Honeywell ID50, ID60 Installation, Commissioning & Configuration Manual

installation,

commissioning &

configuration

ID50/60

997-263-000-11, Issue 11 January 2010

manual

ID50 Series Panel - Installation, Commissioning & Configuration Manual

Contents

1 Introduction 1

1.1 Manual Purpose 1

1.2 System Design and Planning 1

1.3 General 2

1.3.1 Date-dependent Functions 2

1.4 CE Marking 2

1.5 EN54 Functions 3

1.6 Ancillary Functions 4

1.7 Related Documents 5

1.8 Warnings and Cautions 5

1.9 Tips 5

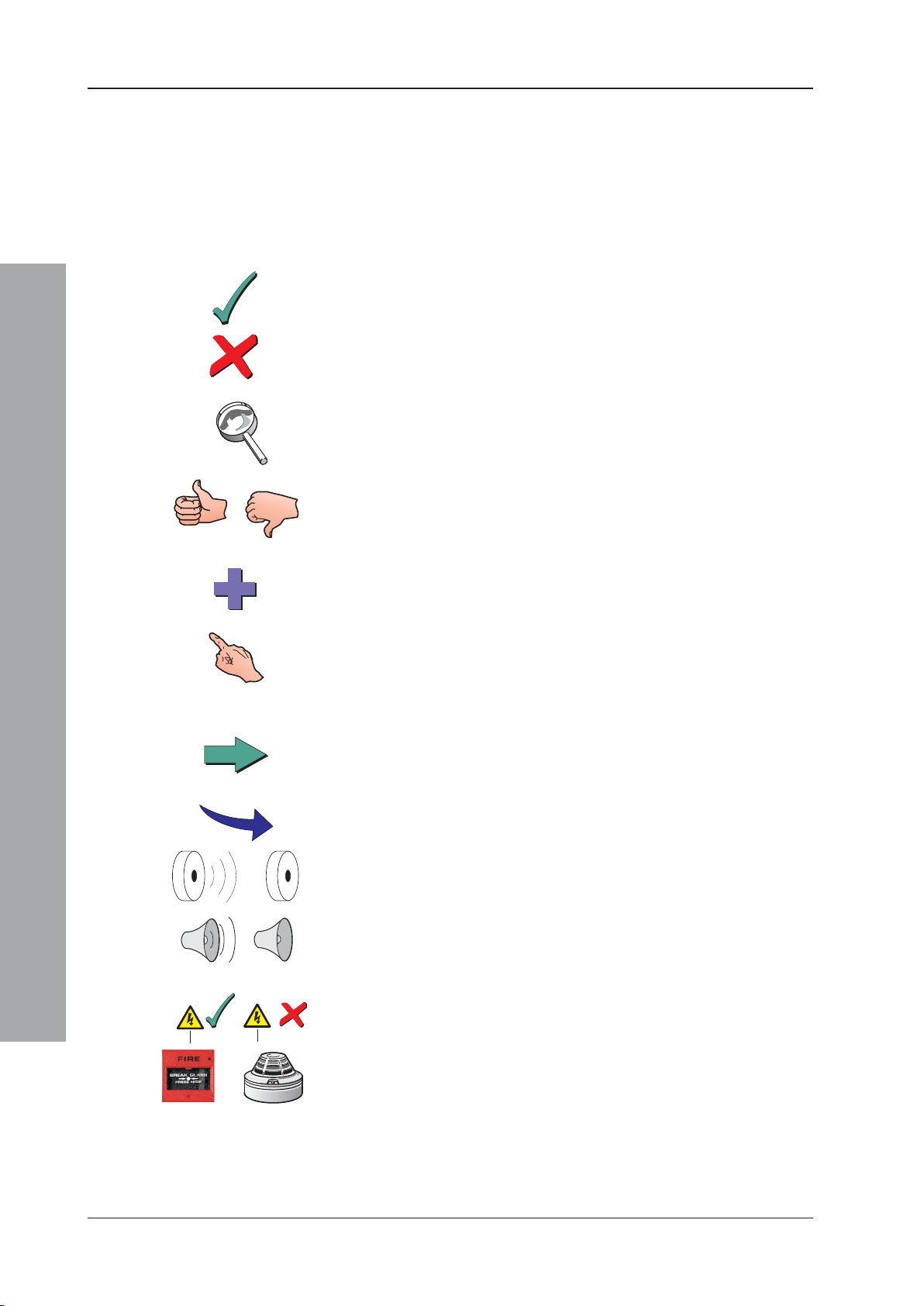

1.10 Glossary of Icons 6

2 Installation Guide 7

2.1 How to Use this Section 7

2.2 Pre-Installation Check List 7

2.1.1 Some Panel DO’s and DON’T’s 7

2.3 Transient Protection 8

2.4 Product Inspection 9

2.4.1 Checking Your Panel for Damage 9

2.4.2 What to do if Panel is Damaged

or Suspect 10

2.5 Dismantling the Panel 11

2.5.1 Removing the Cover 11

2.5.2 Removing the Panel Electronics 12

2.5.3 Back Box Fixing 13

2.5.4 Semi-Flush Mounting Bezel (Optional)14

2.6 Assembling the Panel 15

2.7 RS485 Communications Link 16

2.7.1 Fitting the RS485 Interface Module PCB17

2.8 RS232 Interface Connections 18

Contents

3 Cabling 19

3.1 Cabling Instructions 19

3.1.1 Cable Terminations 20

3.2 Cabling Installation Notes 21

3.2.1 Introduction 21

3.2.2 Quality of Cable and of Cable Installation 21

3.3 EMC Considerations 22

i 997-263-000-11, Issue 11

January 2010

ID50 Series Panel - Installation, Commissioning & Configuration Manual

3.3.1 Screen Termination 22

3.3.2 Ferrite Sleeves (Optional) 22

3.4 MICC Cables 22

4 Commissioning 23

4.1 Introduction 23

4.2 Preliminary Checks 23

4.3 Internal Checks 24

4.3.1 Jumper Link Options 24

4.4 External Wiring Checks 25

4.4.1 Loop Wiring 26

4.4.2 RS485 Communications Link 27

4.4.3 DC Auxiliary Output 27

4.4.4 Sounder Circuit Outputs 28

4.4.5 CFG Outputs C and D 30

4.4.6 -VE Outputs 31

Contents

4.4.7 Digital / ÜE Inputs 31

4.4.8 Switch Connections 31

4.5 Powering the Panel 32

4.5.1 Start-up Language Selection 32

4.5.2 Batteries 33

4.6 Configuration and Handover 34

4.7 Commissioning Tests 35

4.7.1 Test LEDs 35

4.7.2 Test LCD 35

4.7.3 Test Zones 35

4.7.4 Test Auto High Test 35

4.7.5 Test Outputs 35

4.7.6 Test Buzzer 35

4.7.7 Test Keyboard 35

4.8 Sensors and Modules 36

4.8.1 EN54 Requirements 36

4.8.2 Loop Wiring Testing 36

January 2010

5 Configuration 37

5.1 Introduction 37

5.2 Navigation and Number Entry 37

5.3 Level 2 Configuration Options 37

5.4 Level 3 Configuration Options 38

5.5 Setup Options 39

5.5.1 Panel Options 39

ii997-263-000-11, Issue 11

ID50 Series Panel - Installation, Commissioning & Configuration Manual

5.5.2 Site Details 45

5.5.3 Device Options 46

5.5.4 Peripheral Options 53

5.5.5 Day/Night Settings 61

5.6 Circuit Options 67

5.6.1 Signalling Line Circuit (SLC) - Devices 67

5.6.2 Signalling Line Circuit (SLC) - Learn 77

5.6.3 On-Board Circuits 79

5.7 Control-By-Event Output Rules 81

5.7.1 Output Type 84

5.7.2 Filter-by-type 85

5.7.3 Evacuation 86

5.7.4 Silence 86

5.7.5 Interrupt Delay 87

5.7.6 Class Change 87

5.7.7 Two Zone 88

5.7.8 Zones 89

5.7.9 Device Inputs 90

5.7.10 Soak Timer 91

5.8 Zone Texts 91

5.9 Access Options 92

5.10 System Options 93

5.10.1 Crystal Frequency 94

5.10.2 Wipe Memory 95

5.11 Normal 95

Appendix 1 - Specification A1-1 to A1-6

Appendix 2 - ID60 Single Loop Panel

Differences A2-1 to A2-5

Appendix 3 - Fault Messages & Meanings A3-1 to A3-4

Appendix 4 - EN54-2 Options with

Requirements A4-1 to A4-4

Appendix 5 - Configuration of a Fault Routing

Output Using a Zone Monitor A5-1

Contents

iii 997-263-000-11, Issue 11

January 2010

ID50 Series Panel - Installation, Commissioning & Configuration Manual

1 Introduction

1.1 Manual Purpose

The purpose of this manual is to provide the user with all

recommended procedures and full technical details for

the successful installation, commissioning and

programming of a NOTIFIER ID50 Series Panel.

The descriptions and procedures also apply to the

NOTIFIER ID60 panel. Differences between the ID50 and

ID60 panels are given in Appendix 2.

Procedures described in this manual include appropriate

warnings and cautions to guide the user towards adopting

safe and methodical work practices during the installation,

commissioning and programming phases.

The ID50 Series panels support OPAL protocol devices.

These devices support both OPAL and CLIP loop polling

protocols so they can be added to an existing CLIP

protocol loop. However, when OPAL protocol is enabled

on a loop a maximum of 10 CLIP device addresses can

be supported as part of the total of 99 sensors and 99

modules.

Important Note

This manual must be read, and its content clearly

understood, before proceeding with any work relating to

the ID50 Series Panel. Damage to the control panel may

result from NOT following the recommended procedures

described in this manual.

This manual provides all necessary instructions for the

ID50 Series Panel and applies only to fire panels fitted

with compatible software.

CAUTION: In particular, care must be taken when

powering up/down any repeaters.

If there are any areas of doubt, consult your supplier

before continuing with the system installation,

commissioning and programming.

1.2 System Design and Planning

It is assumed that the system, of which the ID50 Series

Panel equipment is a part, has been designed by a

competent fire alarm system designer in accordance with

the requirements of EN54 Part 14 and any other local

codes of practice that are applicable.

Introduction

The design drawings should clearly show the positions

of all the ID50 Series Panel control equipment and field

devices.

1

997-263-000-11, Issue 11

January 2010

ID50 Series Panel - Installation, Commissioning & Configuration Manual

1.3 General

The ID50 Series Panel is designed for use with

NOTIFIER’s range of addressable analogue sensors,

control and monitoring modules and addressable call

points. A unique signalling protocol is used, having digital

address and control signals and analogue pulse width

monitoring for the reply data from devices.

The serial communications interface operates under

RS485 protocol and enables communications between

the fire panel and repeaters.

While every effort is made to ensure the accuracy of the

content of this manual, the manufacturer reserves the

right to change the information without notice.

Installation

Only suitably-qualified

engineers must install,

commission and

configure this product.

Only fit the electronics

module after all the other

trades have completed

their tasks!

The ID50 Series Panel is easy to install providing the

recommended procedures described in this manual are

followed. To avoid inadvertent contamination of the PCB

Assembly, the manufacturer recommends it be installed

in the back box only after all other trades have completed

their tasks.

Commissioning

To commission the ID50 Series Panel, follow the

recommended procedures described in this manual. The

manufacturer recommends that during commissioning

and maintenance, ALL RS485 signal cables are

disconnected at the Panel end, BEFORE powering down

the system and are connected AFTER powering up the

system.

Introduction

Configuration

To configure the panel and system, carefully read and

follow the procedures given in this manual. These

procedures describe the menus that are displayed on

the Liquid Crystal Display (LCD) Unit.

Refer to the ID50 Series Operating manual (ref: 997264-000-X) for a description of compatible addressable

Signalling Loop Circuit (SLC) analogue devices.

1.3.1 Date-dependent Functions

The calendar end date for this product is 31/12/2063

(two thousand and sixty-three) and it will perform correctly

up to this date.

The calendar function has not been tested beyond

this date.

1.4 CE Marking

CE

This panel is CE Marked to show that it conforms to the

requirements of the following European Community

Directives:

January 2010

2997-263-000-11, Issue 11

ID50 Series Panel - Installation, Commissioning & Configuration Manual

The EMC Directive 2004/108/EEC, by the application of

the following EMC Standards:

EN 61000-6-3: Electromagnetic Compatibility (EMC)

Generic emission standard for Residential,

Commercial and Light industrial environments

EN 50130-4: EMC Product family standard: Immunity

requirements for components of fire, intruder and

social alarm systems.

Low Voltage Directive 2006/95/EEC, by the application

of the safety standard:.

EN 60950-1: Safety of information technology

equipment.

The Construction Products Directive 89/106/EEC, by the

application of the following standards:

EN 54-2:1998, (Amd. 1 & 2): Fire detection and fire

alarm systems - Control and indicating equipment.

EN 54-4: 1998 (Amd. 1 & 2): Fire detection and fire

alarm systems - Power supply equipment.

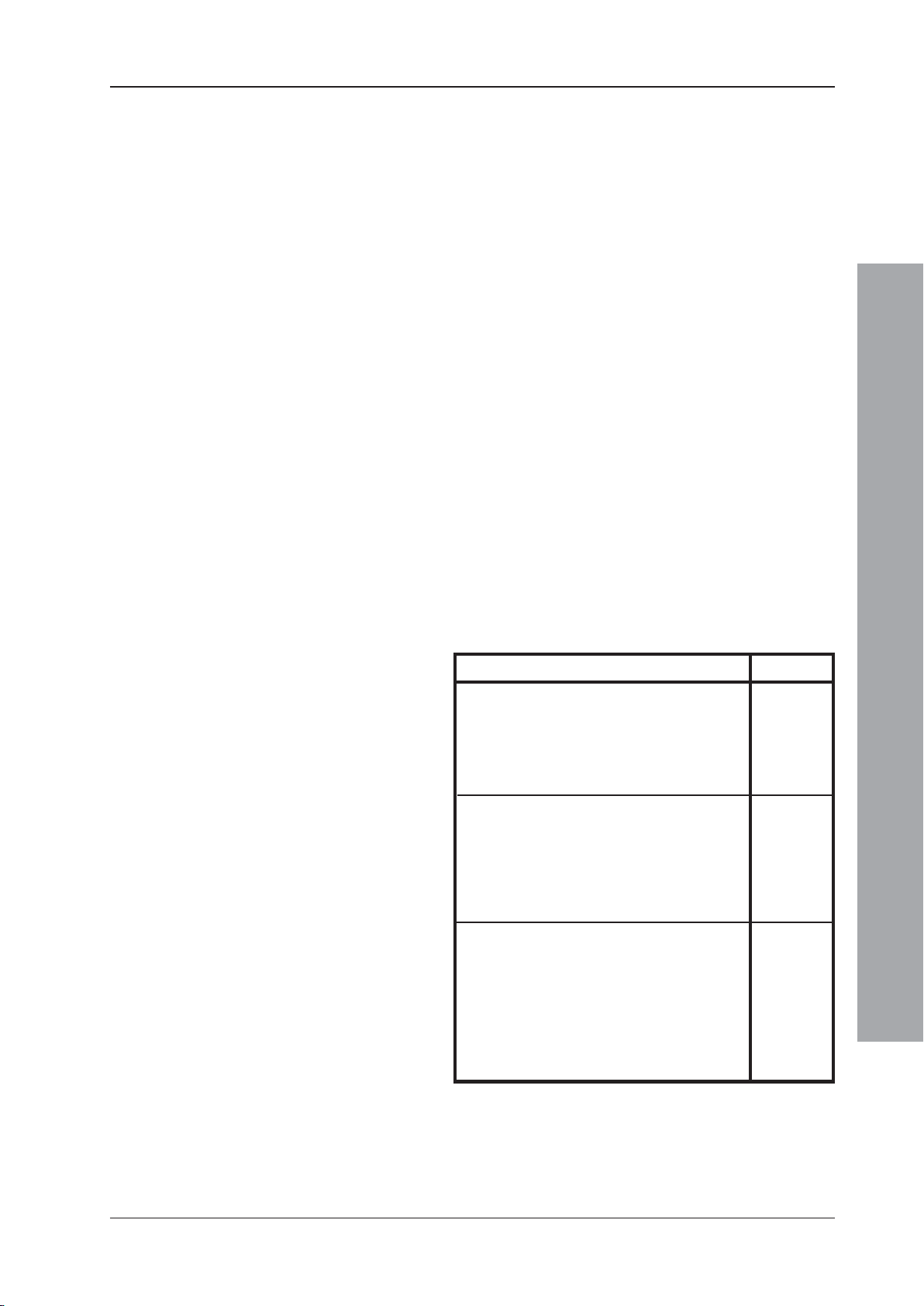

1.5 EN54 Functions

This fire control panel is designed to comply with the

requirements of EN 54 Part 2/4. In addition to the basic

requirements of EN 54-2, the panel may be configured to

conform with the following optional functions - the applicable

clauses of EN 54-2 are referenced as follows:

Options Clause

Indications:

Fault signal from fire protection equipment 7.10.4

Recording of the number of entries

into fire alarm condition 7.13

Fault signals from points 8.3

Controls:

Delay to Outputs 7.11.1

Manual or automatic switching of delays to outputs 7.11.2

Dependency on more than one alarm signal, Type B 7.12.2

Disablement of each address point 9.5

Test condition 10

Outputs:

Fire alarm device(s) 7.8

Fire alarm routing equipment 7.9.1

Fire alarm routing equipment with alarm confimation 7.9.2

Automatic fire protection equipment: Type A 7.10.1

Automatic fire protection equipment: Type C 7.10.3

Fault warning routing equipment 8.9

Introduction

3

997-263-000-11, Issue 11

January 2010

ID50 Series Panel - Installation, Commissioning & Configuration Manual

EN

12094-1

!

