability:

WARNING - Several different sources of power can be

connected to the fire alarm control panel. Disconnect all

sources of power before servicing. Control unit and associated equipment may be damaged by removing and/or inserting cards, modules, or interconnecting cables while the unit is

energized. Do not attempt to install, service, or operate this

unit until manuals are read and understood.

CAUTION - System Re-acceptance Test after Software

Changes: To ensure proper system operation, this product

must be tested in accordance with NFPA 72 after any programming operation or change in site-specific software. Reacceptance testing is required after any change, addition or

deletion of system components, or after any modification,

repair or adjustment to system hardware or wiring. All components, circuits, system operations, or software functions known

to be affected by a change must be 100% tested. In addition,

to ensure that other operations are not inadvertently affected,

at least 10% of initiating devices that are not directly affected

by the change, up to a maximum of 50 devices, must also be

tested and proper system operation verified.

This system meets NFPA requirements for operation at 0-49º

C/32-120º F and at a relative humidity 93% ± 2% RH (noncondensing) at 32°C ± 2°C (90°F ± 3°F). However, the useful

life of the system's standby batteries and the electronic components may be adversely affected by extreme temperature

ranges and humidity. Therefore, it is recommended that this

system and its peripherals be installed in an environment with

a normal room temperature of 15-27º C/60-80º F.

Verify that wire sizes are adequate for all initiating and indicating device loops. Most devices cannot tolerate more than a

10% I.R. drop from the specified device voltage.

Like all solid state electronic devices, this system may

operate erratically or can be damaged when subjected to lightning induced transients. Although no system is completely

immune from lightning transients and interference, proper

grounding will reduce susceptibility. Overhead or outside aerial

wiring is not recommended, due to an increased susceptibility

to nearby lightning strikes. Consult with the Technical Services Department if any problems are anticipated or encountered.

Disconnect AC power and batteries prior to removing or

inserting circuit boards. Failure to do so can damage circuits.

Remove all electronic assemblies prior to any drilling, filing,

reaming, or punching of the enclosure. When possible, make

all cable entries from the sides or rear. Before making modifications, verify that they will not interfere with battery, transformer, or printed circuit board location.

Do not tighten screw terminals more than 9 in-lbs. Overtightening may damage threads, resulting in reduced terminal

contact pressure and difficulty with screw terminal removal.

This system contains static-sensitive components.

Always ground yourself with a proper wrist strap before handling any circuits so that static charges are removed from the

body. Use static suppressive packaging to protect electronic

assemblies removed from the unit.

Follow the instructions in the installation, operating, and programming manuals. These instructions must be followed to

avoid damage to the control panel and associated equipment.

FACP operation and reliability depend upon proper installation.

Precau-D1-9-2005

FCC Warning

WARNING: This equipment generates, uses, and can

radiate radio frequency energy and if not installed and

used in accordance with the instruction manual may

cause interference to radio communications. It has been

tested and found to comply with the limits for class A

computing devices pursuant to Subpart B of Part 15 of

FCC Rules, which is designed to provide reasonable

protection against such interference when devices are

operated in a commercial environment. Operation of this

equipment in a residential area is likely to cause interference, in which case the user will be required to correct

the interference at his or her own expense.

Canadian Requirements

This digital apparatus does not exceed the Class A limits

for radiation noise emissions from digital apparatus set

out in the Radio Interference Regulations of the Canadian Department of Communications.

Le present appareil numerique n'emet pas de bruits radioelectriques depassant les limites applicables aux appareils numeriques de la classe A prescrites dans le

Reglement sur le brouillage radioelectrique edicte par le

ministere des Communications du Canada.

HARSH™, NIS™, NOTI•FIRE•NET™, eVance™, and SWIFT™ are all trademarks; and Acclimate® Plus, FAAST®, FlashScan®, NION®, NOTIFIER®,

ONYX®, ONYXWorks®, UniNet®, VeriFire®, and VIEW® are all registered trademarks of Honeywell International Inc. Echelon® is a registered trademark

and LonWorks™ is a trademark of Echelon Corporation. ARCNET® is a registered trademark of Datapoint Corporation. Microsoft® and Windows® are

registered trademarks of the Microsoft Corporation.

©2014 by Honeywell International Inc. All rights reserved. Unauthorized use of this document is strictly prohibited.

NFS2-640/E Programming Manual — P/N 52742:L2 7/17/14 3

Page 4

Software Downloads

In order to supply the latest features and functionality in fire alarm and life safety technology to our customers, we make

frequent upgrades to the embedded software in our products. To ensure that you are installing and programming the latest

features, we strongly recommend that you download the most current version of software for each product prior to

commissioning any system. Contact Technical Support with any questions about software and the appropriate version for a

specific application.

Documentation Feedback

Your feedback helps us keep our documentation up-to-date and accurate. If you have any comments or suggestions about our

online Help or printed manuals, you can email us.

Please include the following information:

•Product name and version number (if applicable)

•Printed manual or online Help

•Topic Title (for online Help)

•Page number (for printed manual)

•Brief description of content you think should be improved or corrected

•Your suggestion for how to correct/improve documentation

Send email messages to:

FireSystems.TechPubs@honeywell.com

Please note this email address is for documentation feedback only. If you have any technical issues, please contact Technical

Services.

4 NFS2-640/E Programming Manual — P/N 52742:L2 7/17/14

Page 5

Table of Contents

Section 1: General Information................................................................................................7

1.1: UL 864 Compliance.......................................................................................................................................7

1.1.1: Products Subject to AHJ Approval......................................................................................................7

1.1.2: Programming Features Subject to AHJ Approval ...............................................................................7

1.2: About This Manual ........................................................................................................................................8

1.2.1: Cautions, Warning, and Notes.............................................................................................................8

1.2.2: Typographic Conventions....................................................................................................................8

1.2.3: Supplemental Information ...................................................................................................................9

1.2.4: Shortcuts to Operating Functions ......................................................................................................10

1.3: Introduction to the Control Panel ................................................................................................................10

1.4: Features........................................................................................................................................................11

1.5: How to Enter a Password.............................................................................................................................11

Section 2: Programming ........................................................................................................13

2.1: Overview......................................................................................................................................................13

2.2: How to Enter Programming.........................................................................................................................14

2.3: Basic Program..............................................................................................................................................14

2.3.1: Clear Memory (0=

2.3.2: Autoprogram the Control Panel (1=

2.3.3: Modify or Delete a Point (2=

2.3.4: Change a Password (3=

2.3.5: Create a System Message (4=

2.3.6: Create a Custom Zone Label (5=

2.3.7: Program Special Zones (6=

2.3.8: Change Global System Functions (7=

2.3.9: How to Check the Program for Errors (8=

2.4: The Network Program .................................................................................................................................47

2.5: The Utility Program.....................................................................................................................................48

2.6: FlashScan Poll .............................................................................................................................................49

2.7: Setting the Baud Rate of Serial Ports ..........................................................................................................50

2.7.1: Printer Serial Port ..............................................................................................................................50

2.7.2: CRT Serial Port .................................................................................................................................51

CLR)......................................................................................................................15

AUTO)........................................................................................15

POINT)..................................................................................................19

PASSWD) .......................................................................................................25

MESSAGE) ...........................................................................................26

ZONE).............................................................................................27

SPL FUNCT).............................................................................................27

SYSTEM) .................................................................................31

CHECK PRG).....................................................................47

Section 3: Status Change.......................................................................................................52

3.1: Overview......................................................................................................................................................52

3.2: How to Enter Status Change........................................................................................................................52

3.3: Disable or Enable a Point ............................................................................................................................53

3.4: Changing Detector Sensitivity .....................................................................................................................54

3.5: Clearing Alarm Verification Counters .........................................................................................................55

3.6: Clearing the History Buffer .........................................................................................................................55

3.7: Setting the System Time and Date...............................................................................................................55

3.8: Walk Test .....................................................................................................................................................56

3.8.1: Basic Walk Test.................................................................................................................................57

3.8.2: Advanced Walk Test .........................................................................................................................58

3.8.3: Walk Test Activation Indications......................................................................................................58

3.8.4: Viewing Walk Test Results ...............................................................................................................59

A.1: Overview.....................................................................................................................................................60

A.1.1: Description of Releasing Zones........................................................................................................60

A.1.2: NFPA Releasing Applications..........................................................................................................61

A.2: How to Program a Releasing Zone .............................................................................................................61

A.2.1: Programming a Delay Timer ............................................................................................................61

A.2.2: Abort Switches..................................................................................................................................62

A.2.3: Using Cross Zones............................................................................................................................70

A.2.4: Programming a Soak Timer..............................................................................................................72

A.2.5: Using Type Codes for Releasing Zones ...........................................................................................73

NFS2-640/E Programming Manual — P/N 52742:L2 7/17/14 5

Page 6

Table of Contents

A.3: Initiating Devices ........................................................................................................................................91

A.4: Warning Sounders .......................................................................................................................................91

A.5: Auxiliary Control Functions .......................................................................................................................91

A.6: ACS Annunciation ......................................................................................................................................91

B.1: Presignal and Positive Alarm Sequence (PAS) ...........................................................................................92

B.1.1: What is Presignal and PAS?..............................................................................................................92

B.1.2: Selecting Presignal and PAS Outputs ...............................................................................................93

B.2: Time Control Zones.....................................................................................................................................93

B.3: Coding Functions for NACS .......................................................................................................................93

C.1: Overview .....................................................................................................................................................95

C.2: Features .......................................................................................................................................................95

C.2.1: Drift Compensation and Smoothing .................................................................................................95

C.2.2: Maintenance Warnings – Three Levels ............................................................................................96

C.2.3: Self-Optimizing Pre-Alarm...............................................................................................................97

C.2.4: Detector Sensitivity...........................................................................................................................97

C.2.5: Cooperative Multi-Detector Sensing ................................................................................................98

C.3: Pre-Alarm ....................................................................................................................................................99

C.3.1: Definition ..........................................................................................................................................99

C.3.2: Alert Level ........................................................................................................................................99

C.3.3: Action Level....................................................................................................................................100

C.3.4: How to Select a Pre-Alarm Level ..................................................................................................100

C.4: Detector Sensitivity Settings .....................................................................................................................101

C.4.1: How to Select Pre-Alarm and Alarm Sensitivity ............................................................................101

C.4.2: How to Test Detectors Set Below 0.50% Obscuration per Foot.....................................................102

C.5: Detector Maintenance Features.................................................................................................................103

C.5.1: Overview.........................................................................................................................................103

C.5.2: How to Access Detector Maintenance Information........................................................................103

C.5.3: View Detector Maintenance for a Detector ....................................................................................103

C.5.4: Print a Detector Maintenance Report..............................................................................................104

C.5.5: Interpreting a Detector Status Display or Maintenance Report ......................................................104

D.1: Description ................................................................................................................................................106

D.2: Input and Outputs......................................................................................................................................106

D.3: Equations...................................................................................................................................................106

D.4: Equation Entry ..........................................................................................................................................107

D.4.1: Logic Functions ..............................................................................................................................107

D.4.2: Equation Syntax Example...............................................................................................................108

D.4.3: Evaluating an Equation ...................................................................................................................108

D.4.4: Argument Entries............................................................................................................................108

D.4.5: Time Delay Functions.....................................................................................................................109

D.5: CBE Example............................................................................................................................................109

E.1: Overview ...................................................................................................................................................110

E.2: System Testing and Detector Initialization................................................................................................110

E.3: How to Replace a Detector.................................................................................................

.......................110

E.4: How to Manually Initialize a Detector ......................................................................................................111

F.1: What are Type Codes? ...............................................................................................................................112

F.2: How to Select a Type Code........................................................................................................................112

F.3: In this Appendix .........................................................................................................................................112

F.4: Type Codes for Input Devices....................................................................................................................112

F.4.1: Overview .........................................................................................................................................112

F.4.2: Type Codes for Intelligent Detectors ..............................................................................................112

F.4.3: Type Codes for Monitor Modules ...................................................................................................114

F.5: Type Codes for Output Devices .................................................................................................................115

F.5.1: Overview .........................................................................................................................................115

F.5.2: Type Codes for Control Modules ....................................................................................................115

F.5.3: NAC Type Codes ............................................................................................................................116

Index ......................................................................................................................................121

6 NFS2-640/E Programming Manual — P/N 52742:L2 7/17/14

Page 7

Section 1: General Information

1.1 UL 864 Compliance

1.1.1 Products Subject to AHJ Approval

This product has been certified to comply with the requirements in the Standard for Control Units

and Accessories for Fire Alarm Systems, UL 864 9th Edition.

A complete listing identifying which products have or have not received UL 864 9th Edition

certification is located in the installation manual of this fire alarm system. Those products which

have not received UL 864 9th Edition certification may only be used in retrofit applications.

Operation of the NFS2-640/E with products not tested for UL 864 9th Edition has not been

evaluated and may not comply with NFPA 72 and /or UL 864. These applications will require the

approval of the local Authority Having Jurisdiction (AHJ).

1.1.2 Programming Features Subject to AHJ Approval

This product incorporates field-programmable software. The features and/or options listed below

must be approved by the local AHJ.

