Page 1

Remote Bulb Thermostats

75-5559

GENERAL

DESCRIPTION

The LP916 Thermostats are bleed-type controllers with a

fixed throttling range. They have a liquid-filled, remote

thermal element.

APPLICATION

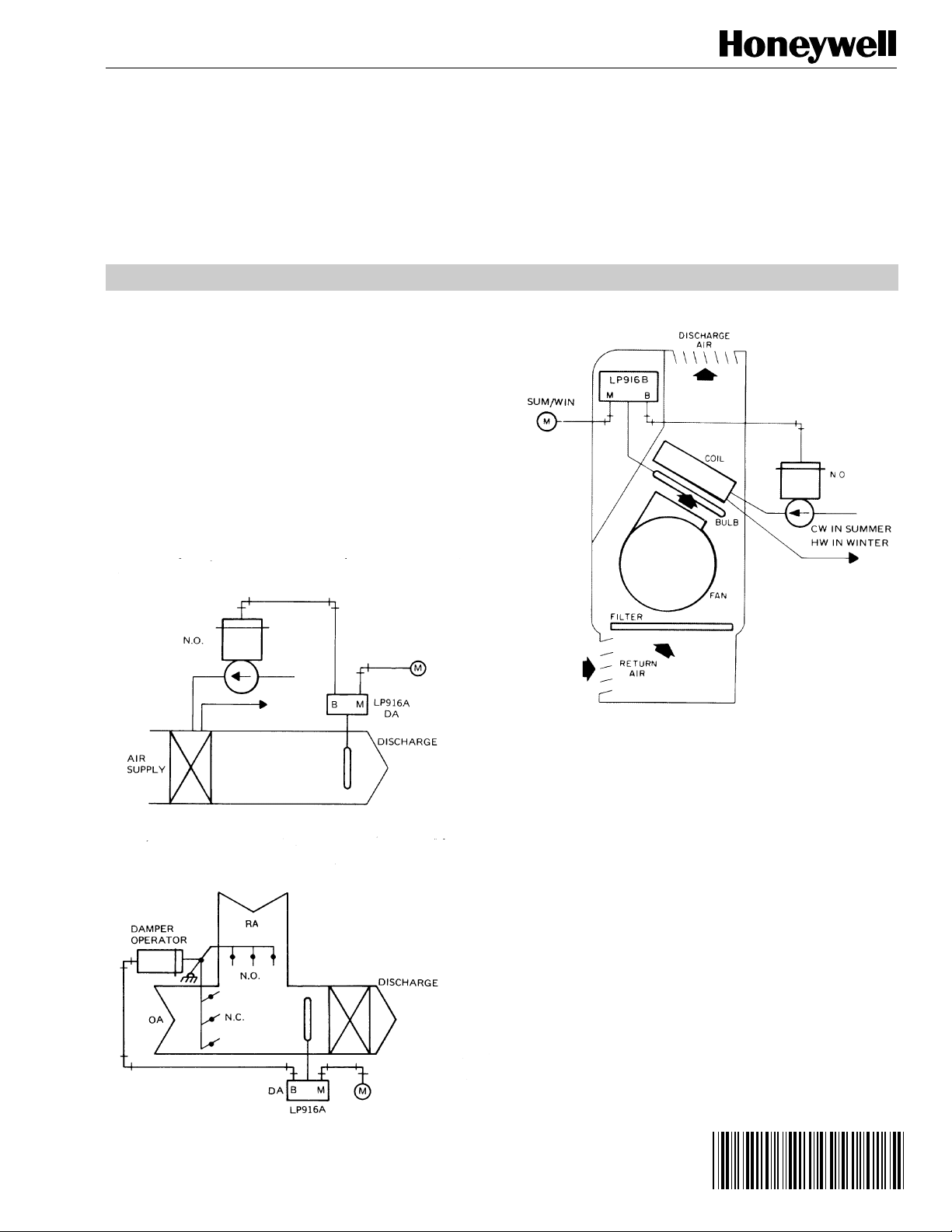

Typical applications for the LP916A are duct-mounted (Fig. 1)