The following features are provided by the Power Supply

Unit (PSU) of the ID50 Series Panel to comply with EN 54-4.

Features of the ID50 EN54-4

Power Supply Unit (PSU) Clause

Derive power supply from main power source 5.1

Derive power supply from and monitor a

standby battery source 5.2

Charge and monitor the standby

battery source 5.3

Detect and signal PSU faults 5.4

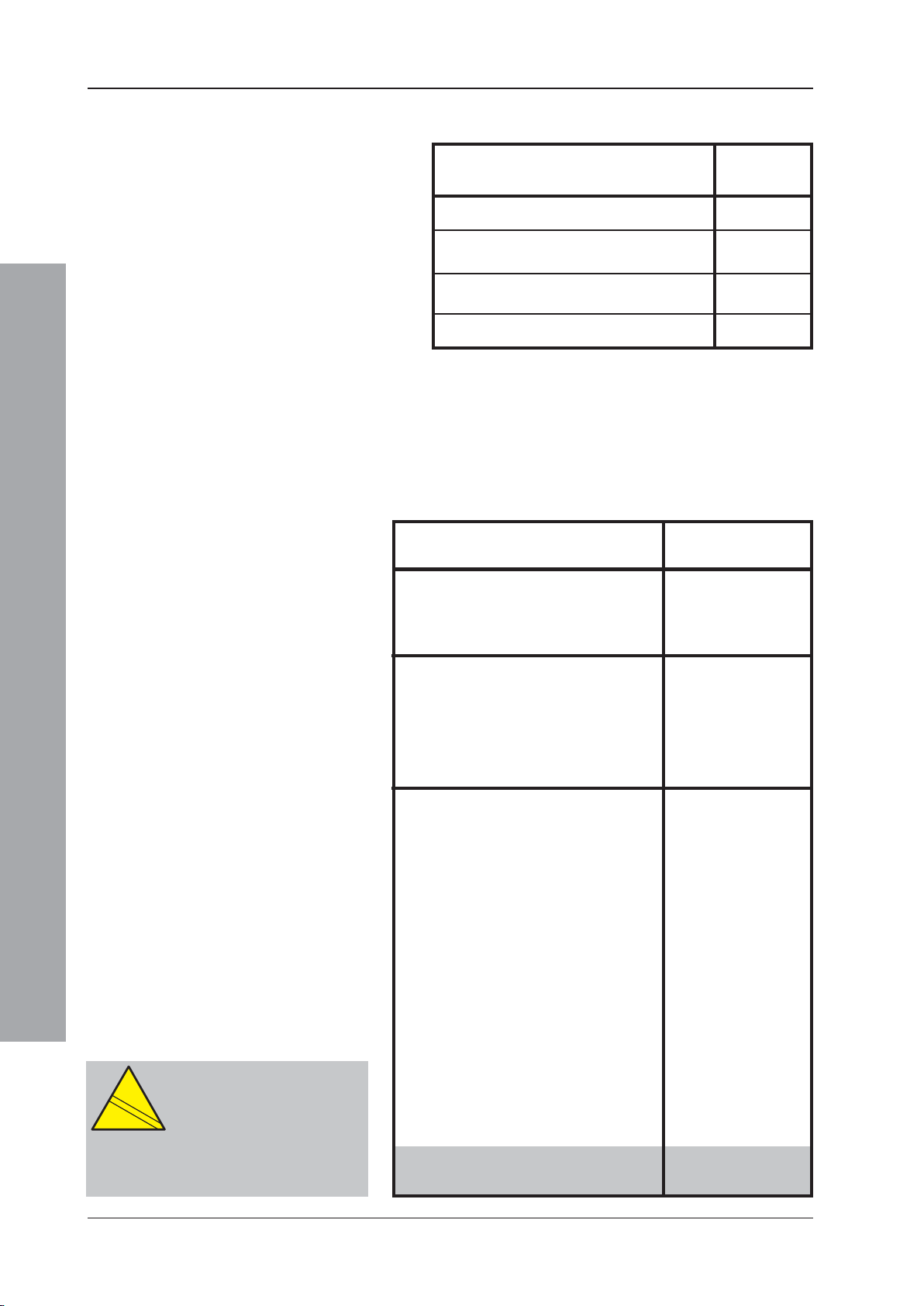

1.6 Ancillary Functions

The following is a list of ancillary functions that are

provided by the ID50 Series panel in addition to the those

required by EN54-2/4. These functions are described in

the section of this manual as referenced (except those

marked thus ‘*’ which are described in 997-264-000-X,

ID50 Series Panel - Operating Manual):

Introduction

Ancillary Manual

Functions Section Refs.

Site Specific Setup Options 5.5

Access Options 5.9

Voltage Indications *4.12

Control-by-Event 5.7

Output modes 5.7.1

Input type pattern 5.7.9

Disable/enablement *4.9

Repeater interface 2.7

Self-learn configuration - manual 5.6.1

Self-learn configuration - auto 5.6.2

Module supervision options 5.6.1

Module silence options 5.7.4

Text editing 5.8

Sensor LED blinking on/off 5.5.3.4

CAUTION:

12094-1

!

with EN 12094-1.

This product is not compliant

EN

Fire extinguishing installations in

Europe are required to be certified as

compliant to this standard.

January 2010

Bell pulsing ratio 5.5.3.5

Display of alarm count *4.11.6

Extend delay timer 5.5.5.3

Sounder Volt-free contact options 4.4.5

Relay drive output option 4.4.6

Extinguishing system features 5.5.3.7, 5.5.3.8, 5.5.3.9,

5.7.1, 5.7.2, 5.7.10

4997-263-000-11, Issue 11

ID50 Series Panel - Installation, Commissioning & Configuration Manual

1.7 Related Documents

This manual only describes the installation,

commissioning and configuration of the ID50 Series

Panel. All operating functions are covered by the:

ID50 Series Panel Operating Manual (ref:

997-264-000-X)

The Panel can support repeaters via the RS485

communications link. This manual does not provide

details about the repeaters or Compact Mimics; these

are described in:

IDR-2A, -2P & -6A Repeaters User Manual

(ref: 997-411-000-X).

IDR Mimic Installation and Commissioning Manual

(ref: 997-412-000-X).

Compact Mimic Installation Instructions (ref. 997-497-

000-X).

Note: The ‘000’ part of the manual reference is the UK

country code for the manual.

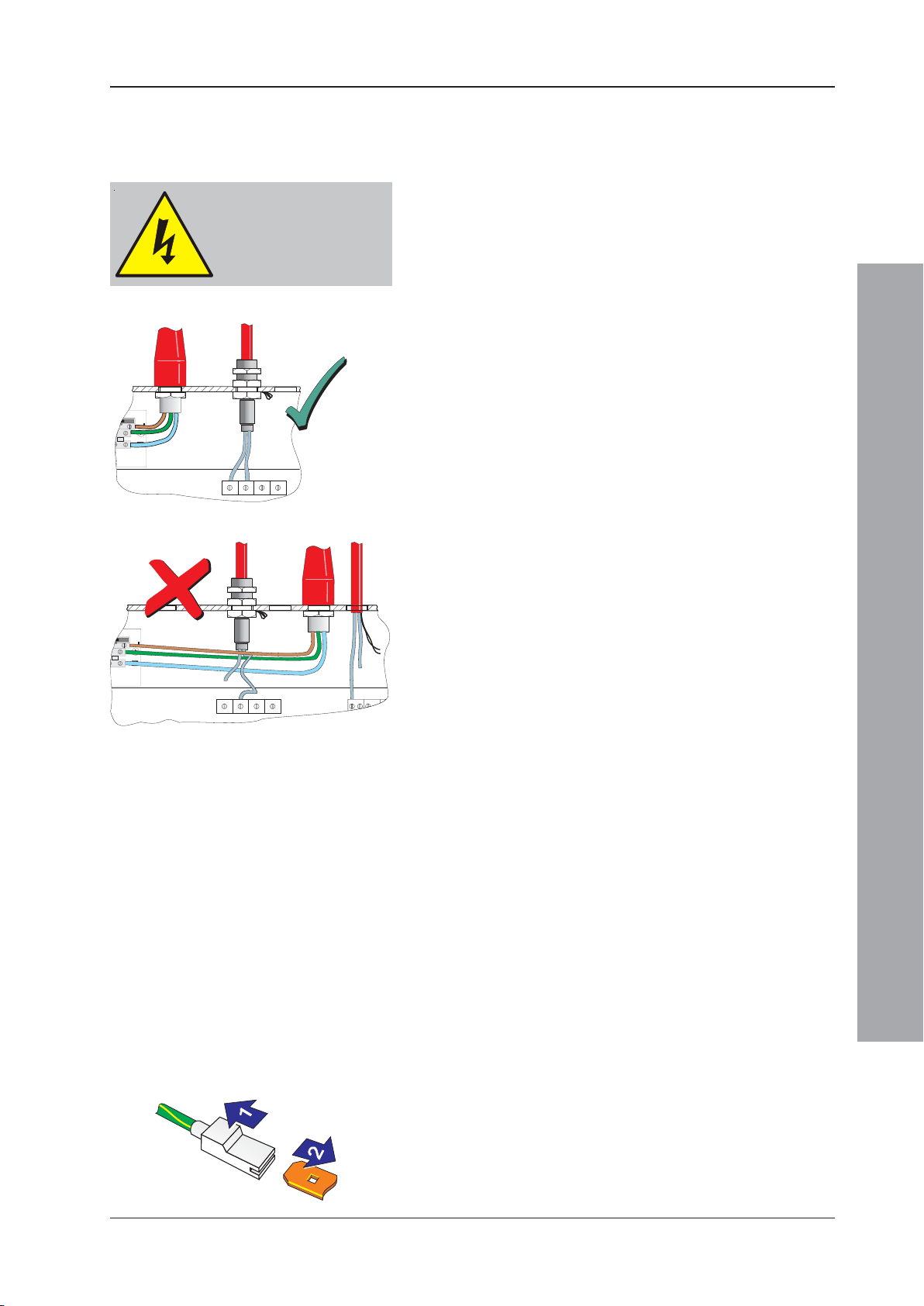

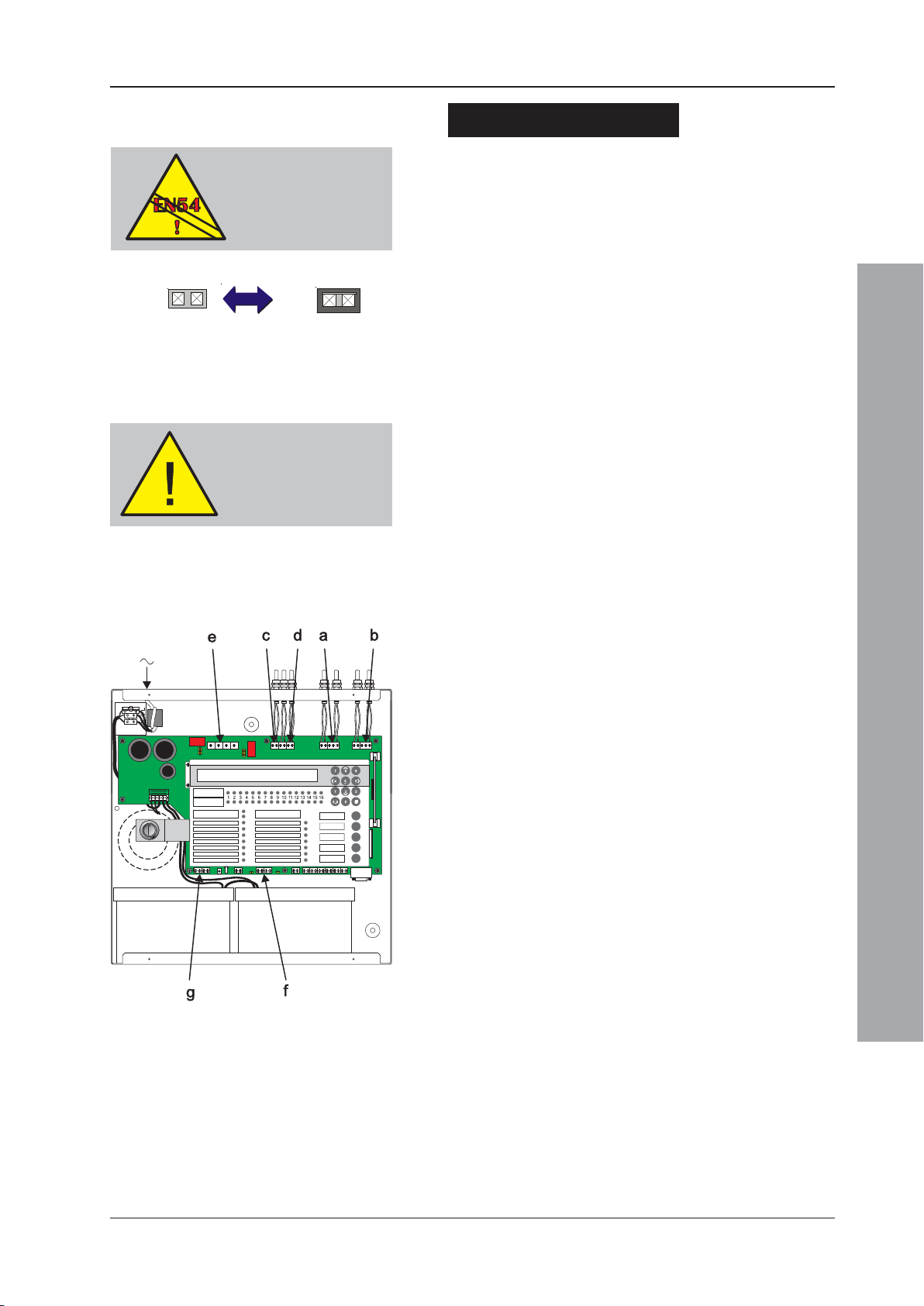

WARNING: High Voltage!

Take suitable precautions to

avoid electric shock

EN54-2:-8.8

One hardware-

configurable output

must be configured

as a fault relay

The ID50 Panel can also support the VIEWTM sensor. This

manual does not attempt to cover all the VIEWTM sensor

programming and calibration issues as these are

described in some detail in the following, which is available

from NOTIFIER’s Technical Support Department:

VIEW

TM

Application Guide (ref: 997-198).

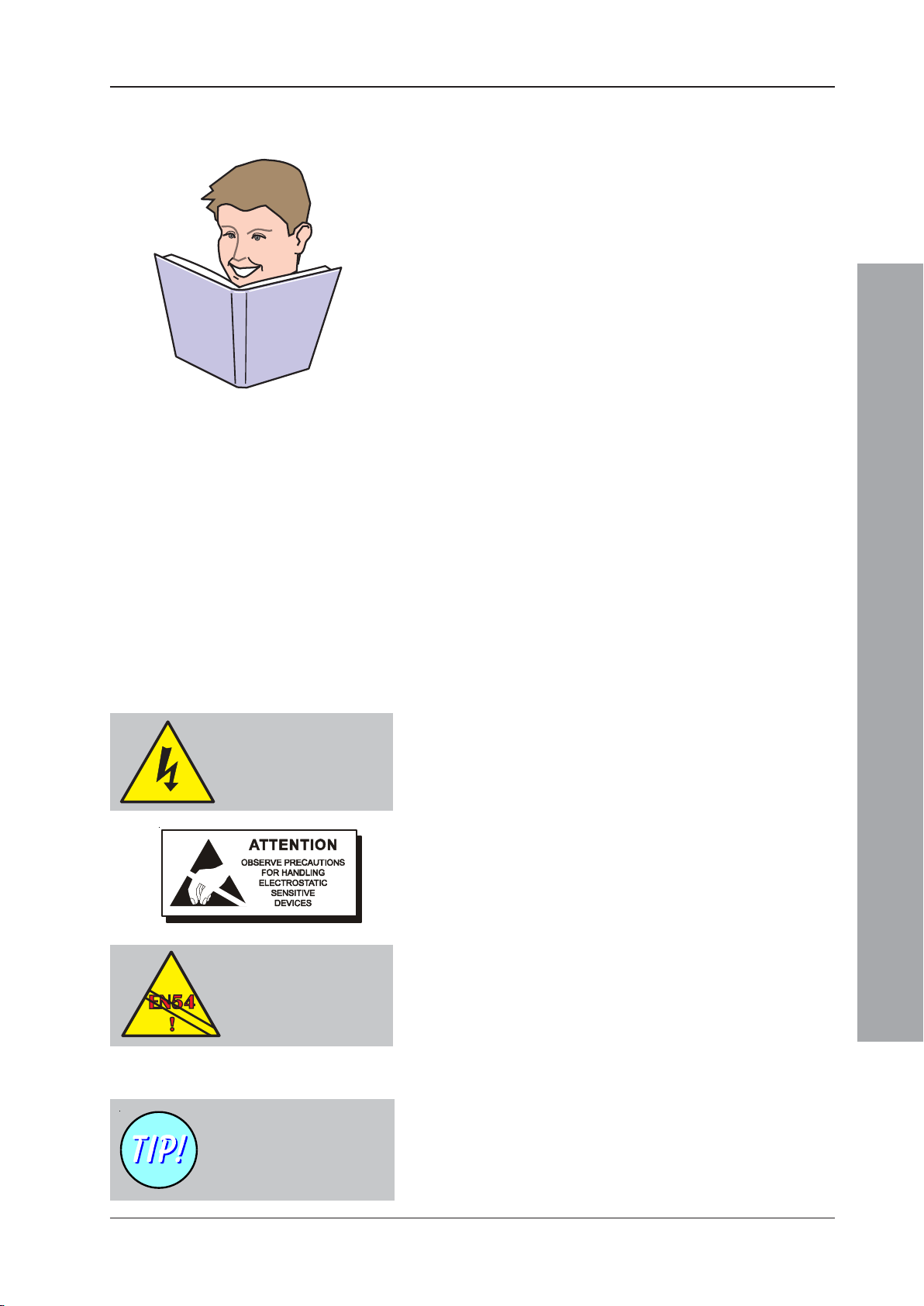

1.8 Warnings and Cautions

Where appropriate, the manual includes advisory

warnings and cautions to remind you to consider safety

at all times, especially when following the procedures

described herein.

