ID3000

997-274-000-6, Issue 6 September 2009

installation &

commissioning

manual

ID3000 Series Installation & Commissioning Manual

1

2

3

4

5

6

7

8

9

0

FAULT

FIRE

1

2

3

4

5

6

7

8

9

0

FAULT

FIRE

FIRE

FIRE

FIRE

FIRE

FAULT

FAULT

FAULT

FAULT

ZONE

ZONE

ZONE

ZONE

ZONE

ZONE

ZONE

ZONE

1

2

3

4

5

6

7

8

9

0

FAULT

FIRE

The ID3000 Series Range of Fire Control Panels

Contents

i 997-274-000-6, Issue 6

September 2009

ID3000 Series Installation & Commissioning Manual

The following markings are used either on

the panel hardware or in the

documentation. They have the following

meaning:

WARNING: Risk of electric shock. Before

working on mains connections, ensure

mains power supply to the panel is

disconnected.

Contents

1 Introduction 1

1.1 CE Marking 1

1.2 System Design and Planning 1

1.3 Personnel 1

1.4 General 1

1.5 Date-dependent Functions 2

Installation: Sections 2-6

2 Installation Guide 3

2.1 How to Use this Guide 3

CAUTION: Refer to the accompanying

documentation. (When used in the

documentation, this marking is normally

associated with additional instructions).’

Contents

2.1.1 Related Documents 3

2.1.2 Warnings and Cautions 3

2.1.3 Tips 3

2.1.4 Glossary of Icons 4

2.2 Pre-Installation Check List 5

2.2.1 Some DO’s and DONT’s 5

2.3 Transient Protection 6

2.4 Installation 7

2.4.1 Checking Your Panel for Damage 7

2.4.2 What to do if Your Module is Damaged 8

2.4.3 Back Box Fixing 9

2.4.4 Electronics Modules 10

2.5 Replacing the Electronics Modules 11

2.6 Flush Mounting Bezel (Optional) 11

2.7 Moulded Front Covers 12

3 Cabling 14

997-274-000-6, Issue 6

September 2009

3.1 Cabling Instructions 14

3.1.1 Cable Terminations 15

3.2 Cable Installation Notes 16

3.2.1 Introduction 16

3.2.2 Quality of Cable and of Cable Installation 16

3.3 EMC Considerations 17

3.3.1 Screen Termination 17

3.3.2 Ferrite Sleeves (Optional) 17

3.4 MICC Cables 17

ii

ID3000 Series Installation & Commissioning Manual

4 Sensors and Modules 18

4.1 EN54 Requirements 18

4.1.1 Loop Devices - Sensors and MCPs 18

4.1.2 Loop Devices - Isolators 18

4.2 Loop Wiring Testing 18

5 Panel Electronics Modules 19

5.1 Introduction 19

5.2 Kit PSU3A 20

5.2.1 Procedure 20

5.3 Dual Transmission Path/Booster Module 23

5.3.1 Procedure 23

5.4 Main Chassis 25

5.4.1 Main Chassis Configurations 25

5.4.2 Procedure 25

5.5 Zonal LED & Printer Options 26

5.5.1 64 Zone LED Extension Chassis 26

5.5.2 PRN-ID Printer 27

5.5.3 LEDs for up to 256 Zones 29

5.6 Display PCB 31

5.7 Base PCB 32

5.7.1 Fitting the Replacement Base PCB 33

5.7.2 Cables and Wiring 33

5.8 Processor PCB 34

5.9 Loop Interface PCB 35

5.9.1 Cables and Wiring 35

5.10 Enhanced Loop Interface PCB 36

5.10.1 Cables and Wiring 37

5.11 Isolated RS232 Interface PCB 38

5.11.1 Cables and Wiring 39

5.12 Isolated RS485 Interface PCB 40

5.12.1 Cables and Wiring 40

Contents

5.13 Label Inserts 41

6 Repeaters and Master/Slave Network 42

6.1 Connecting Repeaters 42

6.2 Master/Slave Network Connections 43

7 Commissioning 44

7.1 Introduction 44

7.2 Preliminary Checks 44

iii 997-274-000-6, Issue 6

September 2009

ID3000 Series Installation & Commissioning Manual

7.3 Powering the Panel 45

7.4 External Wiring 45

7.4.1 Introduction 45

7.4.2 Loop Checks Before Connecting Wiring 46

7.4.3 Connecting the Loop Wiring to the Panel 47

7.4.4 Loop Checks After Connecting Wiring 47

7.4.5 24V Auxiliary Outputs Check 48

7.4.6 Sounder Circuits Check 48

7.4.7 Fault Relay Wiring 48

7.5 Batteries 49

7.5.1 Connecting the Batteries 49

7.5.2 Battery Disposal 50

7.6 Earth Fault Monitoring 50

7.7 Volt-free Contact Output Option 51

7.8 Repeaters 52

Contents

7.9 Configuration and Handover 52

7.10 System Test 52

7.10.1 Zone Walk Test 52

7.10.2 Control Output Test 52

8 Maintenance 53

8.1 Routine Testing 53

8.2 Batteries 53

8.3 Cleaning 53

Appendices:

Appendix 1 - Fault Messages A1-1 to A1-5

Appendix 2 - Specifications A2-1 to A2-5

Appendix 3 - System Design Guide A3-1 to A3-6

Appendix 4 - ID2net Network A4-1 to A4-8

997-274-000-6, Issue 6

September 2009

iv

XLS80e Fire Alarm Control Panels

1 Introduction

The purpose of this manual is to provide the user with all

recommended procedure descriptions and full technical

details for the successful installation and commissioning

of HONEYWELL’s XLS80e Series stand-alone fire alarm

controllers and repeaters, or for a complete XLS80e Series

integrated Fire Control System.

Procedures described in this manual include appropriate

warnings and cautions to guide the user towards adopting

safe and methodical work practices during the installation

and commissioning phases.

1.1 CE Marking

CE

This panel is CE Marked to show that it conforms to the

requirements of the following European Community

Directives:

The EMC Directive 2004/108/EEC, by the application of

the following EMC Standards:

EN 61000-6-3: Electromagnetic Compatibility (EMC)

Generic emission standard for Residential, Commercial

and Light industrial environments

EN 50130-4: EMC Product family standard: Immunity

requirements for components of fire, intruder and social

alarm systems.

Low Voltage Directive 2006/95/EC, by the application of

the safety standard:.

EN 60950-1: Safety of information technology

equipment.

The Constructive Products Directive 89/1-6/EC, by the

application of the following standards:

EN 54-2: Fire detection and fire alarm systems - Control

and indicating equipment.

EN 54-4: Fire detection and fire alarm systems - Power

supply equipment.

1.2 System Design and Planning

It is assumed that the system, of which the XLS80e Series

fire control equipment is a part, has been designed by a

competent fire alarm system designer in accordance with

the requirements of EN54 Part 14 and any other local codes

of practice that are applicable.

The design drawings should clearly show the positions of

all the XLS80e Series control equipment and field devices.

1 Honeywell, Issue 7

September 2009

Only fit the electronics

modules after all the other

trades have completed

their tasks!

XLS80e Fire Alarm Control Panels

1.3 Personnel

Installation of this product must be carried out only by

suitably-qualified electrical engineers.

1.4 General

The XLS80e Series of intelligent fire alarm controllers are

designed for use with HONEYWELL’s range of addressable

analogue sensors, control and monitoring modules and

addressable call points.

The XLS80e Series control panel design complies with the

requirements of EN54 Part 2 and Part 4.

The design of the XLS80e Series fire control panels is based

on a modular build concept which offers the user completely

flexible system solutions. Each control panel comprises a

number of separate build modules to simplify the installation

process. The electronic components are contained in an

easy-to-fit module called the main chassis.

The control panel can be used with either an internal or

external Power Supply Unit (PSU).

Each control panel has space provision for two sealed,

lead-acid batteries.

The panel has a built-in Master/Slave network serial

communications interface which operates under RS485

protocol. Alternatively, the panel can be connected to an

XLSnet fault-tolerant peer-to-peer network.

While every effort is made to ensure the accuracy of the

content of this manual, the manufacturer reserves the right

to change the information without notice.

Installation

The XLS80e Series modules are easy to install providing

the recommended procedures described in this manual

are followed. To avoid inadvertant contamination of the main

chassis (comprising the PCBs) and of the PSU (if mounted

internally), the manufacturer recommends that these items

are installed in the back box only after all other trades

have completed their tasks.

1.5 Date-dependent Functions

It should be noted that the calendar end date for this

product is 31/12/2099 (two thousand and ninety nine) and

it will perform correctly up to this date.

September 2009

The calendar function has not been tested beyond this

date.

2Honeywell, Issue 7

ID3000 Series Installation & Commissioning Manual

2 Installation Guide

2.1 How to Use this Guide

This Installation Guide is intended to provide you with

simple guidelines on how to install an ID3000 Series fire

control panel or system, quickly and safely.

For each stage in the ID3000 Series panel installation

and commissioning procedures a brief description is given

of its purpose, complete with detail drawings, flow

diagrams and/or other graphics to make the instructions

easy to follow. Where required, procedures may be broken

down into one or more related flow diagrams, the number

being dependent upon the complexity of the defined task.

2.1.1 Related Documents

The guide does not describe any of the panel operating

or configuration stages, as these are covered by other

related manuals. For more information refer to:

WARNING High Voltage!

Take suitable precautions

to avoid electric shock.

EN54-2: 12.5.2

Maximum of 32

Sensors and/or MCPs

between isolators.

ID3000 Series Operating Manual (ref. 997-505-000-X)

ID3000 Series Panel Configuration Manual

(ref. 997-506-000-X)

2.1.2 Warnings and Cautions

Where appropriate, this guide and the remainder of the

manual include advisory warnings and cautions to remind

you to consider safety at all times, especially when

following the procedures described in this manual.

You are alerted to any areas where high voltage [i.e. nonSafety Extra-low Voltage (SELV)] is present, or where

there may be a risk of damage to static-sensitive devices

if the recommended procedures described in this manual

are not followed. An example of a high voltage warning

and anti-static caution is provided to the left of this

paragraph.

The ID3000 Series control panel has many powerful builtin features which, if used inappropriately, may contravene

the requirements of EN54. Where there is a possibility

of such an occurence, a suitable warning is given with

brief details of the EN54 requirement. A typical EN54

non-compliance warning is illustrated at left.

Installation Guide

Magnetise the tip of your

screwdriver to help when

offering small screws to

holes in confined spaces.

2.1.3 Tips

‘Handy tips’ are included, where appropriate, to assist

you in following quick and safe procedures for fire

detection system installation and integration.

Look for the ‘TIP!’ icon and supporting text, typically

illustrated at left.

3 997-274-000-6, Issue 6

September 2009

ID3000 Series Installation & Commissioning Manual

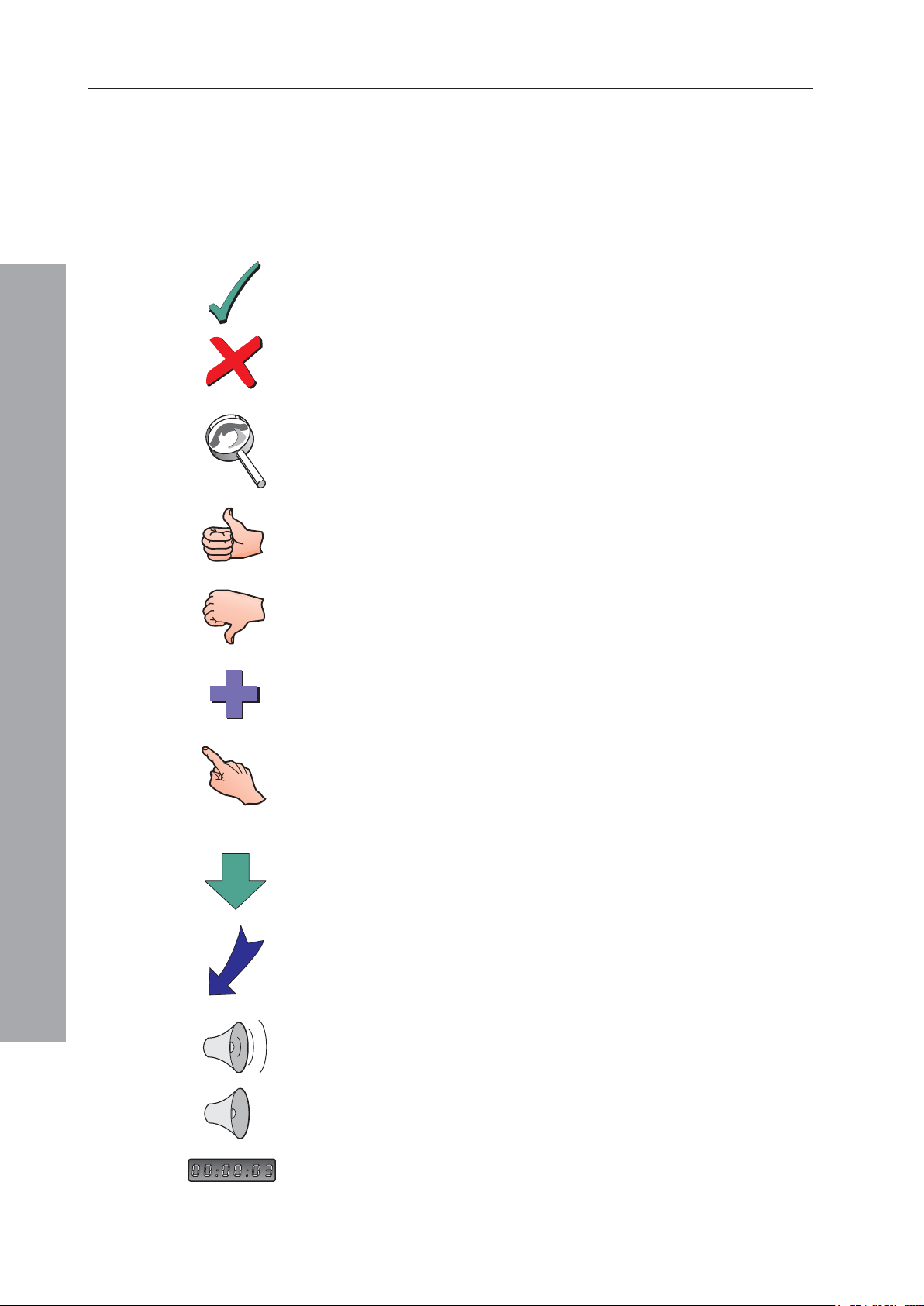

2.1.4 Glossary of Icons

Throughout this Installation and Commissioning Manual

and other supplied user documentation a number of

simple icons are used, either on their own or together

with larger illustrations, to simplify a particular task or

process.

