Page 1

KS20S

Read carefully before starting up!

Leggere attentamente prima della messa in servizio!

Keep instructions for later use!

Conservare le istruzioni per uso futuro!

32303398 Rev. A

Operation Manual Manuale operativo

KaltecSoft Evolution

Water softener Addolcitore d’acqua

Page 2

Page 3

Honeywell GmbH 1 MU5H-1419GE23 R0815

Table of Content

1 Introduction ...........................................................................................................................3

2 Safety guidelines ...................................................................................................................3

3 Scope of delivery ...................................................................................................................4

4 Description of function ...........................................................................................................4

4.1 Meter regeneration .....................................................................................................4

4.2 Valve operation ..........................................................................................................4

4.3 Application ..................................................................................................................4

4.4 Sodium concentration limit .........................................................................................5

5 Technical data .......................................................................................................................5

6 Installation Instructions ..........................................................................................................8

6.1 General advices .........................................................................................................8

6.2 Mounting .....................................................................................................................8

6.3 Residential installation ................................................................................................9

7 Start-up .................................................................................................................................9

7.1 Start-up instructions ....................................................................................................9

7.2 Valve positions .........................................................................................................10

8 Setting .................................................................................................................................11

8.1 General parameters ..................................................................................................11

8.2 Time of the day .........................................................................................................11

8.3 Basic settings ...........................................................................................................12

8.4 Programming - Advanced Installers .........................................................................13

8.5 Basic settings ...........................................................................................................13

8.6 System parameters ..................................................................................................14

9 History .................................................................................................................................15

9.1 History data mode ....................................................................................................15

9.2 Flow rate ...................................................................................................................16

9.3 Regeneration data ....................................................................................................16

9.4 Error log ....................................................................................................................16

10 Maintenance ........................................................................................................................16

10.1 Preparation ............................................................................................................... 16

10.2 Cleaning ...................................................................................................................17

10.3 Spare part sets .........................................................................................................17

10.4 Maintenance log .......................................................................................................18

11 Troubleshooting ..................................................................................................................19

12 Disassembly .......................................................................................................................21

13 Disposal .............................................................................................................................21

Page 4

Honeywell GmbH 2 MU5H-1419GE23 R0815

Contenuto

1 Introduzione ........................................................................................................................23

2 Avvertenze di sicurezza ......................................................................................................23

3 Fornitura ..............................................................................................................................24

4 Descrizione del funzionamento ...........................................................................................24

4.1 Rigenerazione tramite contatore ..............................................................................24

4.2 Funzionamento della valvola ....................................................................................24

4.3 Modalità di impiego ...................................................................................................24

4.4 Concentrazione massima di sodio ............................................................................25

5 Dati tecnici ...........................................................................................................................25

6 Istruzioni di installazione .....................................................................................................28

6.1 Avvertenze generali ..................................................................................................28

6.2 Montaggio .................................................................................................................28

6.3 Installazione domestica ............................................................................................29

7 Messa in servizio .................................................................................................................29

7.1 Istruzioni per la messa in servizio .............................................................................29

7.2 Posizioni della valvola ..............................................................................................30

8 Configurazione ....................................................................................................................31

8.1 Parametri generali ....................................................................................................31

8.2 Ora del giorno ...........................................................................................................32

8.3 Impostazioni di base .................................................................................................32

8.4 Programmazione (per installatori esperti) .................................................................33

8.5 Impostazioni di base .................................................................................................33

8.6 Parametri di sistema .................................................................................................35

9 Storico .................................................................................................................................36

9.1 Modalità dati dello storico .........................................................................................37

9.2 Portata ......................................................................................................................37

9.3 Dati relativi alla rigenerazione ..................................................................................37

9.4 Registro degli errori ..................................................................................................38

10 Manutenzione ......................................................................................................................38

10.1 Preparazione ............................................................................................................ 38

10.2 Pulizia .......................................................................................................................38

10.3 Set di ricambi ............................................................................................................38

10.4 Libretto di manutenzione ..........................................................................................39

11 Guasti / Ricerca guasti ........................................................................................................40

12 Smontaggio ........................................................................................................................43

13 Smaltimento .......................................................................................................................43

Page 5

MU5H-1419GE23 R0815 3 Honeywell GmbH

English

We would like to thank you for choosing the KS2 0S softener.

We are convinced that our product will serve you to your

complete satisfaction as it has been manufactured with

extreme care.

The KS20S softener is delivered in a box and includes a

bypass valve. Please carefully inspect the device in presenc e

of deliveryman for transportation damages.

Your Honeywell team

1. Introduction

This manual is intended for professional installers. Please

read this manual to ensure a danger-free, safe and correct

commissioning of the KS20S softener.

Safety information and notes are characterised b y symbols in

this manual.

2. Safety guidelines

Warning! Indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

Caution! Indicates a potentially hazardous situation

which, if not avoided, could result in minor or moderate

injury or damage to property.

Note! Provides supplementary information or gives

tips for easier operation

Note! Environment protection guidelines

Caution! Before starting up the softener, read this

manual carefully. Handle the softener carefully.

Caution! Keep this instructions for later use.

Caution! Use the softener only according to desig-

nated application.

Caution! Do not perform a total reset of settings. The

device can be used in its full performance only with the

factory settings.

Caution! Keep the softener in proper working order.

Caution! Any malfunctions must be repaired at once

by a professional installer.

Caution! Install a pressure reducer ahead of the

softener, if the input pressure is more than 6bar.

Caution! Ensure that installation is not subject to free-

zing or extreme heat. Avoid exposure to sun.

Caution! Install the softener in a chos en place on a flat

firm and clean surface.

Warning! Do not touch any electrical parts with wet

hands! Disconnect the softener for any electrical works

Warning! Place the power cord carefully to avoid tripping hazard!

Warning! Beware of tripping or slipping hazard due to

escaping media!

Note! Both the softener and the associated packaging

consist mostly of recyclable raw materials. Dipose of

packing and recyclable materials separately, properly

and in environmentally friendly way.

Page 6

Honeywell GmbH 4 MU5H-1419GE23 R0815

3. Scope of delivery

All models of the KS20S softener are delivered in a box

containing:

• KS20S water softener

• Installation instruction

• Chlorinator (mounted ex works)

• Bypass valve with blending

• Inlet check valve (mounted ex works)

• Reinforced hose for inlet/outlet connection

- 2 hoses, length 650 mm, 1" felmale/female

-4 washers

- Connection pieces

• Pipe for drain and regeneration water

- Length 3000 mm

- Diameter 1/2"

- Connection kit (2 screw lamps, hose coupling, washer)