You are alerted to any areas where high voltage [i.e. nonSafety Extra-Low Voltage (SELV)] is present, or where

there may be a risk of damage to static-sensitive devices

if the recommended procedures described in this manual

are not followed.

An example of a high voltage warning and an anti-static

caution is provided to the left of this paragraph.

The ID50 Series Panel incorporates some features

which, if used inappropriately, may contravene the

requirements of EN 54. Where there is a possibility of

such an occurrence, a suitable warning is given with brief

details of the EN 54 requirement. A typical EN 54 noncompliance warning is illustrated at left.

Introduction

Magnetise the tip of your

screwdriver to help when

offering small screws to

holes in confined spaces.

1.9 Tips

‘Handy tips’ are included, where appropriate, to assist

you in following quick and safe procedures for fire

detection system installation and integration.

Look for the ‘TIP!’ icon and supporting text, typically

illustrated at left.

5

997-263-000-11, Issue 11

January 2010

ID50 Series Panel - Installation, Commissioning & Configuration Manual

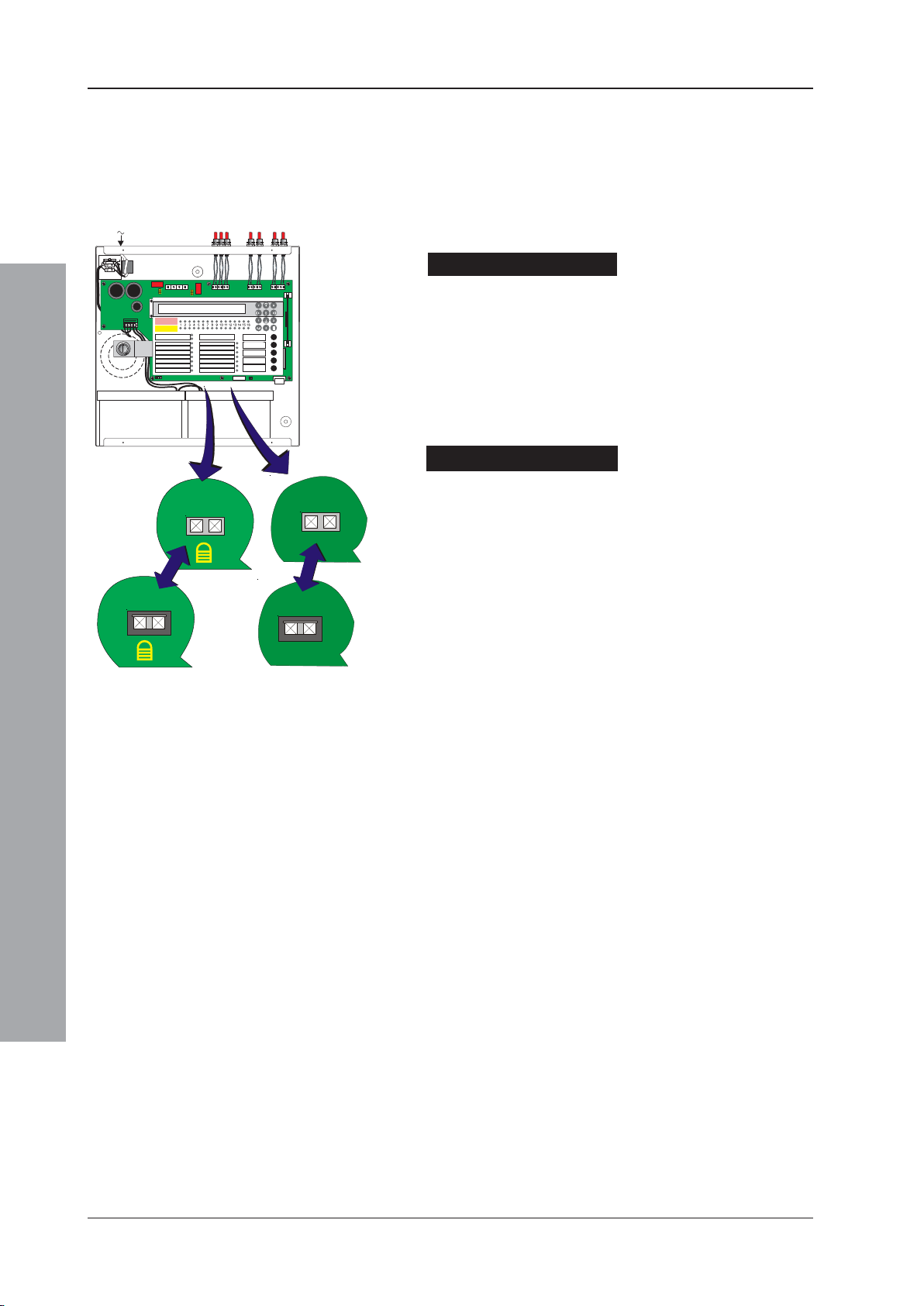

1.10 Glossary of Icons

Throughout this manual, and the other related ID50

Series Panel manuals, a number of icons are used either

as part of the illustrated process descriptions, or in the

main text to help clarify, or simplify, particular

configuration procedures.

The following icons are used to advise or indicate:

a. DO follow the recommended procedure or method.

b. DO NOT use this procedure or method.

c. Inspection of an item or sub-assembly is required at

this point.

d. Following a defined process meets/ does not meet

the required approval/inspection criteria or standards.

Introduction

e. Additional items to be considered.

f. This icon placed next to a pushbutton requires you to

press it while configuring the panel. Where two or

more icons are used, a number may be placed on or

near each hand to indicate the order of selection: 1

coming before 2.

g. Activity process step - flow arrow for single action or

iterative actions.

h. Leader arrow - used with activity processes.

i. Internal buzzer operating/not-operating or silenced.

j. Sounder operating/not-operating or silenced.

k. Power connected and switched ON/disconnected and

switched OFF.

January 2010

l. Manual Call Point (MCP)/Sensor.

6997-263-000-11, Issue 11

ID50 Series Panel - Installation, Commissioning & Configuration Manual

2 Installation Guide

2.1 How to Use this Section

This Installation Guide provides guidelines on how to

install an ID50 Series Panel quickly and safely.

For each stage in the panel installation and

commissioning procedures a brief description is given of

its purpose, complete with detail drawings, flow diagrams

and/or other graphics to make the instructions easy to

follow. Where required, procedures may be broken down

into one or more related diagrams, the number being

dependent upon the complexity of the defined task.

2.2 Pre-installation Check List

Before installing the ID50 Series Panel or fitting sensors,

you must first ensure that the following criteria have been

met. Failure to do this may not only result in damage to

the equipment, but may also cause problems when

commissioning the equipment or adversely affect its

performance.

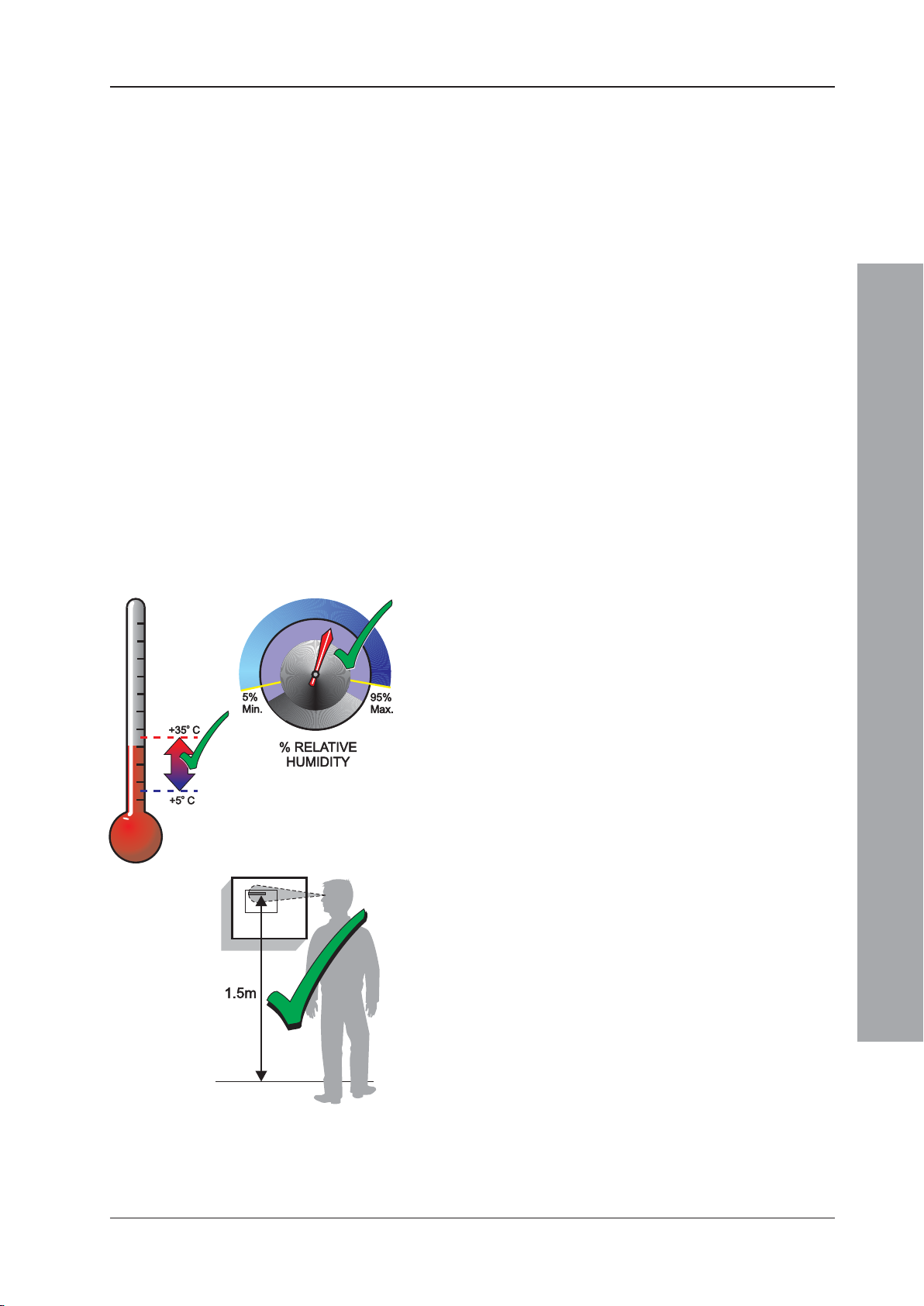

2.2.1 Some Panel DO’s and DON’T’s

Before selecting a location for the ID50 Series Panel,

DO make sure that:

a. The operating ambient temperature is in the

recommended range:

+5oC to +35oC and

b. The relative humidity is between:

5% and 95%

c. The panel is wall mounted in a position which allows

clear visibility of displays and easy access to operating

controls. The height above floor level should be

chosen such that the LCD is just above normal eye

level (approximately 1.5 metres).

Installation Guide

7 997-263-000-11, Issue 11

January 2010

ID50 Series Panel - Installation, Commissioning & Configuration Manual

d. DO NOT locate the panel where it is exposed to high

levels of moisture.

e. DO NOT locate the panel where there are high levels

of vibration or shock.

f. DO NOT site the panel where there would be restricted

access to the internal equipment and cabling/wiring

connections.

Installation Guide

2.3 Transient Protection

This equipment contains transient-protection devices.

Although no system is completely immune from lightning

transients and interference, for these devices to function

correctly, and to reduce susceptibility, this equipment

must be earthed correctly.

As with all solid state devices, this system may operate

erratically or can be damaged if subjected to lightninginduced transients.

The use of overhead or outside aerial wiring is not

recommended due to the increased susceptibility to

nearby lightning strikes.

January 2010

8997-263-000-11, Issue 11

ID50 Series Panel - Installation, Commissioning & Configuration Manual

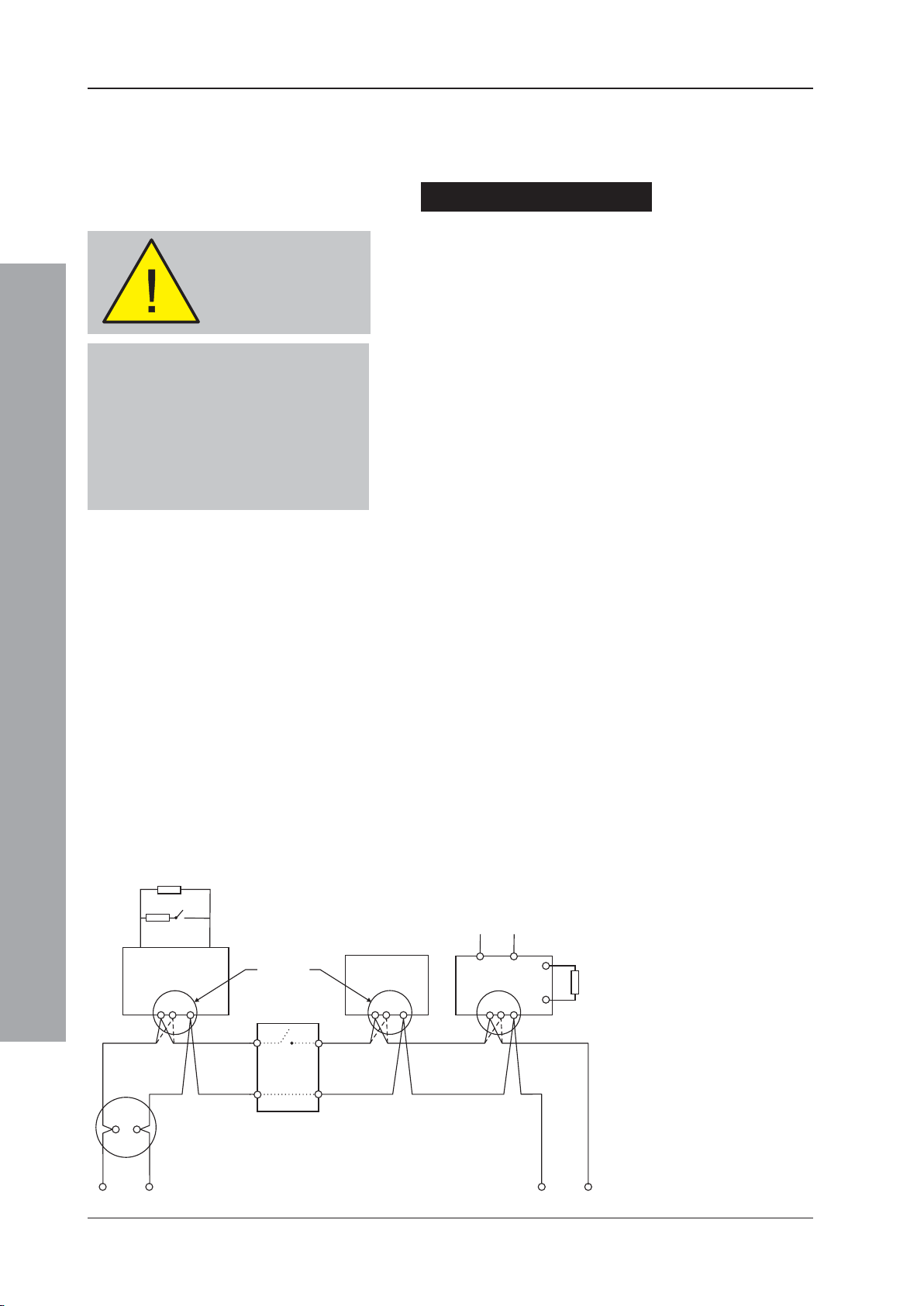

2.4 Product Inspection

The ID50 Series Fire Control Panels are relatively simple

to install providing the recommended procedures

described in this Installation Guide are followed.

