Page 1

Page 2-8 and 8-1 Has been edited by Tech Support. If you have any

questions call 1.800.645.7492

ADEMCO VISTA SERIES

VISTA-20P / VISTA-20PSIA

VISTA-15P / VISTA-15PSIA

Security Systems

Installation and Setup Guide

K5305-1V5 10/04 Rev. A

Page 2

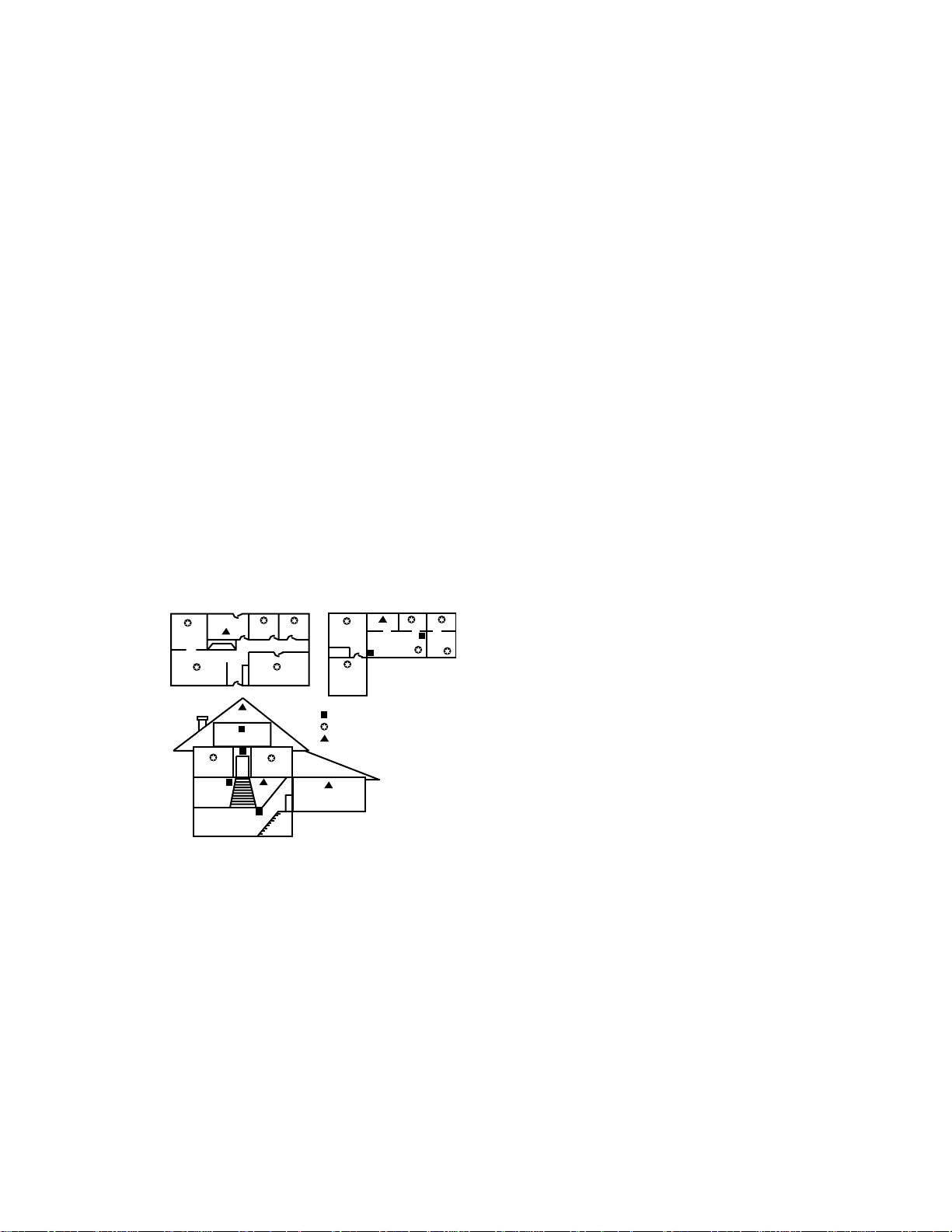

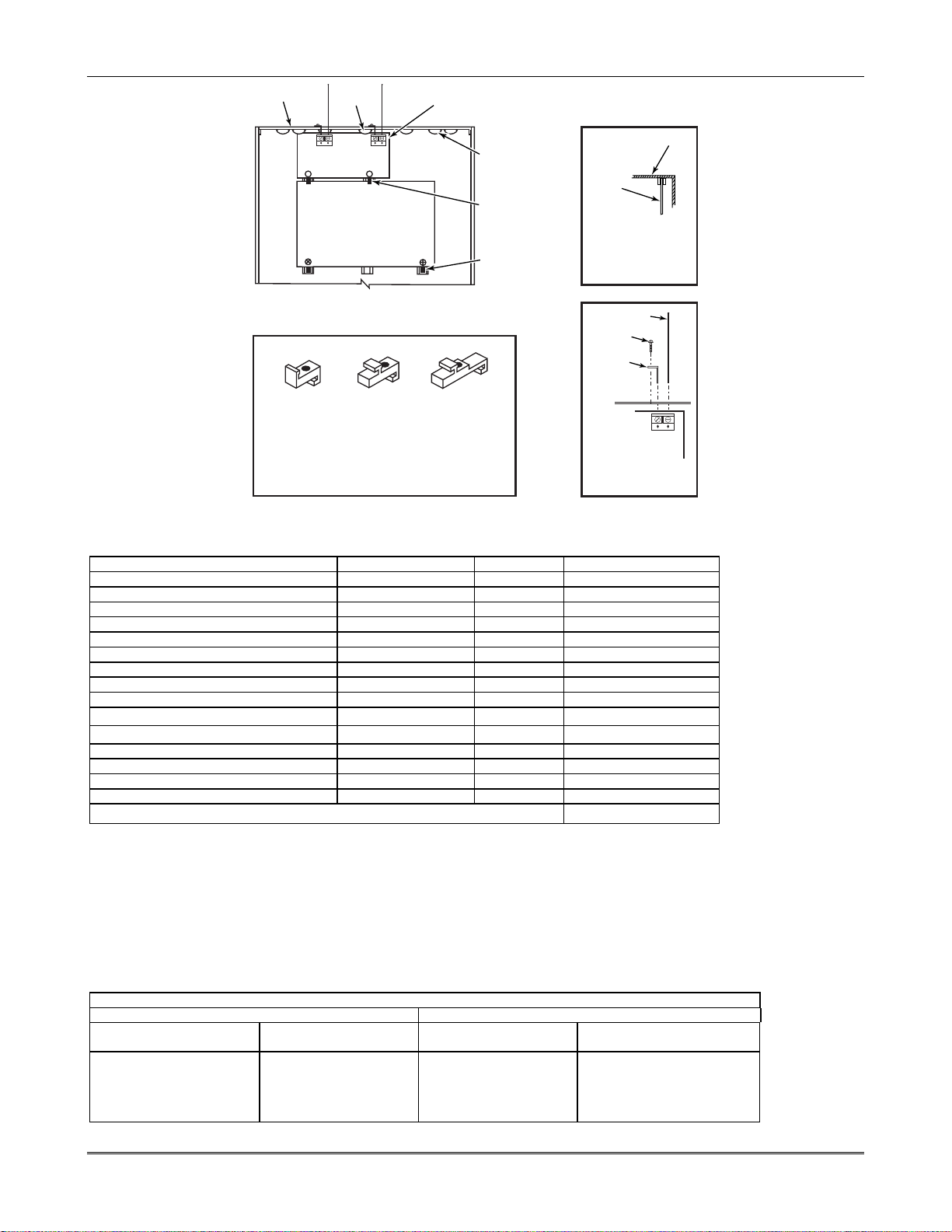

RECOMMENDATIONS FOR PROPER PROTECTION

The Following Recommendations for the Location of Fire and Burglary Detection

Devices Help Provide Proper Coverage for the Protected Premises.

Recommendations For Smoke And Heat Detectors

With regard to the number and placement of smoke/heat detectors, we subscribe to the

recommendations contained in the National Fire Protection Association's (NFPA) Standard #72 noted

below.

Early warning fire detection is best achieved by the installation of fire detection equipment in all rooms

and areas of the household as follows: For minimum protection a smoke detector should be installed

outside of each separate sleeping area, and on each additional floor of a multi-floor family living unit,

including basements. The installation of smoke detectors in kitchens, attics (finished or unfinished), or

in garages is not normally recommended.

For additional protection the NFPA recommends that you install heat or smoke detectors in the living

room, dining room, bedroom(s), kitchen, hallway(s), attic, furnace room, utility and storage rooms,

basements and attached garages.

In addition, we recommend the following:

• Install a smoke detector inside every bedroom where a smoker sleeps.

• Install a smoke detector inside every bedroom where someone sleeps with the door partly or

completely closed. Smoke could be blocked by the closed door. Also, an alarm in the hallway outside

may not wake up the sleeper if the door is closed.

DINING

LIVING ROOM

BEDROOM

LVNG RM

BASEMENT

KITCHEN

BEDROOM

TO

BR

BEDROOM

BEDROOM

BEDROOM

KTCHN

BEDROOM

CLOSED

.

DOOR

KITCHEN

TV ROOM

LIVING ROOM

BEDROOM

Smoke Detectors for Minimum Protection

Smoke Detectors for Additional Protection

Heat-Activated Detectors

GARAGE

DINING

BDRM

BDRM

floor_plan-001-V0

Recommendations For Proper Intrusion Protection

For proper intrusion coverage, sensors should be located at every possible point of entry to a home or

commercial premises. This would include any skylights that may be present, and the upper windows

in a multi-level building.

In addition, we recommend that radio backup be used in a security system so that alarm signals can

still be sent to the alarm monitoring station in the event that the telephone lines are out of order

(alarm signals are normally sent over the phone lines, if connected to an alarm monitoring station).

• Install a smoke detector inside bedrooms

where electrical appliances (such as

portable heaters, air conditioners or

humidifiers) are used.

• Install a smoke detector at both ends of a

hallway if the hallway is more than 40

feet (12 meters) long.

• Install smoke detectors in any room where

an alarm control is located, or in any room

where alarm control connections to an AC

source or phone lines are made. If

detectors are not so located, a fire within

the room could prevent the control from

reporting a fire or an intrusion.

THIS CONTROL COMPLIES WITH NFPA

REQUIREMENTS FOR TEMPORAL PULSE

SOUNDING OF FIRE NOTIFICATION

APPLIANCES.

ii

Page 3

Table Of Contents

Features and Installation Highlights............................................................................................................1-1

Capabilities and Functions................................................................................................................................................1-1

Compatible Devices ...........................................................................................................................................................1-2

Important Installation Highlights (Installer Please Read) .............................................................................................1-2

Mounting and Wiring the Control .................................................................................................................2-1

Installing the Control Cabinet and PC Board.................................................................................................................. 2-1

Cabinet and Lock .........................................................................................................................................................2-1

Mounting the PC Board Alone (no RF Receiver)........................................................................................................2-1

Mounting Board with RF Receiver..............................................................................................................................2-1

AUXILIARY DEVICE CURRENT DRAW WORKSHEET ..............................................................................2-2

AC Power, Battery, and Ground Connections..................................................................................................................2-3

1321 Transformer.........................................................................................................................................................2-3

1361X10 Transformer..................................................................................................................................................2-3

Battery Connections.....................................................................................................................................................2-3

Battery Saver Feature ................................................................................................................................................. 2-3

Earth Ground ............................................................................................................................................................... 2-3

Sounder (Bell) Connections...............................................................................................................................................2-4

Basic Connections ........................................................................................................................................................2-4

Supervised output........................................................................................................................................................2-4

Connecting the Keypads and Other Addressable Devices ...............................................................................................2-4

Connections .................................................................................................................................................................. 2-4

Supplementary Power (optional).................................................................................................................................2-4

Keypad Notes ...............................................................................................................................................................2-5

Long Range Radio Connections................................................................................................................................... 2-5

Table of Device Addresses.................................................................................................................................................2-5

Hardwire Zones and Zone Expansion...............................................................................................................................2-6

Hardwire Zones............................................................................................................................................................2-6

Double-Balanced Zones................................................................................................................................................2-6

Zone Doubling ..............................................................................................................................................................2-6

Smoke Detectors...........................................................................................................................................................2-6

Smoke Detector Notes.................................................................................................................................................. 2-7

4219/4229 Expansion Zones ........................................................................................................................................2-7

Installing the RF Receiver and Wireless Transmitter Zones ..........................................................................................2-8

Compatible Receivers...................................................................................................................................................2-8

Receiver Connections...................................................................................................................................................2-8

RF Receiver Notes........................................................................................................................................................2-8

Installing a 5800TM Module ....................................................................................................................................... 2-9

Installing the Transmitters.........................................................................................................................................2-9

Transmitter Battery Life.............................................................................................................................................2-9

Installing a Keyswitch.....................................................................................................................................................2-10

Keyswitch Connections..............................................................................................................................................2-10

Keyswitch Notes.........................................................................................................................................................2-10

Connecting Relay Modules, Powerline Carrier Devices and Output Triggers..............................................................2-11

4204/4229 Relay Modules..........................................................................................................................................2-11

Powerline Carrier Devices.........................................................................................................................................2-11

On-Board Triggers .....................................................................................................................................................2-12

Phone Line/Phone Module, and Audio Alarm Verification (AAV) Connections............................................................2-13

Phone Line..................................................................................................................................................................2-13

4285/4286 Phone Module...........................................................................................................................................2-13

Phone Module Problems ............................................................................................................................................2-13

Audio Alarm Verification Connections......................................................................................................................2-14

Programming Overview ...................................................................................................................................3-1

About Programming ..........................................................................................................................................................3-1

Mechanics of Programming...............................................................................................................................................3-1

Data Field Programming Procedures..........................................................................................................................3-1

Interactive Mode Programming (∗56, *57, ∗58, ∗79, ∗80, ∗81, ∗82)........................................................................... 3-2

Loading Factory Defaults/Initializing for Download..................................................................................................3-2

Exiting the Programming Mode..................................................................................................................................3-2

Zone Type Definitions........................................................................................................................................................3-2

iii

Page 4

Table Of Contents (continued)

Data Field Programming .................................................................................................................................4-1

About Data Field Programming........................................................................................................................................4-1

System Setup Fields (∗20 – ∗29) .......................................................................................................................................4-1

Zone Sounds & Timing (∗31–∗39) .....................................................................................................................................4-1

Dialer Programming (∗40 – ∗50) ....................................................................................................................................... 4-2

System Status Report Codes.............................................................................................................................................4-4

Miscellaneous System Fields ............................................................................................................................................4-5

Pager Programming Fields................................................................................................................................................4-7

Miscellaneous System Fields ............................................................................................................................................4-8

Configurable Zone Type Fields .........................................................................................................................................4-9

Touch Screen Device (AUI) Enable.................................................................................................................................4-11

Keypad Programming Fields...........................................................................................................................................4-11

Menu Mode Programming ...............................................................................................................................5-1

Zones and Partitions..........................................................................................................................................................5-1

About Zone Programming (∗56 and ∗58 Menu Modes) .................................................................................................... 5-1

✱56 Zone Programming Procedure ................................................................................................................................... 5-1

Completing Zone Programming ........................................................................................................................................ 5-4

∗58 Expert Programming Mode Procedures.....................................................................................................................5-4

Wireless Key Programming Templates ............................................................................................................................5-6

About Output Device Programming (*79/*80 Menu Mode) ............................................................................................. 5-8

Programming Output Devices...........................................................................................................................................5-8

*79 Menu Mode: Output Device Mapping ........................................................................................................................5-8

*80 Menu Mode: Defining Output Functions .................................................................................................................5-10

About Zone Lists (*81 Menu Mode) ................................................................................................................................5-12

Zone List Programming...................................................................................................................................................5-12

About Function Keys (*57 Menu Mode)..........................................................................................................................5-13

Programming Function Keys ..........................................................................................................................................5-13

About Descriptor Programming (*82 Menu Mode) ........................................................................................................5-14

Programming Zone Descriptors (Menu Mode ∗82).........................................................................................................5-14

Adding Custom Words (will not be annunciated by 4285/4286 Phone Module) ...........................................................5-15

Programming Installer and User Schedules ..................................................................................................................5-17

System Communication and Operation .......................................................................................................6-1

Panel Communication with Central Station ....................................................................................................................6-1

Report Code Formats......................................................................................................................................................... 6-1

Ademco Contact ID®.........................................................................................................................................................6-3

System Security Codes ......................................................................................................................................................6-4

Panic Keys......................................................................................................................................................................6-6

Setting the Real-Time Clock .............................................................................................................................................6-6

Various System Trouble Displays.....................................................................................................................................6-7

Testing the System.............................................................................................................................................7-1

About Test Procedures.......................................................................................................................................................7-1

System Test........................................................................................................................................................................7-1

Checking Transmitter Enrollment (Sniffer Mode)...........................................................................................................7-1

Go/No Go Test Mode .......................................................................................................................................................... 7-2

Dialer Communication Test and Periodic Test Reports...................................................................................................7-2

Automatic Standby Battery Tests.....................................................................................................................................7-2

Specifications & Accessories ...........................................................................................................................8-1

Security Control................................................................................................................................................................. 8-1

Compatible Devices ...........................................................................................................................................................8-1

5800 Series Transmitter Input Loop Identification ......................................................................................................... 8-3

Regulatory Agency Statements ......................................................................................................................9-1

Limitations and Warranty .............................................................................................................................10-7

iv

Page 5

SECTION 1

Features and Installation Highlights

This manual applies to the following Honeywell security systems:

ADEMCO VISTA-20P/ADEMCO VISTA-20PSIA/ADEMCO VISTA-20PCN (collectively referred to as

VISTA-20P series), ADEMCO VISTA-15P/ADEMCO VISTA-15PSIA/ADEMCO VISTA-15PCN

(collectively referred to as VISTA-15P series)

Features and procedures apply to all, except where differences are noted.