The following icons are used to advise or indicate:

a. DO follow the recommended procedure or method

b. DO NOT use this procedure or method

c. Inspection of an item or sub-assembly is required at

this point

Installation Guide

d. Following a defined process meets the required

approval/inspection criteria or standards

e. Following a defined process does not meet the

required approval/inspection criteria or standards

f. Additional items to be considered

g. This icon placed next to a pushbutton requires you to

press it as part of a described process, such as isolate

or test, or while programming the panel. Where two or

more icons are used, a number may be placed on or

near each hand to indicate the order of selection: 1

coming before 2, etc.

h. Activity process step - flow arrow for single action or

iterative actions

i. Leader arrow - used with activity processes

September 2009

j. Sounder operating

k. Sounder not-operating or silenced

l. Digital clock timer - press and hold the applicable

pushbutton for the time indicated

4997-274-000-6, Issue 6

ID3000 Series Installation & Commissioning Manual

1.5m

2.2 Pre-installation Check List

Before installing the ID3000 equipment or fitting sensors,

you must first ensure that the following criteria have been

met. Failure to do this may not only result in damage to

the equipment, but may also cause problems when

commissioning the equipment or adversely affect its

performance.

2.2.1 Some DO’s and DON’T’s

Before selecting a location for the control panel and

devices, DO make sure that:

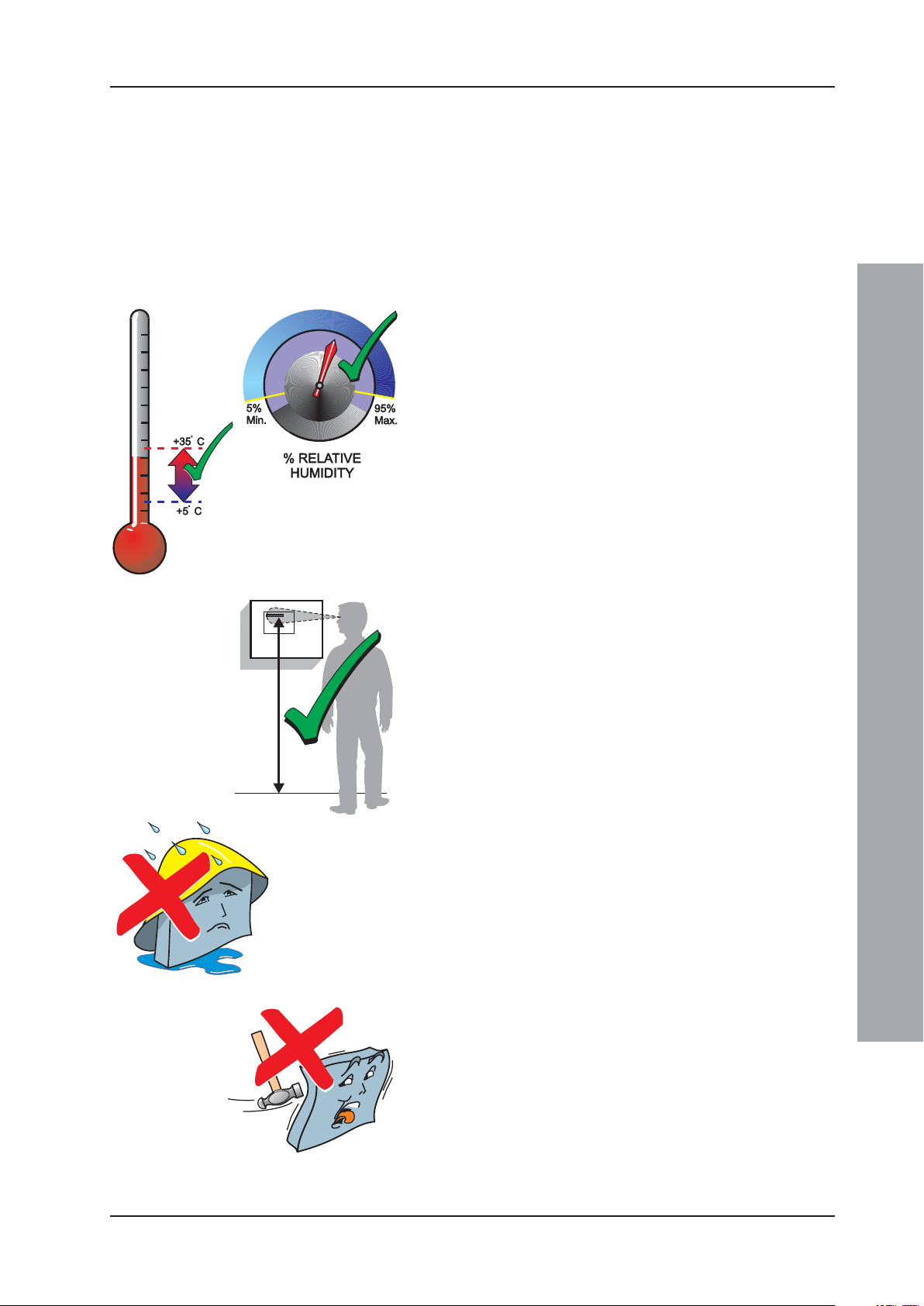

a. The operating ambient temperature is in the

recommended range:

5°C to 35°C and

b. The relative humidity is between:

5% and 95%

c. The panel is wall mounted in a position which allows

clear visibility of displays and easy access to operating

controls. The height above floor level should be chosen

such that the LCD is just above normal eye level

(approximately 1.5 metres)

d. DO NOT locate the panel where it is exposed to high

levels of moisture

Installation Guide

e. DO NOT locate the panel where there are high levels

of vibration or shock

5 997-274-000-6, Issue 6

September 2009

ID3000 Series Installation & Commissioning Manual

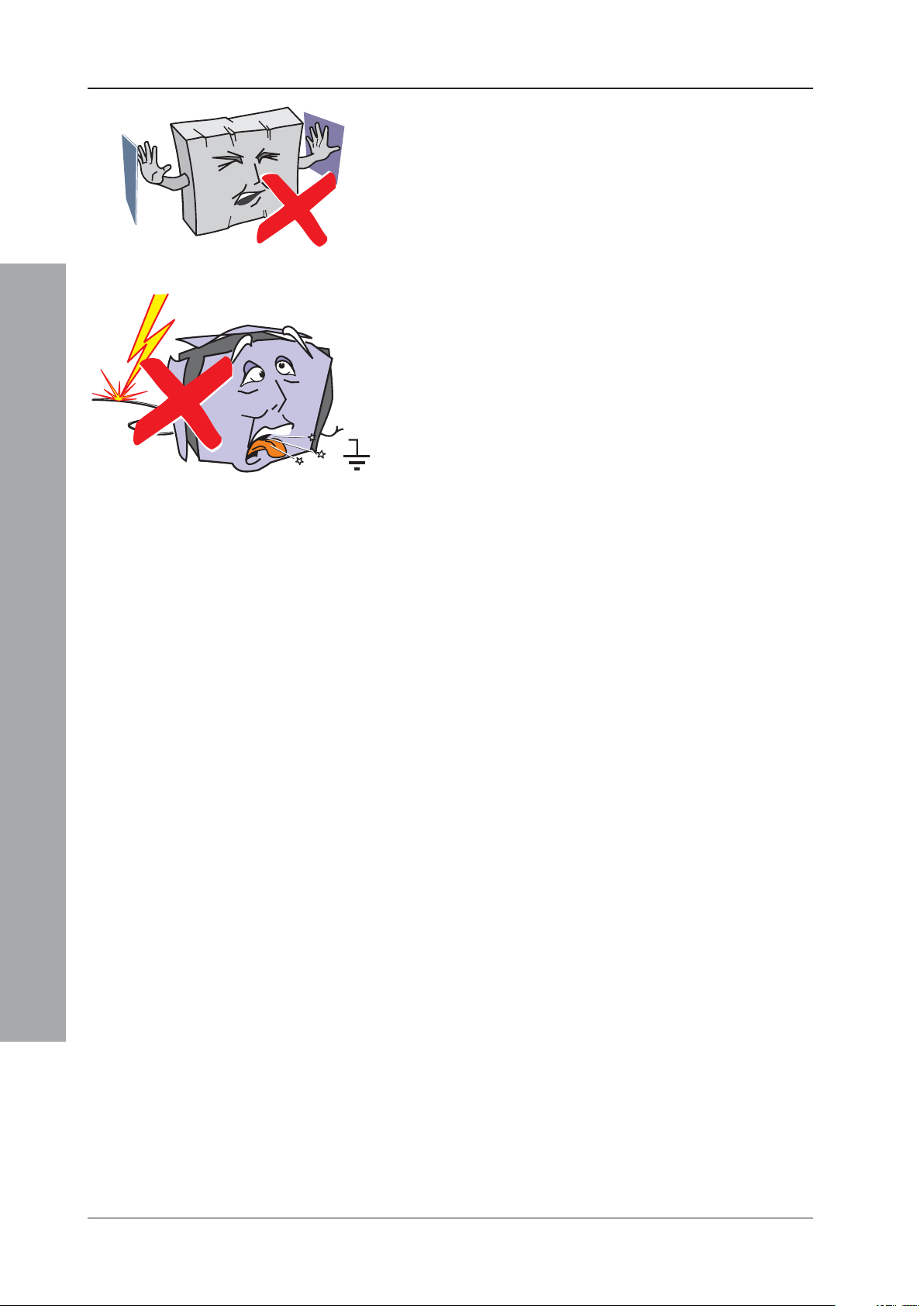

f. DO NOT site the panel where there would be

restricted access to the internal equipment and

cabling/wiring connections.

2.3 Transient Protection

This equipment contains transient-protection devices.

Although no system is completely immune from lightning

transients and interference, for these devices to function

correctly, and to reduce susceptibility, this equipment

must be earthed correctly.

As with all solid state devices, this system may operate

erratically or can be damaged if subjected to lightninginduced transients.

The use of overhead or outside aerial wiring is not

recommended due to the increased susceptibility to

nearby lightning strikes.

Installation Guide

September 2009

6997-274-000-6, Issue 6

ID3000 Series Installation & Commissioning Manual

1

2

To avoid damage to the

control panel ensure that

you follow these

instructions

2.4 Installation

The ID3000 Series of modular fire control panels are

relatively simple to install providing the recommended

procedures described in this Installation Guide are

followed.

Follow all installation instructions described in this

manual. These instructions must be understood and

the manufacturer’s recommendations followed to

avoid damage to the control panel and associated

equipment.

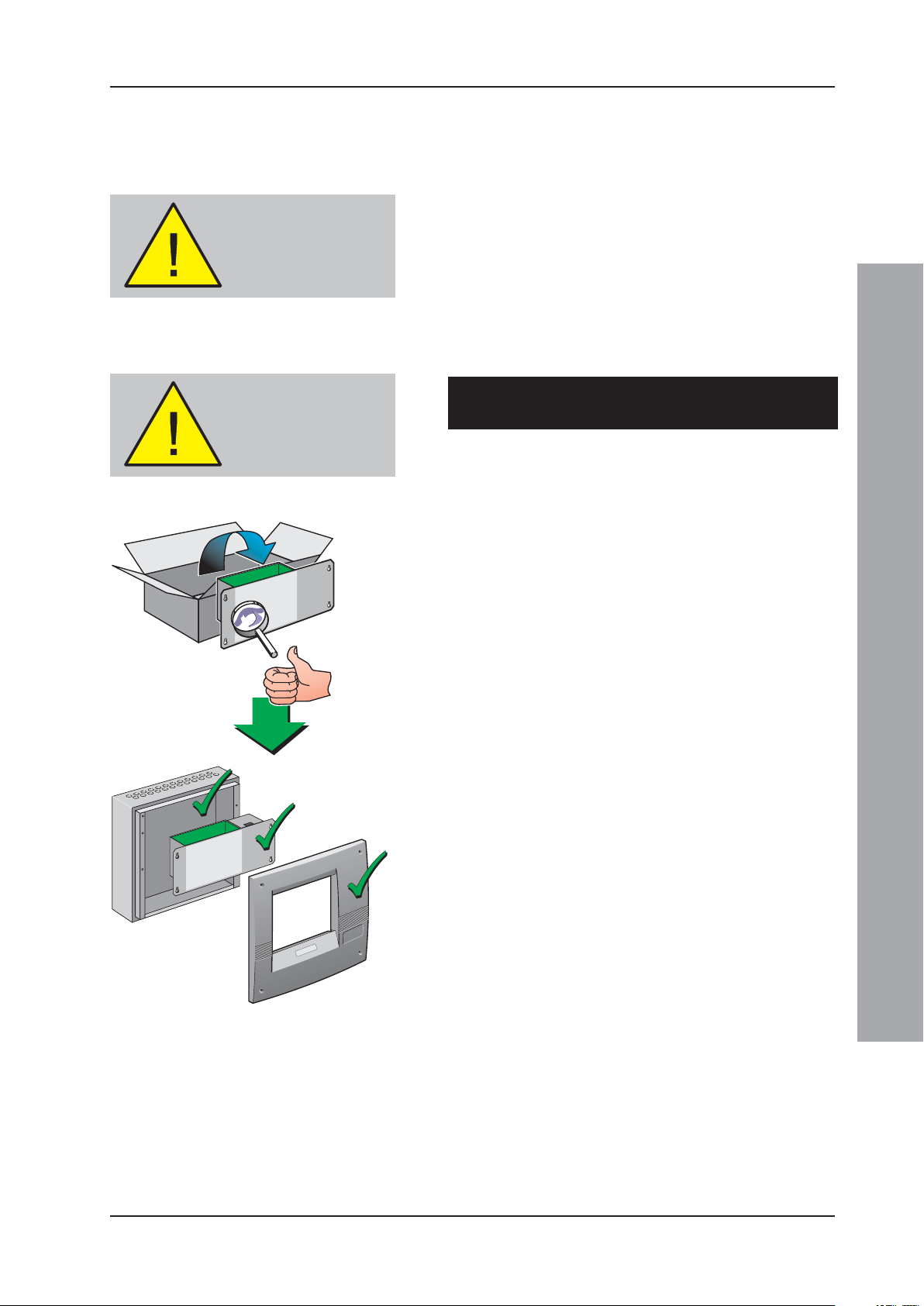

2.4.1 Checking Your Panel for Damage

Do a quality check

before proceeding with

the installation!

