Honeywell MS8103A1030, MS3103J1030, MS7503A2030, MS7403A2030, MS7503A2130 Installation Instructions Manual

...

3 Nm, 5 Nm Series Spring Return

N314

Direct Coupled Actuators

MS3103, MS3105, MS4103, MS4105, MS7403, MS7405, MS7503,

MS7505, MS8103, MS8105

INSTALLATION INSTRUCTIONS

MS3103, MS3105, MS4103, MS4105, MS7403, MS7405,

MS7503, MS7505, MS8103, MS8105 Spring Return Direct

Coupled Actuators (DCA) are used within heating, ventilating,

and air-conditioning (HVAC) systems. They can drive a variety

of quarter-turn, final control elements requiring spring return

fail-safe operation.

Applications include:

• Volume control dampers, mounted directly to the drive

shaft or remotely (with the use of accessory hardware).

• Quarter-turn rotary valves, such as ball or butterfly valves

mounted directly to the drive shaft.

• Linear stroke globe or cage valves mounted with linkages

to provide linear actuation.

• Available with cable on select models

Table 1. Models.

Power Supply

Model Number

Model Number

MS3103J1030 27 lb-in

MS7403A2030

MS7503A2030

MS7503A2130 1

MS8103A1030 45 Two-Position (SPST) 0

MS8103A1130 1

MS4103A1030 100-250 Vac

MS4103A1130 1

MS3105J3030 44 lb-in

MS3105J3130 1

MS7405A2030

MS7505A2030 MS7505W2030

MS7505A2130 MS7505W2130 1

MS8105A1030 MS8105W1030 45 Two-Position (SPST) 0

MS8105A1130 MS8105W1130 1

MS4105A1030 100-250 Vac

MS4105A1130 1

1

Number represents range

2

2-10 Vdc

3

0/2-10 Vdc

(including 3 ft. whip) Torque Voltage

24 Vac/dc

(3 Nm)

(5 Nm)

@50/60 Hz +/-

20%

24Vdc+/-10%

@50/60Hz

24 Vac/dc

@50/60 Hz +/-

20%

24Vdc+/-10%

@50/60Hz

Driving

SPECIFICATIONS

Models:

See Table 1.

Device Weight:

3.5 lbs (1.60 kg)

Ambient Operating Temperature:

-40° to 150°F (-40° to 65°C)

-22° to 150°F (-30° to 65°C) (Two position only)

Shipping and Storage Temperature:

-40° to +150°F (-40° to +65°C)

VA

Drive

1

(sec) Control Input/Output Description

6/3 90 Sylk-enabled 0

Floating, Modulating

Floating, Modulating

6/9 45 Two-Position (SPST) 0

6/3 90 Sylk-enabled (5 addresses & Analog Output) 0

Floating, Modulating

Floating, Modulating3, and Feedback

6/9 45 Two-Position (SPST) 0

2

,Three-Position, Feedback

3

, and Feedback

2

, Three-Position, Feedback

Switch

SPDT

Aux

0

0

0

0

62-0274-07

3 NM, 5 NM SERIES SPRING RETURN DIRECT COUPLED ACTUATORS

M28945

3-55/64 (98)

6-61/64

(177)

1-1/8

(29)

5-27/32

(148)

1-9/16

(40)

3-5/32 (80)

4-9/16

(116)

1-15/16

(49)

1-1/16

(27)

2-1/64

(55)

47/64

(19)

2-27/64 (61)

36 (914)

1

1

CABLE AND STRAIN

RELIEF ON SELECT

MODELS ONLY.

Humidity Ratings:

5% to 95% R.H., Non-Condensing

Electrical Connections:

Field wiring 18 AWG (0.5 mm) to 14 AWG (1.5 mm)

conductors (stranded or solid) and up to 2 - 14 AWG (1.5

mm) conductors (stranded) to screw terminals, located

under the removable access cover.

Auxiliary Switch (One SPDT):

Switch adjustable from 0-95°

500 uA Resistive at 5 Vdc (minimum)

250 Vac, 8 A resistive, 3 A inductive

Mounting: Self-centering shaft adapter (shaft coupling):

Round damper shafts: 3/8 to 5/8 in. (9 to 16 mm)

Square damper shafts: 1/4 to 1/2 in. (6 to 13 mm)

Minimum Damper Shaft Length:

1 in. (25 mm); 3 in.(76 mm) recommended.

