Page 1

L4188A,B; L4189A,B; L6188A-C;

L6189A-C Aquastat® Controllers

FEATURES

• L4188 and L4189 provide spst switching for high and

low limit control.

• L6188 and L6189 provide spst switching for low limit

and circulator control.

• L4188, L6188 models are direct-mounted.

• L4189, L6189 models are remote bulb.

• Diaphragm-operated switch breaks on temperature

rise (spst and normally closed spdt contacts).

Remote Bulb with

Screwdriver Slot

Direct Mount with

Setting Knob

• Compact controller case for application flexibility.

• 3/16 in. diameter bulb for faster response.

• All models available with or without setting knob.

Models without knob are adjusted with screwdriver.

• Choice of manual or auto reset. Auto reset models

available with fixed or adjustable differential.

• 1/4 in. male quick-connects standard; combination

screw and 1/4 in. quick-connects available.

• Field adjustable high or low limit stop available.

• Bracket for surface mounting available on remote bulb

models.

• Capillary on remote bulb models available in several

lengths.

• Immersion well with 1/2 in. NPT spud available as

accessory.

PRODUCT DATA

APPLICATION

Aquastat® Controllers are bulb-type providing operating or

limit control of water temperature in hot water heating systems

and water heaters.

Contents

Application......................................................................... 1

Features ............................................................................ 1

Specifications .................................................................... 2

Ordering Information ......................................................... 2

Installation ......................................................................... 4

Wiring ................................................................................ 6

Operation........................................................................... 7

Adjustments....................................................................... 7

Checkout ........................................................................... 8

68-0061—1

Page 2

L4188A,B; L4189A,B; L6188A-C; L6189A-C AQUASTAT® CONTROLLERS

SPECIFICATIONS

Electrical Ratings:

24 Vac 120 Vac 240 Vac

Full Load 2.0 A 8.0 A 5.1 A

Locked Rotor 48.0 A 30.6 A

Switching: Diaphragm-operated, snap-acting switch.

L4188, L4189: Switch breaks on temperature rise to set

point, remakes when temperature drops below set point

and through differential.

L6188, L6189: Switch breaks C-1 and makes C-2 on

temperature rise to set point; switches back when

temperature drops below set point and through

differential.

Terminals: 1/4 in. male quick-connects standards. Options

(specify when ordering):

Combination screw and 1/4 in. quick connects.

Separate grounding terminal.

Temperature Setting Range: 80° to 200° F (27° to 93° C),

110° to 230° F (43° to 110° C), and 160° to 280° F (71° to

138° C) available. Specify when ordering.

Temperature setting minus differential must be no more

than 9° F (-13° C) below bottom of setting range.

Setting Scale: Marked every 20° F (-7° C), with subdivisions

every 10° F (-12° C), includes OFF setting.

Limit Stop: Limits dial rotation beyond desired high or low

limit temperature. Can be set at 5° F (2.5° C) intervals.

Optional, available on models with knob only. Specify when

ordering.

IMPORTANT

The specifications given in this publication do not include normal manufacturing tolerances. Therefore, this unit may not

match the listed specifications exactly. Also, this product is tested and calibrated under closely controlled conditions,

and some minor differences in performance can be expected if those conditions are changed.

