Page 1

THE L4080 AND L8080 ARE IMMERSION

TYPE CONTROLLERS FOR HYDRONIC

HEATING SYSTEMS THAT TURN OFF THE

BURNER WHENEVER THE BOILER WATER

TEMPERATURE RISESTOTHESET POINT.

0 L4080 High Limit Aquastat Controller has

adjustable set point.

Cl L4080 models available for use with

immersion wells or for direct immersion if

faster response is needed.

0 A factory-set stop is available on L4080 to

prevent setting the control at too high a

temperature.

-

0

Cl L4080 models available with second limit

switch to shut off all gas to the burner.

III L8080 EC0 gas shutoff has fixed set point.

0 Liquid fill in sensing element expands as

the boiler temperature rises.

Cl At the set point temperature, a diaphragmactuated snap switch breaks the power

supply to the burner primary control.

SM.

REV. 4-66m

Form Number 60-2101-2

@Honeywell Inc. 1966

Page 2

I

SPEClFICATIONS

THE SPECIFICATIONS GIVEN IN THIS PUBLICATION DO NOT INCLUDE NORMAL MANUFACTURING TOLERANCES.

THEREFORE, THIS UNIT MAY NOT MATCH THE LISTED SPECIFICATIONS EXACTLY. ALSO, THIS PRODUCT IS TESTED AND

CALIBRATED UNDER CLOSELY CONTROLLED CONDITIONS, AND SOME MINOR DIFFERENCES IN PERFORMANCE CAN BE

EXPECTED IF THOSE CONDITIONS ARE CHANGED.

CASE

MODEL

NUMBER

-~

L408OB

L4080D

L408OF

L4080G

DESCRIPTION

High Limit

Aquastat

Controller

High Limit

Aquastat

Controller

Dual Limit

Aquastat

Controller

Dual Limit

Aquastat

Controller

AND

COVER

Yes

No

Yes

No

IMPORTANT

TABLE I-MODELS

IMMERSION STANDARD

WELL

Yesa

Yesa

Yes

Yes

Yes

RANGE

180Fto240F[82C

to 116 C]; dial

marked in 10 F

[5.6 C] increments.

180Fto240F[82C

to 116 C]: dial

marked in 10 F

[5.6 C] increments.

180 F to 240 F [82 C

to 116 C]; dial

marked in 10 F

[5.6 C] increments;

stop set at 210 F

[98.9 C].

140Fto240F[60C

to 116 C], dial

marked in 10 F

15.6 C] increments;

stop set at 210 F

[98.9 C].

Factory-set, 200 F

[93 C]. Nonadjustable.

OPTIONAL

RANGES

140Fto240F[60Cto116C];

dial marked in 10 F [5.6 C]

increments.

120Fto160F[49Cto71 C];

dial marked WARM-NORMALHOT.

Stop set at 150 F, 200 F, or

220 F [66 C, 93 C, or 104 Cl.

140Fto240F[60Cto116C],

dial marked in 10 F [5.6 C]

increments.

-

-

-

aOn select Band D models, well must be ordered separately. Refer to form 68-0040, “Wells and Fittings for Temperature

Controllers,” to order well, if necessary

V?WiRING INFORMATlON

WHEN PURCHASING REPLACEMENT AND MODERNIZATION PRODUCTS FROM YOUR TRADELINE

WHOLESALER OR YOUR DISTRIBUTOR, REFER TO THE TRADELINE CATALOG OR PRICE SHEETS FOR

COMPLETE ORDERING NUMBER, OR SPECIFY-

1. Order number.

2. Control range (LSOSO only).

IF YOU HAVE ADDITIONAL QUESTIONS, NEED FURTHER INFORMATION, OR WOULD LIKE TO COMMENT ON OUR

PRODUCTS OR SERVICES, PLEASE WRITE OR PHONE:

1. YOUR LOCAL HONEYWELL RESIDENTIAL SALES OFFICE (CHECK WHITE PAGES OF YOUR PHONE DIRECTORY).

2. RESIDENTIAL DIVISION CUSTOMER SERVICE

HONEYWELL INC., 1885 DOUGLAS DRIVE NORTH

MINNEAPOLIS, MINNESOTA 55422-4386 (612) 542-7500

IN CANADA-HONEYWELL CONTROLS LIMITED/HONEYWELL LIMITEE, 740 ELLESMERE ROAD, SCARBOROUGH,

ONTARIO MlP 2V9. INTERNATIONAL SALES AND SERVICE OFFICES IN ALL PRINCIPAL CITIES OF THE WORLD.

