Honeywell L4006 Installation Manual

95-6120B-05

L4006,L4007 Aquastat Controllers

CAUTION

INSTALLATION INSTRUCTIONS

APPLICATION

These boiler-mounted, immersion type controllers

operate in response to temperature changes in hydronic

heating systems.

L4006A,C; L4007 A break the circuit on a temperature

rise to the control setting. They are used tor high limit or

low limit control. When used as a controller or as a low

limit, a separate high limit must be used.

L4006B, L4007Bmake the circuit on a temperature rise.

They are used as a circulator controller, delaying

circulator operation if boiler water temperature is below

the control setting.

L4006E (horizontal well with vertical option) models

include trip-tree manual reset switch. Whenever the

temperature of the controlled medium reaches the high

limit setting, these models are designed to break the

control circuit. A reset button at the front of the case

must be pressed to re-establish the control circuit.

L4006G includes two switches which break

simultaneously on temperature rise to the control

setting. This model is used tor high limit and circulator

control.

Depending on the model, the Aquastat controllers may

include:

• bulb compression titting (L4006C only),

• immersion well tor mounting vertically, or

• immersion well for mounting horizontally.

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable

for your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

Disconnect power supply before beginning

installation to prevent electrical shock or

equipment damage.

Mounting

The boiler manufacturer generally provides a tapping for

insertion of the Aqua stat controller's sensing element.

This tapping is located in a representative point where

typical boiler water temperature can be measured.

Depending on model, the element is either inserted in an

immersion well or through a bulb compression fitting.

It immersion well or bulb compression fitting must be

ordered, refer to form 68-0040 “Wells and Fittings for

Temperature Controllers,” for part numbers and ordering

information.

For Models Using an Immersion Well

The well of the Aquastat controller must always be

exposed to average temperature circulating water, and

must never be located close to a hot or cold inlet or

steam coil. Where the tapping is on the side of the boiler,

use an Aquastat controller in which the well can be

mounted horizontally. Where the tapping is on top ot the

boiler, use a model in which the well can be mounted

vertically. Some models include an adapter for vertical

or horizontal mounting. See Fig. 2.

IMPORTANT

Controller may be used with or without immersion well. Well, if used, must fit sensing bulb

snugly tor good thermal response. Bulb should

be inserted until it rests against bottom of well.

then hold it there while tightening the tubing

clamp.

NOTE: Some models have an adjustable tubing length

to 3 in. [716 mm]. In these models, extra tubing

inside the case may be pulled out, if needed.

Follow the mounting instructions furnished by the

system manufacturer if available; otherwise. proceed as

follows.

L4006,L4007 AQUASTAT CONTROLLERS

M38422

VERTICAL MOUNTING

HORIZONTAL MOUNTING

Installing the Immersion Well

On existing installations, shut off the power and remove

the old control. If the old immersion well appears

suitable, and if the adapter clamp on the Aquastat

controller fits the old well spud, this well need not be

replaced.

To install new well:

1. If the system is filled, drain system to a point below

the boiler tapping.

2. Remove old well from boiler tapping.

3. Install the immersion well. Both 1/2 and 3/4 inch x

14 NPT wells are available. Depending on size of

boiler tapping and model ordered, a reducer fitting

may be required.

4. Fill the system. Make sure that the well is screwed

in tightly enough to prevent leakage. Do NOT use

the case as a handle to tighten well after controller

is secured to well.