SIA Installations: The VISTA-20PSIA and VISTA-15PSIA are certified SIA-compliant controls that

meet SIA specifications for False Alarm Reduction. The other controls described in this manual are

not certified as SIA compliant, but can be programmed for False Alarm Reduction. To program for

False Alarm Reduction, follow the SIA Guidelines noted in the applicable programming fields.

NOTE: Throughout this manual, device model numbers are ADEMCO model numbers

unless otherwise noted.

Capabilities and Functions

Feature/Function ADEMCO VISTA-20P Series ADEMCO VISTA-15P Series

Partitions

Zones Up to 48 protection zones plus 16 keyfob

Security Codes Up to 48 Security Codes, with separate

One-button arming Dedicated keys can arm the system. Dedicated keys can arm the system.

Schedules Up to 32; can control devices and/or auto-

Keypad macros Up to 4; activated by wired keypads Up to 2; activated by wired keypads

Paging Up to 4 pagers; certain system conditions

Event Logging 100 events; log display is done via Ademco

Zone descriptors Can assign for all zones (for alpha display keypads and/or 4285/4286 Phone Module).

Bell supervision Optional, detects external sounder wiring short or open; causes a trouble condition,

RF jam detection Optional, for wireless systems detects a condition that may impede proper RF reception

Telephone Line

Monitoring

Downloading Via an IBM compatible computer, Compass downloading software, and a compatible

• 2 partitions, can protect two independent

areas

• Common zone option allows either

partition to arm, while leaving a common

area (ex. lobby or foyer) disarmed for

access into the other partition.

zones (zones 49-64) for total of 64 zones:

• 8 basic hardwired zones (zones 1-8) with

optional zone-doubling feature

• Up to 40 additional wired zones (zones 9-

48) using up to 5 4219/4229 modules

• Up to 40 wireless transmitter zones (5800

series; zones 9-48)

• Up to 4 configurable zone types

authority levels and partition access

arm/disarm

can report to pagers; can use a dedicated

key on keypads to send a signal to a pager

Compass Downloader software or

installer/master code at Keypad

keypad display, and sends a report to the central monitoring station, if enabled.

(i.e., jamming or other RF interference); causes keypad display, and sends a report to the

central monitoring station (if trouble reporting is enabled).

Built-in option can monitor the telephone line voltage and can cause a local display, or a

display and trouble/alarm sound

HAYES or CIA modem specified by Ademco.

VISTA-15P is not a partitioned system.

Up to 32 zones plus 8 keyfob zones (zones

49-56) for total of 40 zones:

• 6 basic hardwired zones (zone 1-6)

• Up to 16 additional wired zones (zones 9-

24) using up to 2 4219/4229 modules

• Up to 26 wireless transmitter zones

(5800 series; zones 9-34)

• Up to 2 configurable zone types

Up to 32 Security Codes, with separate

authority levels

Up to 8; can control devices and/or autoarm/disarm

Up to 2 pagers; certain system conditions

can report to pagers; can use a dedicated

key on keypads to send a signal to a pager

50 events; log display is done via Ademco

Compass Downloader software or

installer/master code at Keypad

1-1

Page 6

Installation and Setup Guide

Compatible Devices

Device VISTA-20P VISTA-15P Notes

Addressable Keypads 8 8 6150 Fixed-Word Keypad, 6160 Alpha Keypad, 6150V

Fixed-Word Display Voice Keypad, 6160V Alpha

Display Voice Keypad, 6150RF Keypad/Transceiver

Touch Screen (AUI)

Devices

4219, 4229 Zone

Expander Modules

5800 Series Wireless Up to 40 RF

Output relays and/or

Powerline Carrier

Devices (X-10 type)

On-Board Triggers 2 2 Can be used to reset 4-smoke detectors.

Output functions Up to 48 Up to 24 Program output functions via *80 Menu mode.

4285/4286 Phone

Module

Audio Alarm

Verification

Alarm output 12VDC, 2

Auxiliary Power Output See note. See note 12VDC, 600 mA maximum; uses fuse for protection.

Backup Battery See note. See note. Rechargeable (sealed lead-acid type) 12VDC, 4AH

Long Range Radio See note. See note. Primary telephone number messages can be reported

AC Power Supply See note. See note. Plug-in 120VAC transformer, ADEMCO 1321

NOTE: All devices and accessories used in a Canadian installation must be Listed for use in Canada.

2 2 Touch Screen (AUI) devices are in addition to the 8

addressable keypads. E.g., Symphony, 6270

Up to 5 for

up to 40

exp. zones

zones

Up to 16 Up to 8 Use any combination of 4204, 4229 and or Powerline

Partition 1

only

Using AAV

module

AMP output

Up to 2 for

up to 16

exp. zones

Up to 26 RF

zones

yes Provides access to the system via on premises or off-

Using AAV

module

12VDC, 2

AMP output

Zone numbers are predefined according to the device

addresses used. See Expander Module Addresses table

in Wiring section and set addresses accordingly.

Uses 5881/5883 Series Receivers/Transceivers.

Carrier Devices.

Map output devices via *79 Menu mode.

premises phones for arming, disarming, etc., plus

control of relay outputs and Powerline Carrier devices.

Use ADEMCO UVS or Eagle Model 1250; can be used

in conjunction with an output trigger to permit voice

dialog between an operator at the central station and

a person at the premises.

Can drive the compatible sounders; steady output for

burglary/panic, or temporal pulse (3 pulses – pause –

3 pulses – pause – 3 pulses. . .) for fire. Uses current

limiting circuitry for protection.

minimum.

via ECP connection to various Long Range Radios

(check compatibility/availability of specific models)

(1321CN in Canada) or, if using Powerline Carrier

devices, ADEMCO 1361X10 Transformer Module

Important Installation Highlights (Installer Please Read)

• This system uses addressable keypads and Zone Expander Modules (see Table of Addresses in

Section 2. Mounting and Wiring – Wiring the Keypads and Other Addressable Devices).

• Keypads must be set for addresses 16-23 (first keypad is address 16, which is different from

previous controls) and programmed in data fields *190-*196.

• Zone Expander Modules must be set for specific addresses (07-11), based on the zone numbers used.

• 4204 Relay Modules must be set for specific addresses (12-15).

• This control will not power-up unless AC power is connected (will not power-up on battery alone).

However, once the system is powered up, it will operate on battery power in the event of AC loss.

• Relays have two programming menu modes: Use *79 Menu mode to map module addresses and

device (output) numbers. Use *80 Menu mode to define the output functions.

• This system supports programmable function keys. Use *57 Menu mode to define the function

keys.

• This system provides various paging features. Refer to the Programming Overview section for a

summary on pager programming.

1-2

Page 7

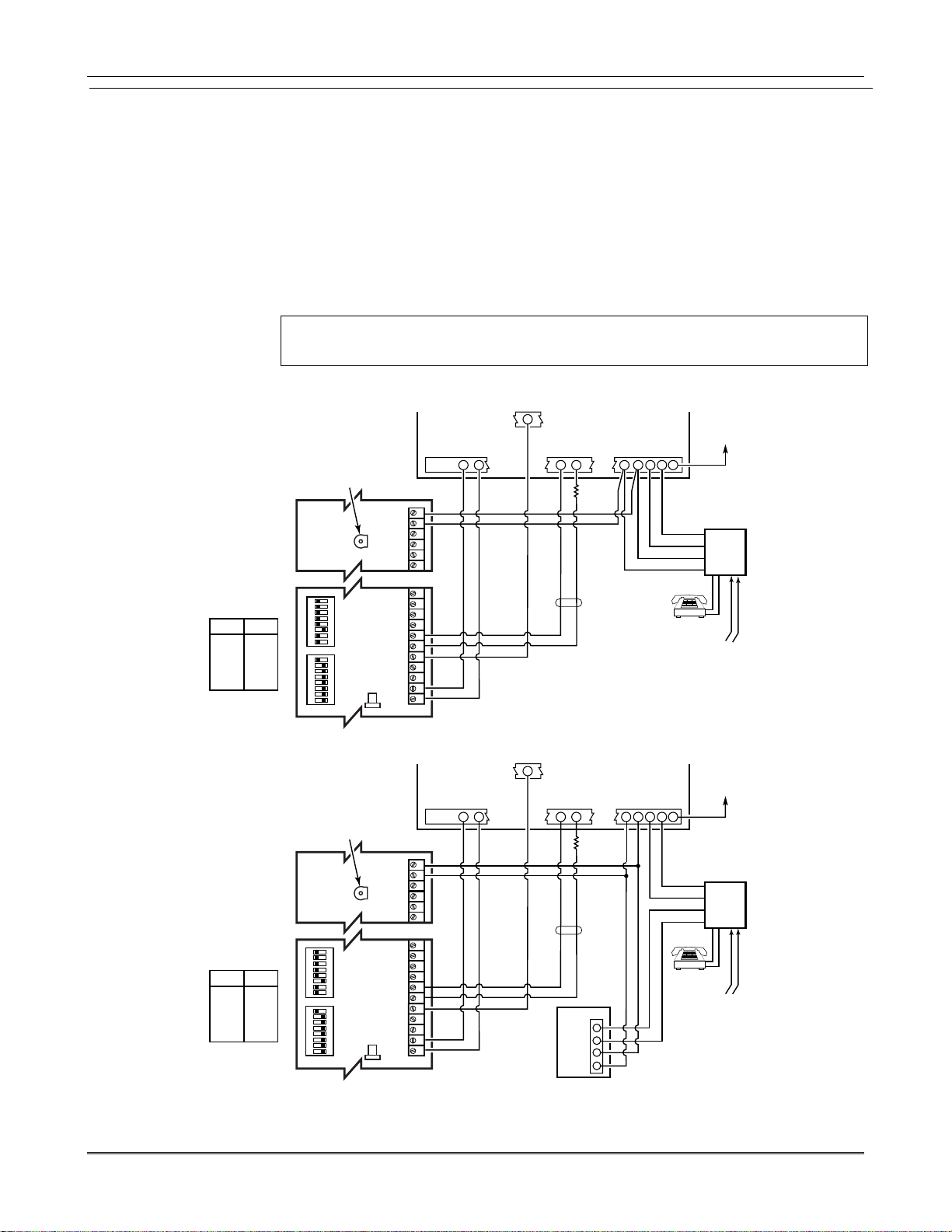

Mounting and Wiring the Control

Installing the Control Cabinet and PC Board

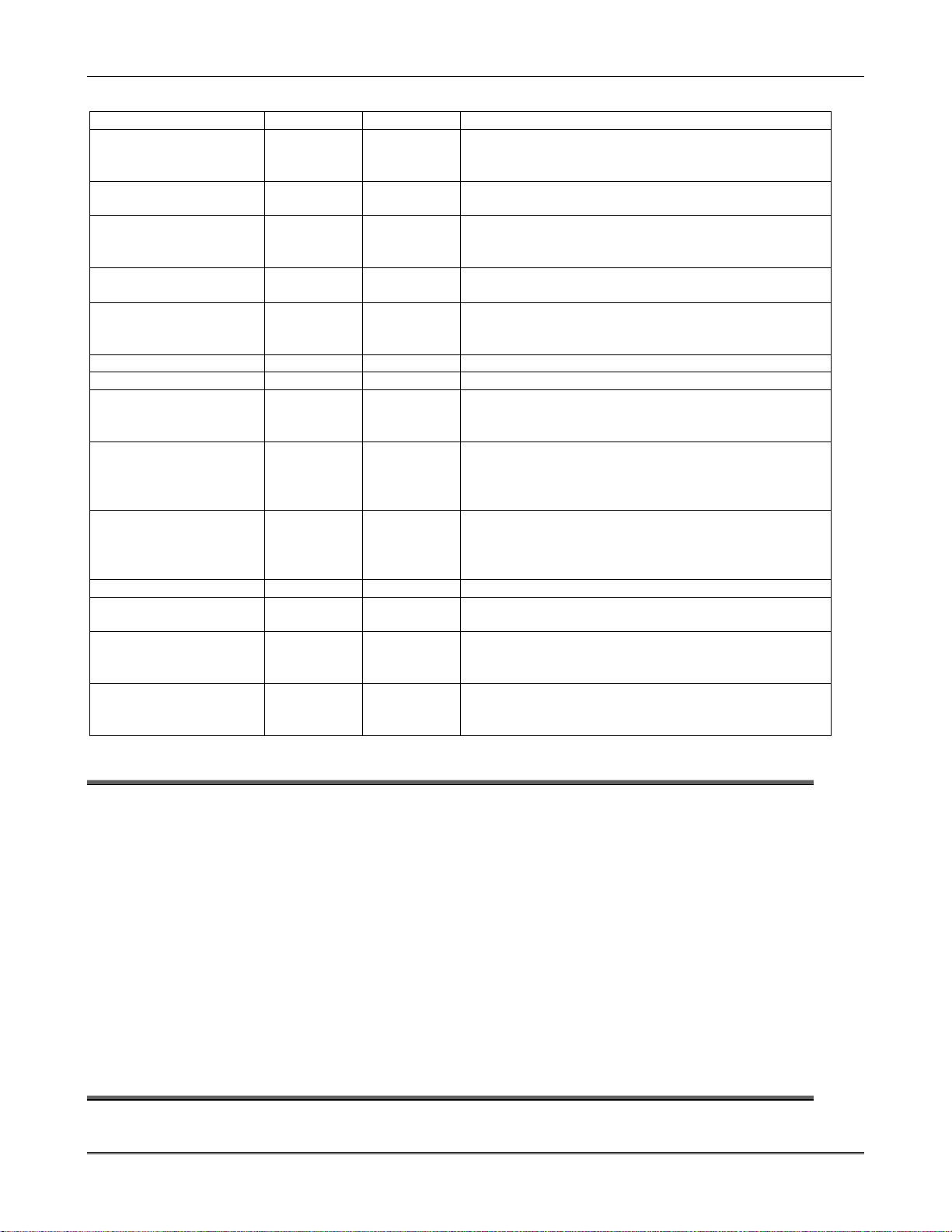

Cabinet and Lock

Mounting the PC Board

Alone (no RF Receiver)

1. Mount the control cabinet to a

sturdy wall in a clean, dry area,

which is not readily accessible to

the general public, using fasteners

or anchors (not supplied) with the

four cabinet mounting holes.

2. Remove cabinet door, then remove

the lock knockout from the door.

Insert the key into the lock.

3. Position the lock in the hole, making certain that the latch will make contact with the

latch bracket when the door is closed. When correctly positioned, push the lock until

the snap tabs hold it securely.

The cabinet can be secured without a lock by using 2 screws in the cover's edge.

