Page 1

INSTALLATION

MANUAL

KNI 582

RADIO MAGNETIC

INDICATOR

Manual Number 006-00193-0003

Revision 3, March/2007

Page 2

Honeywell - Confidential

THIS DOCUMENT AND ALL INFORMATION AND EXPRESSION CONTAINED HEREIN ARE THE

PROPERTY OF HONEYWELL INTERNATIONAL INC., ARE PROVIDED IN CONFIDENCE, AND MAY BE

USED BY PERSONS REQUIRED BY FEDERAL AVIATION REGULATION PART 21.50 TO COMPLY

WITH ANY OF THE TERMS OF THESE INSTRUCTIONS. EXCEPT AS SET FORTH ABOVE, NO

PERSON MAY, IN WHOLE OR IN PART, USE, DUPLICATE OR DISCLOSE THIS INFORMATION FOR

ANY PURPOSE WITHOUT THE PRIOR WRITTEN PERMISSION OF HONEYWELL INTERNATIONAL

INC.

Page 3

KNI 582

Honeywell Materials License Agreement

The documents and information contained herein ("the Materials") are the proprietary data of

Honeywell International Inc. and Honeywell Intellectual Properties Inc (collectively "Honeywell").

These Materials are provided for the exclusive use of Honeywell Service Centers;

Honeywell-authorized repair facilities; operators of Honeywell aerospace products subject to an

applicable product support agreement, their wholly owned-subsidiaries or a formally designated

third party service provider thereunder; and direct recipients of Materials from Honeywell's

Aerospace Technical Publication Distribution. The terms and conditions of this License Agreement

govern your use of these Materials, except to the extent that any terms and conditions of another

applicable agreement with Honeywell regarding the operation, maintenance, or repair of Honeywell

aerospace products conflict with the terms and conditions of this License Agreement, in which case

the terms and conditions of the other agreement will govern. However, this License Agreement will

govern in the event of a conflict between its terms and conditions and those of a purchase order or

acknowledgement.

1. License Grant - If you are a party to an applicable product support agreement, a Honeywell Service

Center agreement, or an authorized repair facility agreement, Honeywell hereby grants you a limited,

non-exclusive license to use these Materials to operate, maintain, or repair Honeywell aerospace products

only in accordance with that agreement.

If you are a direct recipient of these Materials from Honeywell's Aerospace Technical Publication

Distribution and are not a party to an agreement related to the operation, maintenance or repair of

Honeywell aerospace products, Honeywell hereby grants you a limited, non-exclusive license to use these

Materials to maintain or repair the subject Honeywell aerospace products only at the facility to which these

Materials have been shipped ("the Licensed Facility"). Transfer of the Materials to another facility owned

by you is permitted only if the original Licensed Facility retains no copies of the Materials and you provide

prior written notice to Honeywell.

2. Rights In Materials - Honeywell retains all rights in these Materials and in any copies thereof that are

not expressly granted to you, including all rights in patents, copyrights, trademarks, and trade secrets. No

license to use any Honeywell trademarks or patents is granted under this License Agreement.

3. Confidentiality - You acknowledge that these Materials contain information that is confidential and

proprietary to Honeywell. You agree to take all reasonable efforts to maintain the confidentiality of these

Materials.

4. Assignment And Transfer - This License Agreement may be assigned to a formally designated service

designee to the extent allowed under an applicable product support agreement or transferred to a

subsequent owner or operator of an aircraft containing the subject Honeywell aerospace products.

However, the recipient of any such assignment or transfer must assume all of your obligations under this

License Agreement. No assignment or transfer shall relieve any party of any obligation that such party then

has hereunder.

5. Copies of Materials - Unless you have the express written permission of Honeywell, you may not make

or permit making of copies of the Materials. Notwithstanding the foregoing, you may make copies of only

portions of the Material for your internal use. You agree to return the Materials and any copies thereof to

Honeywell upon the request of Honeywell.

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permission of Honeywell. MLA-1

Page 4

KNI 582

6. Term - This License Agreement is effective until terminated as set forth herein. This License Agreement

will terminate immediately, without notice from Honeywell, if you fail to comply with any provision of this

License Agreement or will terminate simultaneously with the termination or expiration of your applicable

product support agreement, authorized repair facility agreement, or your formal designation as a third party

service provider. Upon termination of this License Agreement, you will return these Materials to Honeywell

without retaining any copies and will have one of your authorized officers certify that all Materials have been

returned with no copies retained.