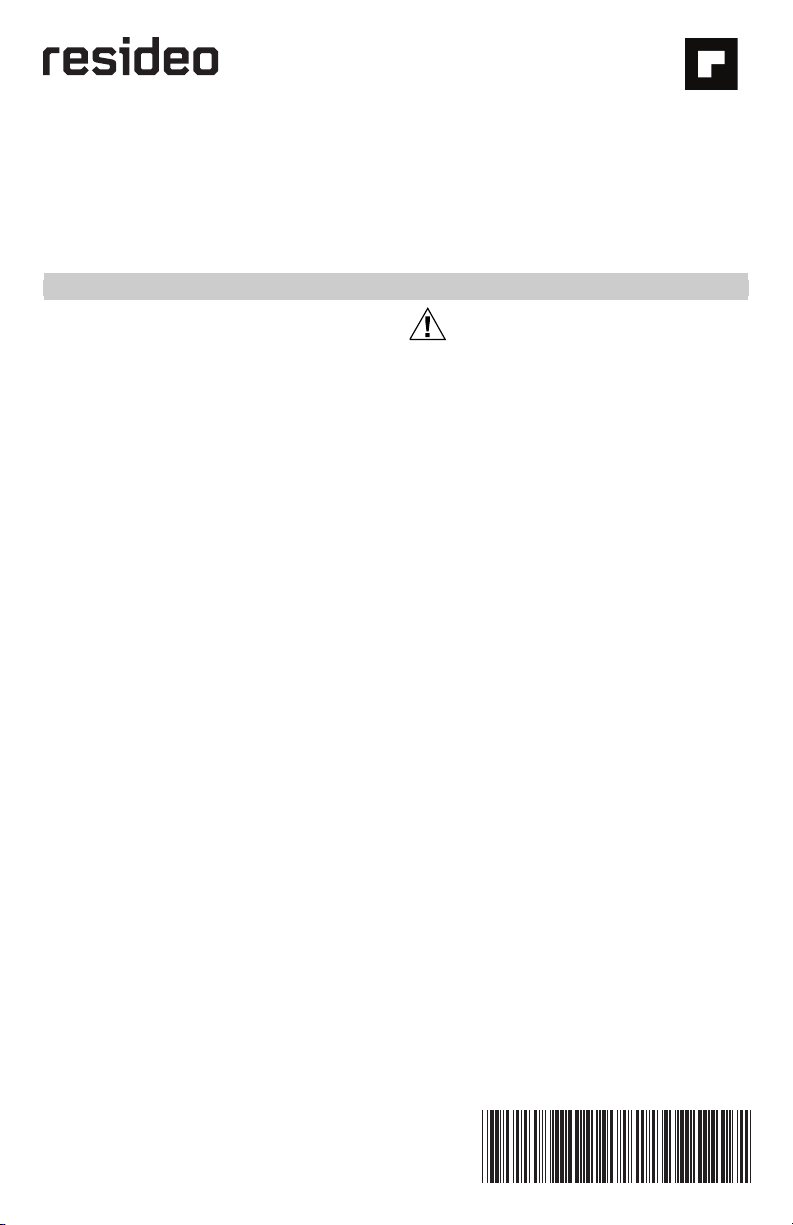

SETPOINT

INDICATING DIAL

SPST

SWITCH

3

DIFFERENTIAL

ADJUSTMENT

WHEEL

ADAPTER CLAMP

SCREWS

2

1

IMMERSION

WELL

3. Fasten the case of the Aquastat controller to the

well with the adapter clamp. Make certain that the

clamp is properly positioned over the groove of the

well spud. Also be sure the flange at the opening of

the well fits snugly into the opening of the case.

The sensing bulb must bottom in the well for best

temperature response.

MODELS WITH FIXED DIFFERENBTIALS DO NOT INCLUDE

1

ADJUSTING WHEEL.

VERTICALLY MOUNTED IMMERSION WELL IS ATTACHED

2

TO THE BOTTOM OF THE CASE.

3

L4006G INCLUDES TWO SPST SWITCHES.

Fig. 1. Internal view showing L4006 (model with

horizontal well).

M38421

For Installation of Sensing Bulb in Immersion Well

1. Loosen screw (at top of case, above scale setting),

and remove cover. Loosen 2 screws that secure

adapter clamp. See Fig. 1.

2. Insert the sensing element into the immersion well.

95-6120B—05 2

Fig. 2. Mounting bracket placement for vertical or

horizontal mounting.