• Test kit for water hardness

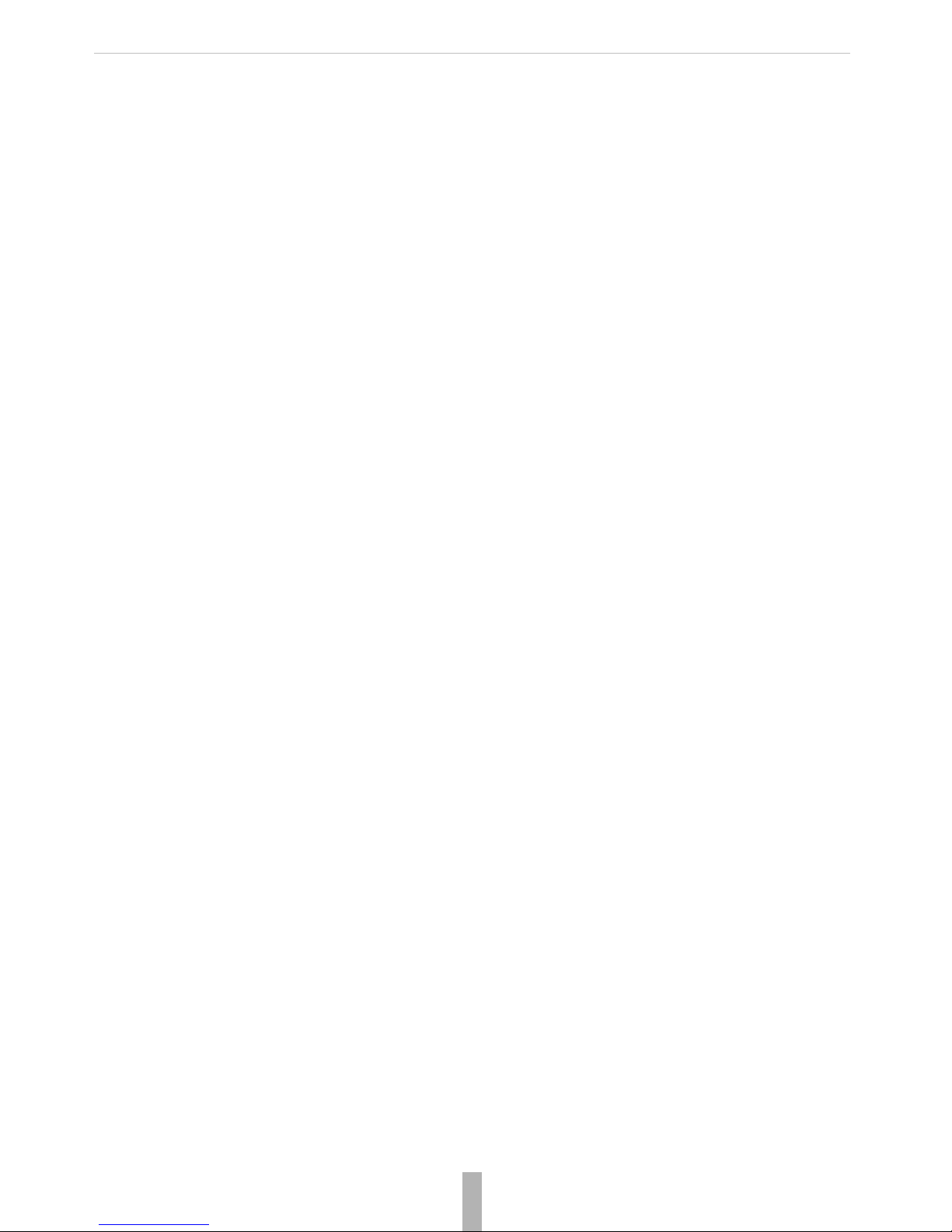

Main components

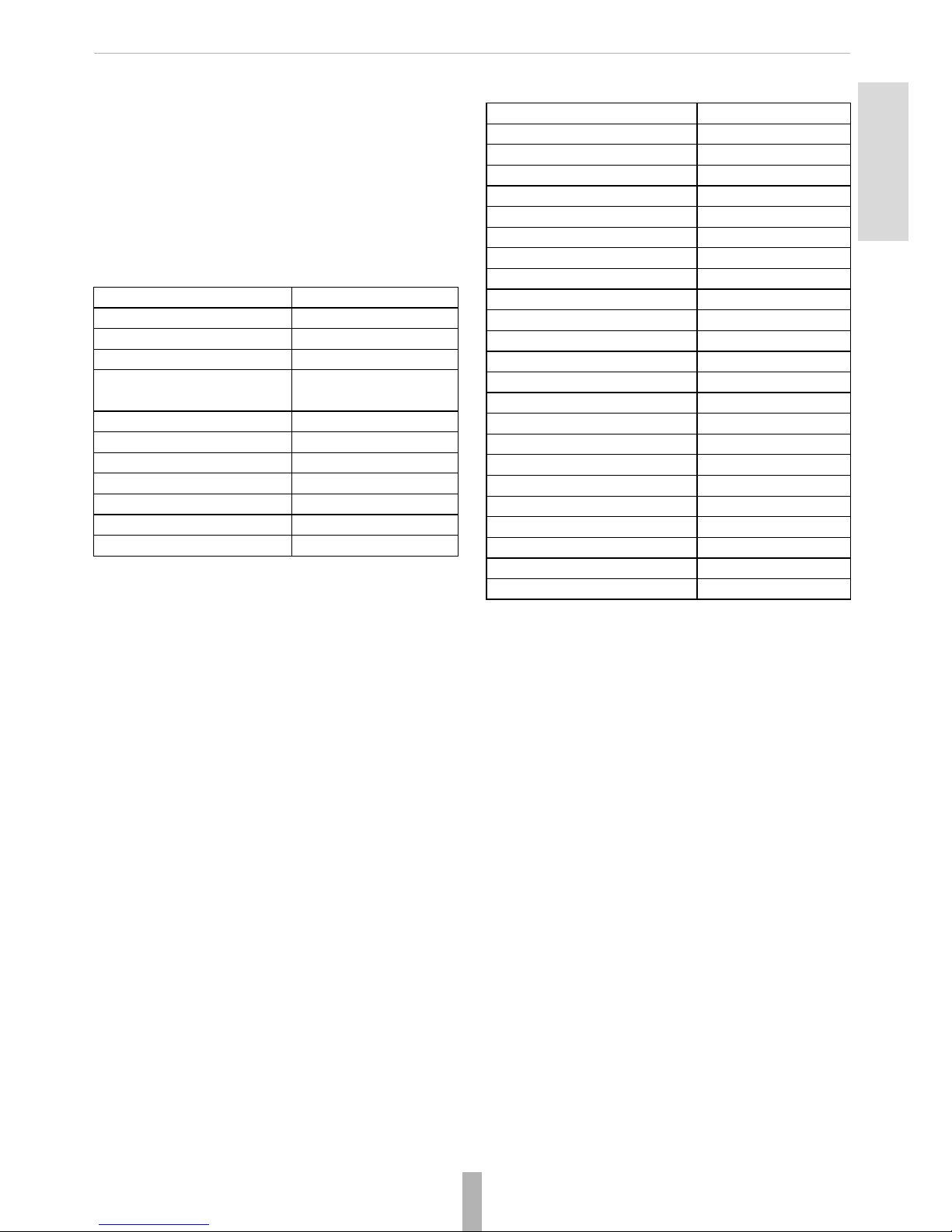

Img. 1 KS20S main components

The KS20S softener consists of the following main components:

1. Controller

2. Brine lid

3. Main hood

4. Brine tank

4. Description of function

4.1. Meter regeneration

In normal use the LCD display alternates between following

indications:

• Time of day

• Remaining capacity (m

3

)

•Flow rate

• Number of days until next regeneration

• Installer name

• Softener name.

At the time of regeneration the controller compares the remaining capacity with the reserve and decides if it is necessary to

start the regeneration. KS20S softener is equipped with a

blending device to insure a residual hardness in softened

water.

Controller

During regeneration the LCD display alternates between

following indications:

• Cycle number

•Cycle name

• Remaining time for the current cycle.

When all the cycles are finished, the valve comes bac k to the

service position.

The controller of KS20S softener can manage:

• Normal brining

• Proportional brining

• Counter current regeneration (upflow ).

4.2. Valve operation

The bypass valve of KS20S softener can be set in different

positions (see 7.2. Valve positions):

• Normal operation

• Bypass

• Diagnostic bypass

• Shut off.

Setting Mode

To enter the program mode put the valve to the normal operation position. During and after the sett ing (see 8. Setting), the

valve will continue to operate normally monitoring all information. The settings are stored in permanent memory.

Power failure

During a power failure the controller of KS20S softener will be

inoperative and any calls for regeneration will be delayed.

The controller will continue normal operation fr om the point of

interruption once the power supply is resumed.

All control display s an d programming will be stored during a

power failure for a later use when the power supply is

resumed. The control will retain these values without loss, if

necessary, for years.

4.3. Application

Honeywell recommends the following applications of KS20S

softener:

1

2

4

3

1

2

4

Type Size Honeywell recommendations

KS20S-15 5 liters 1 point-of-use application (e. g. one sin k)

KS20S-45 14 liters 1-4 family dwelling

KS20S-55 18 liters 3-8 family dwelling

KS20S-85 25 liters 6-21 family dwelling

Note! Values recommended for households with a

water hardness of 30 f°H and an average daily

consuption of 0,1m3 water per person.

Note! Honeywell recommends to install a 100µcartridge filter.

Page 7

MU5H-1419GE23 R0815 5 Honeywell GmbH

English

4.4. Sodium concentration limit

When operating a KS20S softener, the limit value for the

sodium concentration (acc. drinking water ordinance) of

200 mg/l may not be exceeded.

To reduce the water hardness by 1°fH, add about 4,5 mg/l

sodium to the water. Additionally, take into ac count the basi c

sodium content of the raw water. The maximum possible

softening results from these values.

5. Technical data

Remarks

(*) without nods and open at athmospheric pressure

(**) under normal circumstances

KS20S Models:

The further technical paramete rs differ from the size and the

model of the KS20S softener.

Connection IN&OUT 1"

Drain connection (*) 3/4"

Electrical rating 230V, 50Hz, 12 V

Max power rating 6W

IP protection class IP 51, double isolated

transformer

Nominal pressure PN10

Min inlet pressure 2 bar

Max inlet pressure 8 bar

Vacuum no allowance

Average pressure loss (**) 1 bar

Min water temperature 5 °C

Max water temperature 35 °C

KS20S-15

height 530mm

width 230mm

depth 430mm

height IN&OUT 513mm

max. weight 30kg

KS20S-45

height 730mm

width 320mm

depth 530mm

height IN&OUT 50mm

max. weight 70kg

KS20S-55

height 1070mm

width 320mm

depth 530mm

height IN&OUT 82mm

max. weight 129kg

KS20S-85

height 1180mm

width 320mm

depth 530mm

height IN&OUT 96mm

max. weight 178kg

Page 8

Honeywell GmbH 6 MU5H-1419GE23 R0815

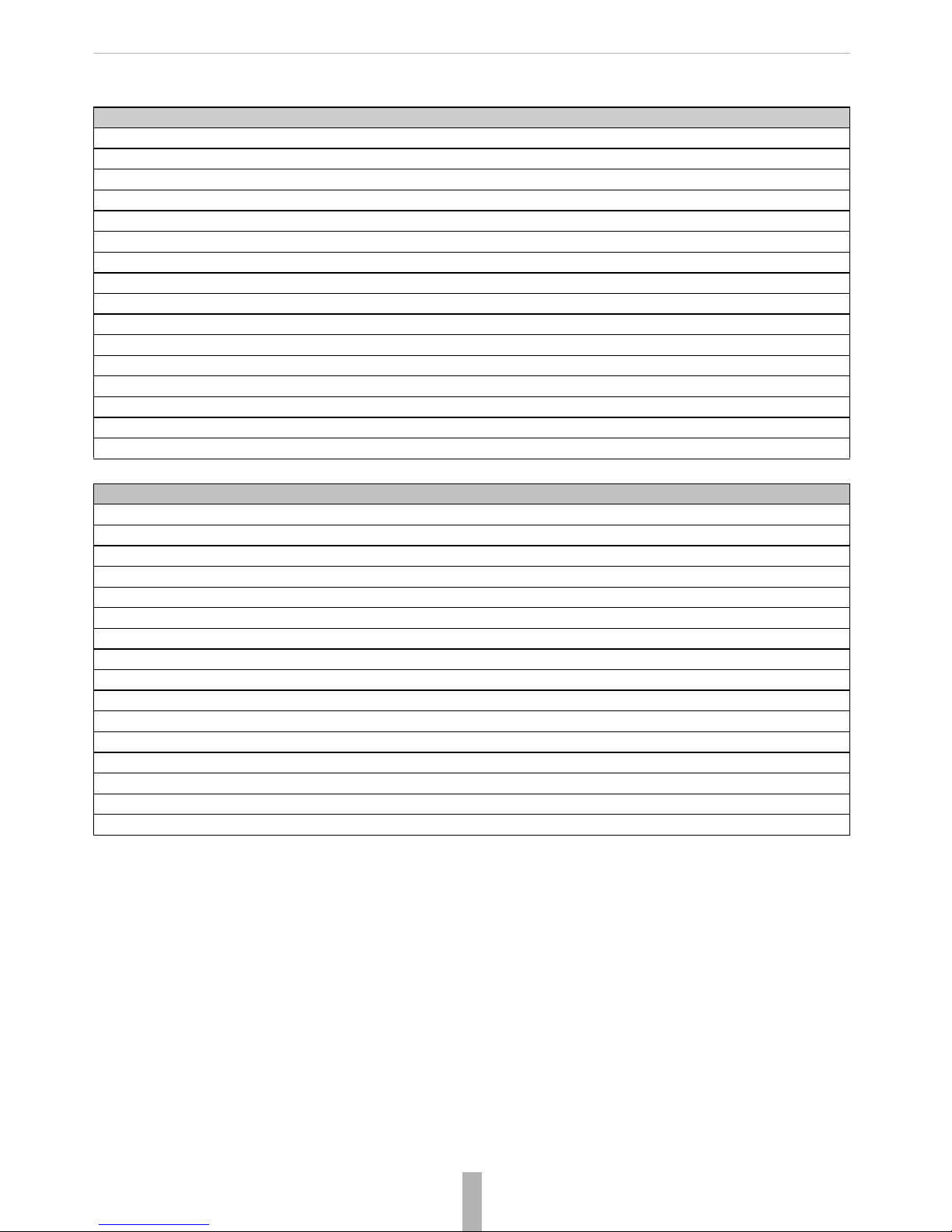

Technical data:

KS20S-15

Ion exchange

Capacity kg CaCO

3

0,15

°F x m

3

15

°dH x m

3

8

salt consumption kg salt/regen. 0,5

kg CaCO

3

/kg salt 0,3

Flow rate

nomial m

3

/h 0,30

peak m

3

/h 0,4

minimum L/h 60

Rinse water consuption

brining & slow rinse liters 15

backwash liters 5

fast rinse liters 20

total liters 40

L/kg CaCO

3

267

KS20S-45

Ion exchange

Capacity kg CaCO

3

0,83

°F x m

3

83

°dH x m

3

47

salt consumption kg salt/regen. 1,8

kg CaCO

3

/kg salt 0,4

Flow rate

nomial m

3

/h 1,2

peak m

3

/h 1,7

minimum L/h 60

Rinse water consuption

brining & slow rinse liters 25

backwash liters 40

fast rinse liters 20

total liters 85

L/kg CaCO

3

102

Page 9

MU5H-1419GE23 R0815 7 Honeywell GmbH

English

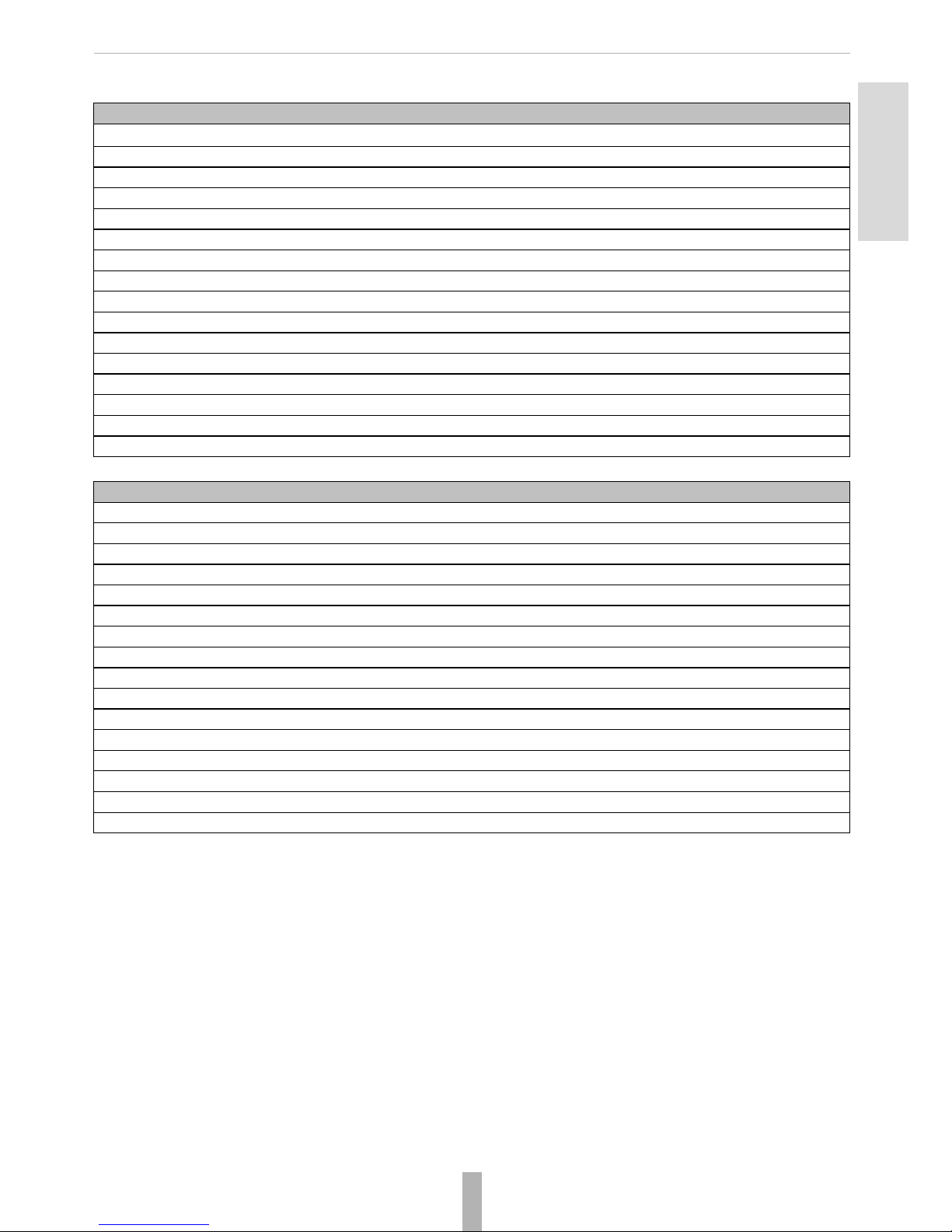

Technical data:

KS20S-55

Ion exchange

Capacity kg CaCO

3

1,04

°F x m

3

104

°dH x m

3

58

salt consumption kg salt/regen. 2,2

kg CaCO

3

/kg salt 0,4

Flow rate

nomial m

3

/h 1,4

peak m

3

/h 1,7

minimum L/h 60

Rinse water consuption

brining & slow rinse liters 35

backwash liters 30

fast rinse liters 20

total liters 85

L/kg CaCO

3

82

KS20S-85

Ion exchange

Capacity kg CaCO

3

1,61

°F x m

3

161

°dH x m

3

90

salt consumption kg salt/regen. 3,4

kg CaCO

3

/kg salt 0,4

Flow rate

nomial m

3

/h 1,8

peak m

3

/h 2,3

minimum L/h 60

Rinse water consuption

brining & slow rinse liters 45

backwash liters 5

fast rinse liters 35

total liters 120

L/kg CaCO

3

75

Page 10

Honeywell GmbH 8 MU5H-1419GE23 R0815

6. Installation Instructions

6.1. General advices

Location

When you choose the softener location, please take into

account the following parameters:

• Install the KS20S softener in a chose n plac e on a f lat firm

and clean surface.

• The KS20S softener must be close to a drain line to allow

an easy connection.

• Make sure there is an electrical earth grounded plug to

power the unit.

Pressure

A minimum pressure of 2 bar is needed to allow the valve to

regenerate properly. Please do not operate over 8bars.

If this is the case, use a pressure reducer upstream of the

installation.

Power connection

Be sure that power cannot be switched off accidentally at

a wall switch. If the power cable is damaged, please ask a

professional electrician to change it.

Plumbing

The plumbing must be in good state. In case of doubt, please

change it. We advise the use of prefilter upstream the installation.

All plumbing for the water inlet, distribution and drain lines

should be done correctly in accordance with the legis lation in

force at the time of the inst allation. The pipe size for the drain

line should be a minimum of 20mm (3/4’’).

To prepare for any maintenance:

1. Shut down water inlet

2. Unplug the KS20S soft ener

3. Drain the installation by opening the taps at the highest

and the lowest level of your house.

Water Temperature

6.2. Mounting

1. Thoroughly flush pipework.

2. Install the KS20S sof tener.

• Note flow direction (indicated by arrow).

• Install without tension or bending stresses.

3. Establish the conn ections to the KS20S softener.

4. Connect the sew e rage tube to the discharge connection

(inner tube ømin. 13 mm, 1/2").

Caution! The installation must be performed by a

professional installer only.

Caution! It is seriously recommended to ins tall a pressure reducer ahead of the softener, if the input pressure is more than 6 bar. Failing to adhere to this saf ety

note can cause irreversible damage.

Caution! During cold weather, bring the softener to

room temperature before operation.

Caution! During hot weather, do not install t he softener

in direct sunlight or in a room with a temperature

above 45°C.

Warning! All electrical and plumbing installations

should be performed by professional electric ians and

installers in accordance with all local codes.

Caution! Finish all the soldering on t he main plumbing

and on the drain, before connecting the softener.

Failing to adhere to this safety note can cause irreversible damage to the KS20S.

Caution! Inlet water temperature must not exceed

35° C. Complete installation must not be allowed to

freeze. Failing to adhere to this safet y note can cause

irreversible damage to the KS20S.

Caution! Finish all welding and soldering works in the

near vicinity to the softener before mounting.

Failing to adhere to this saftey note can cause irreversible damage.

Caution! Make sure the seal is fitted properly!

Page 11

MU5H-1419GE23 R0815 9 Honeywell GmbH

English

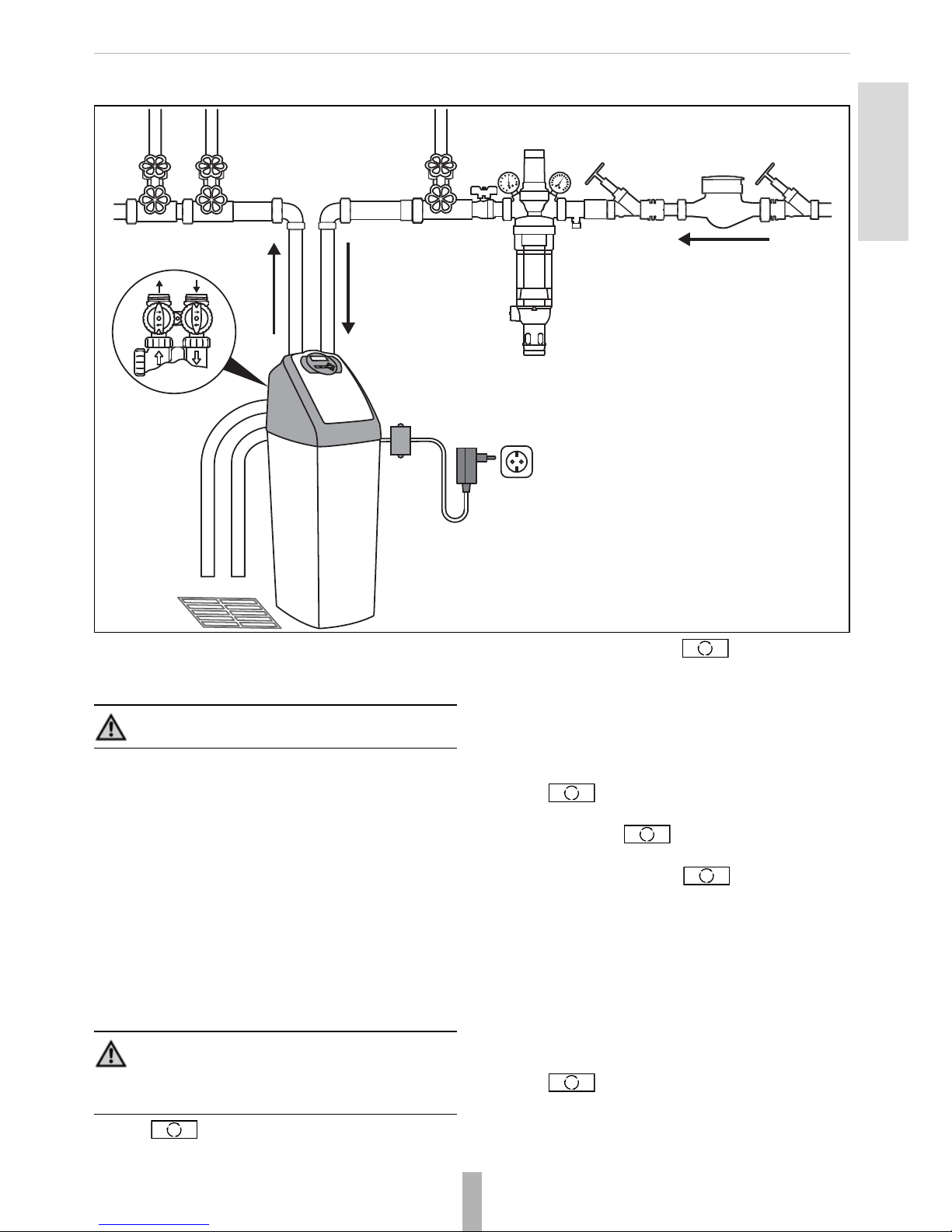

6.3. Residential installation

Img. 2 Residential installation (Example)

The black lines represent the direction of water f low.

7. Start-up

7.1. Start-up instructions

1. Manually add water in brine tank above the aircheck

(around 10 liters)

Do not fill with salt at the moment.

2. Place the valves int o the byp ass po sition (s ee 7.2 . Valve

positions).

3. Turn on the main water supply.

4. Open a cold water tap downstream of the KS20S

softener. Let the water run a few minutes until the KS20S

softener is free from any foreign material (usua lly solder)

that may have resulted from the installation.

5. Once the softener is clean, close the water tap.

6. Switch on the power.

7. Push and hold it down for 3seconds. The system

will advance to the "first" position

8. When the moto r stops, pu sh repeatedly until the

display shows "RINSE".

9. Slowly t urn the bypass valve to close the outlet and open

the system inlet.