Spring Return Timing (at rated load):

< 25 seconds @ -4°F to 130°F (-20°C to 55°C)

< 60 seconds @ -22°F (-30°C)

Cable Specification:

300 V, 75° C, Plenum Rated, 3 ft length from end of access

cover, 18 AWG

Sylk™ Bus:

Sylk is a two-wire, polarity insensitive bus that provides

communications between a Sylk-enabled actuator and a

Sylk-enabled controller. For wiring, the Sylk-enabled

actuator may be mounted up to 200 ft. (61 m) from the

controller; twisted pair wire is recommended for wire runs

longer than 100 ft. (30.5 m). Using Sylk-enabled actuators

saves I/O on the controller and is faster and cheaper to

install since the bus is polarity insensitive.

Stroke:95° ±3°, mechanically limited.

Approvals:

UL873

IEC 60730-1 and Part 2–14

UL1097 for Double Insulation

CE Certification Low Voltage Directive 2006/95/EC

CE EMC 2004/108/EC

C-Tick N314

Enclosure Ratings:

IP54

NEMA 2

Flame Resistance UL94-5VA

Input Impedance:

95 kOhm minimum.

Feedback Signal:

0(2)-10 Vdc, 3 mA minimum.

Analog Output Signal:

0(2)-10 Vdc

Noise Rating at 1m (Maximum):

Driving

Floating/Modulating/Econ/Sylk-enabled: < 40 dB(A)

2-Position: < 50 dB(A)

Spring Return: < 60 dB(A)

Accessories:

27518 Balljoint (5/16 in.)

103598 Balljoint (1/4 in.)

27520B, C, E, G, H, K, L, Q Pushrod (5/16 in. diameter)

STRN-STRNRLF Water-tight Cable Gland/Strain-relief

Fitting (10 pack)

STRN-WMK-01 Wall Mount Kit

STRN-ECONO-01 Economizer Retrofit Kit

STRN-CRK-01 Crank Arm Kit

STRN-SCSA Self Centering Shaft Adapter

STRN-CA-01 Crank Arm (Non-Self-Centering)

STRN-CA-02 Crank Arm (Self-Centering)

STRN-BRKT Anti-Rotation Bracket

62-0274—07 2

Fig. 1. Dimensional drawing of actuator in in. (mm).

TYPICAL SPECIFICATION

CAUTION

CAUTION

CAUTION

Spring return actuators shall be direct coupled type requiring

neither crankarm nor linkage and be capable of direct mounting

to a jackshaft of up to 5/8 in. diameter. The actuator shall connect

to the shaft using a removable output hub with a self-centering

shaft coupling. This coupling shall provide concentric mounting

and include an integral adjustable range-stop mechanism.

The actuator shall provide two-position, floating, proportional, or

Sylk bus control. Proportional control refers to direct acceptance

of 0-10 Vdc, 2-10 Vdc, or (with addition of a 500 ohm resistor) a 420 mA input signal. Proportional and floating control models

shall provide a feedback signal. Sylk-enabled models provide

control and feedback via communication between the actuator

and Sylk-enabled controller. Actuators shall provide wiring terminals located within an integral access cover with conduit

connections. Proportional and floating actuators shall have a

rotation direction control switch accessible on the cover.

All spring return actuators must be designed for either clockwise

or counterclockwise fail-safe operation with a continuously

engaged mechanical spring. This spring must return the valve or

actuator to a fail-safe position within 25 seconds of power loss.

All actuators shall be designed for a minimum of 60,000 fullstroke

cycles at rated torque and temperature, 60,000 spring return

cycles and 1,500,000 repositions. Run time shall be constant and

independent of: load, temperature, and supply voltage (within

specifications). All actuators shall be UL60730 and cUL (CSA22.2)

listed, have a five year warranty, and be manufactured under ISO

9001 International Quality Control Standards. Actuators shall be

as manufactured by Honeywell.

FRONT BACK

3 NM, 5 NM SERIES SPRING RETURN DIRECT COUPLED ACTUATORS

Motor Damage Hazard.

Corrosive vapors and acid fumes can damage

metal and plastic parts.

Install motor in areas free of acid fumes and other

deteriorating vapors.

Equipment Damage Hazard.

Tightly securing actuator to damper housing can

damage actuator.

Mount actuator to allow it to float along its vertical axis.

Preparation

Before mounting the actuator onto the damper shaft,

determine the:

— Damper/valve opening direction for correct spring return

rotation. The actuator can be mounted to provide clockwise

or counterclockwise spring return by flipping or turning the

unit over.

— Damper shaft size (see the Specifications section).

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

Electrical Shock or Equipment Damage Hazard.

Low voltage can shock individuals or short

equipment circuitry.

Disconnect power supply before installation.

IMPORTANT

Location

These actuators are designed to mount directly to a damper

external drive shaft. The shaft coupling fastens to the drive

shaft. The actuator housing includes slots which, along with

an anti-rotation bracket, secure the actuator to the damper

frame or duct work (see Fig. 7).