Before installing the cabinet's contents, remove the metal cabinet knockouts required for

wiring entry. Do not remove the knockouts after the circuit board has been installed.

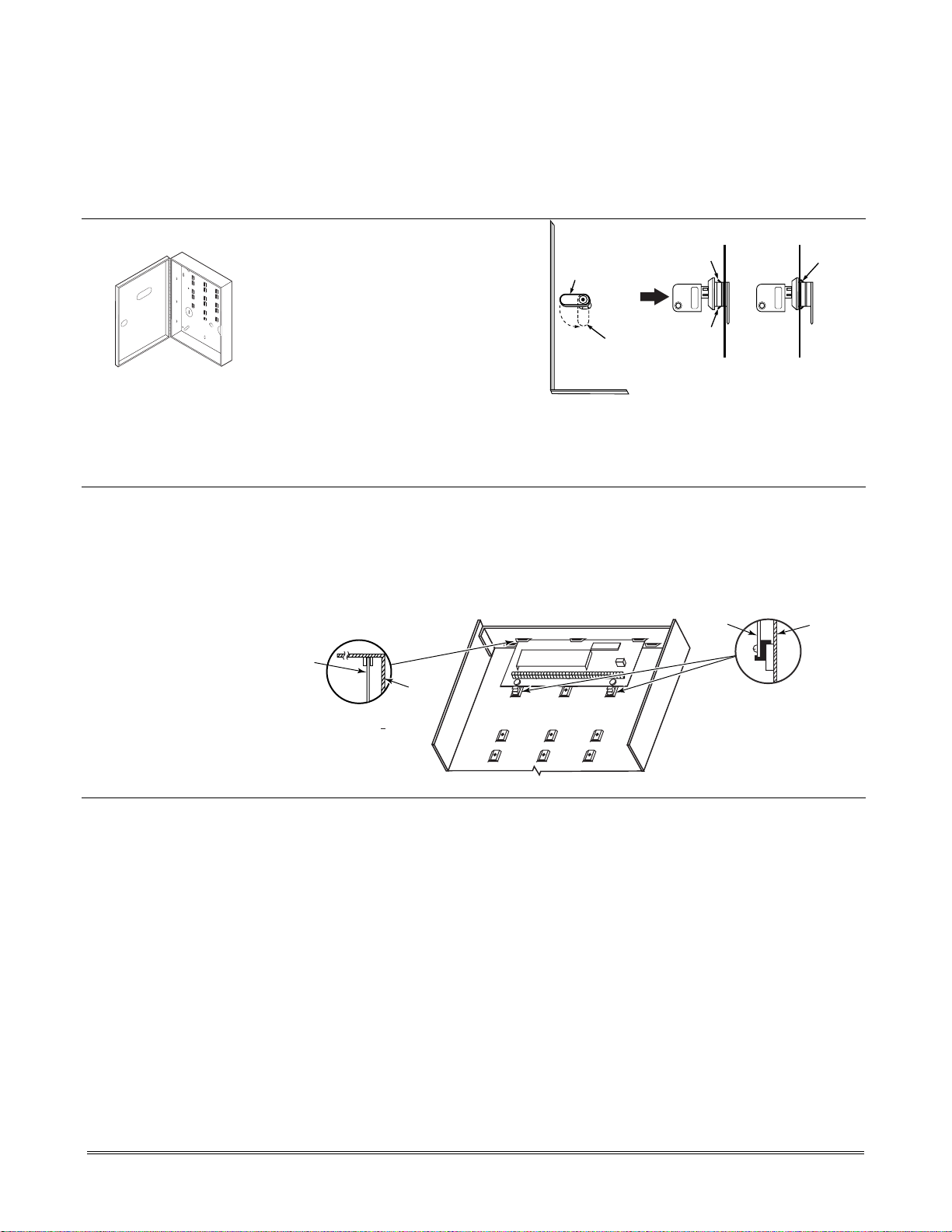

1. Hang two short mounting clips (provided) on the raised cabinet tabs (see Detail B).

2. a. Insert the top of the circuit board into the slots at the top of the cabinet. Make sure

that the board rests on the correct row (see Detail A).

b. Swing the base of the board into the mounting clips and secure the board to the

cabinet with the accompanying screws (see Detail B).

SECTION 2

CHECK

POSITION

LOCKED

UNLOCKED

CABINET DOOR

BOTTOM

PUSH

Figure 1. Installing the Cabinet Lock

SNAP

TAB

ADEMCO

SNAP

TAB

CIRCUIT

BOARD

STEP 2STEP 1

ADEMCO

PUSH

ON LOCK

UNTIL IT

IS SEATED

SECURELY

CABINET

cab_lock_snap-001-V0

Mounting Board with RF

Receiver

CIRCUIT

BOARD

DETAIL A

SIDE VIEW

OF BOARD

SUPPORTING

SLOTS

CABINET

+

+

DETAIL B

SIDE VIEW

OF MOUNTING

CLIPS

MOUNTING-001-V0

Figure 2. Mounting the PC Board

• Do not mount the cabinet on or near metal objects. This will decrease RF range and/or

block RF transmissions from wireless transmitters.

• Do not locate the cabinet in an area of high RF interference (revealed by frequent or

prolonged lighting of the LED in the receiver (random flicker is OK)

1. a. Remove the receiver board from its case, then insert the top of the board into the

slots at the top of the cabinet, as shown in Detail A in Figure 3 on the next page.

Make sure that the board rests on the correct row of tabs.

b. Swing the base of the board into the mounting clips and secure it to the cabinet

with the accompanying screws.

c. Insert the top of the control's board into the slot in the clips and position two clips

at the lower edge of the board.

d. Swing this board into place and secure it with two additional screws.

2. Insert grounding lugs (supplied with the receiver) through the top of the cabinet into

the left-hand terminals of the antenna blocks (at the upper edge of the receiver board)

and secure them to the cabinet top with the screws provided (see Detail B).

3. Insert the receiver's antennas through the top of the cabinet, into the blocks' right-

hand terminals, and tighten the screws.

2-1

Page 8

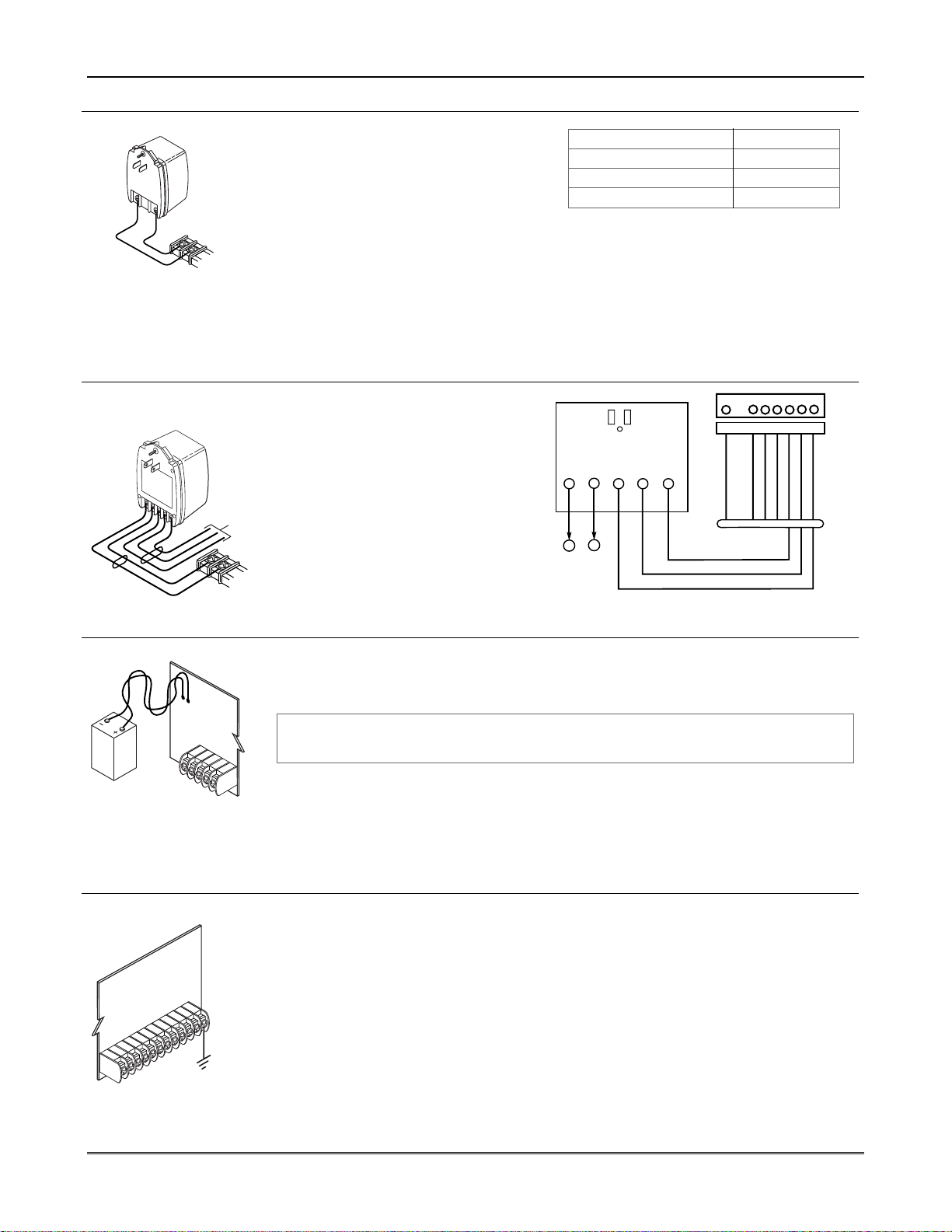

Installation and Setup Guide

CABINET

RECEIVER CIRCUIT BOARD

INSTALLATION WITH RECEIVER CIRCUIT BOARD

WHITE

MOUNTING

CLIP

NOTE

A COMBINATION OF THESE MOUNTING CLIPS HAS BEEN

INCLUDED IN YOUR INSTALLATION KIT.

USE THE APPROPRIATE CLIPS FOR MOUNTING.

IF NO RF RECEIVER IS USED, MOUNT THE PC BOARD USING

EITHER THE WHITE OR BLACK CLIPS, WHICHEVER ARE

INCLUDED IN THE CONTROL PANEL'S HARDWARE KIT.

AB

BOARD

SUPPORTING

RED

MOUNTING

CLIP

SLOTS

MOUNTING

CLIP

MOUNTING

CLIP

CIRCUIT

BOARD

DETAIL A

SIDE VIEW

OF BOARD -

SUPPORTING SLOTS

ANTENNA

(2)

SCREW

(2)

GROUNDING

LUG

(2)

ANTENNA

(2 PLACES)

DETAIL B

ANTENNA AND GROUNDING

LUG INSTALLATION

++

CONTROL

CIRCUIT

BOARD

BLACK

MOUNTING

CLIP

Figure 3. Mounting the PC Board and RF Receiver

CABINET

MOUNT

pc_mount-001-V1

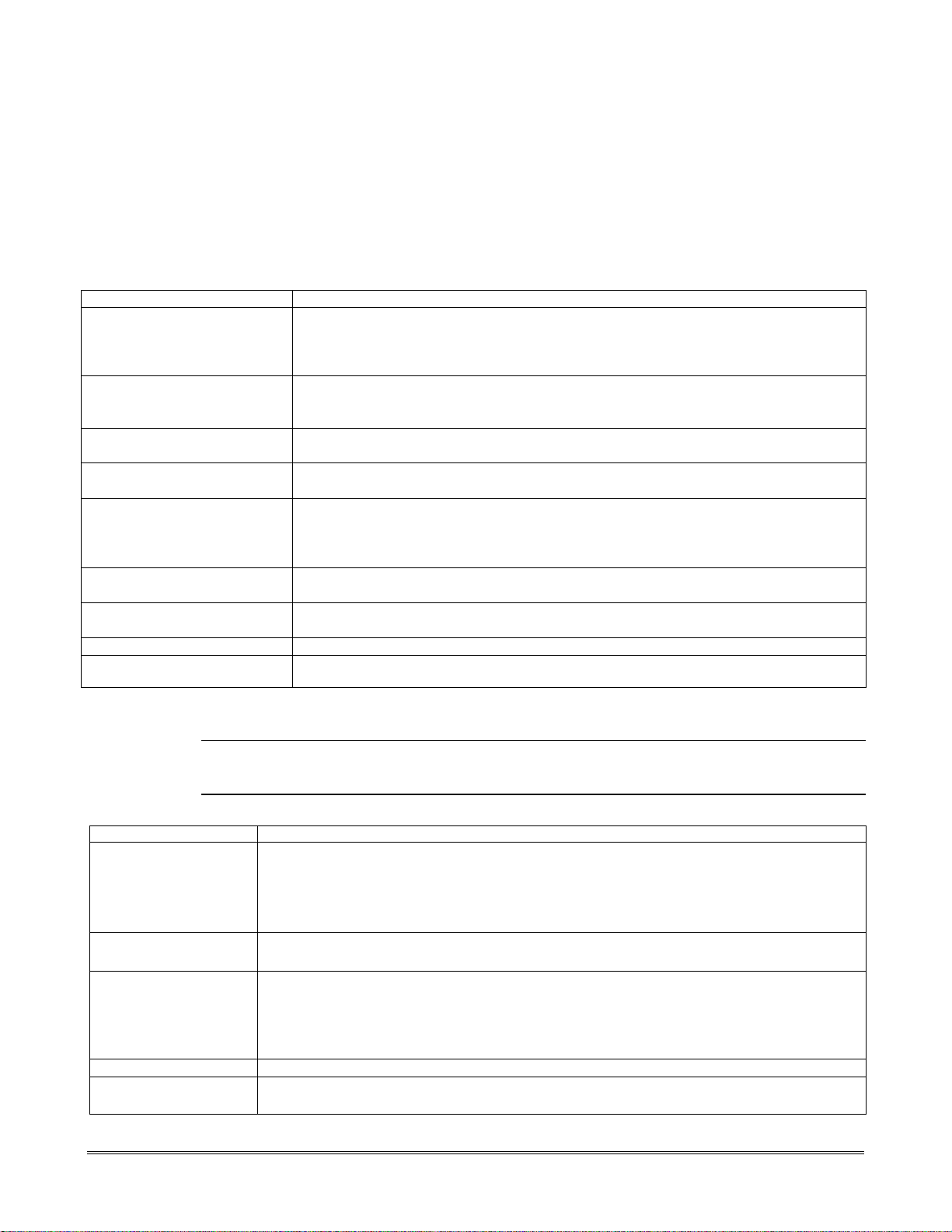

AUXILIARY DEVICE CURRENT DRAW WORKSHEET

6150 Fixed-Word Keypad 40mA/70mA**

6160 Alpha Keypad 40mA/150mA**

6150V Fixed-Word Display Voice Keypad 60mA/160mA**

6160V Alpha Display Voice Keypad 60mA/190mA**

8132/8142 Series AUI (Symphony) 150mA/400mA**

6270 Touch Screen Keypad 180mA/280mA**

5881/5882 RF Receiver 60mA

5883 Transceiver 80mA

4219 Zone Expander 30mA

4204 Relay Unit

4229 Zone Expander/Relay Unit

4285 Phone Module 160mA

4286 Phone Module 300mA

*

(Current available from Aux. terminals = 600 mA max.)

*If using hardwire devices such as PIRs, refer to the specifications for that particular unit's current draw.

** Values are for standby/alarm; alarm for keypads means armed with backlighting on and sounder on

†In UL installations, maximum current draw from the Auxiliary Output and the Alarm Output combined must not exceed 600 mA (500 mA max from Aux. Output).

‡Values are for relays OFF/relays ON.

The California State Fire Marshal and UL have regulations which require that all residential fire alarm control panels must be

provided with a backup battery which has sufficient capacity to operate the panel and its attached peripheral devices for 24 hours in

the intended standby condition, followed by at least 4 minutes in the intended fire alarm signaling condition. This control panel can

meet these requirements without using a supplementary power supply, provided that the panel’s auxiliary power and bell output

currents are limited as indicated below.

Output Current Total Maximum Auxiliary Current Battery Capacity

600mA maximum total of

auxiliary power plus bell

output currents

‡ NOTE: Use two batteries, connected in parallel. Obtain an Ademco Battery Harness Kit SA5140-1. (Both batteries will fit inside the cabinet.)