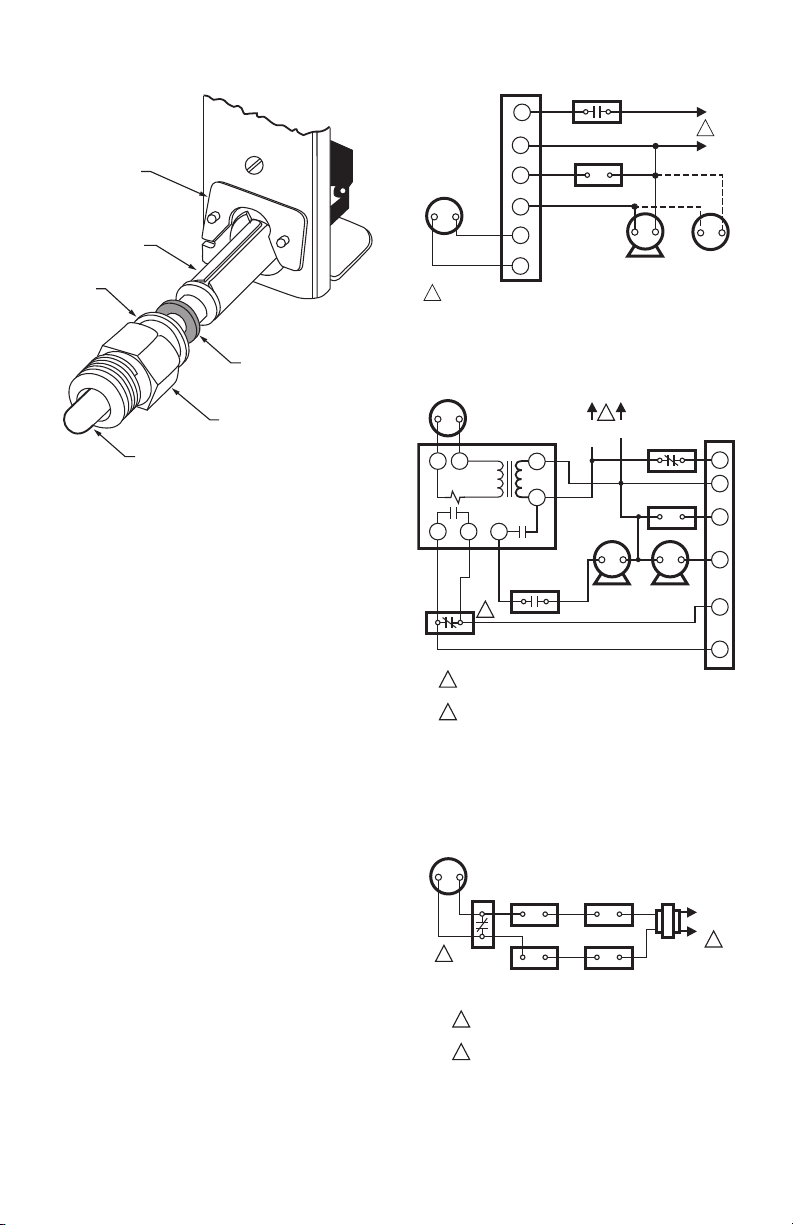

ADAPTER

L1

(HOT)

L2

1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

PROTECTORELAY

CONTROL

L4006A OR L4007A HIGH

LIMIT CONTROLLER

IGNITION

24 VOLT

THERMOSTAT

BURNER

MOTOR

OIL VALVE

(IF USED)

M1054C

1

2

3

4

T

T

1

2

3

4

T

T

IGNITION

BURNER

L4006B OR L4007B

CIRCULATOR

AQUASTAT

CONTROLLER

CIRCULATOR

L4006A OR L4007A LOW LIMIT

AQUASTAT CONTROLLER

L1

(HOT)

L2

L4006A OR L4007A

HIGH LIMIT

AQUASTAT

CONTROLLER

24 VOLT

THERMOSTAT

RA832A

SWITCHING RELAY

PROTECTORELAY

CONTROL

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

USE L4006E FOR MANUAL RESET.

1

2

M2855C

TT

XX

4

2

1

1

2

®

®

®

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

USE L4006E FOR MANUAL RESET.

1

2

M2856D

2

L1

(HOT)

