Page 1

LKS 310

Actuator for air dampers on multi-stage

and modulating burners

Instruction Handbook

CONTENTS

Application ........................................................................... 1

Description ........................................................................... 2

Features ................................................................................ 2

Specification ........................................................................ 2

Type overview ..................................................................... 2

Technical data ..................................................................... 3

Ordering information ............................................................3

Standards and approvals .................................................... 3

Accessories ........................................................................ 3

Dimensional drawing ........................................................... 4

Shaft versions ..................................................................... 4

Circuit diagrams .................................................................. 5

Installation ............................................................................7

Safety Guidelines ................................................................7

Commissioning and Inspection .......................................... 7

Safety Guidelines ................................................................7

Function control .................................................................. 7

Repairing and Disposal ....................................................... 7

APPLICATION

The LKS 310 air damper actuator is designed to be fitted to

multi-stage or modulating oil and gas burners with fully

closed position.

EN1C-0114SZ20 R0506

www.honeywell.com 1

Page 2

LKS 310 Actuator for air dampers on multi-stage and modulating burners

honeyvell.energy

DESCRIPTION

A synchronous motor powers an output shaft and a backlashfree

cam shaft via a gear reducer.

The cam shaft operates limit and auxiliary switches. The position

at which one of the limit or auxiliary switches operates can be adjusted steplessly within the operating range using the associated

cam disc. Manually adjustable lever-operated cams or spindledriven cams, which can be adjusted with a screwdriver, are available.

FEATURES

Electric actuator up to 15 Nm

• Drive times: 3.5 ... 30 sec.

• Gearing can be decoupled

• Position indicator

• Easily adjustable limit and auxiliary switches

• Synchronous motor

• Particulary stable design in aluminium housing

Variants:

• clockwise or counter clockwise rotation

• with integrated electronic circuitry

• different shaft versions

SPECIFICATION

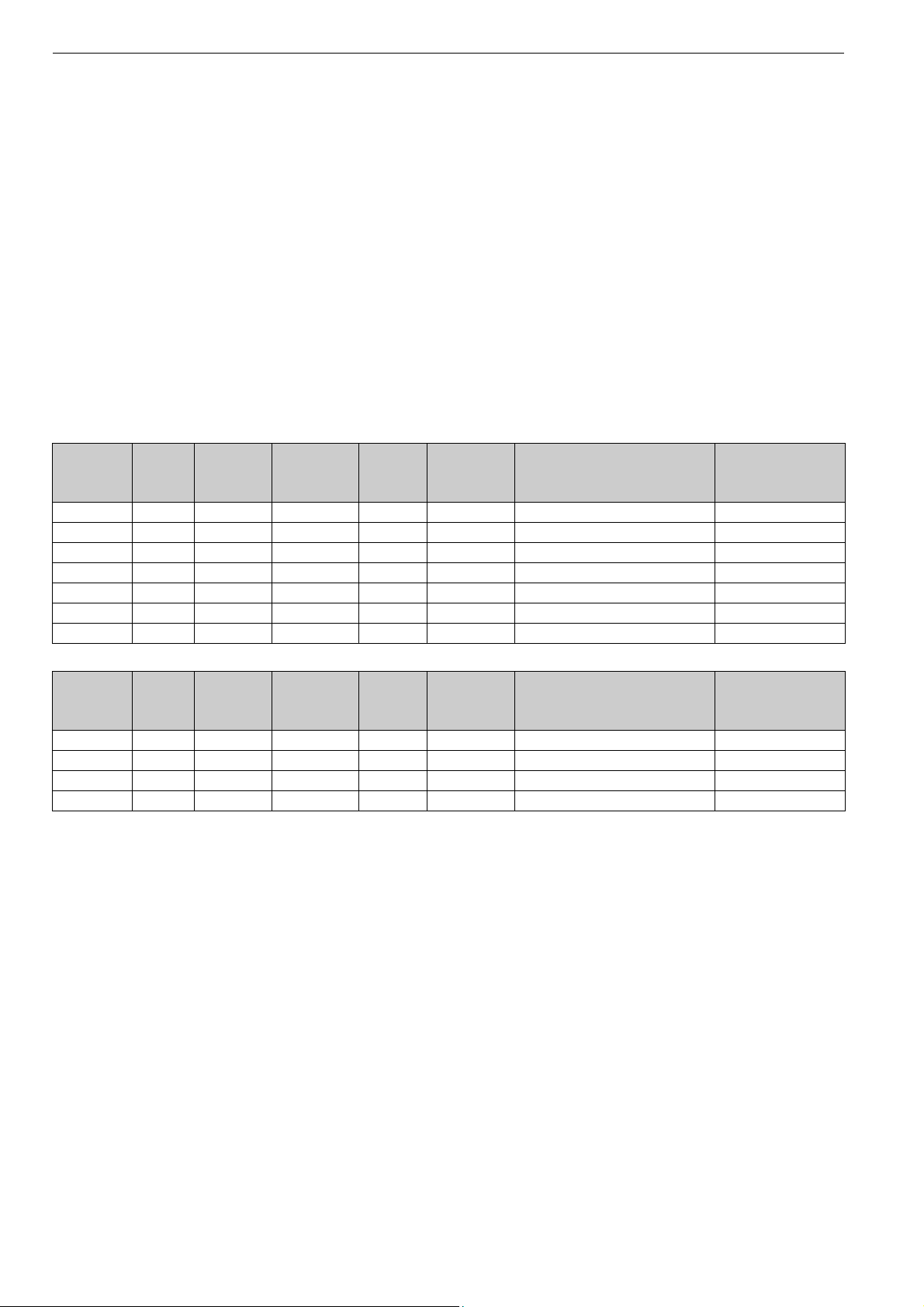

Type overview

Clockwise rotation

Diagram 2)Shaft 3)Drive

Nr. Nr. s Nm Nm V

S1 5D 30 15 10 230 LKS 310-15 (A-5D-30 S1) Spindle-driven cam

S12 5D 30 15 10 230 LKS 310-21 (A-5D-30 S12) Spindle-driven cam

S7 5B 30 15 10 230 LKS 310-22 (A-5B-30 S7)

S7 5B 10 10 10 230 LKS 310-24 (A-5B-10 S7.1)

S7 5B 15 15 10 230 LKS 310-25 (A-5B-15 S7.1)

S12 5D 7 7 7 110 LKS 310-34 (A-5D-7 S12.1) Spindle-driven cam

S7 5C 30 15 10 230 LKS 310-35 (A-5C-30 S7) IP54

Counter-clockwise rotation

Diagram 2)Shaft 3)Drive

Nr. Nr. s Nm Nm V

S8 5A 3,5 3,5 3,5 230 LKS 310-10 (B-5A-3.5 S8)

S7 5C 3,5 3,5 3,5 230 LKS 310-17 (B-5C-3.5 S7.1)

S7 5B 15 15 10 230 LKS 310-31 (B-5B-15 S7.1)

S7 5B 10 10 10 230 LKS 310-32 (B-5B-10 S7.1)

Legende

1) when viewing from direction A (see dimensional drawing)

2) see “Circuit diagrams”

3) see “Shaft versions”

4) at 50 Hz for 90°

at 60 Hz, Drive times are about 20 % shorter

5) under nominal conditions

under extreme conditions (e.g. +60 °C, 230V -15%) the torques will be 25% lower

6) +10% -15%; 50...60Hz

at -15%; torque reduced by approx. 20% at undervoltage

7) Standard: Lever-operated cam

1)

time

time

Load

4)

torque

1)

Load

4)

torque

5)

5)

Holding

torque

Holding

torque

Voltage

Voltage

6)

Type Remarks

6)

Type Remarks

7)

7)

EN1C-0114SZ20 R0506

2 www.honeywell.com

Page 3

LKS 310 Actuator for air dampers on multi-stage and modulating burners

Technical data Ordering information

Housing robust aluminium housing with plastic

cover

Weight approx. 1.8 kg

Drive motor reversible synchronous motor

Clutch red lever,

separates gearing from motor

Gearing spur gearing, maintenance-free

Drive shaft steel

PCBs for all electrical functions, increased

conductor thickness wire crosssection

Connection system terminal blocks

Fitting and fastening front of gear acts as contact area.