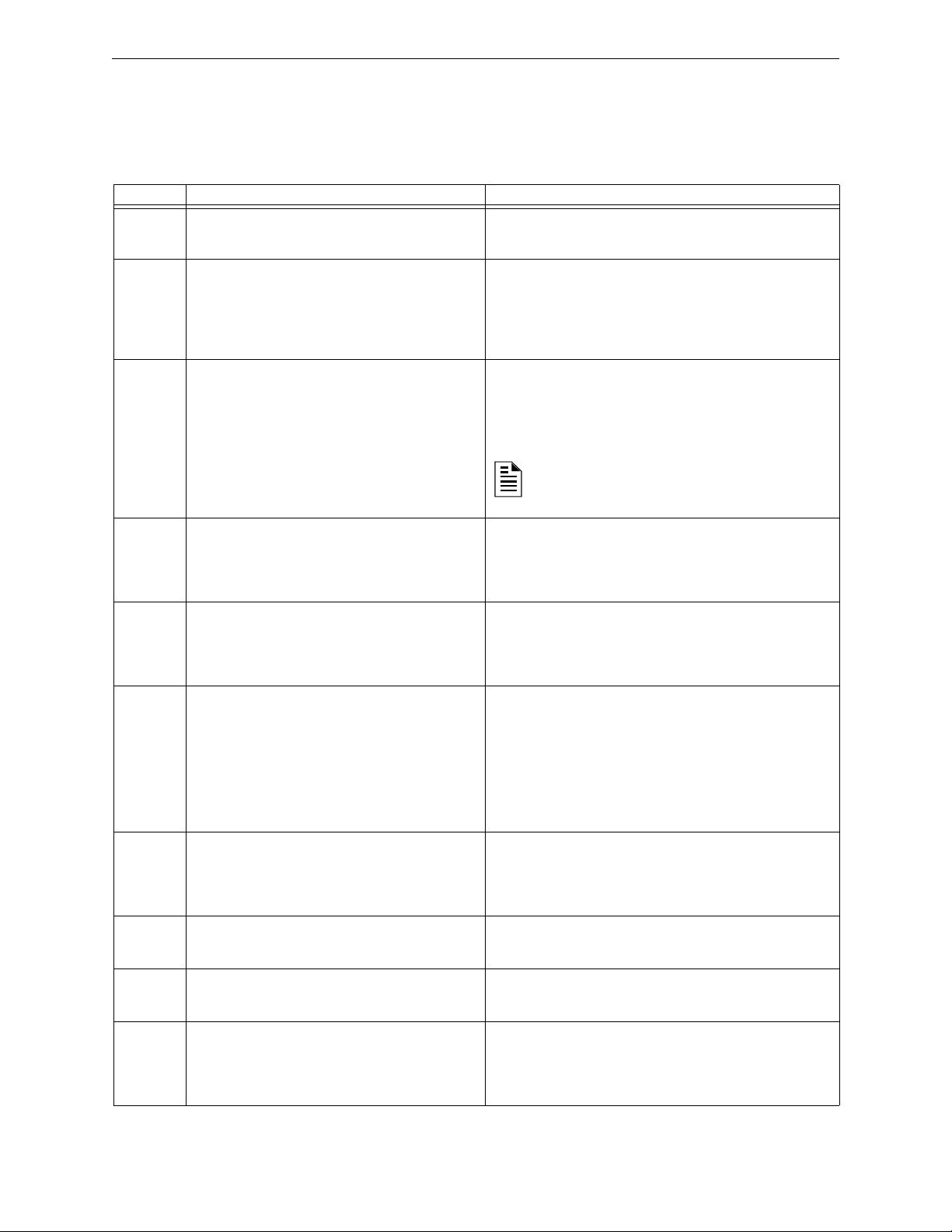

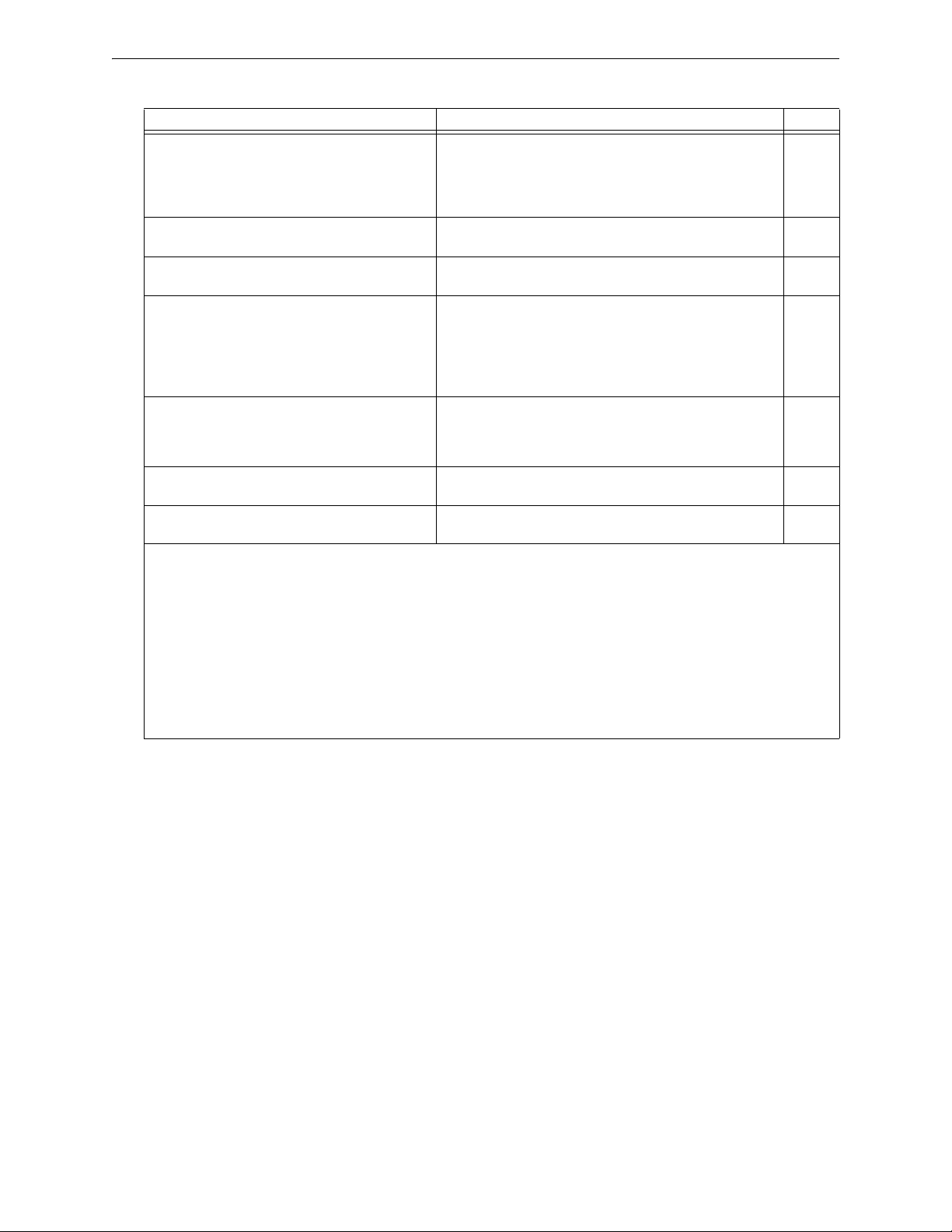

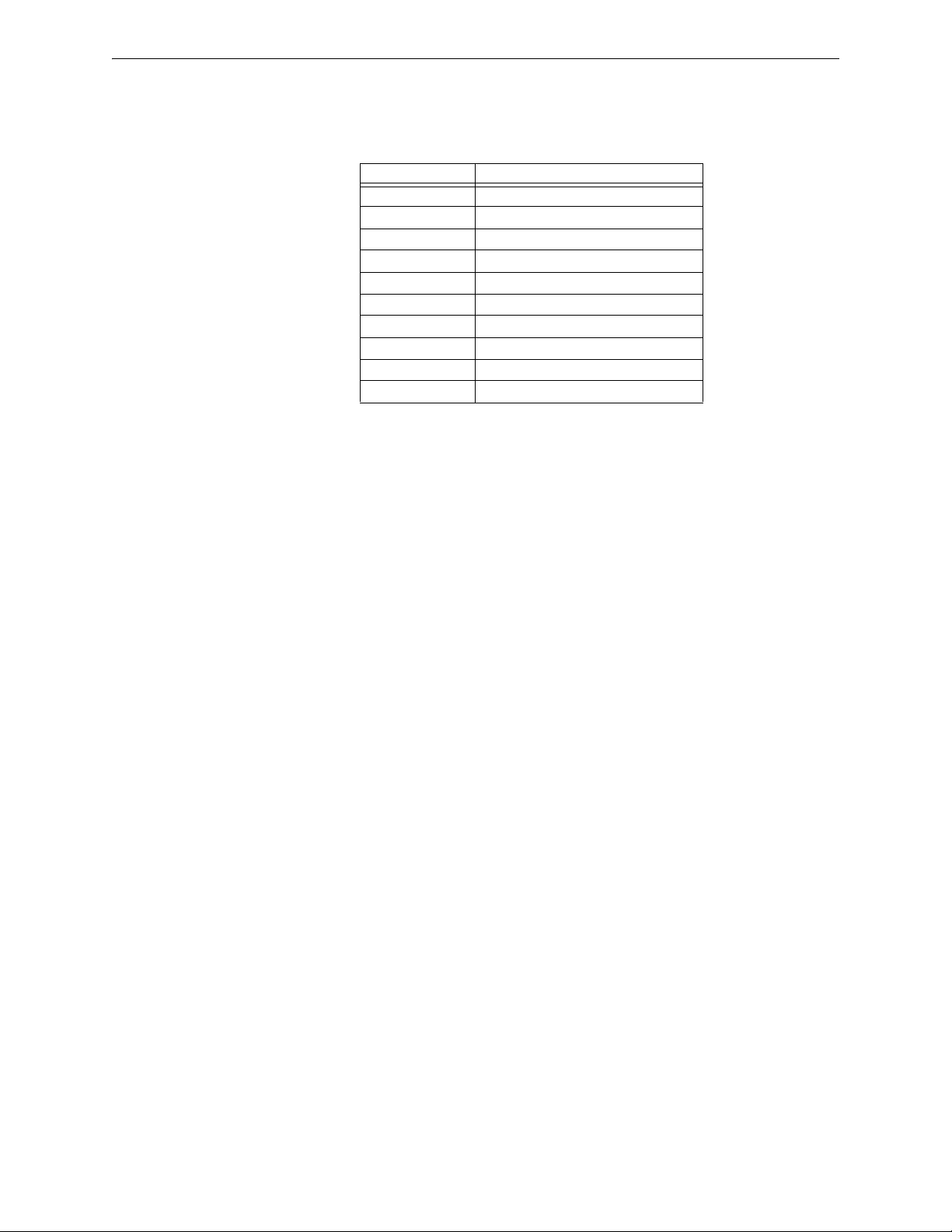

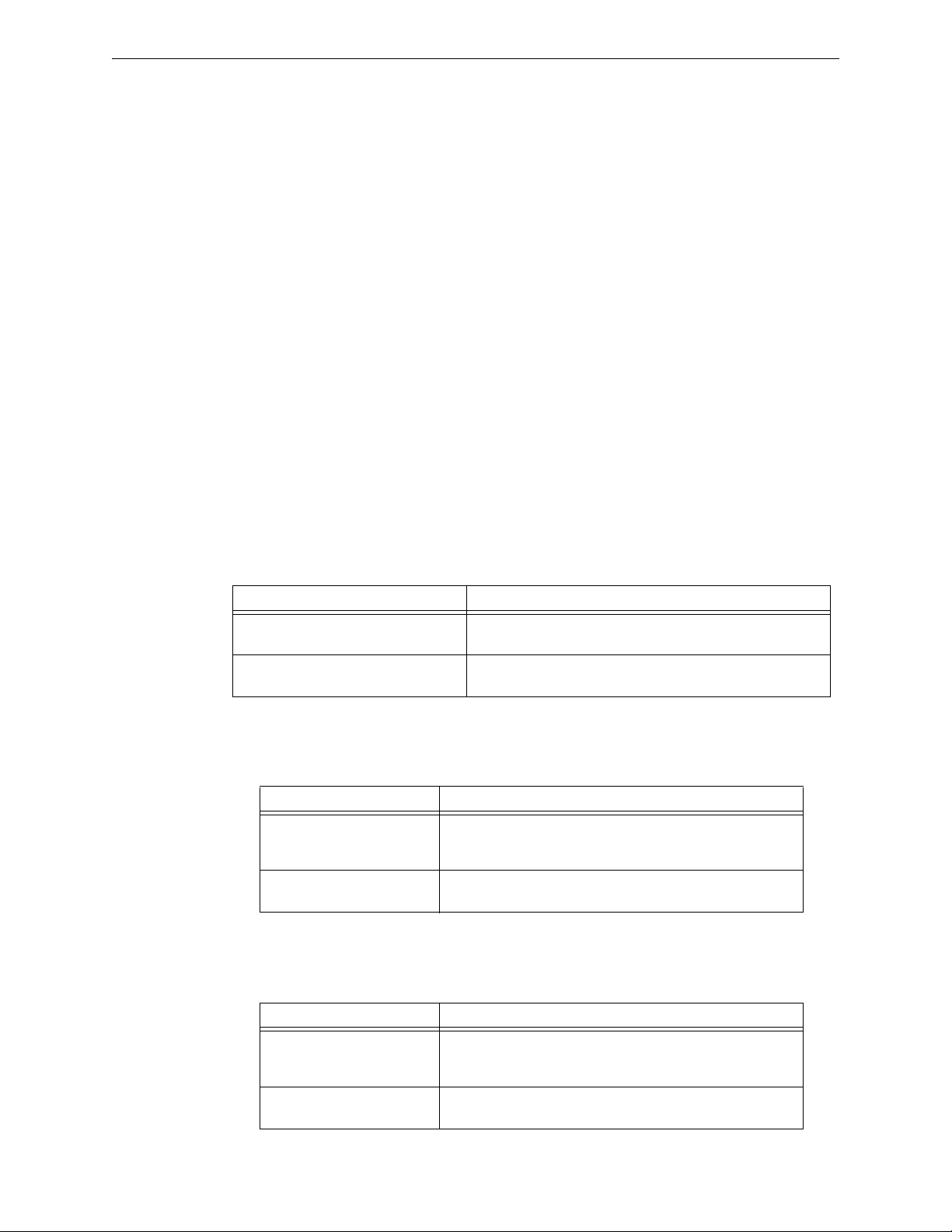

Table 1.1 Programming Settings

This product incorporates field-programmable software. In order for the product to comply with the requirements in the Standard for

Control Units and Accessories for Fire Alarm Systems, UL 864, certain programming features or options must be limited to specific values

or not used at all as indicated below.

Program Feature or Option Permitted in UL 864? (Y/N) Possible Settings Settings Permitted in UL 864

IP downloads over a local area network

(LAN) or the internet (WAN - WIde Area

Network)

Releasing: Abort Switch Yes NYC

Detector Programming: Supervisory

Type Codes

ALA.SCROLL (Scroll Display) No Y

TBL.REMIND Yes *, 1, 2, 3, 4, 5 2

REGION No 0 (No special setting)

No Yes

Yes SUP L(DUCTI)

No

Timed

AHJ

ULI

IRI

SUP T(DUCTI)

SUP T(DUCTP)

SUP L(DUCTP)

SUP L(ION)

SUP T(ION)

SUP L(PHOTO)

SUP T(PHOTO)

SUP L(LASER)

SUP T(LASER)

PHOTO/CO (P SUP)

N

1 (China)

No

ULI

IRI

SUP L(DUCTI)

SUP T(DUCTI)

SUP L(DUCTP)

SUP T(DUCTP)

N

0 (No special setting)

NFS2-640/E Programming Manual — P/N 52742:L2 7/17/14 7

Page 8

General Information About This Manual

!

!

1.2 About This Manual

1.2.1 Cautions, Warning, and Notes

The following graphics appear in the manual to indicate a caution or a warning.

CAUTION:

Information about procedures that could cause programming errors, runtime errors, or equipment

damage.

WARNING:

Information about procedures that could cause irreversible damage to the control panel, irreversible

loss of programming data or personal injury.

NOTE: Information that highlights an important part of the preceding or subsequent text or

illustration.

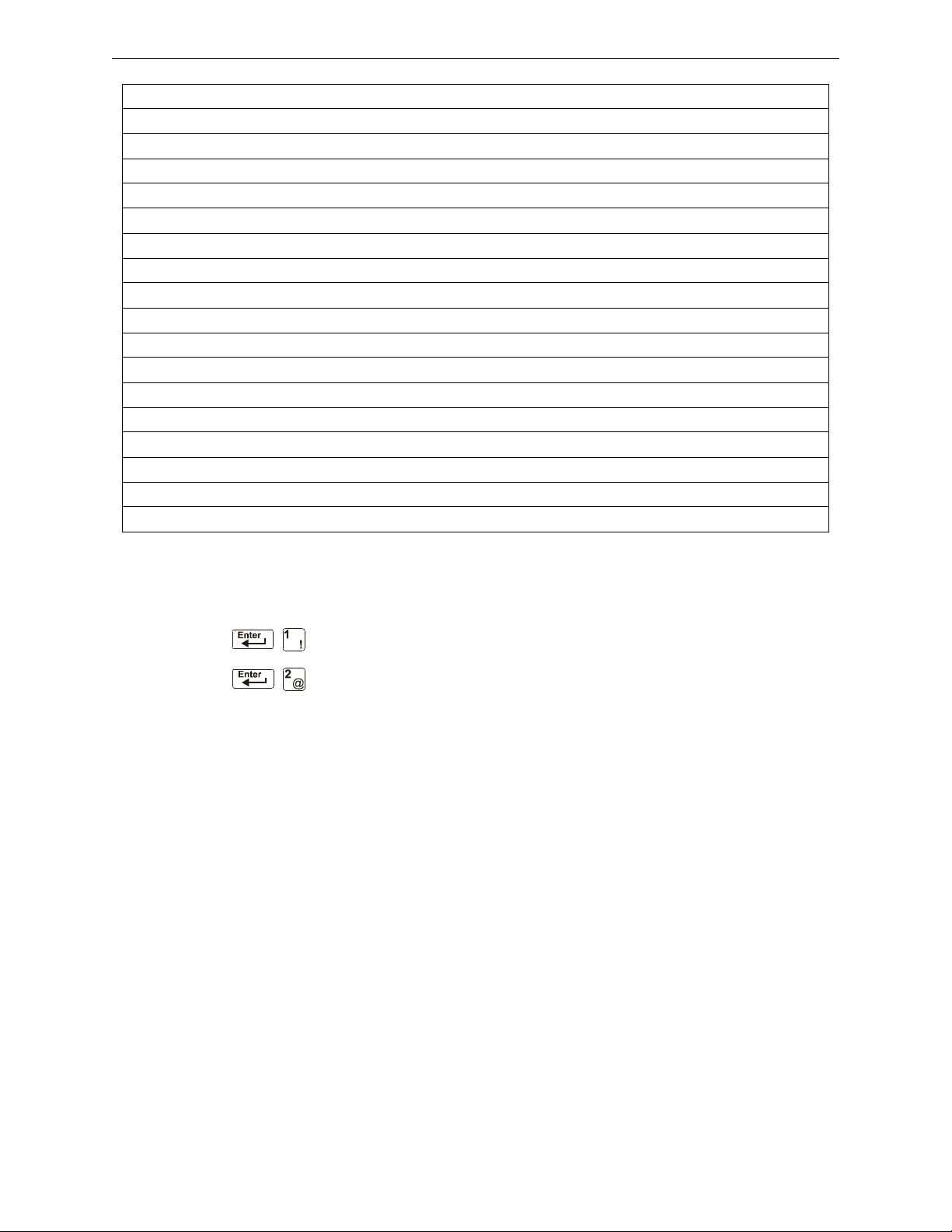

1.2.2 Typographic Conventions

This manual uses the following conventions as listed below:

Table 1.2 Typographic Conventions in this Manual

When you see Specifies Example

the text as it appears in

text in small caps

text in quotes

bold text

italic text a specific document NFS2-640 Installation Manual

a graphic of the key

the LCD display or on the

control panel

a reference to a section or

an LCD menu screen

In body text, a number or

character that you enter

In a graphic, a key as it

appears on the control

panel

MARCH TIME is a selection that appears

in the LCD display; or Press the

key

“Status Change” specifies the Status

Change section or menu screen

Press 1; means to press the number

“1” on the keypad

Press means to press the Escape

key

ENTER

NOTE: The term NFS2-640 is used in this manual to refer to the NFS2-640 and NFS2-640E

unless otherwise noted.

8 NFS2-640/E Programming Manual — P/N 52742:L2 7/17/14

Page 9

About This Manual General Information

1.2.3 Supplemental Information

The table below provides a list of documents referenced in this manual, as well as documents for

selected other compatible devices. The document series chart (DOC-NOT) provides the current

document revision. A copy of this document is included in every shipment.

Compatible Conventional Devices (Non-addressable) Document Number

Device Compatibility Document 15378

Fire Alarm Control Panel (FACP) and Main Power Supply Installation Document Number

NFS2-640/E Installation, Operations, and Programming Manuals 52741, 52742, 52743

SLC Wiring Manual 51253

Note: For individual SLC Devices, refer to the SLC Wiring Manual

Off-line Programming Utility Document Number

Ver iFir e

Veri•Fire Medium Systems Help File

Cabinets & Chassis Document Number

CAB-3/CAB-4 Series Cabinet Installation Document 15330

Battery/Peripherals Enclosure Installation Document 50295

Power Supplies, Auxiliary Power Supplies & Battery Chargers Document Number

ACPS-610 Addressable Power Supply Manual 53018

ACPS-2406 Installation Manual 51304

APS-6R Instruction Manual 50702

APS2-6R Instruction Manual 53232

CHG-120 Battery Charger Manual 50641

FCPS-24 Field Charger/Power Supply Manual 50059

FCPS-24S Field Charger/Power Supply Manual (Sync) 51977

Networking Document Number

Noti•Fire•Net Manual, Network Version 4.0 & Higher 51584

High-Speed Noti•Fire•Net Manual 54013

HS-NCM Installation Document 54014

NCM-W/F Installation Document 51533

NCS Network Control Station Manual, Network Version 4.0 & Higher 51658

NCA-2 Network Control Annunciator Manual 52482

ONYXWorks™ Workstation Manuals 52305, 52306, 52307

System Components Document Number

DVC Digital Voice Command Manual 52411

DAL Device Reference Document 52410

DVC-RPU Manual 50107425-001

DVC-RPU UL Listing Document 50107424-001

DS-DB Digital Series Distribution Board and Amplifier Manual 53622

DAA2 and DAX Amplifiers Manual 53265

Annunciator Control System Manual 15842

Annunciator Fixed Module Manual 15048

®

Tools CD help file

VERIFIRE-TCD

VERIFIRE-CD

Table 1.3 Related Documentation (1 of 2)

NFS2-640/E Programming Manual — P/N 52742:L2 7/17/14 9

Page 10

General Information Introduction to the Control Panel

AFM-16A Annunciator Fixed Module Manual 15207

ACM-8R Annunciator Control Module Manual 15342

LCD-80 Manual 15037

LCD2-80 Manual 53242

FDU-80 Remote Annunciator Manual 51264

LDM Series Lamp Driver Annunciator Manual 15885

SCS Smoke Control Manual (Smoke and HVAC Control Station) 15712

FireVoice-25/50ZS & FireVoice 25/50ZST Manual 52290

FirstCommand Emergency Communication System LS10001-001NF-E

RPT-485W/RPT-485WF EIA-485 Annunciator Loop Repeater Manual 15640

DPI-232 Direct Panel Interface Manual 51499

TM-4 Installation Document (Reverse Polarity Transmitter) 51490

UDACT Manual (Universal Digital Alarm Communicator/Transmitter) 50050

UDACT-2 (Universal Digital Alarm Communicator/Transmitter) Listing Document 54089LD

UDACT-2 Manual (Universal Alarm Communicator/Transmitter) 54089

ACT-2 Installation Document 51118

RM-1 Series Remote Microphone Installation Document 51138

RA100Z Remote LED Annunciator Installation Document I56-0508

Table 1.3 Related Documentation (2 of 2)