7. Remedies - Honeywell reserves the right to pursue all available remedies and damages resulting from

a breach of this License Agreement.

8. Limitation of Liability - IN NO EVENT WILL HONEYWELL BE LIABLE FOR ANY INCIDENTAL

DAMAGES, CONSEQUENTIAL DAMAGES, SPECIAL DAMAGES, INDIRECT DAMAGES, LOSS OF

PROFITS, LOSS OF REVENUES, OR LOSS OF USE, EVEN IF INFORMED OF THE POSSIBILITY OF

SUCH DAMAGES. TO THE EXTENT PERMITTED BY APPLICABLE LAW, THESE LIMITATIONS AND

EXCLUSIONS WILL APPLY REGARDLESS OF WHETHER LIABILITY ARISES FROM BREACH OF

CONTRACT, WARRANTY, TORT (INCLUDING BUT NOT LIMITED TO NEGLIGENCE), BY OPERATION

OF LAW, OR OTHERWISE.

9. Controlling Law - This License shall be governed and construed in accordance with the laws of the State

of New York without regard to the conflicts of laws provisions thereof. This license sets forth the entire

agreement between you and Honeywell and may only be modified by a writing duly executed by the duly

authorized representatives of the parties.

Copyright Notice

Copyright 1988, 2007 Honeywell International Inc. All rights reserved.

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permission of Honeywell. MLA-2

Page 5

KNI 582

REVISION HIGHLIGHTS

Part Number Rev Date Description

006-00193-0003 3 Mar/2007 Replace all pages of the manual. This is a

complete reprint.

Removed NVG versions from the manual.

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permission of Honeywell. RH-1

Page 6

Page 7

KNI 582

TABLE OF CONTENTS

SECTION 1

GENERAL INFORMATION

1.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 EQUIPMENT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 TECHNICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.4 UNITS AND ACCESSORIES SUPPLIED . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.4.1 KNI 582 RMI CONFIGURATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.4.2 KNI 582 RMI INSTALLATION KIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.5 ADDITIONAL EQUIPMENT REQUIRED, BUT NOT SUPPLIED. . . . . . . . . . 1-5

1.6 LICENSE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

SECTION 2

INSTALLATION

2.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 UNPACKING AND INSPECTING EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3 KNI 582 RMI INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.4 POST INSTALLATION CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

SECTION 3

OPERATION

3.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 NORMAL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permission of Honeywell. TOC-1

Page 8

Page 9

KNI 582

LIST OF FIGURES

Figure 2-1 KNI 582 Outline and Mounting Drawing . . . . . . . . . . . . . . . . . . . . . . . 2-5

Figure 2-2 Connector Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Figure 2-3 KNI 582 Pin Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Figure 2-4 KNI 582/KDF 805/KNR 665A/KNR 615 Interconnect . . . . . . . . . . . . . 2-9

Figure 2-5 KNI 582/KDF 805/KNR 630 Interconnect . . . . . . . . . . . . . . . . . . . . . 2-11

Figure 2-6 KNI 582/KR 87/KNS 81/KN 53 Interconnect . . . . . . . . . . . . . . . . . . . 2-13

Figure 2-7 KNI 582/Bendix DF-2071A/Bendix CN2011A/

Collins ADF-60A/Collins VIR-30A Interconnect 2-15

Figure 2-8 KNI 582 Cable Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Figure 2-9 KNI 582 Cable Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Figure 2-10 KNI 582 Serial OBI Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Figure 3-1 KNI 582 Control Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permission of Honeywell. LOF-1

Page 10

Page 11

KNI 582

LIST OF TABLES

Table 1-1 - KNI 582 RMI Technical Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Table 1-2 - KNI 582 RMI Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Table 1-3 - KNI 582 RMI Installation Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Table 1-4 - Additional Equipment, Compatible with KNI 582 RMI . . . . . . . . . . . . . . . . 1-5

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permission of Honeywell. LOT-1

Page 12

Page 13

KNI 582

SECTION 1

GENERAL INFORMATION

1.1 INTRODUCTION

This manual contains information relative to the physical, mechanical, and electrical

characteristics of the KNI 582 Radio Magnetic Indicator. General installation instructions

are also included.