and mixed air control (Fig. 2). The LP916B is typically used

for fan coil unit control (Fig. 3). Typical applications for the

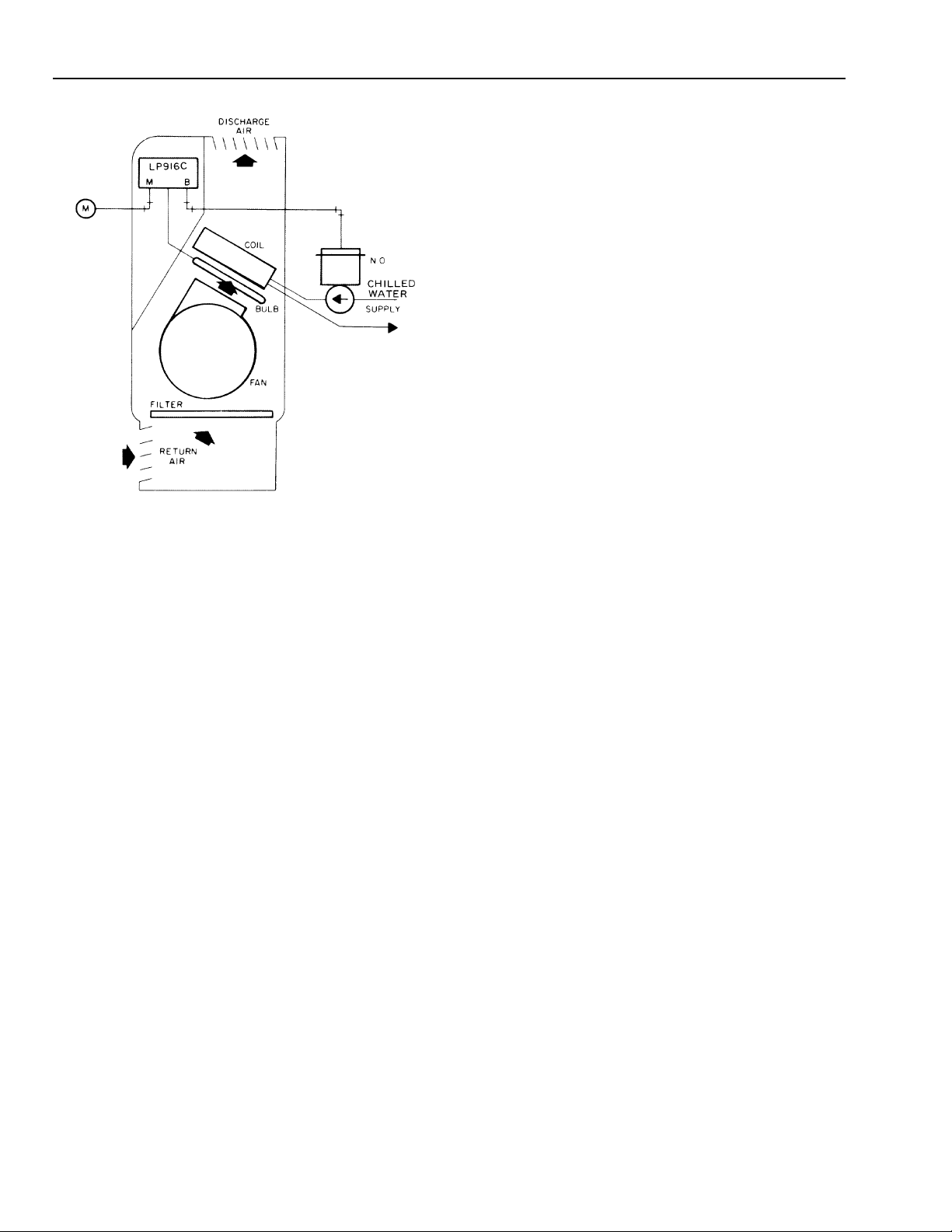

reverse acting LP916C are cooling coil control similar to

Figure 1 or fan coil control (Fig. 4).

LP916A-C Pneumatic

SERVICE DA TA

S5783-1

Fig. 1. Typical LP916A duct-mounted heating application.

S5785-2

Fig. 2. Typical LP916A mixed air application.