DEVICE CURRENT No. UNITS TOTAL CURRENT

15/180mA‡

30/100mA‡

†

TOTAL =

CALIFORNIA STATE FIRE MARSHALL (CSFM) AND UL RESIDENTIAL FIRE

24-HOUR BATTERY BACKUP REQUIREMENTS

OUTPUT CURRENT LIMITATIONS BATTERY INFORMATION

OUTPUT LIMITATIONS AND CORRESPONDING REQUIRED BATTERIES

Recommended Battery

45mA

160mA

200mA

425mA

500mA

To Use (Amp/Hrs)

4AH

7AH

8AH

14AH

17.2AH

(Yuasa Model No.)

NP4-12 (or ADEMCO 467)

NP7-12

NP4-12 (two) ‡

NP7-12 (two) ‡

NPG18-12

2-2

Page 9

AC Power, Battery, and Ground Connections

AC AC

SYNC

COM DATA

2

34

5

1

2

1

SA412OXM

CABLE

CONTROL

BOARD

TERMS.

1361X10 TRANSFORMER

1 345678

8-PIN TRIGGER CONNECTOR

KEY

+12 AUX.

DATA

COM

SYNC

GND (-)

OUTPUT 17

(RED)

OUTPUT 18

(GREEN)

(ORANGE)

(YELLOW)

(BLUE)

(PURPLE)

(BLACK)

1321 Transformer

1361X10 Transformer

(required if using

Powerline Carrier devices)

Battery Connections

Battery Saver Feature

Earth Ground

TERMINALS

1 AND 2

BLACK

TO

AC

AC

S

y

n

c

O

u

tp

S

ig

u

t

n

a

C

l

o

m

m

X

1

o

0

n

D

a

ta

RED

CONNECT

FLYING LEADS

AFTER AC POWER

IS APPLIED

CONTROL BOARD

25

1

2

CONNECTOR

TO

TERMINALS

1 AND 2

CONNECT

PROPER

EARTH

GROUND

IF

DESIRED

1321X10-001-V0

TO

8-PIN

1

2

Mounting and Wiring the Control

Connect the 1321 Transformer (1321CN in

Canada) to terminals 1 and 2 on the

control board. See Wire Run Chart for

wire size to use.

• Use caution when wiring the

transformer to the control to guard

against blowing the transformer fuse

(the fuse is non-replaceable).

• Wiring to the AC transformer must not exceed 250 feet using 16 gauge wire. The

voltage reading between terminals 1 and 2 of the control must not fall below 16.5VAC

or an “AC LOSS” message will be displayed.

• Do not plug the transformer into the AC outlet until all wiring connections to the

control are complete. As a safety precaution, always power down the control when

making such connections.

1. Splice one end of a 3-conductor cable

to the wire ends of the SA4120XM-1

Cable.

2. Connect the SA4120XM-1 cable plug

to the 8-pin connector on the control

(see the Summary of Connections

diagram for location of the 8-pin

connector).

3. Connect the other end of the

3-conductor cable to the 1361X10

Transformer, as shown in Figure 4.

Canadian Installations: See

Powerline Carrier Device section for

1361X10-001-V0

connections to the PSC04 X-10 Interface

and trigger pins.

1. Place the 12-volt backup battery in the cabinet.

2. After all connections to the control are completed and AC power has been applied,

connect the red and black flying leads on the control board to the battery. Do not

attach these leads to the battery terminals until all connections are completed.

U

For UL installations and Residential fire installations, refer to the chart on page 2-2

L

at left for the correct battery size required to meet the mandatory standby time.

batt_conn-001-V0

The battery will disconnect from the system after its voltage decreases below 9VDC.

This assists the control panel in recharging the battery when AC is restored.

IMPORTANT: The panel will not power up initially on battery power only. You must

plug the transformer in first, and then connect the battery.

• This product has been designed and laboratory-tested to ensure its resistance to

damage from generally expected levels of lightning and electrical discharge, and does

not normally require an earth ground.

• If an earth ground is desired for additional protection in areas of severe electrical

activity, terminal 25 on the control board, or the cabinet, may be used as the ground

connection point. The following are examples of good earth grounds available at most

installations.

Metal Cold Water Pipe: Use a non-corrosive metal strap (copper is recommended) firmly

secured to the pipe to which the ground lead is electrically connected and secured.

AC Power Outlet Ground: Available from 3-prong, 120VAC power outlets only. To test

earth_gnd-001-V0

the integrity of the ground terminal, use a 3-wire circuit tester with neon lamp

indicators, such as the UL Listed Ideal Model 61-035, or equivalent, available at most

electrical supply stores.

Wire Run Chart

Distance from control Wire Size

Up to 50 feet # 20

50–100 feet # 18

100-250 feet # 16

Figure 4. 1361X10 Transformer Connections

2-3

Page 10

Installation and Setup Guide

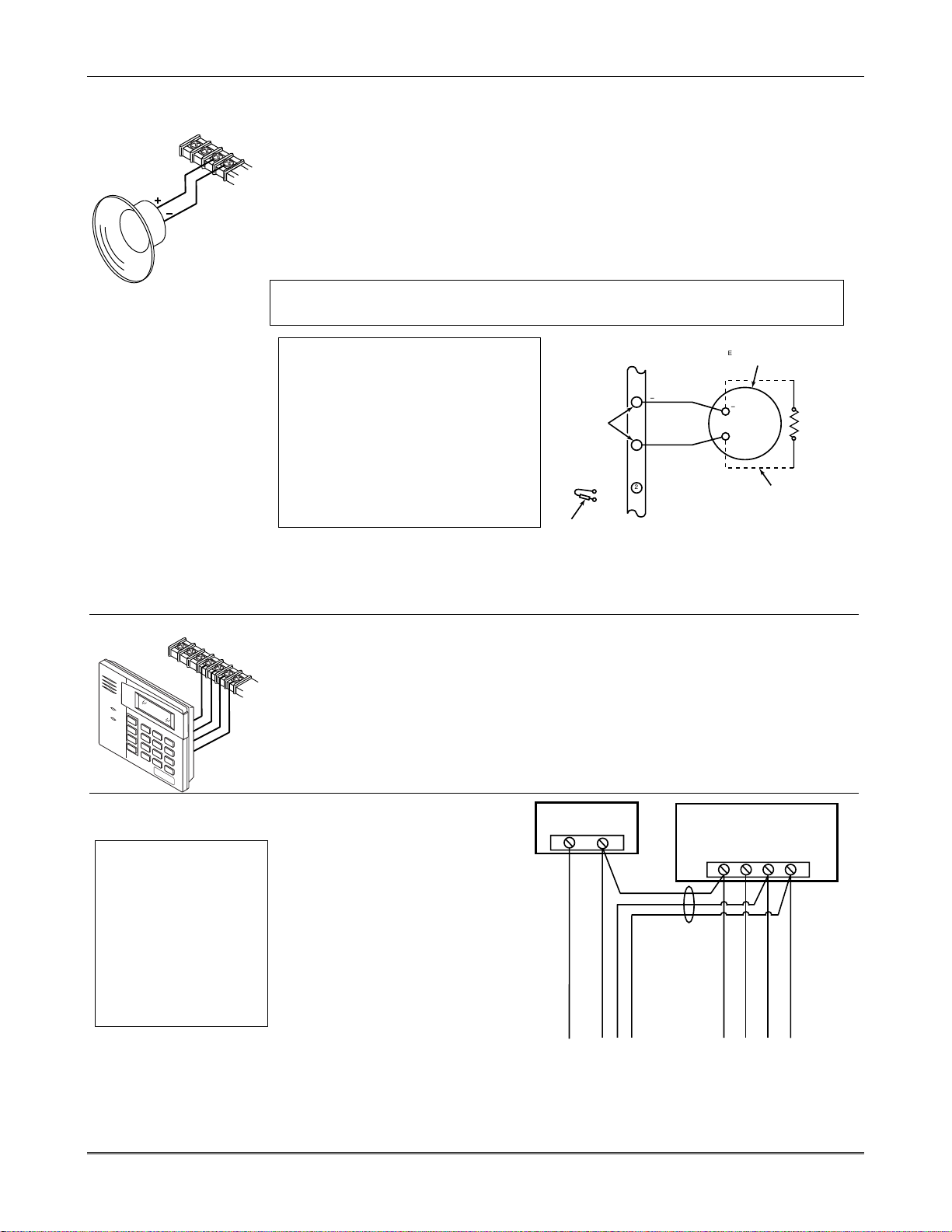

Sounder (Bell) Connections

Basic Connections

ALARM OUTPUT

10.5 - 13.5 VDC

2A MAX.

Make sounder connections to alarm output terminals 3 (+) and 4 (–).

• The 12VDC sounder output activates when an alarm occurs.

3

4

• Total current drawn from this output cannot exceed 2 amps (going beyond 2 amps will

overload the power supply, or may cause the electronic circuit protecting the sounder

output to trip).

• You must install a battery, since the battery supplies this current.

Supervised output

1. Cut the red Bell Supervision Jumper located above terminals 2 and 3 on the PC board.

2. Connect a 2k ohm resistor across the terminals of the last sounder. See Figure 5.

spkr_conn-001-V0

This control complies with NFPA requirements for temporal pulse sounding of fire notification

appliances. Temporal pulse sounding for a fire alarm consists of: 3 pulses – pause – 3 pulses –

pause – 3 pulses–etc..

U

L

• Use only UL Listed sounding devices for

UL installations.

• Bell supervision is required for fire alarm

installations.

• The total current drawn from the alarm

ALARM

OUTPUT

TERMINALS

output and the auxiliary power output,

combined, cannot exceed 600 mA. In

addition, the sounding device must be a

UL Listed audible signal appliance rated

to operate in a 10.2-13.8 VDC voltage

range, and must be mounted indoors.

CUT RED JUMPER ON CONTROL

BOARD TO ENABLE BELL

(SOUNDER) SUPERVISION.

Figure 5. Sounder Wiring (Supervised)

Connecting the Keypads and Other Addressable Devices

Connections

A

R

M

E

D

R

E

A

D

Y

_

4

+

5

BLACK

RED

GREEN

YELLOW

Connect keypads and other addressable devices (4204, 4219, 4229, 4286, 5881, LRR,

etc.) to the control’s keypad terminals as shown on the Summary of Connections

diagram. The system supports up to 8 keypads, which can be assigned to partitions in

6 IN

7 OUT

any combination (see program fields *190-*196).

Determine wire size using the Wire Run Chart on the following page. For single 4-wire

runs, determine the current drawn by all units, then refer to the Wiring Run chart to

determine the maximum length that can be safely used for each wire size.

TERMINALS ON

CONTROL BOARD

_

4

+

3

2

EXTERNAL ALARM

SOUNDER

_

OBSERVE

POLARITY

+

IF BELL SUPERVISION IS ENABLED

(RED JUMPER ON CONTROL BOARD IS CUT)

CONNECT A 2000 OHM RESISTOR ACROSS

THE EXTERNAL SOUNDER AS SHOWN BY

THE DOTTED LINE.

DO NOT CONNECT THE RESISTOR AT THE

ALARM OUTPUT TERMINALS THEMSELVES!

2000

OHM

EOL

RESISTOR

sounder-001-V0

Supplementary Power

(optional)

U

Use a UL Listed,

L

battery-backed supply for

UL installations. The battery

supplies power to these

keypads in case of AC

power loss.

The battery-backed power

supply should have enough

power to supply the

keypads with the UL

required minimum standby

power time.

2-4

conn-001-V0

Use supplementary power if the

control’s aux. power load for all

devices exceeds 600mA (suggested

power supply: AD12612). Connect

as shown in Figure 6. Be sure to

connect the negative (–) terminal

on the power supply unit to

terminal 4 (AUX –) on the control.

IMPORTANT: Keypads

powered from supplies that do

not have a backup battery will

not function if AC power is lost.

Make sure to power at least one

keypad in each partition from

the control’s auxiliary power

output.

SUPPLEMENTARY

POWER SUPPLY

+

–

TO KEYPAD RED WIRE

TO KEYPAD BLK WIRE

TO KEYPAD GRN WIRE

TO KEYPAD YEL WIRE

CONTROL TERMINAL STRIP

IMPORTANT:

MAKE THESE

CONNECTIONS

DIRECTLY TO

SCREW

TERMINALS AS

SHOWN.

AUX. DATA

AUX.

IN

+

–

456 7

TO KEYPAD BLK WIRE

TO KEYPAD RED WIRE

TO KEYPAD GRN WIRE

DATA

OUT

supp_pwr_supply-V0

TO KEYPAD YEL WIRE

Figure 6. Using a Supplementary Power Supply

Page 11

Mounting and Wiring the Control

Keypad Notes

Set device addresses. Refer to the instructions included with the devices and set each

address according to the Table of Devices Addresses.

See Keypad Programming Fields (fields *190-*196) in Section 4. Data Field

ARMED

READY

1

O

F

F

2

A

W

4

A

Y

M

A

X

3

S

T

5

A

Y

T

E

7

S

T

IN

ST

ANT

6

B

Y

P

8

A

S

S

C

O

D

E

R

E

A

D

Y

9

C

H

I

0

M

E

#

Programming for details on enabling keypad addresses, assigning keypad partitions

and selecting keypad sounding options.

IMPORTANT: Each keypad must be assigned a unique, predefined address, from 16 to

23. The first keypad is address 16 (default = partition 1, all sounds enabled).

TOUCH SCREEN KEYPAD (AUI) NOTES:

•••• Use of up to 2 AUI devices (e.g., 6270, Symphony) is independent from standard

keypads and does not affect the number of standard keypads the system can support.

•••• AUI devices must be set for either address 1 or address 2, depending on which unit is

enabled in field *189.

•••• To ensure proper AUI device operation, connect only to controls having microprocessor

version 3.0 or higher, and use AUI devices with the following rev levels: 6270 series

use version 1.0.9 or higher; 8132/8142 (Symphony) series use version 1.1.175 or higher.

Long Range Radio

Connections

Connect the data in/data out terminals and voltage input terminals of the Long Range

Radio to the control's keypad connection points.

Set the radio’s address to “03” following the instructions provided with the radio.

• Use compatible Long Range Radios (e.g., 7720PLUS, 7820, 7835C, or 7845C).

Wire Run Chart For Devices* Drawing Aux Power From The Control (12V+ & 12V–)

Wire

TOTAL CURRENT DRAWN BY ALL DEVICES CONNECTED TO A SINGLE WIRE RUN

Size 50 mA or less 100 mA 300 mA 500 mA 600 mA

#22 900 ft (274m) 450 ft (137m) 150 ft (46m) 90 ft (27m) 75 ft (23m)

#20 1400 ft (427m) 700 ft (213m) 240 ft (73m) 140 ft (43m) 120 ft (37m)

#18 1500 ft (457m) 1100 ft (335m) 350 ft (107m) 220 ft (67m) 170 ft (52m)

#16 1500 ft (457m) 1500 ft (457m) 550 ft (168m) 350 ft (107m) 270 ft (82m)

* Includes Keypads, RF Receivers, Zone Expander/Relay Units, 4285/4286 Phone Module, and Long Range Radio.

Maximum wire lengths for any device that is homerun to the control can also be determined from the Wiring Run Chart, based on the

current draw of that device alone

The length of all wire runs for both partitions combined must not exceed 1500 feet (457m) when unshielded quad conductor cable is used

(750 feet if shielded cable is used). This restriction is due to the capacitive effect on the data lines when quad cable is used.

.

