Page 1

Actuators IC 40

Technical Information · GB

3 Edit i o n 0 7. 1 8

• For complex applications with programmable functions for

flexible adjustment to the process, with statistics and fault history

to support service personnel

• Position indicator that can be read externally

• Spacious connection chamber for ease of installation

• Actuators can be delivered ready installed on butterfly valves

BVG, BVGF, BVA, BVAF, BVH, BVHS or linear flow control VFC

Page 2

Contents

Actuators IC 40 .....................................1

Contents ............................................2

1 Application ........................................4

1.1 Examples of application ...........................6

1.1.1 Staged control .........................................6

1.1.2 Staged control with three burner capacity levels .....6

1.1.3 Continuous control by three-point step signal........7

1.1.4 Staged control with pre-purge ........................8

1.1.5 Continuous control with defined ignition position ....9

1.1.6 Hot-air compensation ...............................10

1.1.7 Staged control with online adjustment of the

burner capacity ............................................10

2 Certification ......................................11

3 Function ..........................................12

3.1 Operating modes .................................13

3.2 Standard and analogue operating modes ........13

3.3 Closed, low-fire rate, intermediate and open

position ...............................................13

3.4 Running times ....................................14

3.5 Standard operating modes 1–12 ................15

3.5.1 2-point operation....................................15

3.5.2 2-point operation with flame proving period ....... 16

3.5.3 2-stage operation with one or two digital inputs ....17

3.5.4 2-stage operation with two digital inputs...........19

3.5.5 3-point step operation ..............................20

3.5.6 3-stage operation with one or two digital inputs ....21

3.5.7 2-point operation with switchover of the

adjustment angle for the “open” position .................23

3.5.8 2-point operation with input-dependent

adjustment angle for the “open” position .................25

3.5.9 2-point operation with switchover of the running

times .......................................................26

3.5.10 3-point step operation with running time

fractions ....................................................27

3.5.11 3-stage operation with t wo digital inputs .........29

3.5.12 3-point step operation with low position ..........30

3.6 Analogue operating modes 21–27 ..............31

3.6.1 2-point operation.....................................31

3.6.2 2-point operation with switchover of the

adjustment angle for the “open” position .................33

3.6.3 2-point operation with input-dependent

adjustment angle for the “open” position .................35

3.6.4 2-point operation with switchover of the running

times .......................................................36

3.6.5 2-point operation with characteristic curve

switchover I ................................................38

3.6.6 2-point operation with characteristic curve

switchover II ...............................................40

3.6.7 2-stage operation with t wo digital inputs and

variable adjustment angle for the “open” position ........ 42

3.6.8 Emergency closing function ........................43

3.7 Parameters....................................... 44

3.7.1 Parameter sets.......................................45

3.7.2 Factor y default parameters...........................47

3.8 Inputs ............................................ 48

3.8.1 Digital................................................48

3.8.2 Analogue ............................................48

3.9 Outputs .......................................... 50

3.10 Manual mode....................................51

3.10.1 Direct position preset ...............................51

3.10.2 Simulate inputs .....................................51

3.11 Statistics.........................................52

3.11.1 Counters ...........................................52

3.11.2 Measured values...................................52

3.11.3 Resetting statistics ................................ 52

3.11.4 Resetting a signal ..................................52

3.12 Connection diagram.............................53

3.13 Display ...........................................54

3.13.1 During operation ...................................54

3.13.2 Warnings and faults................................54

3.14 Relay outputs RO 1 and RO 2 function..........56

IC 40 · Edition 07.18 2

= To be continued

▼

Page 3

4 Replacement possibilities for actuators ..........57

4.1 GT 31 is to be replaced with IC 40 ................57

4.2 M 5/M 6 is to be replaced with IC 40 .............58

5 Selection ........................................ 59

5.1 Selection table ....................................59

5.2 Type code .........................................59

6 Project planning information .................... 60

6.1 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.1.1 Cable selection ......................................60

6.1.2 Digital inputs ........................................60

6.1.3 Feedback signalling ..................................61

6.2 Feedback potentiometer .........................62

6.3 Installation........................................62

6.4 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

7 Accessories ...................................... 64

7.1 Heat deflectors ....................................64

7.2 “Single application” attachment set...............64

7.3 BCSoft.............................................65

7.3.1 Opto-adapter PCO 200 ..............................65

7.4 Cable gland with pressure equalization element .65

8 Technical data ................................... 66

8.1 Running times and torques.......................67

8.2 Dimensions ...................................... 68

8.2.1 IC 40.................................................68

9 Maintenance cycles ............................. 69

10 Glossary ........................................ 70

10.1 Start fuel flow rate ...............................70

10.2 Positions .........................................70

10.3 Adjustment angle for the “open” position .......70

11 Legend ..........................................71

Feedback ...........................................72

Contact.............................................72

IC 40 · Edition 07.18 3

Page 4

Application

1 Application

Actuator IC 40 is designed for all applications that require precise, controlled rotary movement between 0°

and 90°. It can be mounted directly onto the butterfly

valves BVG, BVGF, BVA, BVAF, BVH, BVHS or linear flow

control VFC in order to control the gas and air flow rates

on gas burners.