3. Dlfferentlal.

4. Optional specifications.

2

Page 3

SWITCH ACTION: Breaks contact on temperature rise to

set point.

DIFFERENTIAL: Approximately 15 F [8.3 C] non-

adjustable. Special models available with 8 F (4.4 C]

differential.

ELECTRICAL RATINGS (A):

I L4080 I L8080

Inductive

0.25 to 12 Vdc

Powerpile

Second Limit (bimetal switch) on L4080F,G:

Powerpile 750 mV at 0.4 A.

Thermocouple 30 mV at 0.4 A.

PRESSURE RATINGS: 225 psi [1551 kPa] with immersion

well.

MAXIMUM TEMPERATURE RATING: 40 F [22 C] above

set point, or 265 F [129.4 C], whichever is lower.

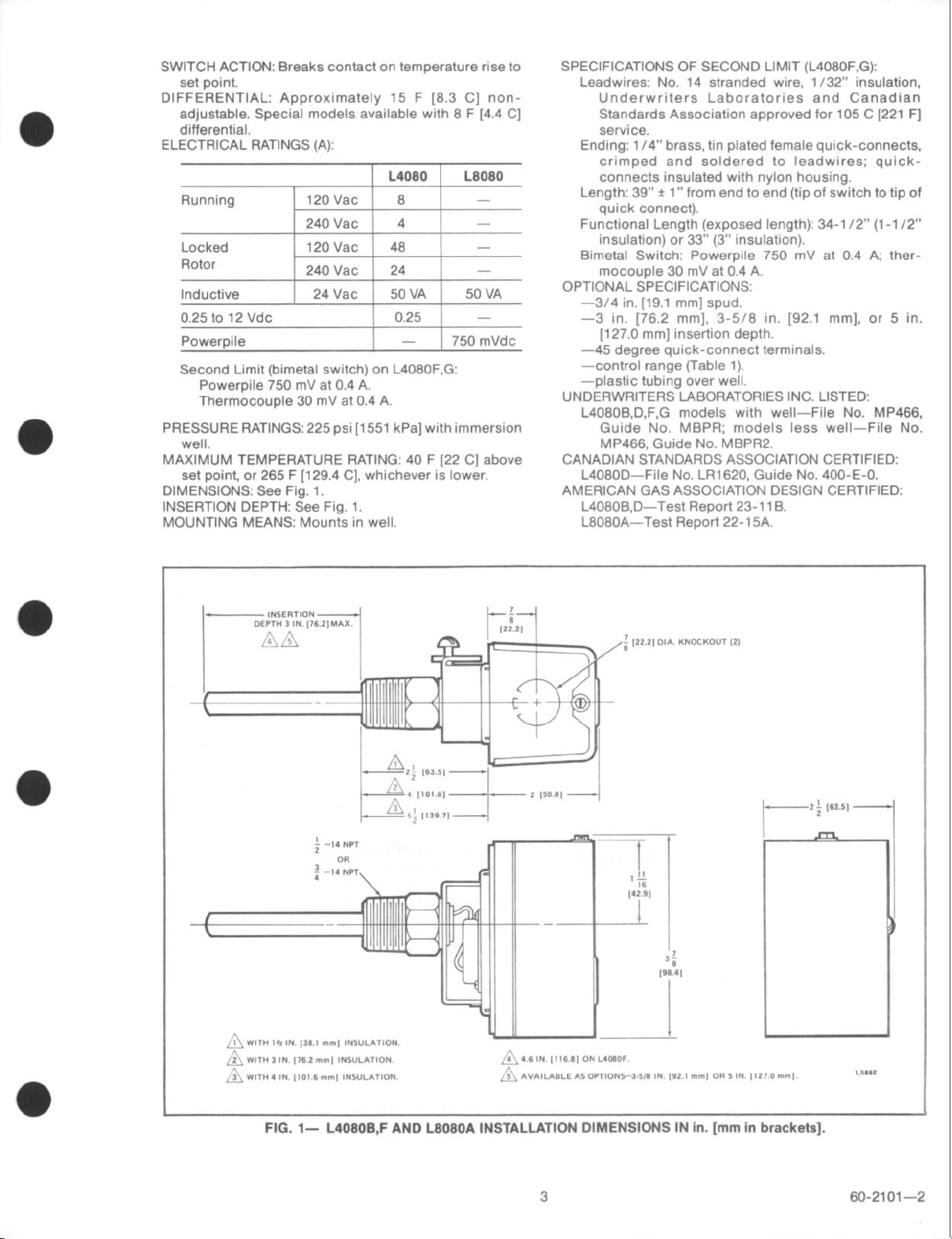

DIMENSIONS: See Fig. 1.

INSERTION DEPTH: See Fig. 1.

MOUNTING MEANS: Mounts in well.

I 24Vac i 50~~ i

1 0.25 i -

-

50 VA

750 mVdc

SPECIFICATIONS OF SECOND LIMIT (L4080F.G):

Leadwires: No. 14 stranded wire, l/32” insulation,

Underwriters Laboratories and Canadian

Standards Association approved for 105 C [221 F]

service.

Ending: l/4” brass, tin plated female quick-connects,

crimped and soldered to leadwires; quickconnects insulated with nylon housing.

Length: 39” f 1” from end to end (tip of switch to tip of

quick connect).

Functional Length (exposed length): 34-l 12” (l-l /2”

insulation) or 33” (3” insulation).

Bimetal Switch: Powerpile 750 mV at 0.4 A; ther-

mocouple 30 mV at 0.4 A.

OPTIONAL SPECIFICATIONS:

-3/4 in. [19.1 mm] spud.

-3 in. [76.2 mm], 3-5/E in. [92.1 mm], or 5 in.

[127.0 mm] insertion depth.

-45 degree quick-connect terminals.

-control range (Table 1).

-plastic tubing over well.

UNDERWRITERS LABORATORIES INC. LISTED:

L4080B,D,F,G models with well-File No. MP466.

Guide No. MBPR; models less well-File No.

