Page 1

LP907A

g

(

y

y

g

g

g

g

g

g

ge(s)

(

g (

(

g

[

j

y

g

g

g

g

1-1/16 (27)

7/8 (22)

5/8

(16)

3/8 NPT

NUT

SPACERS (2)

DUCT WALL

18-3/4 (476)

3-7/16

(87)

1/8 NPT

2

(51)

2-1/4 (57)

1/2

(13)

HONEYWELL

11/32

(9)

3/4 DIAM. HOLE

(MINIMUM)

REQUIRED

FOR MOUNTING

M7996A

)

g

yrig

95- 1612EF

Airstream Insertion Thermostat

INSTALLATION INSTRUCTIONS

APPLICATION

The LP907 Airstream Insertion Thermostat is a direct-acting,

le-pipe, bleed-type controller with a rigid element. The

sin

LP907B

with lockout capabilit

for lockout durin

replacin

Switchin

no longer available) was the same as the LP907A

. It included a pneumatic switching rela

summer (cooling) operation. When

the LP907B, use an LP907A and an RP670A

Relay.

SPECIFICATIONS

Model:

Dimensions:

Temperature Ratings:

Operatin

Storage (Maximum Safe): 150°F (66°C).

Throttlin

Setpoint Ran

Setpoint Adjustment:

Element:

Direct-acting, bleed-type controller.

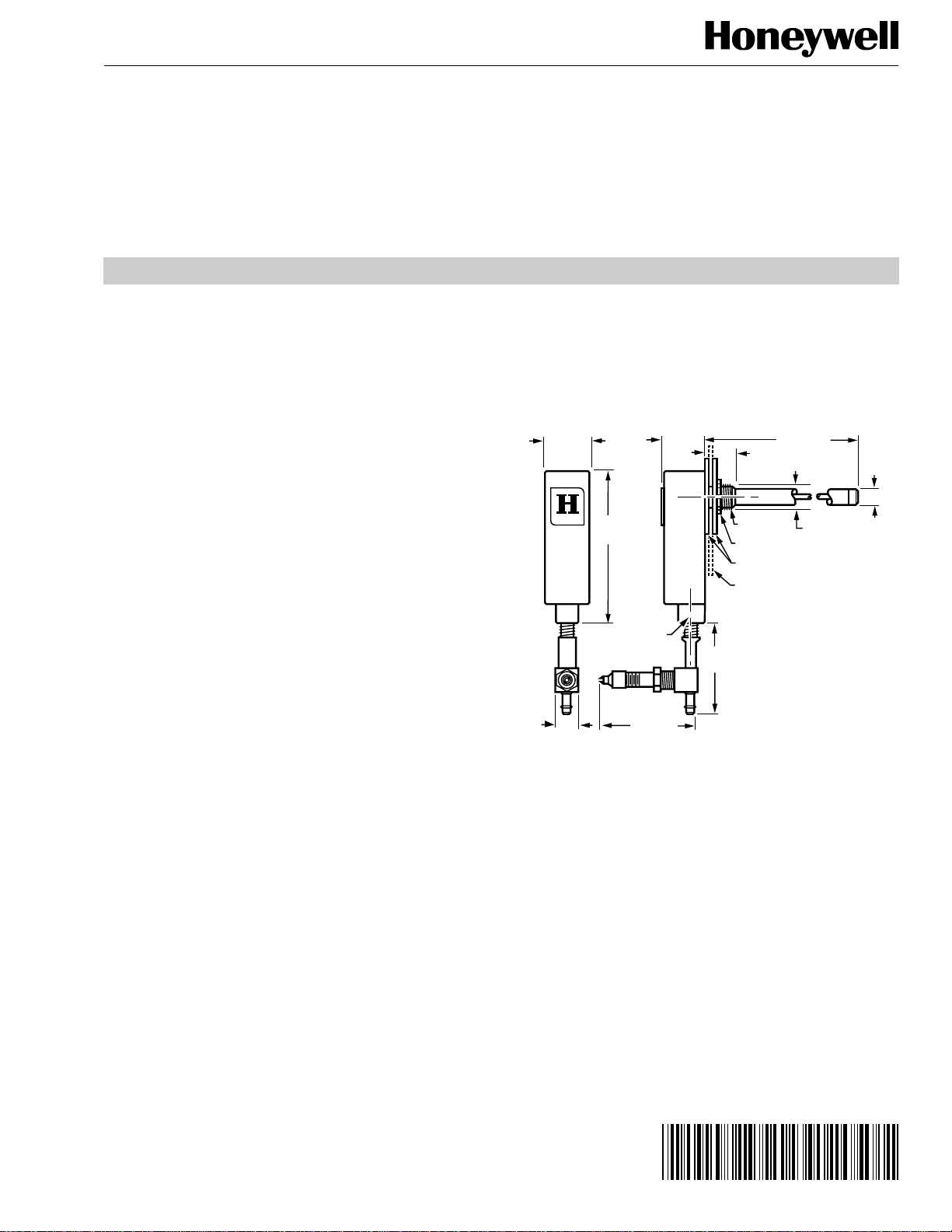

See Fi

. 1.