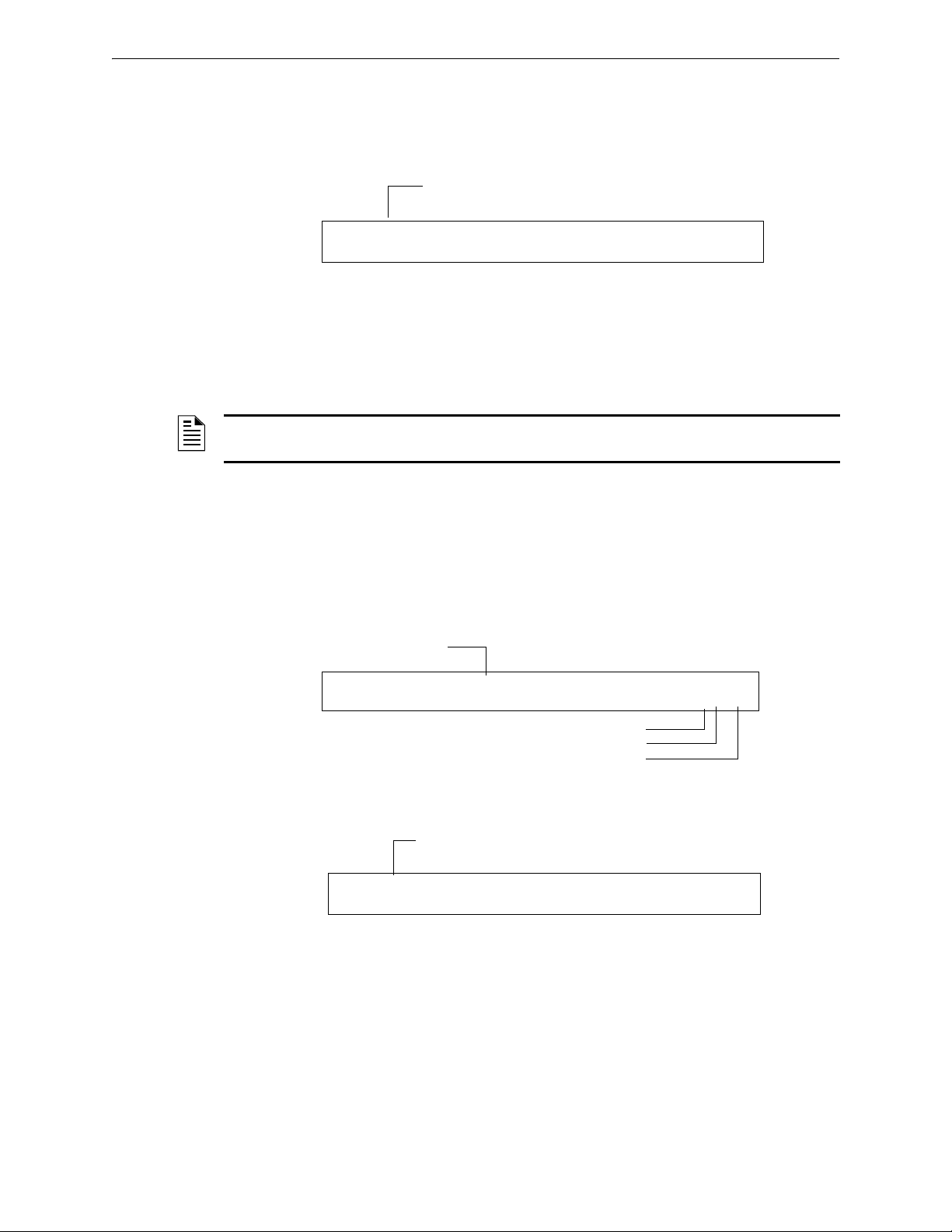

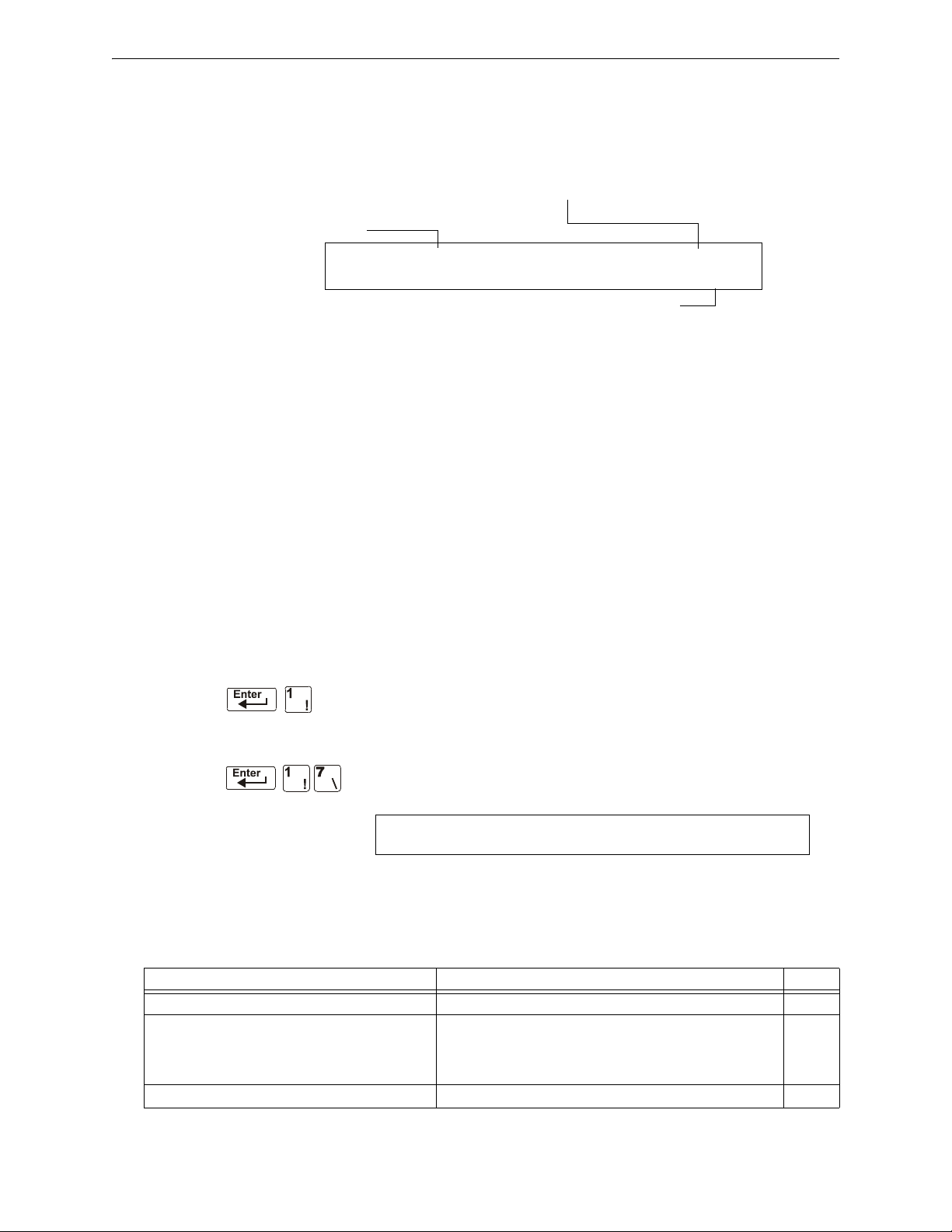

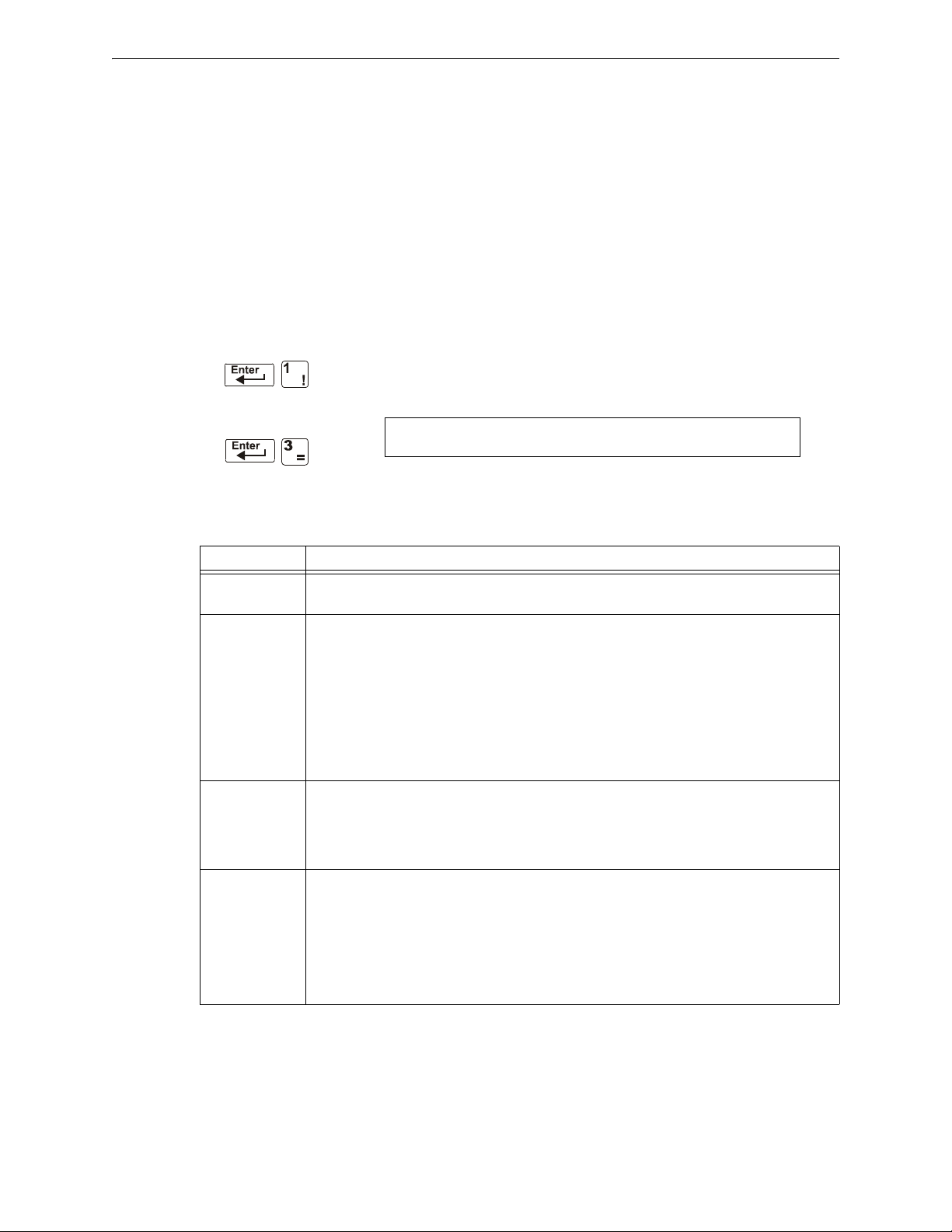

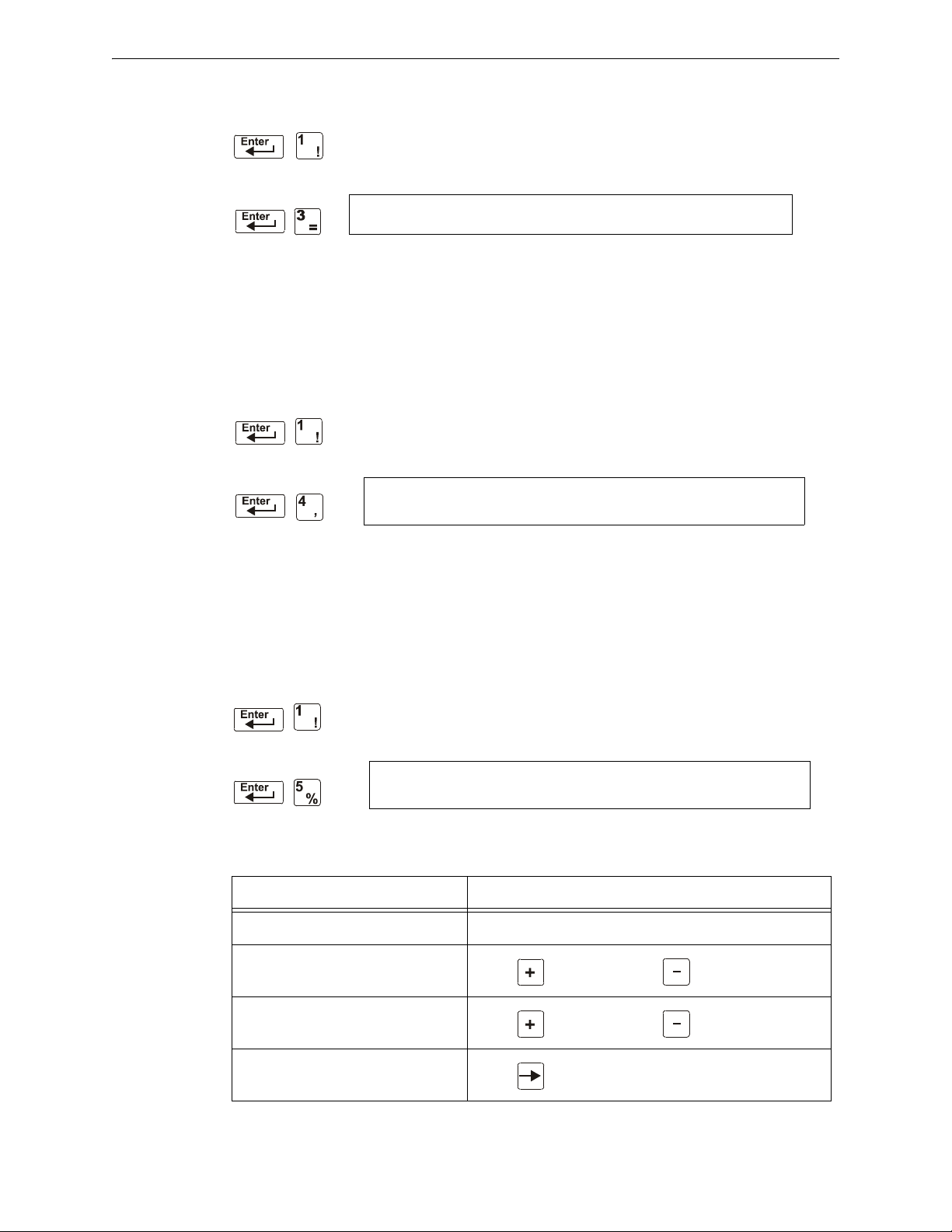

1.2.4 Shortcuts to Operating Functions

To the left of each program function, you’ll find a keypad shortcut, which contains

a series of keypad entries required to access the program function. All shortcuts

start with the control panel in normal operation.

For example, the keypad shortcut to the left shows how to enter the Read Status

function with the control panel in normal operation.

1.3 Introduction to the Control Panel

The NFS2-640 is an intelligent, field-programmable Fire Alarm Control Panel. Field-programming

the control panel lets you customize the fire alarm system by selecting and setting program options

for intelligent/addressable detectors and modules, and Notification Appliance Circuits (NACs).

This manual provides information for programming using the NFS2-640 keypad connected to the

control panel. VeriFire™ Tools must be used for programming if no keypad is used, or if a network

control annunciator is used as the keypad in either a network or standalone application. Refer to

VeriFire™ Tools for information on programming without the NF2S-640 keypad, and the NF2S-

640 Installation Manual and NCA-2 Manual for installation information.

For details on control panel operation, refer to the NFS2-640 Operations Manual.

The NF2S-640 provides two methods for field-programming the control panel:

• Using the built-in “Program Change” interface

• The VeriFire™ Tools Programming Utility

10 NFS2-640/E Programming Manual — P/N 52742:L2 7/17/14

Page 11

Features General Information

The benefits of each method are listed below:

Programming method Benefits Refer to

1.4 Features

Programming features include the following:

Program Change Speed and convenience of

putting the control panel on

line quickly (using the

Autoprogram function) and

changing programming

information.

VeriFire™ Tools

Programming Utility

Efficient means of creating

and editing programs that

require a lot of data entry.

Section “Programming” on

page 13

Product documentation &

Software help file

• Ease-of-use – Field program the control panel without needing special software skills.

• Autoprogram option – Automatically detects newly installed, addressable devices, allowing

quicker installation.

• Local programming – program directly from the control panel keypad to reduce installation

time.

• PC programming – input long data entry programming information on a PC; transfer

programming data between a PC and the control panel using VeriFire™ Tools programming

utility.

• Security – use passwords to control access to the control panel and protect memory.

• 80-Character (2x40) Liquid Crystal Display – view programming and device information on

the control panel.

1.5 How to Enter a Password

The control panel provides two types of selectable passwords:

• Program Change

•Status Change

Listed below are uses and the factory-setting for each password type:

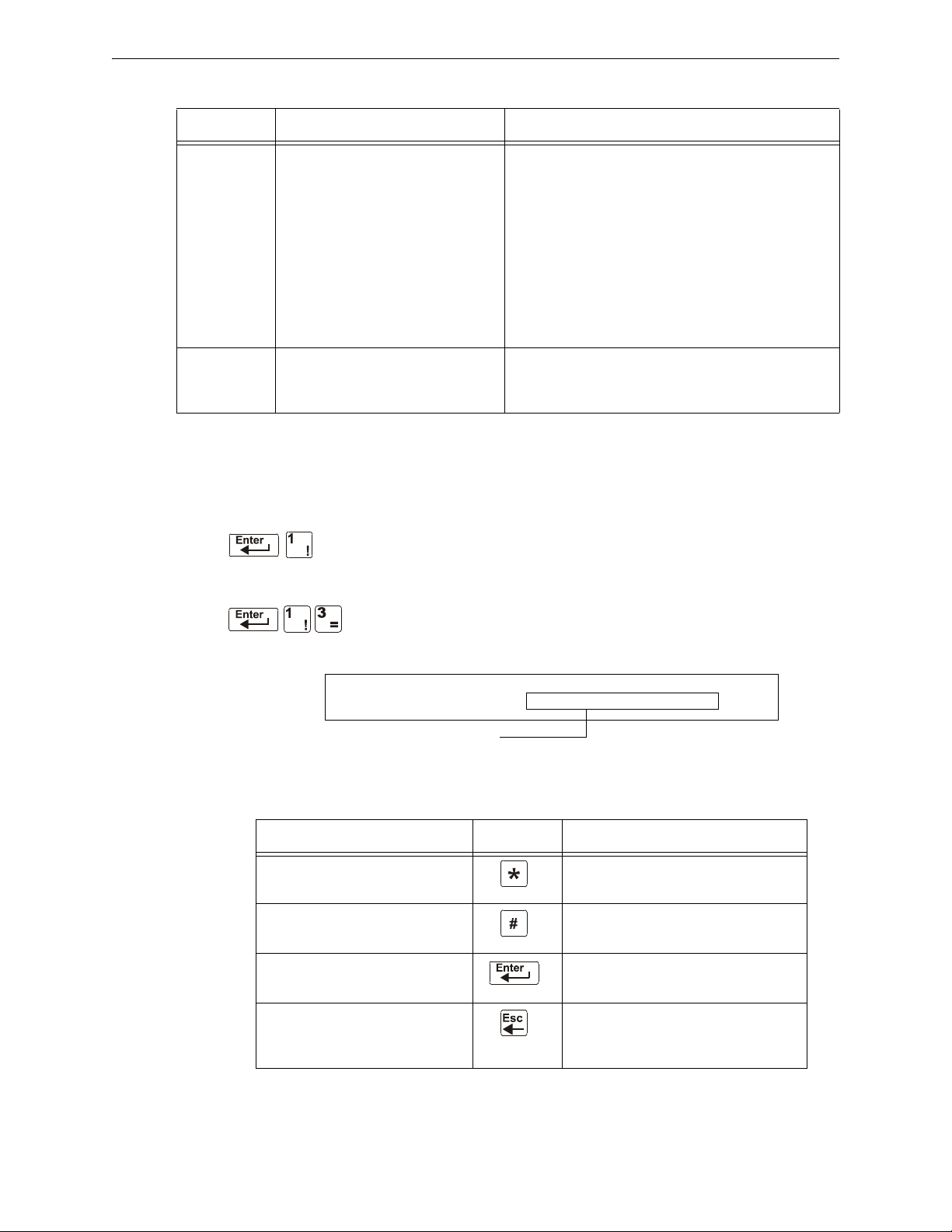

Table 1.4 Programming Passwords

Password

type

Program

Change

(high level)

Status Change

(low level)

Use to

Enter Program Change option to program

essential control panel functions, including basic

system functions and utility options.

Enter Status Change option to program minor

functions.

Factory

Setting

00000

11111

NFS2-640/E Programming Manual — P/N 52742:L2 7/17/14 11

Page 12

General Information How to Enter a Password

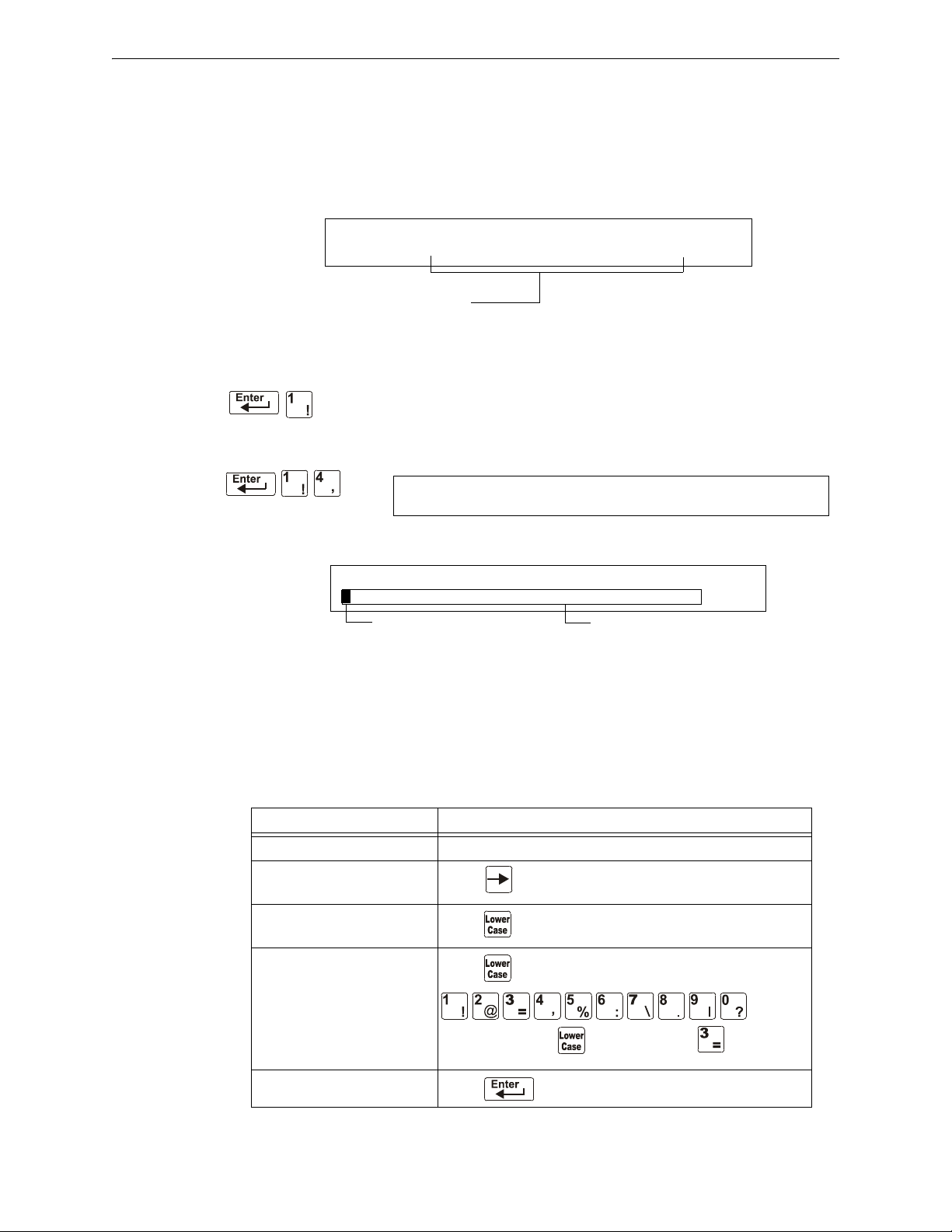

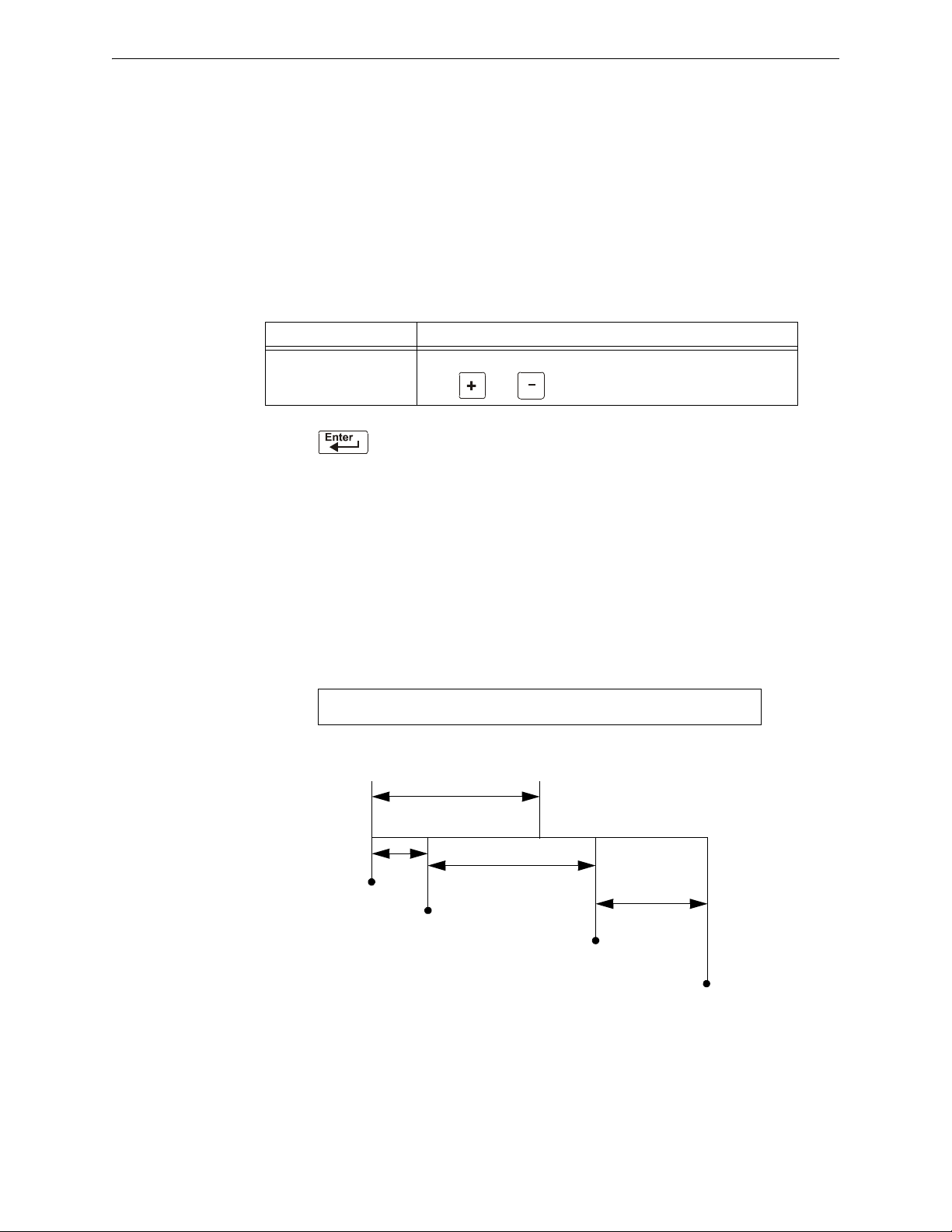

Enter password here (00000 or 11111)

ENTER PROG OR STAT PASSWORD, THEN ENTER.