1.2 EQUIPMENT DESCRIPTION

The KNI 582 Radio Magnetic Indicator (PN 066-3060-00/01/02/03/04/10/11/12/13)

provides bearing information to either ADF or VOR stations by means of two pointers,

each of which is read against the compass card. The type of information displayed by

each needle (assuming applicable inputs are present) is determined by the corresponding

front panel switch.

A servo drive compass card with a fixed lubber line displays aircraft heading information.

A flag falls into view in the upper left corner of the display when the aircraft heading

information being displayed is invalid.

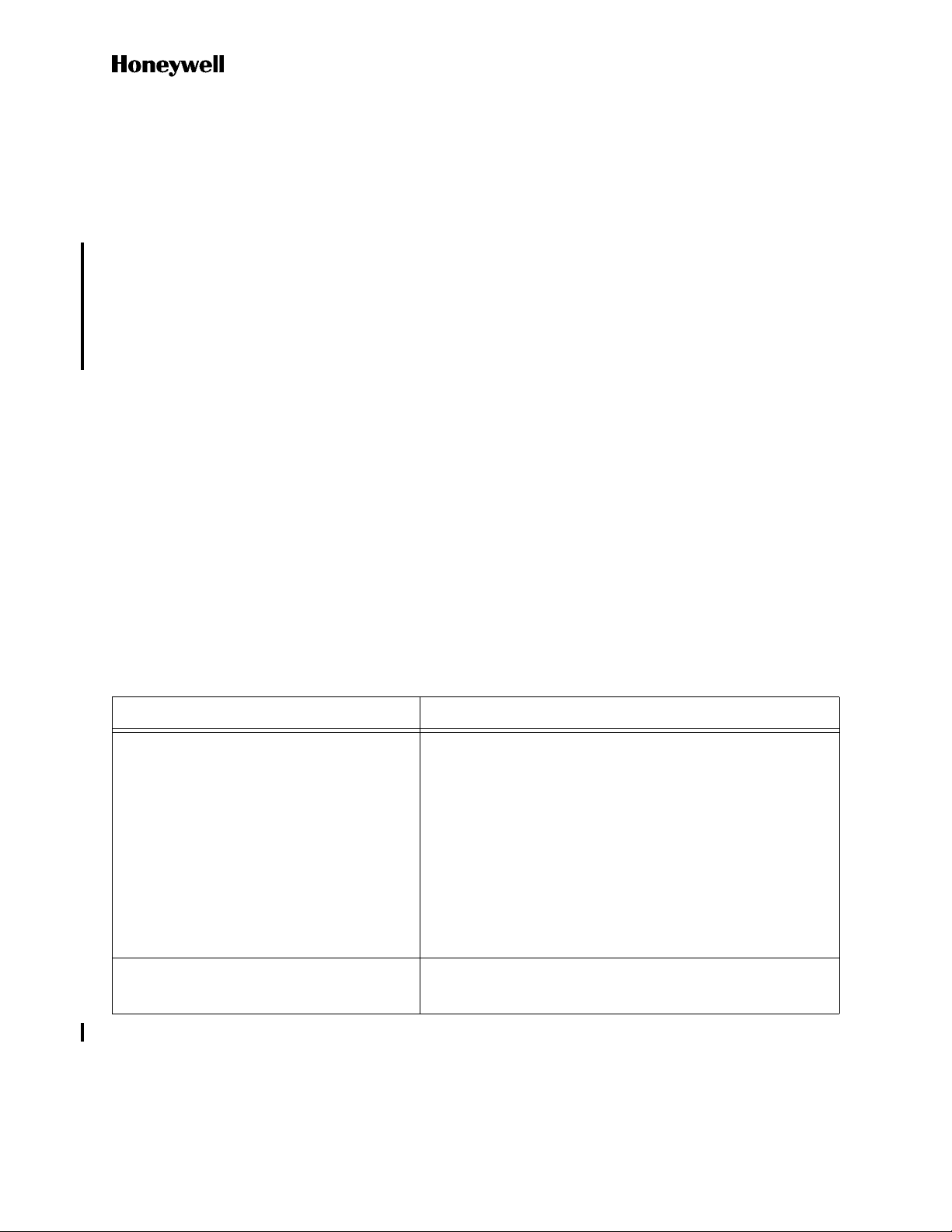

1.3 TECHNICAL CHARACTERISTICS

SPECIFICATION CHARACTERISTIC

TSO Compliance: Env. Cat. RTCA DO-160A

A1D1/A/SKP/XXXXXSABAAA

Temperature: -20°C to +55°C

Altitude: 50,000 feet

Compass: TSO C6c

ADF: TSO C41c Class A

VOR: TSO C40a

WEIGHT and DIMENSIONS: See Figure 2-1 KNI 582 Outline and Mounting

Drawing.