Range: 40°F to 140°F (4°C to 60°C).

Range (adjustable internally): 10 to 70°F (6 to 39K).

: 40°F to 140°F (4°C to 60°C);

Dial Front: 40°F to 90°F (4°C to 32°C),

Dial Back: 90°F to 140°F

32°C to 60°C).

Dial under cover.

18-3/4 in. (476 mm) long x 3/8 in. (10 mm) diameter

invar rod and seamless brass tube.

When mountin

with an immersion well, use 107408 Heat

Conductive Compound in the well to improve response.

NOTE: For further information concernin

wells, see Form

68-0040 Immersion Wells and Compression Fittin

for Temperature Controllers.

Fig. 1. Dimensions of LP907A in in. (mm).

s

Maximum Safe Air Pressure:

Air Connections:

Mounting:

Push-on barb for 1/4 in.

Insertion with locknut on insertion couplin

20 psi

138 kPa).

6 mm) poly tubing.

Accessories:

14002913-002 External Restriction

301572A00767 Calibration Ad

309387 Filter Assembl

CCT2085 Gage Adapter.

BEFORE INSTALLING

Use with a 0.007-inch (0.17 mm) diameter restriction such as

the 14002913-002 Filter/Restriction Cartrid

restriction in the MP516B and C Damper Operators.

® U.S. Registered Trademark

Cop

ht © 2001 Honeywell • All Rights Reserved

.

0.007 in. (0.2 mm)].

ustment Key.

e or the integral

INSTALLATION

.

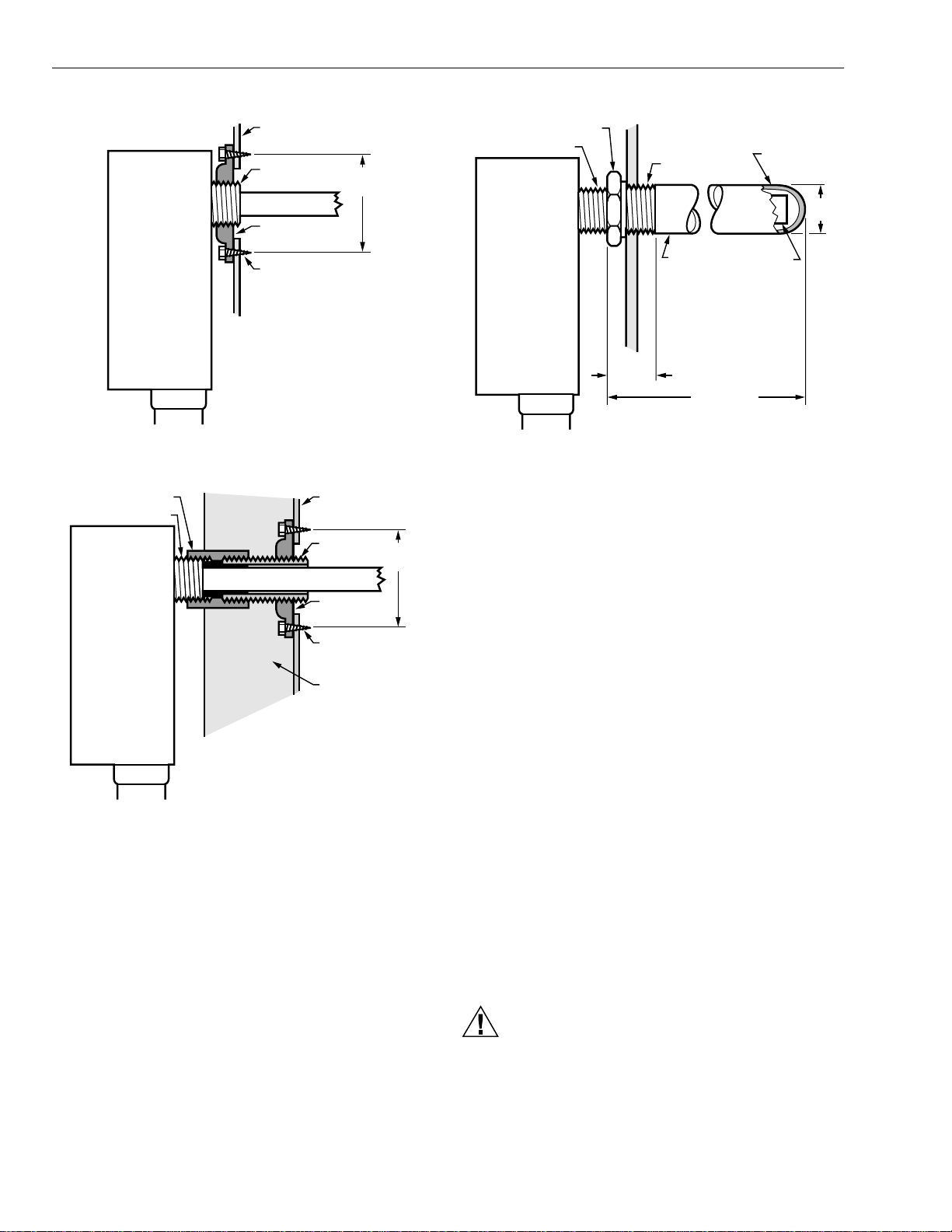

The LP907A can be mounted in any position. See Fig. 2

through 4 for mounting configurations.