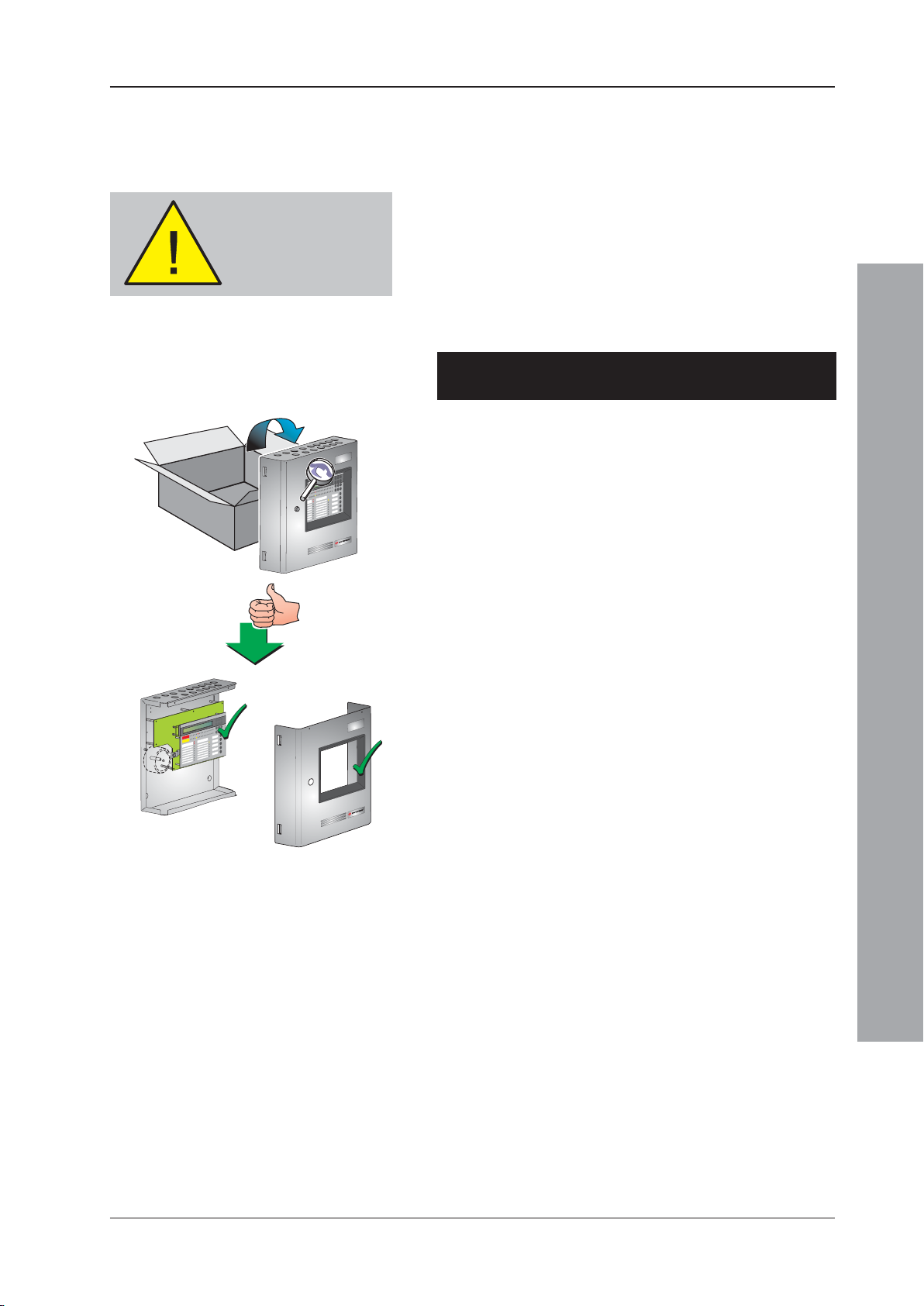

To avoid damage to the

control panel ensure that

you follow these

instructions.

Follow all installation instructions described in this

manual. These instructions must be understood and

the manufacturer’s recommendations followed to

avoid damage to the control panel and associated

equipment.

2.4.1 Checking Your Panel for Damage

It is important to check all supplied equipment for

damage before proceeding with the installation!

1

2

Before attempting to install your ID50 Series Panel, you

should do the following:

1 After removing the panel, from its packing, and before

you proceed with installing it in its chosen location,

check for any damage that may have been caused

during transit.

Note: In the unlikely event that the panel supplied has

been damaged, you MUST NOT install it but return

it to your supplier. The procedure for returning faulty

items is described in Section 2.4.2, What to do if

Your Panel is Damaged or Suspect.

2 If you are satisfied that the panel has NOT been

damaged you can now proceed with the installation

procedure. This manual addresses the recommended

installation methods of the panel. Refer to the relevant

sections that apply to your configuration requirements.

To prevent unnecessary damage to the electronic

components, the back box should be installed without

the electronics fitted. Refer to Sections 2.5.1 to 2.5.3

for details.

Installation Guide

9 997-263-000-11, Issue 11

January 2010

ID50 Series Panel - Installation, Commissioning & Configuration Manual

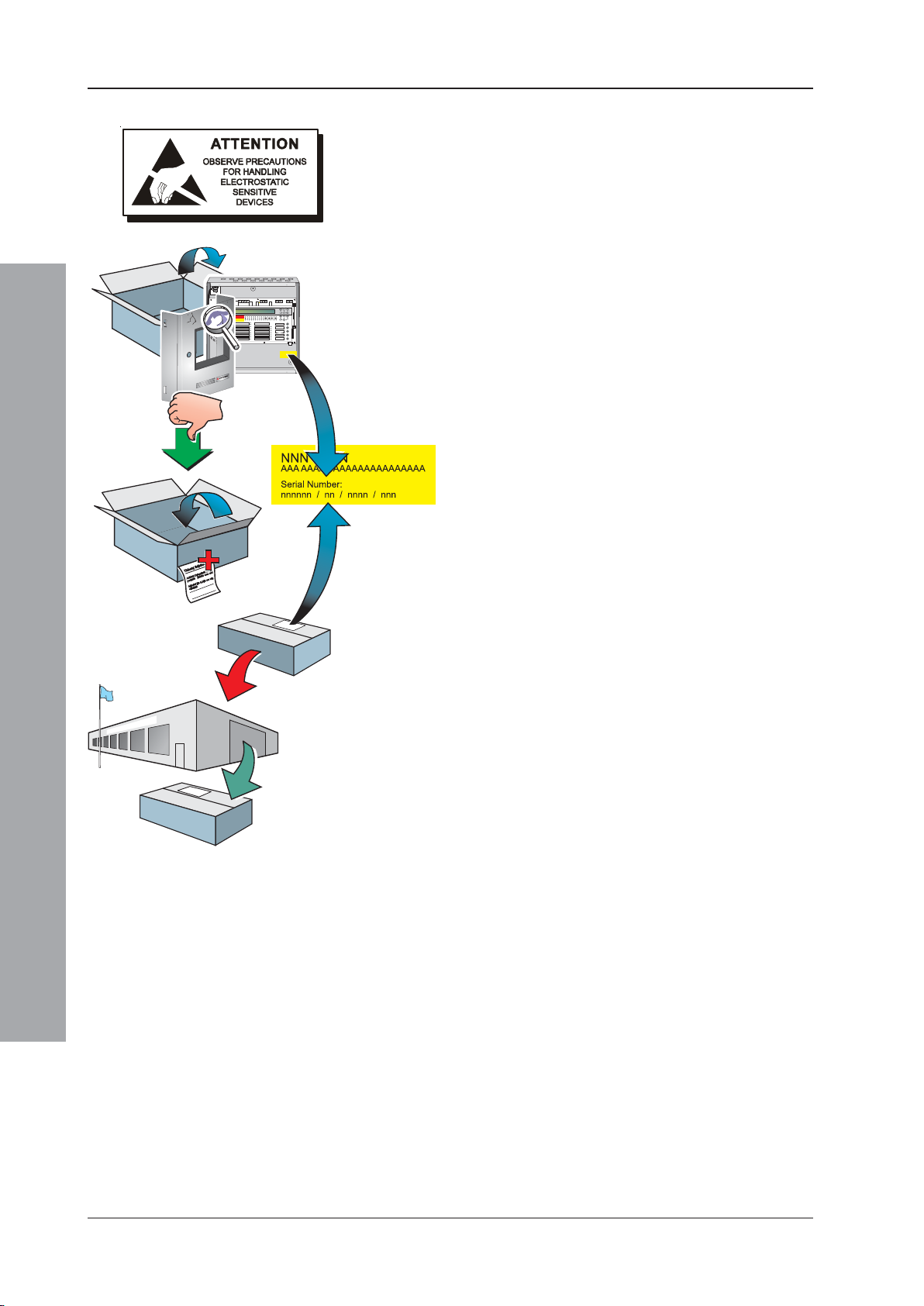

2.4.2What to do if Panel is Damaged or Suspect

If you have problems regarding the quality of any supplied

order items including the control panel, its ancillaries or

this manual or items are missing, follow the procedure

below:

1

2

3

1 DO NOT continue with the installation but contact your

supplier for advice on what to do next.

Similarly, if the product is found to be faulty during

installation or while in use contact your supplier

immediately.

2 To aid your supplier and the manufacturer, you are

requested to:

a. Quote the manufacturer’s unique batch reference

number which can be found on the packaging or

inside the back box.

b. With reference to PCB’s, quote the part number

and revision level which can be found along one

edge of the PCB - refer to the applicable section

of this manual for specific details.

c. Note all the details relevant to your complaint, date

of receipt, packaging condition, etc. and forward

this to your supplier.

3 Where the product needs to be returned to your

supplier, you are requested to use the original

packaging, or suitable anti-static equivalent,

wherever possible.

Installation Guide

January 2010

10997-263-000-11, Issue 11

ID50 Series Panel - Installation, Commissioning & Configuration Manual

1

2

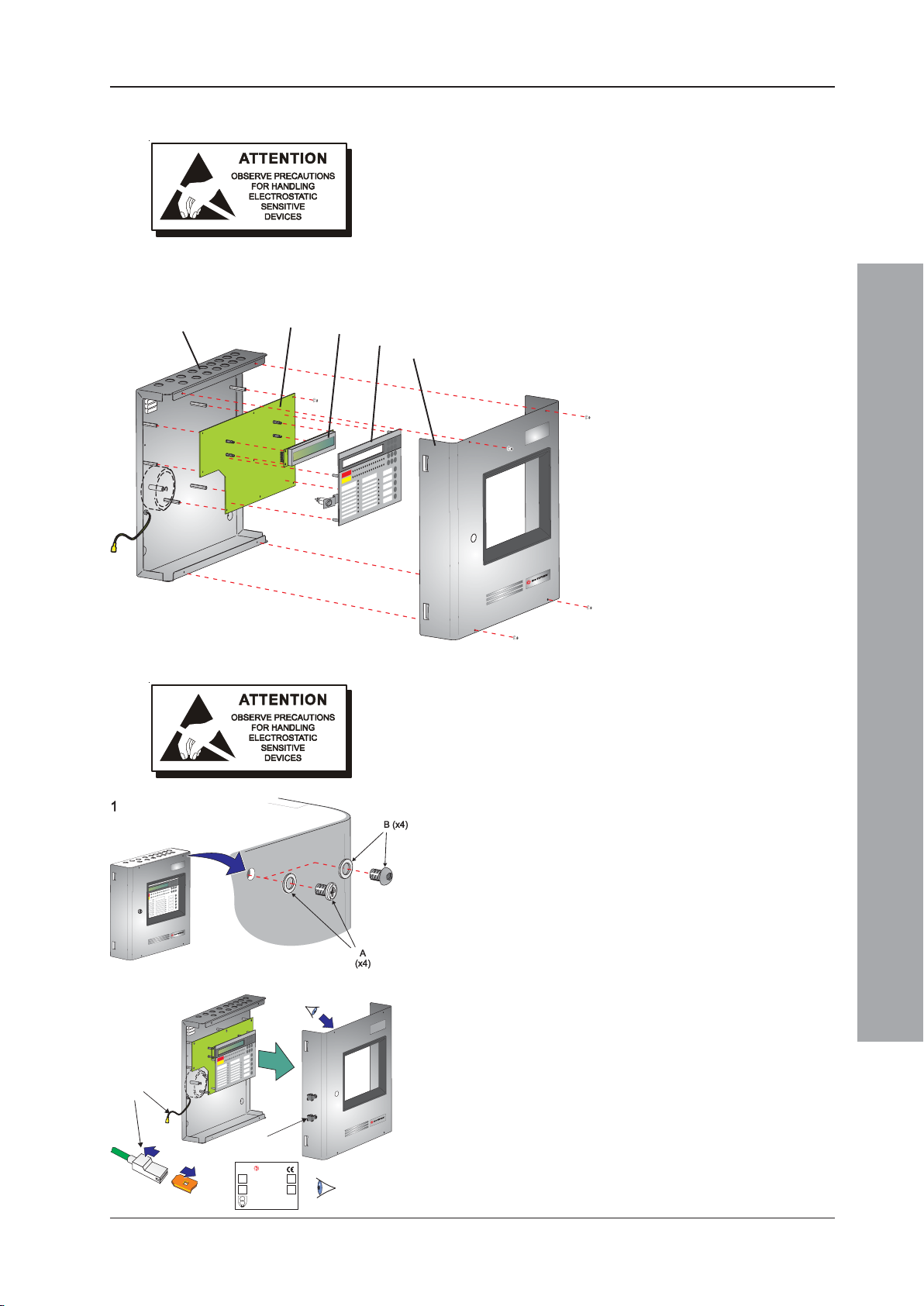

2.5 Dismantling the Panel

For installation purposes, it is recommended that the

cover is removed from the back box and stored in a safe

place until ready for commissioning.

If any other trades, e.g. plasterers or decorators, will be

working in the vicinity after fitting the ID50 Series Panel,

it is strongly recommended that before re-fitting the cover

you remove the panel electronics and store in a safe place

until ready for commissioning. The main components

A

B

C

D

within the ID50 Series Panel are shown below.

E

ID50 Series Panel Assembly

A. Back box

B. PCB Assembly

C. LCD Unit

D. Fascia & Control Keypad

E. Cover

2.5.1 Removing the Cover

To remove the ID50 Series Panel cover, it is

recommended that the following procedure is carried out

on a work bench BEFORE siting the panel on the wall:

1 Remove the four M3 x 6mm screws and washers (A)

using a No. 1 Posidriv screwdriver, or the four hex

button-headed screws and clear washers (B) using a

2mm hex key, from the cover, and store safely.

2 Carefully withdraw the cover away from the back box,

until the earth blade terminal (C) within the cover is

accessible.

3 Carefully detach the shrouded earth lead spade

terminal (D) from the earth blade terminal (C) located

in the left-hand inner side wall of the cover.

2

E

Note: All blade connections to earth incorporate a locking

barb. To make a connection push the shrouded

receptacle on to the earth blade (1). To remove

2

3

D

this connection, pull the shroud (2), NOT the earth

wire.

4 Remove and store the cover in a safe place.

Installation Guide

3

C

NOTIFIER

byHoneywell

ID50

ID60

NF50-A

NF30-A

230VAC, 50Hz, 1.0A

‘E’

The power supply ratings label (view ‘E’) is affixed to the

inside face of the fire control panel cover.

Before installing the back box, remove the panel

electronics (see Section 2.5.2, Panel Electronics).

