Page 1

Put UPC Code Here

L4079A,B,W

PressureTrol® Limit Control

FEATURES

• L4079A has two ganged spst switches; breaks two

circuits (may be both sides of the power supply)

simultaneously.

• L4079B has one spst switch.

• L4079W is the same as L4079B but has seals for oil

applications.

®

• MICRO SWITCH

through transparent cover.

• Switches open automatically but must be reset

manually.

• Trip-free reset mechanisms do not permit the limiting

role of the PressureTrol

jamming the reset lever.

• Control does not need leveling.

• The L4079 is unaffected by moderate vibration.

snap-acting switches are visible

®

Control to be defeated by

PRODUCT DATA

APPLICATION

The L4079A,B, and W PressureTrol® Limit Controls are high

pressure limit switches that break electrical circuits when

pressure rises to a preset value.

The L4079A and B can be used with steam, air,

noncombustible gases, and fluids noncorrosive to the sensing

element.

L4079W is for use on oil burner systems.

Contents

Application .......................................................................... 1

Features ............................................................................. 1

Specifications ..................................................................... 2

Installation .......................................................................... 3

Wiring ................................................................................. 3

Checkout ............................................................................. 4

60-2156—05

Page 2

L4079A,B,W PRESSURETROL® LIMIT CONTROL

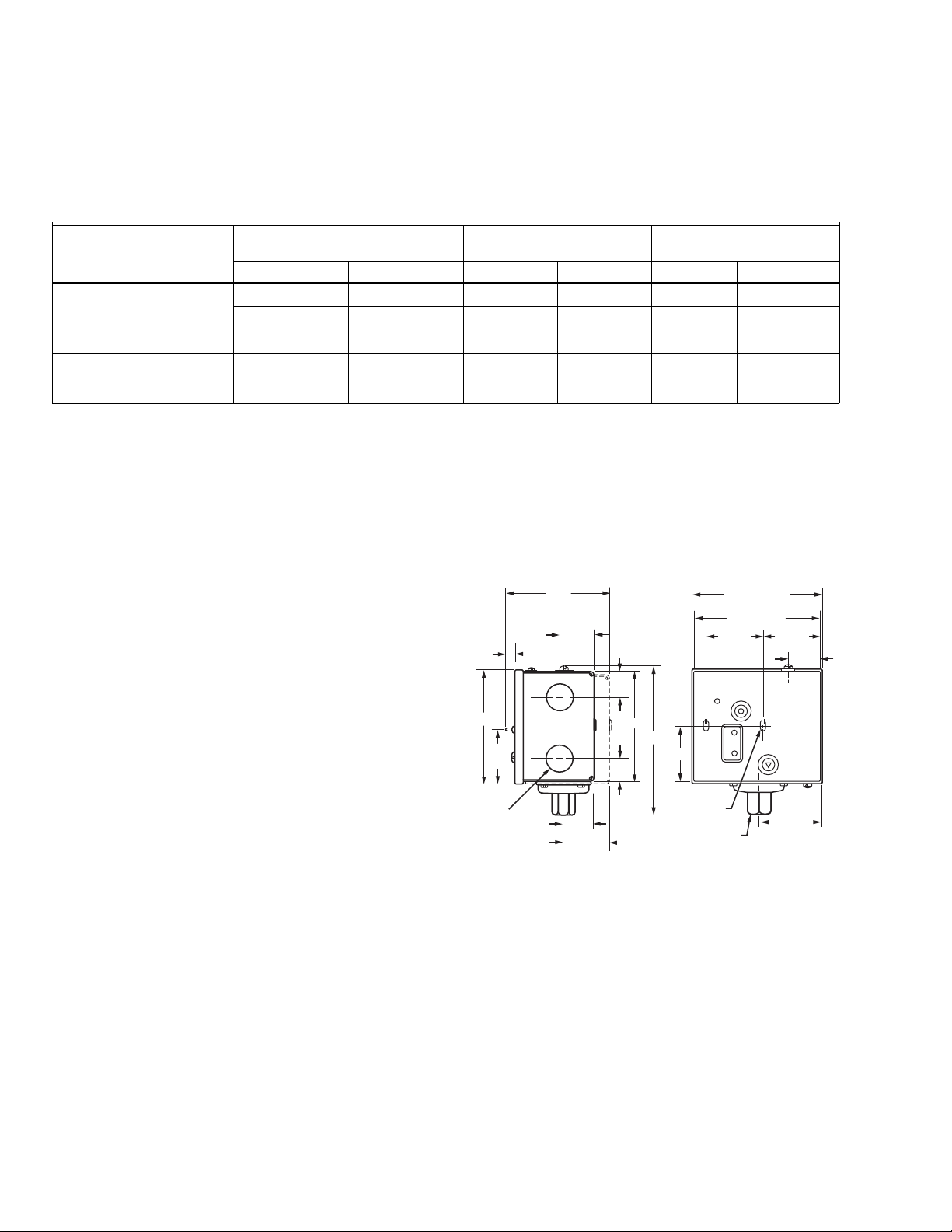

3-7/8

1/4

(2-15 PSI ONLY)

KNOCKOUT

FOR 1/2 INCH

CONDUIT (2)

1/4

4-15/16

KNOCKOUT

(2) FOR NO.

10 SCREW

1/4 - 18 NPT

1-

1/16

M22435

2-1/8

1-

13/16

1-

13/16

13/16

13/16

3-1/2

1-1/2

3/16

1-13/16

4-1/2 (COVER)

4-3/8 (CASE)

1-15/16

1-15/16

SPECIFICATIONS

Models: See Table 1.

Pressure Ratings: See Table 1.

Table 1. Pressure Ratings.

Range

Model Number

L4079A

a

and L4079B

b