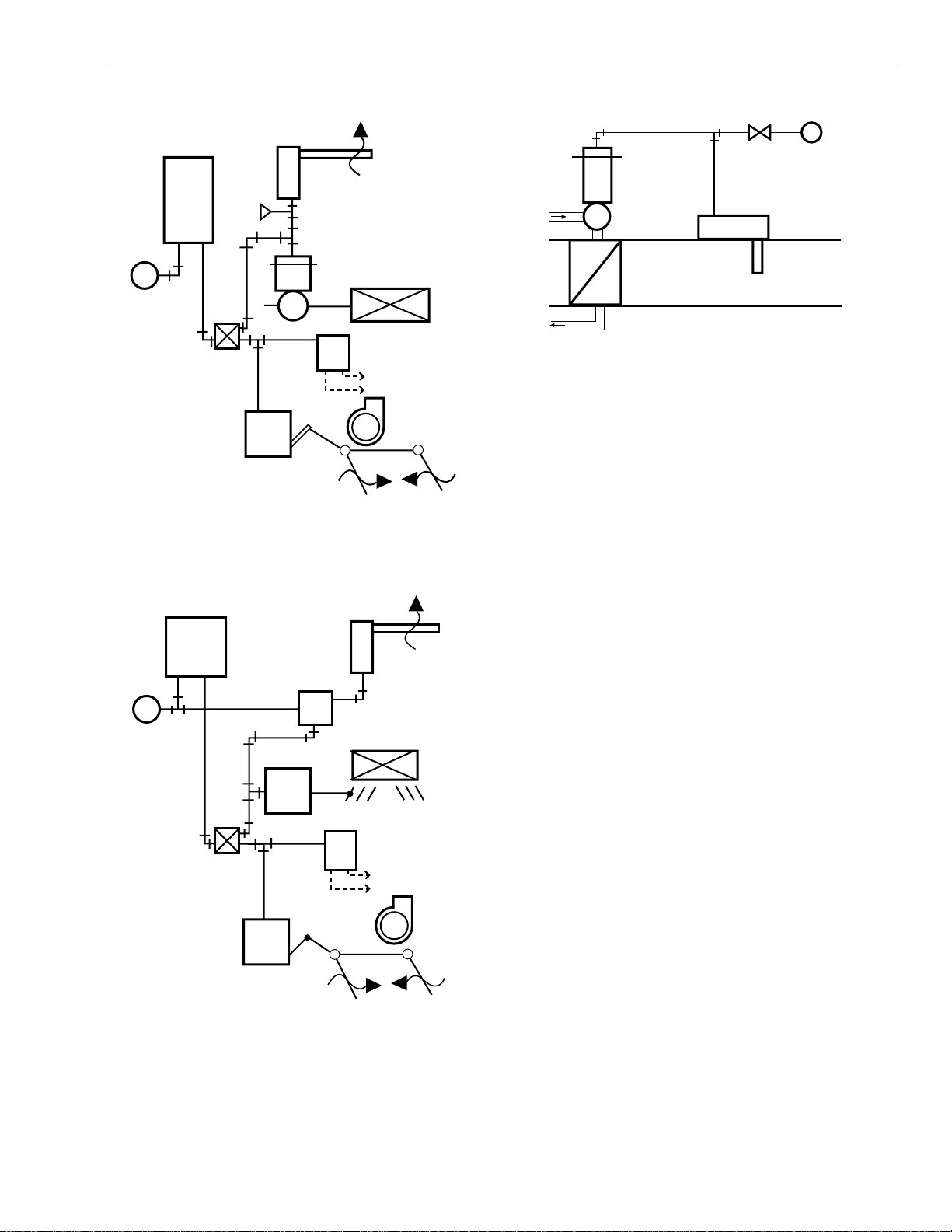

OPERATION

Due to its bleed-type construction and wide throttling range,

the LP907A provides submaster-type operation (most often

low-limit control

h 7 for typical hookups.

throu

in a normal unit ventilator system. See Fig. 5

Page 2

LP907A AIRSTREAM INSERTION THERMOSTAT

g

(

y

g

g

g

y

g

(

g

)

g (

g

(

j

y (

y

y

g

g

gly

j

DUCT

LP907

3/8 NPT

3/8

WASTE NUT

SHEET METAL

MTG. SCREWS (2)

M17676

1-11/16

(43)

Fig. 2. Mounting on standard sheet metal duct.