It is important to check all supplied equipment for

damage before proceeding with the installation!

Before attempting to install the modular components of

your ID3000 Series control panel, or other equipment,

you should do the following:

1 After removing the various control panel modules or

other related equipment from its packaging, and

before you proceed with installing it in its chosen

location, check for any damage that may have

occurred while in transit.

Note: In the unlikely event that any of the supplied ID3000

Series items has been damaged, you MUST NOT

fit it but return it to your supplier. The procedure

for returning faulty items is described in

Section 2.4.2, What to do if Your Module is

Damaged or Suspect.

2 If you are satisfied that none of the supplied items

has been damaged you can now proceed with the

installation procedure. This manual addresses the

recommended installation methods of the various

ID3000 Series equipment components which are

supplied as separate build modules. Refer to the

relevant sections that apply to your configuration

requirements.

Installation Guide

To prevent unnecessary damage to the electronic

components, the panel back box(es) should be installed

first, i.e. without fitting the main chassis at this stage.

Refer to Section 2.4.3, Back Box Fixing for details.

7 997-274-000-6, Issue 6

September 2009

ID3000 Series Installation & Commissioning Manual

Thhshj

iidjdhhh

Adfddd

jhjhgdjsfff

iiiiojh

yudjdfh

jfklrlkr

uuu

uui

hjfjufhf

jjjk

k,kljk

uu

ulg

efjkfjkjk

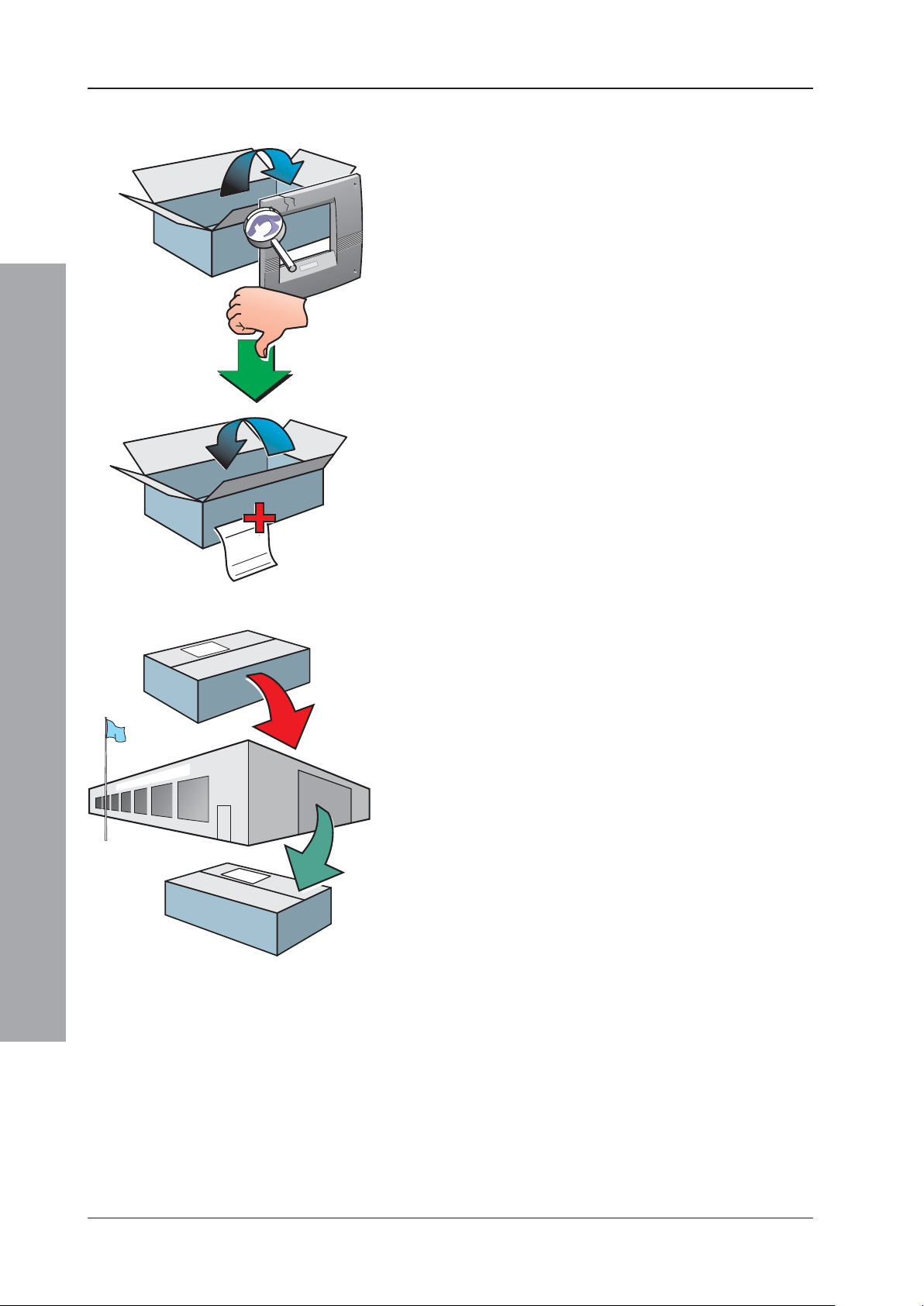

2.4.2 What to do if Your Module is Damaged or

Suspect

1

If you have problems regarding the quality of any supplied

order items including the control panel, its ancillaries or

this manual or items are missing, follow the procedure

below.

1 DO NOT continue with the installation but contact your

supplier for advice on what to do next.

Similarly, if the product is found to be faulty during

installation contact your supplier immediately.

2 To aid your supplier and the manufacturer, you are

requested to:

2

Thhshj iidjdhhh

Adfdddjhjhgdjsfff iiiiojh

yudjdfh jfklrlkruuu uui

hjfjufhfjjjk k,kljk uu ulg

efjkfjkjk

3

Installation Guide

a. Quote the manufacturer’s unique batch reference

number which can be found on the packaging, main

chassis or inside the back box

b. With reference to PCBs, quote the part number and

revision level which can be found along one edge of

the PCB - refer to the applicable section of this manual

for specific details.

c. Note all the details relevant to your complaint, date of

receipt, packaging condition, etc. and forward this to

your supplier.

3 Where the product needs to be returned to your

supplier, you are requested to use the original

packaging, or suitable anti-static equivalent, wherever

possible.

September 2009

8997-274-000-6, Issue 6

ID3000 Series Installation & Commissioning Manual

Continued overleaf.....

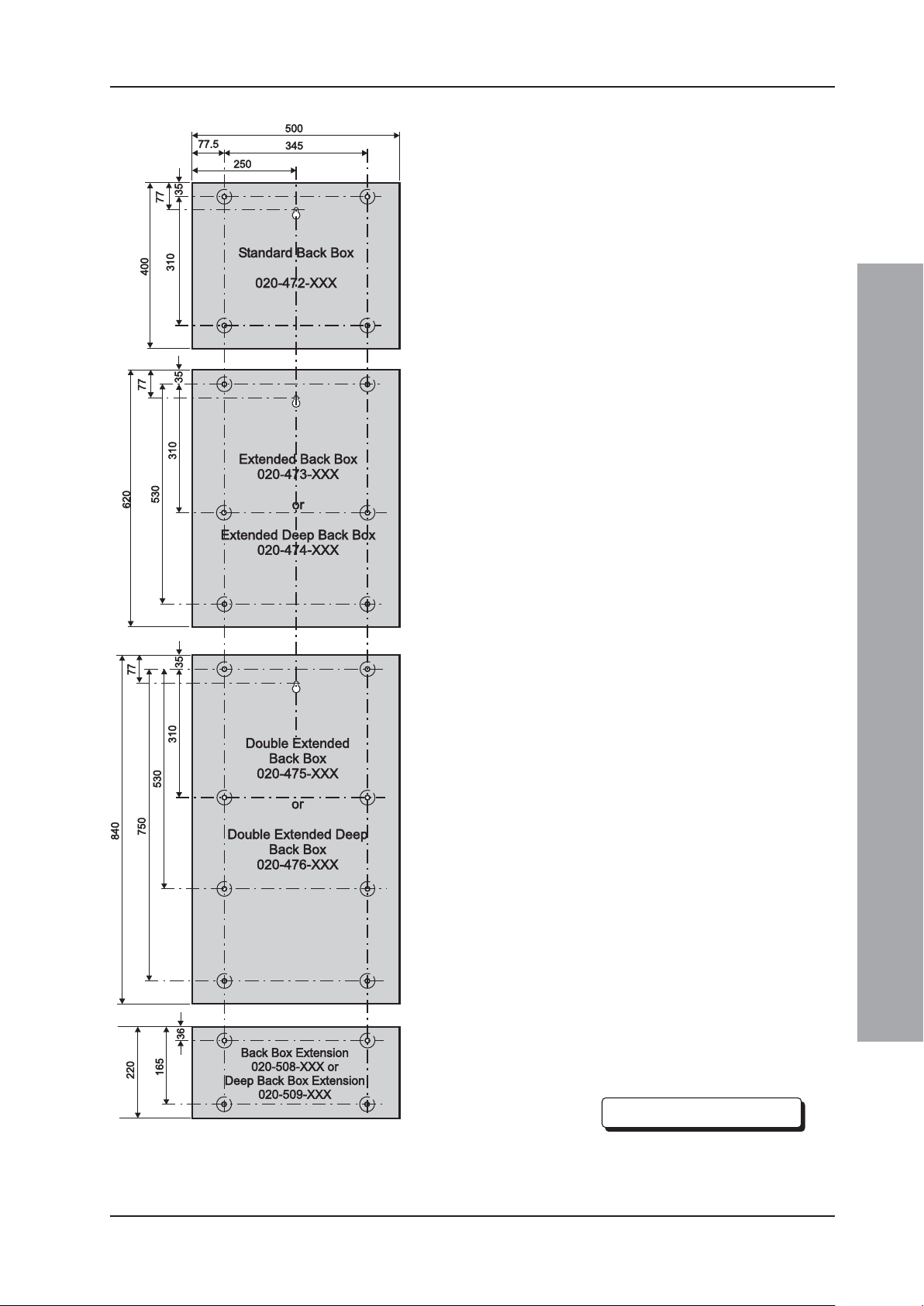

2.4.3 Back Box Fixing

The ID3000 Series control panel back boxes are available

122mm deep and 220mm (external dimensions including

fixing dimples). Where required, the deeper back boxes

allow the fitting of high-capacity-rated batteries as defined

in Section 7.5 Batteries and internally-mounted PSUs other

than the 3A-rated version. Where two part numbers are

quoted in the drawing at left, the first number refers to the

shallower back box and the second number refers to the

deeper back box.

The standard back box (PN: 020-472-XXX) is available

only in the 122 mm depth.

The fixing dimensions given below are applicable

irrespective of the back box depth.

Back Box Extension

In addition to the main back boxes, a smaller version, known

as a back box extension, is available. The back box

extension is also available in two depths: standard and deep.

The back box extension is designed to be wall mounted

immediately below any of the range of similar depth main

back boxes and is provided with corresponding 20mm

knockouts on the top and bottom faces. 20mm knockouts

are also provided on the top, bottom and rear faces of the

back box extension.

Wall Flatness

To prevent distortion, the ID3000 Series back box MUST

be installed on the wall as flat as possible, i.e. with a

maximum flatness deviation between any two points of

3mm. Where the wall is out of tolerance, use appropriate

packing pieces when installing the back box to meet the

above requirements.

Failure to comply with this requirement will result in

the misalignment of the internal and external screw

fixings.