Table 1-1 - KNI 582 RMI Technical Characteristics

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permission of Honeywell. 1-1

Page 14

KNI 582

SPECIFICATION CHARACTERISTIC

POWER REQUIREMENTS

Primary: 11.33VDC 0.4A maximum

26VAC 400Hz 6VA

Lighting: 28V at 80mA maximum

5V at 460mA maximum

Note: 14V Installations may use 5V Versions

with dropping resistor.

COMPASS HEADING INPUT Operates from any slaved magnetic compass

with ARINC X, Y, and Z outputs. Z grounded

externally.

COMPASS VALID Valid = +27.5VDC

Invalid = 0VDC 2mA maximum

VOR/LOC COMPOSITE INPUT

(-04 Version TACAN

Compatible)

NAV SUPERFLAG

(Horizontally parked needle)

ILS ENERGIZE

(Horizontally parked needle)

0.5VRMS 0° phase composite 30Hz variable AM

and 30Hz reference FM on a 9960Hz carrier

(ARINC Std.) (0.7VRMS maximum)

Flag < +3.5VDC

No Flag > +10VDC

ILS < +1VDC (GND)

VOR = Open (+33VDC Maximum)

ADF X, Y, Z Operates from any ADF receiver with ARINC X,

Y, Z outputs. Z grounded externally. 11.8VRMS

400Hz 180° index, positive rotation reference.

OBI SIN/COS 4 wire SIN/COS 10VRMS 400Hz. 0° when SIN =

0VRMS and COS = maximum positive VRMS.

Positive rotation reference with COS decreasing

and SIN increasing in-phase for increasing

degrees.

ADF DC SIN/COS Common Mode: 0 to ± 5VDC

Differential: 3VDC ± 10%

OBI DIGITAL

I Electrical Characteristics

A. Driver 1. Open collector referenced to ground

2. Maximum “low” voltage (with 2 receiver loads

(500 Ohm) returned to 10.35 volts) = 1.0V.

Table 1-1 - KNI 582 RMI Technical Characteristics (Cont)

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permission of Honeywell. 1-2

Page 15

SPECIFICATION CHARACTERISTIC

B. Receiver 1. Input resistance = 1K ± 5% returned to +V

2. +V = 9.0V ± 15%

C. Interconnecting Lines 1. Maximum Shunt Capacity = 2000 pF

II Waveform Timing

A. Data 1. Data Rate - Approx. 1KHz

2. Negative Logic (“Low True”)

B. Clock 1. The negative going edge of the clock

waveform will be greater than 10us and less

than 250us from any data transistors point.

2. The minimum time that the clock spends in

either the high or low state will be greater

than 10us.

C. Sync 1. The sync pulse is a negative going pulse

following the data word.

2. The negative going edge of the sync pulse

will be a minimum of 70us and a maximum of

350us after the negative going edge of the

last clock pulse.

3. The sync pulse will be a minimum of 10us

wide and a maximum of 260us wide.

KNI 582

III Data Word Format 1. BCD, 0.1’s, 1’s, 10’s, 100’s

2. LSD to MSD

3. LSB to MSB

4. Maximum Word Rate = 12Hz

5. When “8” Bit of 100’s is High (False) = Flag.

6. When “4” Bit of 100’s is High (False) = ILS

Mode.

