Honeywell LKS 160 Product Handbook

1 EN2C-0112SZ20 R0202

PRODUCT HANDBOOK

ACTUATOR

LKS 160

FOR AIR DAMPERS ON MULTI-STAGE AND

MODULATING BURNERS

CONTENTS

GENERAL

Description ................................................................. 2

Features ...................................................................... 2

TECHNICAL DATA

Specification ............................................................... 3

Dimensional drawings ................................................ 5

INSTALLATION AND OPERATION

Installation and final checkout .................................... 6

Citrcuit diagrams ........................................................ 7

VARIOUS

Standards and approvals ........................................... 9

Ordering information .................................................. 9

Accessories ................................................................ 9

APPLICATION

The LKS 160 air damper actuator is designed to be fitted to

multi-stage or modulating oil and gas burners with fully

closed position.

EN2C-0112SZ20 R0202 2

Electric actuator up to 3.0 Nm

• Drive times: 3 ... 65 sec.

• Variants: - clockwise or counter clockwise rotation

- with integrated electronic circuitry

- shaft version

GENERAL

DESCRIPTION

A synchronous motor powers a drive shaft and a backlashfree cam shaft via a gear reducer.

The cam shaft operates limit and auxiliary switches. The

position at which one of the limit or auxiliary switches operates

can be adjusted steplessly within the operating range using

the associated cam disc. Manually adjustable lever-operated

cams or spindle-driven cams, which can be adjusted with a

screwdriver, are available.