S3803-1

Fig. 3. Typical LP916B fan coil application, heating/

cooling with seasonal changeover.

Copyright © 1987 Honeywell Inc. • All Rights Reserved

Page 2

LP916A-C PNEUMATIC REMOTE BULB THERMOSTATS

S22642

Fig. 4. Typical LP916C fan coil application, cooling only.

SPECIFICATIONS

Models:

LP916A: Direct Acting.

LP916B: Reverse acting at 9 or 13 psi (62 or 90 kPa)

supply pressure (Summer), direct acting at 18 psi

(124 kPa) supply pressure (Winter).

LP916C: Reverse Acting.

Maximum Safe Air Pressure:

25 psi (172 kPa).

Maximum Safe Temperature:

Duct-mounted models 190F (88C); all others 135F (57C).

Nominal Main-Line Pressure:

LP916A & C: 18 psi (124 kPa).

LP916B: 18 psi (124 kPa) heating, 9 or 13 psi (62 or

90 kPa) Cooling.

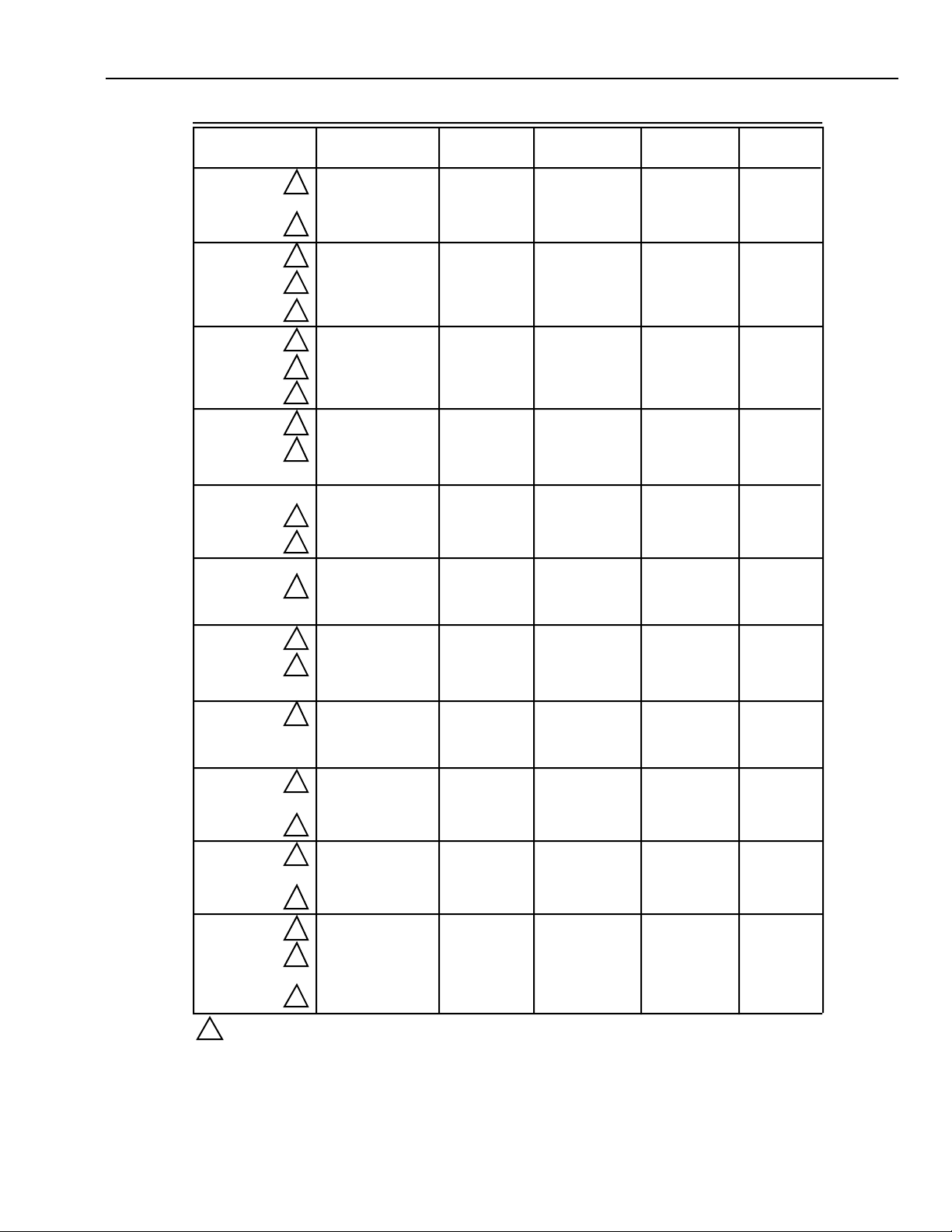

For other LP916 specifications refer to Table 1.

75-5559

2

Page 3

Model

Setpoint

Range F/C

LP916A-C PNEUMATIC REMOTE BULB THERMOSTATS

Table 1. LP916 Specifications.

Throttling

Range F/C

Restrication

Size In.

Bulb Size

Inches

Mounting

Bracket

1LP916A1001 65-85F 3.5F 3/8 x 9 Separate

0.007

LP916A1019 65-85F or 19-30C 3.5F or 2C 0.007 1/2 x 5 Integral

1LP916A1027 65-85F 3.5F 0.007 3/8 x 9 Integral

1 Integral

LP916A1050 17-27C 1.95C 0.007 1/2 x 5 Integral

1

1

1

1

1

LP916A1100

1

1

55-95F 7.0F 0.007 3/8 x 6-11/16LP916A1035

17-27C 1.95C 0.007 3/8 x 9LP916A1068 Integral

13-35C 3.89C 0.007 3/8 x 6-11/16LP916A1076 Integral

17-27C 1.95C 0.007 3/8 x 9LP916A1084 Integral