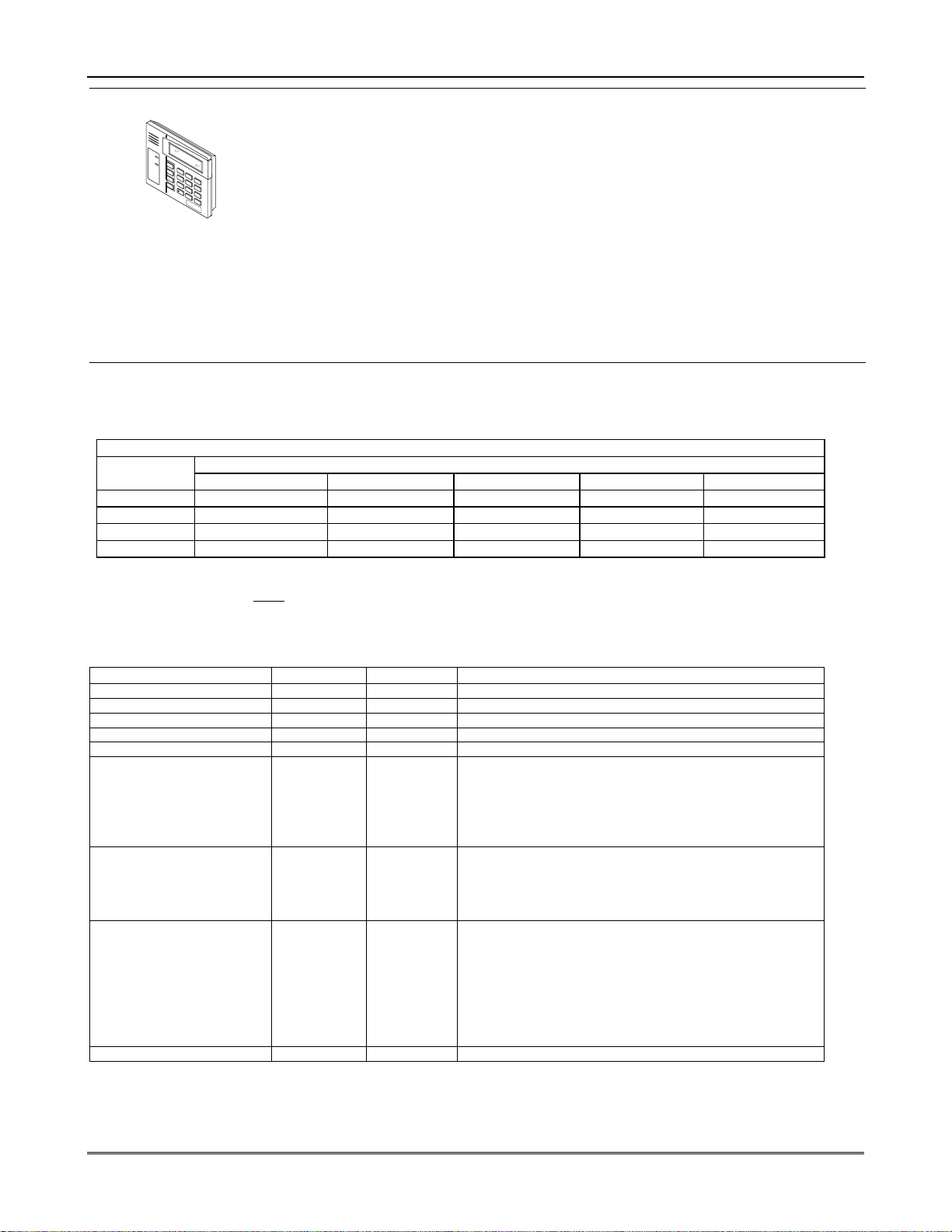

Table of Device Addresses

††

This Device Uses Address

Reports as

RF Receiver 00 100 *56 zone programming: input device type entry

AUI 1 01 101 automatic if AUI enable field *189 enabled for AUI 1

AUI 2 02 102 automatic if AUI enable field *189 enabled for AUI 2

Long Range Radio 03 103 automatic if output to long range radio field *29 enabled

4286 Voice Module 04 104 automatic if phone module access code field *28 enabled

Zone Expanders (4219/4229):

module 1 (for zones 09 - 16)

module 2 (for zones 17 - 24)

module 3 (for zones 25 - 32)

module 4 zones 33 - 40

module 5 zones 41 - 48

Relay Modules (4204):

module 1

module 2

module 3

module 4

Keypads:

keypad 1

keypad 2

keypad 3

keypad 4

keypad 5

keypad 6

keypad 7

keypad 8

5800TM Module 28 n/a automatic

07**

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

†

†

†

†

†

107

108

109

110

111

112

113

114

115

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

** address 07 not available if zone-doubling enabled

† 4219/4229 addresses 9-11 and 4204 addresses 14-15 apply to the VISTA-20P.

†† Addressable devices are identified by “1” plus the device address when reporting. Enter a report code for zone 91 to enable

addressable device reporting (default = reports enabled). See field *199 for addressable device (ECP) 3-digit/2-digit identification

keypad display options.

Enabled By…

*56 zone programming: input device type, entry 2, then:

automatic if zone no. 9-16 set as AW type or relay assigned

automatic if zone no. 17-24 set as AW type or relay assigned

automatic if zone no. 25-32 set as AW type or relay assigned

automatic if zone no. 33-40 set as AW type or relay assigned

automatic if zone no. 41-48 set as AW type or relay assigned

*79 output device programming: device address prompt:

entered at device address prompt

entered at device address prompt

entered at device address prompt

entered at device address prompt

data field programming as listed below:

always enabled for partition 1, all sounds enabled.

data field *190

data field *191

data field *192

data field *193

data field *194

data field *195

data field *196

2-5

Page 12

Installation and Setup Guide

Hardwire Zones and Zone Expansion

Hardwire Zones

HI

LO

Double-Balanced Zones

(V20P only)

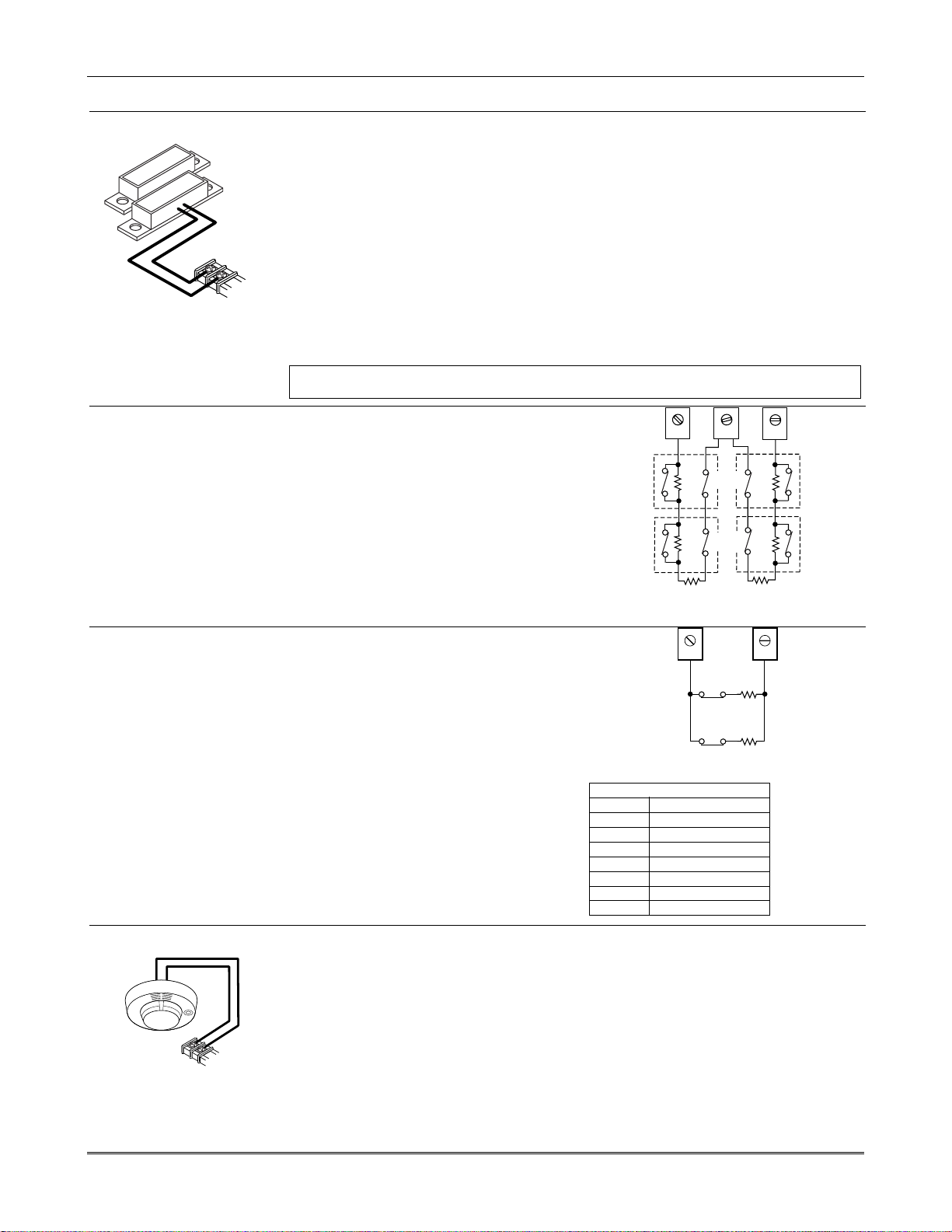

Normally Open Zones/ N.O. EOLR Zones

1. Connect open circuit devices in parallel across the loop; for EOLR zones, connect the

EOLR across the loop wires at the last device.

2. Enable normally open/EOLR zones using Zone Programming mode, “Hardwire Type”

prompt.

Normally Closed Zones/ N.C. EOLR Zones

1. Connect closed circuit devices in series in the high (+) side of the loop; for EOLR

zones, connect the EOLR in series following the last device.

2. Enable normally closed/EOLR zones using Zone Programming mode, “Hardwire

Type” prompt.

zones-001-V0

End of Line Resistor (EOLR) Notes

• If the EOLR is not at the end of the loop, the zone is not properly supervised and the

system may not respond to an “open” on the zone.

• Zone 1 is intended for EOLR only.

U

For UL commercial burglar alarm installations, use EOLR zones.

L

Connect as shown below (resistor provided

for one device).

IMPORTANT: Double-balanced zones

provide zone tamper protection, and should

be used as burglary zones only.

Do not use double-balanced zones as fire

zones.

12 13

TAMPER

2k

CONTACTS

TAMPER

2k

CONTACTS

14

2k

2k

Zone Doubling

(V20P only)

Smoke Detectors

2-WIRE

SMOKE

DETECTOR

HI

LO

ZONE 1

TO ZONE 1

TERMINALS

8

2k

ZONE 3

Fig. 7. Typical Double Balanced Zones

2k

ZONE 4

zone-002-V0

This feature provides two hardwired

normally closed zones for each standard

10 11

hardwired zone connected to the control’s

terminals (but does not increase the total

number of zones supported by the control). If

enabled (Zone Programming mode,

“Hardwire Type” prompt, option “3”),

hardwire zones are automatically paired as

shown in the table. Connect as shown below

(resistors provided).

•••• Do not use zone doubling for fire

zones.

NOTE: A short across the EOL (i.e., at

terminal) on either zone of a zone-doubled

pair or on a double-balanced zone causes a

tamper condition (displayed as CHECK plus

zone numbers).

Fig. 8. Typical Zone Doubling Wiring

Zone Doubling Table

Zone Paired with zone

2 10

3 11

4 12

5 13

6 14

7 15

8 16

ZONE 2

ZONE 10

3k

6.2k

zone-004-V0

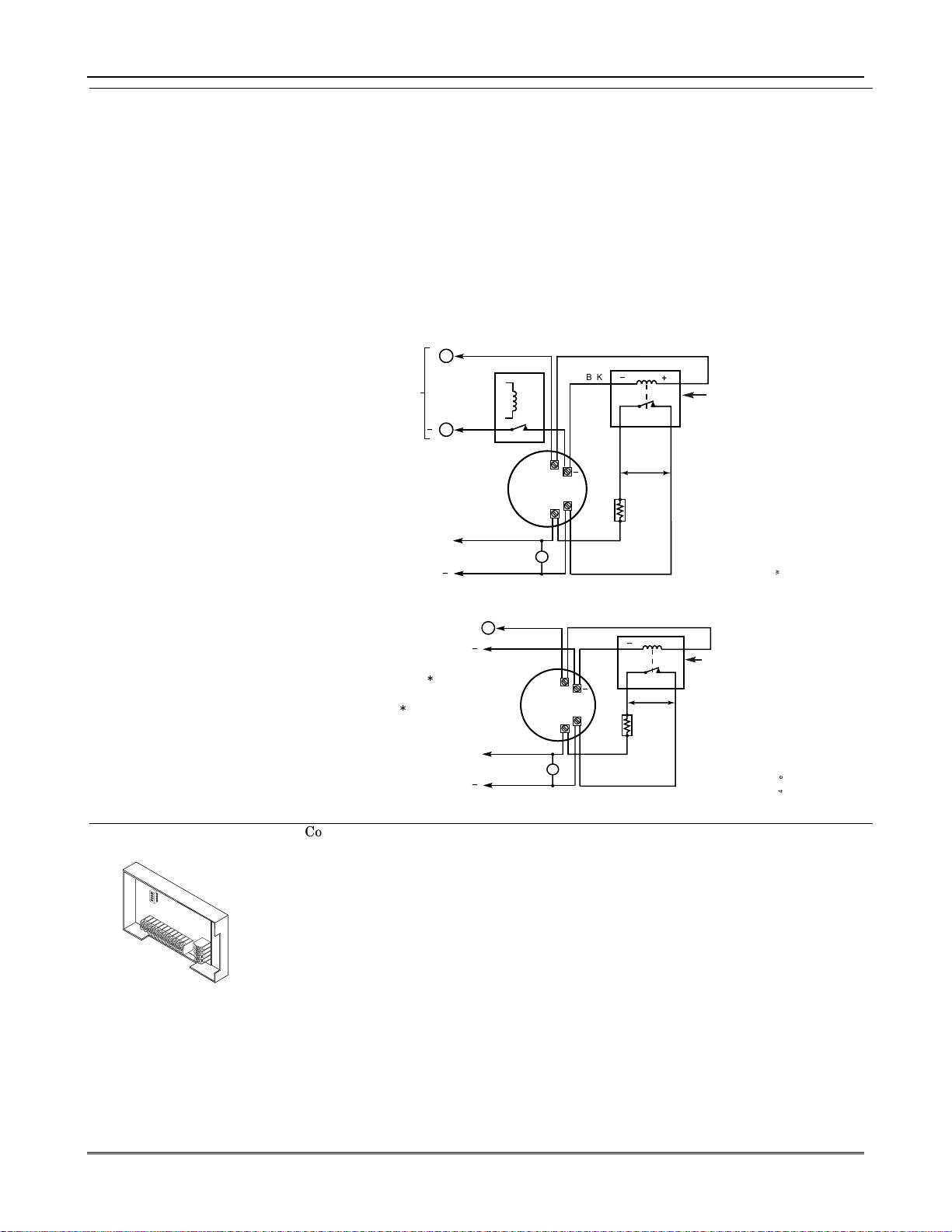

1. Connect up to 16 (10, if “clean me” option used) 2-wire smoke detectors across zone 1

terminals 8 (+) and 9 (-) as shown in the Summary of Connections diagram at the

back this manual. Observe proper polarity when connecting the detectors.

2. Connect an EOL resistor across the loop wires at the last detector.

3.

Connect 4-wire smoke detectors (up to 16, depending on detector current draw) to

any zone from 2-8 as shown in Figure 7 (on next page).

9

Power Reset: This control does not automatically reset power to 4-wire smoke

detector zones, so you must use a relay (e.g., 4204, 4229), or on-board trigger to reset

5806-001-V0

power (also required for fire verification). Do this by programming the designated

relay/trigger as zone type 54 (fire zone reset); see On-Board Trigger section for

other information.

NOTE: Maximum current on trigger 17 is 100mA.

2-6

Page 13

Smoke Detector Notes

4219/4229 Expansion

Zones

Mounting and Wiring the Control

•••• Fire Verification (zone type 16): The control panel will “verify” a fire alarm by

resetting the smoke detectors after the first alarm trigger, and then waiting 90 seconds

for a second alarm trigger. If the smoke detector or thermostat does not trigger again,

the control will disregard the first trigger, and no alarm signal will occur. This feature

eliminates false alarms due to electrical or physical transients.

SIA Installations: If using fire verification on zones other than zone 1, UL Fire Alarm

Listed relay accessories must be used to reset power as described in the Power Reset

paragraph above.

• The zone 1 alarm current supports only one smoke detector in the alarmed state.