psi kPa psi kPa psi kPa

2 to 15 15 to 100 25 170

5 to 50 35 to 350 85 590 10

10 to 150 70 to 1035 225 1550 30

L4079B1066

L4079W1000

a

Ratings apply to each of two separate circuits.

b

One circuit only.

b

b

20 to 300 140 to 2070 350 2410 60

10 to 150 70 to 1035 225 1550 30

Switching Action:

L4079A—Snap-switch. Breaks two circuits automatically on

pressure rise. Each circuit must be manually reset.

L4079B,W—Snap-switch. Breaks one circuit automatically on

pressure rise. Circuit must be manually reset.

Adjustment means: External adjustment screw. Scale is

calibrated in psi and kPa.

Electrical Ratings:

120 Vac: 9.8 Amps for full load; 58.8 Amps for locked rotor

240 Vac: 4.9 Amps for full load; 29.4 Amps for locked rotor

Maximum Diaphragm

Pressure Differentials

3 20.7

68.9

206.8

413.7

206.8

Accessories:

50024585-001 Brass Steam Trap.

14026 Steel Steam Trap.

33312B Knurled adjustment knob.

Dimensions: See Fig. 1.

Maximum Ambient Temperature: 150°F (66°C).

Mounting Means:

Pipe fitting—1/4-18 NPT. Connection on diaphragm assembly.

These devices may be either boiler mounted directly to a

boiler fitting, or may be surface mounted, such as on a wall,

by using the knockouts in the case.

Approvals:

Underwriters Laboratories Inc. (UL) Listed: File No. MP466,

Guide No. MBPR.

Canadian Standards Association (CSA): File No. LR95329,

Certificate No. 1720340

Fig. 1. L4079A,B,W PressureTrol

®

Limit Control

dimensions in inches.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number. If you have additional questions, need further information,

or would like to comment on our products or services, please write or phone:

1. Your local Honeywell Environmental and Combustion Controls Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

3. http://customer.honeywell.com or http://customer.honeywell.ca

International Sales and Service Offices in all principal cities of the world. Manufacturing in Belgium, Canada, China, Czech

Republic, Germany, Hungary, Italy, Mexico, Netherlands, United Kingdom, and United States.