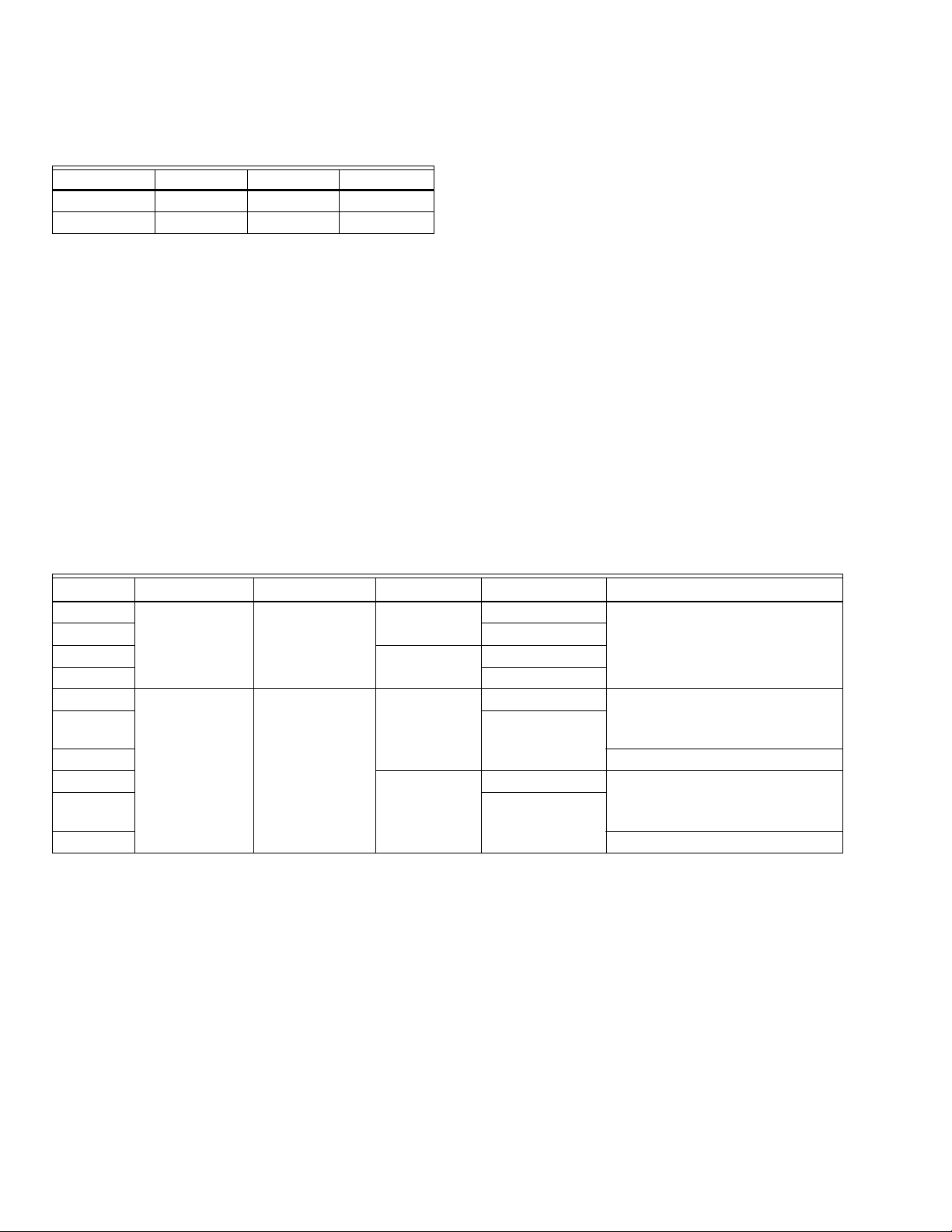

MODELS: See Table 1.

Table 1. Aquastat

Model Application Switching Mounting Setting Differential

L4188A High or low limit Spst, breaks on

L4188B Screwdriver slot

temp. rise

®

Controller Selection Guide

a

Direct Knob 7°, 14° or 22° F (-14°, -10° or -6° C),

a

fixed

L4189A Remote bulb Knob

L4189B Screwdriver slot

L6188A Low limit and

L6188B Screwdriver slot

circulator

Spdt, breaks C-1,

makes C-2 on

temp. rise.

Direct Knob 7°, 14° or 22° F (-14°, -10° or -6° C),

a

fixed

, 7° - 18° F (-16° - -8° C),

adjustable

a

L6188C Manual reset

L6189A Remote bulb Knob 7°, 14° or 22° F (-14°, -10° or -6° C),

a

fixed

L6189B Screwdriver slot

, 7° - 18° F (-16° - -8° C),

adjustable

a

L6189C Manual reset

a

Specify when ordering.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Toronto, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

68-0061—1 2

Page 3

L4188A,B; L4189A,B; L6188A-C; L6189A-C AQUASTAT® CONTROLLERS

Ambient Temperature Range: 32° to 158° F (0° to 70° C).