17-27C 3.80C 0.007 3/8 x 6-11/16LP916A1092 Separate

35-115F 0.007 3/8 x 3-1/214.0F

Integral

55-95F 0.007 3/8 x 77.0FLP916A1118 Integral

65-85F or 19-30C 3.5F or 2CLP916A1126 0.005 3/8 x 9 Separate

3.5F or 2C65-85F or 19-30CLP916A1134 0.005 3/8 x 9 Integral

1

1

55-95F 7.0F 0.005 3/8 x 6-11/16LP916A1142 Integral

17-27C 1.95C 0.005 3/8 x 9LP916A1159 Integral

LP916A1175 0.007 3/8 x 77.0F or 4C40-80F or 4-27C Integral

1

0.007 3/8 x 93.5F65-85FLP916B1009 Separate

3.5F or 2C65-85F or 19-30CLP916B1017 0.007 1/2 x 5 Integral

1

1

65-85F 3.5F 0.007 3/8 x 9LP916B1025 Integral

17-27C 1.95C 0.007 3/8 x 9LP916B1041 Integral

3.5F or 2C65-85F or 19-30CLP916B1058 0.007 1/2 x 5 Integral

1

65-85F 3.5F 0.007 3/8 x 9LP916B1066 Integral

3.5F or 2C65-85F or 19-30CLP916B1074 0.005 3/8 x 9 Separate

3.5F or 2C65-85F or 19-30CLP916B1082 0.005 1/2 x 5 Integral

1

17-27C 1.95C 0.005 3/8 x 9LP916B1090 Integral

3.5F or 2C65-85F or 19-30CLP916B1108 0.005 3/8 x 9 Integral

1

1

65-85F 3.5F 0.007 3/8 x 9LP916C1007 Integral

17-27C 1.95C 0.007 3/8 x 9LP916C1015 Integral

LP916C1023 60-80F or 16-27C 3.5F or 2C 0.007 3/8 x 9 Integral

1

1

1

35-115F 0.007 3/8 x 3-1/214.0FLP916C1072 Integral

55-95F 0.007 3/8 x 77.0FLP916C1080 Integral

3.5F or 2C65-85F or 19-30C 0.007 1/2 x 5LP916C1049 Integral

3.5F or 2C65-85F or 19-30CLP916C1098 0.005 3/8 x 9 Integral

1

40-80F or 4-27C 0.007 3/8 x 77.0F or 4CLP916C1114 Integral

1

Inactive or obsolete.