100° 10° 1° .1°

(8)

Flag

(4)

ILS 2 & 1 MSB LSB MSB LSB MSB LSB ABC

<---- Time

Table 1-1 - KNI 582 RMI Technical Characteristics (Cont)

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permission of Honeywell. 1-3

Page 16

1.4 UNITS AND ACCESSORIES SUPPLIED

1.4.1 KNI 582 Configurations

The KNI 582 RMI is available in the following versions:

PART NUMBER DESCRIPTION

066-3060-00 Black Bezel, 27.5 VDC/26VAC Lights

066-3060-01 Black Bezel, 5 VDC/5VAC Lights

066-3060-02 Black Bezel, 27.5 VDC/26VAC Lights

066-3060-03 Black Bezel, 5 VDC/5VAC Lights

066-3060-04 Black Bezel, 5 VDC/5VAC Lights (TACAN Compatible)

066-3060-10 Black Bezel, 27.5 VDC/26VAC Lights

066-3060-11 Black Bezel, 5 VDC/5VAC Lights

KNI 582

066-3060-12 Black Bezel, 27.5 VDC/26VAC Lights

066-3060-13 Black Bezel, 5 VDC/5VAC Lights

Table 1-2 - KNI 582 RMI Configurations

1.4.2 KNI 582 RMI Installation Kit

KNI 582 RMI Installation Kit PN 050-01823-0000/0001. (solder type)

KNI 582 RMI Installation Kit PN 050-01823-0002/0003. (crimp type)

The -0000/-0002 installation kit is used for black panel mounting. The -0001/-0003

installation kit is for gray panel mounting. (See Paragraph 2.3 KNI 582 RMI

INSTALLATION for installation instructions.)

PART NUMBER DESCRIPTION -00 -01 -02 -03

006-00540-0000 Bulletin 1 1 1 1

073-00044-0001 Mooring Plate 1 1 1 1

073-00045-0000 Black Adapter Plate 1 0 1 0

073-00045-0001 Gray Adapter Plate 0 1 0 1

Table 1-3 - KNI 582 RMI Installation Kit

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permission of Honeywell. 1-4

Page 17

KNI 582

PART NUMBER DESCRIPTION -00 -01 -02 -03

089-05115-0012 Scr. FHP 6-32 x 3/4 4 0 4 0

089-06461-0012 Scr. FHP 6-32 x 3/4 0 4 0 4

030-01157-0011 Socket Crmp 20G 0 0 49 49

030-01176-0000 HSG Conn 50S 0 0 1 1

030-01188-0000 Pin Polrzin Female 0 0 1 1

030-02350-0015 Conn Sub-Min F 50P 1 1 0 0

030-02414-0001 Hood & Lvr Mdfd 1 1 1 1

Table 1-3 - KNI 582 RMI Installation Kit (Cont)

1.5 ADDITIONAL EQUIPMENT REQUIRED, BUT NOT SUPPLIED

The following are navigation receivers, ADF receivers, and compass systems compatible

with the KNI 582 RMI.

NAV RECEIVERS ADF RECEIVERS COMPASS

KN 53: TSO’d. KR 85 (225 01/04) TSO’d KCS 305 TSO’d

KNS 80: Env. DO-160, Area

KR 87 TSO'd KCS 55/55A TSO'd

NAV AC 90-45A

KNS 81: Area NAV AC 90-45A KDF 800 TSO’d KPI 550 TSO’d

KX 155/165: TSO’d KDF 805 TSO’d

KX 170B: Non-TSO’d KDF 8000 TSO’d

KX 175B: TSO’d

KNR 615: TSO’d

KNR 630: TSO’d

KNR 634: TSO’d

KNR 665: Area NAV AC 90-45

KNR 665A: Area NAV AC 90-45

Table 1-4 - Equipment Compatible with KNI 582 RMI

Crimping tools, mooring plates and power tools are referenced in individual installation

manuals.

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permission of Honeywell. 1-5

Page 18

KNI 582

1.6 LICENSE REQUIREMENTS

None.

1.7 CONTINUED AIRWORTHINESS INSTRUCTIONS

1.7.1 Equipment

The instructions for continued airworthiness given in the TC or STC approvals for this

product supplements or supersedes the instructions for continued airworthiness in this

manual.

Most Honeywell products are designed and manufactured to allow "on condition

maintenance". On condition maintenance is described as follows; There are no periodic

service requirements necessary to maintain continued airworthiness. No maintenance is

required until the equipment does not properly perform its intended function. When

service is required, a complete performance test should be accomplished following any

repair action. Consult the appropriate unit Maintenance/Overhaul Manual for complete

performance test information.