Fixing from outside via M5 or M6

screws, thread in housing

Switch point setting stepless cam setting, lever-operated

or spindle-driven cams; if spindledriven, with superimposed scale

Position indicator if desired the cover can contain a win-

dow and pointer, internally via a corunning pointer and scale

Mains voltage 230 V -15% +10%

Mains frequency 50 Hz or 60 Hz

Safety class I VDE 0631

Power consumption 7...15 VA

Duty cycle Depending on motor, 50 to 70 %

in 2 minutes

Interference

suppression

Actuating angle 90°, in exceptional cases also larger

Mounting position any

Protection IP54, with appropriate design of the

Cable entries 2 x PG11

Cable connection terminal block for 0.5 mm

Direction of rotation see “Type overview”

Torque and holding

torque

Drive times 3.5 ... 30 sec for 90°

Limit and auxiliary

switches

EN1C-0114SZ20 R0506

Ambient temperature operation 0....+60° C

N (according to VDE 0785)

cable entries, cover without window

(DIN 40050)

2

2.5 mm

see “Type overview”

max. 7

operation with adjustable cam discs,

cams coloured in normal way:

switching voltage

AC 24 .... 230 V

switching capacity

with inductive loads 250 VA

transport and storage

-20....+60° C

(max.)

blue fully closed position

orange low load

red high load

black spare switches for

additional functions

2

(min.) and

LKS 310-15 A 5D - 30 S1

Standards and approvals

Conformity

Honeywell certifies herewith that the actuator LKS 310 complies

with the following regulations and standards:

• Standards of European Union 73/23 EWG and 93/68 EWG

• EN 60730-1 : 1991 A1 and A11 : 1991

• EN60730-2-5 : 1991

Accessories

Potentiometer-retrofit sets only on request.

CAUTION

Condensation, icing and exposure to water not

permitted

Circuit version

Drive time for 90°

3,5 s (3 Nm)

7 s (7 Nm)

10 s (10Nm)

15 s (15 Nm)

30 s (15 Nm)

Type of drive shaft

5A, 5B, 5C, 5D

see “Shaft versions”