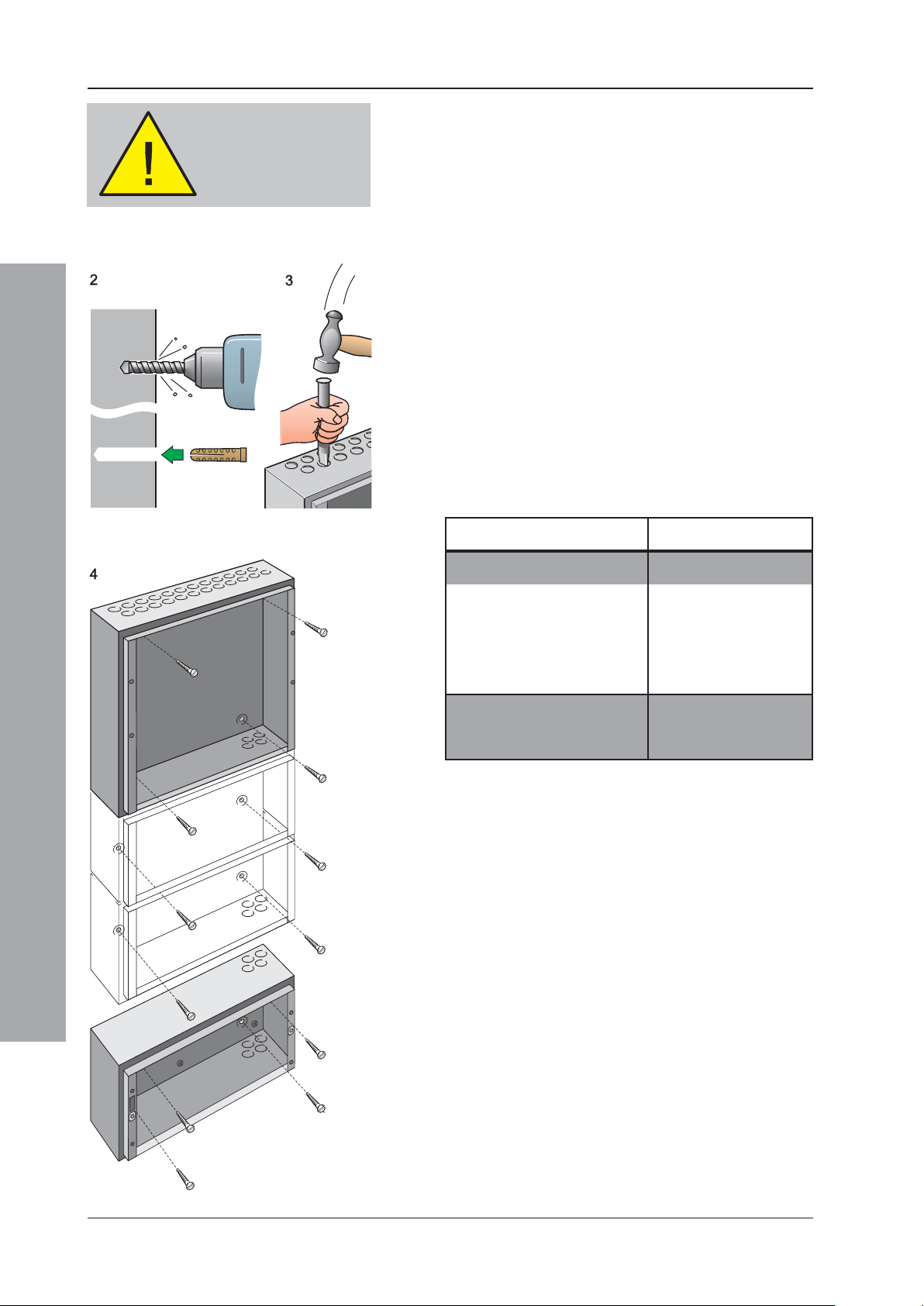

Procedure

When a suitable location has been found for installing the

ID3000 Series control panel, proceed as follows:

1 Using the centrally-positioned keyhole to temporarily

hold the back box in the required position on the wall,

mark the position of the fixing holes while ensuring

the panel is level.

Installation Guide

Notes:

All dimensions are in millimetres.

Fixing hole diameters are 6mm.

Continued overleaf.....

9 997-274-000-6, Issue 6

September 2009

ID3000 Series Installation & Commissioning Manual

DO NOT use the back

box as a guide when

drilling.

2 Using a suitable-sized drilling bit - for holes to take up

to 6mm (No.12-sized) wood screws - drill the required

number of holes.

3 Prepare apertures (20mm knockouts) required for

cable access.

4 Screw the panel back box to the wall using all fixing

holes and appropriate-sized screws. The back box

fixing holes can take up to 6mm (size No.12) roundor pan-headed screws (DO NOT use countersunk

screws).

Note: Make sure the screw in the keyhole is driven fully

into the recess to avoid impacting the main chassis

when this is being fitted.

The number of screws required depends on the size

of the back box. The recommended screw quantities

are as follows:

Installation Guide

Back Box Part Number Screw Quantity

020-472-XXX 4

020-473-XXX 6

020-474-XXX 6

020-475-XXX 8

020-476-XXX 8

020-508-XXX 4

020-509-XXX 4

September 2009

2.4.4 Electronics Modules

The ID3000 Series panel electronics modules, i.e. the

main chassis, which contains all processing, userinterface and input/output processing PCBs, and either

the Power Supply Unit (PSU) or Dual Transmission Path

(DTP) unit, are supplied as separate, self-contained

assemblies. These modules are fitted in the panel back

box once all site power distribution and fire detection loop

cabling has been provided, in accordance with the system

design requirements and applicable local standards.

10997-274-000-6, Issue 6

ID3000 Series Installation & Commissioning Manual

This procedure MUST be followed:

To avoid damage to the

electronics, remove trades’

operation debris before

fitting module.

Before drilling the back

box, make sure that no

equipment is fitted.

1 Fit the DTP or PSU to the main chassis - refer to the

appropriate sub-section of Section 5 for details.

2 Fit the main chassis to the back box - refer to Section 5.3

for details.

3 When individually checked for cable end earth faults,

make all wiring, cabling and battery connections (but

NOT the battery interlink) to the main chassis - refer

to Section 7, Commissioning for details.

2.5 Replacing the Electronics Modules

In the unlikely event that an electronics module becomes

faulty, all necessary instructions are provided with the

replacement item and in this manual under Section 5,

Panel Electronics Modules.

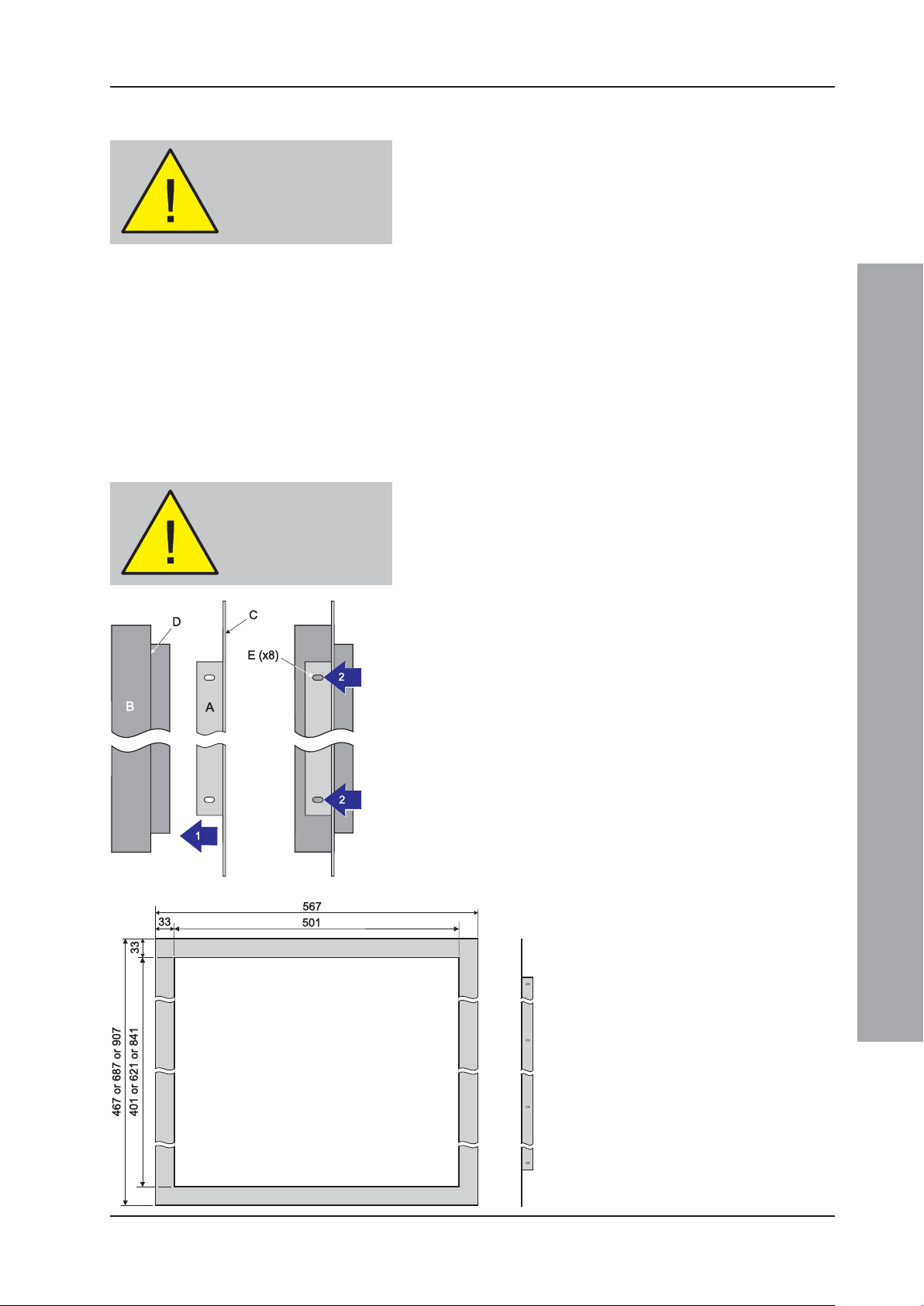

2.6 Flush Mounting Bezel (Optional)

If semi-flush mounting of the ID3000 Series control panel is

required, a recess 110mm deep, for the standard depth

versions, or 208mm, for the deep versions, and large enough

to accommodate the back box must be cut in the wall (refer

to Section 2.4.3 Back Box Fixing for dimensions).

To fit the bezel:

1 Offer the bezel (A), flat side towards you, to the front

of the back box (B) and position it so the bezel front

face (C) is lined up with the front face of the back box

shoulder (D).

2 With the bezel held in position, use the slotted holes

(E) on the bezel side plates as guides to drill eight

3mm holes. Remove any swarf created.

3 Use M3 self-tapping screws for fixing.

Note: The ID3000 Series back box must be fixed using

the rear fixing holes and reliance must not be

placed on the bezel as a means of fixing. The back

box must be fixed to a solid vertical surface, or

sub-frame inside the recess using the normal rearmounting holes.

Installation Guide

All dimensions in millimetres

11 997-274-000-6, Issue 6

September 2009

ID3000 Series Installation & Commissioning Manual

i

ii

C

D (x4)

View

a

or b

View

a

or b

View

a

or b

E (x2)

F

H (x2)

G (x2)

I (x2)

B (x4)

iii

View b

D (x4)

E

(x2)

H

(x2)

View a

D (x4)

E

(x2)

H

(x2)

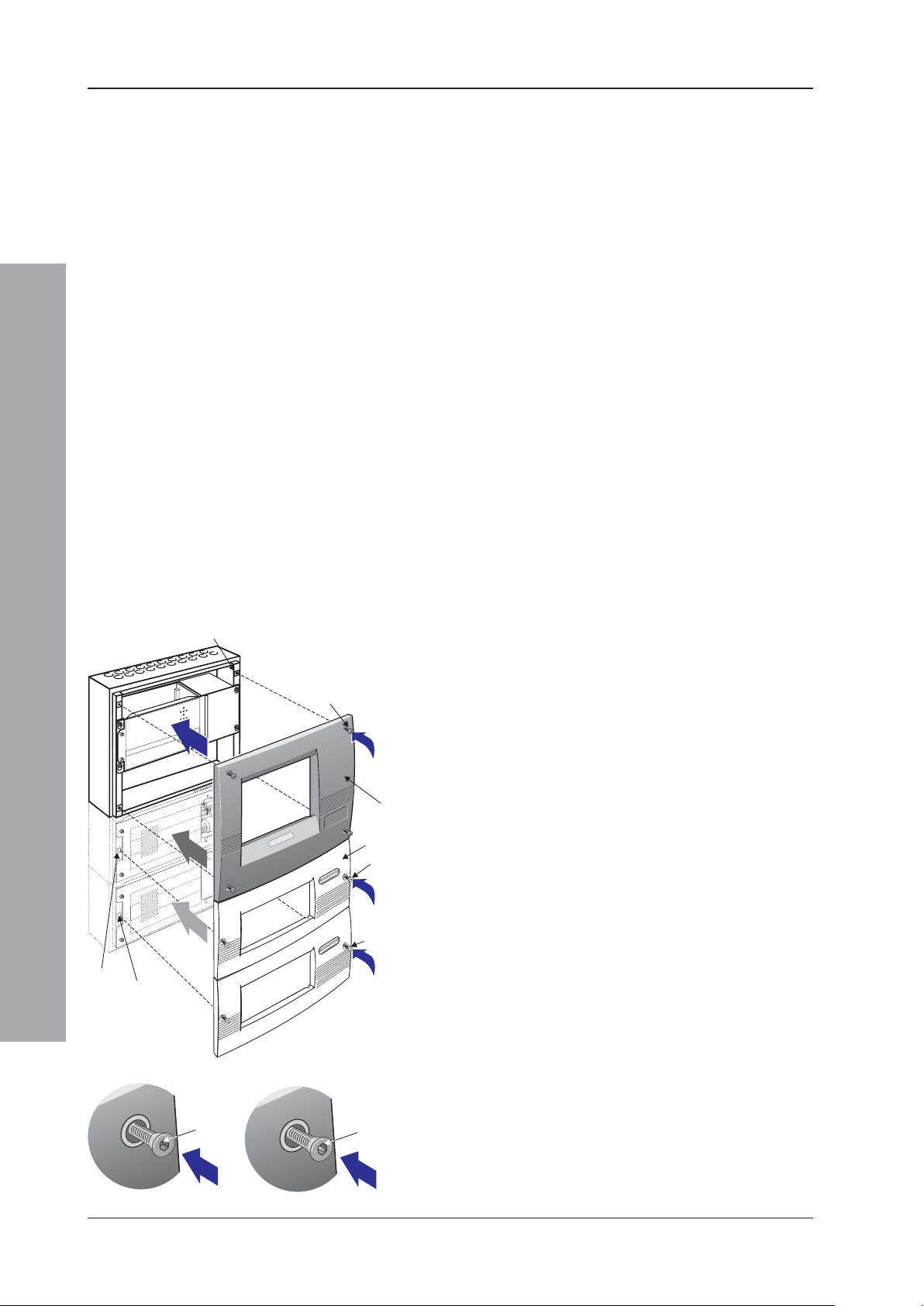

2.7 Moulded Front Covers

The ID3000 Series control panel is supplied with one, two

or three moulded front covers, depending upon your panel

configuration. Two moulded cover types are available; the

main and extension. All panel sizes require a main cover

kit (PN: 020-480). The larger panel sizes also require one

or two extension cover kits (PN: 020-481); the extended

versions use one extension cover and the double-extended

versions require two. The moulded front covers are also

available with high-security fasteners: main cover

(PN: 020-513); extension cover (PN: 020-514).

Note: Where the 256-Zone Status Indication kits are used,

only the main moulded cover is required as a dedicated

cover is provided with this option. Refer to Section 5.5.3.

Observe ALL safety and anti-static precautions when

fitting the covers.

User Interface Doors (Optional)

If required, any cover can be fitted with a lockable,

transparent User Interface Door. This must be done

BEFORE the moulded cover is fitted to the back box (refer

to the instructions supplied with the User Interface Door).