10. Run water to the drain until it runs clear.

11. Place the KS20S softener in the bypass position (syst em

inlet-outlet closed – full bypass).

12. Push until the KS20S softener is back in to

softening mode.

13. Once again, push and hold it down for

3 seconds.

14. When the motor stops, push repeatedly until the

display shows "BACKWASH".

15. Slowly open the inlet bypass valve 1/2 way to feed the

softener with water. Allow water to slowly fill the tank.

16. When a solid stream of water starts coming out of the

drain line, open the inlet b ypass valve all the w ay. Let the

water drain until its clean.

17. Slowly place the bypass valve into "Normal position" (see

7.2. Valve positions) by opening the outlet side of bypass

valve. Now the system inlet-outlet is open.

18. Push until the display shows "REGENERANT

DRAW DN" or "REGENERANT DRAW UP".

19. Carefully check the water level in the brine tank.

If it decreases, skip to the next step or see the section

“Troubleshooting” on page19.

Caution! The start-up must be performed by a professional installer only.

Note! Once put under electrical power, the valve may

automatically run a cycle in order to ge t into the service

position. Display will alternate between installer name,

time of day, flow rate and remaining capacity.

Page 12

Honeywell GmbH 10 MU5H-1419GE23 R0815

20. Push again until the display shows "RINSE".

Allow the rinse cycle to run its full course.

21. While the rinse cycle is finishing, load brine tank with salt.

22. If the refill cycle is at the end of the regeneration cycle,

add around 10 liters of water to allow the first regeneration.

23. Go to section “Programming - Advanced Installers” on

page 13.

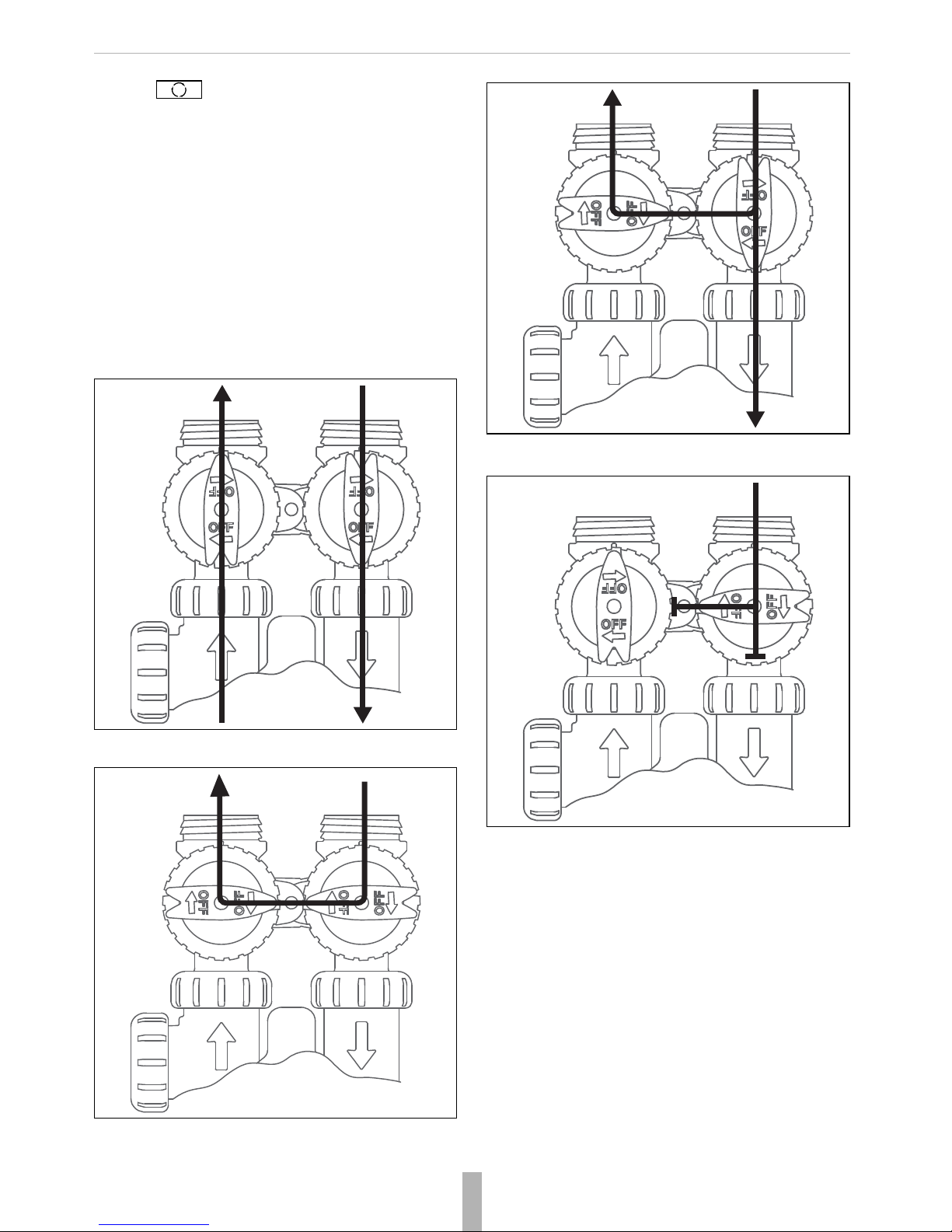

7.2. Valve positions

The bypass valve provided by with the KS20S softener can

be set into four different positions dep ending on th e selected

mode. The following four images depict the valve positions

and the water ways (in/out) within the valve.

Img. 3 Normal position operation

Img. 4 Bypass position

Img. 5 Diagnostic position

Img. 6 Shut-off position

Page 13

MU5H-1419GE23 R0815 11 Honeywell GmbH

English

8. Setting

Display and operating keys

Img. 7 Display and operating keys

1. Confirmation of water flow (detected from water meter)

2. Name of parameter

3. Value of parameter

4. "Confirm and Go ahead" but ton

5. Decreasing butt on

6. Increasing button

7. Regeneration but ton / back button

8. Clock button

8.1. General parameters

The initial display shows general parameters alternating

between TIME OF DAY, CAPACITY REMAINING, DAYS TO

A REGEN, FLOW RATE and Installer name and phone

number, if set

1. Push to start scrolling through the parameters.

2. Each push on displays another parameter in the

following sequence:

• CAPACITY REMAINING

• DAYS TO REGEN

•FLOW RATE

• Installer name and phone number, if set.

8.1.1. CAPACITY REMAINING

You can change the remaining capacity of the KS20S

softener.

1. Push to go to the next parameter

The display shows CAPACITY REMAINING.

2. Push to decrease the capacity.

Each push decreases the capacity by 0.01m³

8.1.2. DAYS TO REGEN

You can change the number of days till the next regeneration .

1. Push to go to the next parameter

The display shows DAYS TO REGEN

2. Push to decrease the number of days.

Each push decreases the days until the next regeneration

by 1.

8.1.3. FLOW RATE

The current flow rate of the KS20S softener is shown in LPM

(liters per minute).

8.1.4. Installer data

The display will show the name and the phone nu mber of the

installer, if set.

8.2. Time of the day

1. Push to set the time

The display shows TIME HOUR and the current hour flas hes.

2. Push or to adjust the hours.

3. Push to go to the next parameter.

Note! An asterix (*) is displayed, if the water meter

detects a water flow.

Note! TIME OF DAY alternates with REGEN TODAY,

if a regeneration is expected today.

1 2 3

4568 7

Page 14

Honeywell GmbH 12 MU5H-1419GE23 R0815

The display shows TIM E M INUTES and the current minutes

flash.

4. Push or to adjust the minutes.

5. Push to exit the settings.

The display shows TIME OF DAY or another general parameter (see 8.1. General parameters).

8.3. Basic settings

8.3.1. Water hardness

1. Push and hold for 3 seconds both buttons and

until the display shows RAW HARDNESS.

2. Push or to change raw water hardness.

3. Push to go to the next parameter.

8.3.2. Service (Residual) hardness

The display shows SERVICE HARDNESS

1. Push or to change raw water hardness in

the unit selected during the start-up. 15°fH is set as

default parameter.

2. Push to go to the next parameter.

8.3.3. Regeneration time

The display shows DAYS BETWEEN REGEN.

1. Push or to set up number of days between

two regenerations.

• Default setting is "4".

• Maximum number of days is "28"

• Display indication "Off" means there is no forced regeneration.

2. Push to go to the next parameter.

The display shows REGEN TIME HOUR and the numbers

indicating the current time in hours start flashing.

1. Push or to set the regeneration time (hour).

2. Push to go to the next parameter.

The display shows REGEN TIME MINUTES and the numbers

indicating the current time in minutes start flashing..

3. Push or to set the regeneration time

(minute).

4. Push to exit the settings.

The display shows TIME OF DAY or another general parameter (see 8.1. General parameters).

8.3.4. Setting the residual water hardness

1. Set the residual water hard ness by turning the screw at

the outlet side of the control valve block

Img. 8 Water hardness screw

• Turn the screw anti-clockwise to decrease water hardness

on the output side

• Turn the screw clockwise to increase water hardness on

the output side

2. Check the mixed water hardness at a tapping point

Caution! These changings are recommended for experienced users and professional installers only.

Note! After 5 minutes without action, the contro ller switches back to the operating mode.

Caution! Do not decrease th e service hardness to less

than 15°fH to avoid corrosion.

Caution! Do not decrease the numb er of days betwee n

regenerations for hygienic reasons .

°

°

Caution! Do not decrease the service hardness to less

than 15°fH to avoid corrosion.

The manufacturer recommends to check the output

water hardness regularly (2 times a year).

Page 15

MU5H-1419GE23 R0815 13 Honeywell GmbH

English

• Open the tapping point completely to ensure a sufficient

flow

3. Readjust by turning the screw if necessary

4. Repeat the above steps until the measured value is equal

to the value set under 8.3.2. (default 15°fH).

8.4. Programming - Advanced Installers

8.5. Basic settings

The basic settings such as changing water hardness and

regeneration time are described in detail in 8.3.

8.5.1. Unlocking the set mode

To unlock the set mode press following buttons one af ter

another .

8.5.2. Locking the set mode

To lock the set mode press following buttons one after

another .