3

75-5559

Page 4

LP916A-C PNEUMATIC REMOTE BULB THERMOSTATS

OPERATION

LP916A (Direct Acting)

When temperature at the sensing element falls below setpoint

of the LP916A, branchline pressure to the normally open

(n.o.) valve is lowered, and the valve is modulated open to

maintain setpoint temperature.

LP916B (Reverse/Direct Acting)

With main-line pressure at 13 psi (90 kPa) for all except

LP916B1058 which requires 9 psi (62 kPa), the LP916B

operates reverse acting. As the sensed temperature

increases, the branchline pressure decreases and chilled

water flow increases with a n.o. valve.

With a high main-line pressure of 18 psi (124 kPa) or above,

the LP916B operates direct acting. As the sensed

temperature increases, the branchline pressure increases

and hot water flow decreases with a n.o. valve.

LP916C (Reverse Acting)

When the LP916C is used with a normally open valve for

cooling, branchline pressure drops with a rise in sensed air

temperature and the n.o. valve is modulated open to maintain

setpoint temperature.

CLEANING

Remove cover. Use cleaning solvent to clean all surfaces.

Clean the element and capillary tubing, making certain

neither is damaged or kinked. Do not bend the capillary

tubing in a short radius.

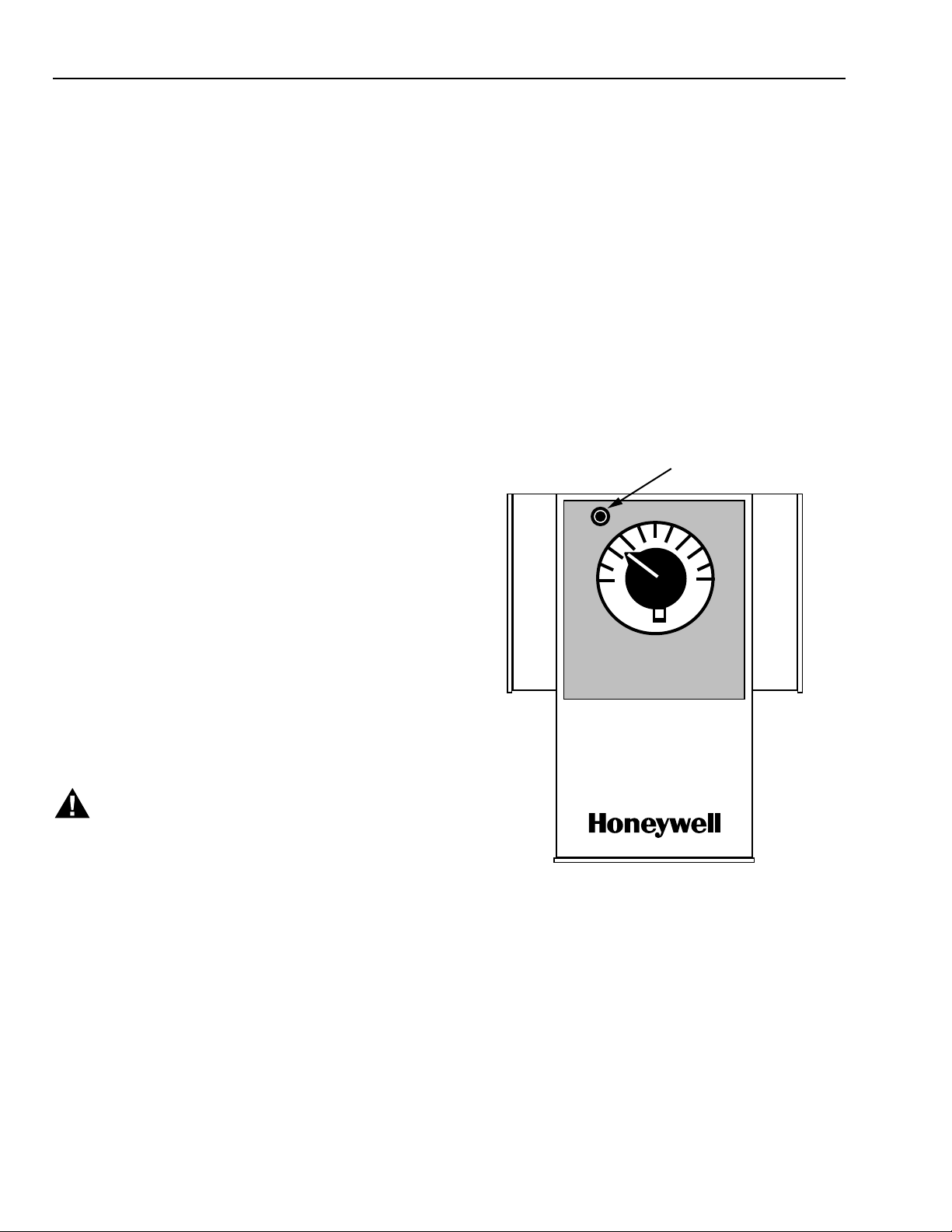

OPERATIONAL CHECK

Use gage adaptor. Insert the gage into the gage tap (Fig. 5)

on the front of the device. Set main-line pressure to 18 psi

(124 kPa), or 13 psi (90 kPa) for LP916B Summer

application. Slowly turn the setpoint knob above and below

bulb ambient temperature. The branchline pressure should

vary from 3 to 13 psi (21 to 90 kPa) pressure, or 13 to 3 psi

(90 to 21 kPa) for reverse acting application within the rated

throttling range. If operation is not satisfactory, recalibrate and

recheck (see CALIBRATION). Turning the knob to above 13

psi (90 kPa) should build branch line to within 2 psi (14 kPa)

of main.

GAGE TAP

NORMAL

COOLER

WARMER

MAINTENANCE

EQUIPMENT REQUIRED