B (x4)

D (x4)

Installation Guide

G (x2)

I (x2)

View a

D (x4)

E (x2)

H (x2)

View b

View

aorb

E (x2)

View

aorb

H (x2)

View

aorb

D (x4)

E (x2)

H (x2)

Taking suitable precautions, remove all packaging and

inspect for any damage that may have occurred during

transit. If damage has occurred, DO NOT PROCEED,

contact your supplier and refer to Section 2.4.2. If no

damage is evident, fit the main cover as follows:

1 Offer the moulded front cover (C) symmetically to the

front of the back box in the correct orientation. The inner

top edge of the moulded front cover rests on the top flange

of the back box.

2 Two types of hexagonal socket-headed M6 screw (D)

are used to fasten the cover to the back box: a. the

standard version, or b. the high-security version. The

standard version is tightened by means of a 4mm

hexagonal socket key, while the high-security version

requires a special 4mm security tool (PN: 334-068).

The tool is supplied with the cover.

To remove the cover, use the appropriate tool to unscrew

the fasteners.

Note: Ensure the cover is supported when releasing the

last fastener!

To fit the upper extension cover (F), follow the same

procedure as described for the main cover but with the

following differences:

1 There are only two M6 screws (E), which must be

inserted into their respective fixing locations (G). If a

PRN-ID printer is fitted, refer to step 2 below.

September 2009

12997-274-000-6, Issue 6

ID3000 Series Installation & Commissioning Manual

PN: 236-624

PN: 345-338

a

b

c

J

K

M

L

eziSlenaP

)mm(

ylbmessAxoBkcaB

rebmuN

forebmuNlatoT

srenetsaF

2 Prior to fitting the cover, if a printer is installed ensure

that you have allowed a sufficient length of printer

paper to be pulled through the cover aperture.

)i(004

)ii(026

)ii(026

)iii(048

)iii(048

XXX-274-020

XXX-374-020

XXX-474-020

XXX-574-020

XXX-674-020

4

6

6

8

8

3 Fit the appropriate plate over the printer paper exit

aperture.

The removal procedure for each extension cover is the

same as for the main cover.

The procedure for fitting the lower extension cover is the

xoBkcaB

:snoisnetxE

XXX-805-020

XXX-905-020

2

2

same as that for the upper extension cover, using two M6

screws (H) and the lowest set of fixing locations (I). The

removal procedure is the same as for above.

If a printer is fitted ....

Use the metal serrated plate with the aperture (J),

provided, and fix over the extension cover recess (K).

Fit the serrated plate to the extension cover as follows:

1 Remove the protective paper strips (L) from the back

PN: 236-624

face of the plate to reveal the adhesive areas.

2 Offer the serrated plate horizontally to the extension

cover and, using sufficient pressure only, fix in the

recess (K).

PN: 345-338

3 Using scissors, cut the end of the printer paper to

produce a straight edge and insert it through the

serrated plate aperture BEFORE fitting the extension

cover.

If a printer is not fitted ....

When fitting any extension cover without a printer use

the blanking label, i.e. with no aperture, (M) provided.

Follow the procedure given above to fix it over the

extension cover printer paper exit aperture (K).

Installation Guide

13 997-274-000-6, Issue 6

September 2009

ID3000 Series Installation & Commissioning Manual

WARNING Risk of electric

shock. Before working on

mains connections, ensure

mains power supply to the

panel is disconnected.

Installation - Cabling

3 Cabling

3.1 Cabling Instructions

All wiring should comply with current IEE wiring

regulations (BS7671) or the applicable local wiring

regulations. Note also the requirements of EN54-14 for

cabling and interconnection of a fire detection and alarm

system.

For information on wiring inputs and outputs refer to the

appropriate module cable and wiring instructions to

identify terminals. Refer also to Section 7.4

Commissioning, External Wiring for details.

Use the following rules when installing cables:

1 Cables should be brought into the cabinet through

the 20mm knockouts provided on the top or top-back

face of the back box. Ensure that all openings in the

back box are closed before connecting power to the

panel. For example, if more knockouts than required

have been removed, then block the holes with

blanking glands. This is to prevent access to

hazardous voltages.

2 Tails should be of sufficient length to connect to the

appropriate termination points at the commissioning

stage.

3 Cables should be screened and should be terminated

in appropriate glands to meet local wiring codes and

to preserve the integrity of the screen connection. The

cable screen is to be clamped inside the cable gland,

which must be fitted to ensure a 360o bond is formed

with the metal of the back box.

4 The supply to the panel must be provided with a

suitable and readily accessible double-pole mains

disconnect device. The mains supply must be suitably

fused and rated according to the specifications (see

Appendix 2, Specifications).

5 The knockouts on the extreme right-hand side and

those provided on the bottom of the back box should

be used for mains cable entry. DO NOT bring mains

cables in through any other knockout holes and

ensure that the mains wiring is always separated from

the low voltage wiring. Tails of mains cables should

be provided with suitable additional sleeving before

connecting to the mains terminal block.

6 All low voltage cables should have a minimum 300Vac

rating.

General cable installation notes are given in Section 3.2,

Cable Installation Notes.

September 2009

Earth Blade Connections

Note: All blade connections to earth incorporate a locking

barb. To remove this connection, pull the shroud,

NOT the earth wire.

14997-274-000-6, Issue 6

ID3000 Series Installation & Commissioning Manual

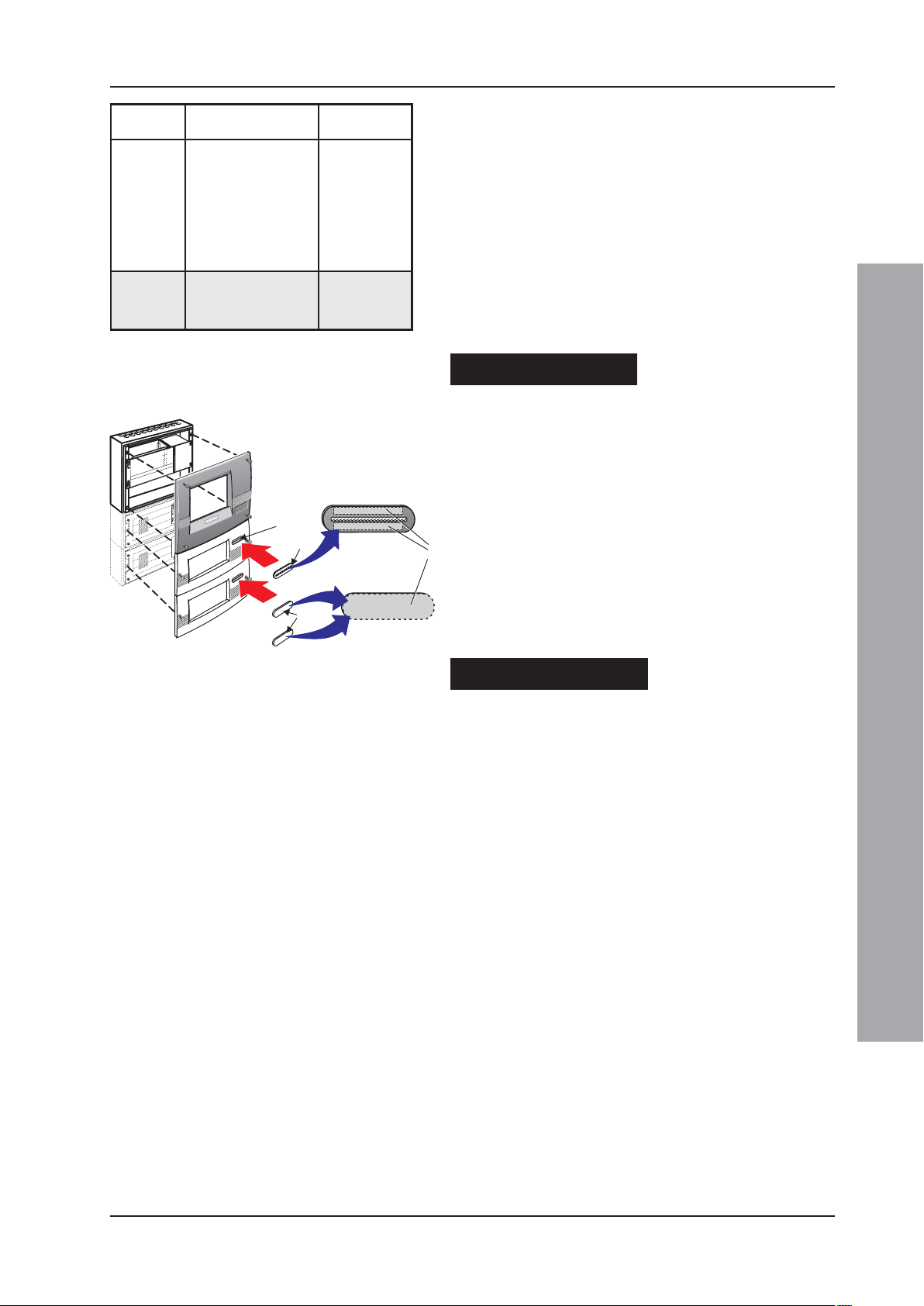

3.1.1 Cable Terminations

This section provides guidance on where to bring cables

into the back box for ease of termination. Ensure the

following requirements are met:

a. If the power supply unit (PSU) is mounted in the back

box, the mains supply should be brought into the

control panel such that the cable path to the mains

termination block is kept as short as possible.

b. If the PSU is mounted externally to the panel, the dual-

supply power cables and appropriate fault condition

wiring should be brought into the panel using the

bottom face’s knockouts (as indicated). Refer to

Section 5.3 Dual Transmission Path/Booster

Module for termination details.

c. All loop and ancillary cable terminations should be

brought into the panel at suitable positions to ensure

tails are kept as short as possible.

d. A row of knockouts, ‘u’, should be left to provide

adequate mains supply input/signal cable segregation.

The drawing shows the recommended points

of entry so that cabling can meet these

requirements.

Panel with internal PSU

i. Base PCB cabling/wiring terminations

using top-face knockouts ‘a, b, f and g’.

ii. Base PCB cabling/wiring terminations

using rear knockouts ‘d, e, h and i’.

iii. RS232 or RS485 cabling terminations using

rear knockouts ‘k and l’.

iv. Loops 3/4, 5/6, 7/8 cabling using top face

knockouts ‘m/n, o/p and q/r’ respectively.

v. Power supply cable entry using knockouts ‘s’.

Panel with external PSU

As above except for item v above, which is

replaced with:

vi. DTP/Booster Module cabling using

knockouts ‘t’. See external PSU and DTP/

Booster Module instructions for details.

Installation - Cabling

15

997-274-000-6, Issue 6

September 2009

ID3000 Series Installation & Commissioning Manual

3.2 Cable Installation Notes

3.2.1 Introduction

The following notes are intended to assist installers of

analogue addressable control systems. They have been

produced from information derived from the supplier's

technical resource and from information fed back

concerning existing systems.

3.2.2 Quality of Cable and of Cable Installation

It is vitally important that good quality cable is used, and

that correct installation techniques are followed. In general,

the following cable installation requirements must be met:

a. All cable sections must be circular to allow effective

cable clamping using the cable glands.

b. The cable must be screened (sheathed) to provide

protection against Radio Frequency Interference (RFI) and

the screen must be connected to earth at the control panel.

c. Multiple earthing of the screen should be avoided.

NOTIFIER’s field products use insulated mounting bases

and back boxes to achieve this. We recommend that

this practice be continued if other connections are made.

To achieve this with MICC cable may require the use

of insulated cable glands at one end of the cable.

d. The screen must be continuous throughout the loop.

e. The maximum resistance of the loop should not exceed

the limits defined in Section 7.4.2 Loop Checks

before Connecting Wiring, step 2. To check this,

measure between IN- and OUT-, multiply the result by

2 and add the resistance of each isolator (range 0.1 to

0.13 ohms each). The cable capacitance should be less

than 0.5μF. Typically this will allow a maximum loop length

of 2000m of screened 1.5mm2 cable. Cable recommended

for use is MICC with a LSF PVC overcovering, a fire

resilient cable to BS7629 or PVC/SWA/PVC to BS6387.

Installation - Cabling

September 2009

Recommended Cables:

Manufacturer Product Name Part Number Type

AEI MICC 2L1.5 Enhanced

AEI Firetech 298-052 Standard

Draka FiretufPlus FTPLUS2E1.5RD Enhanced

Draka Firetuf FTZ2E1.5 Standard

Prysmian FP Plu s FP Plus 2x1.5 Red Enhanced

Prysmian FP200 Gold FP200 Gold 2x1.5 Red Standard

Arrow - 7-2-4S Not rated

1

For a definition of ‘Standard’ and ‘Enhanced’ cable requirements and their different

applications, refer to BS 5839-1 Section 26. Enhanced cable is typically required

for spur sounder outputs, while standard cables may be adequate for other firerelated I/O provided there is diverse cable routing. The multi-core cable from Arrow

is suitable for RS232 connections to a printer.

1

f. We recommend that the system should be wired in 2-core

cables and each 2-core cable should be specific to one

function.

g. The RS485 communication cable used should be rated

as suitable for up to 200mA in a short circuit condition.

16997-274-000-6, Issue 6

ID3000 Series Installation & Commissioning Manual

3.3 EMC Considerations

Following the above instructions and by using suitable

cables EMC problems will be avoided. In particularly

difficult EMC environments, or where non-preferred cabling

is used, it is possible to fit additional ferrite suppressors

(sleeves) to cables entering the control panel.