8.5.3. Setting parameters

The KS20S softener can be programmed by defining the

following parameters:

• Operating mode

•Cycle times

• Capacity

• Brine tank refill type

• Regeneration start time

• Reserve type

• Service alarm

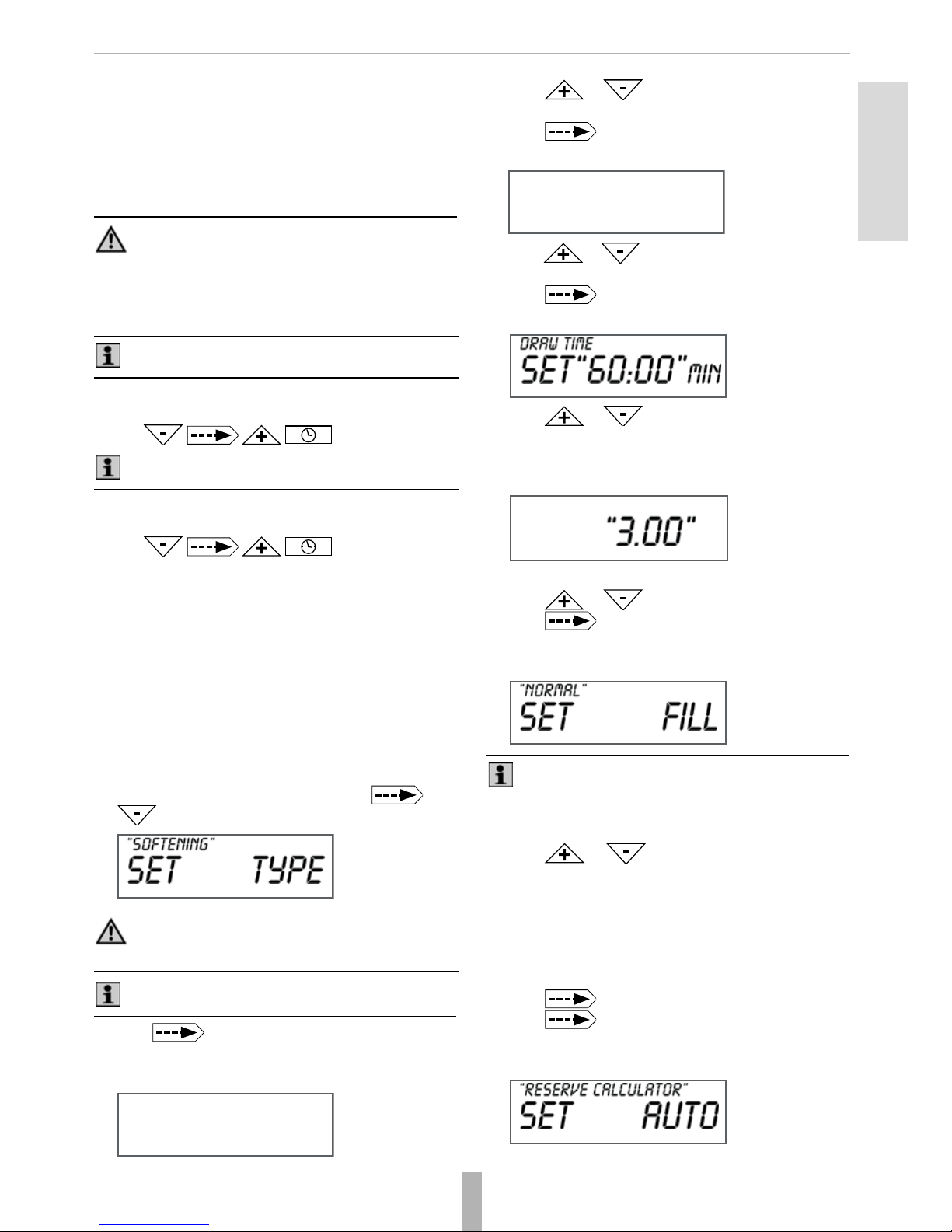

8.5.4. Set mode

1. Push and hold for 3seconds both buttons and

until the display shows "SOFTENING".

2. Push to go to the next parameter.

8.5.5. Cycle times

The display shows FILL TIME.

1. Push or to set up the amount of salt in kg

for cycle1 (see 8.6.4. Operation cycles).

2. Push to go to the next parameter.

The display shows SOFTENING TIME

3. Push or to set up the number of minutes for

cycle 2 (see 8.6.4. Operation cycles).

4. Push to go to the next parameter.

The display shows DRAW TIME

5. Push or to set up the parameters for

cycles 3, 4 and 5 (see 8.6.4. Operation cycles).

8.5.6. Capacity

The display shows SOFTENING CAPACITY.

• If hardness unit is f°H then capacity unit is m

3

.

6. Push or to set up the softener capacity.

7. Push to go to the next parameter.

8.5.7. Brine tank refill

The display shows FILL.

You can select between "NORMAL" and "PROPORTIONA L"

brine tank refill.

8. Push or to change between the brine tank

refill types.

• NORMAL: the unit regenerates completely.

• PROPORTIONAL (default): corresponds with ratio of

used capacity on total capacity multiplied

by refill for a complete regeneration

of resin bed.

9. Push to go to the parameter "Reserve type".

10. Push to go to the next parameter.

8.5.8. Reserve calculator

The display shows RESERVE CALCULATOR

Caution! Programming must be perfomed by

authorized personnel only.

Note! To set the parameters the setting mode must be

unlocked!

Note! Remember to lock the set mode after the setting

of the parameters.

Caution! Do not change any settings in the FI LTERING

mode. Any changes in the FILTERING mode will

prevent the device from functioning correctly.

Note! In this manual, only the SOFTENING operating

mode is described.

Note! This pa rameter is o nly available if con figured

as a 25 mm Pre-Fill Up-Flow brining softener.

Page 16

Honeywell GmbH 14 MU5H-1419GE23 R0815

11. Push or to change between the reserve

types:

• AUTO (default): capacity and reserve are automatically

calculated.

• OFF: reserve calculato r is not active.

8.5.9. Regeneration start time

1. Push to go to the next parameter.

The display shows DELAYED.

2. Push or to select the regeneration start

time between:

• DELAYED: regeneration on a specific time

• IMMEDIATE:immediate regeneration when volume

is at 0

• DELAY+IMMEDIATE (default): delayed regeneration

with override on 0 volume

8.5.10.Service alarm

1. Push to go to the next parameter.

The display shows SERVICE ALARM.

You can set the service alarm basing on time, volume or both.

2. Push or to set the unit:

• TIME: based on time

• m³: based on volume

• BOTH: based on time and volume

• OFF: no service alarm defined

Example:

Service alarm every 3months

If set up service alarm is based on time ea ch push inc reases

or decreases the time by 3 months.

The display shows SERVICE ALARM if setting is based on

volume or both.

Example: Service alarm every 500m³

Push to go to the next parameter.

8.5.11.Scheduled service

The display shows SCHEDULED SERVICE.

For more information on scheduled service go to paragraph

10. Maintenance.

3. Push to exit the settings.

The display shows TIME OF DAY or another general parameter (see 8.1. General parameters).

8.6. System parameters

Push and hold for 3 seconds both buttons and

and repeat this for further 3 seconds until the display

shows DISPLAY and the system language flashes.

8.6.1. Language settings

1. Push or to change the language.

2. Push to go to the next parameter.

8.6.2.

Valve parameters

The display shows VALVE TYPE and the type number

flashes.

Example:

25 mm is set as default.

8.6.3. Valve body and hardness unit

1. Push or to set up the size.

2. Push to go to the next parameter.

The display shows HARDNESS UNITS.

3. Push or to set the hardness unit:

• ppm: parts per million

• °dH: German degree

• °fH: French degree, default

• NA: no hardness setting

4. Push to go to the next parameter.

°

Page 17

MU5H-1419GE23 R0815 15 Honeywell GmbH

English

8.6.4. Operation cycles

First cycle

The display shows set CYCLE 1 and the cycle type flashes.

Push to scroll through the cylces.

WS1CI Only Upflow Regenerant Refill After Rinse

• 1st cycle: Fill

• 2nd cycle: Softening

• 3rd cycle: Draw up

• 4th cycle: Backwash

• 5th cycle: Rinse

• 6th cycle: End

Last cycle

Push to go to the last cylce.

The display shows END.

Setting the contact data of the installer

1. Push and for 3 seconds to enter the level

to set the contact data of the installer.

2. Push or to change the first digit of the

telephone number of the installer.

3. Push to go to the next digit.

4. Push to set the name of the installer.

5. Push or to change the first letter of the

name of the installer.

6. Push to go to the next letter .

7. Push to exit the settings.

The display shows TIME OF DAY or another general parameter (see 8.1. General parameters).

To lock the set mode please see 8.5.2. Locking th e set mode.

9. History

The KS20S softener saves the follwing parameters in controller history:

• Number of days since the last regeneration

• Salt consumtion since the last regenetation

• Salt consumption since start-up

• Total number of regenerations since start-up

• Reserve history

• Usage history

• Maximum flow rate in the last 7 days

9.1. History data mode

Push and hold for 3secondes both buttons and

until the display shows DAYS SINCE REGEN, the

number of days since the last regeneration.

9.1.1. Consumption - last regeneration

Push to go to the next parameter.

The display shows SINCE LAST REGEN, the consumption in

m³ since last regeneration.

Push to go to the next parameter.

9.1.2. Usage history

The display shows USAGE HISTORY.

1. Push or to show the usage history on a

certain day. You can choose between day 1 and 63.

2. Push to go to the next parameter.

Caution! Do not change the operation cycles or their

order. Any changes of the oper ation cycles will prevent

the device from functioning correctly.

Caution! Do not change t he contro l valves from downflow to upflow brining or vice versa.

The valve bodies for downflow and upflow are unique

to the regeneration type and should not be interchanged. A mismatch of valve body and regeneration

piston will result in hard water bypass during service.

Note! Maximum number of digits to set is eleven.

Note! Maximum number of digits to set is eighteen.

Note! Remember to lock the set mode after the setting

of the parameters.

Day 1

Day 2

:

Day 63

Yesterday

The day before yesterday

:

63 days before

Page 18

Honeywell GmbH 16 MU5H-1419GE23 R0815

9.1.3. Reserve history

The display shows RESERVE HISTORY.

Reserve history (at the time of regeneration):

3. Push to exit the settings.

The display shows TIME OF DAY or another general parameter (see 8.1. General parameters).

9.2. Flow rate

The display shows MAX FLOW.

The display shows the maximum flow rate of the last 7days.

1. Push and hold for 5seconds both buttons and

to reset the flow rate.

2. Push to exit the settings.

The display shows TIME OF DAY or another general parameter (see 8.1. General parameters).

9.3. Regeneration data

1. Push and hold twic e for 3seconds both buttons

and .

The display shows TOTAL DAYS - the total number of days

since start up.

2. Push to go to the next parameter.

The display shows TOTAL REGENS - the total number of

regenerations since start up.

3. Push to go to the next parameter

The display shows TOTAL CUBIC METERS - the total

amount of used water in m³ since the start up. -

9.4. Error log

1. Push to go to the next parameter.

The display shows ERROR LOG. .

The error log includes the last10 errors generated by the

controller.

2. Push or to scroll through the list of 10.

3. Push to exit the settings.

The display shows TIME OF DAY or another general parameter (see 8.1. General parameters).

10. Maintenance

The completed maintenance wo rk needs to be documented in

the “Maintenance log” on page18.

10.1.Preparation

1. Shut down water inlet

2. Unplug the KS20S soft ener

3. Drain the installation by opening the taps at the highest

and the lowest level of your house.

Day 0

Day 1

Day 2

:

Day 6

Today

Yesterday

The day before yesterday

:

(max)

Note! Not visible in time mode, when the volume

setting is 0. The function day override triggers the regeneration.

Note! "R" is displayed if regeneration has occured in

the last 24 hours.

Note! Only available when controller is switched on.

Caution! All the maintenance works must be performed

by authorized personnel only.

Warning! Switch off the softener before the maintenance and prevent switching on without authorisation

(mains disconnection)!

Page 19

MU5H-1419GE23 R0815 17 Honeywell GmbH

English

10.2.Cleaning

Clean inside and the outside of the housing with damp cloth.

10.3.Spare part sets

Maintenance interval: 2 and 6 years

The sets of spare parts for the 2 years interval maintenance

differ from the size of the KS20S softener.

The set of the spare parts for the 6 years interval maintenace

is the same for all KS20S softeners.