(ESCAPE TO ABORT) _

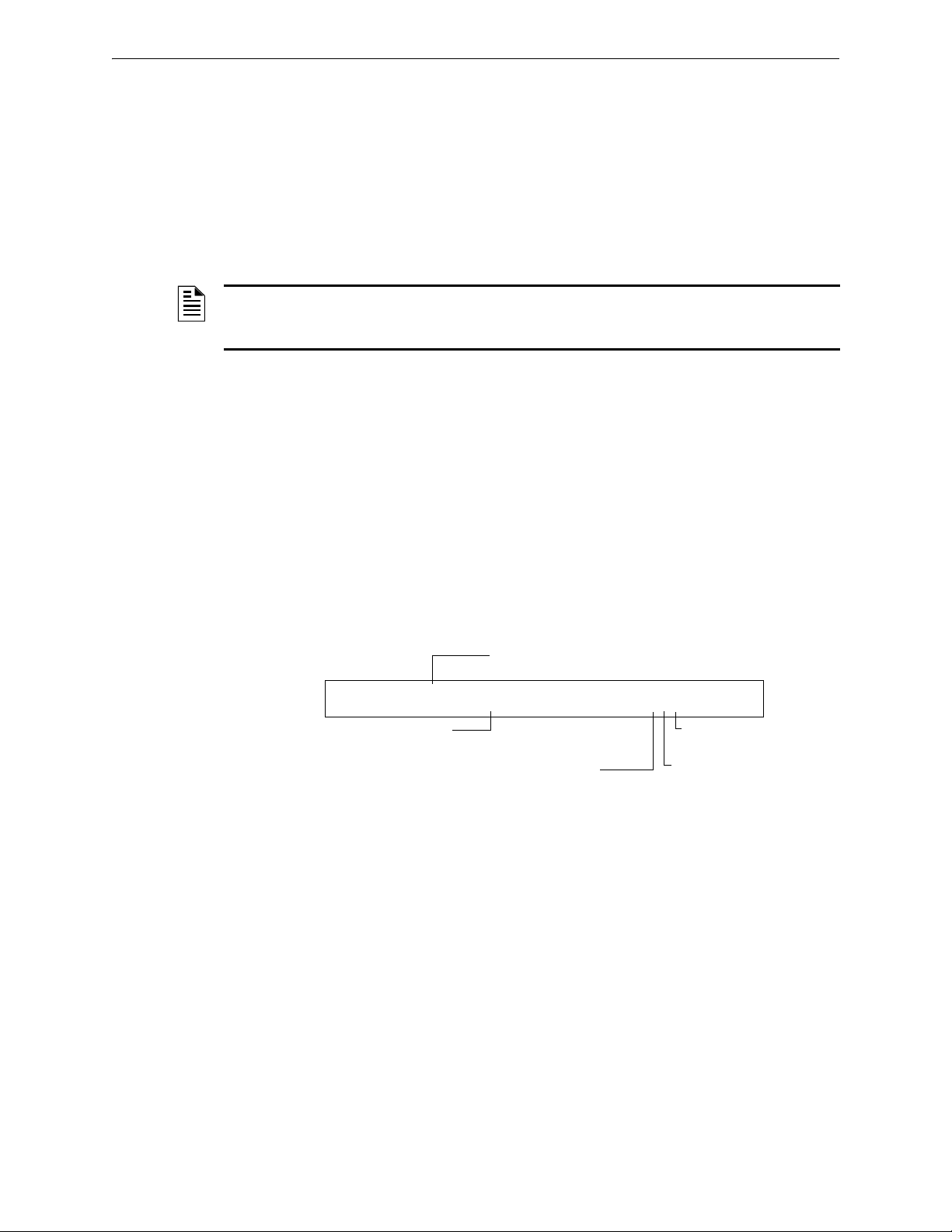

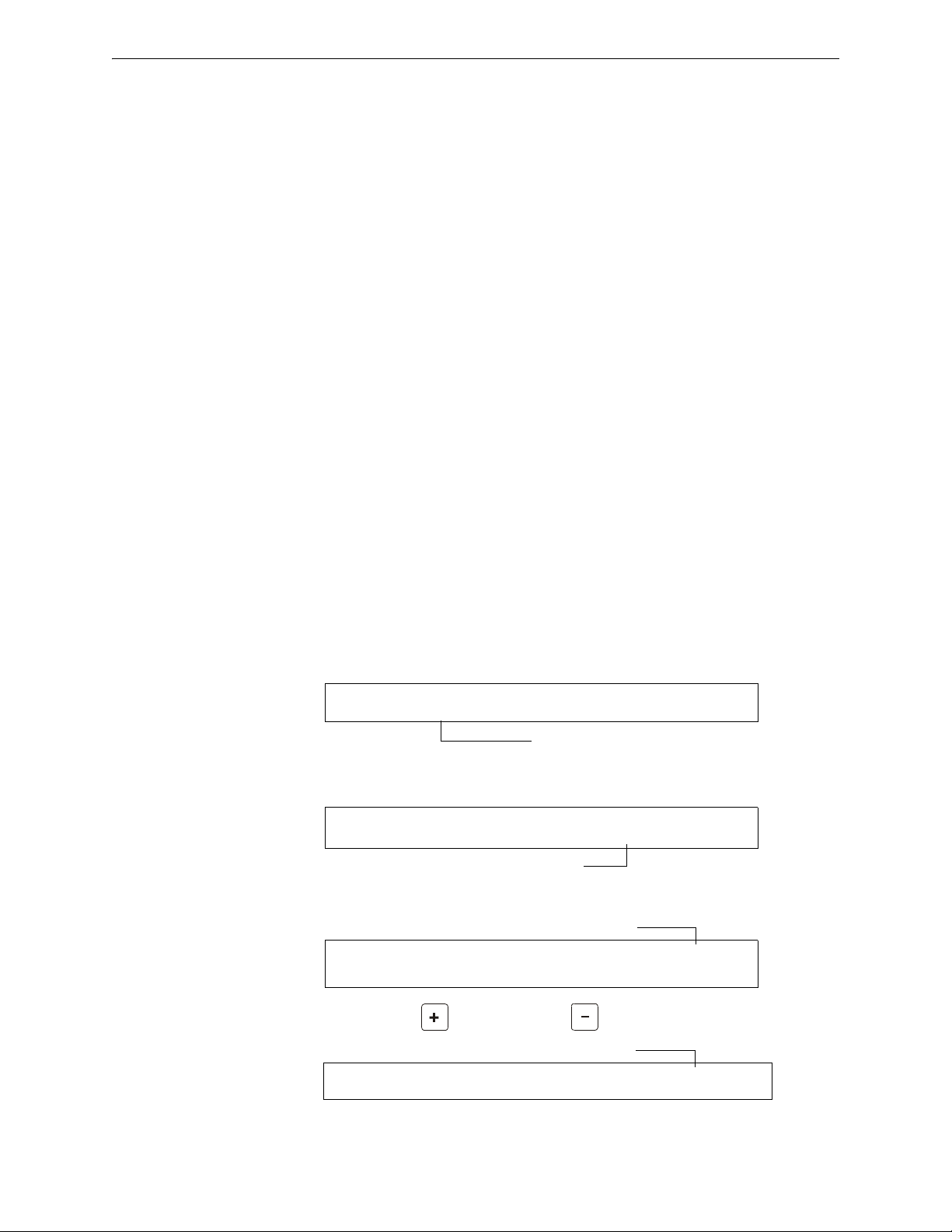

From the “SYSTEM NORMAL” screen: Press ENTER, press 1 (the password screen will display).

Enter a password, then press

ENTER

Figure 1.1 Password Screen

In Program Change or Status Change, the control panel does the following:

• Activates the System Trouble relay

• Shuts off the panel sounder

• Flashes the

SYSTEM TROUBLE LED, which continues to flash while programming

For security purposes, passwords can be changed. To do so, follow the instructions in “Change a

Password (3=passwd)” on page 25.

NOTE: The Read Status selection, which does not require a program password, is covered in

the NF2S-640 Operations Manual.

NOTE: The NF2S-640 continues to monitor and report alarms in programming mode, except in

autoprogramming.