Mounting: Must be mounted in an enclosure that meets local

electrical codes.

Direct: Unit mounts on immersion well at desired sensing

location.

Remote bulb: Sensing bulb is inserted into immersion well

at desired sensing location. Controller case mounts

behind remote panel with two self-tapping M4 or No. 8

sheetmetal screws (supplied). Optional mounting bracket

allows mounting on front of panel. Specify bracket when

ordering.

KNOB MODEL

2-11/16

(68)

1-1/4

(32)

7/16

(11)

1-7/8

(48)

3/8

(9)

19/32

(15)

1

1-7/8

(48)

5/8

(16)

HOLE FOR

UP TO NO. 10

SCREW

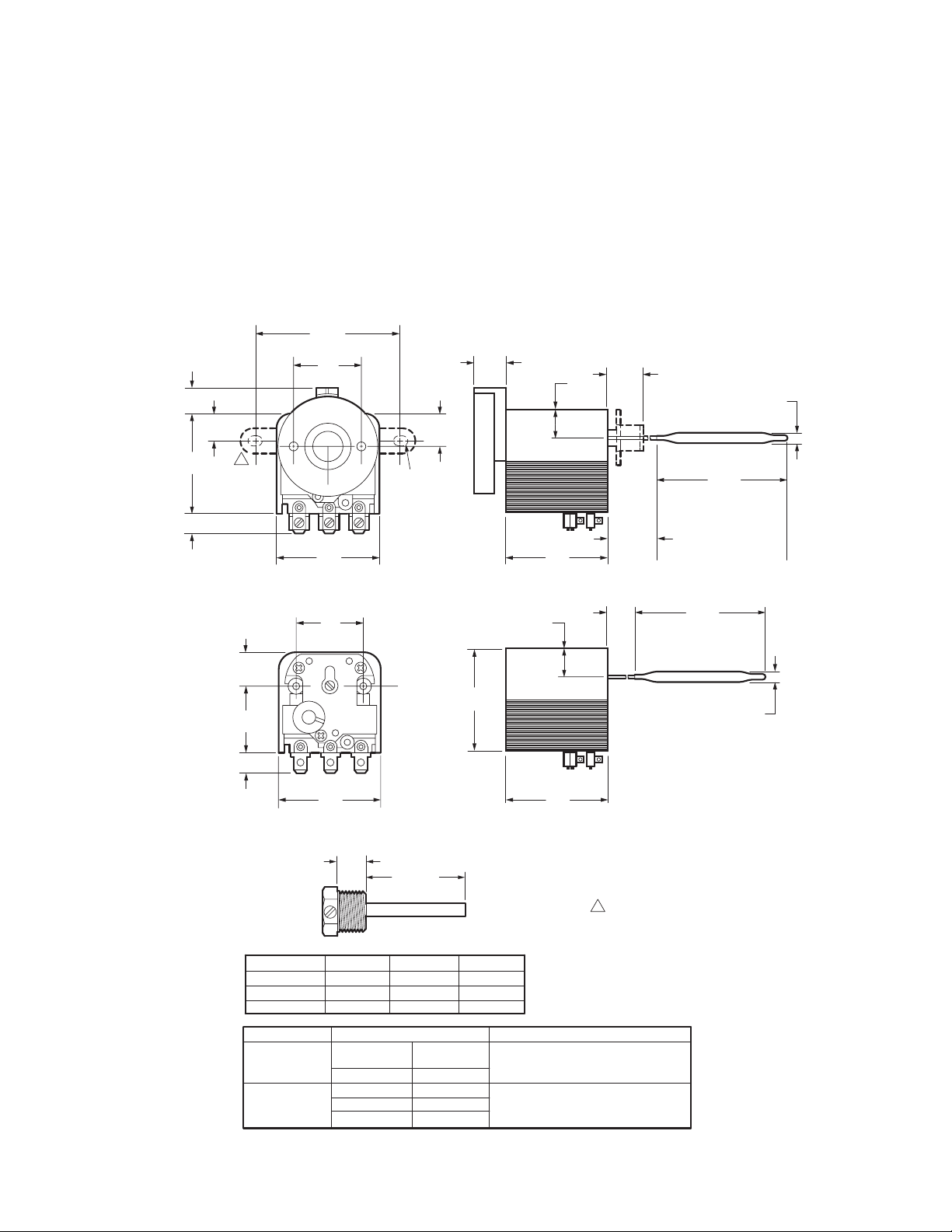

Dimensions: See Fig. 1.

Sensing Bulb: Liquid-filled copper (See Fig. 1).

Underwriters Laboratories Inc. Component Recognized:

File No. MP466, Guide No. MBPR.

Canadian Standards Association Listed:

19/32

(15)

1-7/8

(48)

1/2

(13)

11/ 16

(17)

SEE

TAB LE

4 (101)

File No. LR62051-1.

3/16

(5)

SCREWDRIVER SLOT MODEL

5/8

(16)

1-7/8

(48)

3/8

(9)

1-1/4

(32)

1-7/8

(48)

1-7/8

(48)

1/2

(13)

IMMERSION WELLS

INSULATION

PART NO. SPUD INSULATION INSERTION

45900409-003B 1/2 in. BSPT 1 in. 3-1/2 in.

45900409-009B 1/2 in. NPT 1-1/2 in. 3 in.

45900409-010B 3/4 in. NPT 1-1/2 in. 3 in.

MODEL CAPILLARY LENGTH MOUNTING

DIRECT MOUNT

L4188, L5188

REMOTE MOUNT

L4189, L5189

INSERTION

30 MM USE IMMERSION WELLS SHOWN AT RIGHT1-3/16 IN.

50 MM2-5/16 IN.

1000 MM39-3/8 IN.

1500 MM50 IN.

2000 MM78-11/16 IN.

USE IMMERSION WELLS SHOWN AT RIGHT

OR CAPILLARY COMPRESSION FITTINGS

1-7/8

(48)

SEE

TAB LE

OPTIONAL MOUNTING BRACKET

1

4 (101)

3/16

(5)

M25414