11 997-263-000-11, Issue 11

January 2010

ID50 Series Panel - Installation, Commissioning & Configuration Manual

6

A

1

B

394-191

issue

XXX

TB3

J19

1

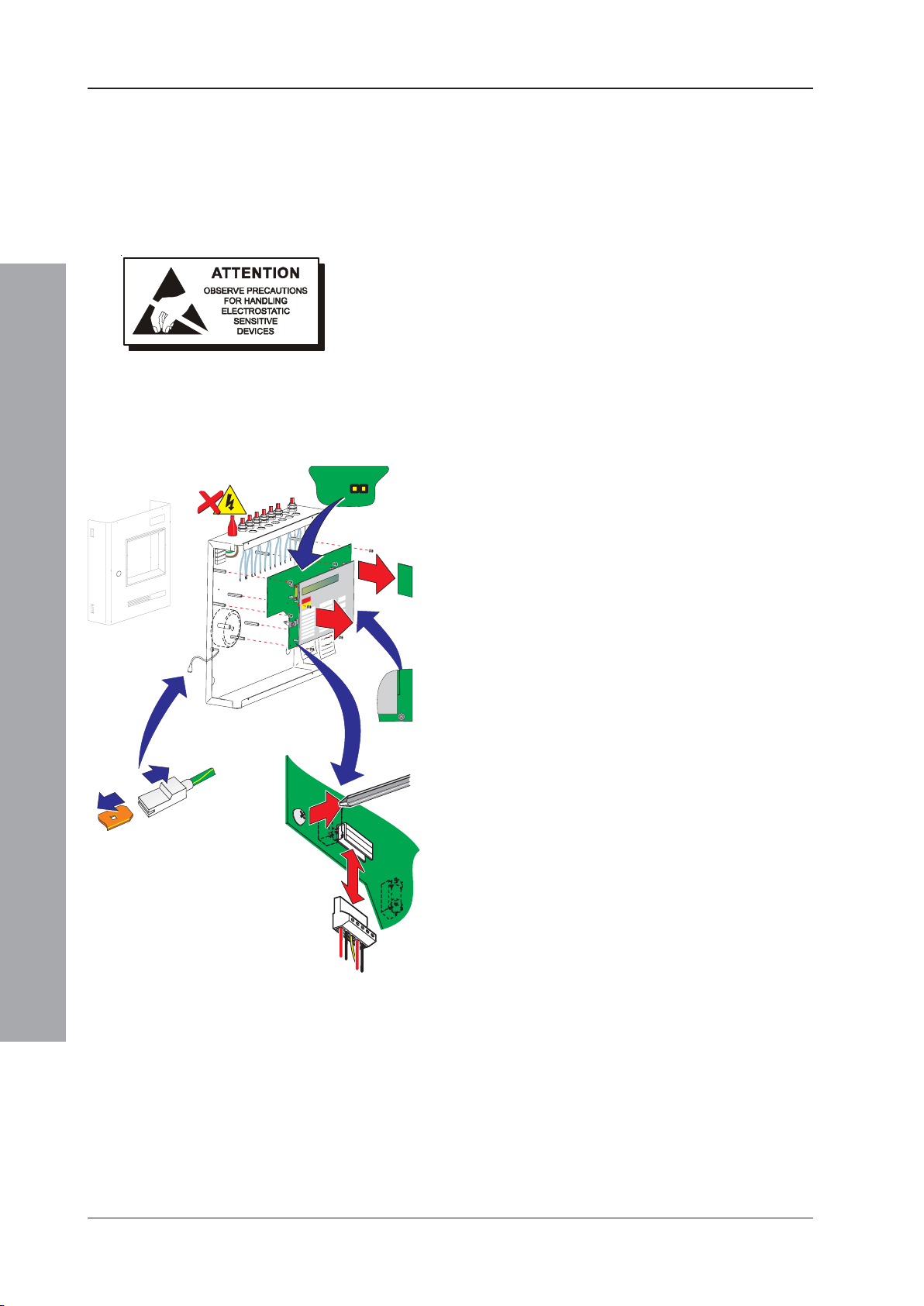

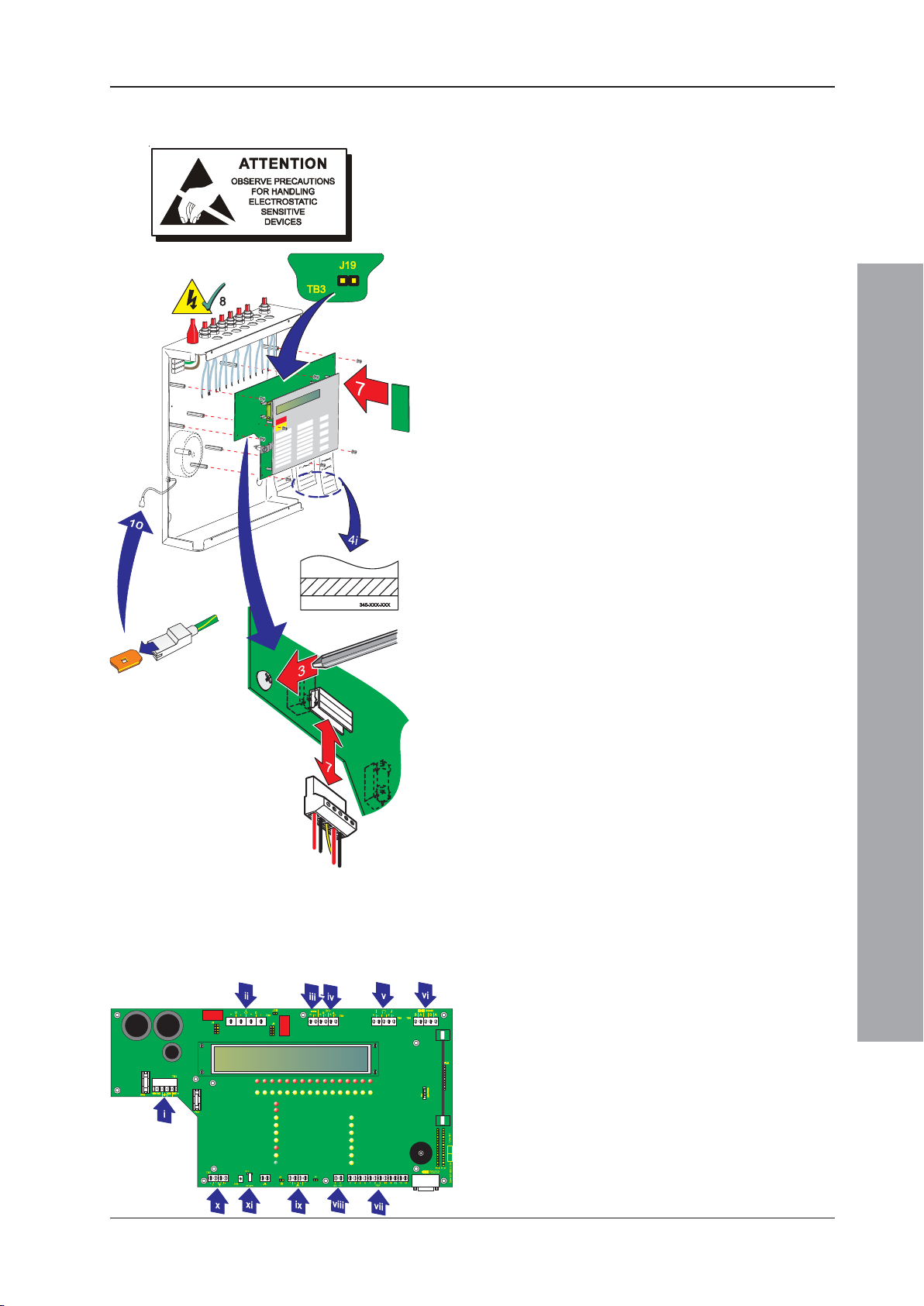

2.5.2 Removing the Panel Electronics

The ID50 Series Panel electronics comprises the PCB

assembly with mounted LCD unit and the mounted fascia.

These are supplied as one spared item in kit

PN: 020-635-XXX. This assembly is located within the

back box, but should ONLY be removed when installing

the back box or if the PCB requires replacement.

CAUTION: The electronic circuits of the ID50 Series

Panel use CMOS devices which can be damaged by

static discharge. Suitable precautions MUST be taken

when handling circuit boards.

Procedure

When installing the back box or, if it becomes necessary

to remove the PCB assembly for another reason, follow

this recommended procedure:

1 Remove the cover and store in a safe place, see

Section 2.5.1, Removing the Cover. Then make a

back-up of the current system configuration,

remembering to disconnect the link at jumper J19.

Installation Guide

Note: The blade connection to the cover fitted in back

4

boxes incorporates a locking barb. To remove this

connection, pull the shroud (B), NOT the earth wire,

6

from the earth blade terminal (A).

2 Isolate the mains power supply and disconnect the

battery interlink wire if fitted.

3 At the two-part connector TB1 (on the PCB assembly),

4i

ue XXX

using a constant pulling action carefully disconnect

394-191 iss

the mains and battery power supply wiring.

4 Taking suitable anti-static precautions remove the

RS485 Interface PCB, if fitted (refer to Section 2.7.1,

Installing the RS485 Interface Module PCB).

5 At the PCB assembly, note the polarity and

connections of all cables and any jumper configuration

settings. Using a screwdriver, loosen all the connector

securing screws. Carefully secure all external cable

3

tails away from the electronics and from the back box.

6 Using a No. 1 Posidriv screwdriver, remove the eight

(8) M3 x 8mm clinch screws from the PCB assembly.

Gently lift the PCB assembly clear of the supporting

pillars, place it in an anti-static bag and store safely.

Note: If the PCB is to be returned to the manufacturer

note its Serial Number and Revision Level (located

along one edge).

12997-263-000-11, Issue 11

January 2010

ID50 Series Panel - Installation, Commissioning & Configuration Manual

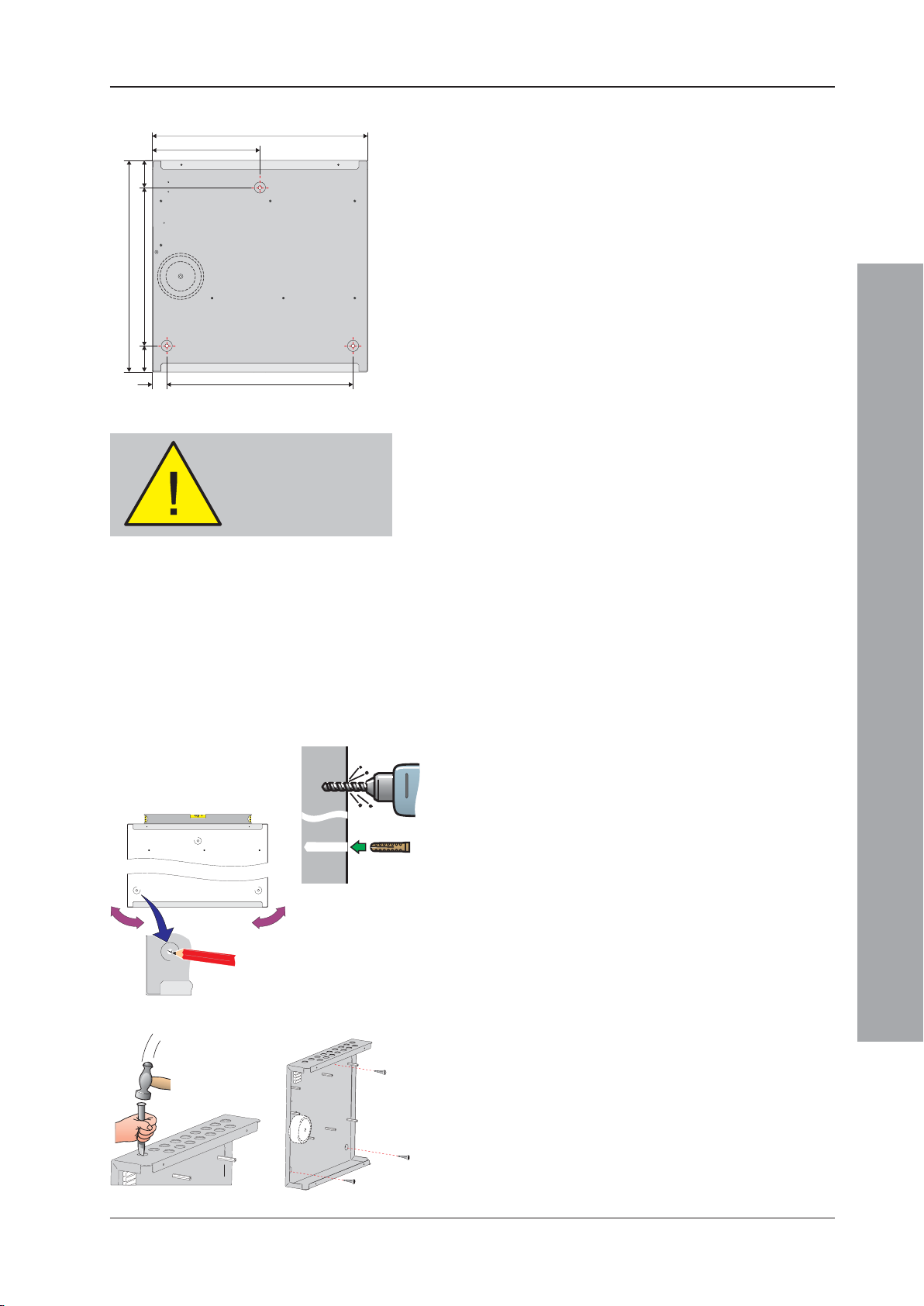

376.00

301.00

365.00

37.50

188.00

45.00

275.00

45.00

All dimensions are in millimetres. Fixing

hole diameters are 6mm.

DO NOT use the back

box as a guide when

drilling

2.5.3 Back Box Fixing

The ID50 Series Panels (PN: 002-455-XXX) are 110mm

deep (external dimensions including fixing dimples). The

back box holds two 12V batteries, up to a maximum rating

of 12Ah each.

The back box must be fixed to the wall with screws at

three fixing locations (see drawing) using the procedure

given below.

The back box must only be installed when the panel

electronics have been removed (see Section 2.5.2,

Removing the Panel Electronics).

Wall Flatness

To prevent distortion, the back box MUST be installed on

the wall as flat as possible, i.e. with a maximum flatness

deviation between any two points of 3mm. Where the

wall is out of tolerance, use appropriate packing pieces

when installing the back box to meet the above

requirements.

Failure to comply with this requirement will result in

the misalignment of the cover’s securing screws,

which may cause difficulties in fitting the cover.

Procedure

When a suitable location has been found for installing

the panel and the panel electronics have been removed,

fix the back box to the wall as follows:

1 Using a suitable-sized drilling bit - for holes to take up

1, 3

to 6mm (No. 12-sized) wood screws - drill a hole at

position A in the wall. Fit a suitable-sized Rawl-plug,

or equivalent.

2

A

B

B

2 Hold the back box in position at hole A (ensure the

panel is level) and mark the position of the remaining

fixing holes (B). Remove the back box and store safely.

3 Drill two holes at positions B in the wall, and fit suitable-

sized Rawl-plugs, or equivalent.

Installation Guide

4 Prepare apertures (20mm knockouts) required for

cable access.

Note: Make sure paint is scraped from the area

surrounding the knockouts, to ensure good

earthing for glands.

4

5

5 Secure the back box to the wall using all three fixing

holes and appropriate-sized screws (up to 6mm

[No. 12-sized] round or pan-head screws - do not use

countersunk screws).

13 997-263-000-11, Issue 11

January 2010

ID50 Series Panel - Installation, Commissioning & Configuration Manual

367

437

383

453

329

375

D

B

C

2

5

2

WALL

RECESS

E (x4)

3

3

A

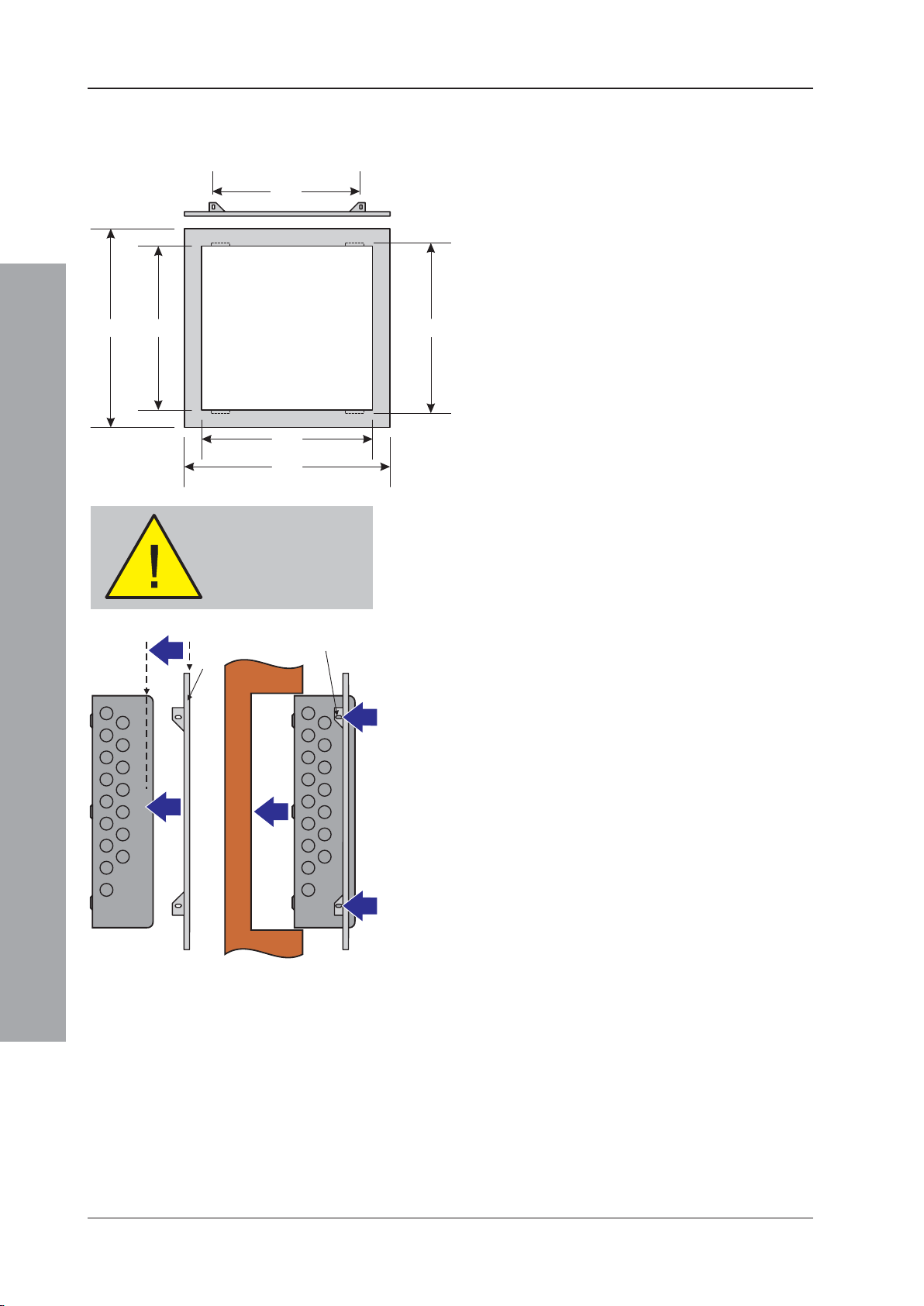

2.5.4 Semi-Flush Mounting Bezel (Optional)

If semi-flush mounting of the ID50 Series Panel is

required, a recess 80mm deep and just large enough to

accommodate the back box must be cut in the wall (see

dimensions below).