3.3.1 Screen Termination

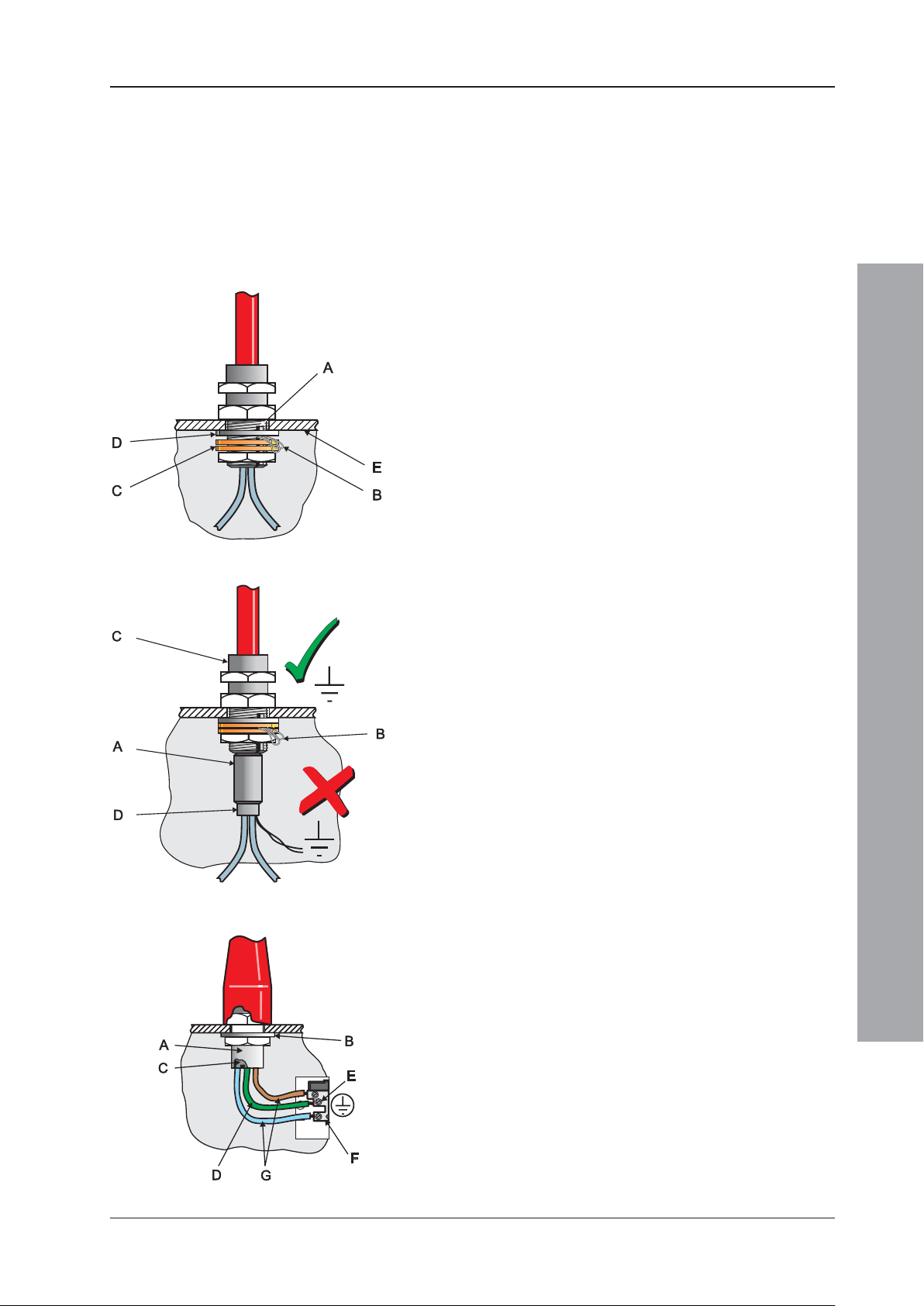

Use the following method to terminate the cable screens:

Use a metal gland with slots (A) that allow the drain

wire or screen (B) to be clamped between flat washers

(C). Use a steel locking washer (D) between the brass

washers and the internal surface of the back box (E).

This will provide the best EMC termination. Suitable

glands are the CTX range available from CMP UK Ltd.

The part chosen should fit the 20mm knockouts.

3.3.2 Ferrite Sleeves (Optional)

Ferrite sleeves are not normally required with the ID3000

Series control panel. In difficult EMC environments, or

where non-preferred cables are used, optional ferrite

sleeves should be fitted to both the loop and sounder

wiring. The ferrite sleeves (A) are to be fitted over the

conductor(s) of each cable - and NOT over the screen of

the cable, which should pass outside of the sleeve. They

should be fitted as close as possible to the entry point of

the cable, i.e. as near as possible to the screen termination

(B) to the metal cable gland (C). The sleeve should be

held in place using a cable tie (D).

The ferrite sleeves are available for purchase from

NOTIFIER’s distributors (quote Part No. 538-143).

3.4 MICC Cables

MICC cables must be fitted with metal cable glands (A) use Type A2 glands. Use a steel locking washer (B) to

ensure good earthing continuity and correct termination

of the gland. In particular, the mains cable requires that

the cable gland (A) is fitted with an earth tail kit (C). The

earth tail kit must be connected, using an insulated wire

(D), to the panel safety earth connection (E) at the mains

termination block (F). The bare mains wiring from the MICC

cable must be suitably-insulated (G) and terminated in

accordance with appropriate local wiring regulations.

Installation - Cabling

17

997-274-000-6, Issue 6

September 2009

ID3000 Series Installation & Commissioning Manual

4 Sensors and Modules

Each of these devices is packaged with an instruction

leaflet showing the correct interconnections for various

applications.

4.1 EN54 Requirements

The ID3000 Series Control Panel design allows for the

connection of up to 198 loop devices per analogue loop;

i.e. up to 99 sensors and 99 modules.

4.1.1 Loop Devices - Sensors and MCPs

EN54-2: 13.7

Without E-LIBs -

Maximum of 512

Sensors and/or

MCPs per system.

EN54-2: 13.7

With mix of LIBs and

E-LIBs - Maximum of

512 Sensors and/or

MCPs not connected

to E-LIBs.

EN54-2: 12.5.2

Maximum of 32

Sensors and/or MCPs

between isolators.

If Enhanced Loop Interface Boards (E-LIBs) are not fitted,

then to comply with the requirements of EN54-2, a

maximum of 512 sensors and/or MCPs should be

connected to the control panel across ALL analogue

loops, including all conventional zone detectors and/or

MCPs connected.

If E-LIBs (PN: 124-292) are fitted, the design limits given

above in Section 4.1 apply. If a mixture of E-LIBs and

LIBs (PN: 124-323) are fitted, then the restrictions of the

first paragraph of Section 4.1.1 apply to all loops not

connected to E-LIBs.

Failure to comply contravenes the requirements of

EN54-2 in the event of a system fault.

4.1.2 Loop Devices - Isolators

Isolators must be used on each analogue loop to separate

sensors and/or MCPs, including all loops with

conventional zone detectors and/or MCPs connected.

To comply with the requirements of EN54-2, isolators

should be fitted between a maximum of 32 loop devices.

For the ID3000 Series, do not place more than 25 loop

devices between isolators (20 if FET isolators are used).

Failure to comply contravenes the requirements of

EN54-2 in the event of a transmission path fault.

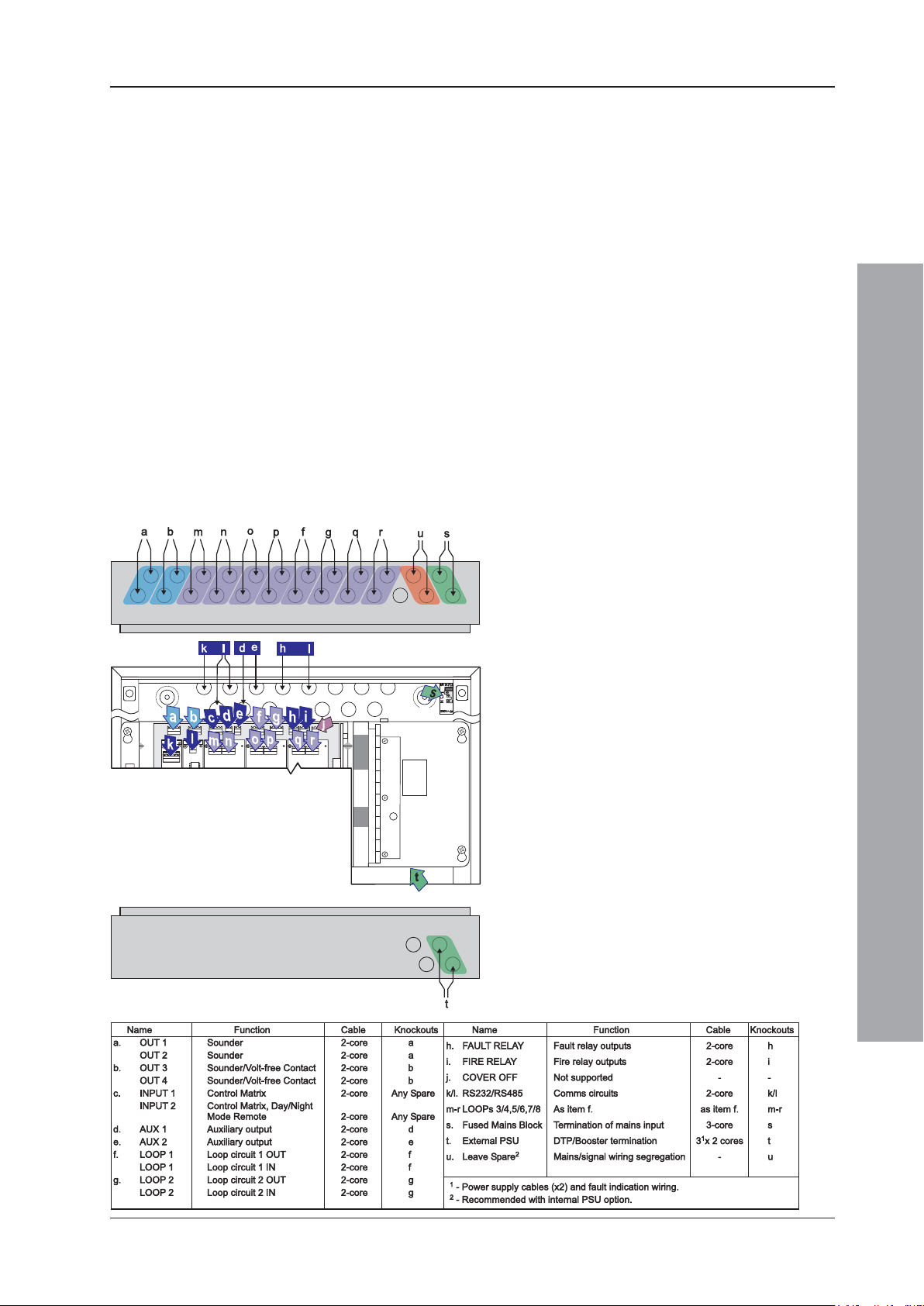

4.2 Loop Wiring Testing

Installation - Sensors and Modules

NEVER use a high

voltage tester on

the loop.

September 2009

Before connecting the panel or devices, the wiring of each

loop may be tested for continuity and insulation. Once

any components are connected, inluding isolators, no

high-voltage testers such as Meggers may be used on

the loop; low-voltage testers such as multimeters may

be used.

Note: If isolators are fitted, the +ve conductor of the loop

will be open circuit.

18997-274-000-6, Issue 6

ID3000 Series Installation & Commissioning Manual

To avoid damage to the

electronics, remove trades’

operation debris before

fitting module.

5 Panel Electronics Modules

5.1 Introduction

This section describes how to install the ID3000 Series

panel electronics, i.e. the Power Supply Unit (PSU) and

the main chassis, which contains all processing PCBs

and the optional PRN-ID printer.

DO NOT install the electronics module(s) until the building

is clear of trades’ operations. Before commencing the

installation, remove any debris, etc. which may have

accumulated in the panel back box.

Instructions are included for the following:

a. Installing either a Dual Transmission Path (DTP) unit/

Booster Module or a Kit PSU3A in the main chassis.

The DTP/Booster Module is designed for use with

PSUs other than the PSU3A unit (separate instruction

sheets are provided with these alternative PSUs). For

the Kit PSU3A, refer to Section 5.2. For the DTP/

Booster Module, refer to Section 5.3.

Note: For details of installing the PSU7A kit (PN: 020-

579) refer to separate instructions provided with the

kit.

b. Installing the main chassis plus DTP or Kit PSU3A in

the back box. Refer to Section 5.4.

c. Fitting a paper roll to the optional PRN-ID printer.

d. Zonal LED kit options.

Installation - Panel Electronics

19

997-274-000-6, Issue 6

September 2009

ID3000 Series Installation & Commissioning Manual

5.2 Kit PSU3A

The Kit PSU3A module is very easy to fit to the main

chassis, providing the instructions described below are

followed. The PSU is located in an open, rear

compartment of the main chassis and MUST be fitted

before installing the main chassis in the back box. The

PSU3A module is secured to the main chassis using four

M4 x 8 SEM screws.

Note: To replace a PSU3A, disconnect the batteries and

isolate mains power, reverse the installation

procedure to remove the faulty unit, then install

the replacement as described below.

Check Your Equipment....

Before proceeding with the PSU installation, first remove

all packaging and inspect for any damage which may

have occurred in transit. If no damage is evident, proceed

with the installation of the PSU module.

A Cautionary Note....

During this procedure, various wiring connections are

made and it is important that the manufacturer’s

recommendations are followed to avoid the possibility of

damage occuring when fitting the PSU module.