14 CFR Part 25.1529 Instructions for Continued Airworthiness is met per the following

instructions:

A. The removal of the equipment is on the condition of failure. There is no re-

quired maintenance.

1.7.2 Wires/Coax Cables

During on-condition or regularly scheduled maintenance, inspect wires and coax cables

following the guidelines listed in AC 43.13-1B Chapter 11, 12 as necessary.

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permission of Honeywell. 1-6

Page 19

KNI 582

SECTION 2

INSTALLATION

2.1 GENERAL

This section contains the suggestions and information to consider before installation of the

KNI 582 Radio Magnetic Indicator into the aircraft. Close adherence to these suggestions

will assure optimum performance from the equipment.

2.2 UNPACKING AND INSPECTING EQUIPMENT

Exercise extreme care when unpacking the equipment. Make a visual inspection of the

unit for evidence of damage during shipment. If a claim for damage is to be made, save

the shipping container to substantiate the claim. The claim should be promptly filed with

the transportation company. It would be advisable to retain the container and packing

material after all equipment has been removed, in the event that equipment storage or

reshipment should become necessary. The KNI 582 RMI installation will conform to

standards designated by the customer, installing agency and existing conditions as to unit

location and type of installation.

2.3 KNI 582 RMI INSTALLATION

A. Plan a location on the aircraft panel that is clearly visible to the pilot with the least

practicable deviation from his normal position and from his line of vision when he

is looking forward along the flight path.

B. Make certain that clearance is available for the installation of the cables and

connectors, and also that normal vibration does not cause the unit to bump

against other equipment cases.

C. If an instrument hole that meets the installation requirements is not available, cut

a 3" ATI hole per Figure 2-1. Secure the unit with four 3/4" long 6-32 instrument

screws.

D. The KNI 582 RMI may be secured in place from front or behind the panel.

2.4 POST INSTALLATION CHECK

These are tests designed to show that the KNI 582 RMI is functioning accurately under

broadly nominal conditions.

A. Compass Card Accuracy

1. With the aircraft on a known magnetic heading, this heading ±2° should be

under the lubber line of KNI 582 RMI.

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permission of Honeywell. 2-1

Page 20

KNI 582

2. The above step should be repeated for at least one additional heading 90°

from the first.

B. ADF Accuracy

1. Depending on the application, the KNI 582 RMI can be tested for either DC

SIN/COS ADF or X, Y, Z, ADF by tuning in a station on the appropriate ADF.

2. In the DC SIN/COS Mode the needles should position the direction of the

station +5°. Repeat for at least one more station.

3. Repeat Step 2 for X, Y, Z, ADF +5°.

C. VOR Accuracy

1. Depending on the application, the KNI 582 RMI can be tested for either OBI

DIGITAL VOR, COMPOSITE VOR, or OBI SIN/COS VOR by tuning in a

station on the appropriate VOR.

2. In the OBI DIGITAL VOR Mode, the single needle should point to the station

+5°. Repeat for at least one more station.

3. Repeat Step 2 for COMPOSITE VOR +5°.

4. Repeat Step 2 for OBI SIN/COS VOR +5°.

D. VOR/LOC Composite Correction Adjustment

If it is necessary to make a VOR/LOC composite needle centering adjustment

due to NAV receiver composite error, the KNI 582 RMI pointer can be adjusted

externally using the following steps:

1. With a ramp-test NAV generator, generate an output so the NAV receiver can

be tuned into a given bearing.

2. With the NAV receiver tuned to the generator frequency, insert a tuning tool

into VOR/LOC composite adjustment hole (refer to Figure 2-1) and adjust

R232 until the selected needle reads the same bearing the ramp generator.

3. Repeat Step 2 for verification of the adjustment for another bearing on the

ramp with generator.

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permission of Honeywell. 2-2

Page 21

TEST DATA

Compass Card Accuracy

(Magnetic Heading) minus (KNI 582 RMI Indication) = Error

ADF (D.C. SIN/COS) Accuracy

(Station Heading) minus (KNI 582 RMI Indication) = Error

ADF (X, Y, and Z) Accuracy

KNI 582

(±2° Max.)

(±2° Max.)

(±5° Max.)

(±5° Max.)