— Commercial Cleaning Solvent or Degreaser.

— Gage Adaptor CCT729A.

— Gage 305965, 0 to 30 psi.

— 5/64-inch Hex wrench.

WARNING

Careless handling of solvents can result in permanent

damage to the respiratory system or skin. Avoid

prolonged inhalation of vapors or contact with skin.

C2861

Fig. 5. LP916 Gage tap location.

75-5559

4

Page 5

CALIBRATION CHECK

Set setpoint knob to temperature measured at bulb location.

Branchline pressure should be 8 ±1 psi (55 ±7 kPa).

CALIBRATION

LP916A & C

LP916A-C PNEUMATIC REMOTE BULB THERMOSTATS

A Apply 18 psi (124 kPa) main-line pressure.

B Measure temperature at sensing bulb location.

C Remove setpoint knob using 5/64-in hex wrench to

loosen setscrew.

D Rotate setpoint shaft to achieve 8 psi (55 kPa)

branchline pressure. Allow enough time for pressure

build-up.

E Replace the knob and position the pointer to

correspond to the temperature sensed by the remote

bulb.

LP916B

A For direct action, follow Steps 1 through 5 for LP916A

and C.

B For reverse action (except LP916B1058), apply 13 psi

(90 kPa) main-line pressure. For the LP916B1058,

apply 9 psi (62 kPa) main-line pressure.

C Adjust switchover lever stop (Fig. 6) to achieve 8 psi

(55 kPa) branchline pressure when the setpoint knob is

set to measured bulb temperature. For the

LP916B1058 model, branchline pressure should be

6 psi (41 kPa).

SWITCHER

LEVER STOP

SWITCHER

SPRING

ADJUSTING NUT

STUD

C8363

Fig. 6. LP916B Automatic switchover mechanism.

5

75-5559

Page 6

LP916A-C PNEUMATIC REMOTE BULB THERMOSTATS

TROUBLESHOOTING

Before troubleshooting the LP916, check branchline piping

and actuators for leaks.

Refer to Figure 7 to troubleshoot the LP916 Thermostat.

BEGIN

MAKE

OPERATIONAL

CHECK

CALIBRATION

YES

CALIBRATION

RECALIBRATE

CHECK PIPING AND

CHECK

OK?

NO

CONTROLLER OK.

ACTUATOR FOR

LEAKS

OPERATES

NO YES

PROPERLY

?

DISCONNECT

BRANCH LINE AT

CONTROLLER

AND PLUG

OUTLET

PRESSURE

BUILDS UP

SMOOTHLY

WHEN SETPOINT

IS CHANGED?