•••• Clean Me Option: If enabled (field *174 = 1; *56 zone programming, response time

prompt = 3), certain ESL smoke detectors send “clean me” reports as appropriate. If

used, the maximum number of detectors is reduced to 10 (not standard 16). Refer to the

ESL documentation included with the smoke detector for information regarding

compatibility with the clean-me option.

• Do not use 4-wire smoke detectors on zone 1.

5

+

AUX PWR

OUTPUT

TERMINALS

_

CONTACT OPENS

MOMENTARILY UPON

FIRE ALARM RESET

TO ZONE TERM. ( )

TO ZONE TERM. ( )

PROGRAM

AS ZONE

TYPE 54

(FIRE ZONE

4

+

_

RELAY

RESET)

RELAY

N.C.

OR COMBUSTION

HEAT

DETECTOR

4-WIRE SMOKE

DETECTOR

Figure 9a. 4-Wire Smoke Detector Using Relay for Power Reset

+

( )

_

( )

+

_

5

DETECTOR

4-WIRE SMOKE

OR COMBUSTION

DETECTOR

HEAT

AUX PWR

TO OUTPUT 17

PROGRAM OUTPUT 17

FOR "OUT NORM

LOW" = YES IN 79 MENU

MODE AND AS ZONE

TYPE 54 IN

80 MENU MODE

TO ZONE TERM. ( )

TO ZONE TERM. ( )

Figure 9b. 4-Wire Smoke Detector Using Output 17 for Power Reset

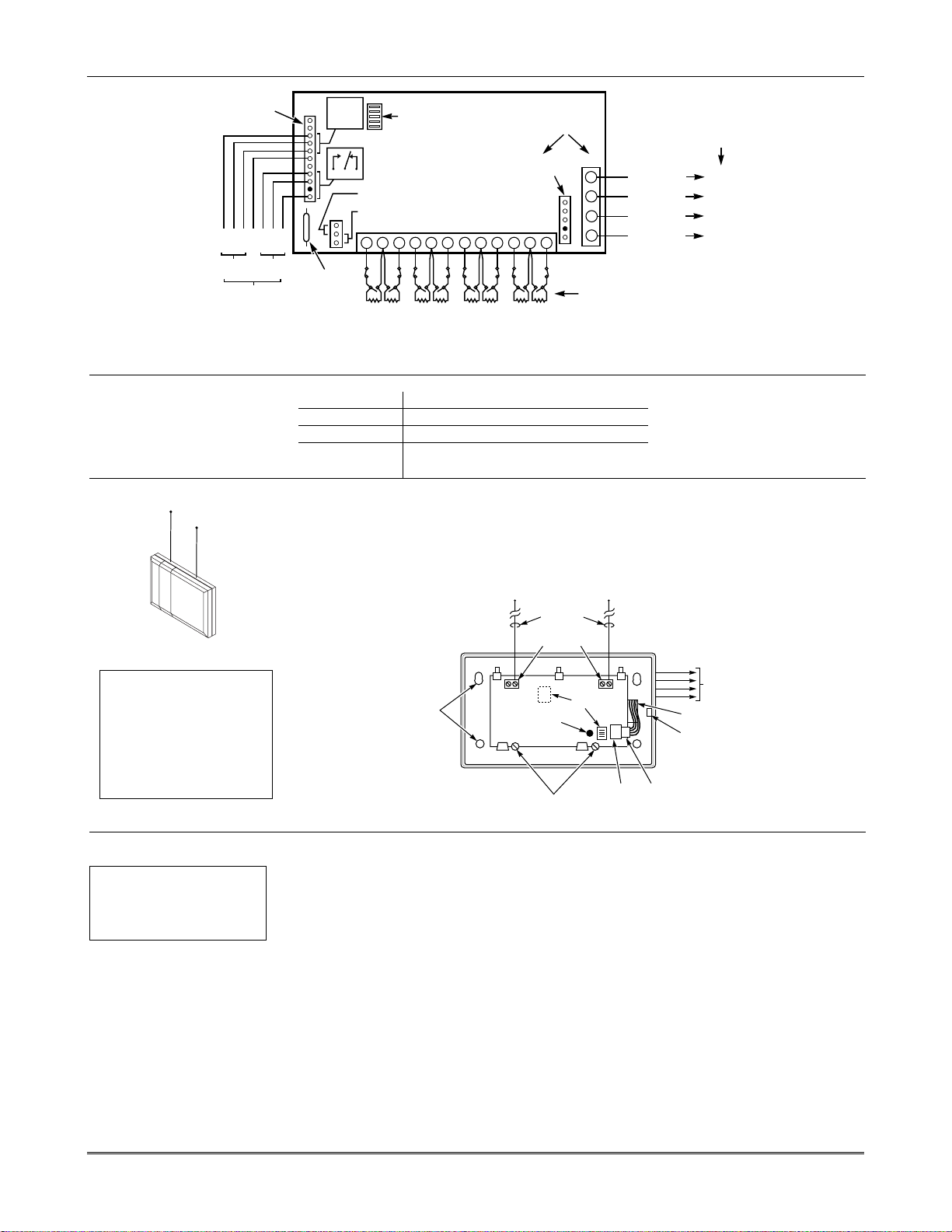

1. Connect each module to the control’s keypad terminals and set the device addresses.

• VISTA-20P: Up to 40 expansion zones using up to 5 Zone Exp. Modules.

• VISTA-15P: Up to 16 expansion zones using up to 2 Zone Exp. Modules.

2. Connect sensors to the module’s loops. See Figure 8 on the following page.

• Use 1000 ohm end-of-line resistors at the end of loops connected to the 4219/4229

modules. (EOLRs used on the control terminals are 2000 ohms.)

•

Expansion zones have normal response time (300–500 msec), except zone connected

to each module’s loop “A,” which can be set for fast response (10–15 msec).

3. If using relays with the 4229, connect the desired field wiring to the unit's relay contact

terminals.

_

BLK

+

_

2000

OHMS

EOLR

VIOLET

_

BLK

+

_

2000

OHMS

EOLR

N.O.

N.O.

VIOLET

+

+

RED

EOL

POWER

SUPERVISION

RELAY MODULE

A77-716B.

USE N.O.

CONTACT,

WHICH CLOSES

WHEN POWER

IS APPLIED.

RED

EOL

POWER

SUPERVISION

RELAY MODULE

A77-716B.

USE N.O.

CONTACT,

WHICH CLOSES

WHEN POWER

IS APPLIED.

4_wiresmk-007-V0

4_wiresmk-008-V0

2-7

Page 14

Installation and Setup Guide

The 6150rf is a Medium receiver

only capable of support 16 wireless

zones

RELAY

CONNECTOR

VIO

BLK

GRY

WHT

NONCC

RLY

2

RELAYS OFF

GND

YEL

NONCC

RLY

ORG

1

BRN

NO C NC

REED

(TAMPER)

SWITCH

ZONES

RELAY

2

RELAY

1

TAMPER JUMPER POSITION

4229 IN CABINET

(NOT TAMPER)

4229 REMOTE

(TAMPER PROTECTED)

1

A

DIP SWITCH

FOR SETTING ADDRESS

AND ZONE "A" RESPONSE

2

4 6

5

3

C

B

EITHER OR BOTH CAN BE USED

4-PIN CONSOLE PLUG

TB1

8

9

7

10

E

D

F

12

11

GH

4229

TB2

4

3

4

3

2

2

1

1

TERMINATE EACH

PROGRAMMED ZONE

WITH 1000 OHM (1K)

END-OF-LINE RESISTOR

(EACH ZONE'S MAX.

LOOP RESISTANCE

300 OHMS + EOL)

Figure 10. Wiring Connections, 4219 & 4229 (4229 shown)

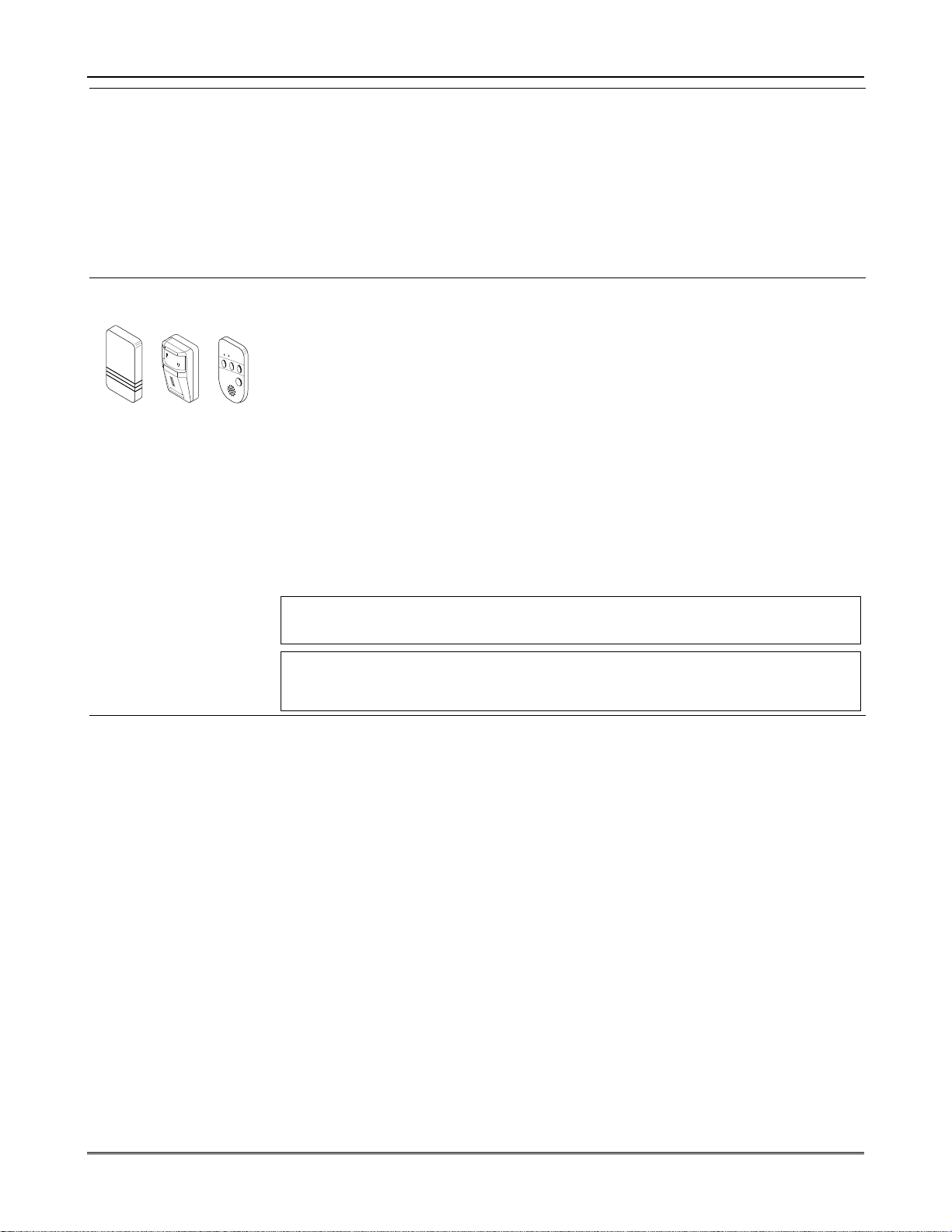

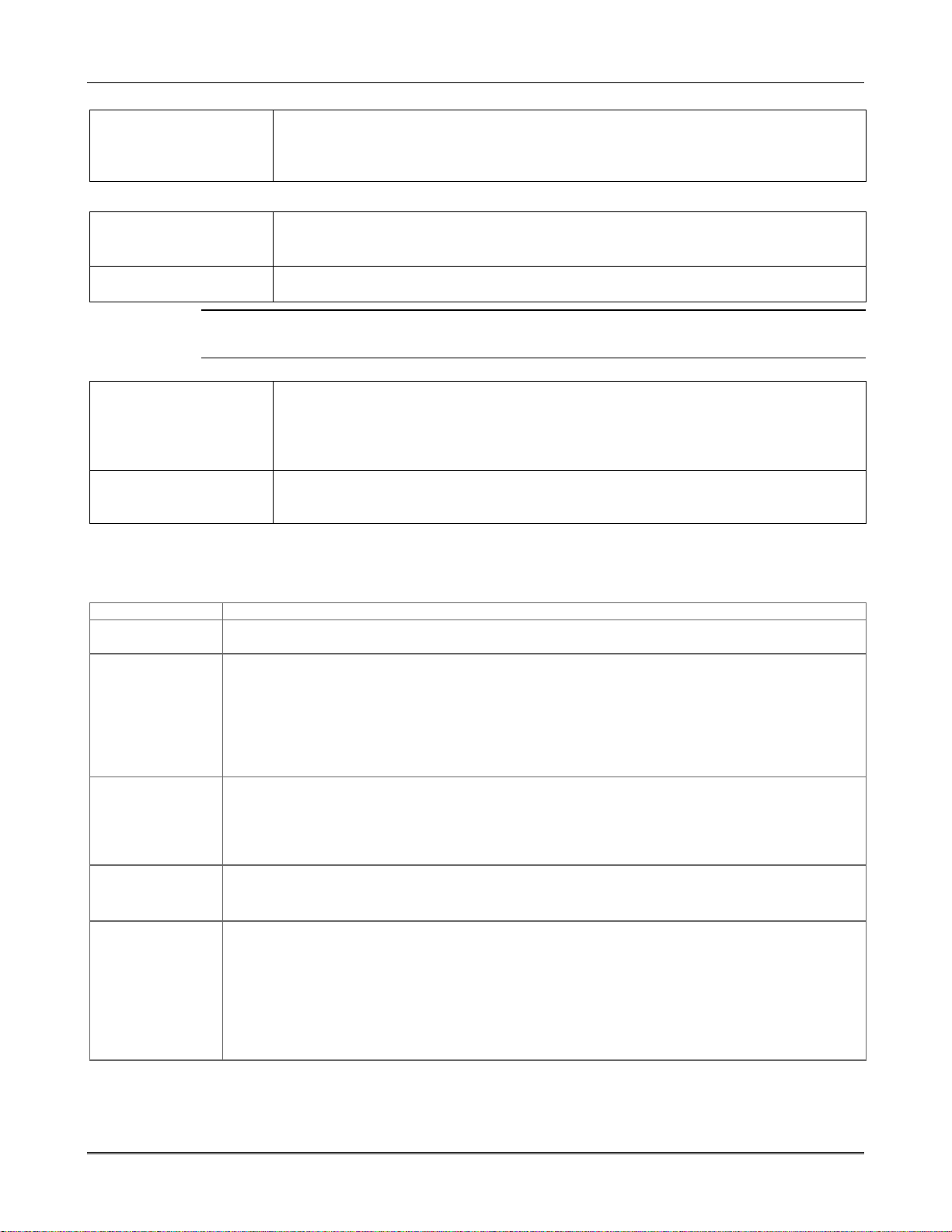

Installing the RF Receiver and Wireless Transmitter Zones

Compatible Receivers

Receiver Connections

WIRELESS ZONE

NUMBERS

VISTA-20P:

transmitter zones 9-48

button zones 49-64

VISTA-15P:

transmitter zones 9-34

button zones 49-56

RF Receiver Notes

† These fields must be

enabled for Residential Fire,

UL Residential Burglar

Alarm, and UL Commercial

Burglar Alarm installations.

Use any ADEMCO 5800 Series Wireless Receivers, such as:

RF Receiver No. of Zones

5881L/5882L up to 8

5881M/5882M up to 16

5881H/5882H, VISTA-20P = up to 40 plus 16 buttons

5883, 6150RF VISTA-15P = up to 26 plus 8 buttons

1. Set Device Address to “00” (set all switches to the right, “off” position).

2. Mount the receiver, noting that the RF receiver can detect signals from transmitters

within a nominal range of 200 feet.

3. Connect the receiver's wire harness to the control's keypad terminals. Plug the

connector at the other end of the harness into the receiver. Refer to the installation

instructions provided with the receiver for further installation procedures regarding

antenna mounting, etc.

NOTE

CIRCUIT BOARD IS MOUNTED IN

CONTROL'S CABINET. GROUNDING

LUGS (2) PROVIDED

IN LEFT-HAND TERMINALS OF ANTENNA

BLOCKS AND SECURED TO CABINET.