3/8 NPT COUPLING

3/8 NPT

LP907

DUCT

3/8 CLOSE

NIPPLE

3/8

WASTE NUT

SHEET METAL

MTG. SCREWS (2)

INSULATION

1-11/16

(43)

HEX COLLAR

LP907

3/8 NPT

1-3/16 (29)

1/2 NPT

IMMERSION

WELL

19-1/16 (484)

CONDUCTIVE

COMPOUND

ELEMENT

Fig. 4. Mounting in boiler wall with immersion well.

MAINTENANCE

IMPORTANT

• Mechanical devices require periodic service to

provide continued satisfactory performance. Controls

are no exception.

• How accurate and how trouble free your control

system remains in years to come depends largely on

the maintenance given to it.

• For best results, service all devices in your system at

one time.

• Time and trouble can be saved by arranging with

Honeywell for a maintenance agreement which will

guarantee expert, economical care, and insure

maximum life and efficiency from your system.

M17678

1/2

(13)

M17679

Fig. 3. Mounting on insulated duct.

When discharge air temperatures are within the throttlin

range, the LP907A control point is reset based upon room

thermostat branch-line pressure

the LP907A to directl

control airstream temperature except

BLP) changes. This allows

during morning warm-up and heavy-load conditions.

NOTE: Usin

a damper operator other than an MP516B

requires a 0.007 in. restriction upstream. The

restriction allows the LP907A to bleed fast enou

h to

control BLP.

. 6, the RP670 switching relay is connected directly to

In Fi

the main. The rela

action

locks out

the LP907A during the

summer (cooling) cycle when main pressure is 14 psi

97 kPa) or less. (Normal pressure ranges from 13 to 18 psi

[90 to 124 kPa]

95-1612EF 2

. This allows 1 psi

7 kPa) main line variation.

Equipment Required

•

3/16-in. open end wrench.

• Commercial cleanin

• Lubricant

part no. 310879).

• Calibration Ad

solvent.

ustment Ke

part no. 301572A00767).

Inspection, Cleaning and Lu bri cati on

1.

Visuall

2.

Remove dirt and corrosion from the element and bod

3.

Check air lines for dama

4.

Remove the cover and inspect internal parts.

5.

Remove dirt and corrosion with soft brush or commercial cleanin

inspect the device exterior.

e and leaks.

solvent.

CAUTION

Equipment Damage Hazard.

Can damage the device beyond repair.

Use lubricant sparin

nozzle (see Fig. 8).

6.

Lubricate pivot points and ad

and keep it away from the air

ustment threads.

.

Page 3

LP907A AIRSTREAM INSERTION THERMOSTAT

M

M5450

LP907A

VP514

14002913-002

0.007 IN. RESTRICTION

(NOT FURNISHED)

)

j

g

g

y

g

g

q

g

g

y

ROOM

THERMOSTAT

M

M

LP907A

B

VP512A

VALVE

H L

MP516A

OPERATOR

Fig. 5. Typical operation.

D.A.

H

RP418 E-P

RELAY

WIRE IN PARALLEL

WITH FAN MOTOR

FAN

R.A.

C

Fig. 7. Typical operation of duct mounted LP907A.

Operational Check

LP907A

1.

Ensure BLP ahead of the restriction (or MP516B

equals mainline pressure. If it does not:

ust the room thermostat in order to obtain equal

O.A.

M5419B

a. Ad

pressure.

b. Decrease the air temperature at the device sensin

element or increase the setpoint.

RESULT:BLP to the valve should decrease, and

vice versa.

Return setpoint to the ori

c.

inal setting.

TP972

M

B

M

WINTER

18 psi (1.24 BAR)

SUMMER

13 psi (.90 BAR)

MP516A

Fig. 6. Typical operation of LP907A in heating-cooling

application (unit ventilator).

RP670

MP516A

LP907A

FACE AND BY-PASS

RP418 E-P

RELAY

H L

WIRE IN PARALLEL

WITH FAN MOTOR

R.A.

D.A.

FAN

O.A.

M5448B

LP907B, or LP907A with RP670A Switching Relay

1.

Supply 13 psi (90 kPa) main air pressure to the LP907B

, or 18 psi (124 kPa) main air pressure to the

rela

RP670A, to simulate summer operation.

2.

Block BLP to the LP907 to ensure temperature chan

at the sensin

element do not affect room thermostat

control of system operation.

3.

BLP to the valve should settle to e

NOTE: The restriction can cause a sli

pressure settlin

4.

5.

18 psi (124 kPa) main air pressure to the relay.

Suppl

Perform the LP907A operational check.

.

ual thermostat BLP.

ht delay in

Calibration Check

When BLP equals 8 ± 1 psi (55 ± 7 kPa) with the air

temperature at setpoint, the controller is properly calibrated.

es

3 95-1612EF

Page 4

LP907A AIRSTREAM INSERTION THERMOSTAT

y

(

(

(

)

(

(

g

g

g

)

y

y

g

(

j

j

g

j

g

gag

g

g

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

Adjustments

Refer to Fig. 8 and the Maintenance section.