60-2156—05 2

Page 3

INSTALLATION

WARNING

M22436

LINE VOLTAGE

THERMOSTAT

L4079A

L4079B, W

L1 (HOT)

L2

POWER

SUPPLY

TO

THERMOSTAT

(HOT)

TO POWER

SUPPLY

MOTOR

TO

MOTOR

RISE

RISE

RISE

1

PROVIDE DISCONNECT MEANS AND OVERLOAD

P

ROTE

CTION

AS REQUIRED.

1

M22437

PRESSURE

ADJUSTING

SCREW

PRESSURE

SETTING

INDICATOR

SCALEPLATE

MANUAL

RESET

BUTTONS

When Installing This Product…

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check on the ratings given in the instructions and

marked on the product to make sure the product is

suitable for your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out the product operation as provided in these instructions.

Location

PressureTrol® Limit Controllers must be mounted above the

water line in steam boilers. They can be mounted alongside the

pressure gauge, at a remote location, in a fitting provided by

the boiler manufacturer, or in special mountings on

low-water cutoffs.

Mounting

See Fig. 1 for mounting dimensions.

L4079A,B,W PRESSURETROL® LIMIT CONTROL

A steam trap must always be connected between the

PressureTrol

®

unit and the boiler. The steam trap prevents

boiler scale and corrosive vapors from attacking the

diaphragm.

Pressure Gauge Mounting

To mount the limit control beside a pressure gauge, remove the

gauge and install in its place a steam trap with a tee on top.

Mount the PressureTrol® unit and pressure gauge on the side

of the tee by means of nipples and elbows.

Remote Mounting

If excessive vibration seems likely to affect the operation of the

control, it may be located remotely, as long as all piping is

suitable and properly pitched to drain all condensation back to

the boiler.

Boiler Mounting

If it is not convenient to mount the control adjacent to the

pressure gauge, install a steam trap at a location on the boiler

recommended by the boiler manufacturer and screw the unit

directly to the steam trap.

WIRING

All wiring must comply with local codes and ordinances. See

Fig. 2 for internal schematics and wiring.

Electrical Shock Hazard.

Can cause severe injury, death or property damage.

Disconnect the power supply before beginning wiring.

More than one power supply disconnect may be

required.

Fig. 2. Schematics and wiring. L4079A breaks both sides

of power supply; L4079B,W breaks hot side only.

Setting

To set the control, turn the pressure adjusting screw (see Fig.

3) until the pressure setting indicator on the front of the case is

in line with the required control pressure setpoint. The indicator

setting is the point at which the switch breaks contact.

Fig. 3. Controls and indicators on L4079A. L4079B,W is the

same except for having only one reset button.

3 60-2156—05

Page 4

L4079A,B,W PRESSURETROL® LIMIT CONTROL

Manual Resetting

When the circuits have broken automatically, they must be

manually reset. After the pressure returns to setpoint, minus

the differential (shown in Table I), manually reset by firmly

depressing the manual reset button(s) and releasing.

NOTES:

— The circuit is not complete until the reset button is

released.

— The trip-free manual reset mechanism prevents

the limit controller from operating as an automatic

controller (self-resetting) even if the manual reset

button has been tied down.

CHECKOUT

After the control has been installed and wired, test as follows:

1. Note the boiler pressure by checking the boiler pressure

gauge (boiler pressure should be near the middle of the

PressureTrol® pressure scale to perform this test properly).

2. Rotate the PressureTrol

FIg. 3) until the pressure setting indicator on the front of

the case corresponds to the boiler pressure gauge

reading.

NOTE: The limit control should break the control circuit(s)

when the boiler pressure gauge reading equals or

slightly exceeds the PressureTrol

3. If the limit control is operating properly, manually reset it

and adjust the pressure adjusting screw until the pressure setting indicator is in line with the required limit setpoint.

®

pressure adjusting screw (see

®

pressure setting.

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

® U.S. Registered Trademark

© 2013 Honeywell International Inc.

60-2156—05 KK. Rev. 07-13

Printed in United States

Loading...

Loading...