(SEE RECEIVER'S AND CONTROL'S

INSTRUCTIONS)

MOUNTING

HOLES

MUST

BE INSERTED

ANTENNAS

(INSERT IN

RIGHT-HAND

TERMINALS)

INSERT IN

RIGHT- HAND

TERMINALS

MODEL NO. IS INDICATED ON CIRCUIT BOARD

5882

LOCATION

INTERFERENCE

INDICATOR

CIRCUIT BOARD

TO RELEASE CIRCUIT BOARD,

REMOVE SCREWS AND

LED

BEND BACK TABS

DIP

SWITCH

Figure 11. 5881/5882 RF Receiver (cover removed)

Set the following options:

*22 RF Jam Option†

*24 RF House ID Code (if using wireless keypads) for each partition

*67 Transmitter Low Battery Report Code†

*75 Transmitter Low battery restore report code†

• The receiver is supervised and a trouble report is sent (“CHECK 100” displayed) if

communication between the panel and receiver is interrupted, or if no valid RF signals

from at least one supervised transmitter are received within 12 hours.

If the receiver is mounted remotely:

• Place the RF receiver in a high, centrally located area for best reception.

• Do not locate the receiver or transmitters on or near metal objects. This will decrease

range and/or block transmissions.

• Do not locate the RF receiver in an area of high RF interference (indicated by frequent

or prolonged lighting of the LED in the receiver; random flicker is OK).

• Do not locate RF receiver closer than 10 feet from any keypads to avoid interference

from the microprocessors in those units.

GRN

BLK

RED

YEL

SOCKET

DATA OUT (>)

TO CONTROL

(–) GROUND

(+) 12VDC

DATA IN (<)

FROM

CONTROL

YELLOW

RED

BLACK

GREEN

PLUG

TERMINALS ON

CONTROL PANEL

(TERM 6)

(TERM 4)

(TERM 5)

(TERM 7)

4229-002-V0

TO CONTROL'S

REMOTE KEYPAD

CONNECTION

POINTS.

WIRING OPENING

KNOCKOUT AREA

FOR SURFACE WIRING

5881-003-V0

2-8

Page 15

Installing a 5800TM

Module

Installing the

Transmitters

Transmitter Battery Life

Mounting and Wiring the Control

• Use this module only if you are using one or more wireless bi-directional keypads or

keyfobs with a wireless Receiver; 5800TM is not necessary if using a Transceiver (e.g.,

5883).

• The 5800TM must be set to address 28 (cut red-W1 jumper).

• The 5800TM can be used in partition 1 only.

• For additional information regarding the 5800TM, refer to the 5800TM’s instructions.

1. Mount the 5800TM next to the RF receiver (between one and two feet from the

receiver’s antennas) using its accompanying mounting bracket. Do not install within

the control cabinet.

2. Connect the 5800TM to the control panel’s keypad connection terminals as shown on

the Summary of Connections diagram and set to address 28.

• Refer to the table of compatible devices at the back of this manual.

• Supervised transmitters† send check-in signals to the receiver at 70-90 minute

intervals. If at least one check-in message is not received from each transmitter within

a 12-hour period, the “missing” transmitter number(s) and “CHECK” is displayed. (†

Hand-held transmitters, e.g., 5802, 5802CP, 5804, 5804BD, 5827, 5827BD, do not send

check-in signals.)

• To be sure reception of the transmitter's signal at the proposed mounting location is

adequate, perform a Go/No Go Test, described in the Testing the System section.

• Install transmitters in accordance with the instructions provided with each.

• Set 5827, 5827BD, 5804BD wireless keypads to the programmed House ID (field *24),

using its DIP switches (5827) or follow the instructions provided with the device.

• Use *56 or *58 Zone Programming Menu modes to program zone information and enroll

transmitters (VISTA-20P: zones 9-48, buttons 49-64; VISTA-15P: zones 9-34, buttons

49-56).

•••• Wireless Keys: Use Wireless Key Programming Templates section of the *58 Zone

Programming Menu mode to program zone information and enroll each button of the

wireless keys used. Once a wireless key is enrolled, it must be assigned to a user before

it becomes active. See Adding/Deleting Security Codes section for procedure.

ULC NOTE: In accordance with ULC standards, the RF supervision period for the VISTA-20PCN

and VISTA-15PCN is three hours for Fire zones (Zone Type 9 and 16) and 12 hours for all other zone

types.

U

L

The following transmitters are not intended for use in UL installations: 5802MN, 5802MN2, 5804,

5804BD, 5814, 5816TEMP, 5819, 5819WHS & BRS, and 5850.

The 5827BD and 5800TM can be used in UL Listed Residential Burglar installations.

• See Wireless Transmitter paragraph in the Limitations of This Alarm System

statement located at the end of this manual for information on transmitter battery

life.

• Some transmitters (e.g., 5802 and 5802CP) contain long-life but non-replaceable

batteries, and no battery installation is required. At the end of their life, the complete

unit must be replaced (and a new serial number enrolled by the control).

• Button-type transmitters (such as 5801, 5802, and 5802CP) should be periodically

tested for battery life.

• The 5802MN and 5804 Button Transmitters have replaceable batteries.

Do not install batteries in wireless transmitters until you are ready to enroll during

system programming. After enrolling, batteries need not be removed.

2-9

Page 16

Installation and Setup Guide

Installing a Keyswitch

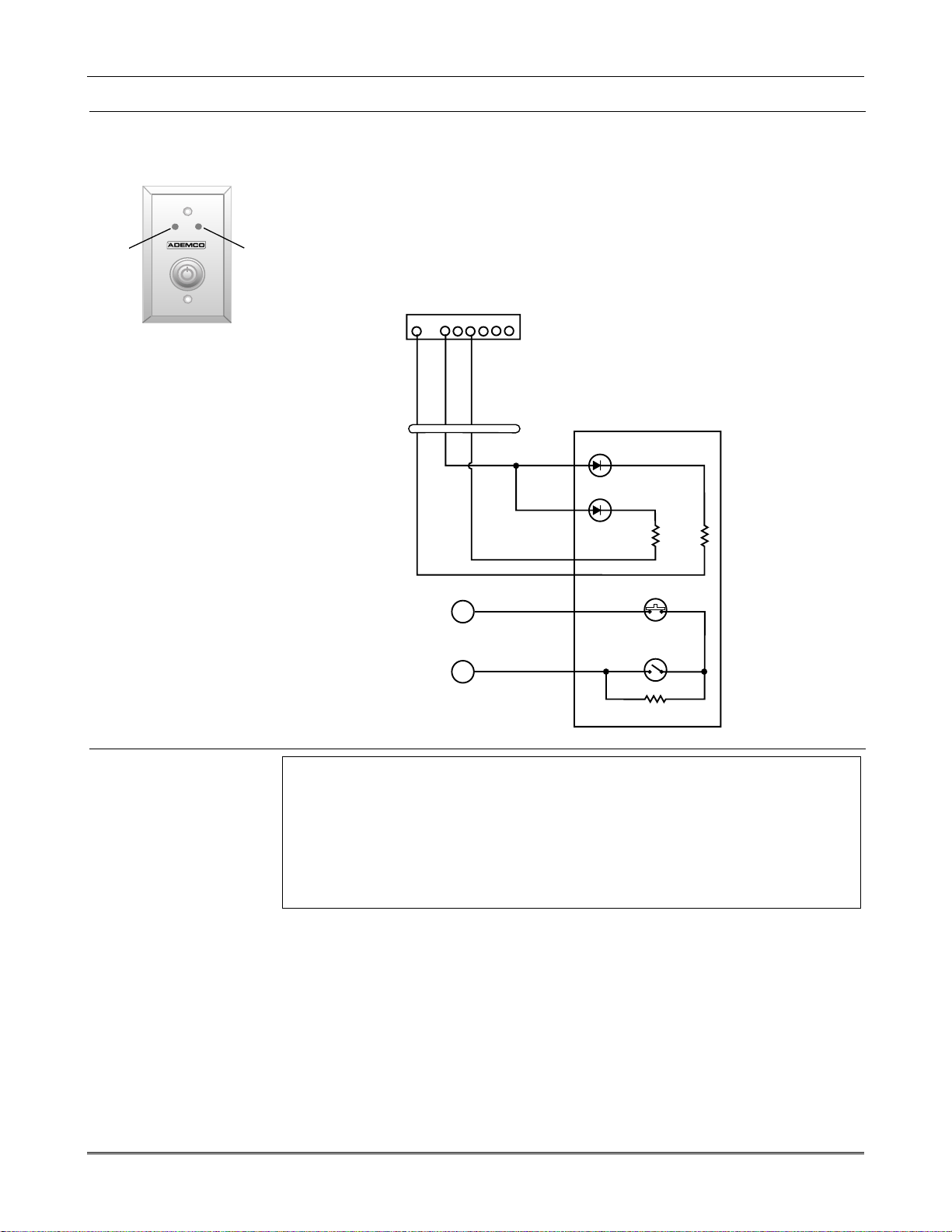

Keyswitch Connections

GREEN

1. Connect the 4146 keyswitch's normally open momentary switch to a zone’s (2-8)

2. Using a standard keypad cable as shown:

Connect the Red and Green LED wires to the appropriate output 17/output 18

3. Connect a 2000 ohm EOL resistor across the momentary switch.

4. You can wire an optional closed-circuit tamper switch (model 112) in series with the

RED

If the tamper is opened when the system is armed, an alarm will occur.

terminals. Remove the 2000 ohm EOL resistor if connected across the selected zone.

Connect the yellow and white keyswitch wires to trigger connector pin 3 (+12V).

trigger connector pins.

zone. If the switchplate is then removed from the wall, the tamper will open,

disabling keyswitch operation until the system is next disarmed from the keypad.

8-PIN TRIGGER CONNECTOR

1345678

KEY

(RED)

(YELLOW)

OUTPUT 17

(GREEN)

+12 AUX.

OUTPUT 18

11

TYPICAL ZONE

ON CONTROL

BOARD

10

STANDARD

KEYPAD

CABLE

YELLOW

WHITE

BLACK

RED

BROWN

BLUE

(ARMED)

RED

(READY)

GREEN

4146 KEYSWITCH

820

ohms

TAMPER

SWITCH (N. C.)

LOCK

SWITCH (N. O.)

820

ohms

BROWN

BLUE

Keyswitch Notes

EOLR

(use appropriate value)

U

A UL Listed keyswitch is required for fire installations and UL commercial and residential

L

burglar alarm installations. The Ademco 4146 keyswitch is UL Listed.

If a keyswitch is used on:

Figure 12. Keyswitch Wiring Connections

00-trigcon-004-V1

• an installation that transmits opening and closing signals, the keyswitch zone must be programmed

to send opening and closing signals.

• a UL commercial burglar alarm installation, the keyswitch’s tamper switch must be connected in to

the alarm system. This tamper switch zone must also be programmed for Zone Type 05 – Trouble

by Day / Alarm by Night.

• a fire alarm installation, the keyswitch must be located next to an alphanumeric display keypad.

• Use 4146 keyswitch or any N.O. keyswitch.

• Use only one keyswitch per partition.

• When using a keyswitch, the zone it is connected to is no longer available for use as a

protective zone.

• Use *56 Menu mode to program the keyswitch zone and assign it zone type 77.

• Use *80 Menu mode to program the LED functions: program outputs 17 and 18 for

system operation zone type 78 (red LED) and 79 (green LED) as appropriate (see

Output Device Programming section).

