Installation and Operation Guide

IFP-2100/ECS

RFP-2100

Analog/Addressable Fire System

Emergency Communication System

Document: LS10143-001SK-E Rev: B

ECN: 17-0364

Fire Alarm & Emergency Communication System Limitations

While a life safety system may lower insurance rates, it is not a substitute for life and property

insurance!

An automatic fire alarm system—typically made up of smoke

detectors, heat detectors, manual pull stations, audible warning

devices, and a fire alarm control panel (FACP) with remote notification capability—can provide early warning of a developing

fire. Such a system, howe ver, does not assu re protection

against property damage or loss of life resulting from a f ire.

An emergency communication system—typically made up of

an automatic fire alarm system (as described above) and a life

safety communication system that may include an autonomous

control unit (ACU), loca l operating console (LOC), voi ce communication, and other var i ous inter-operable communication

methods—can broadcast a mass notification message. Such a

system, however, does not assure pro te ct io n against property

damage or loss of life resulting from a fire or life safety event.

The Manufacturer recommends that smoke and/or heat

detectors be located throughout a protected premises following

the recommendations of the cur r ent edi t i on of the Na t ional Fi re

Protection Association Standard 72 (NFPA 72), manufacturer's

recommendations , State and local codes, and the

recommendations contained in the Guide for Proper Us e of

System Smoke Detectors, which is made available at no charge

to all installing dealers. This docu ment can be found at http://

www.systemsensor.com/appguides/. A study by the Federal

Emergency Manage m ent Agency (an agency of th e U nit ed

States government) indicated that smoke detectors may not go

off in as many as 35% of all fires. Wh ile fire alarm systems are

designed to provide earl y w ar ni ng against fire, they do not

guarantee warning or protection against fire. A fire alarm

system may not provide timely or adequate warni ng, or simply

may not funct i on, for a vari ety of reasons:

Smoke detectors may not se nse fire where smoke cannot

reach the detectors such as in chimneys, in or behind walls, on

roofs, or on the other side of clo sed doors. Smoke detectors

also may not sense a fire on another level or floor of a building.

A second-floor detector, for example, may not sense a first-floor

or basement fire.

Particles of combustion or “smoke” from a developing fire

may not reach the sensing chambers of smoke detectors

because:

• Barriers such as closed or partially closed doors, walls,

chimneys, even wet or humid areas may inhibit particle or

smoke flow.

• Smoke particles ma y become “cold,” stratify, and not reach

the ceiling or upper walls where detectors are locate d.

• Smoke particles ma y be blown away from detec to rs by air

outlets, such as air conditioning vents.

• Smoke particles may be drawn into air returns before reaching the detector.

The amount of “smoke” pres ent may be insufficient t o alarm

smoke detectors. Smoke detectors are design ed t o al ar m at

various l evels of smoke de nsity. If such de nsity level s are not

created by a developing fire at the location of detectors, the

detectors will not go into ala rm.

Smoke detectors, even when working properly, have sensing

limitations. Detector s th at have photoelectronic se nsing chambers tend to detect smolder i ng f i re s bet t er th an f lam i ng f ires,

which have little visible smoke. Detectors that have ionizingtype sensing chamber s te nd to detect fast-flaming fire s better

than smoldering fires. Because fires develop in different ways

and are often unpredictable in their growth, neither type of

detector is necessar ily be st and a given type of detector ma y

not provide adequate war ni ng of a fire.

Smoke detectors cannot be expected to provide adequate

warning of fire s cau sed by ar son, chi ldren play in g with matche s

(especially in bedrooms), smoking in bed, and vio le nt exp lo -

sions (caused by escaping gas, improper storage of flammable

materials, etc.) .

Heat detectors do not sense particles of combustion and alarm

only when heat on their s ensors increases at a predetermined

rate or reaches a predet er m i ned le vel . Ra te-of-rise heat detectors may be subject to re duc ed sensitivity over time. For th is

reason, the rate-of- rise featur e of each detector should be

tested at least once per y ear by a qualified fire protection specialist. Heat detector s ar e des i gned to protect property, not life.

IMPORTANT! Smoke detectors must be installed in the same

room as the control panel and in rooms used by the sy st em f or

the connection of alarm transmission wiring, communicati ons,

signaling, and/or power. If detectors are not so located, a developing fire may damage the alarm system, compromising its

ability to report a fire.

Audible warning devices such as bells, horns, strobes ,

speakers and displays may not alert people if these devices

are located on the other side of closed or partly open doors or

are located on another floo r of a building. Any warning device

may fail to alert people with a disability or those who have

recently consumed drugs, alcohol, or medication. Please note

that:

• An emergency communication system may take priority over

a fire alarm system in the event of a life safety emerg enc y.

• Voice messaging systems must be designed to meet intelligibility requirements as defined by NFPA, local codes, and

Authorities Having Jurisdiction (AHJ).

• Language and inst r u cti onal requirements must be cl e arly

disseminated on any lo cal displays.

• Strobes can, under certain circumstances, cause seizures in

people with conditions such as epilepsy.

• Studies have sho w n t hat certain people, even when they

hear a fire alarm signal, do not re spond to or comprehend

the meaning of the sign al . Audible devices, such as horns

and bells, can have different tonal patterns and frequencies.

It is the property owner's responsibility to conduct fire drills

and other training exer cises to make people aware of fire

alarm signals and instr uc t them on the proper reaction to

alarm signals.

• In rare instances, the sounding of a warning device can

cause temporary or perman ent hearing loss.

A life safety system will not operate without any electrical

power. If AC power fails, the system w i ll op era t e from st andby

batteries only for a speci fied time and only if the batteries have

been properly maintained and replaced regular ly.

Equipment used in the system may not be technically compatible wi th the control panel. It is essential to use only equipment listed for service w ith your control panel.

Telephone lines needed t o t r ans mi t al ar m si gn al s f ro m a p re m ises to a central monitoring station may be out of service or

temporarily disabled . For a dde d protection against telepho ne

line failure, backup radio transmission syst em s ar e recommended.

The most common cause of life safety system malfunction is

inadeq u ate maintenance. To keep the en tire life safety sys tem

in excellent working order, ongoing maintenance is required per

the manufacturer's recommendations, and UL and NFPA standards. At a minimum, the requirements of NFPA 72 shall be followed. Environments with large amounts of dust, dirt, or high air

velocity require more frequent maintenance. A maintenance

agreement should be arranged through t he local manufacturer's representat ive. M ai nt enance should be sched uled

monthly or as required by National and/or local fire codes and

should be performed by authorized professional l ife safety system installers only. Adequate written records of all inspections

2

Installation Precautions

Adherence to the following will aid in problem-free installation with long-term reliability:

WARNING - Several different sources of power can be

connected to the fire alar m cont rol panel. Disconnect all

sources of power be fore servi cing . Contr ol uni t and associ ated

equipment may be damaged by removing and/ or in serting

cards, modules, or in te rc on necting cables while the uni t is

energized. Do not attem pt to install, service, or ope ra te th is

unit until manuals are read and understood.

CAUTION - System Re- acceptance Test after Software

Changes: To ensure proper system operation, this product

must be tested in acc or dance with NFPA 72 after any programming operatio n or change in site-specific softw are. Reacceptance testin g is req u ir ed af t er any change, addition or

deletion of system co mponents, or after any modification,

repair or adjustmen t to sy st em hardware or wiring. All components, circuits, syst em operations, or software f unc tions

known to be affected by a change must be 100% tested. In

addition, to ensure that ot her operations are not inadver tent ly

affected, at least 10% of initiat i ng devi ces that are not directly

affected by the change, up to a maximum of 50 devices, must

also be tested and proper system operation verified.

This system meets NFPA requirements for operation at 0-49º

C/32-120º F and at a relative humidity. However, the useful

life of the system's standby batteries and the electronic components may be adversely affected by extreme temperature

ranges and humidity. Therefore, it is recommended th at th is

system and its peripherals be installed in an environment with

a normal room temperature of 15-27º C/60-80º F.

Verify that wire sizes are adequate for all initiating and indicating device loops. Most devices cannot tolerate more than a

10% I.R. drop from th e specified device voltage .

Like all solid state electronic devices, this system may

operate erratically or can be damaged when subjected to lightning induced transients. Although no syste m is com pletely

immune from lightning tr ans i ent s and interference, proper

grounding will reduce susceptibility. Overhead or outside

aerial wiring is not recommended, due to an increased susceptibility to nearby lig ht ni ng strikes. Consult with the Technical Services Department if any problems are anticip at ed or

encountered.

Disconnect AC power and batteries prior to removing or

inserting circuit boards . Fa ilur e t o do so can damage circuits.

Remove all electronic assemblies prior to any drilling, filing,

reaming, or punching of th e enclosure. When possib le , ma ke

all cable entries from the sides or rear. Before making modifications, verify that they will not interfere with battery, transformer, or printed circuit board location.

Do not tighten screw terminals more than 9 in -lbs . Overtightening may damag e t hr eads, resulting in reduced term i nal

contact pressure and di fficu lty wit h screw terminal removal .

This system contains st at ic- sensitive components .

Always ground yourself with a proper wrist strap before han-

dling any circuits so that static charges are removed from the

body. Use static suppressive packaging to protect electronic

assemblies remov ed from the unit.

Follow the instructio ns in th e i nst allation, operating, and

programming manuals. These instructions must be followed to

avoid damage to the control panel and associated equipment.

FACP operation and reliability depend upon proper installation.

Precau-D1-9-2005

3

Documentation Feedback

Your feedback helps us keep our documentation up-to-date and accurate. If you have a question or encounter a

problem not covered in this manual, contact Honeywell Silent Knight Technical Support at 800-446-6444.

Please give the following information:

• Product name and version number (if applicable)

• Printed manual

• T opic T itle

• Page number (for printed manual)

• Brief description of content you think should be improved or corrected

• Your suggestion for how to correct/improve documentation

To order parts, contact Honeywell Silent Knight inside sales at 800-328-0103.

eVance®, Farenhyt™ are trademarks; and Honeywell®, Silent Knight® and SWIFT® are registered trademarks of Honeywell Internati onal Inc.

Microsoft® and Windows® are registered trade ma rks of t he M icro soft C o rpo ra tion. Chrome™ and Google™ are trademarks of Google Inc. Firefox®

is a registered trademark of The Mozilla Foundation.

©2017 by Honeywell Internati onal Inc . All rights reserved. Una utho ri zed use of this docu me nt is stric tly prohibit ed .