All dimensions in millimetres

To fit the bezel:

Before drilling the back

box, make sure that no

equipment is fitted

E (x4)

WALL

RECESS

Installation Guide

1 Before continuing, remove panel electronics and

batteries (if fitted) - see Section 2.5, Dismantling the

Panel.

2 Offer the bezel (A), flat sideways towards you, to the

front of the back box (B) and position it so the bezel

front face (C) is lined up with the rear of the rounded

sides of the back box (D).

3 With the bezel held in position, use the slotted holes

(E) on the bezel as guides and drill four appropriate

sized holes to fit M3 screws centrally in the slots.

Remove any swarf created.

4 Secure the bezel using suitable M3 fixings. Ensure

the fixings are accessible from the outside of the back

box.

Note: The ID50 Series Panel back box must be fixed to

a solid vertical surface, or sub-frame inside the

recess, using its rear fixing holes. Do NOT rely on

the bezel as a means of fixing.

5 Fit back box with attached bezel to the wall recess

and assemble the panel, see Section 2.6.

January 2010

14997-263-000-11, Issue 11

ID50 Series Panel - Installation, Commissioning & Configuration Manual

2.6 Assembling the Panel

With the back box secured to the wall and all external

cabling ready for termination, assemble the panel as

follows:

1 Ensure that all power to the panel is isolated and

observe ALL safety and anti-static precautions when

installing the PCB assembly.

2 Install all kits that require the removal of the PCB

assembly.

3 Align the PCB assembly to the supporting pillars and,

using a No. 1 Posidriv screwdriver, screw the eight

(8) M3 x 8mm SEM screws into position.

4 Fit the labels. They may require the application of a

low tack adhesive:

i Apply low tack adhesive to hatched area indicated.

ii Slide each label into position.

iii Apply slight pressure to the area along the bottom

edge of the fascia to ensure the labels are secure.

5 Apply the mains power supply and then connect the

batteries. Check the PCB assembly operates correctly

and then isolate all power to the panel.

6 At the PCB assembly:

i Noting the cable polarity, connect all cables and

secure at the correct termination blocks, see

Cables & Wiring.

ii Set all required hardware jumper configurations,

refer to the Section 4 Commissioning.

7 Fit the RS485 Interface Module PCB, if applicable,

refer to Section 2.7.1 Fitting the RS485 Interface

Module PCB.

8 Re-apply the mains power supply and then connect

the batteries.

9 Disconnect the links at the earth fault monitoring

jumper, J19, and configuration lock, J9. Then connect

the RS232 9-way ‘D’ type Data Transfer Lead

(PN 082-173) to the panel at the RS232 connector,

PL5. Using the Support Tool, transmit the latest system

configuration to the panel.

10 Remove the lead and fit the links at J9 and J19, then

fit the cover.

Installation Guide

Note: Connect the earth wire to the inner side wall of the

cover at the tag marked with the earth symbol.

Cables & Wiring

i Power Supply from transformer (TB1),

ii CFG Outputs D and C (TB3),

iii 24 V Auxiliary Power Supply (TB4),

iv Sounder Outputs B and A (TB4),

v Loop Cable Output (TB5),

vi RS485 Communications Cable (TB6),

vii FBF Communications Cable (VdS Only) (TB10),

viii FBF Power Supply (VdS Only) (TB9),

ix Digital / ÜE Cable (TB8), and

x Switchable -VE Outputs (TB2),

xi Keyswitch (PL7).

15 997-263-000-11, Issue 11

January 2010

ID50 Series Panel - Installation, Commissioning & Configuration Manual

RS485

B A B A

RS485

B A B A

RS485

B A B A

TB6

TB6

TB6

N

L

ZONEFIRE

ZONEFAULT

DISABLE/TEST

4

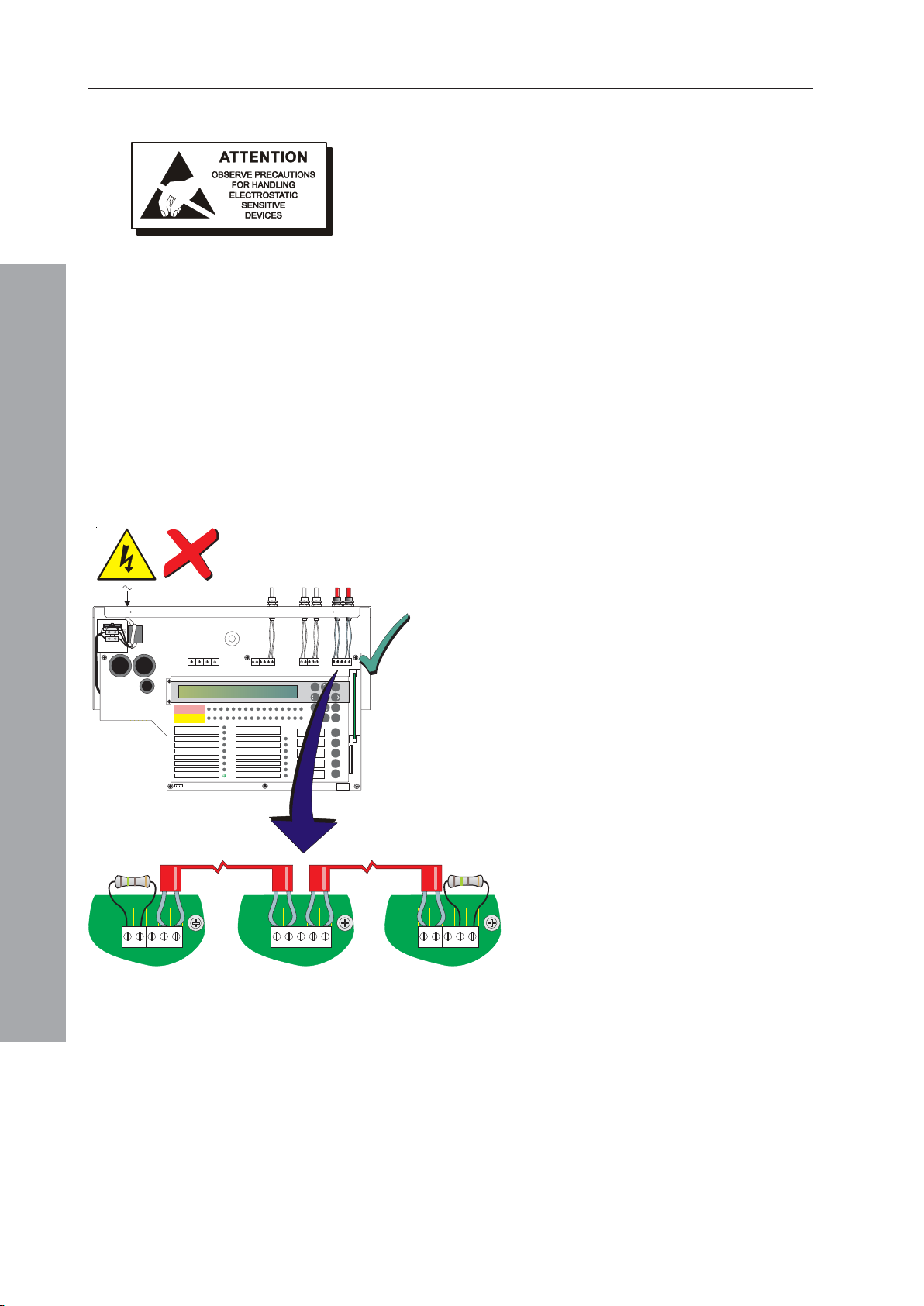

2.7 RS485 Communications Link

The panel is capable of communicating with a maximum

of sixteen (16) repeaters (active IDR-2A or passive

IDR-2P) or mimic panels (IDR-M) (for further details

concerning the repeaters refer to 997-411, IDR-2A, -2P

& -6A Repeaters User Manual or 997-412, IDR Mimic

Installation and Commissioning Manual). The panel

is connected to the repeaters in a ‘daisy-chain’

arrangement via the RS485 Communications terminal

block, TB6, on the PCB assembly. The panel must be

fitted with the RS485 Interface Module PCB at connector

PL3 on the PCB assembly (see Section 2.7.1, Fitting

the RS485 Interface Module PCB).

The two end stations require a termination resistor to be

fitted as illustrated below.

To connect a panel to an RS485 communications link:

1 Ensure the following:

i All power to the panel is isolated.

98

7

5

46

[

31

ZONEFIRE

1234567

ZONEFAULT

DISABLE/TEST

FIRE

DISABLEMENT

DELAYSACTIVE

FIREOUTPUT: FAULT/ DISABLED

FIREOUTPUT ACTIVE

PLANTALARM

POWER

TEST

8910

11 1 21314

ID50FIRE CONTROL PANEL

Complieswith EN54-2/4 1997

Periodof Manufacture 1999

FAULT

POWERSUPPLY FAULT

EARTHFAULT

SYSTEMFAULT

SOUNDER:FAULT / DISABLED

PRE-ALARM

FIRECONTROL O/P: FAULT/ DISABLED

15 16

MUTEBUZZER

EXTENDDELAY

ENDDELAY/

EVACUATE

SILENCE/

RESOUND

2

00..9

RESET

Installation Guide

TB6

TB6

ii Access to the panel electronics is possible.

ii The interlink wire is disconnected at the batteries.

2 Fit the RS485 Interface Module PCB as described in

the instructions in Section 2.7.1, Fitting the RS485

Interface Module PCB).

3 Connect the RS485 communications cable to the

RS485 Communications terminal block, TB6, refer

to Section 4.4.2, RS485 Communications Link.

Note: If connecting the panel at either end of the RS485

communications link, connect a 150R termination

resistor (supplied separately) as shown below.

4 Using the configuration procedure - refer to

Section 5.5.4.6, Number of Repeaters, configure the

panel and RS485 communications link.

If Fitted As First

Station On RS485

Comms Link

January 2010

Intermediate

Station(s)

If Fitted As Last

Station On RS485

Comms Link

16997-263-000-11, Issue 11

ID50 Series Panel - Installation, Commissioning & Configuration Manual

A

D

E

B

F

C

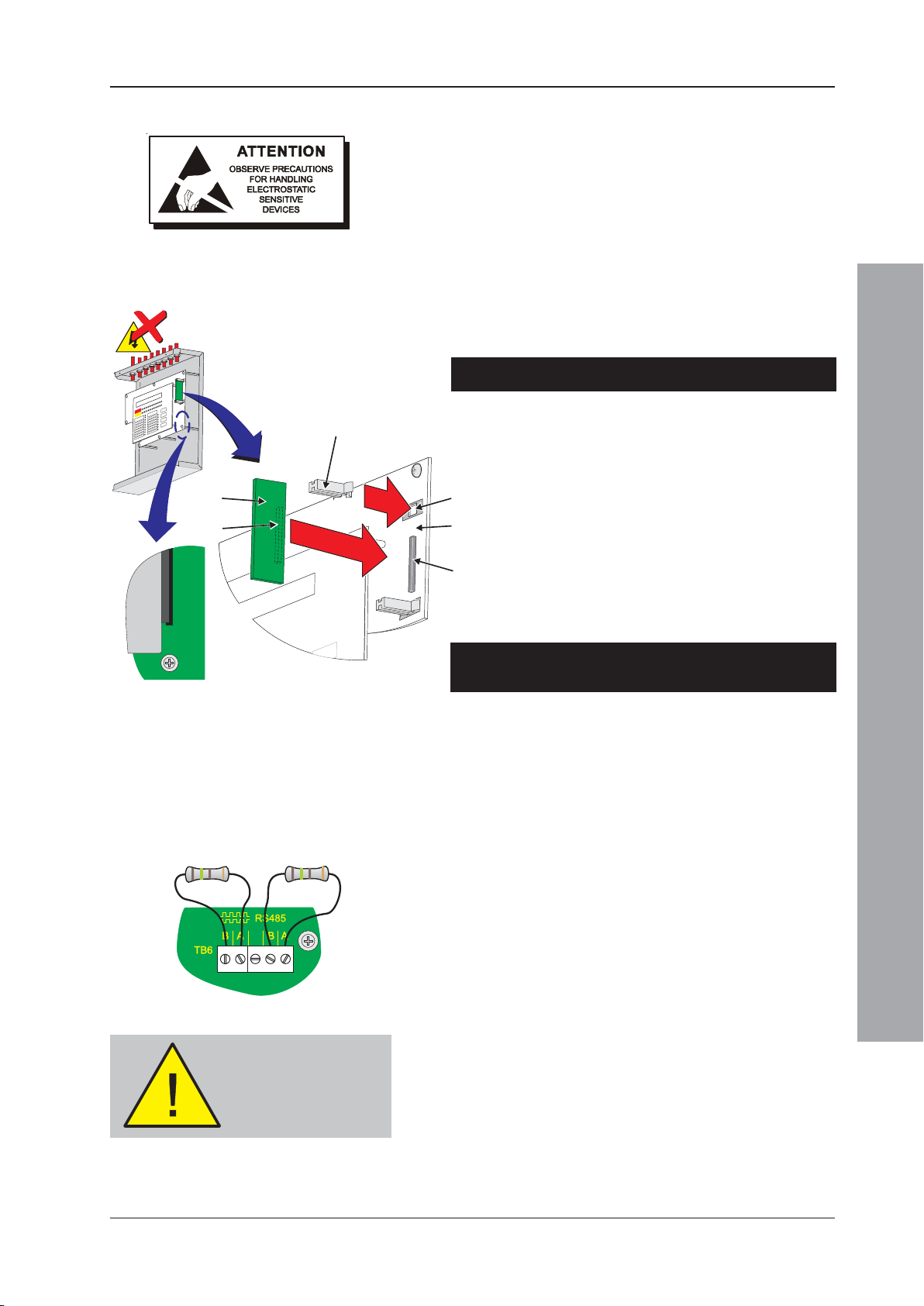

2.7.1 Fitting the RS485 Interface Module PCB

With the back box fitted to the wall, install the RS485

Interface Module PCB as described below (ensure

suitable anti-static precautions are taken):

1 Remove the cover (see Section 2.5.1) to expose the

panel electronics. Disconnect the battery interlink wire

from the batteries and isolate the mains supply.

2 Carefully fit the two plastic PCB support pillars (A) in

to the holes (B) on the right-hand side of the PCB

Assembly (C).

3 Fit the RS485 Interface Module PCB (D).

Fitting to PCB Assembly PN: 394-191-001, 002 or 003

i Make sure the RS485 Interface Module PCB

components are facing the membrane and rest the

PCB in the PCB Support pillar guides.

ii Gently ease the RS485 PCB and PCB Support

2

3

3

pillars away from the membrane and carefully slide

the RS485 PCB down the pillars until the 10-way

socket (E) aligns with the connector, PL3 (F) on

the PCB Assembly. Ensure that the components

do NOT foul on the membrane.

394-191 Issue XX

When fitted as first

station on RS485

Communications Link

Apply power BEFORE

When fitted as last

station on RS485

Communications Link

making any RS485

connections!

iii Carefully return the PCB Support pillars to their

normal position and, with a firm and constant

pushing action, connect the PCB.

Fitting to PCB Assembly PN: 394-191 Issue 4, or later,

or PCB Assembly PN: 394-390, or later.

i Make sure the RS485 Interface Module PCB

components are facing away from the membrane

and rest the PCB in the PCB Support pillars’ guides.

ii Carefully slide the PCB along the pillars until the

10-way socket (E) aligns with the connector, PL3

(F) on the PCB Assembly.

iii With a firm and constant pushing action, connect

the RS485 PCB to the PCB Assembly.