YES

PRESSURE

YES NO

BLEEDS OFF

WHEN SETPOINT

IS MOVED IN

OPPOSITE

DIRECTION?

YES

NO

CHECK MAIN

AIR

PRESSURE

CORRECT

PRESSURE

FOR SEASON

OR

APPLICATION?

NO

TROUBLESHOOT

AIR SUPPLY

REPLACE FILTERS AND

RESTRICTION PLATE

YES

PRESSURE

BUILDS UP

PROPERLY?

NO

REPLACE

CONTROLLER

75-5559

C2860

Fig. 7. LP916 Troubleshooting flowchart.

6

Page 7

REPAIR

LP916A-C PNEUMATIC REMOTE BULB THERMOSTATS

The only repair recommended for the LP916 is the

replacement of the plate and tube assembly, gaskets,

restriction plate, and filters with connector assembly and

gasket. Since February 1984, models have a different

connector assembly with a single gasket, these are included

in Repair Kit 14003113-002, as shown in Figure 8. All

available parts are listed in the PARTS AND ACCESSORIES

section.

EQUIPMENT REQUIRED

Gulmite Head Screw Wrench 316744-00021.

14003113-002 REPAIR KIT INSTALLATION

A Turn off system air and remove LP916 from system.

B Remove and save the three No. 8-32 x 7/16-in. pan

head screws from the connector assembly (Fig. 8) or

plate and tube assembly (Fig. 9 or 10).

C Lift off the connector assembly and gasket or plate and

tube assembly, restriction gasket, restriction plate, body

gasket, and two filters and discard.

D Place new gasket on body and align screw holes.

E Position the new connector assembly on gasket and

align screw holes. A 0.007 in. restriction may be used

for models with a 0.005 in. restriction with no effect on

operation except a slightly higher air consumption. If air

consumption is a problem, connector assembly with a

0.005 in. restriction may be ordered and substituted.

F Insert and tighten the three screws.

G Make operational check (See OPERATIONAL CHECK).

GASKET

CONNECTOR

ASSEMBLY

INDICATES 0.005 IN. RESTRICTION

INDICATES 0.007 IN. RESTRICTION

Fig. 8. Repair kit 14003113-002 (0.007 in. restriction

included in kit).

C8362

NOTE: For 14003113-001 Repair Kit follow directions on

package.

7

75-5559

Page 8

LP916A-C PNEUMATIC REMOTE BULB THERMOSTATS

P ARTS AND ACCESSORIES

PARTS LIST

See Figure 9 for LP916A &C exploded view and Figure 10 for

LP916B exploded view. See Tables 2 and 3 for LP916A &C

parts list and Tables 3 and 4 for LP916B parts list.

Table 2. LP916A and C Parts list (Fig. 9).

Key Part No. Description

Cover

6-32 x 3/16 in. rd-hd slotted screw

6-32 x 1/4 in. pan-hd slotted screw with washer (2)

Spring

Plate

6-32 x 0.31 (5/16) in. rd-hd slotted screw with washer (2)

Base

Baseplate

Scaleplate

8-32 x 5/16 in. slotted pan-hd screw (7)

Palnut

Setpoint Shaft

Knob (includes 8-32 x 5/16 in. hex socket setscrew). Use 5/64 in. key to tighten.

Repair Kit—Consists of Filters, Body Gasket, 0.007 Restriction, and Restriction Gasket

Filters (2)

BodyGasket

0.007 Restriction Plate

Restriction Gasket

Plate and Tube Assembly

8-32 x 7/16 in. pan-hd slotted screw (3)

Connector Assembly (0.007)

Connector Assembly (0.005)

Gasket

Repair Kit—Consists of 14004378-001 Connector Assm. (0.007) & 14004376-001 Gasket

Nozzle

Flapper

Spring

4-40 x 3/16 rd-hd slotted screw

Element and Lever Assembly (see Table 3)

Element and Lever Assembly (see Table 3)

Element and Lever Assembly (see Table 3)

Lever (LP916A)

Lever (LP916C)

Spring

8-32 x 5/16 in. pan-hd slotted screw with star lockwasher

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

1

2

3

4

5

6

7

8

9

316294

—

—

—

—

—

—

—

—

—

—

—

—

14003113-001

—

—

—

—

—

—

14004378-001

14004378-002

14004376-001

14003113-002

—

—

—

—

316372A

316372B

316372C

—

—

—

—

75-5559

8

Page 9

LP916A-C PNEUMATIC REMOTE BULB THERMOSTATS

Fig. 9. LP916A and C Exploded view (See Tables 2 and 3).