12 NFS2-640/E Programming Manual — P/N 52742:L2 7/17/14

Page 13

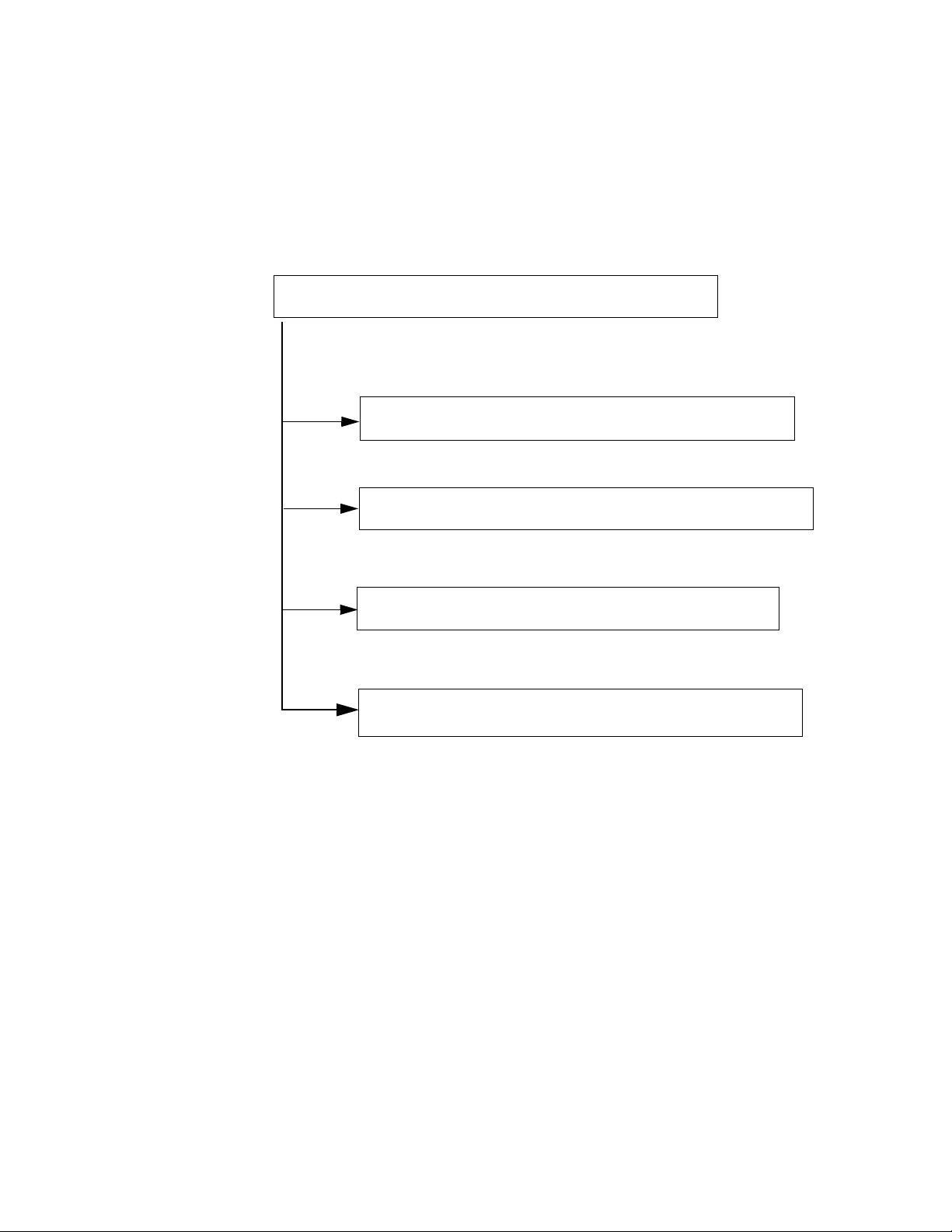

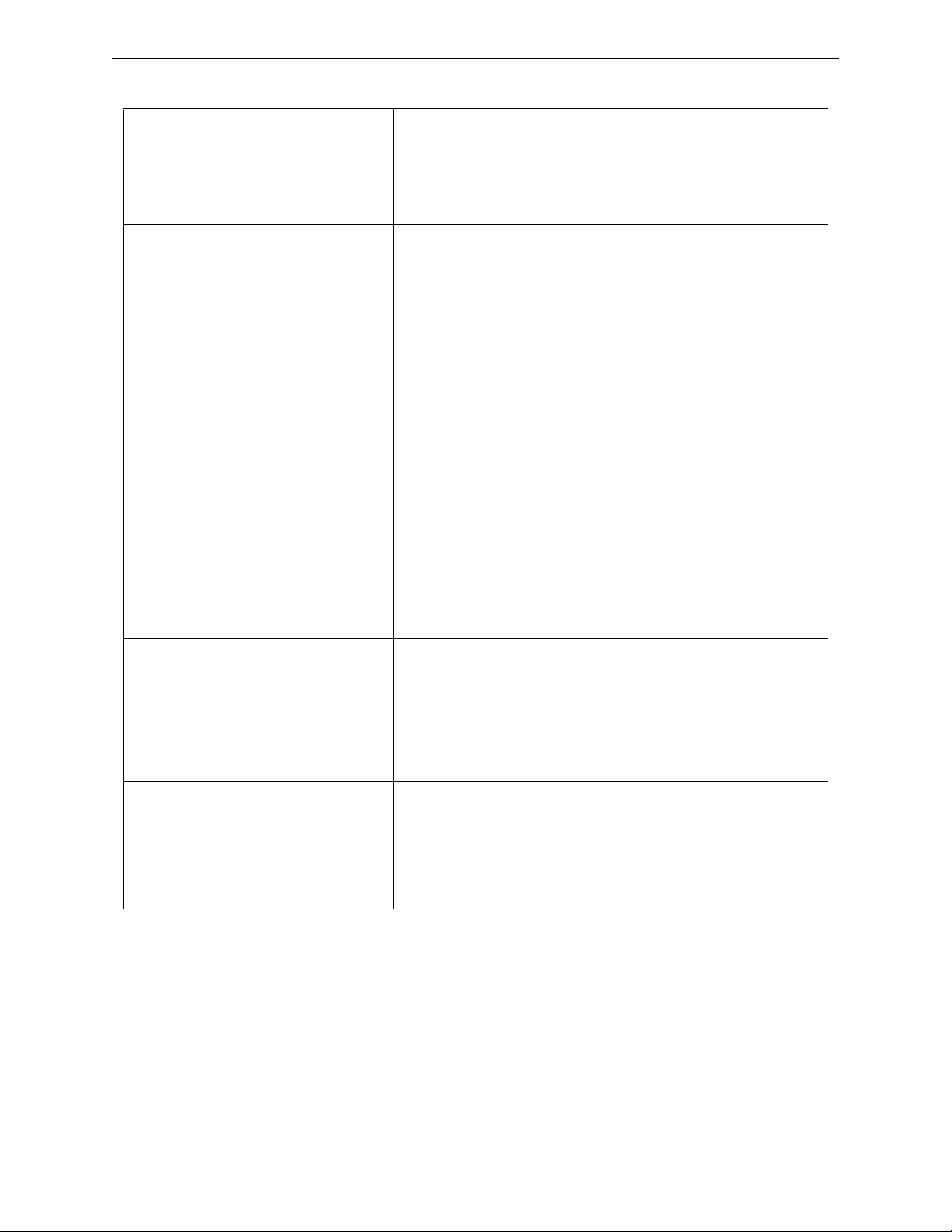

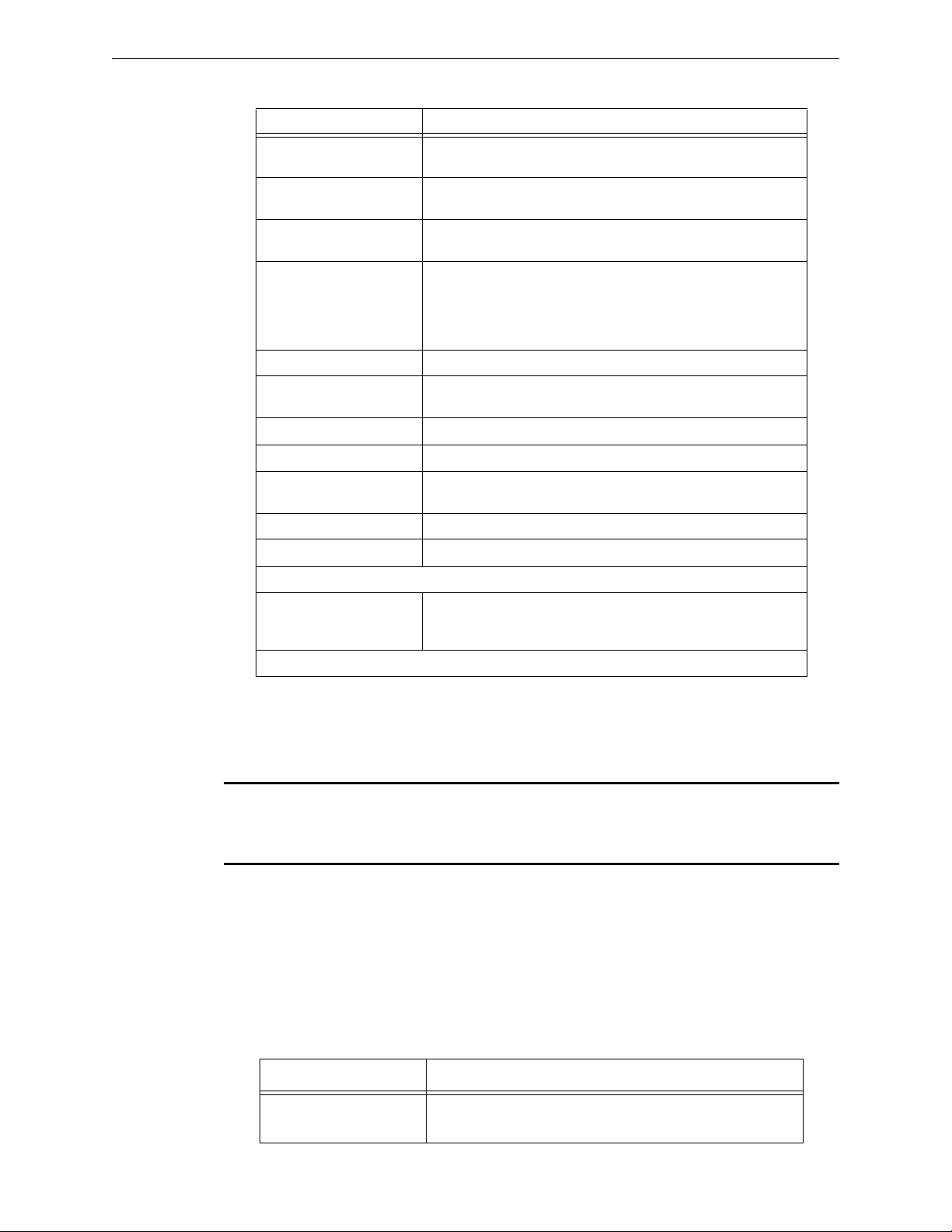

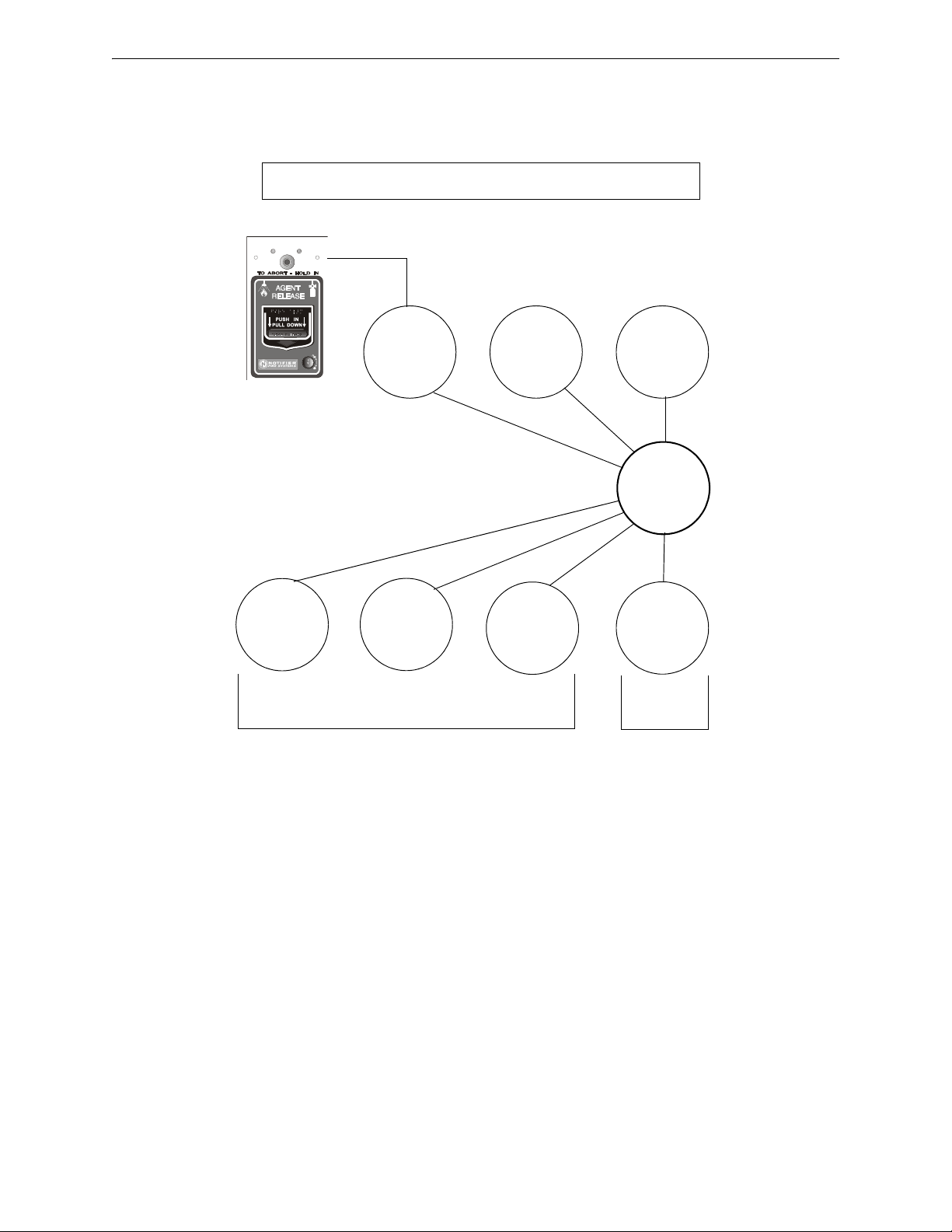

2.1 Overview

Choose one of the Program Change selections: 1, 2, 3 or 4

1 Basic Program options

3 Utility Program options

4 FlashScan Poll options

2 Network Program options

1=BASIC PROGRAM 2=NETWORK

3-UTILITY 4=FLASHSCAN POLL

0=CLR 1=AUTO 2=POINT 3=PASSWD 4=MESSAGE

5=ZONES 6=SPL FUNCT 7=SYSTEM 8=CHECK PRG

THRESHOLD CH.A:H, THRESHOLD CH.B:H

NODE: .000, STYLE7:Y, <ENTER>

REGION=0 TBL.REMIND=2 ALA.SCROLL=N

LOCAL CONTROL=0

FLASHSCAN L1DET L1MOD L2DET L2MOD

NYNY

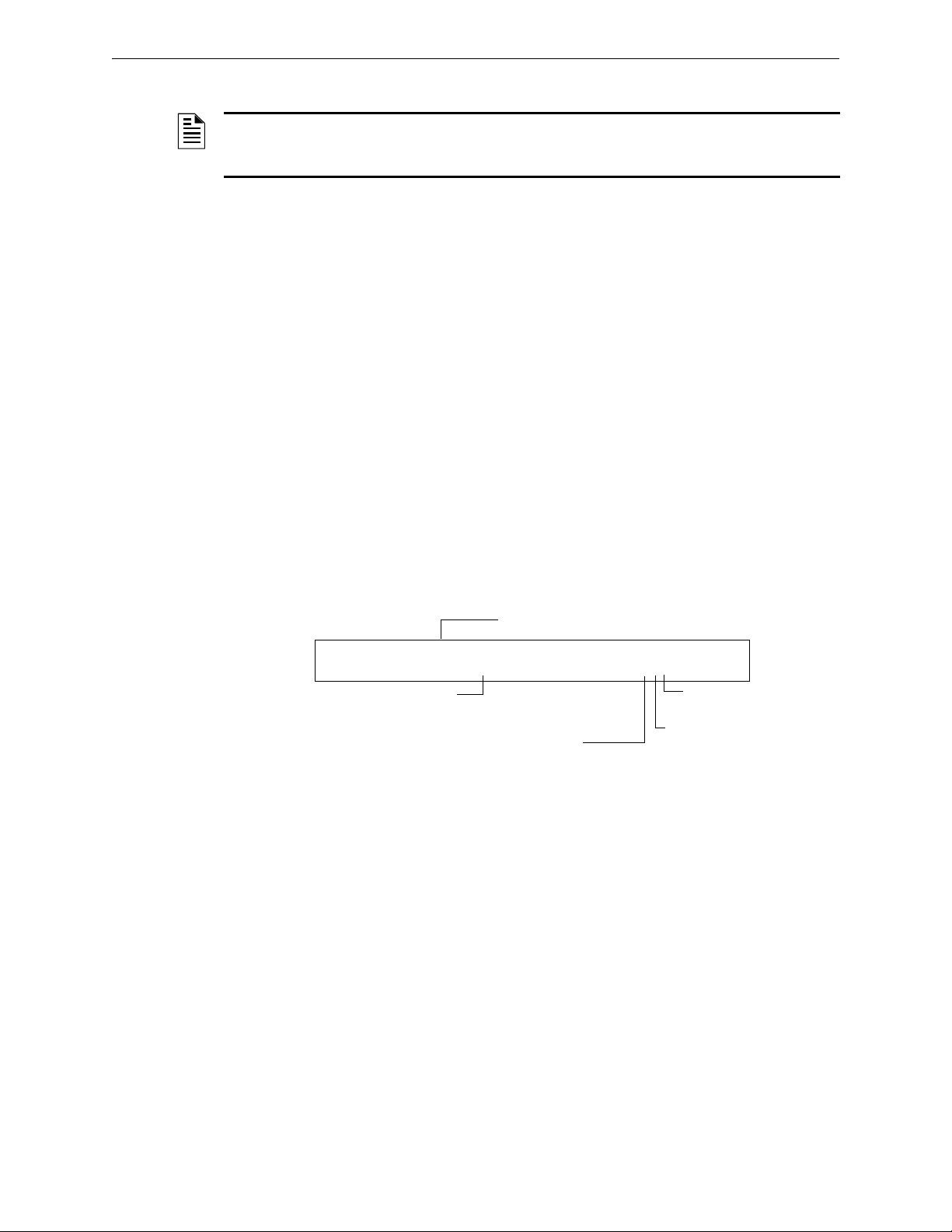

Program Change is the programming level that lets you change the essential control panel

functions, such as point programming, changing passwords, changing system functions. Included

are four options: Basic Program, Network, FlashScan Poll, and Utility Program.

The structure of the Program Change option is shown below:

Section 2: Programming

This section contains instructions and sample screens for using the Programming selections:

Figure 2.1 Program Change Selections

• Basic Program The Basic Program lets you program essential functions, such as clearing

the program, Autoprogramming the system, programming points, and setting system

functions. Refer to “Basic Program” on page 14.

• Network Program The Network Program allows programming of network channel

thresholds, network node number, and wiring style.“The Network Program” on page 47.

• Utility Program The Utility Program screen provides selections for selecting a Trouble

Reminder per NFPA, a Region setting, and enabling or disabling local control of the

ACKNOWLEDGE/SCROLL DISPLAY, SIGNAL SILENCE, SYSTEM RESET and DRILL keys. Refer to

“The Utility Program” on page 48.

• FlashScan Poll The FlashScan Poll screen provides the option for selecting between CLIP

NFS2-640/E Programming Manual — P/N 52742:L2 7/17/14 13

(Classic Loop Interface Poll) and FlashScan Poll. Refer to “FlashScan Poll” on page 49.

Page 14

Programming How to Enter Programming

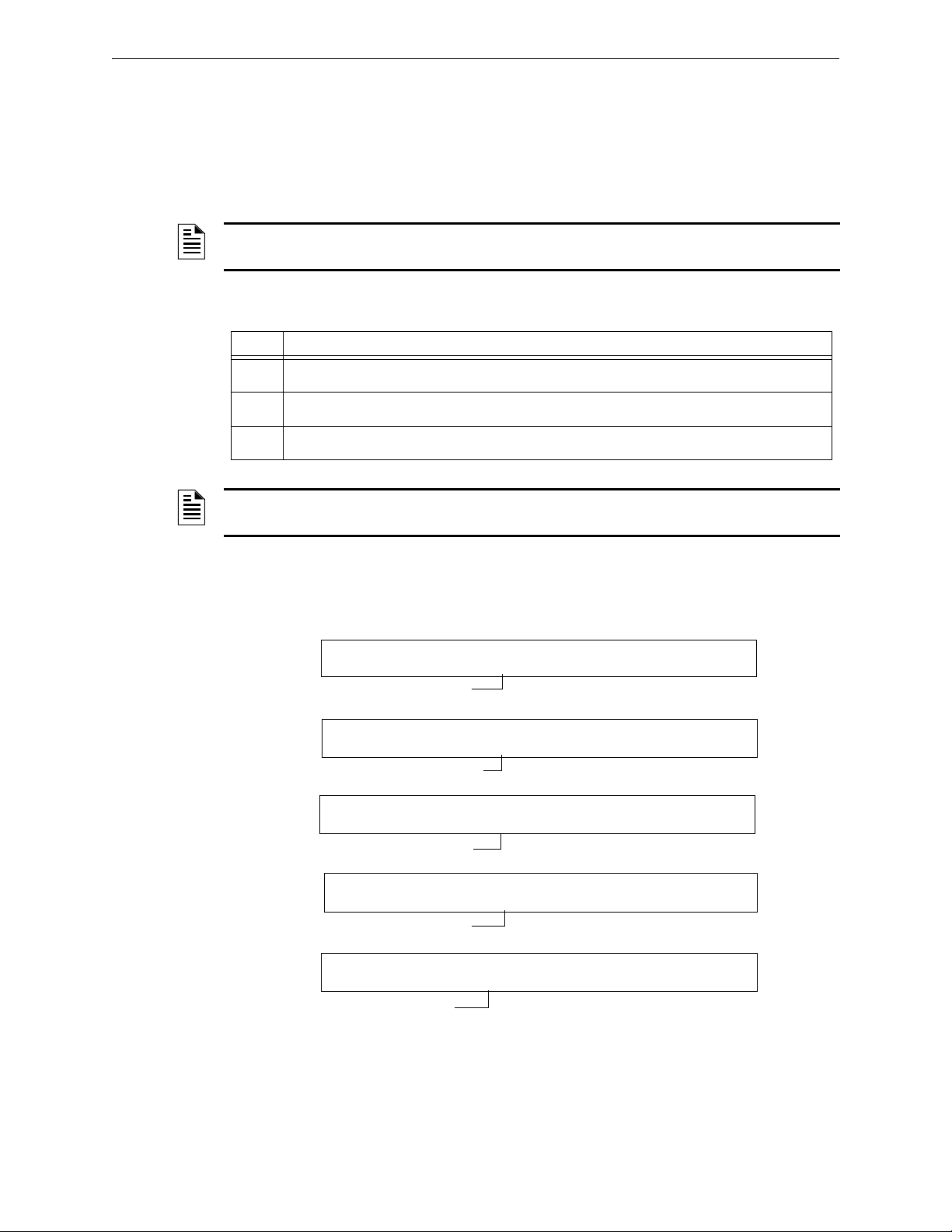

1=PROGRAMMING 2=READ STATUS ENTRY

(ESCAPE TO ABORT)

ENTER PROG OR STAT PASSWORD, THEN ENTER.

(ESCAPE TO ABORT) _

1=BASIC PROGRAM 2=NETWORK

3-UTILITY 4=FLASHSCAN POLL

0=CLR 1=AUTO 2=POINT 3=PASSWD 4=MESSAGE

5=ZONES 6=SPL FUNCT 7=SYSTEM 8=CHECK PRG

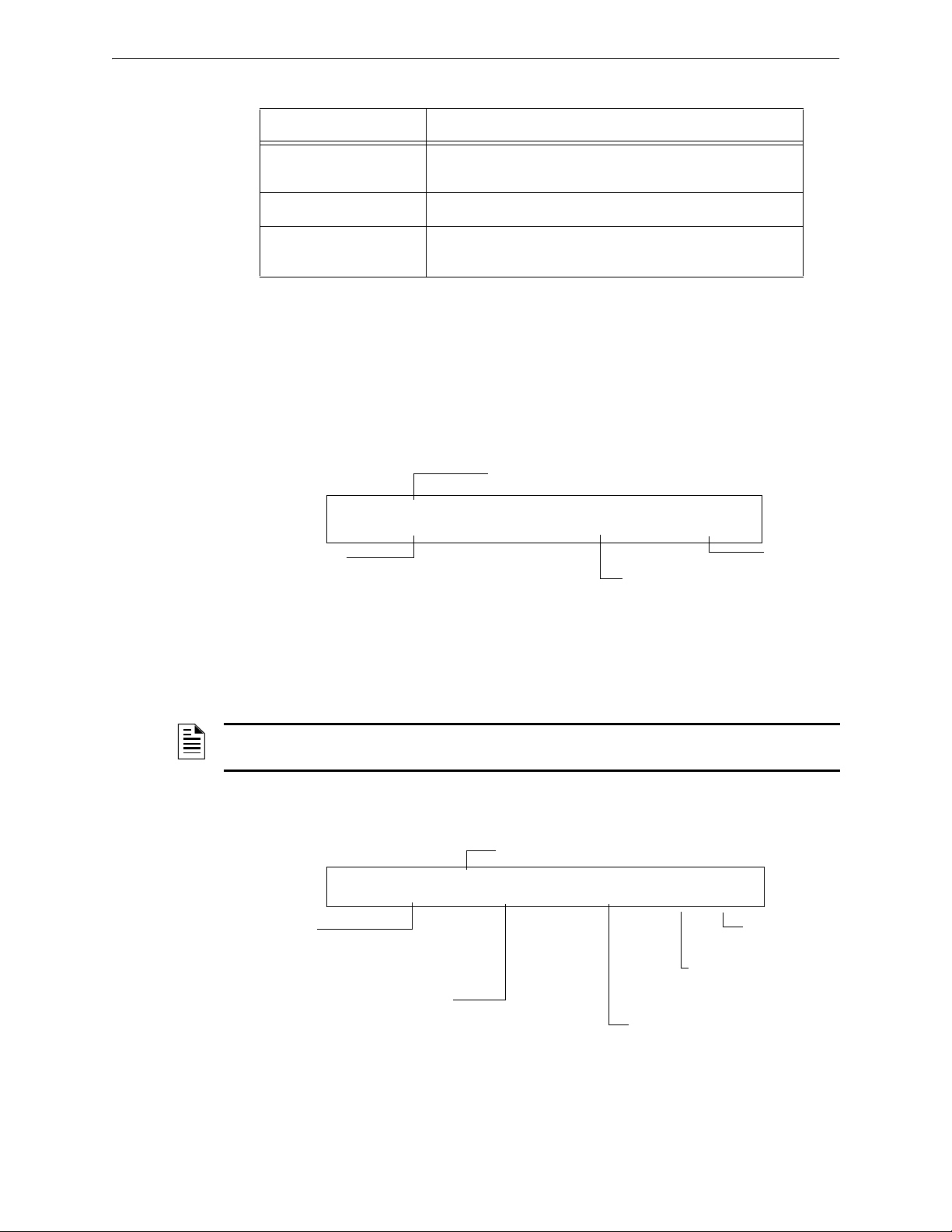

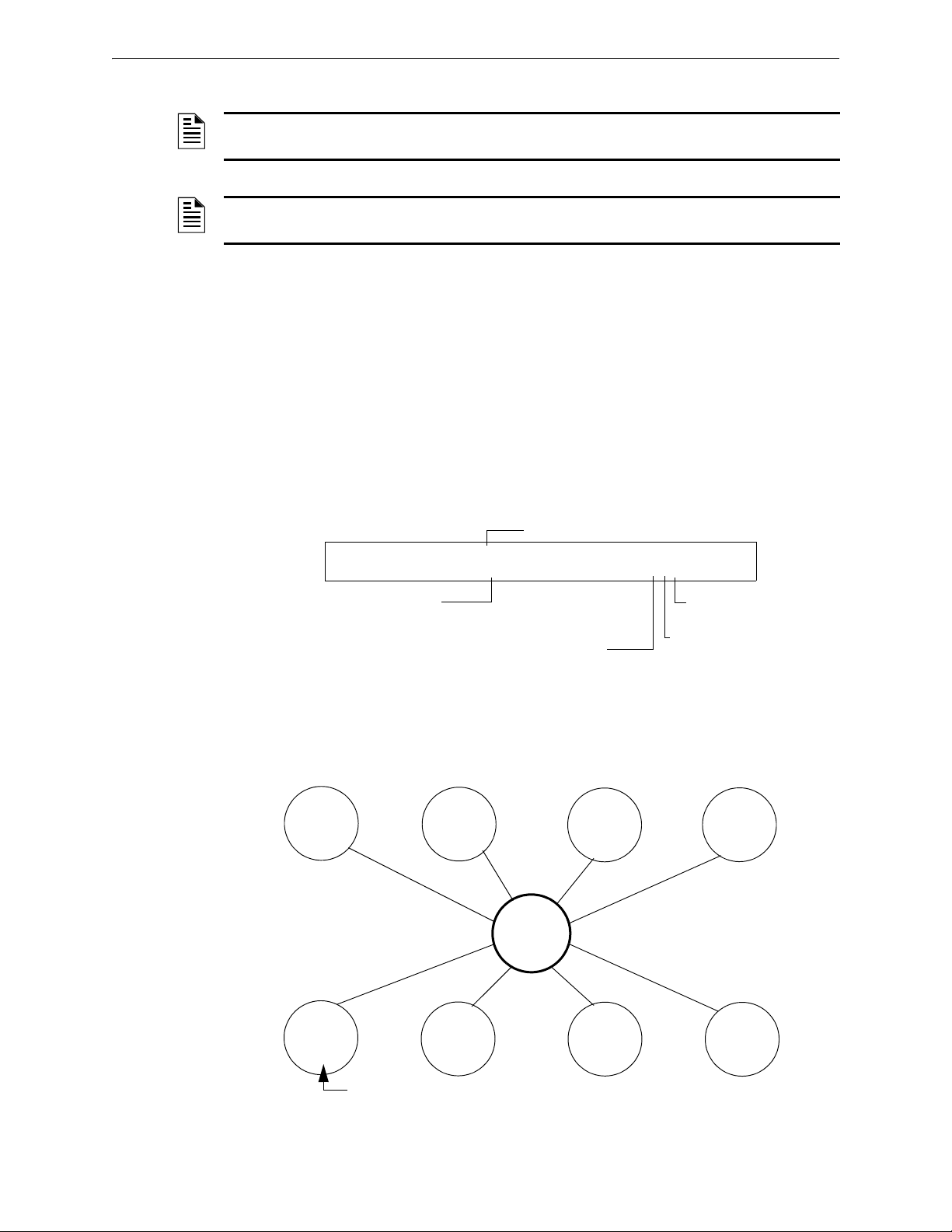

2.2 How to Enter Programming

To enter Program Change, follow these steps:

1. At the “SYSTEM NORMAL” screen, press the

“Entry” screen, as shown below:

2. At the “Entry” screen, press the 1 key. The control panel displays the “Enter Password” screen

as shown below:

3. Enter your Program Change password (See “How to Enter a Password” on page 11). The

control panel displays the “Program Change Selection” screen, as shown below:

4. Select a Program Change selection: 1, 2, 3 or 4.

2.3 Basic Program

From the “Program Change Selection” screen, press the 1 key to display the “Basic Program”

screen which provides nine (9) options as shown below:

ENTER key. The control panel displays the

Press the number of any one of the nine (9) options as detailed below

Option 0=CLR - Clears all existing user programming. For details, refer to How to Clear Memory

(0=

CLR) on page 15. Note: The user is prompted to double-check that this is what is really wanted.

Option 1=AUTO - Add or remove addressable devices to the control panel program. For details,

refer to How to Autoprogram the Control Panel (1=

AUTO) on page page 15.

Option 2=POINT - Modify or delete a point. For details, refer to “How to Modify or Delete a

Point (2=

POINT)” on page page 19.

Option 3=PASSWD - Change the Program Change or the Alter Status password. For details, refer

to “How to Change a Password (3=

PASSWORD)” on page page 25.

Option 4=MESSAGE - Edit the 40-character message that displays on the first line. For details,

refer to “How to Create a System Message (4=

MESSAGE)” on page page 26.

Option 5=ZONES - Edit the 20-character custom zone label for zones 01-99. For details, refer to

“How to Create a Custom Zone Label (5=

ZONE)” on page page 27.

Option 6=SPL FUNCT - Program Releasing Zones and Special Zones. For details, refer to “How

to Program Special Zones (6=

SPL FUNCT)” on page page 27.

Option 7=SYSTEM - Program Global System Functions. For details, refer to “How to Change

Global System Functions (7=

SYSTEM)” on page page 31.

Option 8=CHECK PRG - Check the program for errors. For details, refer to “How to Check the

Program for Errors (8=check prg)” on page 47.