NOTES:

All wiring must agree with applicable codes,

ordinances and regulations.

— When mounted correctly, these slots allow the

actuator to float without rotating relative to the

damper shaft.

— Using other brackets or linkages, the actuator can

be foot-mounted or tandem-mounted.

Determine Appropriate Mounting

Orientation

The actuators are designed to open a damper by driving the

damper shaft in either a clockwise or counterclockwise

direction (see Fig. 2).

NOTES:

— Actuators are shipped in the fully closed (spring

return) position.

— An arrow on the hub points to a location on the

label to indicate the hub rotary position.

0

90

45

45

CW TO CLOSE

(FAIL-SAFE POSITION)

CCW TO OPEN

0

90

1

.5

0

.5

AUX

AUX

6

6

5

5

1

1

4

4

4

2

2

MODE

MODE

3

3

M27713

CCW TO CLOSE

(FAIL-SAFE POSITION)

CW TO OPEN

90

90

1

1

.5

.5

0

0

6

6

1

1

2

2

3

3

0

0

1

45

45

AUX

AUX

5

5

4

4

MODE

MODE

1

0

0

Spring

Spring

Spring

Spring

Return

Return

Return

Return

Fig. 2. Spring Return DCA mounting orientation.

Measure Damper/Valve Shaft Length

If the shaft is less than three inches in length, the shaft

coupling must be located between the damper/valve and

actuator housing. If the shaft length is more than three inches,

the shaft coupling may be located on either side of the

actuator housing.

3 62-0274—07

3 NM, 5 NM SERIES SPRING RETURN DIRECT COUPLED ACTUATORS

CAUTION

M32676

Spring

Return

AUX

.5

90

0

0

1

45

MODE

6

5

4

3

2

1

Spring

Return

AUX

.5

90

0

0

1

45

MODE

6

5

4

3

2

1

MODE SELECT

1 = 2... 10 VDC

2 = 10... 2 VDC

3 = 0... 10 VDC

4 = 10... 0 VDC

5 = FLOATING (FWD)

6 = FLOATING (REV)

MS74 SERIES

MODE SELECT

1 = 2...10 VDC

2 = 10...2 VDC

3 = 3K OHM NTC

THERMISTOR

4 = 3 POSITION

5 = FLOATING

(FWD)

6 = FLOATING (REV)