4

Contents

Section 1

Introduction ..................................................................................................................................................1

1.1 Overview of Basic System ...........................................................................................................1

1.1.1 Hardware Features ...............................................................................................................1

1.1.2 Network System Hardware Features ....................................................................................2

1.1.3 Software Features ................. ...... ....... ...... ............................................. ................................2

1.1.4 IFP-2100ECS Features .........................................................................................................2

1.1.5 Terms Used in this Manual ...................................................................................................3

1.2 Compatible Products ...................................................................................................................3

Section 2

Agency Listings, Approvals, and Requirements .......................................1

2.1 Federal Communications Commission (FCC) .............................................................................1

2.2 Underwriters Laboratories (UL) ...................................................................................................2

2.2.1 Requirements for All Installations .........................................................................................2

2.2.2 Requirements for Central Station Fire Alarm Systems .........................................................3

2.2.3 Requirements for Local Protected Fire Alarm Systems ........................................................3

2.2.4 Requirements for Remote Station Protected Fire Alarm Systems ........................................3

2.2.5 Requirements for the Installation of Carbon Monoxide (CO) Detection and Warning

Equipment, NFPA 720 ..........................................................................................................3

2.2.6 NFPA Requirements .............................................................................................................3

Section 3

Before You Begin Installation ..............................................................................................1

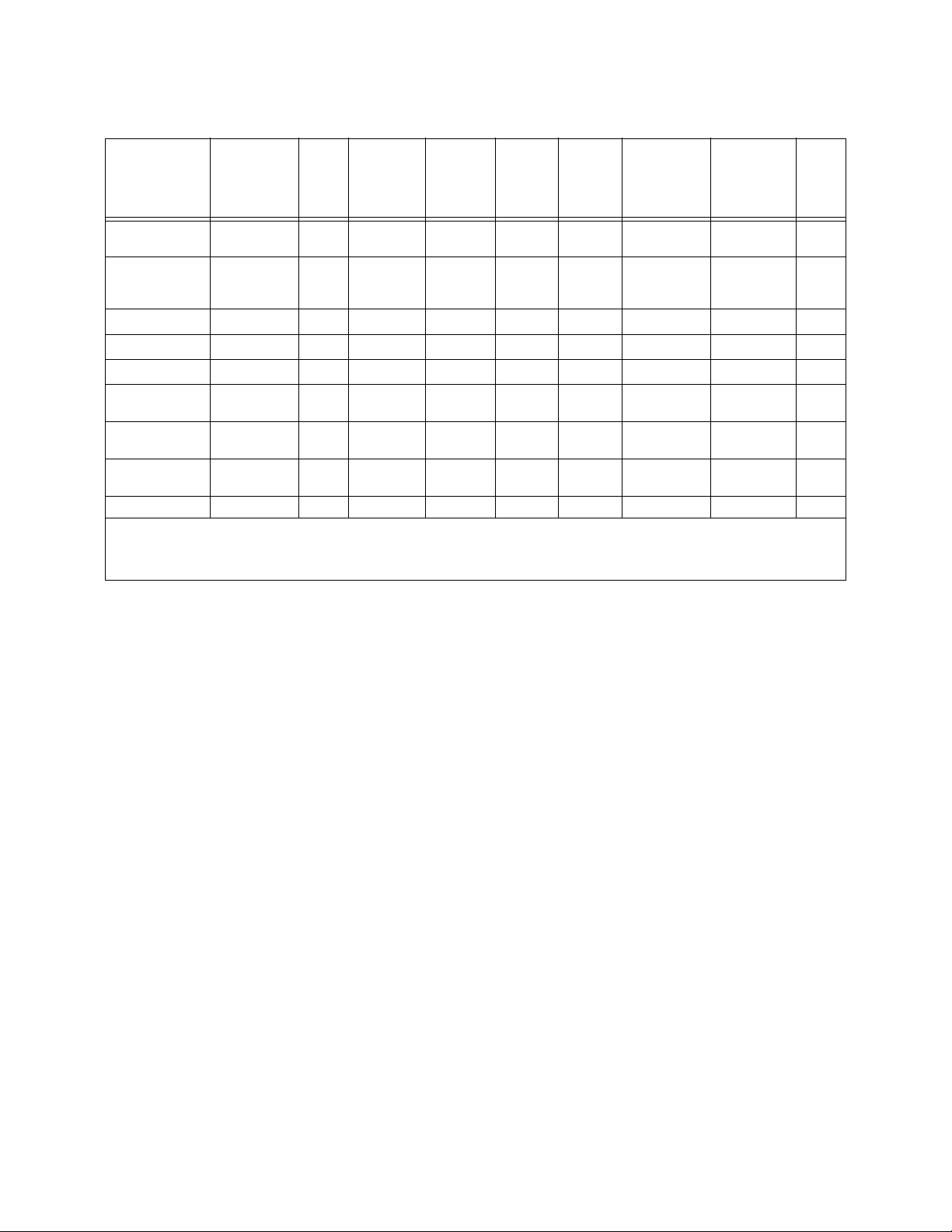

3.1 Inventory ............................... .................... ................... ................... .................... .........................1

3.2 Environmental Specifications ......................................................................................................1

3.3 Software Downloads ............................................. ...... ...... ....... ...... .............................................1

3.4 Electrical Specifications ...............................................................................................................2

3.5 Wiring Specifications ...................................................................................................................4