Throttling Range

4.

ust the setpoint dial until the setpoint indicator

Ad

matches the current temperature at the sensin

5.

Tighten the setpoint-dial locking screw.

6.

ust the calibration screw until BLP is 8 psi (55 kPa).

Ad

7.

Turn the setpoint dial to the desired setpoint.

element.

IMPORTANT

— Always check calibration after adjusting the throttling

range.

— Set the throttling range as near to the minimum value

that the system permits without causing short cycling.

NOTE: For unit ventilator use, the throttling range is factor

set at 25°F

14K) and requires no further adjustment.

TO CHECK THE ACTUAL THROTTLING RANGE:

1.

Turn the setpoint dial until branch line pressure

BLP) is

less than 1 psi (7 kPa).

2.

Turn dial counterclockwise until BLP is 3 psi

21 kPa

and note setpoint.

3.

Continue to turn the dial until BLP is 13 psi

4.

The difference between the setpoints at 3 and 13 psi

90 kPa).

21 and 90 kPa) BLP is the throttling range.

TO ADJUST THE THROTTLING RANGE:

1.

Loosen the throttlin

range indicator locking screw with

the thermostat key. See Fig. 8.

NOTE: If there is no lockin

screw, simply squeeze the

throttling range adjustment clip to release it.

2.

Slide the indicator until its leadin

edge is on the

desired setting.

IMPORTANT

When replacing the cover, be careful not to disturb

the throttling range adjustment clip.

Calibration

NOTE: Calibration procedures are the same for all models

with the exception that the LP907B (or LP907A used

with an RP670

main air pressure suppl

1.

Loosen the setpoint-dial lockin

2.

With 3/16 in.

ad

ustment screw until the primary lever is parallel with

the base.

3.

Turn the calibration screw until the nozzle lever is

parallel with the base.

cannot be calibrated unless the rela

is 18 psi (124 kPa).

screw.

5 mm) open-end wrench, turn the setpoint

IMPORTANT

When replacing the cover, be careful not to disturb

the throttling range adjustment clip.

PRIMARY

LEVER

THROTTLING RANGE

INDICATOR LOCKING

SCREW

INSET "A"

SETPOINT

ADJUSTMENT

SCREW

GAGE

ADAPTER

TANK

VALV E

GAGE

TEE

CALIBRATION

SCREW

THROTTLING

RANGE

ADJUSTMENT

CLIP

NOZZLE

LEVER

BASE

Fig. 8. LP907A Adjustments.

TROUBLESHOOTING

1.

If the LP907 does not operate smoothly when makin

an operational check, replace the filter (located between

the

2.

If results do not improve, check the pneumatic line

restriction to determine whether there is proper airflow.

3.

If the pneumatic line has evidence of oil, pur

with refri

IMPORTANT

e tee and device base).

erant and eliminate the source of oil.

Keep oil out of the pneumatic line to avoid recurring

problems.

SETPOINT

INDICATOR

SETPOINT

DIAL

LOCKING

SCREW

SETPOINT

DIAL

M17677BB

e the line

Home and Building Control Home and Building Control

Honeywell Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Scarborough, Ontario

95-1612EF B.B. 4-01

M1V 4Z9

www.honeywell.com

Page 5

LP907A

g

q

g

g

)

g

(

ge (

(

glag

(

(

)

g

(

(

y

(

g

q

g

q

g

g

g

g

g

27 (1-1/16)

22 (7/8)

16

(5/8)

3/8 NPT

ÉCROU

ENTRETOISES (2)

PAROI DE LA GAINE

476 (18-3/4)

87

(3-7/16)

1/8 NPT

51

(2)

57 (2-1/4)

13

(1/2)

HONEYWELL

9

(11/32)

OUVERTURE DE

3/4 PO (MINIMUM

REQUIS POUR

L'INSTALLATION)

MF7996A

yrig

95- 1612EF

Thermostat de gaine

NOTICE D’INSTALLATION

APPLICATION

Le thermostat de gaine LP907 est un régulateur de purge à

action directe et à une canalisation comportant un élément

sensible ri

mêmes caractéristi

verrouilla

servant au verrouilla

refroidissement

ide. Le LP907B (qui n’est plus offert) avait les

ues en plus d’offrir une fonction de

e. Il comprenait également un relais de commutation

e pendant les mois d’été (en mode de

. Lors du remplacement du LP907B, utiliser un

LP907A et un relais de commutation RP670A.

CARACTÉRISTIQUES TECHNIQUES

Modèle :

Encombrement :

Températures nominales :

Gamme de service : 4 à 60 °C

Température d’entreposa

Bande proportionnelle : réglage de façon interne de 6 à 39 K

Gamme de ré

Réglage du point de consigne :

régulateur de purge à action directe.

voir la Fi

. 1.

40 à 140 °F).

max. admissible) : 66 °C (150 °F).

10 à 70 °F).

e du point de consigne : 4 à 60 °C

40 à 140 °F).