Fig. 1. Dimensions in in. [mm in brackets] of Aquastat Controller and Immersion Well.

3 68-0061—1

Page 4

L4188A,B; L4189A,B; L6188A-C; L6189A-C AQUASTAT® CONTROLLERS

Accessories (order separately):

Capillary compression fittings.

Part No. 104484A: 1/2 in. NPT spud.

Part No. 104484B: 3/4 in. NPT spud.

Immersion well: Pressure rating 255 psi [1760 kPa].

Part No. 45900409-003B: 1/2 in. BSPT spud, 1 in.

insulation, 3-1/2 in. insertion.

Part No. 45900409-009B: 1/2 in. NPT spud, 1-1/2 in.

insulation, 3 in. insertion.

Part No. 45900409-010B: 3/4 in. NPT spud, 1-1/2 in.

insulation, 3 in. insertion.

Optional Specifications (Specify when ordering):

• Combination screw and 1/4 in. male quick-connect

terminals.

• High or low limit stop (models with knob only).

• Mounting bracket (remote bulb models only).

INSTALLATION

When Installing This Product...

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

CAUTION

Disconnect power supply before wiring to avoid

electrical shock or equipment damage.

Terminal connections must be inside an enclosure

that meets local electrical codes.

Location

The equipment manufacturer generally provides a tapping for

insertion of the temperature controller sensing element. The

tapping should be located at a point where average system

temperature will be measured. Never locate the sensing

element close to a hot or cold water inlet or a steam coil, or

where the well’s pressure rating will be exceeded.

Turn off power and, if the system is filled, drain to a point below

the boiler tapping or wherever the sensing element is to be

located. If no tapping is provided, prepare one, properly

threaded, at the desired location.