Direction of rotation

A clockwise

B counter-clockwise

Model

Series

www.honeywell.com 3

Page 4

LKS 310 Actuator for air dampers on multi-stage and modulating burners

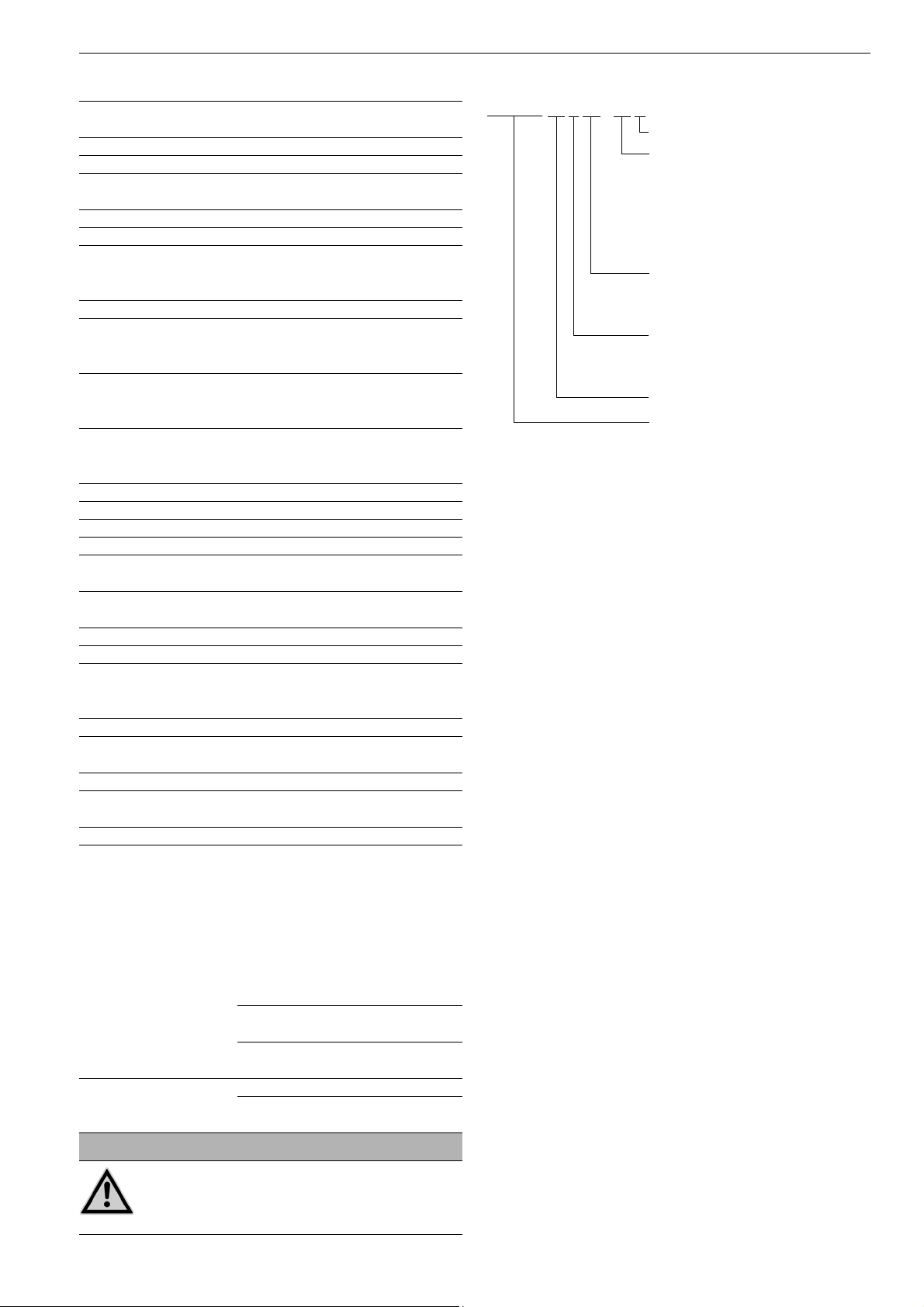

Dimensional drawing

A

alternatively

Shaft versions

see below

Shaft versions

Version 5A

Version 5B

Version 5C

Version 5D

4 www.honeywell.com

EN1C-0114SZ20 R0506

Page 5

Circuit diagrams

S1

LKS 310 Actuator for air dampers on multi-stage and modulating burners

S2

S3

S5

S4

S6

S7

EN1C-0114SZ20 R0506

S7.2

www.honeywell.com 5

Page 6

LKS 310 Actuator for air dampers on multi-stage and modulating burners

S8

S10

S9

S11

S12

EN1C-0114SZ20 R0506

6 www.honeywell.com

Page 7

LKS 310 Actuator for air dampers on multi-stage and modulating burners

INSTALLATION

Safety Guidelines

WARNING

• The regulations and standards applicable in each

particular case must be observed.

• Installation must only be carried out by qualified

technicians.

• Electrical wiring must comply with national and local

regulations.

• Disconnect the actuators completely from the

power supply when working close to terminals

and connections.

1.Screw the housing cover securely in place to provide shockhazard protection on the actuator and all electrical connections.

2. Always lay the burner ignition cable separately and as remotely

as possible from the device and other cables.

3.Electromagnetic emissions must be checked on a case by

case basis.

COMMISSIONING AND INSPECTION

REPAIRING AND DISPOSAL

It is forbidden to do any repairing on actuator

LKS 310.

The distributor of the heating system assures the professional disposol or the forwarding to the manufacturer for inspection.

Safety Guidelines

WARNING

• Commissioning and inspection may only be carried

out by qualified personnel.

• Carefully check all cabling and wiring prior to commissioning.

Function control

For safety reasons the actuator should be tested on commissioning the installation as well as after a service or longer shut-down.

EN1C-0114SZ20 R0506

www.honeywell.com 7

Page 8

LKS 310 Actuator for air dampers on multi-stage and modulating burners

Loading...

Loading...