FEATURES

• Position indicator

• Easily adjustable limit and auxiliary switches

• Synchronous motor

3 EN2C-0112SZ20 R0202

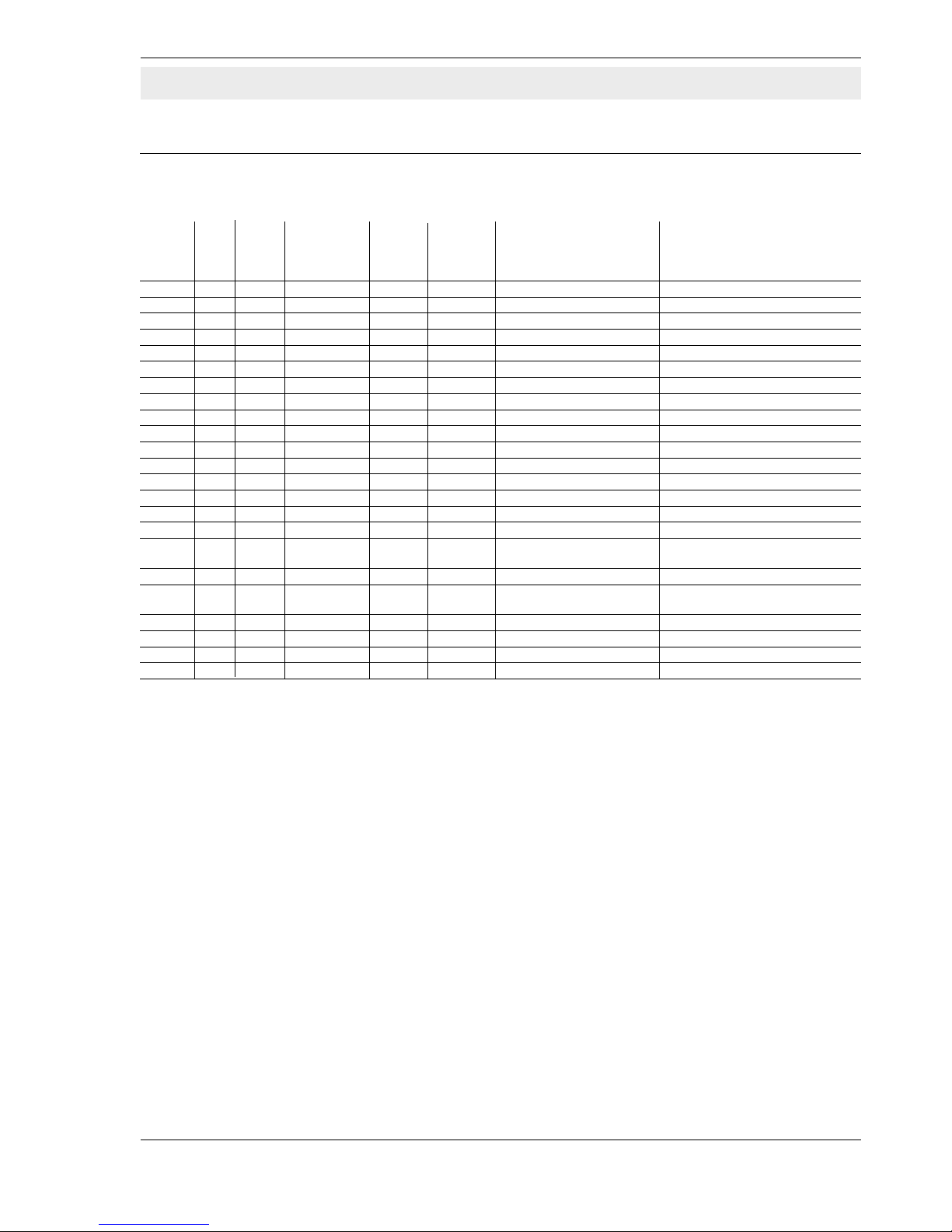

Diagram Shaft Drive Load torque Holding Voltage Type Remarks

time torque

Nr. Nr. s Nm Nm V

S1 5 5 2,5 0,8 230 LKS 160-01 A 5-5 S1 standard version

S2 5 5 2,5 0,8 230 LKS 160-03 A 5-5 S2 standard version

S1 5 12 3 1,5 230 LKS 160-07 A 5-12 S1

S1 5 5 2,5 0,8 230 LKS 160-09 A 5-5 S1 Spindle-driven cam

S7 5 30 3 3 24 LKS 160-22 A 5-30 S7

S7.1 5 30 3 3 110 LKS 160-24 A 5-30 S7.1

S6 5 34 3 3 230 LKS 160-25 A 5-34 S6

S1.2 5 34 3 3 230 LKS 160-26 A 5-34 S1.2

S1 5 12 3 1,5 230 LKS 160-37 A 5-12 S1

S4 5 5 2,5 0,8 230 LKS 160-39 A 5-5 S4

S2 5 3 1,5 0,6 230 LKS 160-40 A 5-3 S2

S13 5 45 3 3 230 LKS 160-42 A 6-45 S13 Spindle-driven cam

S8.P1.1 5 34 3 3 230 LKS 160-44 A 5-34 S8.P1.1 Potentiometer can be retrofitted

S8.P2 5 30 3 3 110 LKS 160-55 A 5-30 S8.P2 Potentiometer can be retrofitted

S8.P4 5 45 3 3 230 LKS 160-59 A 5-45 S8.P4 with Potentiometer, special circuit

S8.P 6 34 3 3 230 LKS 160-63 A 6-34 S8.P Potentiometer can be retrofitted

S8.P4.1 5 38 3 3 120 LKS 160-65 A 5-38 S8.P4.1 Run time at 60 Hz, with Potentiometer,

special circuit

S8.P3 5 30 3 3 24 LKS 160-67 A 5-30 S8.P3 Potentiometer can be retrofitted

S8.P1.1 5 34 3 3 230 LKS 160-68 A 5-34 S8.P1.1 Potentiometer can be retrofitted,

spindle-driven cam

S8.P1 5 5 2,5 0,8 230 LKS 160-70 A 5-5 S8.P1

S4 5 3 1,5 0,6 230 LKS 160-73 A 5-3 S4

S15 5 5 2,5 0,8 230 LKS 160-75 A 5-5 S15 For 3-stage operation

S2 5 12 3 1,5 230 LKS 160-79 A 5-12 S2

2) 3)

4)

6)

5)

7)

1)

SPECIFICATION

TECHNICAL DATA

Type overview

clockwise rotation

Legend

1) when viewing from direction A (see dimensional drawing)

2) see “Circuit diagrams”

3) see “Dimensional drawing”

4) at 50 Hz for 90°

at 60 Hz, Drive times are about 20 % shorter

5) under nominal conditions

under extreme conditions (e.g. +60 °C, 230V -15%) the torques will be 25% lower

6) +10% -15%; 50...60Hz

at -15%; torque reduced by approx. 20% at undervoltage

7) Standard: Lever-operated cam

Loading...

Loading...