MS31 SERIES

MODE SELECT

1 = ADDRESS 11

2 = ADDRESS 12

3 = ADDRESS 13

4 = ADDRESS 14

5 = ADDRESS 15

6 = TEST

AUXILIARY KNOB

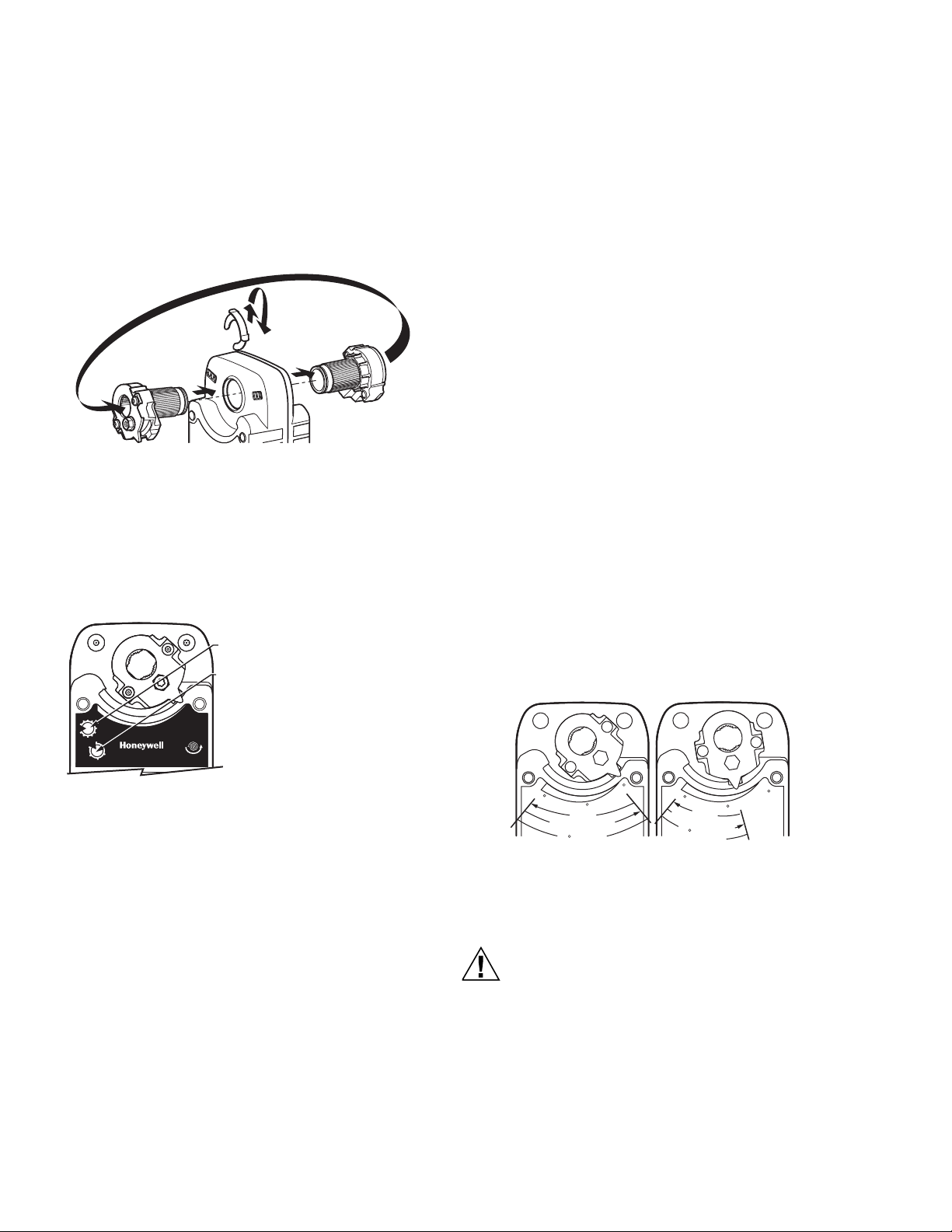

If the coupling must be moved from one side of the actuator to

the other, reverse the spring return direction and flip the

actuator. Follow these instructions (see Fig. 3):

1. Remove the retainer clip from the shaft coupling and set

it aside for later use.

2. Remove shaft coupling from one side of the actuator.

3. Replace the shaft coupling on the opposite side of the

actuator aligning it based on the stroke labeling.

4. Replace the retainer clip on the shaft coupling using the

groove of the coupling.

M27714

Fig. 3. Mounting shaft coupling to actuator opposite side.

Selecting Actuator Control Signal

Selections are made using a dial that appears on both the

front and back of the actuator (see Fig. 4).

SELECT SWITCH POSITION

For switch models, select the degree of rotation you want the

switch to activate.

Non-Standard Stroke

Mechanical Stroke Limit Reduction

For applications requiring a span less than 95 degrees, a

simple adjustment can be made. When the rotational

mounting of the shaft coupling is changed, the actuator drives

less than the full 90 degrees stroke.

The stroke is adjustable in 5 degree increments. Once

adjusted, the actuator drives until the shaft coupling reaches

the mechanical stop (part of the housing). The stop causes

the motor to discontinue driving and the shaft coupling drives

no farther. When the actuator returns, it stops at the fail-safe

position.

To limit the stroke range, proceed as follows:

1. Remove the retainer clip from the shaft coupling and set

it aside for later use.

2. Remove shaft coupling from the actuator.

3. Rotate the coupling to the desired position, aligning it

based on the stroke labelling. See Fig. 5.

NOTE: The shaft coupling location determines the

travel span.

To select the control signal simply turn the mode selection dial

to the desired mode (as indicated on the device label) without

exceeding range indicators.

Fig. 4. Dials for control signal and switch or minimum

position.

Auxiliary Knob

The auxiliary knob can be used to control minimum position

(MS74 Series) or switch position.

SELECT MINIMUM POSITION (MS74 SERIES)

To set the actuator minimum position, turn the AUX dial to the

desired position. Alternatively, minimum position can be set

with an externally connected 1kOhm potentiometer connected

across common (terminal 2) and minimum position (terminal

4); the setting on the AUX dial will be overridden.

EXAMPLE:Setting shaft coupling to an approximate

fail-safe position of 35 degrees (as indicated

on the housing) limits stroke to 60 degrees.

(See Fig. 5)

4. Install the shaft coupling at this position.

5. Replace the retainer clip on the shaft coupling using the

groove of the coupling.

0

90

45

D

E

R

I

V

S

P

R

9

N

R

I

U

N

T

G

E

R

0

E

K

S

O

T

R

90

45

6

D

S

R

I

V

E

P

R

I

N

G

R

E

6

T

U

R

0

S

T

R

O

K

E

0

N

M27716

Fig. 5. Stroke reduction.

Mounting

Device Malfunction Hazard.

Improper shaft coupling tightening causes device

malfunction.

Tighten shaft coupling with proper torque to prevent

damper shaft slippage.

62-0274—07 4

Loading...

Loading...