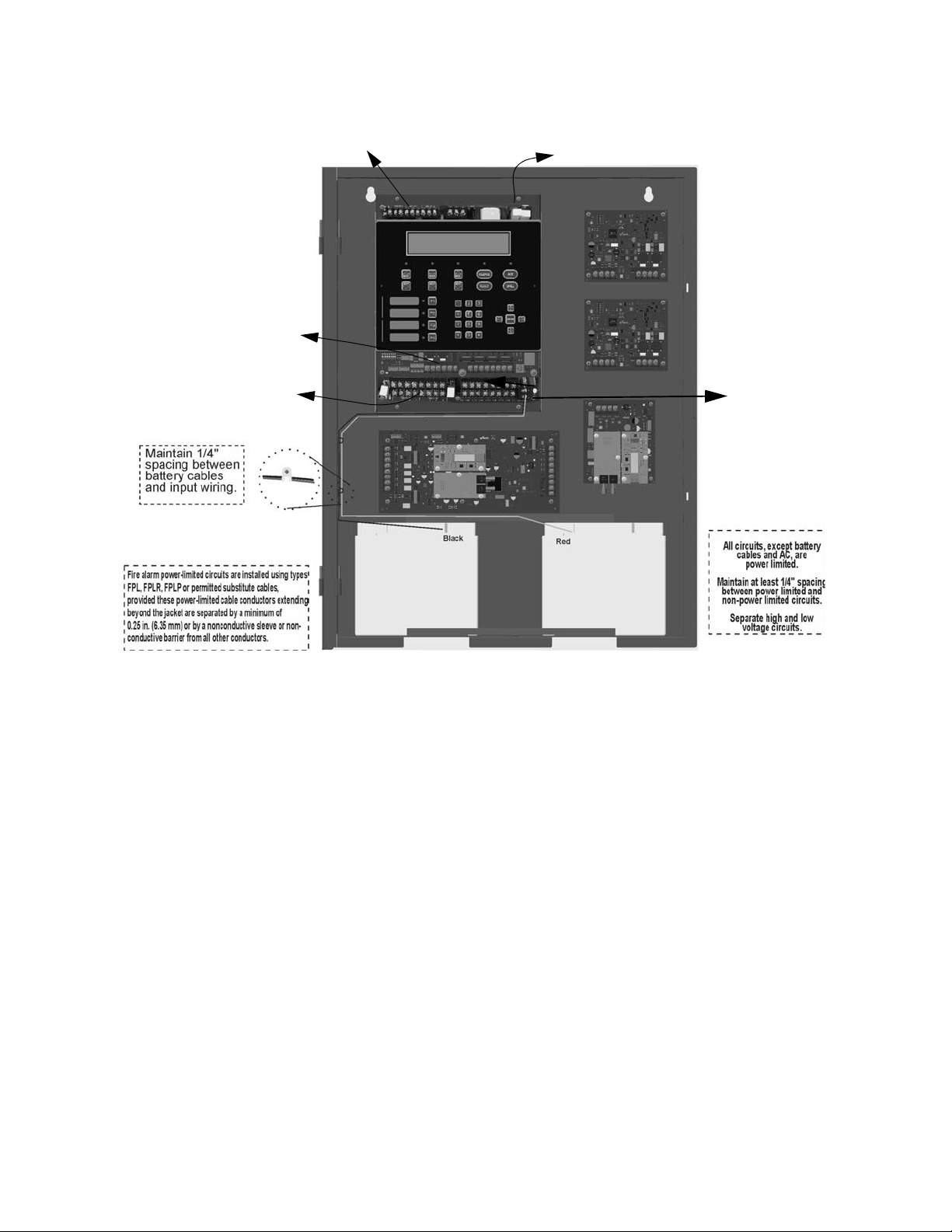

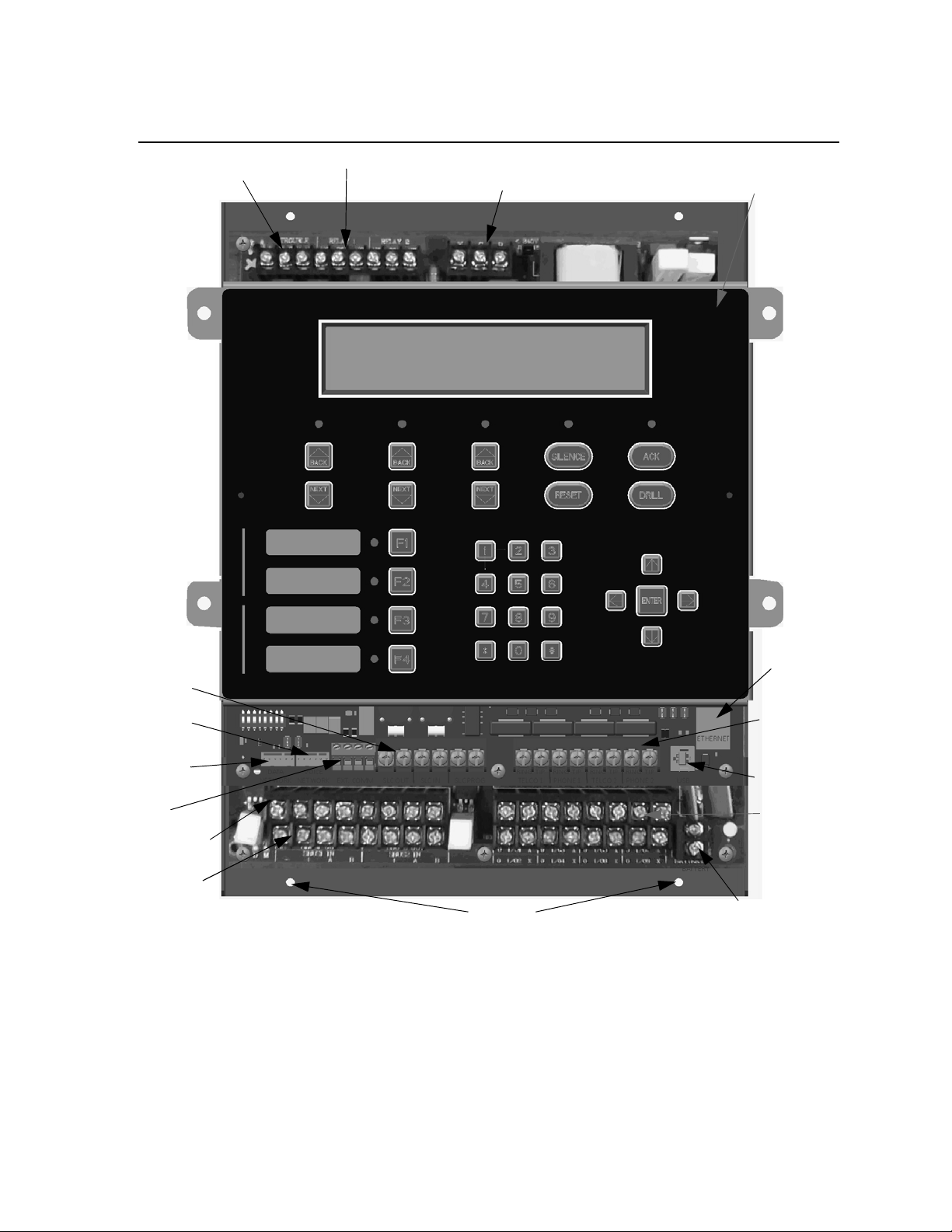

3.6 Board Assembly Diagram ............................................................................................................6

3.7 Calculating Current Draw and Standby Battery ...........................................................................7

3.7.1 Current Draw Worksheet Requirements ...............................................................................7

3.7.2 Current Draw Worksheet for IDP SLC Devices ....................................................................7

3.7.3 Current Draw Worksheet for SK SLC Devices ....................................................................11

3.7.4 Current Draw Worksheet for SD SLC Devices ...................................................................15

3.7.5 Maximum Battery Standby Load .........................................................................................19

Section 4

Control Panel Installation ..........................................................................................................1

4.1 Mounting the Control Panel Cabinet ...........................................................................................1

1

Model IFP-2100/ECS Installation Manual

4.1.1 Preventing Water Damage ....................................................................................................1

4.1.2 Removing the IFP-2100/ECS Assembly from the Housing ...................................................2

4.1.3 Ethernet Connection .............................................................................................................2

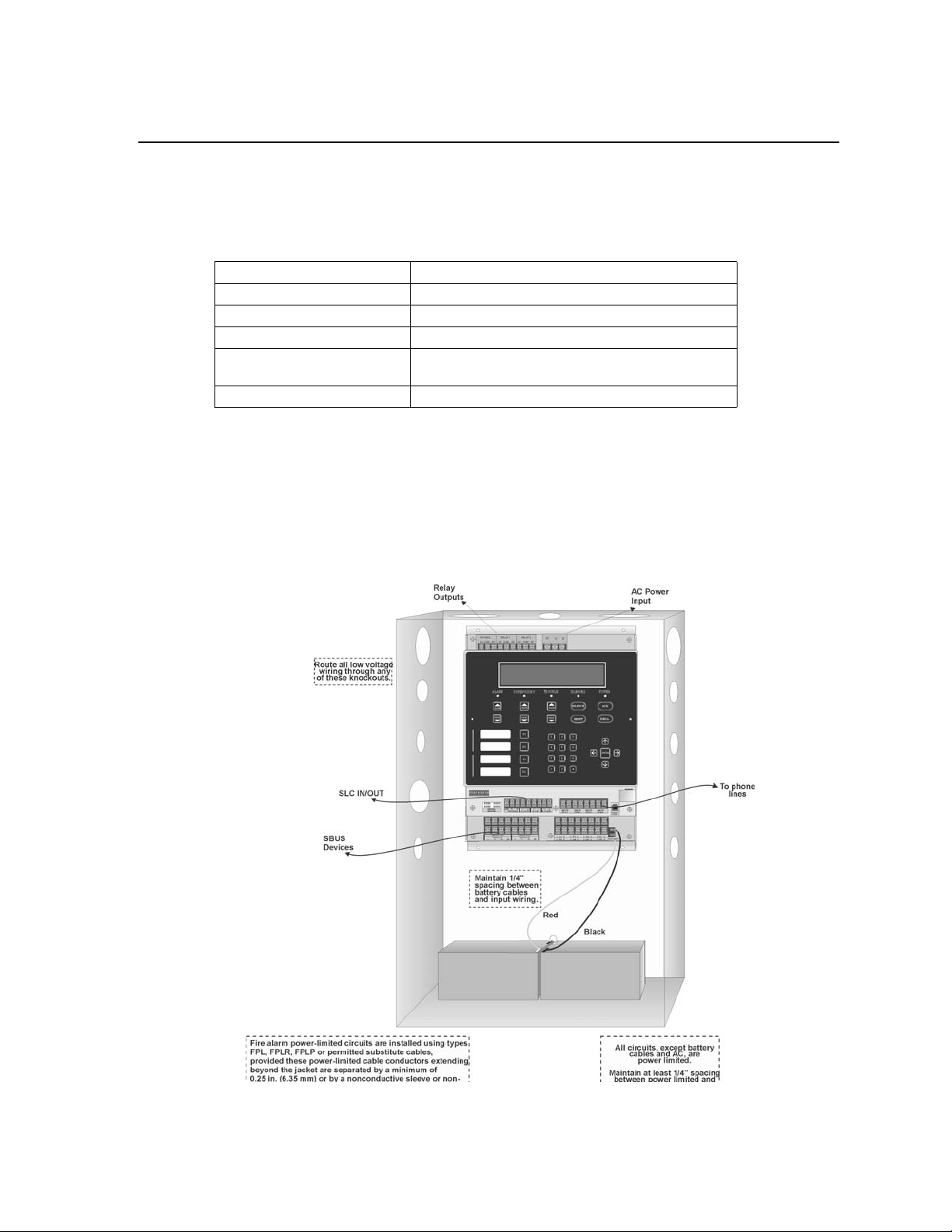

4.2 AC Power Connection ....................................................... ....... ...... ....... ...... ................................2

4.3 Battery Power ..............................................................................................................................3

4.3.1 Battery Accessory Cabinets ..................................................................................................3

4.3.1.1 Installing the RBB or AB-55 Accessory Cabinet and Batteries ...................................3

4.4 SBUS Wiring ...............................................................................................................................5

4.4.1 Calculating Wiring Distance for SBUS Modules ...................................................................5

4.4.2 Wiring Configurations ............................................................................................................8

4.5 RA-2000 Remote Annunciator Installation ..................................................................................9

4.5.1 Mounting the RA-2000 ....................................................... ...... ....... ...... ....... .........................9

4.5.1.1 Flush Mounting ............................................................................................................9

4.5.1.2 Surface Mounting ......................................................................................................11

4.5.2 RA-2000 Connection to the Panel .....................................................................................12

4.5.3 Temporary Programming Display ............ ....... ...... ...... ....... ...... ....... ...... ....... ...... ....... ...... ....12

4.6 RA-1000 Remote Annunciator Installation ................................................................................13

4.6.1 Mounting the RA-1000 ........................................................................................................13

4.6.1.1 Flush Mounting ..........................................................................................................15

4.6.1.2 Surface Mounting ......................................................................................................16

4.6.2 Model RA-1000 Connection to the Panel . ....... ...... ...... ....... ...... ....... ...... ..............................16

4.7 RA-100 Remote Annunciator Installation ..................................................................................17

4.7.1 Mounting the RA-100 ..........................................................................................................17

4.7.1.1 Flush Mounting ..........................................................................................................17

4.7.1.2 Surface Mounting ......................................................................................................19

4.7.2 Model RA-100 Connection to the Panel ..............................................................................20

4.8 5815XL Installation ....................................................................................................................21

4.8.1 5815XL Connection to the Panel ........................................................................................21

4.9 6815 Installation ........................................................................................................................22

4.9.1 6815 Connection to the Panel .............................................................................................23

4.10 5824 Serial/Parallel Interface Module Installation .....................................................................24

4.10.1 Selecting 5824 Options .......................... ....... ...... ...... ....... ...... ....... ...... ....... ...... ....... ..........24

4.11 5880 LED I/O Module ................................................................................................................26

4.11.1 5880 Board Layout ............................................................................................................26

4.11.2 FACP Connection ................ ...... ....... ............................................. ....................................26

4.11.3 LED Wiring ............................................. ............................................. ..............................27

4.11.4 Dry Contact Wiring ............................................................................................................28

4.12 5865-3 / 5865-4 LED Annunciator Installation ...........................................................................29

4.12.1 FACP Connection ................ ...... ....... ............................................. ....................................29

4.12.2 5865 Mounting ........ ...... ....... ...... ....... ...... ............................................. ..............................30

4.13 Configuring SBUS Modules .......................................................................................................31

4.13.1 Assigning SBUS Module IDs .............................................................................................31

4.13.2 SBUS Bandwidth Considerations ......................................................................................31

4.14 Telephone Connection ..............................................................................................................32

4.15 Flexputs

™

I/O Circuits ...............................................................................................................32

4.15.1 Conventional Notification Appliance ..................................................................................32

4.15.1.1 Class B Notification Wiring .......................................................................................32

4.15.1.2 Class A Notification Wiring ......................................................................................33

4.15.2 Conventional Input Switch Circuits ....................................................................................34

4.15.2.1 Class B Inputs ..........................................................................................................34

4.15.2.2 Class A Inputs ..........................................................................................................35