L2

1

24 VOLT

THERMOSTAT

LOW WATER

CUTOFF

PRESSURE

CONTROL

L4006A OR

L4007A

LOW LIMIT

AQUASTAT

CONTROLLER

GAS

VALVE

PILOTSTAT

CONTROL

®

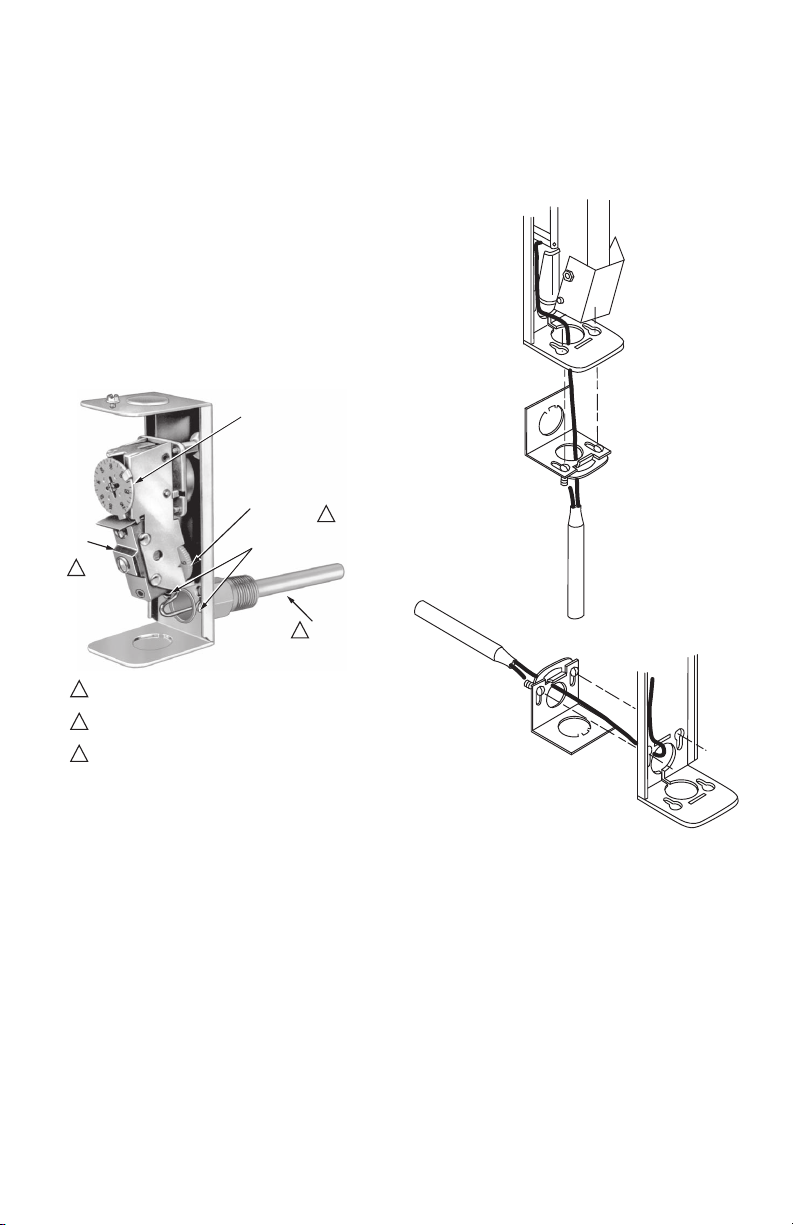

CLAMP

SPLIT SLEEVE

ADAPTER CLAMP

FITS OVER

GROOVE

L4006,L4007 AQUASTAT CONTROLLERS

SEALING WASHER

BULB COMPRESSION

FITTING

SENSING BULB

Fig. 3. Direct Immersion model with bulb compression

fitting partially removed.

Models Designed for Direct Immersion (without well)

For either horizontal or vertical placement of the

mounting bracket, see Fig. 2. Some models, which

provide for direct immersion of the sensing element into

the boiler, include a bulb compression fitting instead of

an immersion well. Install fitting in boiler tapping. Be

sure sealing washer is in place as shown in Fig. 3. Make

sure that spud of fitting is screwed in tightly enough to

prevent leaking. Insert sensing bulb through fitting.

Adjust the adapter clamp so that it fits over the groove at

the opening of the fitting. Tighten adapter clamp screws

so that Aquastat controller is firmly attached to fitting.

WIRING

Disconnect power supply before connecting wiring to

avoid electrical shock or equipment damage.

All wiring must comply with local electrical codes and

ordinances.

Refer to Fig. 4–9 for typical diagrams of Aquastat

controllers used in heating systems.

Fig. 4. Typical hookup for oil-fired gravity system, using

M8774C

Fig. 5. Hookup for oil-fired, summer-winter hydronic

system with domestic hot water using L4006A or B,

L4007 A or B. This Is typical where control for domestic

hot water is added, or where each Aquastat controller is

Fig. 6. Typical hookup for gas-fired system with

domestic hot water, using L4006A,E or L4007A.

3 95-6120B—05

L4006A or L4007A.

mounted in a separate location.

Loading...

Loading...