Caution! Do not use cleaning agents that contain

solvents when cleaning the plastic parts!

Note! Do not let detergents to enter the environment or

the sewerage system!

Caution! Use only original spare parts.

Note! Two different types of maintenance are to be

conducted in a time interval of two and six years

Spare part sets for maintenance every 2 years

KS20S-15

Honeywell part no.

WS1 Injector Asy A Black

EK20S-215A WS1 DLFC 013 (1,3 gpm) For 3/4''

WS1 Refill Flow Control 80.5 gpm)

KS20S-45

Honeywell part no.

WS1 Injector Asy B Brown

EK20S-245A WS1 DLFC 027 (2,7 gpm) For 3/4''

WS1 Refill Flow Control (0.5 gpm)

KS20S-55

Honeywell part no.

WS1 Injector Asy C Violet

EK20S-255A WS1 DLFC 017 (1,7 gpm) For 3/4''

WS1 Refill Flow Control 80.5 gpm)

KS20S-85

Honeywell part no.

WS1 Injector Asy D Red

EK20S-285A WS1 DLFC 022 (2,2 gpm) For 3/4''

WS1 Refill Flow Control (0.5 gpm)

Spare part sets for maintenance every 6 years

KS20S-15/45/55/85

Honeywell part no.

WS1 Spacer Stack Asy

EK20S-6UA WS1 Piston Upflow Asy

WS1 Regenerant Piston

Chlorinator

Page 20

Honeywell GmbH 18 MU5H-1419GE23 R0815

10.4.Maintenance log

Installation date: _________________________

Network pressure: _________________________

Notes:

Date:

Raw water hardness (°fH) measured

Mix water harndess (°fH)

Suction pump maintained

Disinfection unit replaced

Housing cleaned

Page 21

MU5H-1419GE23 R0815 19 Honeywell GmbH

English

11. Troubleshooting

Problem Cause Remedy

Error Code 101

Unable to recognize start of regeneration

Not reading piston position Resynchronize software with piston pos ition.

Push and

for 3 seconds

Incorrect Assembly Disassemble dri ve bracket,verify wires are in

guides & reassemble

Error Code 102

Unexpected stall

Mechanical binding Check Piston and spacer stack assembly for

foreign matter

Error Code 103

Motor ran too long, timed out trying to

reach home position

High drive forces on piston Loosen drive cap gear ¼ turn or replace.

Address high drive forces.

Error Code 104

Motor ran too long, timed out trying to

reach home position

IF OTHER ERROR CODES DISPLAY

CONTACT THE AUTHORIZED

INSTALLER

Control valve piston not in home position Push and

for 3 seconds

Motor not inserted fully to engage pinion,

motor wires broken or disconnected, motor

failure

Check motor and wiring. Replace motor if

necessary

Drive gear label dirty or damaged, missing

or broken gear

Replace or clean drive gear

Drive bracket incorrectly aligned to back

plate

Reseat drive bracket

PC Board is damaged or defective Replace PC board

PC board incorrectly aligned to drive

bracket

Ensure PC board is correctly sna pped on t o

drive bracket

Control valve stalled in regeneration Motor not operating Replace motor

No electric power at outlet Repair outlet or use working outlet

Defective transformer Replace transformer

Defective PC board Replace PC Board

Broken drive gear or drive cap assembly Replace drive gear or drive cap assembly

Broken piston retainer Replace drive cap assembly

Broken main or regenerant piston Replace main or regenerant piston

Control valve does not regenerate

automatically when Regeneration

button is depressed and held

Transformer unplugged Connect transformer

No electric power at outlet Repair outlet or use working outlet

Broken drive gear or drive cap assembly Replace drive gear or drive cap assembly

Defective PC Board Replace PC Board

Water softener delivers hard water Bypass valve in Bypass position Put bypass valve in position service

Defective meter Test meter and clean or replace meter

Restricted/stalled mete r tu rb in e Remove meter and check for rotation or

foreign matter

Set-up error Check control valve set up procedure

No salt or low salt level in brine tank Add salt to brine tank and maintain salt level

above water level

Excessive water usage Check capacity settings

Insussicient brine level in brine tank Check brine refill setting and refill flow

restrictor for blockage

Raw water hardness fluctuation Test raw water hardness and adjust set tings

to highest known hardness

Defective PC board CONTACT THE AUTHORIZED INSTALLER

Time of day flashes on and off. Battery back up maintains time of day up to

2 years in event of power outage and

battery is discharged. Time of day flashes

when battery is discharged

Reset time of day and replace battery on PC

Board (Lithium coin type Battery2032)

Page 22

Honeywell GmbH 20 MU5H-1419GE23 R0815

Unit uses too much salt Improper brine refill setting Check brine refill setting for proper salt

dosage

Improper settings Check water hardness and reevaluate capa-

city setting specifica ti on

Excessive water usage See problem "Excessive water in br ine tan k"

Leaking faucets, toilets, … Repair or replace those items

Softener delivers salt water Low water pressure Check incoming water pressure.

Minimum is 2 bar

Excessive water in brine tank See problem "Excessive water in brine tan k"

Wrong size injector Install correct injector

Excessive water in brine tank Injector is plugged Remove injector and clean ports

Faulty piston/seal assembly Replace piston/seal assembly

Plugged or kinked drain line Correct any kinking or plugging of drain line

Backwash flow controller closed off Check backwash flow controller

Defective brine line flow control Remplace brine line flow controller

Softener fails to draw brine Injector is plugged Remove injector and clean ports

Faulty piston assembly Replace piston assembly

Brine line conntection leak Inspect brine line during refill cycle for leaks

Drain line plugged creating excess back

pressure

Inspect drain line for blokkage

Drain Line too high or too long Refer to drain line specification

Low inlet pressure Increase inlet pressure to a minimum of

2 bar

Continuous flow to drain Piston assembly failure Remplace piston assembly

Motor failure Remplace motor

Circuit board failure Remplacer circuit board

Iron in softened water Iron has fouled resin b ed Use iron reducing resin cleaner to clean

resin bed, and increase salt dosage or rege-

nerate more frequently.

Iron is not in a soluble state Install iron reduction system

Prefilter failure Check prefilter

Iron level excessive Install iron reduction system

Loss of water pressure Iron built up in resin See problem above

Resin bed fouled with sand and sediment Rebed softener and install prefilter

Absent or incomplete LED display Transformer unplugged Plug transformer into uninterrupted outlet

No electric power at outlet Repair outlet or use working outlet

Defective transformer Change transformer

Defective meter Unplug meter from PC board, if LED displays

lights appropriately, replace meter

Defective PC board Replace PC board

Defective or unplugged Ethernet cable Plug or change Ethernet cable

Control does not display correct time

of day

Power outage > 2 years Reset time of day

Power outage < 2 years - Time of day flashing - Battery discharged

Replace lithium battery

No "softening" display when water is

flowing

Bypass valve in bypass position Put bypas s valve in service position

Meter connection disconnected Connect meter to PC board

Restricted/stalled meter turbine Remove meter and ch eck for rotation, clean

foreign material

Defective meter Replace meter

Defective PC board Replace PC board

Problem Cause Remedy

Page 23

MU5H-1419GE23 R0815 21 Honeywell GmbH

English

Control valve regenerates at wrong

time of day

Power outage > 24 h Reset control valve to correct time of day

Time of day not set properly Reset to correct time of day

Time of regeneration incorrect Reset regeneration time

Control valve set up for immediate regeneration

Check control valve set up procedure - rege-

neration time option

Control set up for delayed regeneration or if

capacity is equal to0

Check control valve set up procedure - rege-

neration time option

Customer services tel. .......................

Problem Cause Remedy

Page 24

Honeywell GmbH 22 MU5H-1419GE23 R0815

12. Disassembly

1. Disconnect the sewerage tube to the discharge connection (inner tube ø min. 13 mm, 1/2")

2. Disconnect the connections to the KS20 softener

3. Remove the KS20S softener

4. Thoroughly f lush pipework.

13. Disposal

Both the KS20S softener and the associated packaging

consist mostly of recyclable raw materials.

Caution! The disassembly must be performed by a

professional installer only.

Note! Do not dispose the waste of the electrical or

electronic equipment (EEE) as unsorted municipal

waste. Bring it to the container for separate collection

of used EEE.

Note! Dispose of packing and recyclable materials

separately, properly and in environmentally friendly

way.

Note! Observe the local requirements regarding

correct waste recycling and disposal.

Page 25

MU5H-1419GE23 R0815 23 Honeywell GmbH

Italiano

Grazie per avere scelto un addolcitore d'acqua KS20S.

Siamo convinti che il nostro prodotto soddisferà pienamente

le esigenze dei nostri clienti, poiché è stato costruito con

estrema cura.

L'addolcitore d'acqua KS20S viene fornito all'interno della

sua confezione e include una valvola di bypass. Si consiglia

di ispezionare attentamente il dispositivo in presenza

dell'addetto alla consegna per verificare la presenza di eventuali danni causati dal trasporto.

Il team Honeywell

1. Introduzione

Il presente manuale è destinato a installatori professionisti. Si

prega di leggerlo attentamente al fine di garantire una messa

in funzione sicura, corretta e priva di rischi dell'addolcitore

d'acqua KS20S.

Nel manuale le avvertenze di sicurezza e le note sono

evidenziate con pittogrammi.

2. Avvertenze di sicurezza

Attenzione! Indica una situazione potenzialmen te

pericolosa che, se ignorata, potrebbe causare la morte

o gravi lesioni.

Avviso! Indica una situazione potenzialmente pericolosa che, se ignorata, potrebbe causare lesioni di entità

minore o moderata o danni alle proprietà.

Nota! Fornisce suggerimenti o informazioni supplementari per un migliore utilizzo dell'apparecchiatura.

Nota! Linee guida per il rispetto dell'ambiente.

Avviso! Prima di avviare l'addolcitore d'acqua, si

prega di leggere attentamente il presente manuale.

Maneggiare l'addolcitore d'acqua con attenzione.

Avviso! Conservare le presenti istruzioni per un uso

successivo.

Avviso! Usare l'addolcitore d'acqua solo in modo

conforme alla destinazione d'uso.

Avviso! Non eseguire un ripristino totale delle impostazioni. Il dispositivo può essere utilizzat o a pieno ritmo

solo con le impostazioni di fabbrica.

Avviso! Accertarsi che l'addolcitore d'acqua funz ioni

sempre correttamente.

Avviso! Fare riparare immediatamente qualsiasi

guasto da un installatore professionista.

Avviso! Installare un riduttore di pressione a monte

dell'addolcitore d'acqua, se la pressione in ingresso è

superiore a 6bar.

Avviso! Accertarsi che il luogo di installazione non sia

soggetto a gelo o calore eccessivo. Evita re l'esposizione ai raggi solari.

Avviso! Installare l'addolcitore d'acqua su una superficie piana stabile e pulita.

Attenzione! Non toccare le parti elettriche con le mani

bagnate! Scollegare l'addolcitore d'acqua dall'alimentazione elettrica prima di eseguire qualsiasi lavoro

all'impianto elettrico.

Attenzione! Posizionare il cavo di alimentazione in

modo da evitare qualunque rischio di inciampo!

Attenzione! Fare attenzione a non scivolare o inciampare a causa della fuoriuscita di materiali!

Nota! Sia l'addolcitore d'acqua che la relativa confezione sono costruiti per la maggior parte con materiali

grezzi riciclabili. Smaltire la confezione e i materiali

riciclabili osservando le regole previste per la raccolta

differenziata e la protezione dell'ambiente.