Devant du cadran : 4 à 32 °C

40 à 90 °F

Arrière du cadran : 32 à 60 °C (90 à 140 °F ).

cadran sous le couvercle.

AVANT D’INSTALLER CE PRODUIT…

Utiliser avec un réducteur de 0,17 mm (0,007 po) de diamètre

ue le filtre/cartouche de restriction 14002913-002 ou le

tel

réducteur inté

ue le thermostat de gaine est employé avec une gaine

Lors

ré aux actionneurs de registre MP516B ou C.

d’immersion, utiliser du composé thermoconducteur 107408

dans la

REMARQUE : Pour obtenir des rensei

aine pour que l’élément réagisse mieux.

nements plus détaillés

sur les

aines, consulter la publication 68-0040

sur les gaines d’immersion et raccords à

compression pour ré

ulateurs de température.

INSTALLATION

Le LP907A peut être installé dans n’importe quelle position.

Voir les Fi

d’installation.

. 2 à 4 pour observer différentes méthodes

Type d’élément sensible :

e en invar de 10 mm (3/8 po) de diamètre et de 476 mm

ti

18-3/4 po) de longueur et tube de laiton sans joint.

Pression d’air maximale admissible :

Raccords d’air :

mère de 6 mm (1/4 po).

pol

Installation :

Accessoires :

raccord cannelé à pression pour tube de

par insertion, avec écrou du côté du raccord.

14002913-002 Restriction externe de 0,2 mm

301572A00767 Clé d’étalonna

309387 Filtre.

CCT 2085 Adaptateur pour manomètre.

® Mar que de commerce déposée aux É.-U.

ht © 2001 Honeywell Tous droits réservés

Cop

e.

138 kPa

20 psig).

0,007 po).

Fig. 1. Encombrement en mm (po) du LP907A.

Page 6

LP907A THERMOSTAT DE GAINE

g

(

g

y

(

q

q

g

g

(cy

)

(

(

yag

(

q

g

yag

g

(

j

GAINE

LP907

MF17676

3/8 NPT

ÉCROU DE VIDANGE

3/8

VIS

AUTOTARAUDEUSES (2)

43

(1-11/16)

Fig. 2. Installation sur une gaine d’air en tôle standard.

RACCORD 3/8 NPT

3/8 NPT

LP907

GAINE

RACCORD

ÉTROIT 3/8

ÉCROU DE

VIDANGE 3/8

VIS

AUTOTARAUDEUSES (2)

ISOLANT

43

(1-11/16)

MF17679

Fig. 3. Installation sur une gaine isolée.

FONCTIONNEMENT

Parce qu’il s’agit d’un thermostat de purge et qu’il offre une

bande proportionnelle lar

du thermostat

et fonctionner dans la plupart des cas à la

manière d’un régulateur à minimum) dans un système de

ventilation ordinaire. Les Fi

raccordement t

pe.

Lorsque la température de l’air de soufflage se situe dans les

limites de la bande proportionnelle du LP907A, les variations

de la pression de la canalisation secondaire provenant du

thermostat d’ambiance déclenchent le fonctionnement du

LP907A

point de contrôle). Ce faisant, le LP907A commande

directement la température de l’écoulement d’air, sauf lors de

la reprise matinale et

REMARQUE : Lors

MP516B est utilisé, il faut ajouter un réducteur

de 0,007 po en amont. Le réducteur permet au

LP907A de pur

rapidité pour commander la pression de la

canalisation secondaire.

e, le LP907A peut prendre la relève

. 5 à 7 illustrent des schémas de

uand la charge est trop importante.

u’un actionneur de registre autre que le

er l’air avec suffisamment de

MANCHON

MF17678

LP907

HEXAGONAL

3/8 NPT

1/2 NPT

29 (1-3/16)

COMPOSÉ

THERMOCONDUCTEUR

GAINE

D’IMMERSION

484 (19-1/16)

ÉLÉMENT

SENSIBLE

Fig. 4. Installation sur la paroi d’une chaudière

avec gaine d’immersion.

MAINTENANCE

IMPORTANT

• Les appareils mécaniques doivent faire l’objet d’un

entretien périodique si l’on veut qu’ils fonctionnent de

façon satisfaisante sans interruption. Les régulateurs

ne font pas l’exception.

• La précision du système de régulation et son bon

fonctionnement dépendent largement des soins

qu’on y apporte.

• Pour de meilleurs résultats, mieux vaut faire l’entretien

de tous les appareils du système en même temps.

• On peut gagner du temps et s’éviter des problèmes

en confiant la maintenance à Honeywell et s’assurer

ainsi d’obtenir des soins experts, garantis et

économiques qui permettront de tirer du système le

meilleur parti et la plus grande efficacité possibles.

Matériel requis

• Clé à fourche de 3/16 po.

Solvant de netto

•

• Lubrifiant

pièce no 310879).

• Clé d’étalonnage (pièce no 310572A00767).

Inspection, nettoyage et lubrification

1.

Inspecter

2.

Enlever la saleté et la corrosion de l’élément et du corps.