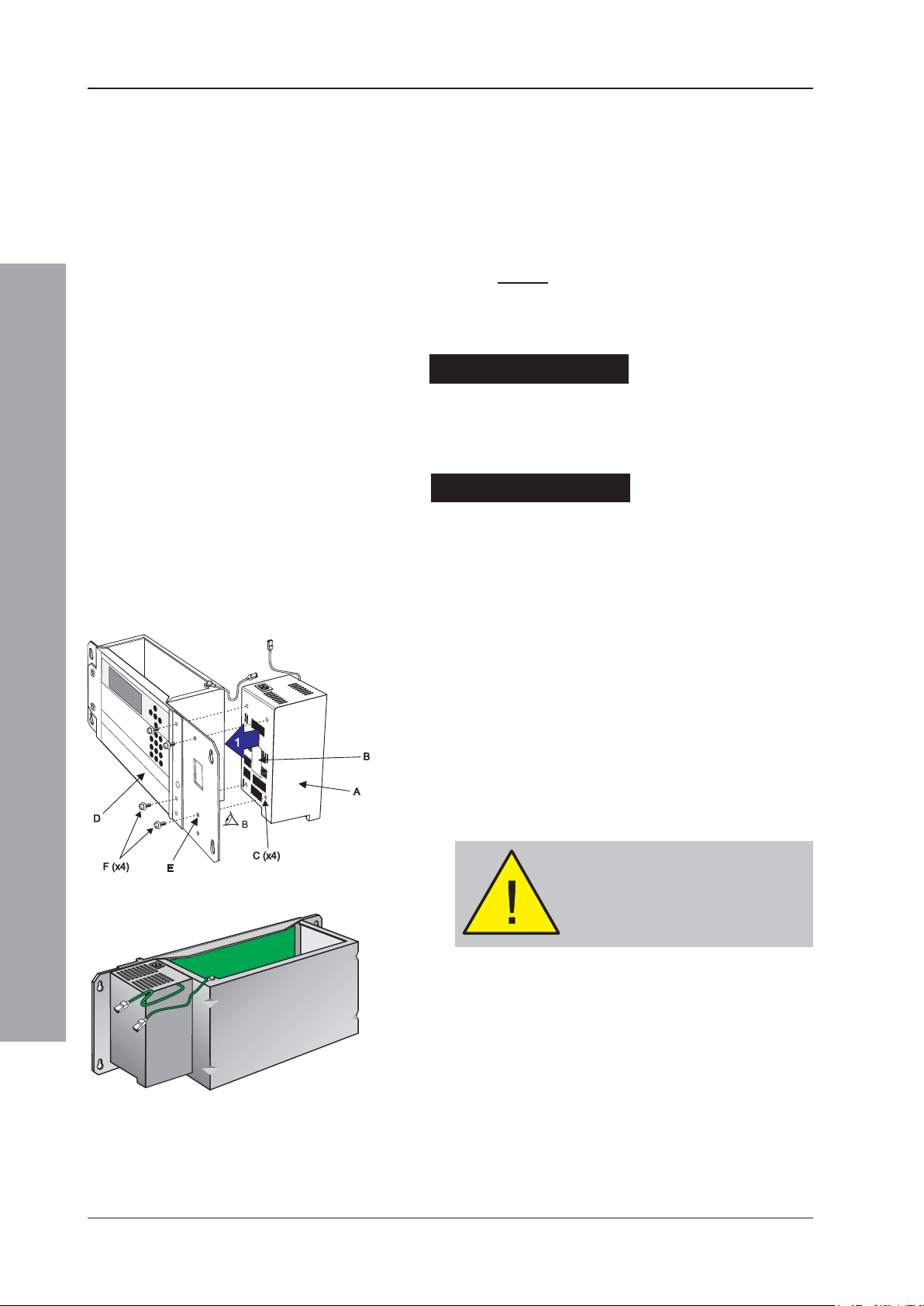

5.2.1 Procedure

Orientate the PSU3A assembly (A) so that the side with

the ‘rating’ label (B) is facing you (see drawing at left) this side is provided with four holes (C) for fitting the

PSU. Fit the PSU to the main chassis assembly (D) as

follows:

1 Line the four holes (E) on the front face of the main

chassis with the corresponding holes (C) on the PSU

assembly.

2 Use a No. 2 Posidriv screwdriver and the four M4 x 8

SEM screws (F) supplied with the PSU to secure the

PSU firmly to the main chassis.

Installation - Panel Electronics

CAUTION

When fitting the PSU, use only the

M4 x 8 screws supplied with the PSU

- and NOT the M4 x 16 screws

supplied with the Main Chassis.

September 2009

The drawing at left shows the PSU3A module correctly

located in the main chassis.

20997-274-000-6, Issue 6

ID3000 Series Installation & Commissioning Manual

G

3

I

J

G

H

4

5

H GL

K

M

H

5.2.1.1 Main Chassis Wiring Connections

3 Connect the 10-way ribbon cable (G) and the power

cable (H) to the PSU3A. The power cable connects

at two positions, as shown.

+ -

TEMPSNSR

'A'

A

4 Ease the connectors of these cables and the ferrite

through the aperture (I) in the main chassis. Pull the

cables through, taking up any slack.

'B'

5 With a sufficient length of each cable pulled through

to connect to the Base PCB, ease the grommet (J) in

to the aperture (I) and then slide it and the cables

sideways into the circular part until secure.

6 Terminate the cables on the Base PCB - the 10-way

ribbon cable (G) at socket SK8 (K) and the power

cable (H) at socket SK12 (L). Ensure the ferrite is

clear of all circuit boards.

Note: Connector (M) may not be fitted.

7 Fit the chassis into the back box (Section 5.4).

Installation - Panel Electronics

21

997-274-000-6, Issue 6

September 2009

ID3000 Series Installation & Commissioning Manual

1

2

230 VAC,

50

Hz

A

B

D

CH

G

F

E

N

L

MF: 5A (T) 250V HRC

L

N

230V (a.c.), 5A

WARNING!

Isolate mains power

before proceeding.

When terminating mains

leads, ensure that the

earth lead is longer than L

and N.

5.2.1.2 Mains and Safety Earth Wiring Connections

WARNING: Before proceeding, refer to the cabling

instructions given in Section 3.1. Isolate

mains power. Note that fuse information is

given in Appendix 1 Section 1.2.

TRANSIT CABLE CLIP: Before proceeding,

CAREFULLY cut the cable clip that secures the ferrite

cable loop to the front of the back box. DO NOT cut the

cable clip that secures the mains cable to the side of the

back box.

The 230V ac mains input wiring (A) must be terminated

at the fused mains termination block (B), located in the

top right-hand corner of the ID3000 Series back box (C).

The PSU mains cable (D) is factory-fitted to the

termination block. Push the mains cable’s connector (E)

into the socket at the top of the PSU3A. Pull tight the

cable clip at the side of the back box.

'X'

230 VAC,

50 Hz

MF: 5A (T) 250V HRC

VIEW

X

230V (a.c.), 5A

The safety earth is provided via a short factory-fitted lead

(F) from the mains termination block to a blade connector

at the right rear corner of the back box roof. All blade

connections to earth incorporate a locking barb. To make

a connection push the shrouded receptacle on to the earth

blade (1). To remove this connection, pull the shroud (2),

Installation - Panel Electronics

NOT the earth wire.

Using the wiring provided, make the following two earth

connections:

a. Between the PSU top plate and the back box (G).

b. Between the main chassis and the back box (H).

September 2009

Connection to the batteries is made using the supplied

battery leads, which may have to be cut to the correct length.

Connection of the batteries (and thermistor) is made at a

four-way socket mounted close to the bottom of the PSU

assembly. Access is gained from underneath the PSU once

the main chassis is fitted to the back box.

For more information on connecting the batteries refer

to Section 7.5, Batteries.

22997-274-000-6, Issue 6

ID3000 Series Installation & Commissioning Manual

5.3 Dual Transmission Path/Booster Module

The Dual Transmission Path (DTP)/Booster module is very

easy to fit to the main chassis, providing the instructions

described below are followed. The DTP/Booster module is

located in an open, rear compartment of the main chassis and

MUST be fitted before installing the main chassis in the back

box. The DTP/Booster module is secured to the main chassis

using four M4 x 8 SEM screws. A 4-wire cable supplied with

the module for backward compatibility is not required and should

be discarded.

Check Your Equipment....

Before proceeding with the DTP/Booster installation, first

remove all packaging and inspect for any damage which may

have occurred in transit. If no damage is evident, proceed with

the installation of the DTP/Booster module.

A Cautionary Note....

During this procedure, various wiring connections are made

and it is important that the manufacturer’s recommendations

are followed to avoid the possibility of damage occuring

when fitting the PSU DTP/Booster module.

5.3.1 Procedure

Place the DTP/Booster module (A) on a clean work

surface so that the side with the ‘rating’ label (B) is

uppermost (see drawing at left) - this side is provided

with four holes (C) for fitting the module. With the module

temporarily supported in this position, fit the main chassis

assembly (D) as follows:

Note: If the PSU is located in the back box, perform ‘Other

Wiring Connections’ step ‘a’ at the DTP/Booster

module end of the connection NOW. Access to the

ribbon cable connector becomes more difficult after

the module is fitted to the main chassis.

1 With the main chassis orientated with the front door

uppermost, carefully lower it until the part to the right

of the front door hinge rests on the DTP/Booster

module.

2 Line the four holes (E) on the front face of the main

chassis with the corresponding holes (C) on the

module.

3 Taking care not to trap the module’s cables and the

earth wiring, insert the four M4 x 8 SEM screws (F)

and, using a No.2 Posidriv screwdriver, tighten them

until the module is secured firmly to the main chassis.

With the module now secured, take the module’s two

cables into the main chassis’ PCB enclosure as follows:

4 First, ease the connector of the 10-way ribbon cable

(G) and the connector of the power cable (H) through

the aperture (I) in the main chassis. Pull the cables

through, taking up any slack.

5 Secondly, with a sufficient length of each cable pulled

through, to connect to the Base PCB, ease the

grommet (J) in to the aperture (I) and then slide it and

the cables sideways into the circular part until secure.

23

997-274-000-6, Issue 6

September 2009

Installation - Panel Electronics

ID3000 Series Installation & Commissioning Manual

A

C

D

B

E

The illustration at left shows the DTP/Booster module

correctly located in the main chassis.

5.3.1.1 Main Chassis Wiring Connections

Once the DTP/Booster module is fitted to the main

chassis, the two wiring assemblies that are held by the

grommet should now be terminated on the Base PCB

connection sockets as follows:

a. The 10-way ribbon cable (A) is to be terminated at

socket SK8 (B).

b. The 4-wire power cable (C) is to be terminated at

socket SK12 (D).

Note: Connector (E) may not be fitted.

5.3.1.2 Other Wiring Connections

CAUTION: Before proceeding, refer to the cabling

instructions given in Section 3.1.

The following additional wiring must be connected:

a. If the DTP/Booster module is to be connected to an

internally-mounted PSU (other than the Kit PSU3A), fit

the supplied ribbon cable between the DTP/Booster

connector (E) and the PSU’s LED status indication output

connector. This connection is not used if the PSU is

Main chassis

wiring -

pre-wired

(see above)

Installation - Panel Electronics

mounted externally.

b. Connect a suitable cable (supplied with the PSU)

between the PSU Charger Inhibit connector (F) and the

equivalent connector on the PSU (on PSU assemblies

PN: 124-190 and 124-190-001, this connector is labelled

ALARM). Connect + to + and - to -.

c. If the DTP/Booster module is to be connected to an

externally-mounted PSU, connect a suitable cable

between the COMMON FAULT connector (G) and the

Normally Open and Common connections of the

equivalent connector on the PSU.

d. Connect suitable (high-current) cables (if PSU is

internal, use cables supplied with the PSU) between

the Power connector (H) and the power supply unit.

Connect + to + and - to - (may be labelled 0V).

e. CAUTION! If using an externally-mounted PSU, it

is essential that an electrical safety earth

connection is made to the back box of the ID3000

panel. This connection should be routed with the other

PSU cables from the external battery box.

24997-274-000-6, Issue 6

September 2009

ID3000 Series Installation & Commissioning Manual

A

E (x4)

F (x4)

B/C

D

G (x4)

3

3

H I

4

4

J

5.4 Main Chassis

The ID3000 Series control panel main chassis provides

DO NOT fit the main

chassis in the back box

until the PSU and/or DTP/

Booster Module has been

fitted!

the following features:

a. System control and monitoring function PCBs

b. User-interface controls and system status indicators,

c. Space provision for three loop-interface PCBs, panel

networking and interface hardware for external

equipment using serial communications.

The main chassis is simple to fit in the back box providing

these instructions are followed.

5.4.1 Main Chassis Configurations

Alternative PSU output ratings and mains standby battery

backup periods can be supported using different main chassis

options. Consequently, the main chassis can be fitted with:

a. The Kit PSU3A, or a

b. DTP/Booster Module for use with PSUs other than

the Kit PSU3A, which can be installed behind the main

chassis in a deep back box or in a separate 78Ah

battery enclosure (refer to separate installation

F (x4)

E (x4)

G (x4)

5.4.2 Procedure

instructions provided with enclosure).

DO NOT fit the main chassis in the back box until the

PSU or DTP/Booster Module is in place (refer to

Section 5.2, Kit PSU3A or Section 5.3 DTP/Booster

Module).

Taking suitable anti-static precautions, such as wearing a

suitably-grounded wrist strap, remove all packaging from the

main chassis and ensure that it has not been damaged in

transit before proceeding any further. If no damage is evident,

and with the back box (A) secured to the wall in its chosen

location, ensure that either the Kit PSU3A (B) or DTP/Booster

Module (C) is fitted, then fit the main chassis (D) as follows:

1 Locate the four supplied M4 x 16 SEM screws (E) in

the back box holes (F).

2 Drive the four screws (E) in approximately half their length.

3 Taking suitable anti-static precautions, ensure the

main chassis is correctly orientated and offer the four

Installation - Panel Electronics

slotted holes (G) and locate on the threaded part of

the top two of the four screws (E) to avoid twisting the

chassis when securing in position.

4 Once the main chassis has been located on the SEM

screws (E) use a cross-headed screwdriver to tighten them.

5 Connect the earth lead (H) between the Kit PSU3A top

plate or DTP/Booster module and the earthing blade

terminals adjacent to the mains termination block (not

shown) in the back box. (See also step 5.2.1.2).

6 Connect the earth lead (I) between the main chassis earth

blade terminals and the earthing blade terminals adjacent to

the mains termination block (not shown) in the back box.

Note: The power supply ratings label is visable through

the aperture (J) in the main chassis.

25

997-274-000-6, Issue 6

September 2009

ID3000 Series Installation & Commissioning Manual

Up to 128 Zones plus

PRN-ID Printer

5.5 Zonal LED & Printer Options

The section describes the procedures for fitting zonal

LED modules and the integral PRN-ID printer. One or

two extension chassis are required to provide the zonal

LEDs required with or without the integral printer. The

following options are described in this section:

a. LEDs for up to 64 Zones. For panels with up to 64

zonal LEDs follow the instructions in Section 5.5.1.

b. LEDs for up to 128 Zones (as ‘LEDs for up to 64

zones’ x2, with a double-extended back box).

c. Fitting the PRN-ID Printer. The integral PRN-ID printer

can only be fitted with the extended or double-extended

back boxes. An extension chassis is required, either with

zonal LEDs 1-64 or with a blank fascia if these zonal LEDs

are not required. Refer to Section 5.5.2.

d. LEDs for up to 256 Zones. For panels with up to 256

zonal LEDs refer to Section 5.5.3. For this option the doubleextended back box and 256 Zone LED Kit is required.