4 Connect RS485 Communications wiring at TB6 (see

left), ensuring correct polarity where applicable, and

fit the cover.

If the panel is the first or last station on the RS485

Communications Link, connect a 150R Termination

resistor to the PCB Assembly on the left-hand side

or the right-hand side terminals of TB6 respectively.

5 Apply the mains power supply and connect the battery

interlink wire. Configure the panel, refer to Section 5.

Removing the RS485 Interface Module PCB

If removing the RS485 Interface Module PCB, follow the

procedures above in reverse order.

Ensure a back-up of the current configuration has been

made and all power is isolated.

Installation Guide

17 997-263-000-11, Issue 11

January 2010

ID50 Series Panel - Installation, Commissioning & Configuration Manual

N

L

TB3

J19

ZONEFIRE

ZONEFAULT

DISABLE/TEST

4

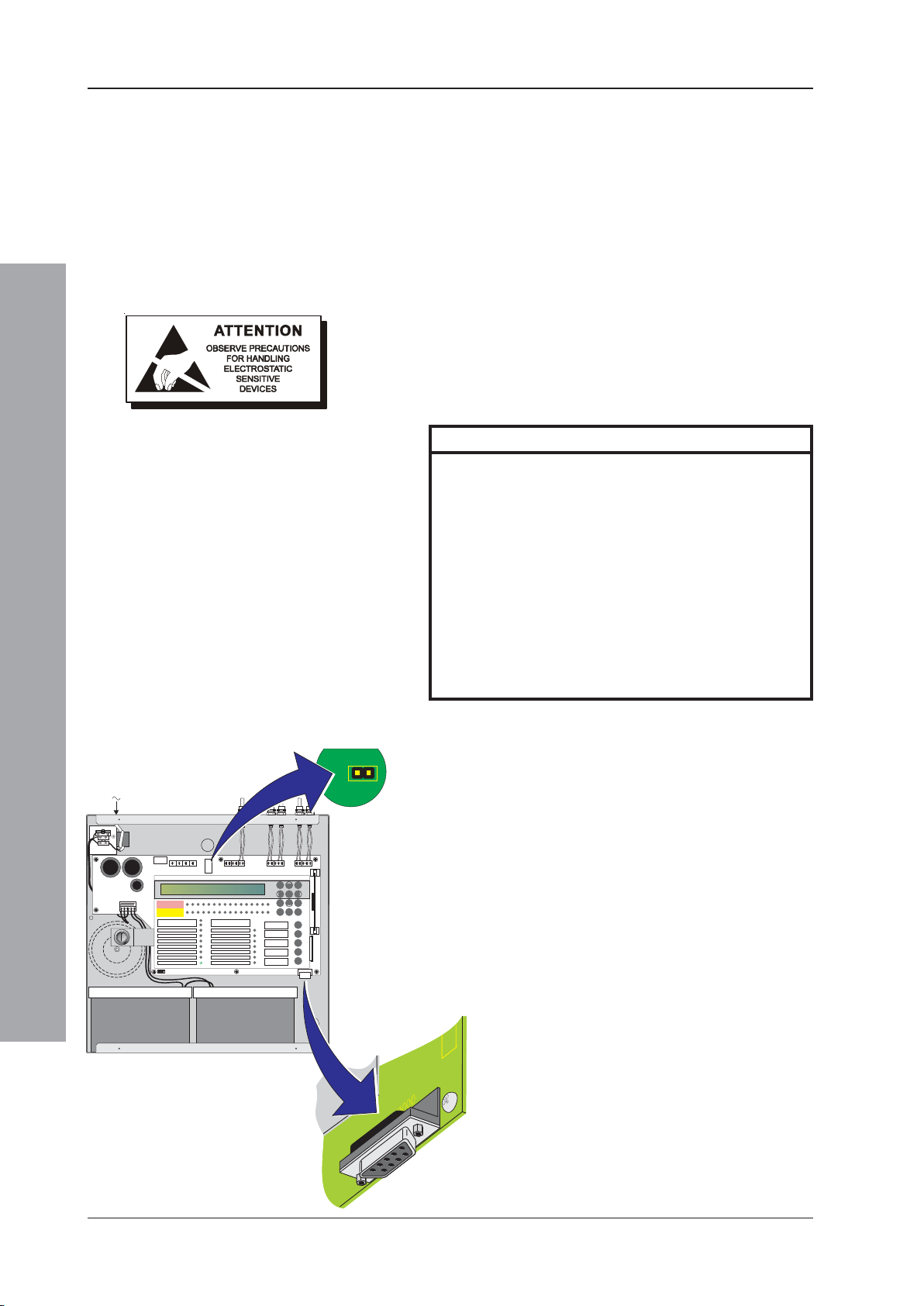

2.8 RS232 Interface Connections

The panel is fitted with a standard 9-way ‘D’-type RS232

Interface connector, located at the bottom right-hand

corner of the PCB assembly. The RS232 connector is

used for the following purposes:

a. Configuration using the PC Support Tool (refer to

997-405, ID50 Series Panel - Offline Configuration

Manual).

b. Upgrading the Panel Software (refer to 997-415, ID50

Series Panel - Upgrading Instructions).

Before starting any of the above operations ensure

suitable anti-static precautions have been taken.

The RS232 connector has the following pin out:

Pin Description

1 Data Carrier Detect (DCD)

2 Receive (RX) Data *

3 Transmit (TX) Data *

4 Data Terminal Ready (DTR)

5 GND *

6 Data Set Ready (DSR)

7 Request To Send (RTS)

8 Clear To Send (CTS)

9 Not Applicable

Installation Guide

ZONEFIRE

ZONEFAULT

DISABLE/TEST

DISABLEMENT

DELAYSACTIVE

FIREOUTPUT: FAULT/ DISABLED

FIREOUTPUT ACTIVE

PLANTALARM

1234567

FIRE

TEST

POWER

8910

ID50FIRE CONTROL PANEL

Complieswith EN54-2/4 1997

Periodof Manufacture 1999

POWERSUPPLY FAULT

EARTHFAULT

SYSTEMFAULT

SOUNDER:FAULT / DISABLED

PRE-ALARM

FIRECONTROLO/P: FAULT / DISABLED

11 121314

FAULT

15 16

MUTEBUZZER

EXTENDDELAY

ENDDELAY/

EVACUATE

SILENCE/

RESOUND

RESET

98

7

5

46

[

31

2

00..9

Note: Pin numbers marked thus ‘*’ are the only

required connections. Any others fitted will

be ignored.

A Data Transfer Lead (PN: 082-173) is required. Jumpers

must be removed as follows:

1 Remove the cover (refer to Section 2.5.1, Removing

the cover) to access the panel electronics.

2 Remove the Jumper Links J19 (earth fault monitoring)

and J9 (configuration memory lock).

Note: Refer to Section 4.3.1 Jumper Link Options/

Earth Fault Monitoring (J19) when connecting

third-party equipment to the panel.

3 Fit the Data Transfer Lead to the RS232 Interface

connector, PL5.

4 Perform required operation.

5 After satisfactory completion disconnect the lead and

then fit the jumpers.

RS232

January 2010

18997-263-000-11, Issue 11

ID50 Series Panel - Installation, Commissioning & Configuration Manual

3 Cabling

3.1 Cabling Instructions

WARNING: Risk of electric

shock. Before working on

mains connections, ensure

mains power supply to the

panel is disconnected.

All wiring should comply with current IEE wiring

regulations (BS7671) or the applicable local wiring

regulations. Note also the requirements of EN54-14 for

cabling and interconnection of a fire detection and alarm

system.

For information on wiring inputs and outputs refer to the

appropriate module cable and wiring instructions to

identify terminals. Refer also to Commissioning,

Section 4.4 External Wiring Checks for details.

Use the following rules when installing cables:

1 Cables should be brought into the cabinet through the

20mm knockouts provided on the top face of the back

box. Ensure that all openings in the back box are

closed before connecting power to the panel. For

example, if more knockouts than required have been

removed, then block the holes with blanking glands.

This is to prevent access to hazardous voltages.

2 Tails should be of sufficient length to connect to the

appropriate termination points at the commissioning

stage.

3 Cables should be screened and should be terminated

in appropriate glands to meet local wiring codes and

to preserve the integrity of the screen connection. The

cable screen is to be clamped inside the cable gland,

which must be fitted to ensure a 360o bond is formed

with the metal of the back box.

4 The supply to the panel must be provided with a

suitable and readily accessible double-pole mains

disconnect device. The mains supply must be suitably

fused and rated according to the specifications (see

Appendix 1, Specifications).

5 The knockout on the extreme left-hand side should

be used for mains cable entry. DO NOT bring mains

cables in through any other knockout holes and ensure

that the mains wiring is always separated from the

low voltage wiring. Tails of mains cables should be

provided with suitable additional sleeving before

connecting to the mains terminal block.

6 All low voltage cables should have a minimum 300Vac

rating.

General cable installation notes are given in Section 3.2,

Cable Installation Notes.

Earth Blade Connections

Note: All blade connections to earth incorporate a locking

barb. To remove this connection, pull the shroud

(1), NOT the earth wire from the earth blade

terminal (2).

Installation Guide - Cabling

19 997-263-000-11, Issue 11

January 2010

ID50 Series Panel - Installation, Commissioning & Configuration Manual

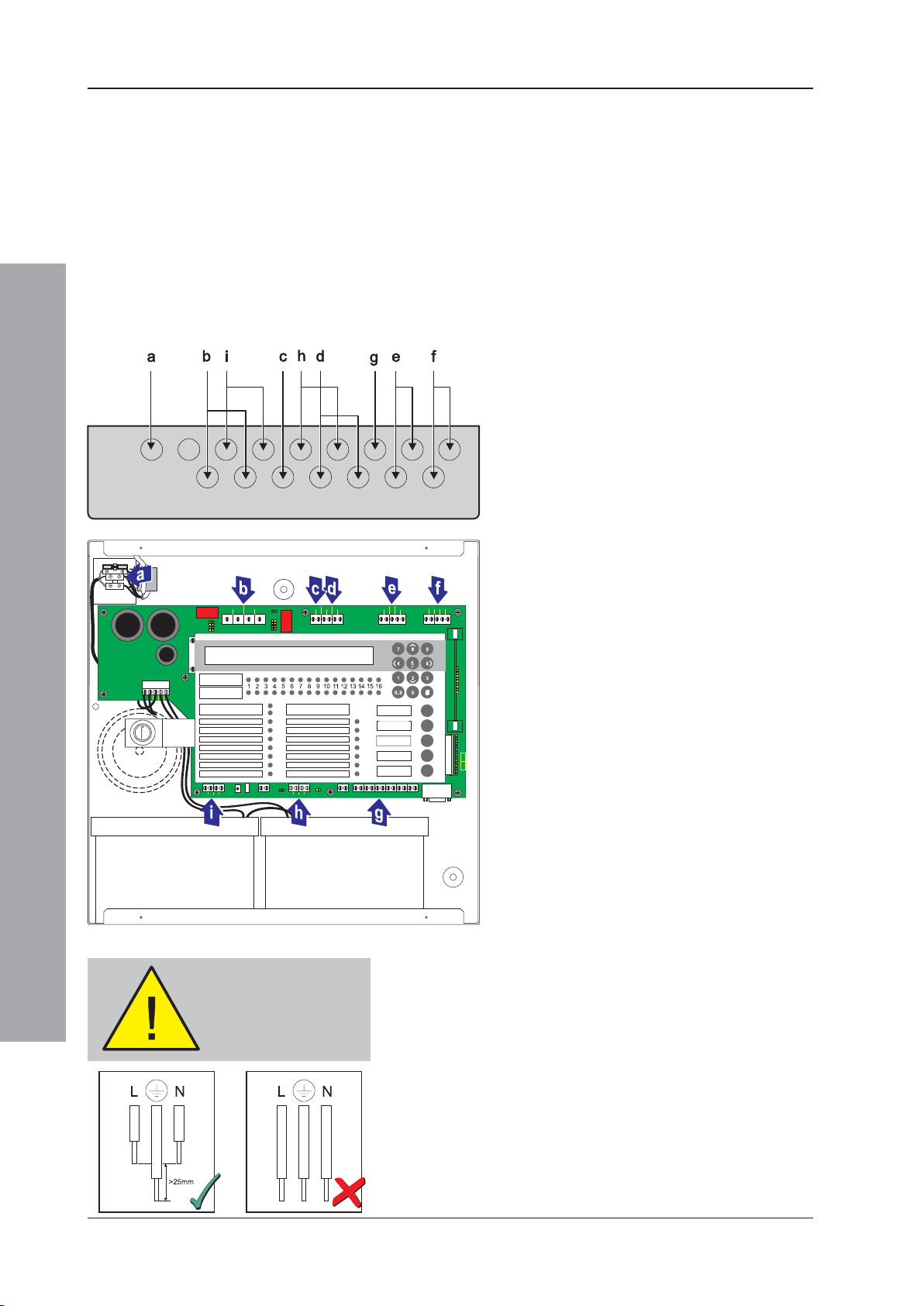

3.1.1 Cable Terminations

This section provides guidance on where to bring cables

into the back box for ease of termination:

a. The mains supply should be brought into the control

panel such that the cable path to the mains termination

block is kept as short as possible.

b. All loop and ancillary cable terminations should be

brought into the panel at suitable positions to ensure

tails are kept as short as possible.

The drawings below show recommended points of entry

so that cabling can meet these requirements.

Knockout/

Termination Point Cable Type

a Power supply cable

b Output D and C cables

c DC Auxiliary Supply

d Sounder Output B and A

Installation Guide - Cabling

When preparing mains

wiring for termination,

ensure the earth wire is

longer than the L(ive)

and N(eutral) wires.

Section 4.4.1, Loop Wiring,

Section 4.4.2, RS485 Communications Link,

Section 4.4.3, DC Auxiliary Output,

Section 4.4.4, Sounder Circuits Outputs A and B,

e Loop Wiring

f RS485 Communications

g FBF Connections

(Not Supported)

h Digital / ÜE

(ÜE Not Supported)

i Switched -VE Outputs

Note: The FBF Signal and Power supply

cables (g), and Digital / ÜE (h) port 2

are only valid when the panel is in VdS

mode.

For specific PCB cable termination details

see Commissioning:

January 2010

Section 4.4.5, CFG Outputs C and D,

Section 4.4.6, -VE Outputs, and

Section 4.4.7, Digital / ÜE Inputs.

20997-263-000-11, Issue 11

ID50 Series Panel - Installation, Commissioning & Configuration Manual

3.2 Cabling Installation Notes

3.2.1 Introduction

The following notes are intended to assist installers of

analogue addressable control systems. They have been

produced from information derived from the supplier’s

technical resource and from information fed back

concerning existing systems.

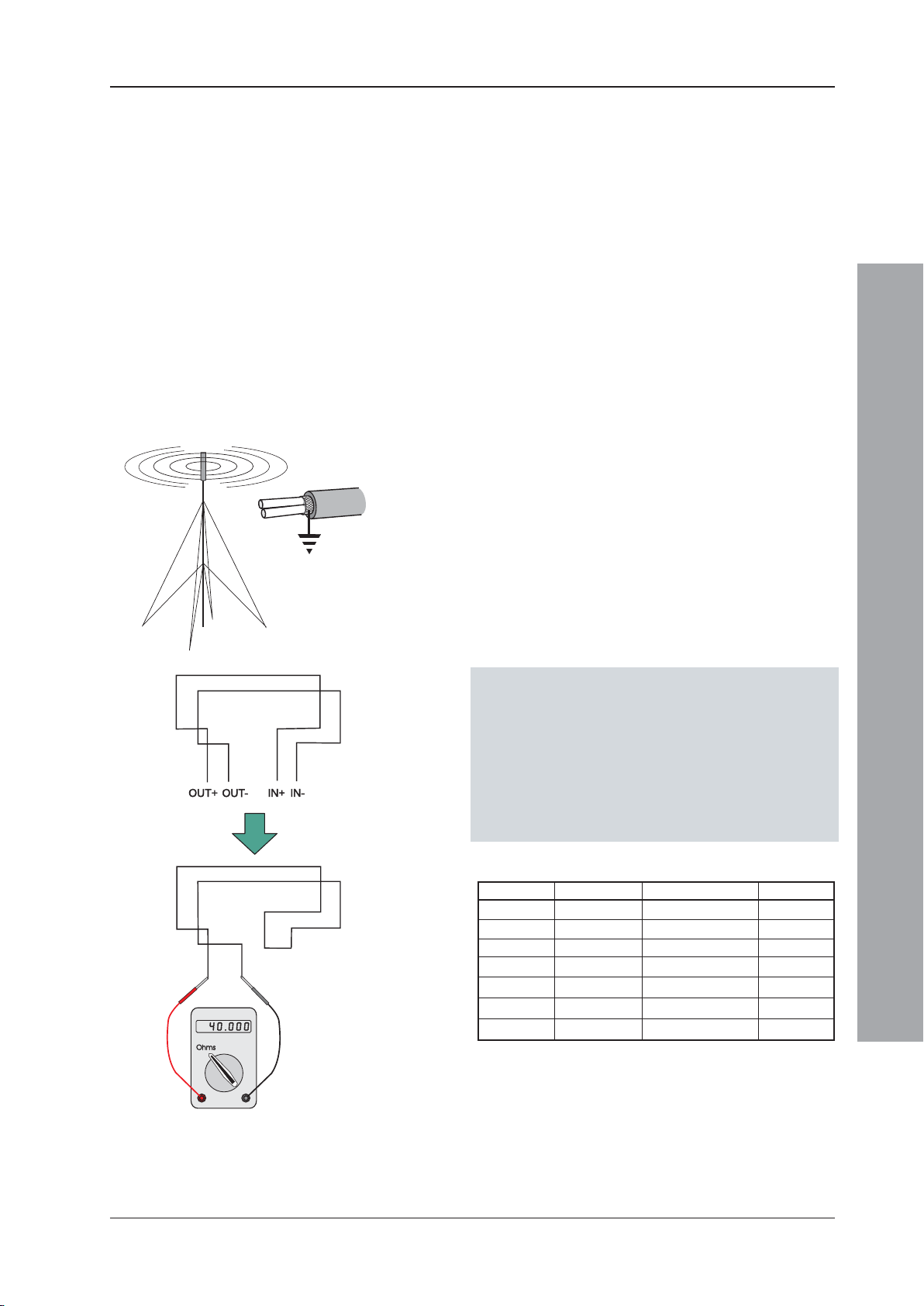

3.2.2 Quality of Cable and of Cable Installation

It is vitally important that good quality cable is used, and

that correct installation techniques are followed. In general,

the following cable installation requirements must be met:

a. All cable sections must be circular to allow effective

cable clamping using the cable glands.

b. The cable must be screened (sheathed) to provide

protection against Radio Frequency Interference (RFI)

and the screen must be connected to earth at the

control panel.

c. Multiple earthing of the screen should be avoided.