If this is a remote bulb unit, the controller case can be mounted

in a panel or, with the optional bracket, on any flat surface.

Choose a location within reach of the sensing element. Allow

for gradual bends and some slack in the capillary.

3. Refill the system. Check for and correct any leaks.

USE MODERATE AMOUNT

OF PIPE COMPOUND

LEAVE 2 END THREADS BARE

M25415

Fig. 2. Use good Piping Practice when Installing

Immersion Well.

To Install Direct Mount Controller

1. Slide the sensing bulb all the way into the well. The metal

collar around the capillary should slip into the well spud.

2. Line up the case so the setting indicator is on top.

3. Tighten the setscrew in the well spud snugly against the

metal collar.

CONTROLLER

SETSCREW

METAL

COLLAR

SPUD

WELL

BULB

CAPILLARY

M25416

Fig. 3. The Direct Mount Model is held in place by the

Setscrew in the Well Spud.

To Mount Remote Bulb Controller

Insert Sensing Bulb in Well

1. Slide sensing bulb into well. Make sure bulb rests

against the bottom of the well. Don’t bend the capillary

where it connects to the bulb.

2. Hold bulb in place and tighten setscrew all the way

down. It won’t fit tight against the capillary, but it will keep

the bulb from sliding out.

SETSCREW

SPUD

CAPILLARY

SETSCREW

CAPILLARY

SPUD

BULB

WELL

M25417

Mount the Immersion Well

1. Coat the well threads with a moderate amount of pipe

dope, leaving two end threads bare. Teflon

also be used.

2. Screw the immersion well into the tapping and tighten

securely.

68-0061—1 4

®

tape may

Fig. 4. The Setscrew keeps the Remote Sensing Bulb in

the Well.

Page 5

L4188A,B; L4189A,B; L6188A-C; L6189A-C AQUASTAT® CONTROLLERS

Mounting Behind Panel-Controller with Knob

NOTE: The panel can be up to 5/64 in. thick.

1. Uncoil capillary, starting at bulb. Avoid sharp bends or

kinks in the capillary. Leave excess capillary loosely

coiled below controller case.

2. Remove the setting knob by pulling straight off.

3. Remove the two screws that hold the setting indicator in

place and remove the setting indicator (See Fig. 5).

CONTROLLER

4. ADJUSTABLE DIFFERENTIAL MODELS ONLY: Set

differential. See Adjustment and Checkout section.

5. Using setting indicator as a template, mark and drill

holes in the panel for the mounting screws and for the

knob shaft.

6. Mount the controller behind, and the setting indicator in

front of, the panel using the two screws removed earlier

(See Fig. 5).

7. MODELS WITH TEMPERATURE LIMIT STOP ONLY:

Adjust to desired setting, as described under “To Set

Temperature Limit Stop,” page 8.

8. Replace knob on shaft.

SETTING

INDICATOR

PAN EL

(MAX. 5/64 IN. THICK)

NO. 8

MOUNTING

SCREWS (2)

Fig. 5. The Mounting Screws hold the Setting Indicator and Controller in place.

Mounting Behind Panel-Controller with Screwdriver Slot

1. Mark and drill three holes in the panel, using the tem-

plate in Fig. 6 as a guide.

2. MANUAL RESET MODELS ONLY: Drill a fourth hole to

make the manual reset button accessible.

3. ADJUSTABLE DIFFERENTIAL MODELS ONLY: Drill a

hole for the differential dial, if desired, Set the differential.

See Adjustment and Checkout section.

4. Hold controller against back of panel with terminals

pointed down and fasten with two No. 8 sheetmetal

screws (not supplied) (Refer to Fig. 6).

KNOB

M25418

5 68-0061—1

Page 6

L4188A,B; L4189A,B; L6188A-C; L6189A-C AQUASTAT® CONTROLLERS

MOUNTING TEMPLATE

3/4

3/16

1

3/16

1

DRILL 2 MOUNTING SCREW HOLES.