4.15.3 Installing 2-Wire Smoke Detectors ....................................................................................35

4.15.3.1 Installing 2-Wire Class B Smoke Detectors .............................................................36

4.15.3.2 Installing 2-Wire Class A Smoke Detectors ............................................................36

2

4.15.4 Installing 4-Wire Smoke Detectors ....................................................................................36

4.15.4.1 Installing a Class B 4-Wire Smoke Detectors ..........................................................37

4.15.4.2 Installing 4-Wire Class A Smoke Detectors .............................................................37

4.15.5 Auxiliary Power Installation ........................................ ........................................................38

4.15.5.1 Door Holder Power ...................................................................................................39

4.15.5.2 Constant Power ........................................................................................................39

4.15.5.3 Resettable Power .....................................................................................................39

4.15.5.4 Sounder Sync Power ...............................................................................................39

4.16 On-Board Relays (Conventional) ..............................................................................................39

4.16.1 Trouble Relay ...................... ...... ....... ...... ....... ...... ...... ....... ...... ...........................................39

4.16.2 Programmable Relays ................................... ...... ...... ....... ...... ....... ...... ....... .......................39

4.17 Remote Station Applications ....................................... ...... ....... ...... ....... ...... ....... ...... ....... ..........40

4.17.1 Keltron Model 3158 Installatio n ................................. ....... ...... ....... ...... ....... ...... ....... ...... ....40

4.17.2 City Box Connection Using the 5220 Module ....................................................................40

4.17.3 Using the Addressable Relay Module for City Box Connection .........................................41

4.17.4 NFPA 72 Polarity Reversal ........ ....... ...... ....... ...... ...... ....... ...... ....... ...... ....... .......................41

4.17.4.1 Using the 5220 Module ............................................................................................42

4.17.4.2 Using the 7644-L8 Module .......................................................................................43

4.17.5 Transmitter Activated by Dry Contacts ..............................................................................44

Section 5

Networking ....................................................................................................................................................1

5.1 Network System Hardware Features ..........................................................................................1

5.1.1 Networked Sites ....................................................................................................................1

5.1.2 Wiring Options to Connect Networked Panels ......................................................................1

5.2 Model RFP-2100 .........................................................................................................................1

5.3 Network Wiring ............................................................................................................................1

5.4 SK-NIC Wiring Options ................................................................................................................3

5.4.1 Fiber Loop Modules ..............................................................................................................3

5.4.1.1 Accessory Mounting Kits .............................................................................................4

5.4.2 SK-NIC Installation ................................................................................................................4

5.4.2.1 Unshielded Twisted Pair Wiring between Multiple Panels ..........................................6

5.4.2.2 Fiber Optic Multi-Mode Wiring between Multiple Panels .............................................7

5.4.2.3 Fiber Optic and Twisted Pair Wiring between Multiple Panels ....................................9

5.5 Setting the Network ID for each Panel ......................................................................................10

Section 6

Network Management .....................................................................................................................1

6.1 Network Diagnostics ....................................................................................................................1

6.1.1 Ping Panel .............................................................................................................................1

6.1.2 Data Network Status ............................................................................................................1

6.1.3 Voice Network Status ............................................................................................................1

6.2 Network Programming .................................................................................................................1

6.2.1 Learn Network .......................................................................................................................1

6.2.2 Edit Network Names .............................................................................................................2

6.2.3 Edit Panel ID .........................................................................................................................2

6.2.4 Computer Access ........... ....... ...... ....... ...... ....... ...... ...... .............................................. ............2

6.2.5 Access Codes .......................................................................................................................3

6.2.5.1 Edit Name ...................................................................................................................4

3

Model IFP-2100/ECS Installation Manual

6.2.5.2 Edit Access Code ........................................................................................................4

6.2.5.3 Panel Functions ..........................................................................................................4

6.2.6 Communicator Options .........................................................................................................5

6.2.6.1 Communicator Assignments .......................................................................................5

6.2.6.2 Communicator Miscellaneous .....................................................................................5

6.2.6.3 Receiver Configuration ................................................................................................5

6.2.6.4 Communicator Reporting Table ..................................................................................6

6.3 Voice Options ..............................................................................................................................6

6.3.1 Edit Timers ............................................................................................................................6

6.3.1.1 Control Lockout ...........................................................................................................6

6.3.1.2 Auto Reset ECS MIC Triggered Event ........................................................................7

6.3.2 Edit Voice Commands ..........................................................................................................7

6.4 Sync Network Options .................................................................................................................8

6.5 Network Management Quick Reference .....................................................................................9

Section 7

IDP, SK, SD and SWIFT™ SLC Device Installation ................................1

7.1 List of IDP SLC Devices ..............................................................................................................1

7.2 List of SK SLC Devices ...............................................................................................................2

7.3 List of SD SLC Devices ...............................................................................................................3

7.4 List of SWIFT Wireless SLC Devices ..........................................................................................4

7.5 Maximum Number of SLC Devices .............................................................................................4

7.6 Wiring Requirements for SLC Devices ........................................................................................4

7.6.1 Wire Sizing on 5815XL for SD Devices ................................................................................5

7.6.2 Wire Sizing for 6815 ..............................................................................................................5

7.6.3 Wiring Requirements for IDP or SK Modules .......................................................................5

7.6.4 Wiring 5815XL or 6815 in Style 6 & 7 (Class A) Configuration .............................................6

7.7 Addressing IDP or SK SLC Devices ............................................................................................7

7.8 Wiring SD Detectors ....................................................................................................................8

7.9 Addressing SD Devices ............... ...... ............................................. .............................................8

7.9.1 SLC Devices with DIP Switches .........................................................................................10

7.10 Wiring the WIDP-WGI or SK-WGI .............................................................................................11

7.10.1 Power Connections for the Gateway .................................................................................11

Section 8

Programming Overview ...............................................................................................................1

8.1 JumpStart® AutoProgramming ...................................................................................................1

8.1.1 Input Points ...........................................................................................................................1

8.1.2 Output Points ........................................................................................................................1

8.1.3 Running JumpStart® AutoProgramming ..............................................................................2

8.2 Mapping Overview .......................................................................................................................4

8.2.1 Input Point Mapping ..............................................................................................................5

8.2.2 Output Circuit Mapping .........................................................................................................6

8.2.3 Event Mapping .....................................................................................................................7

8.2.4 Mapping LED Points ...........................................................................................................11

8.2.5 Mapping LED Points for a Networked System ....................................................................12

8.3 Programming Using the HFSS Honeywell Fire Software Suite .................................................12

8.4 Programming Using an Annunciator .........................................................................................12

8.4.1 Entering / Exiting Panel Programming ................................................................................12

4

8.4.1.1 Moving through the Menus ........................................................................................13

8.4.1.2 Selecting Options and Entering Data ........................................................................13

8.5 Programming Menu Quick Reference .......................................................................................14

Section 9

Programming .............................................................................................................................................1

9.1 UL 864 / UL 2572 Programming Requirements ..........................................................................1

9.2 Modules .......................... ............................................. ................................................................2

9.2.1 Edit Modules .........................................................................................................................2

9.2.1.1 Editing Module ID ........................................................................................................2

9.2.1.2 Naming Modules .........................................................................................................2

9.2.1.3 Changing Module Options ...........................................................................................3

9.2.2 Adding a Module ...................................................................................................................3

9.2.3 Deleting a Module .................................................................................................................3

9.2.4 View Module List ...................................................................................................................3

9.3 Zone ............................................................................................................................................4

9.3.1 Edit Zone ...............................................................................................................................4

9.3.1.1 Edit Zone Name ..........................................................................................................4

9.3.1.2 Edit Zone Properties ...................................................................................................4

9.3.1.3 Zone Accessory Options .............................................................................................6

9.3.2 View Zone Points ..................................................................................................................7

9.4 Group ..........................................................................................................................................7

9.4.1 Edit Group .............................................................................................................................7

9.4.1.1 Edit Group Name ........................................................................................................7

9.4.1.2 Edit Group Properties ..................................................................................................7

9.4.2 View Group Points ................................................................................................................9

9.4.3 Edit OPG Template ...............................................................................................................9

9.5 Point ............................................................................................................................................9

9.5.1 Point Programming For 5815XL Module ...............................................................................9

9.5.2 Point Programming For 6815 Module .................................................................................12

9.5.3 Point Programming For Internal or External Power Module (RPS-1000) ...........................15

9.5.4 Point Programming For 5880/5865 Modules ......................................................................17

9.5.5 Point Programming for 5496 ...............................................................................................17

9.5.6 Point Programming for ECS-AMP .......................................................................................18

9.5.7 Point Programming for ECS-VCM, ECS-NVCM or ECS-RVM ...........................................19

9.6 System Options .............................................. ....... ...... ............................................. .................21

9.6.1 Communication Options ......................................................................................................21

9.6.1.1 Auto Test Time ..........................................................................................................21

9.6.1.2 Phone Lines ..............................................................................................................22

9.6.1.3 Edit Ethernet .............................................................................................................24

9.6.1.4 AlarmNet Timers .......................................................................................................24

9.6.1.5 Phone Line Gains ......................................................................................................25

9.6.2 Daytime/Nighttime Sensitivity .............................................................................................25

9.6.3 Holiday Days .......................................................................................................................25

9.6.4 Time Options .......................................................................................................................26

9.6.4.1 Water Flow Delay ......................................................................................................26

9.6.4.2 Alarm Verify ...............................................................................................................26

9.6.4.3 AC Report Delay .......................................................................................................27

9.6.4.4 Change AC Line Frequency ......................................................................................27

9.6.4.5 Clock Format (AM/PM or Military) .............................................................................27

9.6.4.6 Auto-Resound (4 or 24 hours) ...................................................................................27

5

Model IFP-2100/ECS Installation Manual

9.6.5 Miscellaneous Options ........................................................................................................27

9.6.5.1 Strobes Active when Silenced ...................................................................................27

9.6.5.2 Auto Display Events ..................................................................................................28

9.6.6 Daylight Saving Options . ....... ..............................................................................................28

9.6.6.1 Automatic Daylight Saving Adjustment .....................................................................28

9.6.6.2 Daylight Saving Time Start and End .........................................................................28

9.6.7 Edit Banner .........................................................................................................................29

9.6.8 SLC Family .........................................................................................................................29

9.7 JumpStart® AutoProgramming .................................................................................................30

9.8 Restore Defaults ............. ...... ....... ...... ....... ...... ....... ...... ...... ....... ...... ....... ...... ....... .......................30