3.

Vérifier les raccords d’air pour s’assurer

domma

4.

Retirer le couvercle et inspecter les pièces internes.

5.

Enlever la saleté et la corrosion à l’aide d’une brosse

douce ou d’un solvant de netto

e ni fuite.

e commercial.

de visu

l’extérieur de l’appareil.

u’il n’y a ni

e commercial.

13

(1/2)

. 6, le relais de commutation RP670 est directement

Dans la

Fi

relié à la canalisation principale. L’action de ce relais met le

LP907A hors service pendant les mois d’été

refroidissement

, lorsque la pression de la canalisation

cle de

principale est de 97 kPa (14 psig) ou moins [pression normale

90 à 124 kPa

variation de 7 kPa

95-1612EF 2

13 à 18 psig)]. On peut ainsi obtenir une

1 psig) dans la canalisation principale.

MISE EN GARDE

Risque d’endommager le matériel.

Risque de dommage irréparable.

Utiliser très peu de lubrifiant et le tenir éloi

buses d’air

6.

Lubrifier les points d’articulation et les filets d’a

voir la Fig. 8).

né des

ustement.

Page 7

THERMOSTAT

g

MF5448B

AIR REPRIS

AIR FRAIS

MP516A

LP907A

AIR DE

SOUFFLAGE

M

B

M

VENTILATEUR

TP972

RP670

EN HIVER

1,24 BAR (18 psi)

ÉTÉ

0,90 BAR (13 psi)

REGISTRE FRONTAL

ET DE DÉRIVATION

MP516A

H L

RELAIS

É/P RP418

RACCORDER EN

PARRALÈLE AVEC LE

MOTEUR DU VENTILATEUR

(

j

g

g

É

g

q

(

)

(

q

q

y

g

g

q

(

D'AMBIANCE

M

B

LP907A

AIR DE

SOUFFLAGE

LP907A THERMOSTAT DE GAINE

5.

Vérifier le fonctionnement du LP907A.

Vérification de l’étalonnage

Lorsque la pression de la canalisation secondaire est de 55

±7 kPa (8 ± 1 psi) et que la température de l’air est égale au

point de consi

ne, le régulateur est correctement étalonné.

M

MF5419B

OPÉRATEUR

MP516A

VANNE

VP512A

H L

AIR REPRIS

H

RELAIS

É/P RP418

RACCORDER EN

PARRALÈLE AVEC LE

MOTEUR DU VENTILATEUR

VENTILATEUR

Fig. 5. Fonctionnement type.

Vérification du fonctionnement

LP907A

1.

S’assurer que la pression de la canalisation secondaire

en amont du réducteur

pression de la canalisation principale. Si ce n’est pas le

cas :

uster le thermostat d’ambiance pour obtenir une

a. A

pression é

ale.

b. Réduire la température de l’air à l’élément sensible

de l’appareil ou au

SULTAT :La pression de la canalisation

R

Ramener le point de consi

c.

LP907B ou LP907A avec relais de commutation

RP670A

1.

Appli

90 kPa

au RP670A pour simuler le fonctionnement en mode de

refroidissement

2.

3.

4.

uer la pression de la canalisation secondaire au

Blo

LP907 pour veiller à ce

à l’élément sensible n’influence pas la commande du

stème par l’entremise du thermostat d’ambiance.

s

La pression de la canalisation secondaire à la vanne

devrait se stabiliser et é

canalisation secondaire au thermostat.

REMARQUE : Le réducteur pourrait retarder

Appli

principale de 124 kPa

uer une pression de la canalisation principale de

13 psi) au relais LP907B ou de 124 kPa (18 psi

lé

uer une pression de pression de la canalisation

pression.

ou du MP516B) est égale à la

menter le point de consigne.

secondaire à la vanne devrait diminuer

et vice versa.

ne à sa valeur d’origine.

été).

ue la variation de la température

aler la pression de la

èrement la stabilisation de la

18 psi) au relais.

C

AIR FRAIS

Fig. 6. Fonctionnement type d’un LP907A au sein d’un

système de chauffage-refroidissement

(ventilateur autonome).

M

14002913-002

RÉDUCTEUR

VP514

DE 0,2 mm (0,007 PO)

(NON FOURNIE)

LP907A

MF5450A

Fig. 7. Fonctionnement type d’un LP907A monté en gaine.

Ajustements

Voir la Fig. 8 et la section sur la Maintenance.

Bande proportionnelle

IMPORTANT

— Il faut toujours vérifier l’étalonnage après avoir ajusté

la bande proportionnelle.

— Régler la bande proportionnelle le plus près possible

de la valeur minimale acceptée par le système sans

provoquer des cycles de fonctionnement trop courts.

3 95-1612EF

Page 8

LP907A THERMOSTAT DE GAINE

g

j

glag

jusq

jusq

q

g

jusq

(

g

g

y

g

) q

q

(

g

À

j

q

ge jusq

j

jusq

g

g

g

glag

(

y

q

q

q

g

REMARQUE : Lorsque le régulateur est destiné à un

ventilateur autonome, la bande proportionnelle

lée en usine à 14 K (25 ° F) et n’a pas

est ré

besoin d’être a

ustée.