MP466, Guide No. MBPR2.

CANADIAN STANDARDS ASSOCIATION CERTIFIED:

L4080D-File No. LR1620, Guide No. 400-E-0.

AMERICAN GAS ASSOCIATION DESIGN CERTIFIED:

L408OB,D-Test Report 23-l 1 B.

L8080A-Test Report 22-l 5A.

FIG. l- L408OB,F AND L8080A INSTALLATION DIMENSIONS IN in. [mm in brackets].

I

3

60-2101-2

Page 4

l-

141 3, ,794,

,\ 16 IN ,116 6, ON L4066G.

2 AYAILABLE AS OPTIONS-_).5/6 IN p2.1 mm, OR 5 IN ,127.o mm,.

A

FIG. 2-L4080D,G INSTALLATION DIMENSIONS IN in. [mm in brackets].

W-y

MVSTALLATION

t-’

WHEN INSTALLING THIS PRODUCT. . .

1. Read these tnstructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

ND MOUNTING

.,

,I

The L4080 or L8080 is mounted in a tapping which is

usually provided by the boiler manufacturer, at a location

where it will sense average water temperatures.

1. Disconnect power supply and drain boiler.

2. If no tapping is provided, prepare one at a location

that will permit boiler water of average temperature to

circulate freely about the element.

3. L4080A-insert in boiler tapping. Using wrench on

hex nut only, tighten securely. Do not use the L4080 as a

lever to tighten the connection.

4. L4080B,D and L8080A-install immersion well in

boiler tapping, tighten securely. Insert sensing element in

well, tighten setscrew.

5. Refill boiler and check for water leaks. If well needs

tightening, use wrench on hex nut only.

SETTINGS (L4080 only)

Because heating systems differ, follow the burner

manufacturer’s recommendations when selecting the

proper Aquastat controller setting.

Turn the notched wheel until the desired high limit

setting coincides with the arrowhead indicator at the side

of the switch.