9.9 Voice Options ............................................................................................................................30

9.9.1 VCM Maintenance ..............................................................................................................30

9.9.2 Voice Settings .....................................................................................................................30

9.9.2.1 Enable Dual Channel System ...................................................................................31

Section 10

System Operation ................................................................................................................................1

10.1 Default User and Installer Codes ................................................................................................1

10.2 Annunciator Description ..............................................................................................................1

10.2.1 LCD Display ............ .................................................................................... .........................2

10.2.2 Banner .................................................... ....... ...... ...... ....... ...... ....... ...... ................................2

10.2.2.1 Single Key Acknowledge ............................................................................................2

10.3 Menu System .............................................................................................................................2

10.3.1 Main Menu Overview ........... ...... ....... ...... ....... ...... ...... ....... ...................................................2

10.3.2 Using the Menus ..... ...... ....... ...... ....... ...... ....... ...... ...... ....... ...... ....... ......................................3

10.4 Basic Operation .................... ....... ...... ....... ............................................. ......................................3

10.4.1 Setting Time and Date .........................................................................................................3

10.4.2 Disable / Enable a Point ............ ....... ...... ....... ...... ...... ....... ...... .............................................3

10.4.2.1 Disable / Enable NACs by Template ..........................................................................3

10.4.2.2 Disable / Enable NACs by Group ...............................................................................3

10.4.2.3 Disable / Enable Zone Points .....................................................................................3

10.4.2.4 Disable / Enable Point ................................................................................................4

10.4.2.5 Inhibit Output Group ...................................................................................................4

10.4.3 View Event History ..............................................................................................................4

10.4.3.1 To clear the event history ...........................................................................................4

10.4.4 Conduct a Fire Drill ..............................................................................................................4

10.4.5 Conduct an Indicator Test ................................... ...... ....... ...... ....... ...... ....... ...... ....... ...... ......5

10.4.6 Conduct a Walk Test ...........................................................................................................5

10.4.7 Conduct a Communicator Test ............................................................................................5

10.4.8 Manual AlarmNet Registration .............................................................................................6

10.4.9 Silence Alarms or Troubles .................................................................................................6

10.4.10 Reset Alarms .....................................................................................................................6

10.4.10.1 Reset Communicator ..............................................................................................6

10.4.11 Check Detector Sensitivity Through Point Status .............................................................6

10.4.12 View Status of a Point ......................................................................................................7

10.4.13 View Alarms or Troubles ..................................................................................................8

10.4.14 System Information ...........................................................................................................8

10.5 Event Priority ..............................................................................................................................9

10.5.1 System Control .............................................. ...... ...... ....... ...... ....... ...... ....... ...... ....... ............9

10.5.2 System Override ........................................................ ....... ...................................................9

10.5.3 Event Priority ................ ....... ................................................................................................9

6

10.5.4 Priority Rules ................ ....... ............................................. .................................................10

10.5.5 Other Priority Considerations ............................................................................................10

10.6 Operation Mode Behavior .........................................................................................................11

10.6.1 Multi-Site Annunciator and Multi-Site User Access ...........................................................14

10.7 Releasing Operations ................................................................................................................15

10.7.1 Single Interlock Zone Releasing ........................................................................................16

10.7.2 Double Interlock Zone Releasing ........................ ...... ....... ...... ....... ...... ....... ...... ....... ...... ....17

10.8 Smoke Alarm Verification ..........................................................................................................18

10.9 Function Keys ...........................................................................................................................18

10.9.1 Recording an F-Key Macro ................................................................................................19

10.9.2 Aborting an F-Key Macro Recording Session ...................................................................19

10.9.3 Erasing an F-Key Macro ....................................................................................................19

10.9.4 Using a Recorded F-Key Macro ............. ....... ...... ...... ....... ...... ....... ...... ....... ...... ....... ...... ....19

10.9.5 F-Key Status Event ............................................................................................................19

10.9.6 F-Key Map Inhibit ..............................................................................................................19

Section 11

Emergency Communication System Operation ..........................................1

11.1 Overview .....................................................................................................................................1

11.2 LOC Functionality ........................................................................................................................1

11.2.1 Keys and LEDs ....................................................................................................................1

11.2.1.1 ECS Control Key ........................................................................................................1

11.2.1.2 ECS Control LED .......................................................................................................2

11.2.1.3 ECS Message Keys ...................................................................................................2

11.2.1.4 ECS Message LEDs ..................................................................................................2

11.2.1.5 Select Keys ................................................................................................................2

11.2.1.6 Select Key LEDs ........................................................................................................2

11.2.2 Gaining ECS Control ...........................................................................................................3

11.2.2.1 LOC Priority ................................................................................................................3

11.2.2.2 LOC Lockout ..............................................................................................................3

11.2.2.3 User Profile Access Control .......................................................................................4

11.2.3 Manual ECS ..................................... ...... ....... ...... ...... ....... ...... ....... ...... ....... ...... ....... ............4

11.2.3.1 Switching between Microphone Mode and Message Mode .......................................4

11.2.3.2 Activating Output Groups Dynamically .......................................................................4

11.2.4 Microphone Mode ......... ....... ...... ....... ...... ....... ............................................. .........................5

11.2.5 Message Mode .............................................. ...... ...... ..........................................................5

11.2.6 Custom ECS Event ........................................ ............................................. .........................5

11.2.7 Passing ECS Control ...........................................................................................................5

11.2.8 Exit ECS Control Menu ........................................................................................................6

11.2.9 Relinquish ECS Control .......................................................................................................6

11.2.10 ECS Reset ........................................................................................................................6

11.3 ECS Super User ..........................................................................................................................6

11.4 ECS Point Functionality ...............................................................................................................7

11.4.1 ECS Point Activations ..........................................................................................................7

11.4.2 ECS-VCM, ECS-NVCM & ECS-RVM Points .......................................................................7

11.5 Amplifier Programming ................................................................................................................7

11.5.1 Adding an Amplifier .............................................................................................................7

11.5.2 Editing an Amplifier ..............................................................................................................8

11.6 LOC Programming ......................................................................................................................8

11.6.1 Adding an LOC ....................................................................................................................8

11.6.2 Editing an LOC ....................................................................................................................9

7

Model IFP-2100/ECS Installation Manual

11.6.2.1 LOC Priority ................................................................................................................9

11.6.2.2 LOC Association ........................................................................................................9

11.7 Using the Microphone .................................................................................................................9

11.7.1 Microphone Functionalit y ............................... ...................................... ....... ...... ....... ............9

11.7.2 Custom ECS Event ........................................ ............................................. .........................9

11.7.3 Fire Page ....................................................... ...... ...... ....... ...... ....... ...... ....... ...... .................10

11.7.4 Emergency Page .................................... ....... ...... ...... ....... ...... ....... ...... ....... ...... ....... ..........10

11.7.4.1 Paging ......................................................................................................................10

11.8 Recording Custom Messages ........... ....... ...... ....... ...... ............................................. .................11

11.8.1 Recording Messages 1-15 Using Aux Audio Input ............................................................12

11.8.2 Recording Messages 1-15 Using the Microphone .............................................................14

11.8.3 Erasing User Message ......................................................................................................15

11.8.4 Using HFSS Voice Message Load Software .....................................................................15

11.9 Network Paging .........................................................................................................................16

11.9.0.1 Priority ......................................................................................................................16

11.9.0.2 Configuration ............................................................................................................17

Section 12

Reporting .........................................................................................................................................................1

12.1 Receivers Compatible with the Control Panel .............................................................................1

12.2 SIA - IntelliKnight / IFP-2100/ECS Panels PI Modifier Reporting: .............................................13

12.3 SIA – IFP-2100/ECS Panel Communicator: ..............................................................................14

Section 13

Testing and Troubleshooting ...............................................................................................1

13.1 Troubleshooting ....... .................... ................... ................... .................... ................... ...................1

13.2 Common Problems ......................................................................................................................1

13.3 Periodic Testing and Maintenance ..............................................................................................2

13.4 Event History ...............................................................................................................................3

13.5 Built-in Troubleshooting and Testing Tools .................................................................................3

13.5.1 SLC Device Locator ............. ............................................. ...................................................3

13.5.2 SLC Multiple Device Locator ..... ....... ...... ....... ...... ...... ....... ...... ....... ...... ....... ...... ....... ............3

13.5.3 I/O Point Control ..................................................................................................................4

13.5.4 Earth Fault Resistance ........................................................................................................5

Section 14

Installation Records ..........................................................................................................................1

14.1 Detector and Module Point Record .............................................................................................1

14.2 Conventional Output Point Record ..............................................................................................5

8

Appendix A

Compatible Devices ..........................................................................................................................1

Appendix B

Editing Text Using the Built-In Programmer ....................................................1

Appendix C

Cadence Patterns .................................................................................................................................1

Appendix D

Expanded Receiver/Panel Relationship .................................................................1

Panel Security

Manufacturer Warranties and Limitation of Liability

Model IFP-2100 Basic Operating Instructions

Model IFP-2100ECS Basic Operating Instructions

9

Model IFP-2100/ECS Installation Manual LS10143-001SK-E

Section 1 Introduction

The IFP-2100 (red) / IFP-210 0B (black) and IFP-2100 ECS (red) / IF P-2100ECSB (black) are analog addr essable

fire alarm control panels (FACP), that meets the requirements of UL 864. The IFP-2100ECS is an analog

addressable fire control system combined with an Emergency Communication System that meet the

requirements for Mass Notification as described in UL 864 and UL 2572.

The RFP-2100 (red) or RFP-2100B (black) are the same as the IFP-2100 without the display. The RFP-2100 is

used in a networked system where there is at least one IFP-2100/ECS in the system. When using the RFP-2100

as a stand alone local unit, one LCD annunciator must be connected, and the annunciator must be wired in

conduit within 20’of the RFP-2100.

Note: All references to IFP- 2100 o r IFP-2 100ECS within this manu al are ap plicab le t o the IFP-2 100B an d IFP-

2100ECSB. All References to the IFP-2100HV are applicable to the IFP-2100HVB, RFP-2100HV, RFP2100HVB, IFP-2100ECSHV and the IFP-2100ECSHVB.

Note: All references to RFP-2100 within this manual are applicable to RFP-2100B.

1.1 Overview of Basic System

The IFP-2100/ECS base system is packaged as an assembled stack of 3 circuit boards mounted to an aluminum

housing.