POUR VÉRIFIER LA BANDE PROPORTIONNELLE ACTUELLE :

1.

Faire tourner le cadran de ré

e du point de consigne

u’à ce que la pression de la canalisation secondaire

soit inférieure à 7 kPa (1 psi).

2.

Faire tourner le cadran dans le sens antihoraire

ue la pression de la canalisation secondaire

ce

atteigne 21 kPa (3 psi) et prendre note du point de

3.

Continuer de tourner le cadran

u’à ce que la

ne.

consi

pression de la canalisation secondaire atteigne 90 kPa

13 psi).

4.

La différence entre les points de consi

ne à 21 et à

90 kPa (à 3 et à 13 psi) de pression dans la canalisation

secondaire correspond à la bande proportionnelle.

POUR AJUSTER LA BANDE PROPORTIONNELLE :

1.

Desserrer la vis de blocage de l’indicateur de la bande

proportionnelle à l’aide de la clé à thermostat. Voir la

. 8.

Fi

REMARQUE : S’il n’

a pas de vis de blocage, il suffit

de serrer la pince de réglage de la bande

proportionnelle puis de la relâcher.

2.

lisser l’indicateur jusqu’à ce que son rebord

Faire

avant soit à la position désirée.

IMPORTANT

Prendre soin de ne pas bouger la pince de réglage de

la bande proportionnelle en refermant le couvercle.

u’à

5.

Resserrer la vis de bloca

point de consi

6.

Ajuster la vis d’étalonnage jusqu’à ce que la pression de

ne.

la canalisation secondaire attei

7.

Faire tourner le cadran de ré

e du cadran de réglage du

ne 55 kPa (8 psi).

e du point de consigne

à la valeur désirée.

IMPORTANT

Prendre soin de ne pas bouger la pince de réglage de

la bande proportionnelle en refermant le couvercle.

CADRAN DE RÉGLAGE

DU POINT DE CONSIGNE

VIS DE BLOCAGE

DU CADRAN DE

RÉGLAGE DU POINT

DE CONSIGNE

INDICATEUR

DU POINT DE

CONSIGNE

VIS D’AJUSTEMENT

ADAPTATEUR

DE

MANOMÈTRE

VANNE DU

RÉSERVOIR

MF17677

VIS DE BLOCAGE DE

L’INDICATEUR DE LA

BANDE PROP.

EN

MÉDAILLON

VIS D’ÉTALONNAGE

PINCE D’AJUSTEMENT

DE LA BANDE

PROPORTIONNELLE

PRISE DE

MANOMÈTRE

DÉTENTE

BASE

LEVIER

PRINCIPAL

DU POINT DE CONSIGNE

Fig. 8. Ajustement du LP907A.

Étalonnage

DÉPANNAGE

REMARQUE : La méthode d’étalonnage est la même pour

tous les modèles à l’exception du LP907B (ou

du LP907A utilisé avec un RP670

être ré-étalonné à moins

ue la pression

ui ne peut

fournie par la canalisation principale soit de

124 kPa

1.

Desserrer la vis de bloca

18 psi).

e du cadran de réglage du

point de consigne.

2.

l’aide d’une clé à fourche de 5 mm (3/16 po), faire

tourner la vis d’a

ce

3.

ue le levier principal soit parallèle à la base.

Faire tourner la vis d’étalonna

ustement du point de consigne jusqu’à

u’à ce que la

détente soit parallèle à la base.

4.

uster le cadran de réglage du point de consigne

A

u’à ce que l’indicateur du point de consigne

corresponde à la température actuelle à l’élément

sensible.

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your use

or modification to, the literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and against

any liability, cost, or damages, including attorneys’ fees, arising out of, or resulting from, any modification to the literature

by you.

Régulation résidentielle Régulation résidentielle et commerciale

et commerciale

Honeywell 35, Dynamic Drive

1985 Douglas Drive North Scarborough (Ontario)

Golden Valley, MN 55422 M1V 4Z9

Honeywell Limited-Honeywell Limitée

1.

Si le LP907 ne fonctionne pas correctement à la

vérification, remplacer le filtre

situé entre la prise de

manomètre et la base de l’appareil.

2.

3.

a pas d’amélioration, vérifier le réducteur de la

S’il n’

canalisation pneumati

est adé

uat.

ue pour établir si le débit d’air

S’il semble y avoir de l’huile dans la canalisation

pneumati

fri

ue, vidanger la canalisation avec du

origène et éliminer la source d’huile.

IMPORTANT

Pour éviter que le problème ne se répète, éviter que

de l’huile ne pénètre dans la canalisation

pneumatique.

95-1612EF B.B. 4-01

Imprimé aux États-Unis sur du papier

recyclé contenant au moins 10 %

de fibres post-consommation.

www.honeywell.com

Loading...

Loading...