NOTIFIER’s field products use insulated mounting

bases and back boxes to achieve this. We recommend

that this practice be continued if other connections are

made. To achieve this with MICC cable may require

the use of insulated cable glands at one end of the cable.

d. The screen must be continuous throughout the loop.

e. The maximum resistance of the loop should not

exceed 40 ohms. You may check this by joining the

return legs IN+ and IN- together and measuring across

the start legs OUT+ to OUT-. Also the cable

capacitance should be less than 0.5μF. Typically this

will allow a maximum loop length of 2000m of screened

1.5mm2 cable. Cable recommended for use is MICC

with a LSF PVC overcovering, a fire-resilient cable to

BS7629 or PVC/SWA/PVC to BS6387.

Recommended Cables:

Manufacturer Product Name Part Number Type

AEI MICC 2L1.5 Enhanced

AEI Firetech 298-052 Standard

Draka FiretufPlus FTPLUS2E1.5RD Enhanced

Draka Firetuf FTZ2E1.5 Standard

Pirelli FP Plus FP Plus 2x1.5 Red Enhanced

Pirelli FP200 Gold FP200 Gold 2x1.5 Red Standard

Arrow - 7-2-4S Not rated

1

For a definition of ‘Standard’ and ‘Enhanced’ cable requirements and their different

applications, refer to BS 5839-1 Section 26. Enhanced cable is typically required

for spur sounder outputs, while standard cables may be adequate for other firerelated I/O provided there is diverse cable routing. The multi-core cable from Arrow

is suitable for RS232 connections to a printer.

1

Installation Guide - Cabling

f. We recommend that the system should be wired in

2-core cables and each 2-core cable should be specific

to one function.

g. The RS485 communication cable used should be rated

as suitable for up to 200mA in a short circuit condition.

21 997-263-000-11, Issue 11

January 2010

ID50 Series Panel - Installation, Commissioning & Configuration Manual

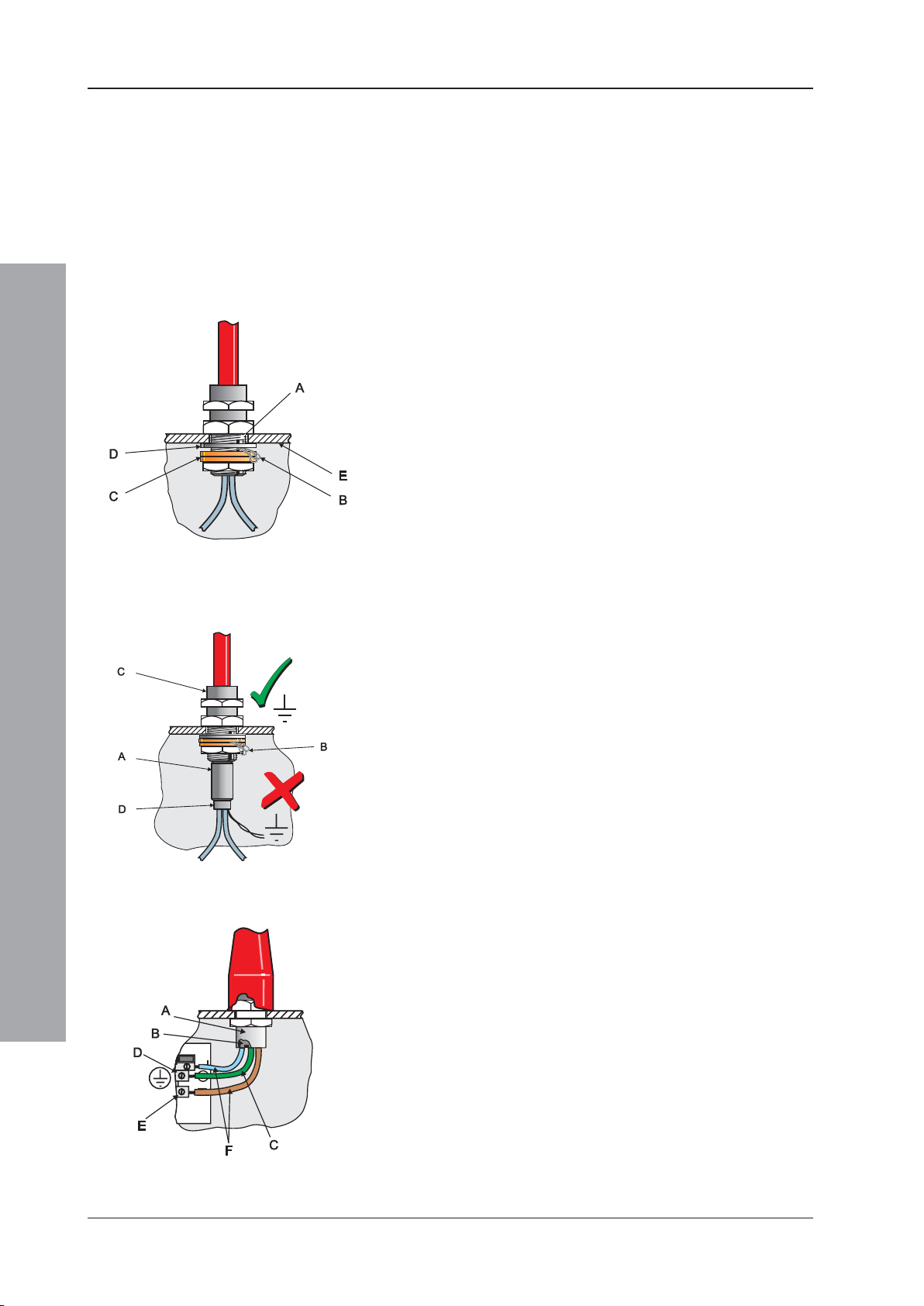

3.3 EMC Considerations

Following the above instructions and by using suitable

cables EMC problems will be avoided. In particularly

difficult EMC environments, or where non-preferred

cabling is used, it is possible to fit additional ferrite

suppressors (sleeves) to cables entering the control

panel.

3.3.1 Screen Termination

Use the following method to terminate the cable screens:

Use a metal gland with slots (A) that allow the drain

wire or screen (B) to be clamped between flat washers

(C). Use a steel locking washer (D) between the brass

washers and the internal surface of the back box (E).

This will provide the best EMC termination. Suitable

glands are the CTX range available from CMP UK

Ltd. The part chosen should fit the 20mm knockouts.

3.3.2 Ferrite Sleeves (Optional)

Ferrite sleeves are not normally required with the panel.

In difficult EMC environments, or where non-preferred

cables are used, optional ferrite sleeves should be fitted

to both the loop and sounder wiring. the ferrite sleeves

(A) are to be fitted over the conductor(s) of each cable and NOT over the screen of the cable, which should pass

outside of the sleeve. They should be fitted as close as

possible to the entry point of the cable, i.e. as near as

possible to the screen termination (B) to the metal cable

gland (C). The sleeve should be held in place using a

cable tie (D).

The ferrite sleeves are available for purchase from

NOTIFIER’s distributors (PN: 538-143).

Installation Guide - Cabling

3.4 MICC Cables

MICC cables must be fitted with metal cable glands (use

Type A2 glands) to ensure good earthing continuity and

correct termination. In particular, the mains cable requires

that the cable gland (A) is fitted with an earth tail kit (B).

The earth tail kit must be connected, using an insulated

wire (C), to the panel safety earth connection (D) at the

mains termination block (E). The bare mains wiring from

the MICC cable must be suitably-insulated (F) and

terminated in accordance with the appropriate local wiring

regulations.

January 2010

22997-263-000-11, Issue 11

ID50 Series Panel - Installation, Commissioning & Configuration Manual

4 Commissioning

4.1 Introduction

This section describes how to bring the ID50 Series Panel

into an operational state (commissioning) ready for

configuration. To commission this series of panels follow

the steps detailed below. Information on how to configure

the panel is given in Section 5, Configuration.

1 Check that the panel is installed and assembled

correctly, refer to Section 4.2, Preliminary Checks.

2 Check internal panel configuration, Section 4.3,

Internal Checks.

3 Check and connect the external wiring, refer to

Section 4.4, External Wiring Checks.

4 Configure the panel for the particular system

requirements, refer to Section 5, Configuration.

5 Check that the system is working correctly.

4.2 Preliminary Checks

Before connecting the mains power to the panel, check

that:

a. All PCBs are correctly fitted.

b. All internal wiring is correctly connected.

c. The loop wiring and external sounder circuits have

NOT, at this stage, been connected to the PCB.

d. Check that there are no more than 10 CLIP device

addresses on a mixed-protocol loop. Be aware that

some modules, e.g. M720, M721 use more than one

loop address - the first device address taken up is

OPAL while the others are CLIP, so an M721 module

uses one OPAL and two CLIP addresses.

e. The appropriate end-of-line devices are connected to

the sounder outputs. For backwards compatibility, the

default is set for 6k8 resistor end-of-line devices.

However, an option is provided to select diode endof-line devices to meet the requirements of EN54-13,

which requires the ability to monitor for partial-open

and partial-short circuit faults. A diode is provided for

each sounder circuit should this option be selected.

Commissioning

f. The 150R termination resistors are connected to the

first and the last panels on the RS485

Communications Link.

23 997-263-000-11, Issue 11

January 2010

ID50 Series Panel - Installation, Commissioning & Configuration Manual

4.3 Internal Checks

When all PCBs have been installed and all cabling has

been successfully checked, the following jumper links

allow the implementation of panel software or

configuration updates, as described below.

4.3.1 Jumper Link Options

Software Upgrade (J4)

The Software Upgrade Jumper in conjunction with the

Upgrade kit is used to upgrade the panel operating

software. To enable the panel upgrade, fit a link to J4

and connect the appropriate cable. The link J4 must be

removed on completion of the upgrade (see 997-415,

ID50 Series Panel - Upgrading Instructions). This

jumper is situated to the right of the Digital/ÜE terminal

block (TB8).

DISABLEDUNLOCKED

J9

J9

LOCKED

J4

J4

ENABLED

Commissioning

Configuration Lock (J9)

The Configuration Lock Jumper is used to lock and unlock

the system configuration. If the link is fitted the system

configuration is locked and changes will NOT be allowed.

If the link is removed system configuration is possible.

The panel can only be configured with the Configuration

Lock (J9) in the unlocked position. The jumper is situated

to the left of the Digital / ÜE terminal block (TB8).

January 2010

24997-263-000-11, Issue 11

ID50 Series Panel - Installation, Commissioning & Configuration Manual

Earth Fault Monitoring (J19)

Earth fault monitoring should be enabled during normal

EN54-2 : 8.2.4c.

Earth Fault Monitoring

is required.

operation; this is the default condition and is indicated by

a fitted jumper link on J19 to the right of the CFG Outputs

C and D terminal block (TB3). To disable the earth fault

monitoring, remove the link.

J19

DO NOT remove link if

there is an existing earth

fault. If link is removed,

ensure it is fitted before

replacing front cover.

J19

ENABLEDDISABLED

The presence of an earth fault is indicated by a yellow

Earth Fault and general Fault LED.

Warning: If an earth fault already exists, DO NOT attempt

to connect additional equipment likely to cause

earth faults as damage may result, i.e. inhibiting

the monitoring will not protect the equipment.

Note: Direct connection of a VDU etc. to the RS232 serial

port D-type plug connector PL5, will result in an

earth fault and potential damage to the connecting

equipment. This fault can be removed by use of

an isolated RS232 link or by (temporarily) disabling

the earth leakage detection. Wait at least one

minute after disabling the earth fault monitoring

circuit before plugging into PL5.

4.4 External Wiring Checks

The following sections describe the procedures for

checking and connecting the external wiring:

a. See Section 4.4.1, Loop Wiring*,

b. See Section 4.4.2, RS485 Communications Link,

c. See Section 4.4.3, DC Auxiliary Output,

d. See Section 4.4.4, Sounder Circuit Outputs A and B,

e. See Section 4.4.5, CFG Outputs C and D,

f. See Section 4.4.6, -VE Outputs, and

g. See Section 4.4.7, Digital / ÜE Inputs.

* Notifier has a PC-based Loop Diagnostic Tool (LDT).

This tool is easy to use and its purpose is to reduce

the amount time spent resolving cable and wiring

termination faults. Contact Notifier Technical Support

for details.

Commissioning

25 997-263-000-11, Issue 11

January 2010

ID50 Series Panel - Installation, Commissioning & Configuration Manual

The loop wiring MUST

be disconnected from

the panel during this

procedure

OPAL Protocol Devices

Most OPAL devices have internal isolators.

With OPAL-compatible bases the isolator is

connected across terminals +2 and +4 on

the positive loop leg. OPAL devices will

work satisfactorily on B501 bases except

the internal isolator, when fitted, cannot

be operated.

4.4.1 Loop Wiring

Typical connections of analogue addressable loop pair

to a loop are shown below.

Checks Before Connection

To check the Loop wiring:

1 For CLIP devices link out any isolators on the Loop

by temporarily shorting terminals 2 and 4 on each

isolator. For OPAL protocol-compatible sensor bases

(B501 AP) remove the device from the base. These

bases have +leg terminals (+2 OUT and +4 IN) that

connect automatically when the sensor is removed.

Check Appendix 1 of this manual or the LBC for OPAL

device types fitted with internal isolators.

2 These tests should then be carried out using a low-

voltage multimeter. Check the continuity of each leg

of the loop and measure the end-to-end resistance.

Verify that the total loop resistance (sum of both legs)

is less than 40 ohms. Typically, this will allow a

maximum loop length of 2,000m of screened 1.5mm

cable.

2

Commissioning

4k7

18k

Monitor used

(see Note a)

LOOP IN LOOP OUT LOOP OUT LOOP OUTLOOP IN LOOP IN

as input

A

See Note c

Isolator

(see Note b)

M500KAC/

M700KAC

Note: The cable capacitance should be less than 0.5μF.

3 Connect the meter in ‘normal’ polarity (+ve to loop +ve

and -ve to loop -ve). The meter should initially read low

resistance but this should increase as the capacitor in

each of the loop devices charges. If the meter indicates

the presence of a forward-biased diode then it is

probable that one or more of the loop devices is

connected in reversed polarity or the wiring is crossed.

4 If reversed device(s) are indicated in step 3, they may

be located by successive halving of the loop (if the

site layout makes this difficult, the affected section of

the loop can be identified from the panel fault

messages after the system has been configured and

the links in the isolators removed - CLIP devices only).

Notes:

a. A = Normally open switch

- closes under an alarm

28V Supply

Output

Module

See Note c

47k

Supervised

Load

condition.

b. To comply with the

requirements of EN54,

isolators should be fitted

between a maximum of

32 loop devices. For the

ID50 Series Panel, do not

place more than 25 loop

devices between isolators

(20 if FET isolators are

used).

See Note c

B501/B501 AP

+

Loop Start

-

January 2010

c. Refer to device

instruction sheet for

wiring terminations.

Loop Finish

+

26997-263-000-11, Issue 11

Loading...

Loading...