1.1.1 Hardware Features

• The basic IFP-2100/ECS panel contains one built in signaling line circuit (SLC), which supports up to 159

IDP or SK sensor s and 159 ID P or SK mod ules or 127 SD SLC devices. Additional SLC loops can be added

to increase overall point capacity.

• Additional 6815 SLC expanders supports 159 IDP or SK sensors and 159 IDP or SK modules for a

maximum of 2100 points per IFP-2100/ECS control panel.

• Additional 5815XL SLC expander supports only SD Protocol for a maximum of 2032 points per IFP-2100/

ECS control panel.

• 9.0A of output power is available through 8 sets of terminals for notification and auxiliary applications.

Each circuit is power limited per UL 864 and can source up to 3.0A (total output power must not exceed

9.0A). The constant auxiliary power load must not exceed 6.0A for normal standby.

• Built-in dual phone line, digital alarm communicator/transmitter (DACT), IP or optional cellular

technologies.

• Reports events to central station by point or by zone.

• UL Listed for pre-action and deluge releasing systems.

• Dedicated Form C trouble relay and two general purpose Form C programmable relays.

• Can be used with RA-2000s

• Supports the 5865-3, 5865-4, and 5880 LED annunciators

information on these models.

• Printing of event log available through the Model 5824

• Supports conventional 2-wire & 4-wire detectors using the 8 Flexput™ circuits or SLC zone modules.

• 999 software zones, 999 output groups.

• Add four notification/auxiliary power circuits with each 5496 Intelligent Power Module.

• Add six Flexput™ circuits with each RPS-1000 Remote Power Supply.

1

, RA-1000s2 or RA-100s2 in any combination.

1

. See sections 4.11 and 4.12 for additional

1

serial/parallel printer interface module.

1-1

Introduction

1. The system can have a maximum of 63 SB US devices in any combination.

2. RA-1000 and RA-100 can have a maximum of 31 devices used.

1.1.2 Network System Hardware Features

• The default network setup can contain up to 32- IFP-2100/ECS / RFP-2100 panels connected.

• Network support for up to 32 Sites.

• Each building is referred to as a “site”.

• Panels can be interconnected using CLASS B or CLASS A topology.

• To network panels together use the SK-NIC network card. Copper wire or fiber optic cable panel

connectivity can be used within the same networked system.

• The network architecture provides true peer to peer capability allowing network survivability for all

hardware that remains operational in the event of partial system failure.

1.1.3 Software Features

• Advanced analog smoke detector features:

Three sensitivity settings (high, medium, low)

Automatic drift compensation

Maintenance alert region

Point status meets calibrated smoke test requirements for NFPA 72

Automatic day/night sensitivity adjustment

• “JumpStart Auto Pr ogr amming” feature for easy programming

• Non-volatile event history stores 1000 events per panel

• A choice of output patterns available for notification outputs, including ANSI 3.41 temporal signal

• Built-in synchronization appliance support for AMSECO, Gentex

®

, System Sensor®, and Wheelock

®

1.1.4 IFP-2100ECS Features

• 15 Recordable one minute messages that can be mapped to eight ECS buttons.

• ECS messages can be selected as priority over fire.

• Support of up to 15 ECS-LOC’s.

• Programmable trigger inputs from an external source, such as a Monaco system, to either the ECS-VCM,

ECS-NVCM, ECS-RVM, 5880, any SLC input module or Flexput module.

• Support for up to 16 SBUS addressable amplifiers using a combination of ECS-50W, ECS-125W, ECSINT50W or ECS-DUAL50W for a maximum of 2000 watts per system and up to 128 mappable speaker

circuits.

• Support for dual channel and backup audio using the ECS-DUAL50W amplifier and ECS-50WBU back-up

amplifier.

• Single enclosure for both Fire and Emer gency Control System components.

• Support for one ECS-VCM or ECS-NVCM.

1-2

Model IFP-2100/ECS Installation Manual LS10143-001SK-E

1.1.5 Terms Used in this Manual

The following terminology is used with the above mentioned control panels:

Term Description

SLC Signaling line circuit

Module The term module is used for all hardware devices except for SLC addressable devices and

notification appliances. This includes the IFP-2100/ECS/RFP-2100 panels itself and the built-in

power supply. It also refers to any (optional) 5815XL or 6815 SLC expansion modules.

Input Point An addressable sensing device, such as a smoke, heat detector or a contact monitor device

Input Zone A protected area made up of input points

Output Point

(or “Output Circuit”)

Group (or “Output Group” or

OPG)

Mapping Mapping is the process of specifying which outputs are activated when certain events occur in

Networking Up to 32 panels can be networked.

Network System Consist of any combination of 32 panels of these model numbers: IFP-75, IFP-300, IFP-

ECS Emergency Communication System

SWIFT Smart Wireless Integrated Fire Technology

A notification point or circuit for notification appliances. Relay circuits and auxiliary power

circuits are also considered output points

A group of output points. Operating characteristics are common to all output points in a group