On the L408OF and G, the second high limit is not

adjustable.

WIRING

Disconnect power supply before connecting wiring to

prevent electrical shock or equipment damage.

All wiring must comply with applicable codes and

ordinances.

Wire the L4080 in the control circuit. Wire the L8080 in

series with the gas control power unit. Figs. 3-10 show

typical wiring diagrams.

4

Page 5

POWERPILE

THERMOSTAT

I

L----u**Ar---!

POWER UNIT COIL

(r**A*)OPERATOR COIL

FIG. 3-L4080B,D; L8080A TYPICAL WIRING HOOKUP

FOR 3 TERMINAL POWERPILE SYSTEMS.

1 BROKEN LINES REPRESENT INTERNAL WIRING.

2 PILOTSTAT POWER “NIT COIL.

3 VALVE OPERATOR COIL.

n

IO,,M

I

FIG. 4-L4080B,D; L808OA TYPICAL WIRING HOOKUI

FOR 4 TERMINAL POWERPILE SYSTEMS.

LINE VOLTAGE

THERMOSTAT

OR CONTROLLER

LINE VOLTAGE

OPERATOR

3

1 POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PRO.

n

TECTlON AS REQUIRED

FIG. 5-L4080B,D: L8080A TYPICAL WIRING HOOKUP

FOR 24 V SYSTEMS.

1 POWER SVPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAO

n

PROTECTtON AS REOVIRED.

FIG. 844080B,D; L8080A TYPICAL WIRING HOOKUP

FOR LINE VOLTAGE SYSTEM.

5

60-2101-2

Page 6

I

L--7****r---?

POWER “NIT COIL

(****A) OPERATOR COIL

‘IG. 7-L4080F,G TYPICAL WIRING HOOKUP FOR 4-

TERMINAL POWERPILE CONTROL SYSTEMS.

FIG. 844080F,G TYPICAL WIRING HOOKUP FOR 3-

TERMINAL POWERPILE CONTROL SYSTEMS.

I

(SUGGESTED AS FIELD REPLACEMENT ONLY;

FOR NEW SYSTEMS, USE 4-TERMINAL

MODEL.)

1 POWER SVPPLY. PROVIDE DISCONNECT MEANS ANOO”ERLOAD PR

n

TECTION AS REOVIREO.

.._^

FIG. 9-L408OF,G TYPICAL WIRING HOOKUP FOR 24 V

SYSTEMS.

FIG. lO-L4080F,G TYPICAL WIRING HOOKUP FOR

LINE VOLTAGE SYSTEMS.

6

Page 7

OPERATidN

When the water temperature rises to the L4080 or

LB080 set point, the liquid fill in the sensing unit expands,

actuating a diaphram which interrupts the power supply

to the burner primary control (L4080) or the Pilotstat

power unit (L8080).

When the L4080 interrupts powerto the burner primary

control, the system automatically recycles when the

water cools and the L4080 switch closes.

CHECKOUT

Do not operate burner by lumpenng gas valve

terminals; this bypasses the temperature and limit

1

Turn on the power supply. Start the heating system

according to instructions supplied with the burner con-

On the L408OF and G, when the second limit is

reached, the Pilotstat power unit circuit opens, shutting

off all gas to the heater. Manual reset of the system is

required to restart

When the La080 interrupts powerto the Pilotstat power

unit, the water must cool to approximately 120 F [49 C]

and the gas control’s power unit must be reset before the

system will operate.

trol or main gas valve. Turn the L4080 to the low end of its

range, and be sure the control shuts off the burner when

the set point is reached. Set the L4080 High Limit Aquastat

Controller to the manufacturer’s recommended setting

before leaving job.

The L8080A is factory-set and nonadjustable. Check

that the power unit drops out and that gas flow is

interrupted when the L808O’s set point is reached (200 F

[93 C]. Reset power unit before leaving job.

lwwywoll Inc.

1666 Douglas Dnve N.

Golden Valley, MN 55422-4366

rnremationer tires OmCes in all principal Cities of the world. Manufachrrlng in Australia,

France, Germany. Japan, Mexico. Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

I

Canada, Finland,

PRINTED IN USA

Loading...

Loading...