2-10

Page 17

Mounting and Wiring the Control

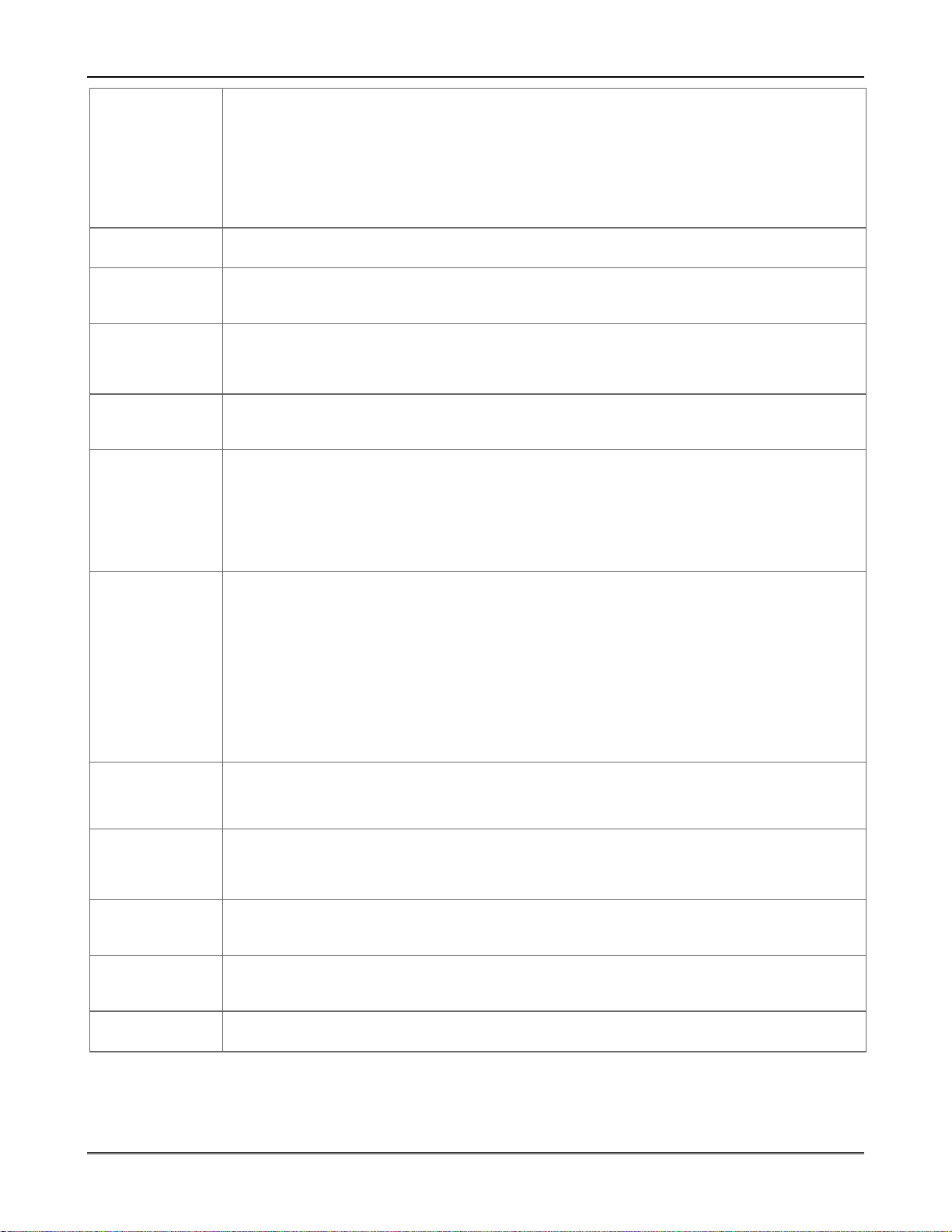

Connecting Relay Modules, Powerline Carrier Devices and Output Triggers

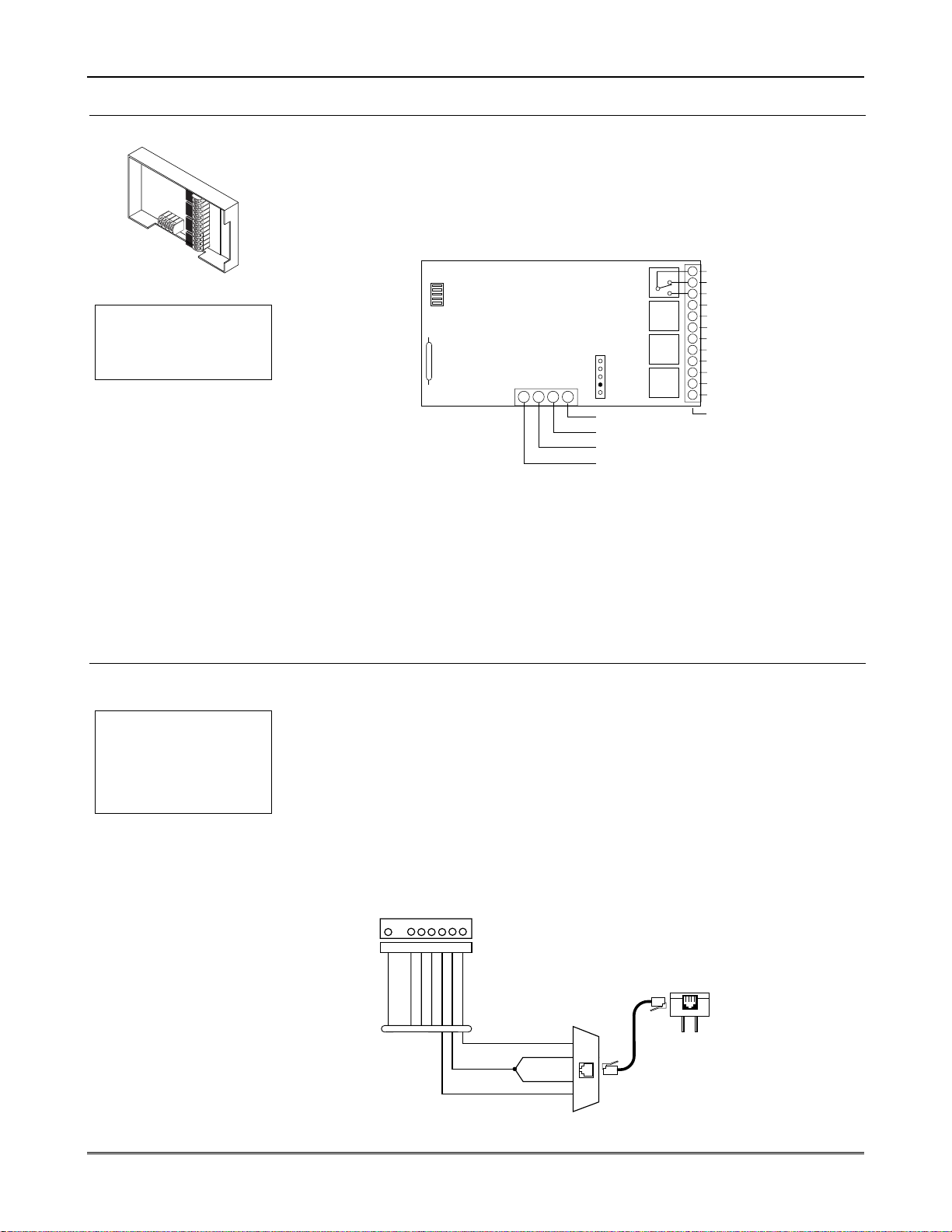

4204/4229 Relay Modules

U

For UL installation

L

requirements, refer to the

Installation Instructions for

the 4204.

Powerline Carrier

Devices

U

Powerline Carrier

L

devices and the 1361X10

Transformer are not UL

Listed for fire or burglary

functions and are intended

for home automation.

1. Mount either remotely or in the control panel.

2. Connect each module to the control’s keypad terminals and set the device addresses

as previously described in the Connecting Keypads and Other Addressable

Device section. Use the connector harness supplied with the module. Use standard

4-conductor twisted cable for long wiring runs.

VISTA-20P: Up to 16 relays (if no powerline carrier devices are used)

VISTA-15P: Up to 8 relays (if no powerline carrier devices are used)

3. Connect the desired field wiring to the unit's relay contact terminals.

4204

DIP SWITCH

FOR SETTING DEVICE ADDRESS

AND ENABLING/DISABLING TAMPER

COVER TAMPER (REED) SWITCH

4-PIN TOUCHPAD PLUG

EITHER OR BOTH

CAN BE USED

TB1

13 14 15 16

Figure 13. 4204 Connections to Control

YEL

BLK

GRN

RED

RELAY

4

TYPICAL

(SHOWN "OFF")

DATA IN

FROM CONTROL

(–) GROUND

DATA OUT

TO CONTROL

(+) 12V

RELAY

3

RELAY

2

RELAY

1

C

121110

NC

NO

9

C

87654321

NC

NO

TB2

4204_conn-1-V0

C

NC

NC

NO

C

NC

NO

• Supervision: 4204 and 4229 modules are supervised against removal. The module’s

device address is displayed as follows if a module is disconnected from the control’s

terminals, or if the module cover is removed and the tamper jumper is installed:

Alpha: CHECK xx Wire Expansion

FAULT xx Wire Expansion

ALARM xx Wire Expansion

Fixed-Glass: lxx (or 91 if field *199 set for 2-digit display)

where “xx is the module’s address.

• If communication/tamper failure occurs on a device with zones wired to it, all zones on

the device will be displayed in their respective partitions.

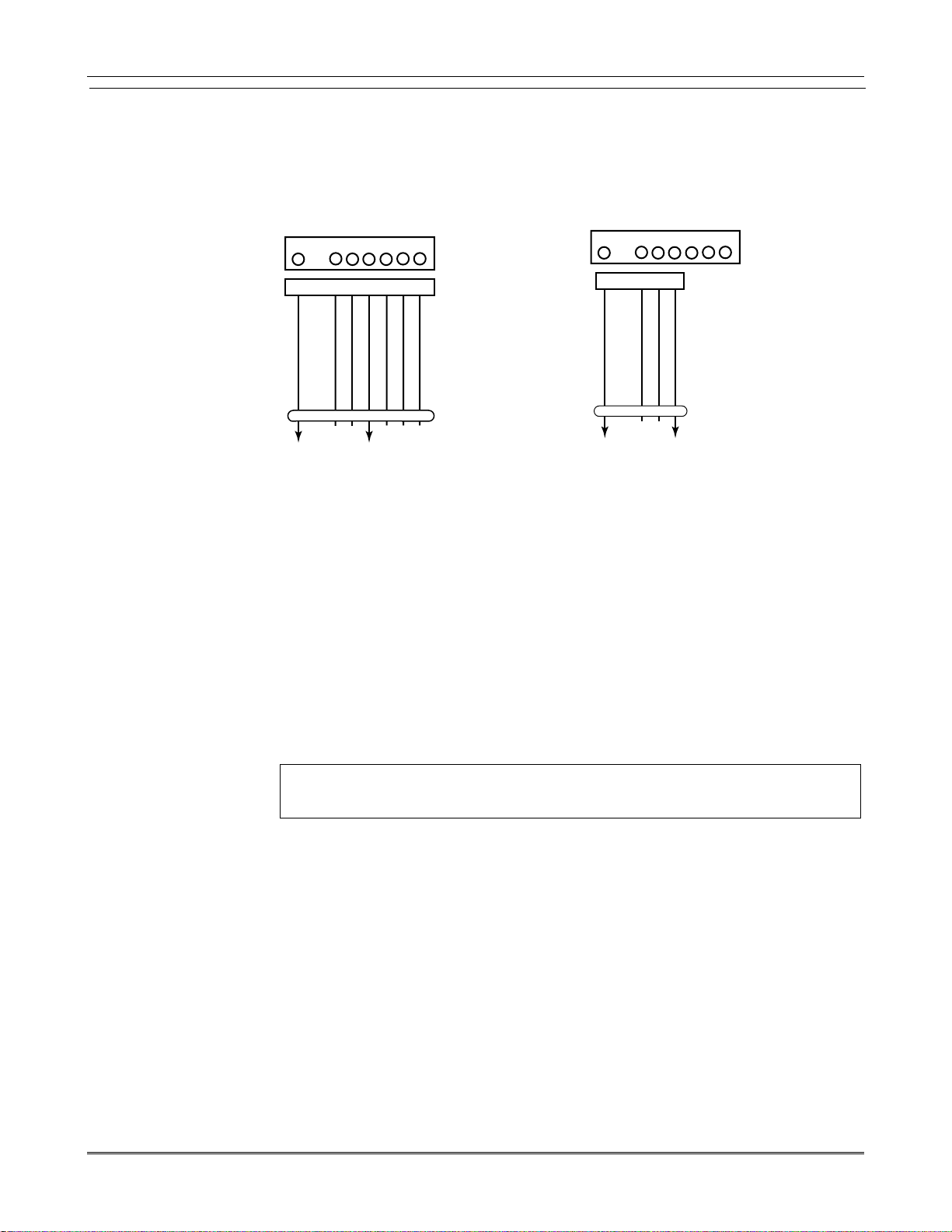

1. Install the powerline carrier devices according to the instructions included with each.

VISTA-20P: Up to 16 devices (if no relays are used)

VISTA-15P: Up to 8 devices (if no relays are used)

2. Use Programming Mode to enter the device house ID in data field*27, and enter the

unit code using *79 Output Device menu Mode.

3. See connections diagram in the AC Wiring section for connecting the 1361X10

transformer to the triggers.

• You must use a 1361X10 Transformer instead of the 1321 Transformer.

• The 1361X10 Transformer provides AC power to the control panel, and also supplies

signals from the control panel through the premises AC wiring to the Powerline

Carrier devices (which are plugged into AC outlets). You can then make devices that

are plugged into Powerline Carrier devices perform various functions in response to

commands you enter at the security system keypads.

Canada: Use the PSC04 Powerline Interface as shown below.

8-PIN TRIGGER CONNECTOR

1345678

KEY

(RED)

OUTPUT 17

(BLUE)

(BLACK)

(YELLOW)

(ORANGE)

GND (-)

+12 AUX.

(GREEN)

OUTPUT 18

DATA

(PURPLE)

COM

SYNC

SYNC

COM

DATA

SA4120XM-1 CABLE

BLK

GRN

RED

YEL

X-10 PSC04

POWERLINE INTERFACE

1 2 3 4

MODULAR PHONE CORD (not supplied)

1 - BLACK

2 - RED

3 - GREEN

4 - YELLOW

Figure 14. PSC04 Powerline Interface Connections

2-11

Page 18

Installation and Setup Guide

On-Board Triggers

Connect field wiring to the desired trigger pin on the 8-pin trigger connector centrally

located above the terminal strip.

• If using 1361X10 transformer and powerline carrier devices, use the SA4120XM-1

• If only using the on-board triggers, you can use a 4-wire cable (N4632-4, supplied

cable (part of 4120TR Trigger Cable). See Wiring the AC Transformer section for

transformer connections.

with the control) as shown below.

8-PIN TRIGGER CONNECTOR

1345678

KEY

8-PIN TRIGGER CONNECTOR

1345678

KEY

(RED)

(ORANGE)

+12 AUX.

OUTPUT 17

Figure 15a. On-Board Trigger Connector Figure 15b. On-Board Trigger Connector

(GREEN)

(YELLOW)

GND (-)

OUTPUT 18

(BLUE)

(PURPLE)

COM

DATA

(BLACK)

SYNC

SA412OXM-1

CABLE

00-trigcon-003-V1

(RED)

(YELLOW)

+12 AUX.

OUTPUT 17

(BLACK)

(GREEN)

GND (-)

OUTPUT 18

4-WIRE

CABLE

00-trigcon-005-V2

with SA4120XM-1 Cable for Use With with 4-Wire Cable for Trigger Use Only

1361X10 Transformer

• Trigger outputs are normally high, and go low upon programmed condition.

• The outputs can be programmed for inverted operation (normally low, go high) using

*79 Menu mode.

• Program these triggers using *80/*81 Menu modes as you would for any other relay

output.

• When using these outputs, note:

pin 1 = output number 17 (trigger 1):

15 ohms to ground when closed (output low), open when off (output high, normal

default); can be used to reset smoke detector power (must set “output normal low

= yes” in *79 Menu mode, and set for zone type 54, fire zone reset, in *80 Menu

mode); or can support 12V relay module (

e.g., Altronix AX-RBS) that draws less

than 100mA

pin 5 = output number 18 (trigger 2):

100 ohms to ground when closed (output low); open when off (output high,

normal default); or can support 12V relay module that draws less than 20mA

U

If on-board triggers are used, the wiring between the control unit and the UL Listed device must

L

be run in conduit, be no more than 3 feet apart and have no intervening barriers or walls.

2-12

Page 19

Mounting and Wiring the Control

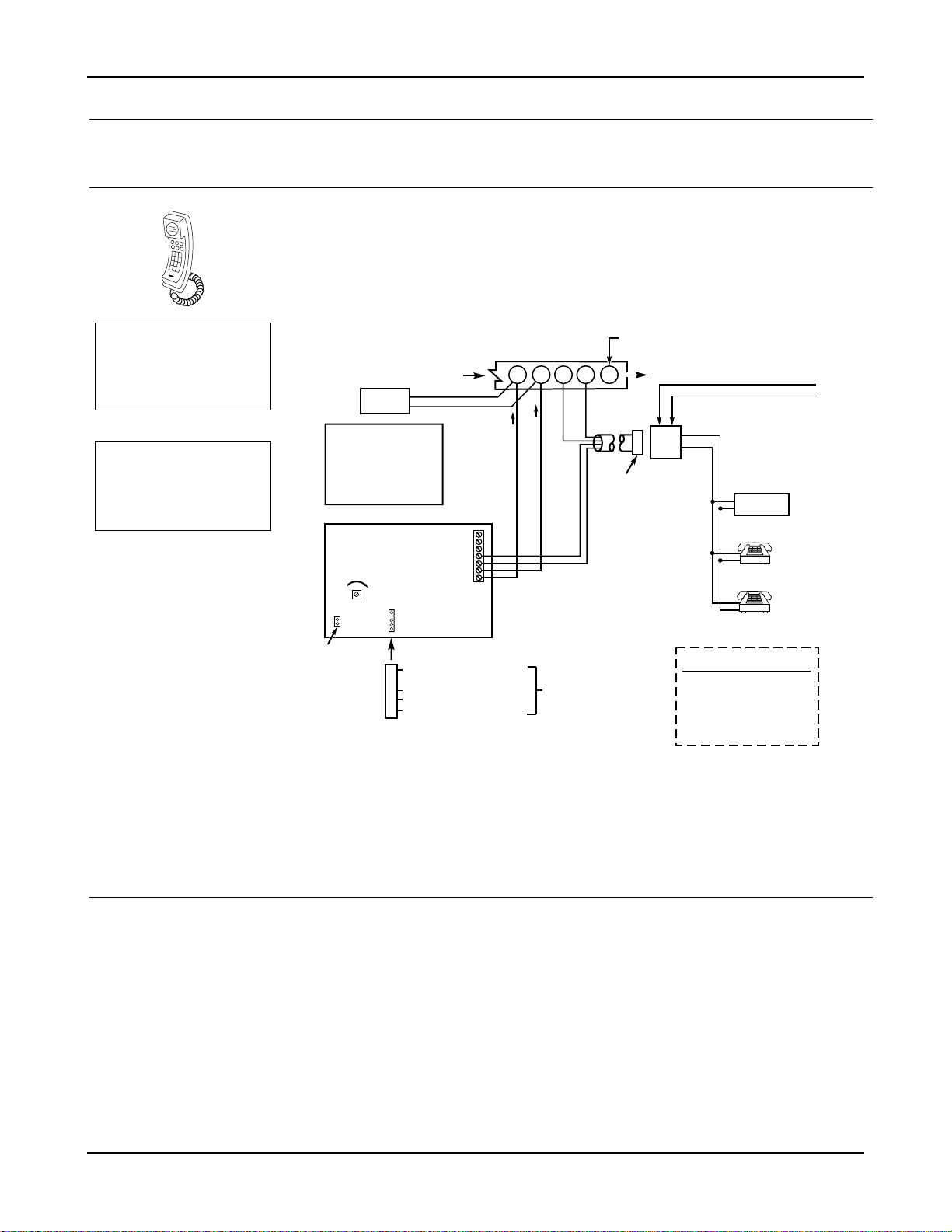

Phone Line/Phone Module, and Audio Alarm Verification (AAV) Connections

Phone Line

4285/4286 Phone Module

Compatibility: 4286 Phone

Modules must have

software version WA4286-

15.1 or higher (refer to the

label on the square 4286

microprocessor chip).

U

The 4285 and 4286

L

modules are UL Listed only

for use on residential fire

and UL residential burglar

alarm installations.

Connect incoming phone line and handset wiring to the main terminal block (via an

RJ31X jack) as shown in the Summary of Connections diagram at the back of this

manual.

Wire colors represent the colors of the cable to the RJ31X jack.

1. Make 12V (+) and (–) and data in and data out connections from the phone module to

the control, using the connector cable supplied with the phone module, then insert

the keyed connector at the other end of the connector cable into the header on the

phone module.