the system. Section 8.2 explains mapping in detail

300ECS, IFP-2100, IFP-2100ECS, RFP-2100, IFP-2000, or IFP-2000ECS

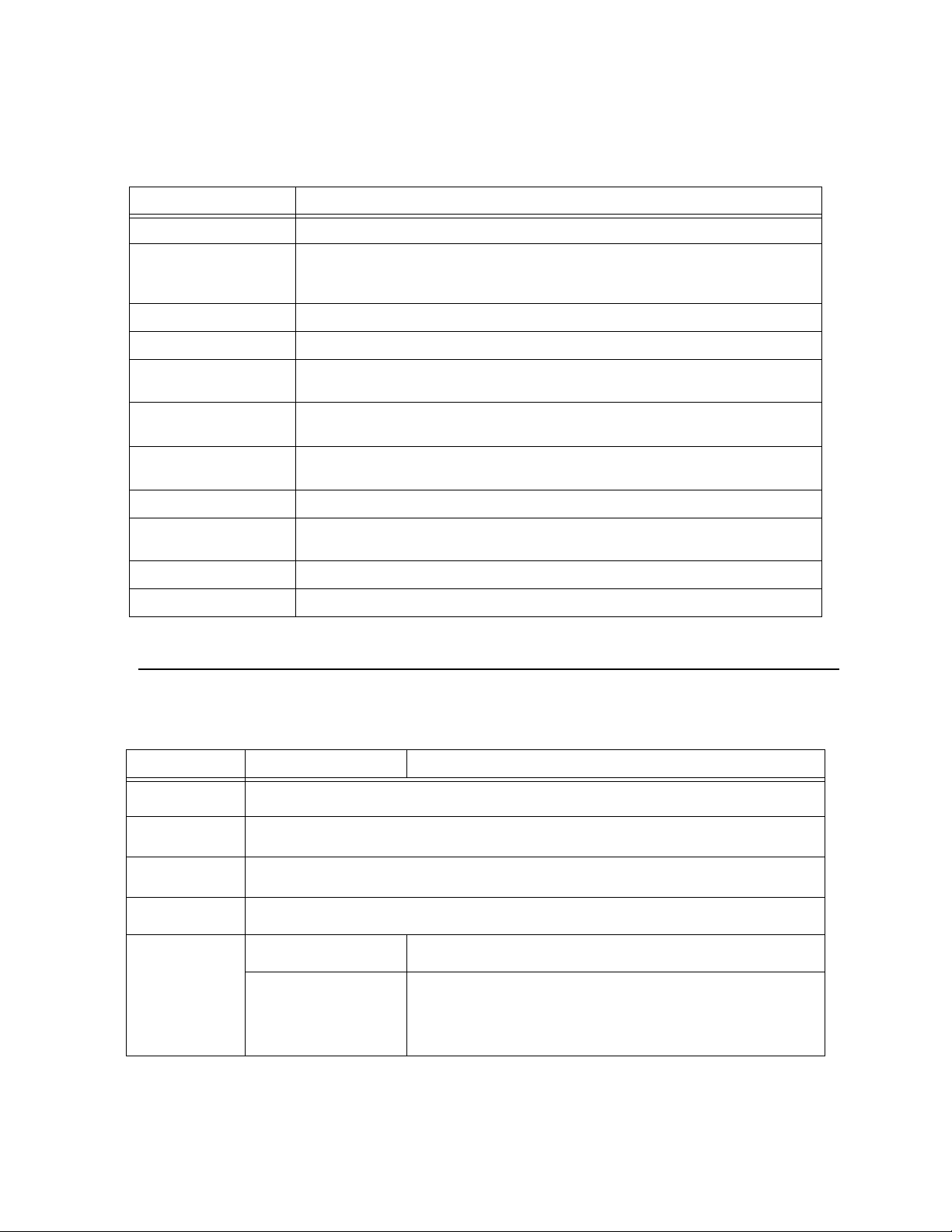

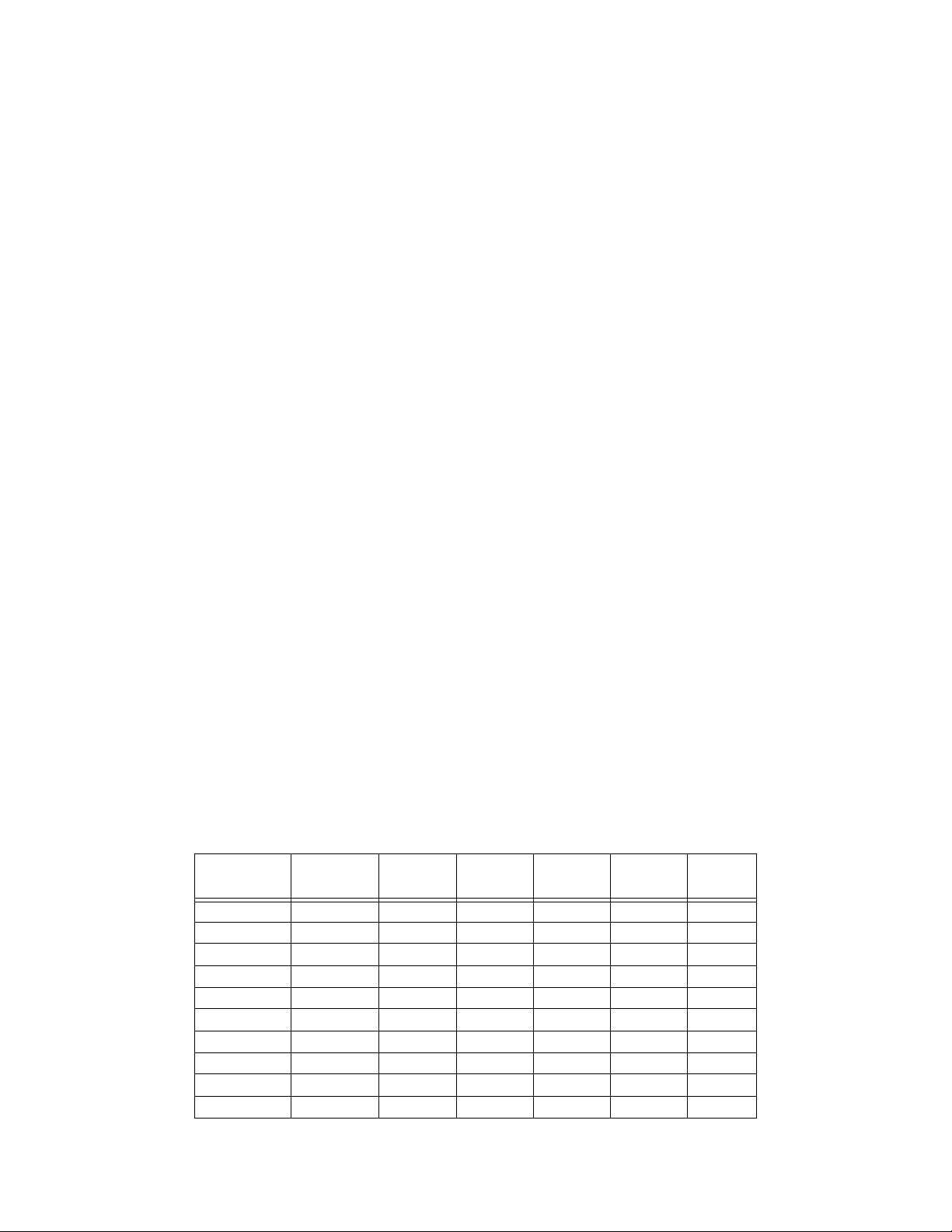

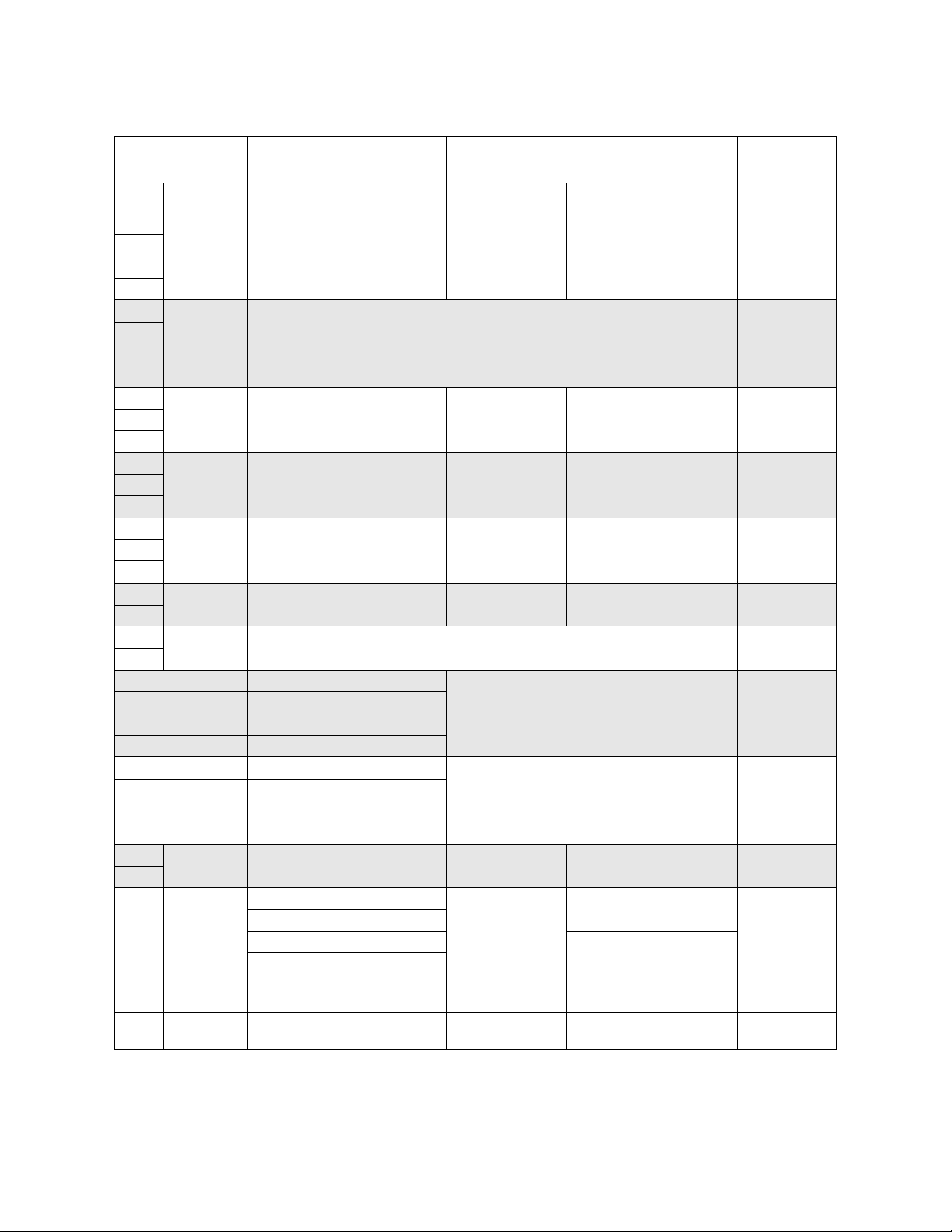

1.2 Compatible Products

Table 1-1 lists the products available for use with the IFP-2100/ECS.

Table 1-1: IFP-2100/ECS Compatible Products

T ype of Device Model Description

IDP Addressable

SLC Devices

SK Addressable

SLC Devices

SD Addressable

SLC Devices

SWIFT Wireless

SLC Devices

Other Modules

See Section 7.1 for a list of compatible devices

See Section 7.2 for a list of compatible devices

See Section 7.3 for a list of compatible devices

See Section 7.4 for a list of compatible devices

5824 Serial/Parallel Printer

Interface Module

5815XL (Rev H or above)

SLC Expander

Allows a printer to be attached for the system for on-site logging. Four

maximum per system.

Each 5815XL allows up to 127 SD devices to be added to the system. The

number of 5815XLs that can be added to the system is limited only by the

maximum number of SBUS devices. However the maximum SD point

count is limited to 2032 per panel. 5815XL will only support SD protocol

devices

1-3

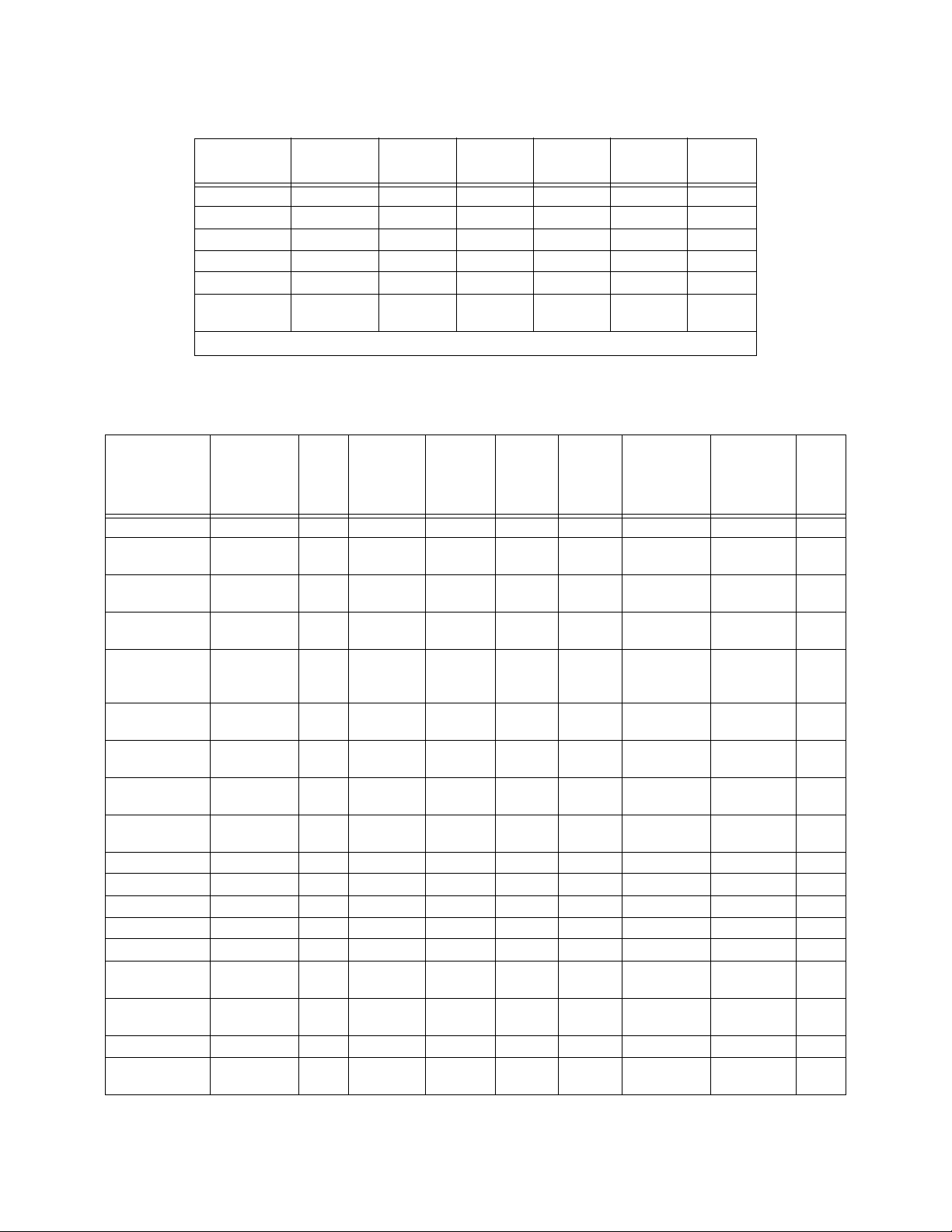

Table 1-1: IFP-2100/ECS Compatible Products

T ype of Device Model Description

Other Modules

(con’t)

6815 SLC EXPANDER Each 6815 supports up to 159 IDP or SK sensors and 159 IDP or SK

RFP-2100 Remote Fire

Panel w/no display

5824 Serial/Parallel Printer

Interface Module

RPS-1000 (Rev F or

higher) Intelligent Power

Module

5496 (Rev F or above) NAC

Expander

RA-2000 LCD Alarm

Annunciator

RA-1000 LCD Alarm

Annunciator

RA-100 LCD Alarm

Annunciator

5865-3 and 5865-4 LED

Annunciator

5880 (Rev C or above) LED

I/O Module

5883 General Purpose

Relay Module

ECS-VCM Voice Control Module

ECS-NVCM Network Voice Control Module

ECS-SW24 24 Switch expander

ECS-50W 50 watt audio amplifier

ECS-125W 125 watt audio amplifier

ECS-INT50W 50 watt internal amplifier

ECS-DUAL50W Dual Channel amplifier

ECS-50WBU Backup daughter card

ECS-CE4 Provides 4 additional audio circuits for the

ECS-RVM Remote Voice Microphone

SK-NIC Network Interface Card

ECS-LOC2100 Local Operating Console Refer to

modules. The maximum point count for IDP or SK devices is limited to 2100

per panel. 6815 supports System Sensor devices (IDP or SK)

Same operation as IFP-2100/ECS without display

Allows a printer to be attached for the on-site event logging. Maximum of

four 5824s per control panel.