Page 26

Honeywell GmbH 24 MU5H-1419GE23 R0815

3. Fornitura

Tutti i modelli dell'addolcitore d'acqua KS20S sono forniti

all'interno di una confezione

contenente:

• Addolcitore d'acqua KS20S

• Istruzioni di installazione

• Cloratore (montato in loco)

• Valvola di bypass con valvola di miscelazione

• Valvola di ritegno lato ingresso (montata in loco)

• Tubo flessibile rinforzato per l'attacco di ingresso/uscita

- 2 tubi flessibili lunghi 650 mm, 1", femmina/femmina

- 4 rondelle

- Elementi di collegamento

• Tubo per l'acqua di rigenerazione e di scarico

- Lunghezza 3000 mm

- Diametro 1/2"

- Kit di collegamento (2 lampade a vite, raccordo per tubo

flessibile, rondella)

• Kit di analisi del grado di durezza dell'acqua

Componenti principali

Img. 1 Componenti principali di KS20S

L'addolcitore d'acqua KS20S consiste nei seguenti componenti principali:

1. Controller

2. Coperchio del serbatoio di salamoia

3. Copertura prin cipale

4. Serbatoio di salamoia

4. Descrizione del funzionamento

4.1. Rigenerazione tramite contatore

Durante la modalità di funzionamento normale sul display

LCD vengono visualizzati i seguenti parametri in sequenza:

• Ora del giorno

• Capacità residua (m

3

)

• Portata

• Numero di giorni fino alla rigenerazione successiva

• Nome dell'installatore

• Nome dell'addolcitore d'acqua.

Al momento stabilito per la rigenerazione il controller

confronta la capacità residua con la riserva e decide se è

necessario avviare la rigenerazione. L'addolcitore d'acqu a

KS20S è dotato di un dispositivo di miscelazione che garantisce un determinato grado d i durez za residua dell'acqua

addolcita.

Controller

Durante la rigenerazione sul display LCD vengono visualizzati i seguenti parametri in sequenza:

• Numero del ciclo

• Nome del ciclo

• Tempo rimanente del ciclo in corso.

Quando tutti i cicli sono terminati, la valvola torna nella posizione di servizio.

Il controller dell'addolcitore d'acqua KS20S è in grado di

gestire le seguenti funzioni:

• Addolcimento normale

• Addolcimento proporzionale

• Rigenerazione controcorrente (upflow).

4.2. Funzionamento della valvola

La valvola di bypass dell'addolcitore d'acqua KS20S può

essere impostata in diverse posizioni (vedere 7.2. Posizioni

della valvola):

• Funzionamento normale

• Bypass

• Bypass diagnostico

• Intercettazione.

Modalità di configurazione

Per accedere alla modalità di configurazione, mettere la

valvola in posizione di funzionamento normale. Durante e

dopo la configurazione (vedere 8. Configurazione) la valvola

continua a funzionare normalmente monitorando tutte le

informazioni. Le impostazioni vengono conservate nella

memoria permanente.

Assenza di corrente

Durante un'interruzione dell'alimentazione elettrica il controller dell'addolcitore d'acqua KS20S non è operativo. Tutti i

cicli di rigenerazione previsti vengono posticipati. Una volta

ripristinata la corrente, il controller riprende il suo funzionamento normale a partire dal momento in cui si è verificata

l'interruzione.

Durante l'assenza di corrente tutti i v alori visualizzati a display

e i cicli programmati vengono memorizzati, per essere utilizzati di nuovo una volta ripristinata l'alimentazione elettrica. Se

necessario, il controller mantiene in memoria quest i valori per

anni, senza alcuna perdita di dati.

1

2

4

3

1

2

4

Page 27

MU5H-1419GE23 R0815 25 Honeywell GmbH

Italiano

4.3. Modalità di impiego

Honeywell consiglia le seguenti modalità di impiego per

l'addolcitore d'acqua KS20S

:

4.4. Concentrazione massima di sodio

Durante il funzionamento dell'addolcitore d'acqua KS20S, la

concentrazione di sodio non deve superare la soglia di

200 mg/l (secondo la legge sulle acque potabili).

Per ridurre la durezza dell'acqua di 1fH, aggiungere ad essa

circa 4,5 mg/l di sodio. Occorre inoltre considerare il contenuto di sodio naturale dell'acqua non trattata. Da questi va lori

risulta il massimo addolcimento possibile.

5. Dati tecnici

Spiegazioni

(*) Senza oscillazioni e aperta a pressione atmosferica

(**) In circostanze normali

Modelli KS20S:

Eventuali parametri tecnici diversi non si riferiscono alle

dimensioni dei modelli dell'addolcitore d'acqua KS20S.

Tipo Dimen-

sioni

Impiego consigliato da Honeywell

KS20S-15 5 litri 1 punto di applicazione (ad es. un lavan-

dino)

KS20S-45 14 litri Casa da 1-4 famiglie

KS20S-55 18 litri Casa da 3-8 famiglie

KS20S-85 25 litri Casa da 6-21 famiglie

Nota! Valori consigliati per abitazioni con grado di

durezza dell'acqua di 30 fH e consumo medio giornaliero di 0,1 m3 di acqua a persona.

Nota! Honeywell consiglia di installare un filtro a

cartuccia da 100 µ.

Connessioni di ingresso e uscita1"

Connessione di scarico (*) 3/4"

Potenza nominale 230 V, 50 Hz, 12 V

Potenza nominale max 6W

Classe di protezione IP IP 51, trasformatore con

doppio isolamento

Pressione nominale PN10

Pressione min di ingresso 2 bar

Pressione max di ingresso 8 bar

Vuoto Non consentito

Perdita media di pressione (**) 1 bar

Temperatura min acqua 5 °C

Temperatura max acqua 35 °C

KS20S-15

Altezza 530 mm

Larghezza 230mm

Profondità 430mm

Altezza ingresso e uscita 513mm

Peso massimo 30 kg

KS20S-45

Altezza 730mm

Larghezza 320mm

Profondità 530 mm

Altezza ingresso e uscita 50mm

Peso massimo 70kg

KS20S-55

Altezza 1070mm

Larghezza 320mm

Profondità 530 mm

Altezza ingresso e uscita 82mm

Peso massimo 129kg

KS20S-85

Altezza 1180mm

Larghezza 320mm

Profondità 530 mm

Altezza ingresso e uscita 96mm

Peso massimo 178kg

Page 28

Honeywell GmbH 26 MU5H-1419GE23 R0815

Dati tecnici:

KS20S-15

Scambio ionico

Capacità kg CaCO

3

0,15

°F x m

3

15

°dH x m

3

8

Consumo di sale kg sale/rigen. 0,5

kg CaCO

3

/kg sale 0,3

Portata

Nominale m

3

/h 0,30

Di picco m

3

/h 0,4

Minima L/h 60

Consumo acqua di risciacquo

Addolcimento e risciacquo lento litri 15

Controlavaggio litri 5

Risciacquo rapido litri 20

Totale litri 40

L/kg CaCO

3

267

KS20S-45

Scambio ionico

Capacità kg CaCO

3

0,83

°F x m

3

83

°dH x m

3

47

Consumo di sale kg sale/rigen. 1,8

kg CaCO

3

/kg sale 0,4

Portata

Nominale m

3

/h 1,2

Di picco m

3

/h 1,7

Minima L/h 60

Consumo acqua di risciacquo

Addolcimento e risciacquo lento litri 25

Controlavaggio litri 40

Risciacquo rapido litri 20

Totale litri 85

L/kg CaCO

3

102

Page 29

MU5H-1419GE23 R0815 27 Honeywell GmbH

Italiano

Dati tecnici:

KS20S-55

Scambio ionico

Capacità kg CaCO

3

1,04

°F x m

3

104

°dH x m

3

58

Consumo di sale kg sale/rigen. 2,2

kg CaCO

3

/kg sale 0,4

Portata

Nominale m

3

/h 1,4

Di picco m

3

/h 1,7

Minima L/h 60

Consumo acqua di risciacquo

Addolcimento e risciacquo lento litri 35

Controlavaggio litri 30

Risciacquo rapido litri 20

Totale litri 85

L/kg CaCO

3

82

KS20S-85

Scambio ionico

Capacità kg CaCO

3

1,61

°F x m

3

161

°dH x m

3

90

Consumo di sale kg sale/rigen. 3,4

kg CaCO

3

/kg sale 0,4

Portata

Nominale m

3

/h 1,8

Di picco m

3

/h 2,3

Minima L/h 60

Consumo acqua di risciacquo

Addolcimento e risciacquo lento litri 45

Controlavaggio litri 5

Risciacquo rapido litri 35

Totale litri 120

L/kg CaCO

3

75

Page 30

Honeywell GmbH 28 MU5H-1419GE23 R0815

6. Istruzioni di installazione

6.1. Avvertenze generali

Scelta della posizione

Nella scelta della posizione dell'addolcitore d'acqua tenere

presenti i seguenti criteri:

• Installare l'addolcitore d'acqua KS20S su una superficie

piana stabile e pulita.

• Posizionare l'addolcitore d'acqua KS20S vicino a una linea

di scarico per consentirne un attacco rapido.

• Accertarsi che sia presente una presa elettrica con messa

a terra per alimentare l'unità.

Pressione

Deve essere garantita una pressione minima di 2bar per

consentire alla valvola di eseguire la rigenerazione correttamente. Non operare il dispositivo a una pressione superiore

a 8 bar.

In questo caso installare un ridut tore di pressione a monte del

dispositivo.

Allacciamento all'elettricità

Accertarsi che sia impossibile interrompere l'alimentazione

elettrica premendo per errore

un interruttore da parete. Se il cavo dell'alimentazione risulta

danneggiato, chiedere a un elettricist a professionista di sostituirlo.

Attacchi idraulici

Gli attacchi idraulici devono essere in buono stato. In caso di

dubbi si prega di sostituirli. Si consiglia di installare un prefiltro

a monte del dispositivo.

Tutti gli attacchi idraulici per l'ingresso, la distribuzione e lo

scarico dell'acqua devono essere eseguiti correttamente in

conformità alla legislazione vigente al momento dell'installazione. Le dimensioni minime del tubo di scarico devono

essere pari a 20 mm (3/4’’).

In preparazione di ogni intervento di manutenzione è necessario:

1. Chiudere l'acqua di ingresso.

2. Scollegare l'addolcitore d'acqua KS20S dall'alimentazione elettrica.

3. Svuotare il dispositivo aprendo i rubinetti posti al livello

più alto e più basso dell'abitazione.

Temperatura dell'acqua

6.2. Montaggio

1. Lavare bene le tubazioni.

2. Installare l'addolcitore d'acqua KS20S.

• Osservare la direzione di flusso (direzione della

freccia).

• Durante l'installazione assicurarsi che i tubi non siano

flessi o tesi.

3. Eseguire il collegamento agli attacchi dell'addolcitore

KS20S.

4. Collegare il flessibile di scarico all'attacco di scarico (ø

interno min. del flessibile 13mm, 1/2").

Avviso! Il montaggio deve essere eseguito esclusiva mente da un installatore professionista.

Avviso! Si raccomanda di installare un riduttore di

pressione a monte dell'addolcitore d'acqua, se la pressione in ingresso è superiore a 6bar. L'inosservanza di

questa regola di sicurezza può causare danni irreversibili.