14 NFS2-640/E Programming Manual — P/N 52742:L2 7/17/14

Page 15

Basic Program Programming

Program Change

Password

PRESS ENTER TO CLEAR ENTIRE PROGRAM

OR ESCAPE TO ABORT

Program Change

Password

2.3.1 Clear Memory (0=CLR)

The Clear option removes all programming information from control panel

memory. If installing the control panel for the first time, use option 0 to clear

control panel memory. To do so, follow these steps:

1. From the “Basic Program” screen, press the 0 (zero) key to display the Clear Program screen.

The control panel prompts for verification as shown below:

2. Press the

ENTER key to clear control panel memory or press the ESC key to exit the screen

without clearing.

2.3.2 Autoprogram the Control Panel (1=AUTO)

Purpose

The Autoprogram option identifies all addressable devices connected to the control panel. Devices

include addressable detectors and modules connected to SLC 1 or SLC 2, and NACs. You can use

the Autoprogram option to create a new program and add or remove devices. A summary of the

Autoprogram functions, when to use the functions, and where to find information on using the

functions is found below:

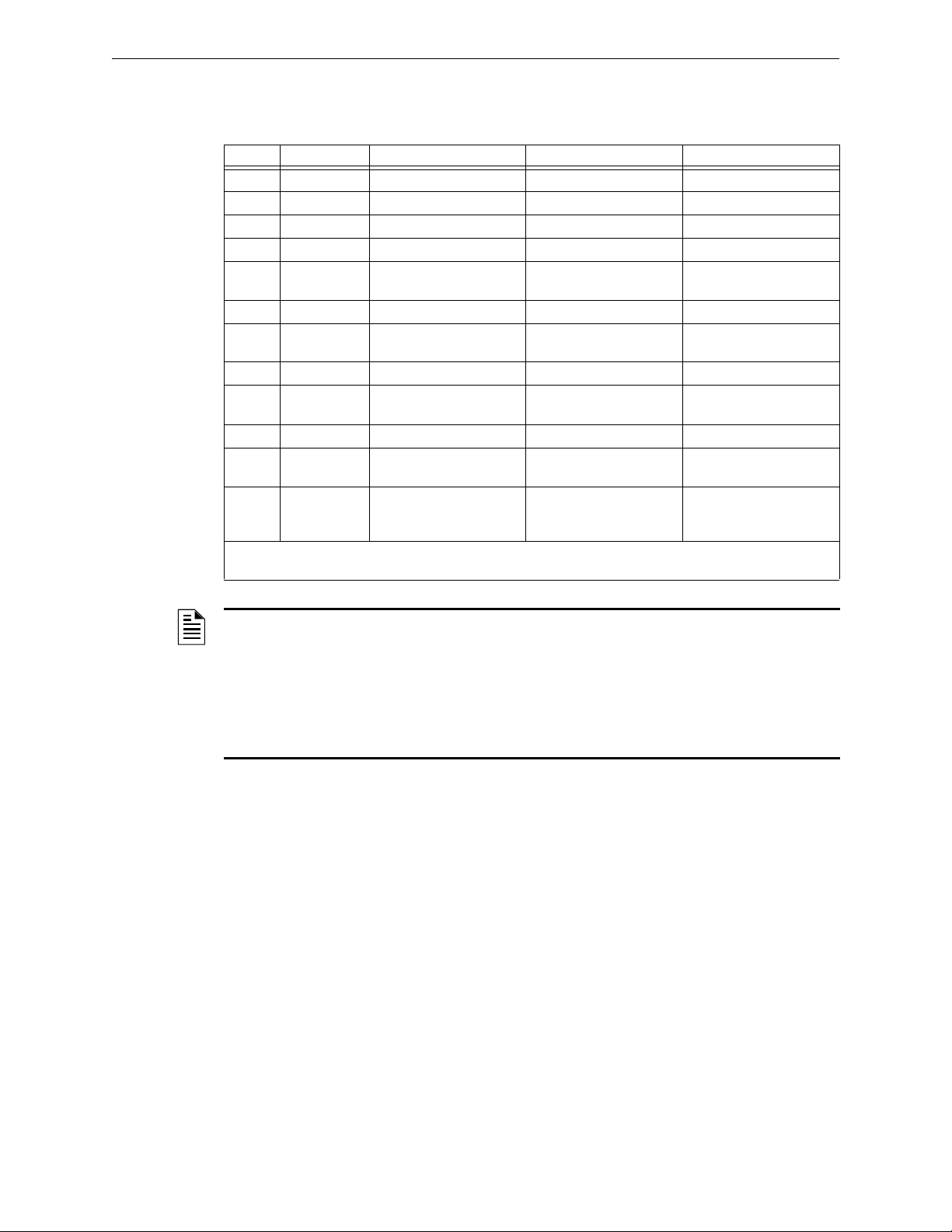

Autoprogram Function Control Panel Configuration Refer to...

Create a new program for

the control panel

Add one or more

SLC-connected detectors

and modules to an

existing program

Remove one or more

SLC-connected detectors

and modules from an

existing program

A new control panel or a control panel with no

existing program in memory.

A program exists in memory and you want to

add a detector or module to the existing

program—without modifying information for

existing detectors and modules.

A program exists in memory and you want to

remove an installed detector or module from

the existing program—without modifying

information for existing detectors and

modules.

“Create a New Program for the

Control Panel” on page 15

“Add a Device to the Program”

on page 16

“Remove a Device from the

Program” on page 17

View system defaults A program exists in memory and you want to

view system settings assigned during

Autoprogram, such as custom labels,

passwords, and so on.

Page 19 “Change Autoprogram

Default Value” to see the system

defaults

Create a New Program for the Control Panel

This section covers how to use the Autoprogram option to create a new

program for the control panel. The control panel will identify all addressable

detectors and modules connected to the SLC.

To create a new program for the control panel, follow these steps:

NFS2-640/E Programming Manual — P/N 52742:L2 7/17/14 15

Page 16

Programming Basic Program

AUTOPROGRAM PLEASE WAIT

L1:010Dets, 159Mods L2:159Dets, 159Mods

SB L1:000, L2:159 Bells: 04

ACCEPT ALL DEVICES Please Wait!!!

PROGRM SMOKE(PHOTO) DETECTOR ADDR 1D147

03 __ __ __ __A8P8** 1D147

1. Use the Clear option to clear program information from memory. For instructions on clearing

memory, refer to “How to Clear Memory (0=

NOTE: Once Step 1 is completed, Step 2 will cause the panel to assess whether a loop is

comprised of all FlashScan devices or not. If they are all FlashScan, autoprogramming will

change the loop setting to FlashScan if it was not already at that setting. If the devices are not all

FlashScan, autoprogramming will not make a change to the default setting of CLIP. (See

“FlashScan Poll” on page 49 for FlashScan settings.)

CLR)” on page page 15.

2. From the “Basic Program” screen, press the 1 key to start Autoprogram. While the control

panel scans the system to identify all SLC devices and NACs, it displays the following screen:

When the autoprogram is finished identifying SLC devices and NACs, it displays a summary

screen that gives a count of all the devices it has located. Refer to the following screen for an

example of this display.

SB represents detectors with B200 series sounder bases. Refer to VeriFire Tools for B200 sounder

base programming.

3. Press

ENTER. All devices are automatically accepted during initial autoprogramming. The

following screen displays briefly, followed by the

SYSTEM NORMAL screen.

To edit the autoprogramming default values for a point, refer to “How to Modify or Delete a Point

(2=

POINT)” on page page 19.

To edit the autoprogram default values assigned to all modules and detectors during

autoprogramming, refer to “Change Autoprogram Default Values” on page 18.

Add a Device to the Program

You can also use the Autoprogram option to add addressable devices to the control panel program.

NOTE: When using the Autoprogram option with an existing program, the control panel does not

change program information for installed and programmed devices. However, it will assess

whether a loop contains all FlashScan devices and change the loop setting to FlashScan if

necessary.

The following steps describe how to add a new detector at SLC address 1D147 with 10 detectors in

the existing program:

1. Physically install the addressable detector to SLC 1 at address 147 (for instructions, refer to the

NF2S-640 Installation Manual and the installation document that comes with the detector).

2. From the “Basic Program” screen, press the 1 key to start Autoprogram. The Autoprogram

Prompt screen appears in the LCD display as the control panel identifies addressable devices.

When finished identifying addressable devices, the control panel displays information for the

new detector at SLC address 1D147 on the LCD display as shown below:

16 NFS2-640/E Programming Manual — P/N 52742:L2 7/17/14

Page 17

Basic Program Programming

Note that the number of detectors increases (in this example

from 10 to 11) to show the addition of the detector to SLC 1.

L1:011Dets, 159Mods L2:159Dets, 159Mods

SB Bells: 04

Type Code

SLC loop number

D (detector) or M (module)

Three-digit address (001-159)

PROGRM SMOKE (ION) DETECTOR ADDR 1D133

DEVICE NOT ANSWERING DELETE FR MEM?1D133

Note that the number of detectors decreases (from 11 to

10) to show the removal of the detector from SLC 1.

L1:010Dets, 159Mods L2:159Dets, 159Mods

SB Bells: 04

3. Press the ENTER key to add detector 147 to the program with the default program information.

If you want to change the default information, use the programming keys to do so, then press

the

ENTER key to add detector 147 to the program.

The Autoprogram Summary screen appears. You can verify addition of the detector to the

program by noting the new count of detectors as shown below:

4. Press the

ENTER key, then press the esc key to save the program in memory and return to the

“Basic Program” screen).

Remove a Device from the Program

You can also use the Autoprogram option to remove addressable detectors and modules from the

control panel program.

NOTE: When using the Autoprogram option with an existing program, the control panel does not

change program information for installed and programmed devices.

The following steps describe how to delete a detector at SLC address 1D133 with 11 detectors

connected to SLC 1 in the existing program:

1. Disconnect and remove the detector from SLC 1 at address 1D133.

2. From the “Basic Program” screen, press the 1 key to start Autoprogram. The Autoprogram

Prompt screen displays while the control panel identifies addressable devices.

3. When finished identifying addressable devices, the control panel displays a screen, indicating a

missing detector at SLC address 1D133 as shown below:

4. Press the

ENTER key to delete detector 1D133 from the program.

The Autoprogram Summary screen appears. You can verify removal of the detector from the

program by noting the new count of detectors as shown below:

5. Press the

ENTER key, then press the ESC key to save the program in memory and return to the

“Basic Program” screen.

NFS2-640/E Programming Manual — P/N 52742:L2 7/17/14 17

Page 18

Programming Basic Program

NOTE: The FCM-1-REL has an inherent two second

delay, which must be factored into the DELAY TIME

and SOK (soak time) entries.

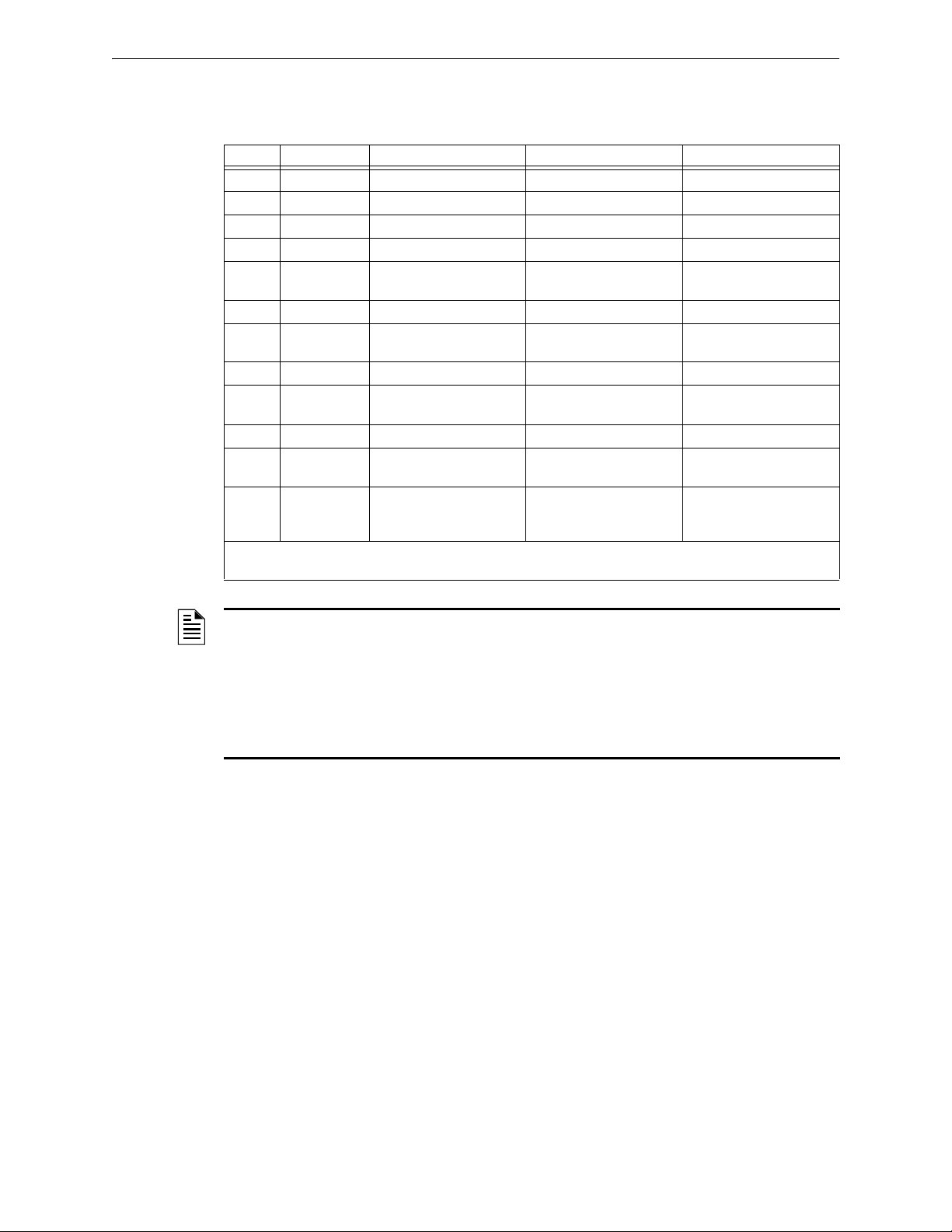

Change Autoprogram Default Values

To assign system default values from the basic program screen, Press 0 (clear), then press 1

(autoprogram). Refer to the chart below for default values and how to modify them.

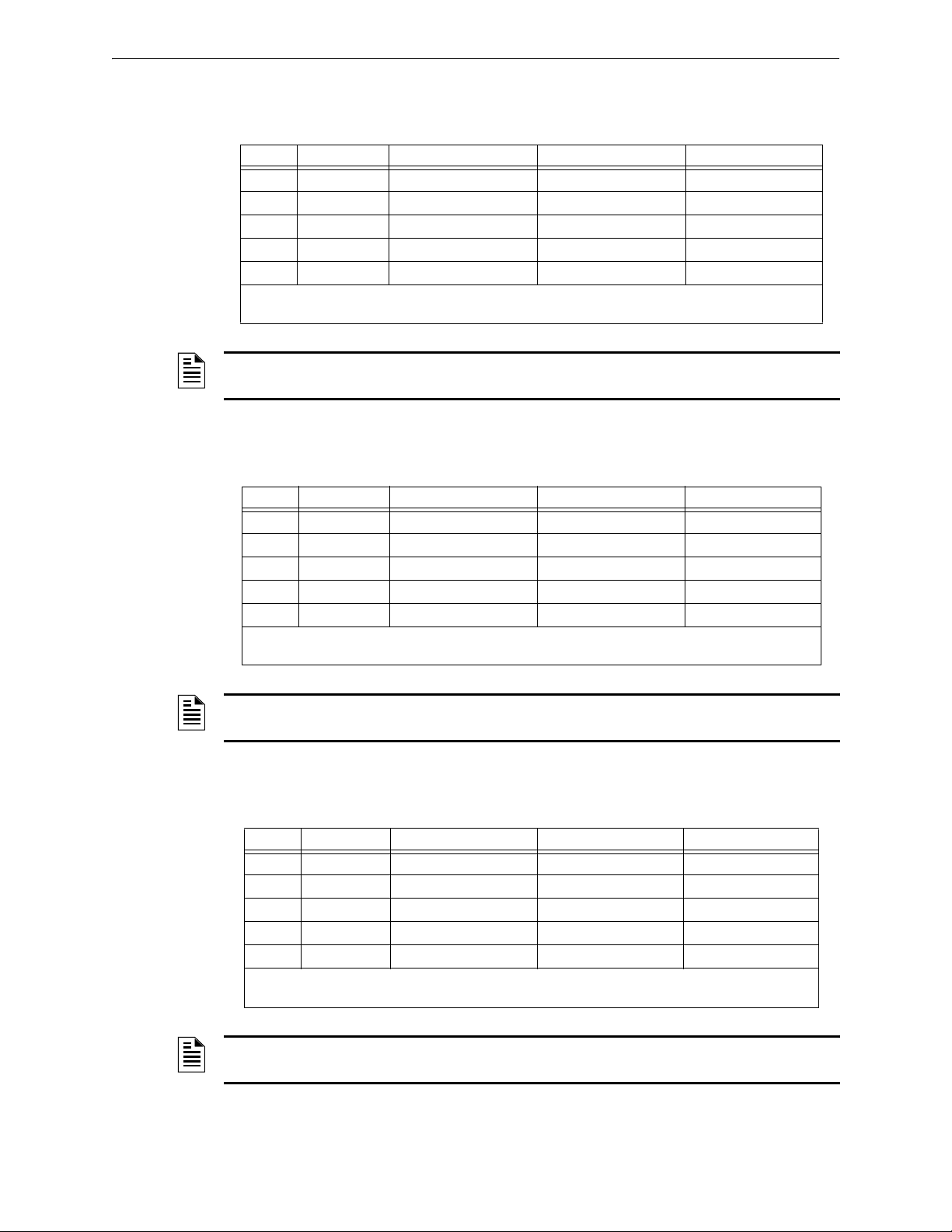

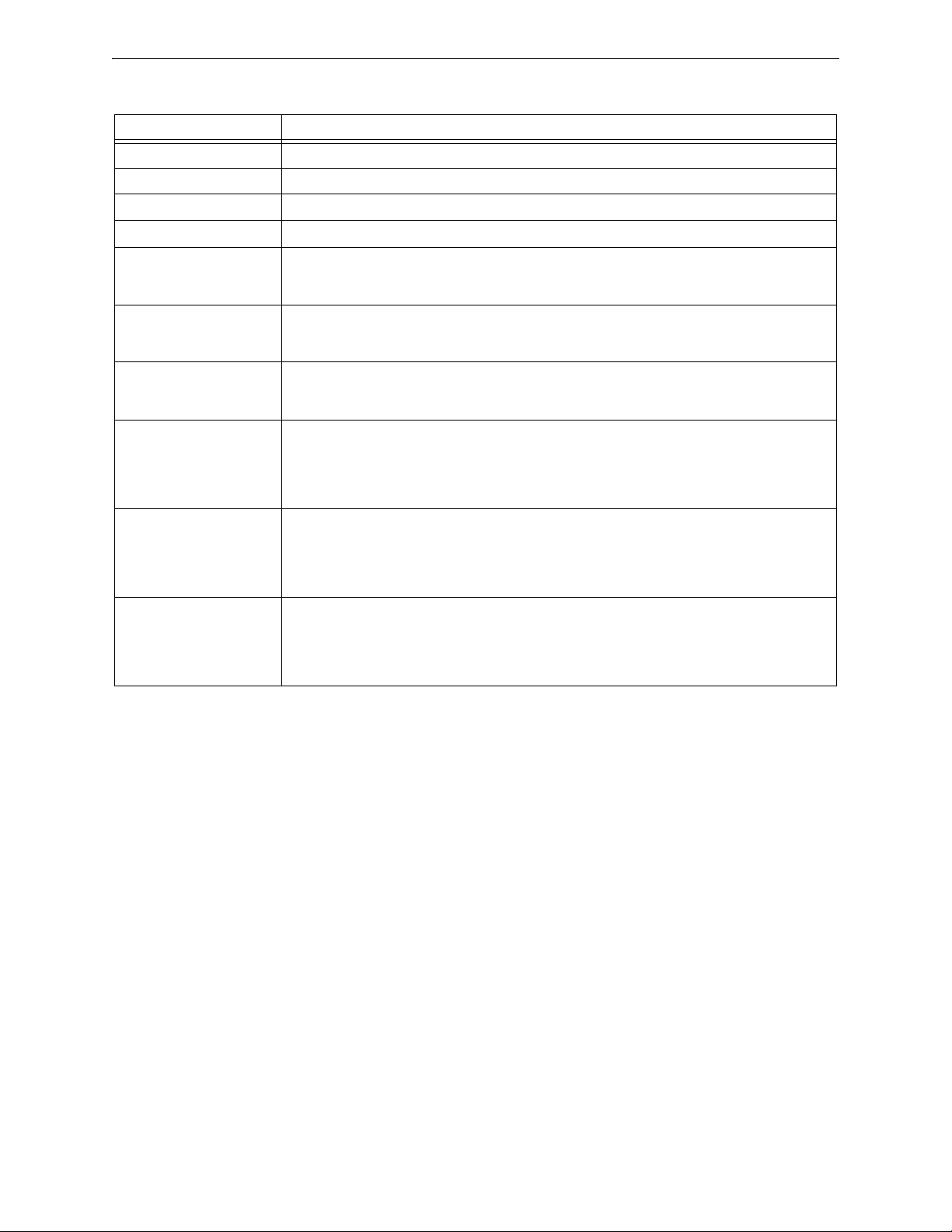

Table 2.1 Autoprogram Defaults (1 of 2)

Function Default Values To Alter, refer to

Software

Zones

01-99

F0 PRG PRESIGNAL FUNCT PRESIGNAL DELAY

Releasing

Zones

R0-R9

Default custom label “Zone xx” where xx is the

number of the zone

Note: Zone 00 is reserved for a general alarm.