Provides additional power, six Flexput™ circuits, and two Form C relays.

See Model RPS-1000 Installation Instructions P/N 151153.

Provides four additional Notification Appliance Circuits/Auxiliary power

4x40 LCD annunciator.Same operation, similar appearance as on-board

annunciator. Any combination of supported annunciators for a max of 63.

4x20 LCD annunciator. Any combination of supported annunciators for a

max of 31.

4x20 LCD annunciator. Any combination of supported annunciators for a

max of 31.

LED annunciator can display up to 30 LEDs (15 red and 15 yellow). 58654 has key switches for silence and reset, and a system trouble LED.

Driver for up to 40 LEDs. Interfaces with customized annunciator boards.

In addition, the 5880 has eight generic switch input points.

Provides 10 Form C relays. Designed to be driven by the 5880. Up to four,

5883s can be used with each 5880 module.

ECS-50W or the ECS-125W

Introduction

Refer to the ECS-Series

installation manual PN

151455 for more info on

these accessories.

LS10188-0001SK-E

1-4

Model IFP-2100/ECS Installation Manual LS10143-001SK-E

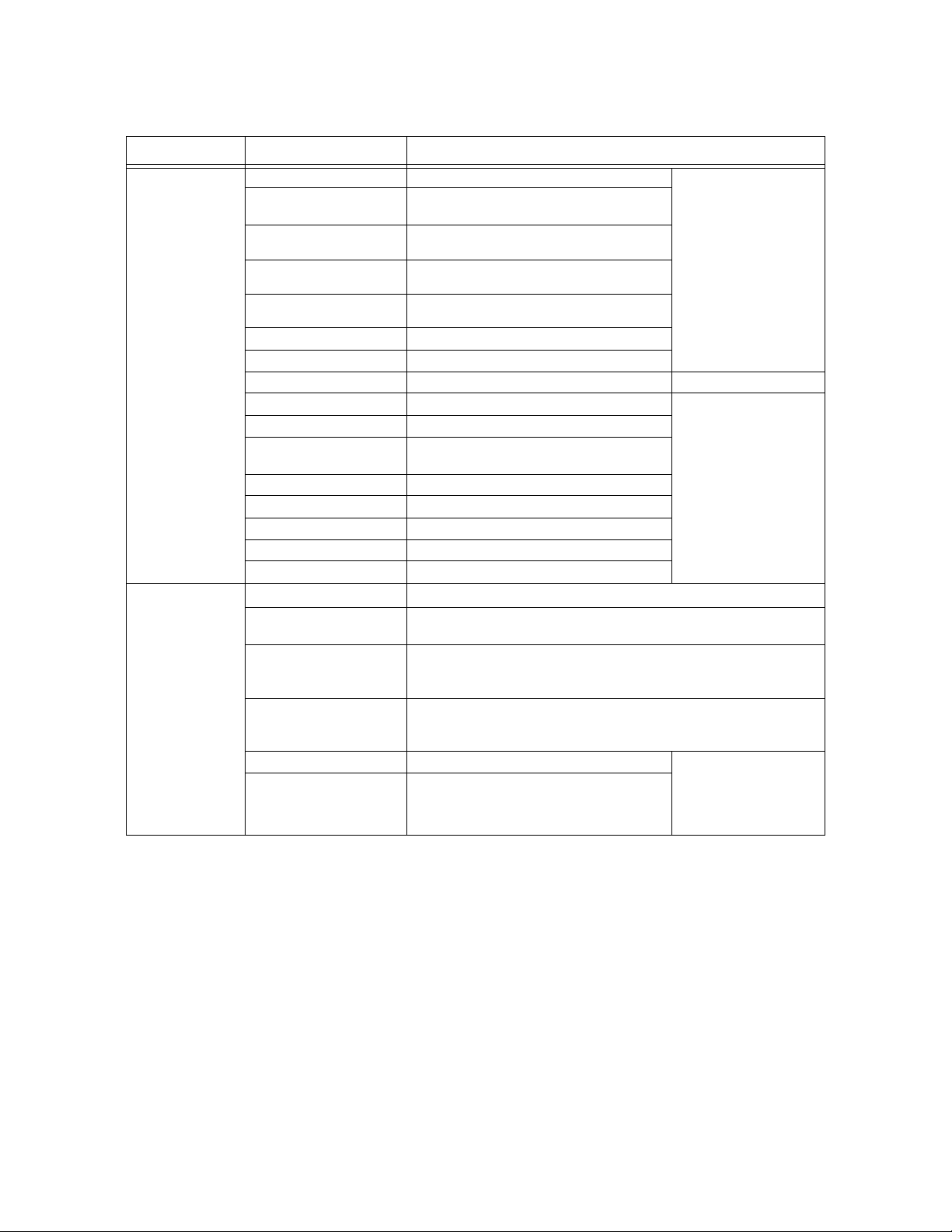

Table 1-1: IFP-2100/ECS Compatible Products

T ype of Device Model Description

WIDP-WGI Wireless Gateway

Wireless

Misc.

WIDP-PHOTO Wireless Photoelectric Smoke Detector w/ 4"

WIDP-ACCLIMATE

WIDP-HEAT-ROR

WIDP-HEAT

WIDP-MONITOR Wireless Addressable Monitor module

WIDP-RELAY Wireless Addressable Relay module

B210W 6" wireless base

WSK-WGI Wireless Gateway

WSK-PHOTO Wireless photo with 4" base

WSK-PHOTO-T Wireless Multi criteria photoelectric smoke

WSK-HEAT-ROR Wireless heat, ROR/ 135° fixed with 4" base

WSK-HEAT Wireless Heat, 135° fixed with 4" base

WSK-MONITOR Wireless monitor module

WSK-RELAY Wireless relay module

B210W 6" wireless base

7860 Telephone Cord

HFSS Honeywell Fire

Software Suite

RBB Remote Battery Box for mounting backup batteries up to 35AH that are too

AB-55 Remote Battery Box for mounting backup batteries up to 55AH that are too

CELL-MOD Cellular board with Plastic Enclosure Refer to the CELL-CABCELL-CAB-SK Cellular board with Metal Enclosure. Lock &

base

Wireless Multi criteria photoelectric smoke

detector with thermal (135°F) w/ 4" base

Wireless Heat Rate of Rise Detector 135°

fixed w/4” base

Wireless Heat, 135° fixed Heat Detector w/4”

base

detector with thermal (135°F) with 4" base

RJ31X cord for connecting phone line to the IFP-2100/ECS

For communication and panel programming with a Windows-based

computer. Enables remote viewing of detector status and event history.

large to fit into the main control panel cabinet. Dimensions: 16" W x 10" H x

6" D (40.64 cm W x 25.4 cm H x 15.24 cm D)

large to fit into the main control panel cabinet. Dimensions: 20" W x 12" H x

7.5" D (50.8 cm W x 30.48 cm H x 19.05 cm D)

key

Refer to the SWIFT

wireless Installation

Manual P/N LS10036-FH-

E for more information on

these accessories.

Refer to the SWIFT

wireless Installation

Manual P/N LS10036-SK-

E for more information on

these accessories.

SK/CELL-MOD

Installation Manual P/N

LS10182-001SK-E for

more information.

1-5

Model IFP-2100/ECS Installation Manual LS10143-001SK-E

Section 2 Agency Listings, Approvals, and Requirements

2.1 Federal Communications Commission (FCC)

1. The following information must be provided to the telephone company before the IFP-2100/ECS can be

connected to the phone lines:

A Manufacturer: Honeywell Silent Knight

B Model Number: IFP-2100; IFP-2100ECS

C FCC registration number: US: HS9AL10A2100

Ringer equivalence: 1.0A

D Type of jack: RJ31X

E Facility Interface Codes: Loop Start: 02LS2

F Service Order Code: 9.0F

This equipment complies with Part 68 of the FCC rules and the requirements adopted by ACTA. On the insid e

cover of this equipment is a label that contains, among other information, a product identifier. If requested, this

information must be provided to the telephone company.

A plug and jack used to connect this equipment to the premises wiring and telephone network must comply with

the applicable FCC Part 68 rules and requirements adopted by the ACTA. A compliant telephone cord (not

provided) and modular jack must be utilized with this product. It is designed to be used with a modular jack that

is also compliant.

The REN (ringer equivalence number) provided on this installation sheet is used to determine the number of

devices that may be connected to the public switched telephone network. This number must not exceed 5.0.

Since this product has an REN of 1.0A, the number of devices is limited. The REN number is embedded in the

FCC registration number as 10A.

If the IFP-2100/IFP-2100HV/ IFP-2100ECS or IFP-2100ECSHV causes harm to the telephone network, the

telephone company will notify you in advance that the temporarily discontinuance of service may be required.

But if advance notice is not practical, the telephone company will notify the customer as soon as possible. Also,

you will be advised of your right to file a complaint with the FCC if you believe it is necessary.

The telephone company may make changes in its facilities, equipment, operations or procedures that could affect