2

DRILL HOLE FOR SLOTTED SHAFT. USE SMALL HOLE FOR SHAFT

ONLY; LARGE HOLE SHAFT PLUS SETTING SCALE.

3

DRILL SMALL HOLE FOR MODEL WITH MANUAL RESET BUTTON OR

LARGE HOLE FOR MODEL WITH DIFFERENTIAL ADJUSTMENT.

MANUAL

RESET

BUTTON

PAN EL

5/16

5/8

3

CONTROLLER

3/16

1

2

SLOTTED

SHAFT

NO. 8

MOUNTING SCREWS (2)

(OBTAIN LOCALLY)

Fig. 6. Drill holes in the Panel as shown.

M25419

NO. 10

SHEETMETAL

SCREWS (2)

PAN EL

MOUNTING

BRACKET

CAPILLARY

CONTROLLER

(OBTAIN LOCALLY)

M25420

Fig. 7. The Controller with Bracket Mounts on the Front of

the Panel.

WIRING

All wiring must comply with applicable codes and ordinances,

Disconnect power before beginning wiring.

Connect as shown in equipment manufacturer’s instructions, if

provided. Otherwise, use the typical hookups shown

(See Fig. 8) (refer to Figures 9 and 10).

24V

THERMOSTAT

Mounting on Panel-Controller with Bracket

1. Using controller bracket as a template, mark and drill two

holes in the panel.

2. Mount controller with terminals down.

3. Run capillary neatly along panel, avoiding sharp bends

and interference with other components on the panel.

4. MODELS WITH TEMPERATURE LIMIT STOP ONLY:

Adjust to desired setting, as described under “To Set

Temperature Limit Stop,” page 8.

68-0061—1 6

LOW WATER

CUTOFF

L4188.9

LOW LIMIT

2

TH-TR

TH TR

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

2

USE L6188.9C (C-1 CONTACTS) IF MANUAL RESET IS REQUIRED.

PRESSURE

CONTROLLER

24V

GAS VALVE

L4188.9

HIGH LIMIT

L1

(HOT)

L2

M25421

1

Fig. 8. Low and High Limit Application on a Gas-Fired

System with Domestic Hot Water.

Page 7

L4188A,B; L4189A,B; L6188A-C; L6189A-C AQUASTAT® CONTROLLERS

24V THERMOSTAT

RELAY CENTER

RG

PROTECTORELAY

CONTROL

BLACK

ORANGE

WHITE

T

T

1

2

3

HIGH LIMIT

BURNER MOTOR

IGNITION

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

L4188 OR L4189 USED AS HIGH LIMIT.

L6188 OR L6189 USED AS LOW LIMIT/CIRCULATOR CONTROLLER.

2

3

LOW LIMIT

C1

CIRCULATOR

2

L1

(HOT)

CIRCULATOR

MOTOR

M25422

L2

Fig. 9. High Limit and Low Limit/Circulator Application in

an Oil-Fired Hydronic System with domestic hot water.

24V

THERMOSTAT

SWITCHING RELAY

RA832A

TT

XX4

L4188.9

LOW LIMIT

LINE VOLTAGE

LOW VOLTAGE

1

PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS

REQUIRED.

2

1

L4188.9

CIRCULATOR

1

L1

(HOT)

CIRCULATOR

L2

L4188.9

HIGH LIMIT

IGNITION

BURNER

BLACK

WHITE

ORANGE

T

T

PROTECTORELAY

CONTROL

M25423

OPERATION

As the liquid filing the sensing bulb and capillary expands and

contracts, it moves a diaphragm. Movement of the diaphragm

is transferred by a lever to the snap-acting switch in the

controller.

High or Low Limit Action (L4188, L4189)

The normally closed C-1 contacts open on temperature rise to

the set point, shutting off power to the controlled circuit. On

auto recycle models, the switch closes C-1 after the

temperature falls past the set point and through the differential

(See Fig. 11).