Avviso! Quando il tempo è freddo, portare l'addolcitore d'acqua alla temperatura ambiente, prima di

metterlo in funzione.

Avviso! Quando il tempo è caldo, non installare

l'addolcitore d'acqua alla luce diretta del sole o in una

stanza con temperatura superiore a45°C.

Attenzione! Tutte le installazioni idrauliche ed elettriche devono essere eseguite da elettricisti e installatori professionisti in conformità a tutte le norme locali.

Avviso! Portare a termine tutti i lavori di brasatura riguardanti i principali attacchi idraulici e lo scarico prima di

collegare l'addolcitore d'acqua. L'inosservanza di

questa regola di sicurezza può causare danni irreversibili al KS20S.

Avviso! La temperatura di ingresso dell'acqua non

deve superare i 35° C. Occorre evitare il congelamento

dell'intero dispositivo. L'inosservanz a di questa regola

di sicurezza può causare danni irreversibili al KS20S.

Avviso! Portare a termine tutti i lavori di saldatura e

brasatura in prossimità dell'addolcitore d'acqua prima

dell'installazione.

L'inosservanza di questa regola di sicurezza p uò

causare danni irreversibili.

Avviso! Accertarsi che la guarnizione sia inserita

correttamente!

Page 31

MU5H-1419GE23 R0815 29 Honeywell GmbH

Italiano

6.3. Installazione domestica

Img. 2 Installazione domestica (esempio)

Le linee nere rappresentano la direzione del flusso d'acqua.

7. Messa in servizio

7.1. Istruzioni per la messa in servizio

1. Versare manualmente acqua nel serbatoio di salamoia

fino a superare il livello del pescante salamoia (circa

10 litri).

Non aggiungere sale per il momento.

2. Mettere le valvole in posizione di bypass (vedere 7.2.

Posizioni della valvola).

3. Aprire la condotta principale dell'acqua.

4. Aprire un rubinetto di acqua fredda a valle dell'addolcitore

d'acqua KS20S. Lasciare scorrere l'acqua per alcuni

minuti fino a rimuovere dall'addolcitore d'acqua KS20S

ogni residuo di materiale estraneo (normalme nte lega per

saldature) che potrebbe essere rimasto dall'installaz ione.

5. Quando l'addolcitore d'acqua appare pulito, chiudere il

rubinetto dell'acqua.

6. Allacciare l'alimentazione elettrica.

7. Premere il pulsante e tenerlo premuto per

3 secondi. Il sistema avanza verso la "prima" posizione.

8. Quando il motore si arresta, premere ripetutamente

fino a quando sul display viene visualizzato

"RISCIACQUO".

9. Ruotare lentamente la valvola di bypass fino a chiudere

l'uscita e aprire l'ingresso del sistema.

10. Lasciare scorrere l'acqua verso lo scarico fino a quando

non appare pulita.

11. Mettere l'addolcitore d'acqua KS20S in posizione di

bypass (ingresso-uscita del sistema chiusi – bypass

completo).

12. Premere fino a quando l'addolcitore d'acqua

KS20S non torna nella modalità di addolcimento.

13. Premere ancora una volta il pulsante e tenerlo

premuto per 3secondi.

14. Quando il motore si arresta, premere ripetutamente

fino a quando sul display viene visualizzato

"CONTROLAVAGGIO".

Avviso! La messa in servizio deve essere eseguita

esclusivamente da un installatore professionista.

Nota! Quando viene allacciata l'alimentazione ele tt rica, la valvola potrebbe eseguire automatic amente un

ciclo per mettersi in posizione di servizio. Il display

visualizza in sequenza il nome dell'installatore, l'ora del

giorno, la portata e la capacità residua.

Page 32

Honeywell GmbH 30 MU5H-1419GE23 R0815

15. Aprire lentamente fino a metà la valvola di bypass di

ingresso per aggiungere acqua all'add olcitore. Riempire

lentamente il serbatoio di acqua.

16. Quando dalla linea di scarico comincia a uscire un getto

d'acqua continuo, ap rire completamente la va lv ola di

bypass di ingresso. Lasciare scorrere l'acqua fino a

quando non appare pulita.

17. Mettere lentamente la valvola di bypass in "Posizione

normale" (vedere 7.2. Posizioni della valvola) aprendo il

lato esterno della valvola. Ora l'ingresso e l'uscita del

sistema sono aperti.

18. Premere fino a quando sul display viene visualizzato "PRELIEVO RIGENERANTE EQUICORRENTE"

o "PRELIEVO RIGENERANTE CONTROCORRENTE".

19. Controllare attentamente il livello dell'acqua nel serbatoio

di salamoia.

Se diminuisce, passare alla fase successiva o consultare

la sezione 11. "Guasti / Ricerca guasti".

20. Premere di nuovo fino a quando sul display

viene visualizzato "RISCIACQUO".

Lasciare che il ciclo di risciacquo venga completato

interamente.

21. Quando il ciclo di risciacquo è quasi al termine, riempire

di sale il serbatoio di salamoia.

22. Se il ciclo di riempimento è al termine del ciclo di rigenerazione, aggiungere circa 10 litri di acqua per consentire

l'avvio della prima rigenerazione.

23. Accedere alla sezione 8.4. "Programmazione (per installatori esperti)".

7.2. Posizioni della valvola

La valvola di bypass fornita in dotazione con l'addolcitore

d'acqua KS20S può essere impostata in quattro posizioni

diverse a seconda della modalità selezionata. Le quattro

immagini riportate di seguito raffigurano le posizioni della

valvola e i flussi di acqua (in ingresso e in usc ita) all'interno di

essa.

Img. 3 Posizione di funzionamento normale

Img. 4 Posizione di bypass

Page 33

MU5H-1419GE23 R0815 31 Honeywell GmbH

Italiano

Img. 5 Posizione diagnostica

Img. 6 Posizione di intercettazione

8. Configurazione

Display e pulsanti di comando

Img. 7 Display e pulsanti di comando

1. Conferma del flusso d'acqua (rilevato dal contatore

d'acqua)

2. Nome del parametro

3. Valore del parametro

4. Pulsante "Conferma e procedi"

5. Pulsante "Più"

6. Pulsante "Meno"

7. Pulsante di rigenera zione / Pulsante Indietro

8. Pulsante dell'orologio

8.1. Parametri generali

Il display mostra inizialmente in sequenza i parametri generali

ORA DEL GIORNO, CAPACITÀ RESIDUA, GIORNI ALLA

RIGENERAZIONE e PORTATA, come pure il nome e il

numero di telefono dell'installatore, se impostati.

1. Premere per iniziare a sfogliare i parametri.

2. Ogni volta che si preme viene visualizzato un

parametro diverso in base a questa sequenza:

• CAPACITÀ RESIDUA

• GIORNI ALLA RIGENERAZIONE

•PORTATA

• Nome e numero di telefono dell'installatore, se impostati.

Nota! Se il contatore d'acqua rileva un flusso d'acqua,

viene visualizzato un asterisco (*).

Nota! Se nel giorno attuale è prevista una rigenerazione, sul display vengono visualizzati in sequenza

ORA DEL GIORNO e RIGENERAZIONE OGGI.

ORA DEL GIORNO

21:00

*

1 2 3

4568 7

ORA DEL GIORNO

12:01

/

Page 34

Honeywell GmbH 32 MU5H-1419GE23 R0815

8.1.1. CAPACITÀ RESIDUA

È possibile modificare la capacità residua dell'addolcitore

d'acqua KS20S.

1. Premere per accedere al parametro successivo .

Sul display viene visualizzato CAPACITÀ RESIDUA.

2. Premere per diminuire la capacità.

Ogni volta che si preme il pulsante la capacità viene diminuita

di 0,01 m³.

8.1.2. GIORNI ALLA RIGENERAZIONE

È possibile modificare il numero di giorni che ci separano

dalla rigenerazione successiva.

1. Premere per accedere al parametro successivo.

Sul display viene visualizzato GIORNI ALLA RIGENERAZIONE.

2. Premere per diminuire il numero dei giorni.

Ogni volta che si preme il pulsante i giorni che ci separano

dalla rigenerazione successiva vengono diminuiti di1 unità.

8.1.3. PORTATA

La portata attuale dell'addolcitore d'ac qua KS20S è espressa

in LPM (litri per minuto).

8.1.4. Dati dell'installatore

Sul display LCD vengono visualizzati il nome e il numero di

telefono dell'installatore, se impostati.

8.2. Ora del giorno

1. Premere per impostare l'ora.

Sul display viene visualizzato ORA e il numero corrispondente all'ora attuale inizia a lampeggiare.

2. Premere o per regolare l'ora.

3. Premere per accedere al parametro successivo.

Sul display viene visualizzato MINUTI e il numero corrispondente ai minuti attuali inizia a lampeggiare.

4. Premere o per regolare i minuti.

5. Premere per uscire dalle impostazioni.

Sul display viene visualizzato ORA DEL GIORNO o un altro

parametro generale (vedere 8.1. Parametri generali).

8.3. Impostazioni di base

8.3.1. Durezza dell'acqua

1. Premere contemporaneamente i pulsanti e

e tenerli premuti per 3 secondi fino a quando sul

display viene visualizzato DUREZZA ACQUA.

2. Premere o per modificare il grado di

durezza dell'acqua non trattata.

3. Premere per accedere al parametro successivo.

8.3.2. Durezza (residua) in servizio

Sul display viene visualizzato DUREZZA IN SERVIZIO

1. Premere o per modificare il grado di

durezza dell'acqua non trattata nell'unità di misura selezionata durante la messa in servizio. 15°fH è impostato

come parametro predefinito.

2. Premere per accedere al parametro successivo.

8.3.3. Intervallo di rigenerazione

Sul display viene visualizzato GIORNI F RA DUE RIGENERAZIONI.

m³

CAPACITÀ RESIDUA

4.41

/

m³

CAPACITÀ RESIDUA

4.41

/

GIORNI ALLA RIGENERAIONE

14

/

l/m

PORTATA

0

XXXXXXXXXXXXX

XXXXX

TEL

ORA

12:00

Set

Avviso! Queste impostazioni sono riservate esclusivamente agli utenti esperti e agli installato ri professionisti.

Nota! Dopo 5 minuti di inattività il controller torna automaticamente alla modalità operativa.

Avviso! No n diminuire la durezza in servizio portandola

a un valore inferiore a 15°fH per evitare fenomeni di

corrosione.

MINUTI

12:01

Set

ORA DEL GIORNO

12:01

/

DUREZZA ACQUA

34

Set

°fH

DUREZZA IN SERVIZIO

0

Set

°fH

GIORNI FRA DUE RIGENERAZIONI

14Set

Page 35

MU5H-1419GE23 R0815 33 Honeywell GmbH

Italiano

1. Premere o per impostare il numero di giorni

che deve intercorrere tra un a rigenerazione e l'altra.

• L'impostazione predefinita è "4".

• Il numero massimo di giorni è "28".

• Se sul display appare "Off", non è prevista alcuna rige-

nerazione forzata.

2. Premere per accedere al parametro successivo.

Sul display viene visualizzato ORA (ORARIO RIGENERAZIONE) e il numero corrispondente all'ora attuale inizia a

lampeggiare.

1. Premere o per impostare il tempo di rigenerazione (ora).

2. Premere per accedere al parametro successivo.