Note: All fitting instructions assume that the correct back

box option has been installed in each case.

Taking suitable anti-static precautions, such as wearing

a grounded wrist strap, remove all packaging and inspect

for any damage that may have occurred in transit. If no

damage is evident, proceed with these instructions.

Up to 256 Zones

CAUTION!

Make sure ALL power to

the panel has been

disconnected.

Installation - Panel Electronics

5.5.1 64 Zone LED Extension Chassis

Before attempting this procedure, make sure ALL

power to the control panel is disconnected.

Fit the extension chassis (A) to the back box (B) as

follows:

1 Locate the four supplied M4 x 16 SEM screws (C) in the

back box holes (D) and insert them approximately half way.

2 Connect one end of the supplied, 10-way ribbon cable

(E) to the top connector (F), marked ‘IN’, of the LED PCB

(also refer to the drawing overleaf).

3 Connect one end of the supplied earth lead (G) to the

earthing blade terminal (H) on the extension chassis.

4 With the extension chassis correctly orientated (refer

to drawing at left), locate the keyholes onto the four

screws with the threaded part in contact with the top

flats of the keyholes.

September 2009

5 With the extension chassis now located on the back

box, open the main chassis front door and connect

the other end of the 10-way ribbon cable at socket

SK19 on the Base PCB.

6 Connect the other end of the earth lead to the earthing

blade terminals located inside the back box and to the

right of the chassis.

26997-274-000-6, Issue 6

ID3000 Series Installation & Commissioning Manual

M

O

P

N

5a

5b

Q

4

3

7 Having made the connections described in steps 5

and 6 above, use a Posidriv No.2 screwdriver to

secure the extension chassis.

5.5.2 PRN-ID Printer

The printer is supplied one of two ways:

a. For panels with up to 64 or 128 zonal LEDs, the printer

first has to be fitted to the extension chassis (refer to

installation instructions 997-452, supplied with the

printer) and then the combined assembly secured to

the back box.

b. For panels with no zonal LEDs, the extension chassis

is supplied with the printer already fitted. Refer to

installation instructions 997-224 and 997-452,

supplied with the extension chassis.

5.5.2.1 Fitting the Paper Roll

It is recommended that the thermal paper roll is fitted

when the printer is in situ and powered up. The paper

MUST be the right way round - see drawing at left. The

printer will automatically try to take up the end of the

paper roll once it has been inserted into the paper entry

slot (located on the underside of the printer mechanism).

To ensure correct alignment of the paper as it exits the

printer, after fitting, adjustment can be made using the

control located on the left-hand side of the printer:

To fit the thermal paper roll, proceed as follows:

1 Make sure the panel is powered up and the batteries

are connected.

2 With the paper (M) orientated as shown at left, offer

the end of the roll to the paper entry slot on the

underside of the printer mechanism (N) - the printer

will automatically try to take up the paper.

Note: If the printer has a problem with taking up the

paper, you may need to feed the paper manually.

Manual feed is achieved by repeatedly pressing

the ‘ ’ pushbutton at the panel controls (while

panel status is normal).

Installation - Panel Electronics

3 Support the paper roll and insert the spindle (O),

orientated as shown, until it protrudes from both ends

of the roll in approximately equal lengths.

4 Gently push the paper roll into the slot, then pull it

forward to check that the spindle (O) has engaged in

the notch (P). After the paper roll/spindle assembly is

in position, gently turn the roll to take up any slack in

the paper.

27

997-274-000-6, Issue 6

September 2009

ID3000 Series Installation & Commissioning Manual

X (x2)

Y

THIS WAY

UP

5 To re-align the paper exit path:

i Locate the paper release control (Q) immediately to

the left of the paper exit slot and pull the top lug

outwards and down through approximately 90O. With

the lug in this position the paper alignment can now

be adjusted. Re-align the paper by gently pulling it

left or right until centrally placed in the slot - make

sure that the slack in the paper is kept to a minimum

between the printer mechanism and paper roll. IF

USING A STAINLESS STEEL COVER ON THE

PANEL, SEE ADDITIONAL INFORMATION BELOW.

ii When satisfied that the paper is aligned correctly,

return the lug to its former position, i.e. locked. Press

the ‘ ’ pushbutton to feed the paper a number of

lines to check the paper re-alignment.

Note: Each press of the button advances the paper one

line.

Instructions for fitting the serrated tear-off plate to the

front cover and cutting the printer paper to length are

given in Section 2.7, Moulded Front Covers.

The drawing at left shows the PRN-ID printer fitted

correctly.

5.5.2.2 Printer Used With Stainless Steel Cover

The following additional steps are required:

X (x2)

1 Before you begin: Remove the two screws (X) that

secure the paper guide in position. Rotate the plate

180O vertically to give the orientation shown as ‘THIS

WAY UP’ in the illustration, then use the two screws

THIS WAY

UP

(X) to re-attach it to the printer.

2 Fitting the paper roll: Manually feed the paper

through the slot in the front cover.

Installation - Panel Electronics

September 2009

28997-274-000-6, Issue 6

ID3000 Series Installation & Commissioning Manual

CAUTION!

Make sure ALL power to

the panel has been

disconnected.

5.5.3 LEDs for up to 256 Zones

Where up to 256 zonal LEDs are required a kit is supplied

for use with the double-extended back box only. The two

Double-extension Chassis 256-Zone Status Kits contain

the following items:

a. Zone LED chassis (zones 1-128)

b. Zone LED chassis (zones 129-256)

c. Ribbon cables (x2)

d. Front cover earth lead

e. M4 x 16 SEM screws (x8)

f. Label inserts (2 per language variant) and

g. Cover.

The 256-Zone Status Indication Kit is simple to fit

providing the instructions below are followed.

Before attempting this procedure, make sure ALL

power to the control panel is disconnected.

With the back box (A) secured to the wall in its chosen

location and the front cover removed, fit each status

indication chassis (B) as follows:

Note: First, fit the chassis with zone LEDs 129-256 in

the lower back box position. Fit the chassis with

zone LEDs 1-128 in the upper position - after fitting

the front cover earth lead.

1 Locate the eight supplied M4 x 16 SEM screws (C) in

the back box holes (D) and insert them approximately

half way. Four screws are required for each chassis.

2 Ensure the factory-fitted internal ribbon cables are

satisfactorily connected to the extension chassis

connectors (i).

3 Fit one end of each loose-provided, inter-chassis

ribbon cable to the ‘zones 1- 128’ chassis as follows:

a. To the ‘IN’ connector (at iii), and

b. To the ‘OUT’ connector (at iv).

4 With each status indication chassis correctly

orientated, locate the keyholes onto four of the screws

with the threaded part in contact with the top flat of

the keyholes. Fit the ‘zones 129-256’ chassis first and

then the ‘zones 1-128’ chassis.

5 With the status indication chassis now located on the

back box, fit the other end of the two inter-chassis

ribbon cables. When fitting the ‘zones 1-128’ chassis,

connect the other end of the ribbon cable (from iv) to

the ‘IN’ connector (at ii) on the ‘zones 129-256’ chassis;

connect the other end of the second ribbon cable (from

iii) to the socket connector SK19 (at v) on the panel

Base PCB.

Installation - Panel Electronics

6 Connect the free end of the earthing lead (at vi) to the

blade terminals on the back box side wall.

7 When all cable connections have been made, use a

Posidriv No.2 screwdriver to secure both status

indication chassis.

29

997-274-000-6, Issue 6

September 2009

ID3000 Series Installation & Commissioning Manual

5.5.3.1 Earthing the Front Cover

The earth lead (E) must be connected to the back box

prior to fitting the upper extension chassis (F) as follows:

1 Connect one end of the earth lead (E) to the blade

terminal located on the right-hand side of the back

box (not shown).

2 Rest the earth lead on the top surface of the U-shaped

channel (G).

3 Fit the upper zone extension and secure.

4 When offering the cover to the back box for fitting

(see below), first locate the free end of the earth lead

on the front cover’s earth blade terminal.

5.5.3.2 Fitting the Front Cover

When the zone extension chassis have been fitted and

all wiring has been connected, fit the front cover as

follows:

1 Offer the cover (H) symmetrically and correctly

orientated to the front of the back box.

Note: To make sure the cover is correctly orientated, the

top of the cover has a ledge (I) which locates on

the flange (J).

2 Use a 4mm hexagonal socket key to tighten each

hexagonal socket-headed M6 screw (K).

3 To remove the cover, use the 4mm socket key to

unscrew the M6 screw (K).

CAUTION: Make sure the cover is supported when

Installation - Panel Electronics

5.5.3.3 Label Inserts

Each extension chassis is provided with a vertical slot

behind the fascia to allow a label (M) to be inserted. Insert

the label as follows:

releasing the last fastener.

September 2009

1 With the label correctly orientated, find the slot in the

top edge of the fascia and insert one corner to start.

2 Once the end has been inserted in the slot, straighten

the label and push in until all windows in the fascia

display the label text. A small amount of the label will

protrude above the fascia.

30997-274-000-6, Issue 6

ID3000 Series Installation & Commissioning Manual

5.6 Display PCB

WARNING -

Disconnect power

from the ID3000 and

remove batteries

Make sure you have

a PC back-up of the

current

configuration data

The Display PCB is located on the inner face of the main

chassis door. In the unlikely event that the Display PCB

becomes faulty and needs to be replaced, the front door

assembly, supplied as part of a kit (PN: 020-571-XXX)

needs to be replaced.

The manufacturer strongly recommends that BEFORE

attempting this procedure, and after isolation of the mains

supply and disconnection of the batteries, that you

remove the batteries from the back box until the panel is

ready for re-application of power.

To replace the main chassis door, the front cover

moulding(s) must be removed by releasing the M6

socket-headed screws using a 4mm hexagonal socket

key (or the special Notifier security tool, if applicable).

Before starting, make sure you have a PC back-up of

the panel’s current configuration data.

Ensure you take appropriate anti-static precautions

before undertaking this procedure.

With ALL power disconnected, follow the instructions below:

1 Using a suitable-sized coin, release the quarter-turn

fasteners (A) located at the left-hand side of the main

chassis front door (B). Open the door to gain access

to the main chassis’ PCB enclosure (C).

2 At connector J2 (D) on the Processor PCB, disconnect

the 34-way ribbon cable (E) from the Display PCB (F).

Close the main chassis front door and secure using

the two fasteners.

3 Holding the top edge of the door, use a nutdriver to

loosen the three M4 x 6 hexagonal-headed screws (G)

located down the right-hand side of the main chassis

door. Remove the centre and lower screws and with

only the top screw securing the right-hand side of the

door, release the two quarter-turn fasteners and support

the door while you remove the last screw.

4 Remove the door assembly and store safely in an

anti-static bag.

5 With the replacement door assembly correctly orientated

- as shown at left - offer it to the main chassis. Support

the door while inserting one of the three screws removed

in step 3. Tighten it by hand and then close the door and

secure. Insert the remaining two screws and, using a

nutdriver, fully tighten all three screws until secure.

6 Re-open the door and re-connect the 34-way ribbon

cable disconnected in step 2.

7 Re-fit the batteries.

Installation - Panel Electronics

8 Re-connect mains power and the batteries.

9 Close the door and secure using the two quarter-turn

fasteners.

10 Replace the front cover(s) and secure.

31 997-274-000-6, Issue 6

September 2009

ID3000 Series Installation & Commissioning Manual

1

4

A

G

D

F

C

B

E

1

F

K

J

H

6

2, 4

D

5.7 Base PCB

WARNING -

Disconnect power

from the ID3000

Series panel

Make sure you have

a PC back-up of the

current

configuration data

Label cables before

disconnecting.

The ID3000 Series Base PCB is located on the rear face

of the main chassis PCB enclosure. In the unlikely event

that the Base PCB becomes faulty and needs to be

replaced a replacement kit (PN: 020-568) is available.

To replace the Base PCB, the manufacturer recommends

the removal of the main chassis from the back box, as

adequate space is required for the Base PCB removal

process.

Ensure you take appropriate anti-static precautions

before undertaking this procedure.

1 Assuming the front cover moulding has been removed

disconnect ALL power to the ID3000 Series control

panel - disconnect the batteries first and isolate the

mains supply input - before continuing. Disconnect

the power lead (A), and the battery charger and

thermistor leads (B), from either the PSU module or

the DTP/Booster Module (not shown).

2 Using a suitable-sized coin, release the two quarter-turn

fasteners (C), and open the main chassis’ hinged door

to access the main chassis PCB enclosure.

3 At the Base PCB (D), disconnect all cable and wiring

terminations (see Section 5.7.2, Cables and Wiring).

Close the hinged door and secure using the quarterturn fasteners.

4 Using a Posidriv screwdriver, loosen the four main

chassis retaining screws (E). Remove the main chassis

(F) from the back box (G), and place on a clean work

surface with the front door uppermost. Open the front

door to gain access to the Base PCB (D).

5 Remove any 3rd-layer PCB(s), if fitted - refer to the

appropriate installation section of this manual.

6 Disconnect the short ribbon cable (H or J), to any 2nd-

layer Module PCBs (if fitted) and remove the PCB(s) refer to Sections 5.11 and/or 5.12 - and place in an

anti-static bag. Keep safe until required for re-fitting.

Note: If fitted, make a note of the position of the Module

Installation - Panel Electronics

7 Remove the Processor PCB (K) from the main chassis

- refer to Section 5.8 for details. Store safely in an

anti-static bag until required for re-fitting.

8 Remove the Base PCB from the main chassis using

a No.1 Posidriv screwdriver to remove the seven (7)

M3 x 10 SEM screws - see overleaf - from the Base

PCB. Keep safe until required for re-fitting.

Note: Note the locations of the user-defined links as

PCBs for re-fitting.

indicated by the two black-filled boxes in the

Cables and Wiring drawing overleaf.