Low Limit/Circulator Action (L6188, L6189)

The low limit is connected to the normally closed C-1 contacts,

and the circulator to the normally open C-2 contacts. As long

as the temperature at the sensing bulb is above set point, the

circulator runs. If sensing bulb temperature falls past the set

point and through the differential, the switch breaks C-2 to turn

off the circulator, and makes C-1 to turn on the burner. When

the temperature rises to the set point, C-2 makes to turn on the

circulator, and C-1 breaks to turn off the burner.

On manual reset models, the reset button must be pushed

before contacts C-1 will close (See Fig. 11).

TEMPERATURE

SETTING

SCALE

220 F

SET POINT

DIFFERENTIAL

100 F

Fig. 11. Aquastat Controller Switch Action on Temperature

L4188.9

HIGH OR LOW

LIMIT

C1

BREAKS

C1

MAKES

Change.

SET POINT

SET POINT

LESS

DIFFERENTIAL

L6188.9

LOW LIMIT/

CIRCULATOR

2

C

1

C-1 BREAKS

C-2 MAKES

AUTO

RECYCLE

2

C

1

C-1 MAKES

C-2 BREAKS

MANUAL

RESET

MAKES C-1

2

1

C

M25424

ADJUSTMENTS

Fig. 10. High Limit and Separate Low Limit and Circulator

Application in an Oil-Fired Hydronic System with

Domestic Hot Water.

7 68-0061—1

To Set Temperature

KNOB MODELS

Line up the desired temperature setting with the temperature

setting indicator behind the knob.

SCREWDRIVER SLOT MODELS

Line up the pointer on the shaft with the desired temperature

setting printed on the case.

Page 8

L4188A,B; L4189A,B; L6188A-C; L6189A-C AQUASTAT® CONTROLLERS

To Set Adjustable Differential (if provided)

Use a screwdriver to turn the differential dial until the slot

molded into the case lines up with the desired degrees of

differential.

CONTROLLER

AJUST LIMIT STOP

LIFT AND PUSH

TO CHANGE LIMIT

SETTING

LIMIT STOP

POINTER

DIFFERENTIAL

ADJUSTMENT

DIAL

SETTING

INDICATOR

M25425

Fig. 12. Twist the Screwdriver Slightly to turn the

Differential Dial.

To Set Temperature Limit Stop (if provided)

CAUTION

Follow these instructions carefully to avoid

placing the limit stop pointer on the wrong side of

the setting indicator. In a high limit application,

incorrect positioning of the pointer will cause

system operation above the limit stop setting,

potentially resulting in overheating or related

conditions.

• Remove the knob.

• Turn the controller shaft all the way counterclockwise

when setting a high limit. Turn it all the way

clockwise when setting a low limit.

• Find the metal limit stop on the back of the knob.

• Lift the limit stop slightly with a pencil or screwdriver and

push to move to desired setting.

• Read the setting from the front of the knob.

• Place the knob on the shaft.

• Turn the knob to make sure it: (1) turns through the desired

adjustment range, and (2) stops at the limit setting.

DO NOT FORCE.

• Return knob to desired setting.

KNOB

REPLACE KNOB ON SHAFT

SETTING INDICATOR:

LIMIT STOP MUST

BE ON RIGHT SIDE OF

SETTING INDICATOR FOR

HIGH LIMIT; ON LEFT

SIDE FOR LOW LIMIT

SHAFT

FOR LOW LIMIT STOP:

TURN SHAFT

FULL COUNTERCLOCKWISE

(SHOWN) BEFORE

REPLACING KNOB.

FOR HIGH LIMIT STOP:

TURN SHAFT

FULL CLOCKWISE

BEFORE REPLACING

KNOB.

KNOB

M25426

Fig. 13. Adjust the Limit Stop with a Screwdriver and

check Orientation when Replacing Knob on Shaft.

CHECKOUT

Turn the system on and observe it through several cycles to

make sure the controller operates as desired.

Teflon® is a registered trademark for E.I. Du Pont De Nemours and Company.

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Toronto, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2007 Honeywell International Inc.

68-0061—1 J.I. Rev. 10-07

Loading...

Loading...