(Station Heading) minus (KNI 582 RMI Indication) = Error

VOR (OBI DIGITAL) Accuracy

(Station Bearing) minus (KNI 582 RMI Indication) = Error

VOR (Composite) Accuracy

(Station Bearing) minus (KNI 582 RMI Indication) = Error

VOR (OBI SIN/COS) Accuracy

(Station Bearing) minus (KNI 582 RMI Indication) = Error

(±5° Max.)

(±5° Max.)

(±5° Max.)

(±5° Max.)

(±5° Max.)

(±5° Max.)

(±5° Max.)

(±5° Max.)

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permission of Honeywell. 2-3

Page 22

KNI 582

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permission of Honeywell. 2-4

Page 23

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permission of Honeywell. 2-5

KNI 582

Figure 2-1 KNI 582 Outline and Mounting Drawing

(Dwg No 155-05353-0000, Rev 0)

Page 24

Page 25

KNI 582

Figure 2-2 Connector Assembly

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permission of Honeywell. 2-7

Page 26

KNI 582

Figure 2-3 KNI 582 Pin Functions

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permission of Honeywell. 2-8

Page 27

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permi ssion of Honeywell. 2-9

KNI 582

Figure 2-4 KNI 582/KDF 805/KNR 665A/KNR 615 Interconnect

(Dwg No 155-01383-0000, Rev 5)

Page 28

Page 29

KNI 582

Figure 2-5 KNI 582/KDF 805/KNR 630 Interconnect

(Dwg No 155-01384-0000, Rev 5)

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permi ssion of Honeywell. 2-11

Page 30

Page 31

KNI 582

Figure 2-6 KNI 582/KR 87/KNS 81/KN 53 Interconnect

(Dwg No 155-01385-0000, Rev 4)

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permi ssion of Honeywell. 2-13

Page 32

Page 33

KNI 582

Figure 2-7 KNI 582/Bendix DF-2071A/Bendix CN2011A/

Collins ADF-60A/Collins VIR-30A Interconnect

(Dwg No 155-01386-0000, Rev 5)

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permi ssion of Honeywell. 2-15

Page 34

Page 35

KNI 582

Figure 2-8 KNI 582 Cable Assembly

(Dwg No 155-02114-0000, R-AA)

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permission of Honeywell. 2-17

Page 36

KNI 582

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permission of Honeywell. 2-18

Page 37

Rev 3, March/2007 ©Honeywell In ternational Inc. Do not print without express permission of Honeywell. 2-19

KNI 582

Figure 2-10 KNI 582 Serial OBI Interface

(Dwg No 155-01563-0013, Rev 0)

Page 38

Page 39

SECTION 3

OPERATION

3.1 GENERAL

The KNI 582 RMI display is discussed below:

A. Compass Card/Lubber Line: This rotating card repeats gyro stabilized

magnetic compass information. Aircraft

heading is read from the compass card

under the orange lubber line.

B. Compass Flag: This flag comes into view whenever the

compass system determines that the

heading is invalid or the indicated heading

has an error of 5° or more.

C. Pointers: The arrow of either pointer indicates the

magnetic heading to a VOR station/area

navigation waypoint of an ADF station

depending on the position of the front panel

switches associated with the pointer.

KNI 582

3.2 NORMAL OPERATION

The KNI 582 RMI repeats magnetic heading information from a directional gyro system.

Aircraft heading is read under the lubber line of the KNI 582 RMI.

When an ADF receiver is tuned to a station and the appropriate pointer placed in the ADF

mode, the arrow of the pointer indicates the magnetic heading to the ADF station. Thus,

if the pilot desires to fly toward the station, he merely turns his aircraft to the magnetic

heading indicated by the pointer.

When a VOR receiver is tuned to a VOR station and the appropriate pointer placed in the

VOR mode, the arrow of the pointer indicates the magnetic heading to the VOR station. If

the KNI 582 RMI is used in an area navigation system, the VOR pointer indicates

magnetic heading to the waypoint. Should a localizer frequency be selected or the VOR

receiver indicates a flagged condition, the VOR pointer is parked 90° to the right of the

lubber line.

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permission of Honeywell. 3-1

Page 40

KNI 582

Figure 3-1 KNI 582 Control Functions

Rev 3, March/2007 ©Honeywell International Inc. Do not print without express permission of Honeywell. 3-2

Page 41

Page 42

Loading...

Loading...