DELAY=180 PAS=NO F00

PRG RELEASE FUNCT RELEASE CONTROL

DELAY=00 ABORT=ULI CROSS=N SOK=0000

“How to Create a Custom Zone Label (5=

“F0 (Presignal/PAS) The Presignal screen provides fields for

changing the delay time or PAS. For details on Presignal

selections, refer to “Presignal and PAS Time” on page 92. From

the Special Function Change screen, press the F key, then

press the 0 key to display the Presignal Function screen.” on

page 29

“R0-R9 (Releasing Functions) The Releasing Function screen

provides fields for changing releasing functions: Delay Timer,

Abort Switch, Cross Zone, and Soak Timer. For details on

releasing applications, refer to “NFPA Releasing Applications”

on page 61.” on page 29 and “How to Program a Releasing

Zone” on page 61.

ZONE)” on page 27

F5 and F6 PRG TIME FUNCTION TIME CONTROL

ON=**:** OFF=**:** DAYS=********

F7 PRG HOLIDAY FUNCTION **/** **/** **/**

**/** **/** **/** **/** **/** **/**

F8 PRG CODING FUNCTION CODE TYPE

MARCH TIME F08

F9 PRE-ALARM FUNCT ALERT

F09

System

Parameters

Passwords Default programming passwords are:

SYSTEM

NORMAL

message

SIL INH=0000 AUTO=0077

0 VERIFY=30 USA TIME

TERM=N AC_DLY=Y LocT BLINK=01 ST=4 ACS=N

Program Change=00000

Status Change=11111

(YOUR CUSTOM SYSTEM MESSAGE HERE)

SYSTEM NORMAL 10:23A 041508 Tue

A message, along with the current day, time, and

date, that displays on the second line of the LCD

display during normal operation.

“F5-F6 (Time Control Functions) The Time Control screen

provides fields for changing the start time, stop time, or days of

the week. For details on time selections, refer to “Time Control

Zones” on page 93. From the Special Function Change screen,

select F5 or F6 to display the Time Control screen:” on page 30

“F7 (Holiday) The Holiday screen provides fields for specifying

up to nine holiday dates. For details on holiday selections, refer

to “Time Control Zones” on page 93. From the Special Function

Change screen, press F7 to display the Holiday screen:” on

page 30

“F8 (Coding Function) The Coding Function screen provides

fields for specifying one of the following coding functions: March

Time, Two-stage, California, Temporal, Two-Stage Canada (3

minutes), Two-Stage Canada (5 minutes), Two-Stage Canada

Manual, System Sensor Strobe, Gentex Strobe, and Wheelock

Strobe. For details on selecting coding functions, refer to

“Coding Functions for NACS” on page 93. From the Special

Function Change screen, press F8 to display the Coding

Function screen:” on page 30

“F9 (Pre-Alarm) The Pre-Alarm screen provides fields for

programming the Alert or Action Pre-Alarm functions. For

details on Pre-Alarm selections, refer to “Pre-Alarm” on

page 99. From the Special Function Change screen, press F9

to display the Pre-Alarm screen:” on page 31

“How to Change Global System Functions (7=

page 31

“How to Change a Password (3=

Note: The second line, “SYSTEM NORMAL”, is a standard

system message that you cannot change

PASSWD)” on page page 25

SYSTEM)” on

18 NFS2-640/E Programming Manual — P/N 52742:L2 7/17/14

Page 19

Basic Program Programming

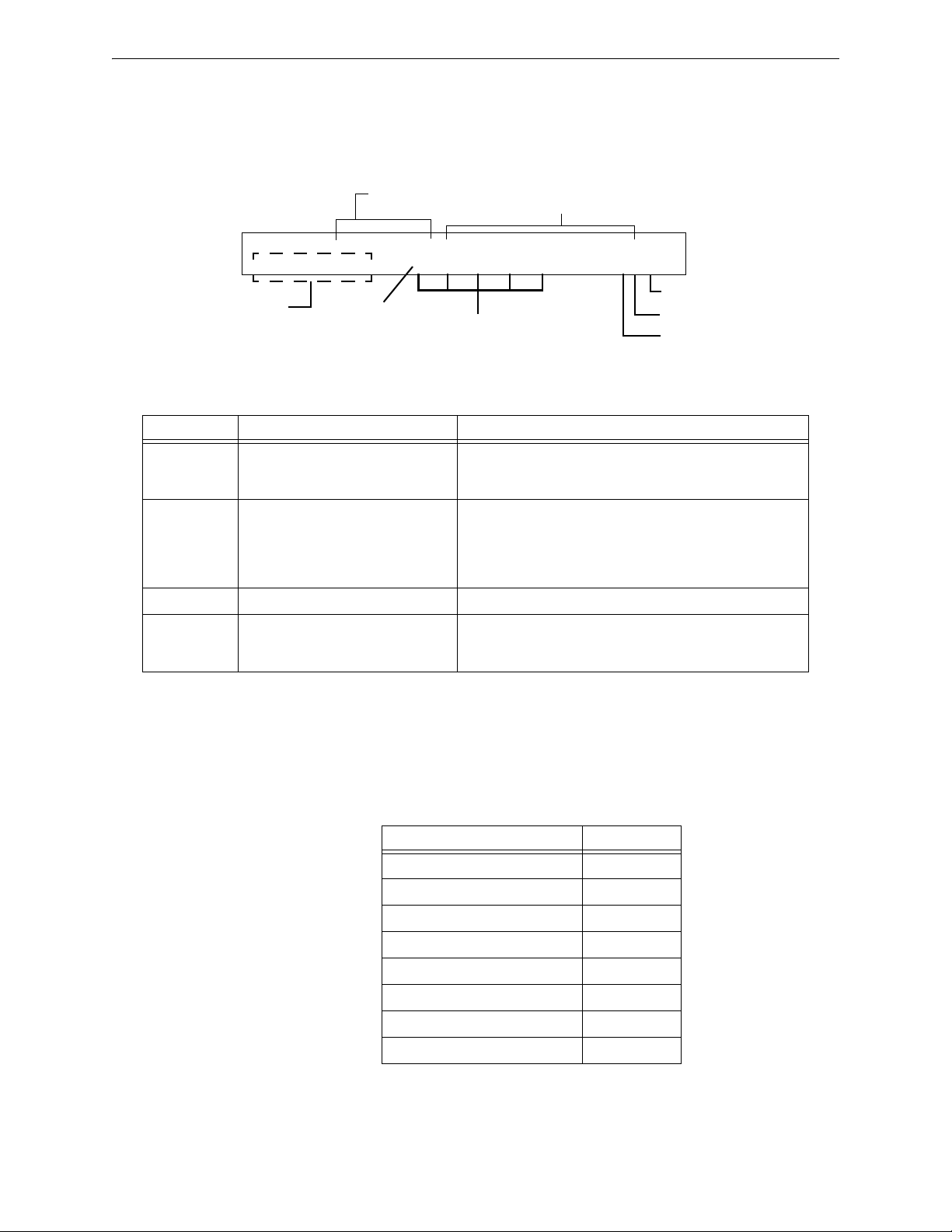

Program Change

Password

POINT PROG. 1=MODIFY POINT

2=DELETE POINT

Press for module point

SLC number

Three-digit address (001-159)

E - press the

ENTER key

Press for detector point.

SLC number

Three-digit address (001-159)

Press for NAC

Modify Point Screen

Delete Point Screen

E - press the

ENTER key

POINT PROG. ENTER:DETECTOR=*,LDAAA,E

MODULE=#,LMAAA,E OUTPUT CKT=&,A-A,E

E - press the

ENTER key

Two-digit address for

NAC (01-04)

DELETE POINT. ENTER:DETECTOR=*,LDAAA,E

MODULE=#,LMAAA,E OUTPUT CKT=&,A-A,E

Table 2.1 Autoprogram Defaults (2 of 2)

Function Default Values To Alter, refer to

System

Message

IP

ACCESS

DCC Mode Default setting is N, no DCC participation. “The Utility Program” on page 48

(YOUR CUSTOM SYSTEM MESSAGE HERE)

SYSTEM NORMAL 10:23A 041508 Tue

The first line of the LCD display contains 40 blank

characters for a custom message.

Default setting is zero (0), IP Access not enabled. “The Utility Program” on page 48

“How to Create a System Message (4=

page 26

MESSAGE)” on page

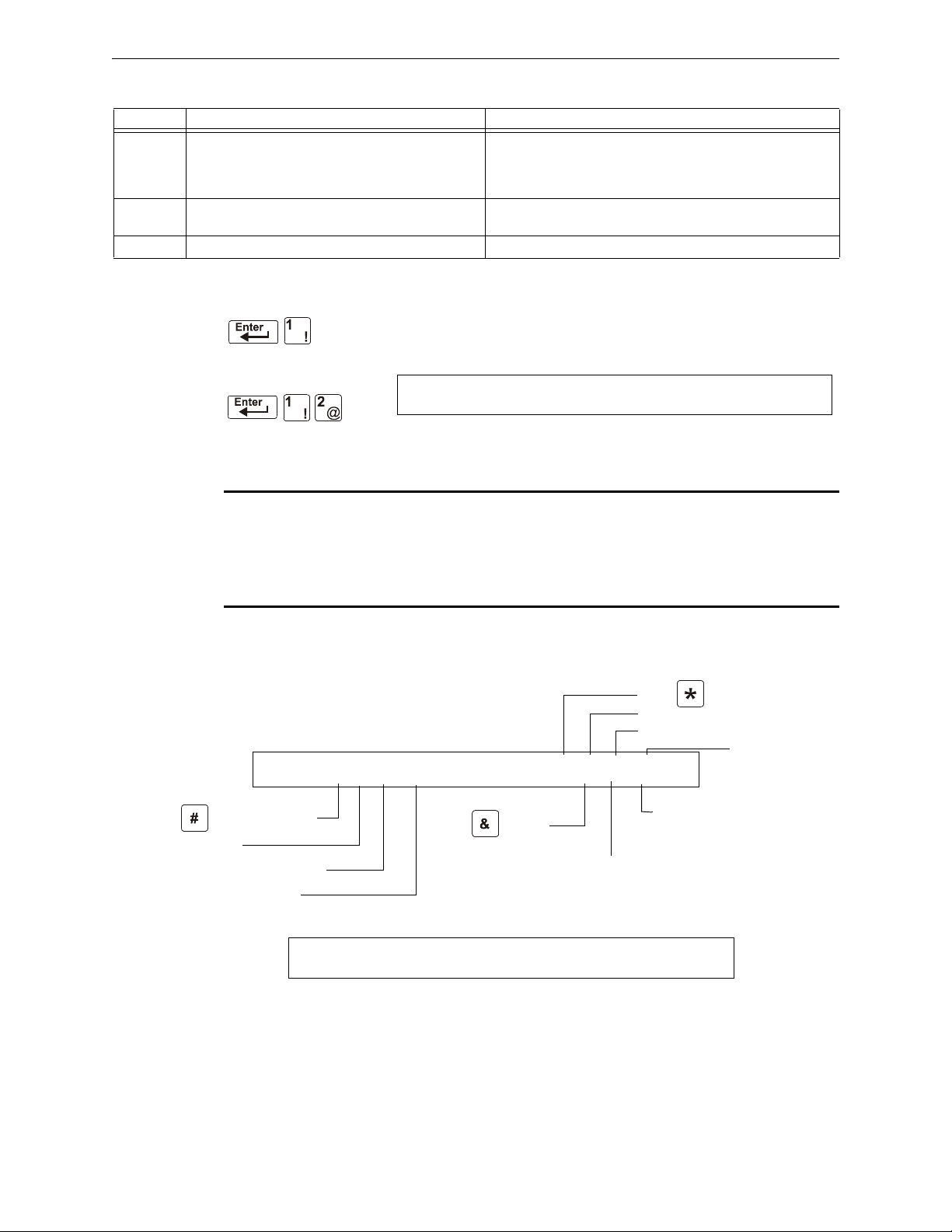

2.3.3 Modify or Delete a Point (2=POINT)

After programming all SLC-connected devices into the system, you can

modify or delete points. From the “Basic Program” screen, press the 2 key to

display the Point Programming screen:

To modify a point for a detector, module, or NAC: press the 1 key to display

the “Modify Point” screen.

NOTE: When programming points, take the following into design consideration:

Each general zone must be dedicated to a single event type (i.e. Fire, MN, Security, etc.)

Map inputs only to general zones designed for the input’s event type. For example, map mass

notification devices to general zones designed for mass notification.

Outputs can be mapped to multiple general zones that are dedicated to different event types. For

instance, a single output can be mapped to an MN general zone and a Fire general zone.

To delete a point for a detector, module, or NAC: press the 2 key to display the “Delete Point”

screen.

NFS2-640/E Programming Manual — P/N 52742:L2 7/17/14 19

Page 20

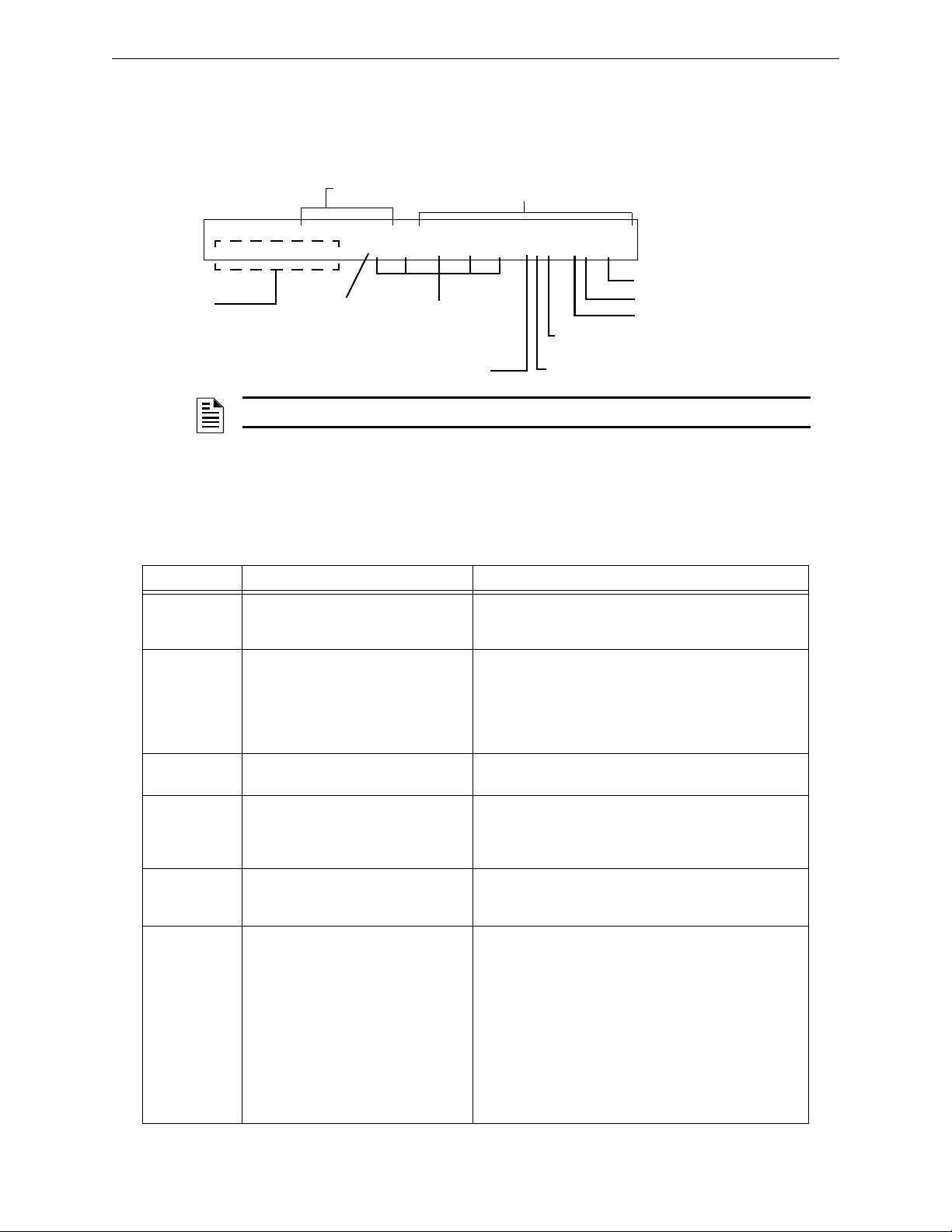

Programming Basic Program

12 spaces for extended custom label

PROGRM SMOKE(PHOTO) DETECTOR ADDR 1D101

03 __ __ __ __A8P8AV 1D101

Blinking Type Code selection

CBE list

(five zones)

D (detector)

SLC address (001-159)

20-character user-editable custom label (in

this example, autoprogramming has used

the first 19 and left a space at the end.)

SLC Loop number

Alarm sensitivity level

Pre-alarm sensitivity level

Cooperative multi-detector

mode indicator

Alarm verification setting

The Modify Point and Delete Point screens let you edit or delete points for a detector, a monitor or

control module, or NAC. To select a point, follow these steps:

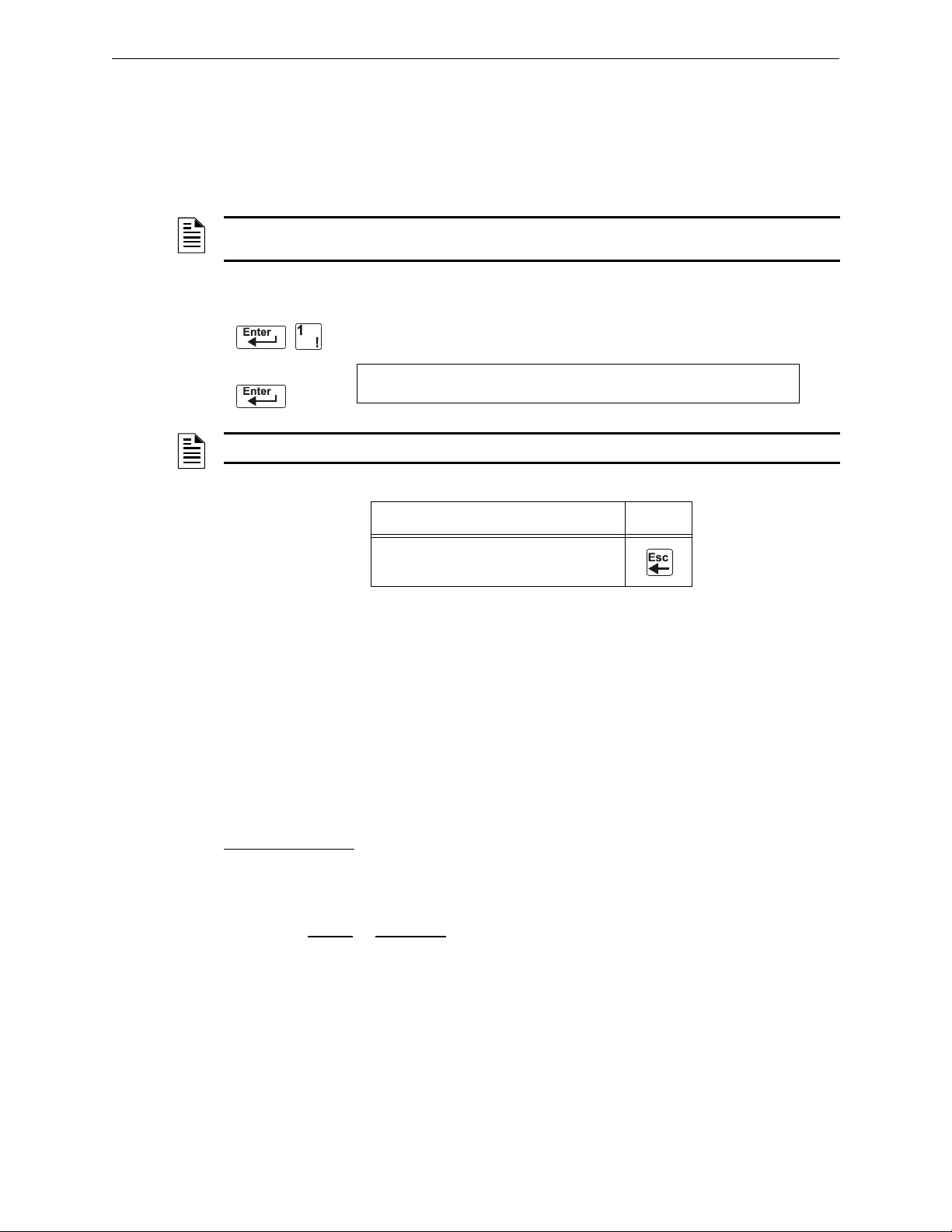

To select Do the following Refer to

an addressable

detector

an addressable monitor

module

an addressable control

module

a NAC Press

Press

Type the SLC number (1 or 2) and

detector (D) and address (001-159)

Press

Press

Type the SLC number (1 or 2) and module

(M) and address (001-159)

Press

Press

Type the SLC number (1 or 2) and module

(M) and address (001-159)

Press

Type the NAC address (01-04)

Press

The next four sections describe how to program the points selected.