9

S22649

75-5559

Page 10

LP916A-C PNEUMATIC REMOTE BULB THERMOSTATS

Table 3. LP916A-C Element and lever assemblies.

Assembly

Part No. Part No. Bulb Size in. (mm)

316372A A1001, A1027, A1068, B1009,

316372B A1019, B1017, B1058, C1049 1/2 x 5-3/4

316372Ç A1035, A1076, A1118, A1126,

Key Part No. Description

Cover

Nut

Lever

Element and Lever Assembly (see Table 3)

Element and Lever Assembly (see Table 3)

Element and Lever Assembly (see Table 3)

Stud

Spring

Lever

4-48 x 3/16 in. hex-hd screw

4-48 nut

8-32 x 0.31 (5/16) in. rd-hd slotted screw with washer (2)

Base

Spring

Disc Assembly

Diaphragm

Baseplate

8-32 x 5/16 in. slotted pan-hd screw (7)

Palnut

Setpoint Shaft

Knob (includes 8-32 x 5/16 in. hex socket setscrew). Use 5/64 in. key to tighten.

Repair Kit—Consists of Filters, Body Gasket, 0.007 Restriction, and Restriction Gasket

Filters (2)

BodyGasket

0.007 Restriction Plate

Restriction Gasket

Plate and Tube Assembly.

8-32 x 7/16 in. pan-hd slotted screw

Connector Assembly (0.007)

Connector Assembly (0.005)

Gasket

Repair Kit—Consists of 14004378-001 Connector Assm. (0.007) & 14004376-001 Gasket

Nozzle

Flapper

Spring

4-40 x 3/16 in. rd-hd slotted screw (3).

6-32 x 3/16 in. rd-hd slotted screw

Spring

8-32 x 5/16 in. pan-hd slotted screw with star lockwasher (2)

10

11

12

13

14

15|

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

1

2

3

4

5

6

7

8

9

316294

—

—

316372A

316372B

316372C

—

—

—

—

—

—

—

—

—

—

—

—

—

—

316732

14003113-001

—

—

—

—

—

—

14004378-001

14004378-002

14004376-001

14003113-002

—

—

—

—

—

—

—

B1025, B1041, B1066, C1007,

C1023

A1134, A1142, A1159, A1175,

B1074, B1082, B1090, B1108,

C1080, C1098, C1114

Table 4. LP916B Parts list (Fig. 10).

3/8 x 9-1/2

(9.5 x 241)

(13 x 146)

3/8 x 6-3/4

(10 x 172)

75-5559

10

Page 11

LP916A-C PNEUMATIC REMOTE BULB THERMOSTATS

Fig. 10. LP916B Exploded view.

11

S22649

75-5559

Page 12

LP916A-C PNEUMATIC REMOTE BULB THERMOSTATS

ACCESSORIES

A Gage 305965 (0 to 30 psi).

B Gage Adaptor MQP729.

C Internal Mounting Bracket AK3993.

D Mounting Kits for fan coil units:

316016A with small bracket.

316016B with full length bracket.

316016C with scaleplate, knob, and mounting

screws only.

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your

use or modification to, the literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and

against any liability, cost, or damages, including attorneys’ fees, arising out of, or resulting from, any modification to the

literature by you.

Home and Building Control

Honeywell Inc.

Honeywell Plaza

P.O. Box 524

Minneapolis MN 55408-0524

75-5559 Rev. 6-87 Printed in U.S.A.

75-5559

Home and Building Control

Honeywell Limited-Honeywell Limitée

155 Gordon Baker Road

North York, Ontario

M2H 2C9

12

Helping You Control Your World

Loading...

Loading...