Modify an Addressable Detector Point

This section contains a sample detector programming screen, detector default selection, and

instructions for modifying a detector point. Autoprogram default values for a detector are shown:

“Modify an Addressable Detector

Point” on page 20.

“Modify an Addressable Monitor

Module Point” on page 22.

“Modify an Addressable Control

Module Point” on page 23.

“Modify NAC Points” on page 24.

Field Description Set as Follows

Type Code Detector function

Custom

Label

20 NFS2-640/E Programming Manual — P/N 52742:L2 7/17/14

Table 2.2 Detector Program Values

specification SMOKE(PHOTO) in example.

20 character custom label. Change by placing the cursor into the first space of the field using the arrow

Press the

Type Code selections. See F.4.2 on page 112 for lists and descriptions.

keys, then typing the descriptor. DETECTOR ADDR 1D101 is the

autoprogram default custom label for the detector at address 101 on SLC 1.

NEXT or PREVIOUS Selection keys to scroll through valid detector

Page 21

Basic Program Programming

Zone 01 (Heat detectors)

Zone 02 (Ion detectors)

Zone 03 (Photo detectors, Beam detectors)

Zone 04 (Laser detectors)

Zone 05 (Multisensor)

A8 (Photo)

A6 (Ion)

A6 (Laser)

A5 (Multisensor)

P8 (Photo)

P6 (Ion)

P6 (Laser)

P5 (Multisensor)

Table 2.2 Detector Program Values

Field Description Set as Follows

Extended

Label

12 character custom label

extension.

CBE List Five zones can be listed - one

zone, Z03, is shown in the

example. Up to 4 more could

be added to this detector.

Alarm

Sensitivity

The alarm sensitivity level,

with 9 the least sensitive

alarm level and 1 the most

sensitive alarm level.

Pre-alarm

level

Shows the Pre-Alarm level

setting—a number between 0

and 9—as follows:

0 – no Pre-Alarm

1 – self optimizing

2 – most sensitive Pre-Alarm

level

9 – least sensitive Pre-Alarm

level

See “Custom Label” above.

Note that spaces must be input by the user, including any space necessary

between the custom and extended label fields. An 80-column printout will

run the two fields together.

Zones can be changed or added to the CBE list by placing the cursor in the

zone field using arrow keys, then typing.

Defaults:

Refer to Table C.2 on page 101 for settings. Select by placing the cursor in

the field using the arrow keys, then either pressing the

NEXT or PREVIOUS

keys to make the selection, or typing the value.

Defaults:

Refer to Table C.2 on page 101 for settings. Select by placing the cursor in

the field using the arrow keys, then either pressing the

NEXT or PREVIOUS

keys to make the selection, or typing the value.

Defaults:

Cooperative

Multidetector

mode

Alarm

verification

Indicates the cooperative

multi-detector mode (A in the

example).

Indicates the alarm

verification setting (V in the

example).

Select by placing the cursor in the field using the arrow keys, then either

pressing the

NEXT or PREVIOUS keys to make the selection, or typing the

value.

* = OFF (Default)

A combines the detector's alarm decision with the next address above

B combines the detector's alarm decision with the next address below

C combines the detector's alarm decision with the next address above and

the next address below

Indicates Alarm Verification (V=on, *=off). Select by placing the cursor in the

field using the arrow keys, then pressing the

NEXT or PREVIOUS keys to make

the selection. Refer to “Interpreting a Detector Status Display or

Maintenance Report” on page 104 for more information on the alarm

verification feature.

Note: Do not use this setting when an alarm activation requires activation of

two or more automatic detection devices.

NFS2-640/E Programming Manual — P/N 52742:L2 7/17/14 21

Page 22

Programming Basic Program

Default zone

Blinking Type Code selection

CBE list

(five zones)

12 spaces for extended

custom label

SLC number (1 or 2)

M (module)

SLC address (001-159)

PROGRAM MONITOR WESTERN ENTRANCE AND

HALLWAY 09 __ __ __ __ 2M101

20-character user-editable custom label.

Modify an Addressable Monitor Module Point

When you select a point address, the control panel returns a screen that displays information about

the point. Below is an example of information for a monitor module (2M101) in the LCD display:

Table 2.3 Modifying Monitor Module Programming Selections

Field Description Set as Follows

Type Code Monitor Module function specification

-

MONITOR in example.

Custom Label 20 character custom label. Change by placing the cursor into the first space of the field

Extended Label 12 character custom label extension. See “Custom Label” above.

CBE List Five zones can be listed - one zone,

Z09, is shown in the example. Up to 4

more could be added to this module.

Press the

valid monitor module Type Code selections. Lists and

descriptions are in See Table F.2 on page 114.

using the arrow keys, then typing the descriptor.

Note: Spaces must be input by the user, including any space

necessary between the custom and extended label fields. An

80-column printout will run the two fields together.

Zones can be changed or added to the CBE list by placing the

cursor in the zone field using arrow keys, then typing.

See Table 2.4 on page 22 for defaults.

NEXT or PREVIOUS Selection keys to scroll through

When finished modifying a point, press the

ENTER key; then press the NEXT or PREVIOUS key to

select another point.

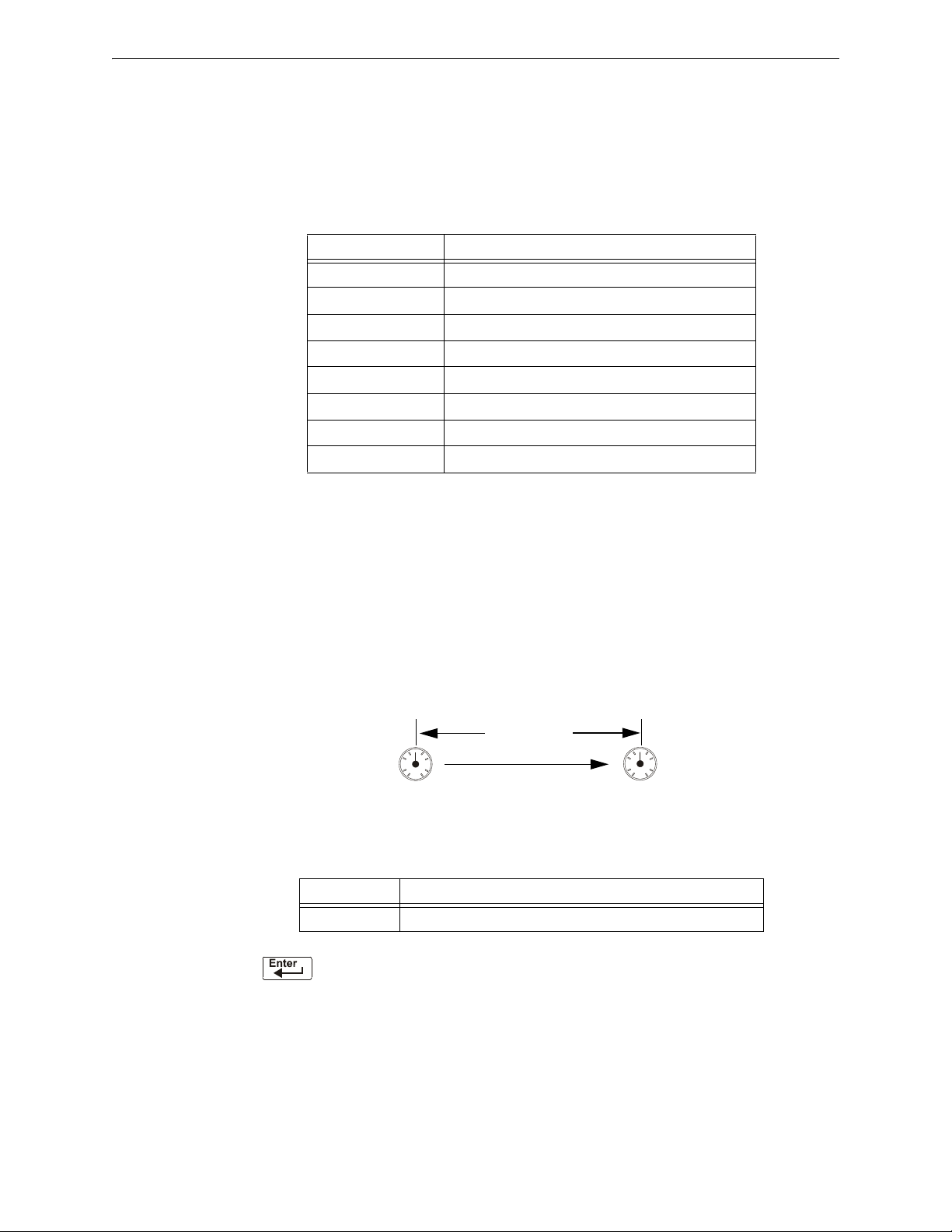

Monitor Module Default Zone Assignments

Listing of the monitor module address range and the default zone assignment for each range:

Table 2.4 Monitor Module Default Zones

Monitor Module Address Zone Default

01 through 19 Z04

20 through 39 Z05

40 through 59 Z06

60 through 79 Z07

80 through 99 Z08

100 through 119 Z09

120 through 139 Z10

140 through 159 Z11

22 NFS2-640/E Programming Manual — P/N 52742:L2 7/17/14

Page 23

Basic Program Programming

Walk Test Selection: *=off

(default); W=selected

Silenceable: O =selected; *=off (default)

Default zone

Blinking Type Code selection

CBE list

(five zones)

12 spaces for extended

custom label

SLC number (1 or 2)

M (module)

SLC address (001-159)

Switch Inhibit: I=selected; *=off (default)

PROGRAM CONTROL MODULE CONTROL 2M101

00 __ __ __ __ IOW 2M101

20-character user-editable custom label

NOTE: On a control module, the default zone is always set to Zone 00 (general alarm).

Modify an Addressable Control Module Point

When you select a point address for modification, the control panel returns a screen that displays

information about the point. For example, the illustration below shows sample information for a

control module (2M101) in the LCD display.

To modify a point, follow these steps. A blinking cursor indicates the selected field.

1. From the programming screen, use the arrow keys to move to a field that you want to modify.

See below for descriptions and settings.

Table 2.5 Modifying Control Module Programming Selections (1 of 2)

Field Description Set as follows:

Type Code Specifies the function of the control

module

Custom Label 20 character custom label. Change by placing the cursor into the first space of the

Extended

Label

CBE list Up to five software zones can be

Switch Inhibit Specifies if an operator can manually

Silenceable Specifies if an operator can manually

12 character custom label extension. See “Custom Label” above.

entered to define the output responses

of the control module based on

various initiating conditions (events)

activate an output

silence an activated output

Press the

through valid control module Type Code selections (listed

in Table F.3 on page 115)

field using the arrow keys, then typing the descriptor.

Note: Spaces must be input by the user, including any

space necessary between the custom and extended label

fields. An 80-column printout will run the two fields

together.

Type the number of up to five zones, including E0-E9, F0F9, L0-L9, R0-R9, and zones 00-99. The first zone default

is Z00 (general alarm).

Type one of the following entries.

I = Switch Inhibit enabled

* = no switch inhibit (default for all but releasing circuits)

Type one of the following entries.

* = output nonsilenceable

F = silenceable, resound by fire alarm

U = silenceable, resound by supervisory alarm

B = silenceable, resound by security alarm

T = silenceable, resound by trouble

O = silenceable, does not resound

If the “Strobe” Type ID is used with System Sensor,

Gentex or Wheelock Strobe synchronization,“*” will

silence the horn portion only, and resound will occur only

by fire alarm. F, U, B, T, or O will silence the entire circuit,

and resound will occur according to the above definitions.

NEXT or PREVIOUS Selection keys to scroll

NFS2-640/E Programming Manual — P/N 52742:L2 7/17/14 23

Page 24

Programming Basic Program

The address of a NAC connected

through NAC 1 (B01), NAC 2

(B02), NAC 3 (B03), or NAC 4

(B04)

Five zones for CBE list; the default zone

selection is 00 (general alarm)

Default zone

12 spaces for extended

custom label

Switch Inhibit: I=selected; *=off (default)

Walk Test Selection: *=off (default);

W=selected

Silenceable: O=selected; *=off (default)

Type Code

20-character user-editable custom label

PROGRAM CONTROL Notification Dev No1

00 __ __ __ __ *OW B01

Table 2.5 Modifying Control Module Programming Selections (2 of 2)

Field Description Set as follows:

Walk Test Specifies if outputs sound during Walk

Te st

Type one of the following entries.

W = devices sound (Basic Walk Test)

* = devices do not sound (Silent Walk Test) (default)

2. When finished modifying a point, press the ENTER key; then press the NEXT or PREVIOUS key to

select another point.

Modify NAC Points

Modifying NACs (four NACs on the NFS2-640) is like modifying control modules—except for the

Type Code and device address.

To modify a point, follow these steps. A blinking cursor indicates the selected field.

1. From the programming screen, use the arrow keys to move to a field that you want to modify

and refer to information below for descriptions and settings.

Table 2.6 Modifying a NAC Programming Selections (1 of 2)

Field Description Set as follows:

Type Code Specifies the function of the NAC. Press the

through the NAC Type Code selections (listed in

Table F.4 on page 116)

Custom Label 20 character custom label. Change by placing the cursor into the first space of the

field using the arrow keys, then typing the descriptor.

Note: Spaces must be input by the user, including any

space necessary between the custom and extended label

fields. An 80-column printout will run the two fields

together.

Extended

Label

CBE zones Specifies up to five software zones to

Switch Inhibit Specifies if an operator can manually

12 character custom label extension. See “Custom Label” above.

define the output responses of the

NAC based on various initiating

conditions (events)

activate an output

Type the numbers of up to five zones, including E0-E9,

F0-F9, L0-L9, R0-R9, and zones 00-99. The first zone

default is 00 (general alarm)

Type in one of the following values.

I = Switch Inhibit enabled

* = Switch Inhibit disabled (default for all but releasing

circuits)

NEXT or PREVIOUS Selection keys to scroll

24 NFS2-640/E Programming Manual — P/N 52742:L2 7/17/14

Page 25

Basic Program Programming

Program Change

Password

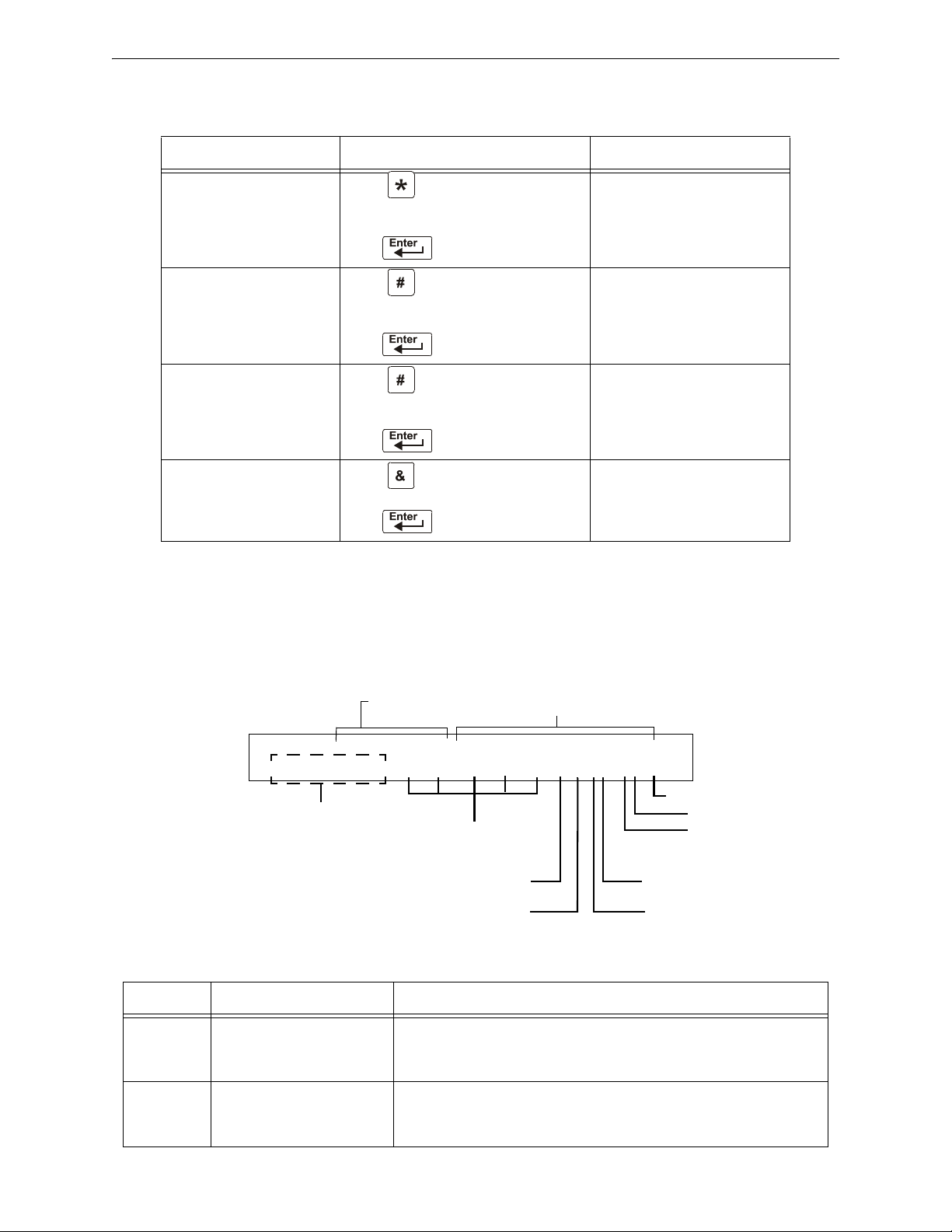

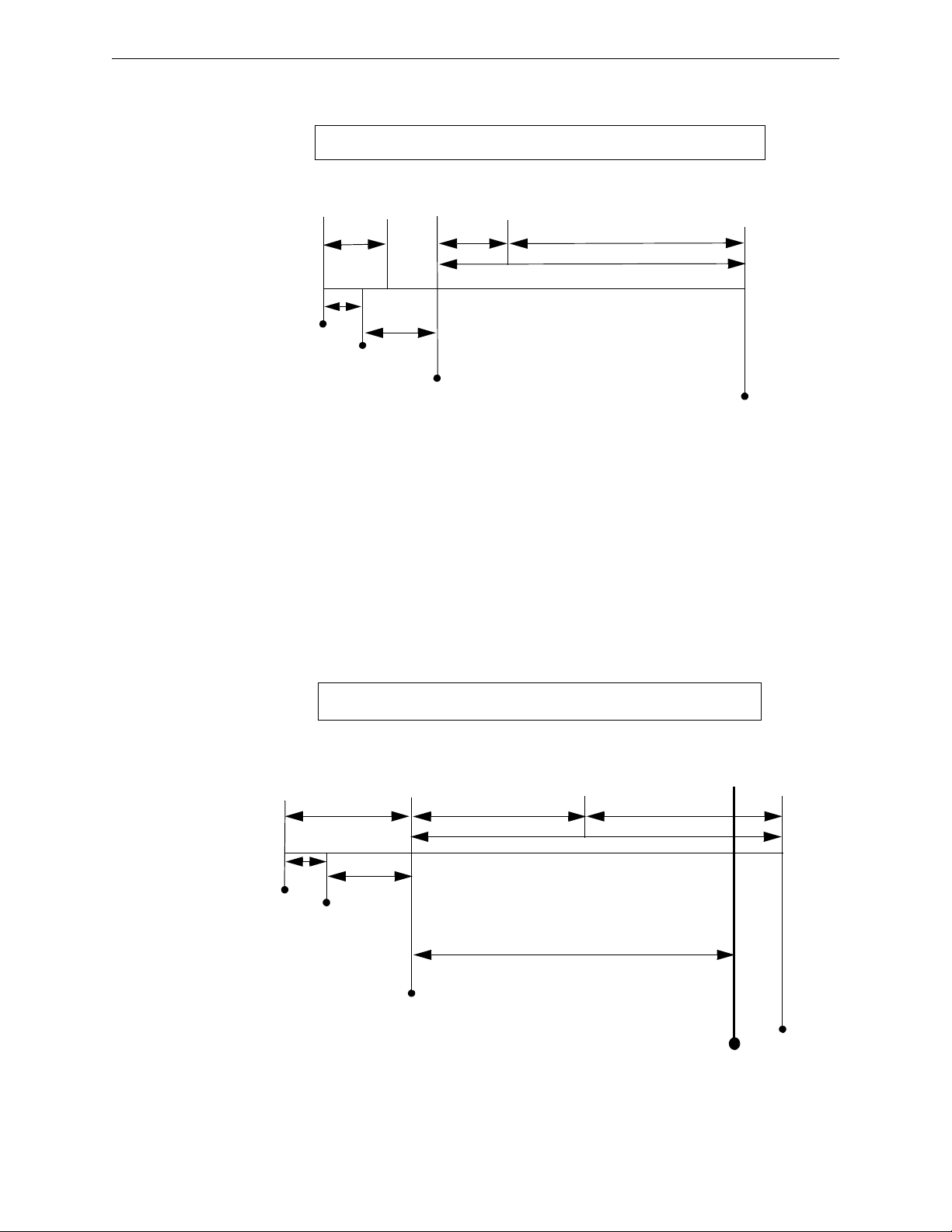

CHANGE PASSWORD *,NNNNN,E=PROGRAM

#,NNNNN, E=STATUS

Entry area for new password