Actuators and butterfly valves or linear flow control

VFC can also be delivered ready assembled as butterfly valves with actuator IBG, IBGF, IBA, IBAF, IBH, IBHS

or linear flow control IFC, see Technical Information

Butterfly valves BVG, BVA, BVH..., IB..., and Linear flow

controls VFC, IFC.

IBG (IC 40 + BVG) IFC (IC 40 + VFC)

An optional integrated feedback potentiometer offers

the option of monitoring the current position of the actuator. This checking function can be used in automation processes.

The IC 40 can be used on continuously-controlled

burners and on stage-controlled burners.

Settings on the actuator IC 40 can be made using a PC

with the programming software BCSoft. All the relevant

settings for the process are made using the software

via an optical interface. Various operating modes, which

may be modified, are stored in the unit. In addition, the

control type (two-point step signal, three-point step

signal or continuous control), running times, adjustment angles and intermediate positions can be programmed.

The actuator can also be controlled “by hand” using the

software.

Once set, all the parameters can be saved on the PC

and copied from there into other actuators, thus saving

time during the commissioning process.

Service technicians can call up statistical data using

BCSoft, such as hours of operation, actuating cycles

and a fault history. Some values can also be set to zero,

for example to record data over a specific period of time.

IC 40 · Edition 07.18 4

Page 5

Application

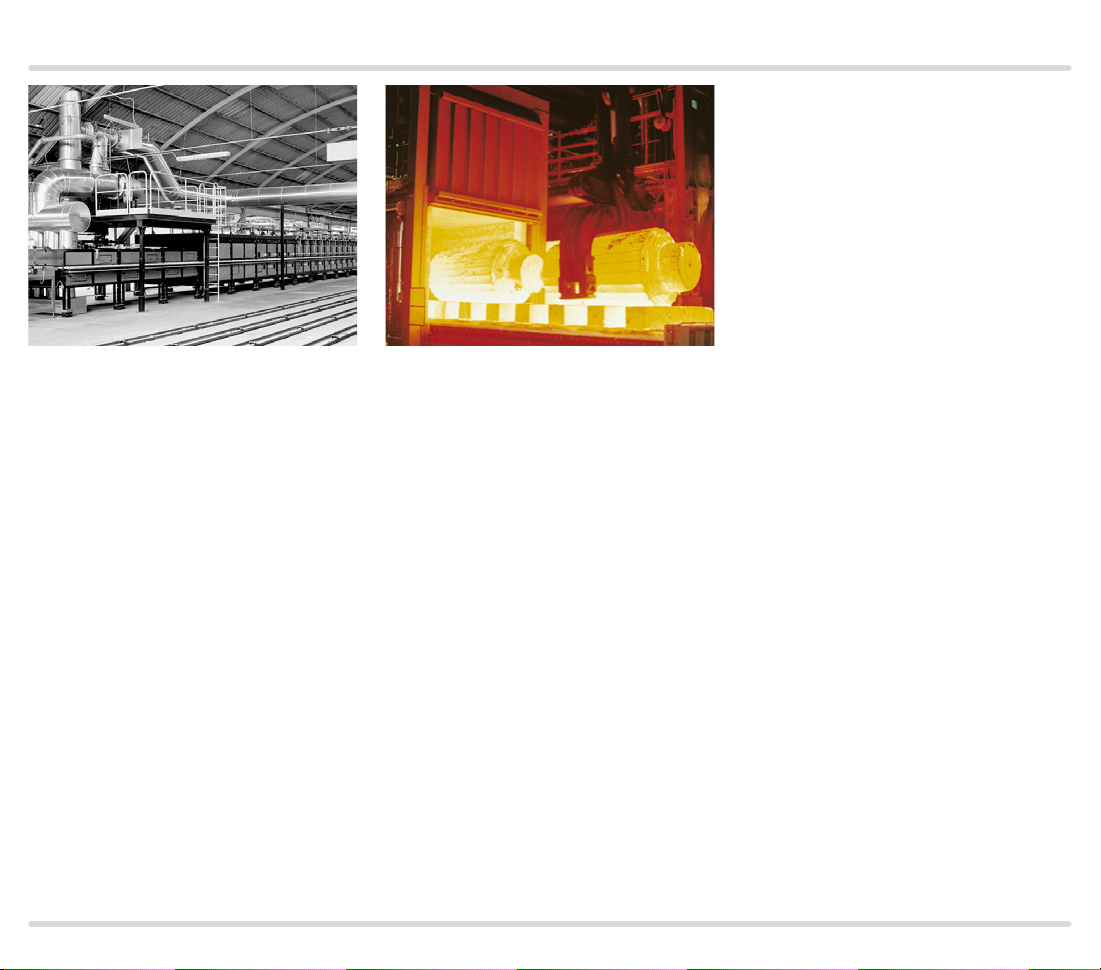

Roller hearth kiln in the ceramics

industry

Forging furnace

IC 40 · Edition 07.18 5

Page 6

Application

1.1 Examples of application

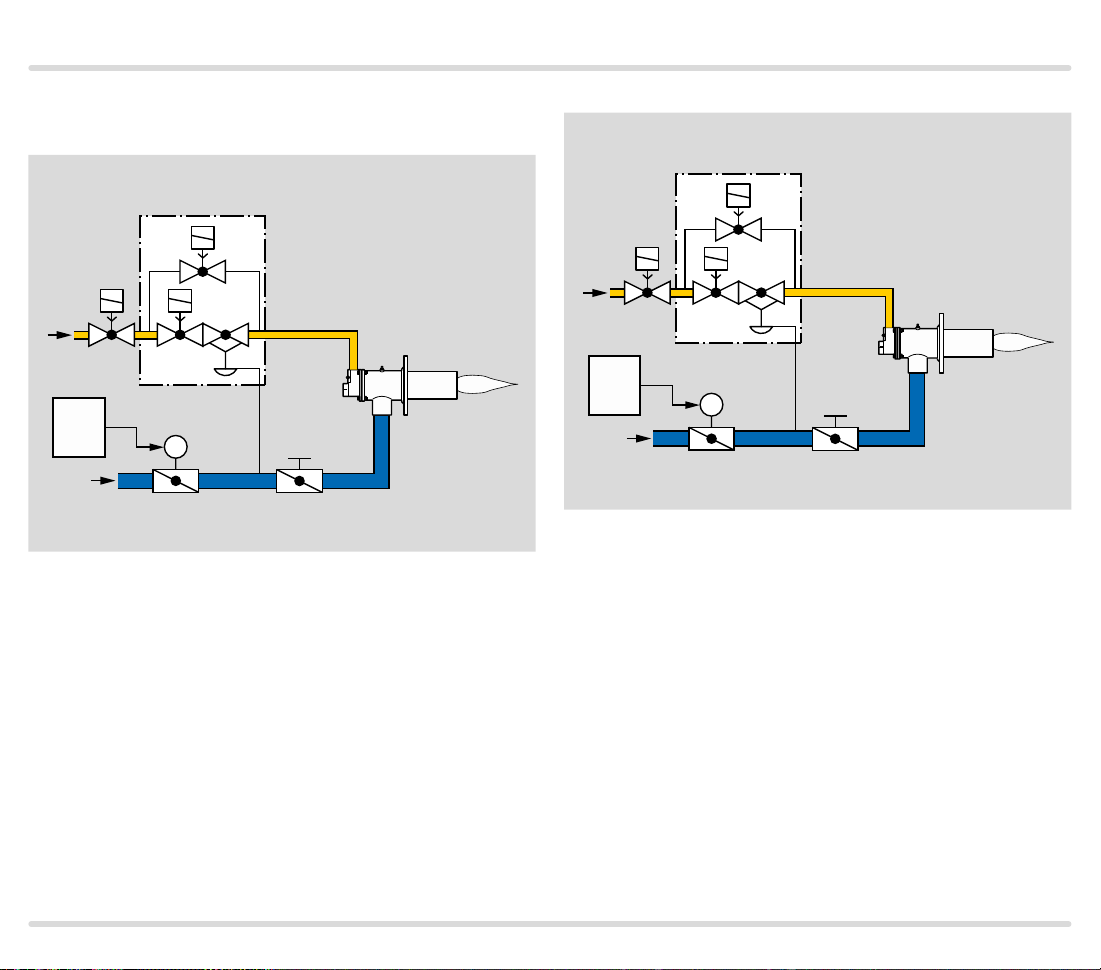

1.1.1 Staged control

VAG + VAS 1

Two-

point

step

For processes that require a homogeneous temperature distribution in the furnace. The actuator IC 40 is

controlled by a two-point controller and operates in

On/Off or High/Low intermittent mode. The actuator

closes when the voltage supply is interrupted. The running time can be infinitely adjusted between 5 and 25

seconds.

M

IC 40 + BVA BVA

Staged control with three burner capacity levels

1.1.2

VAG + VAS 1

PLC

M

IC 40 + BVA BVA

For processes that require a homogeneous temperature distribution in the furnace and three burner capacity levels. The actuator IC 40 is controlled by a programmable logic controller and works in High/Medium/Low

or High/Medium/Low/Off intermittent mode. This allows the ignition stage to be started. The optional pressure switch provides fail-safe monitoring of the maximum pilot air volume. The actuator running time can be

infinitely adjusted between 5 and 50 (75) seconds.

IC 40 · Edition 07.18 6

Page 7

Application

VAGVAS

4 DI 1

IC 40

VAG

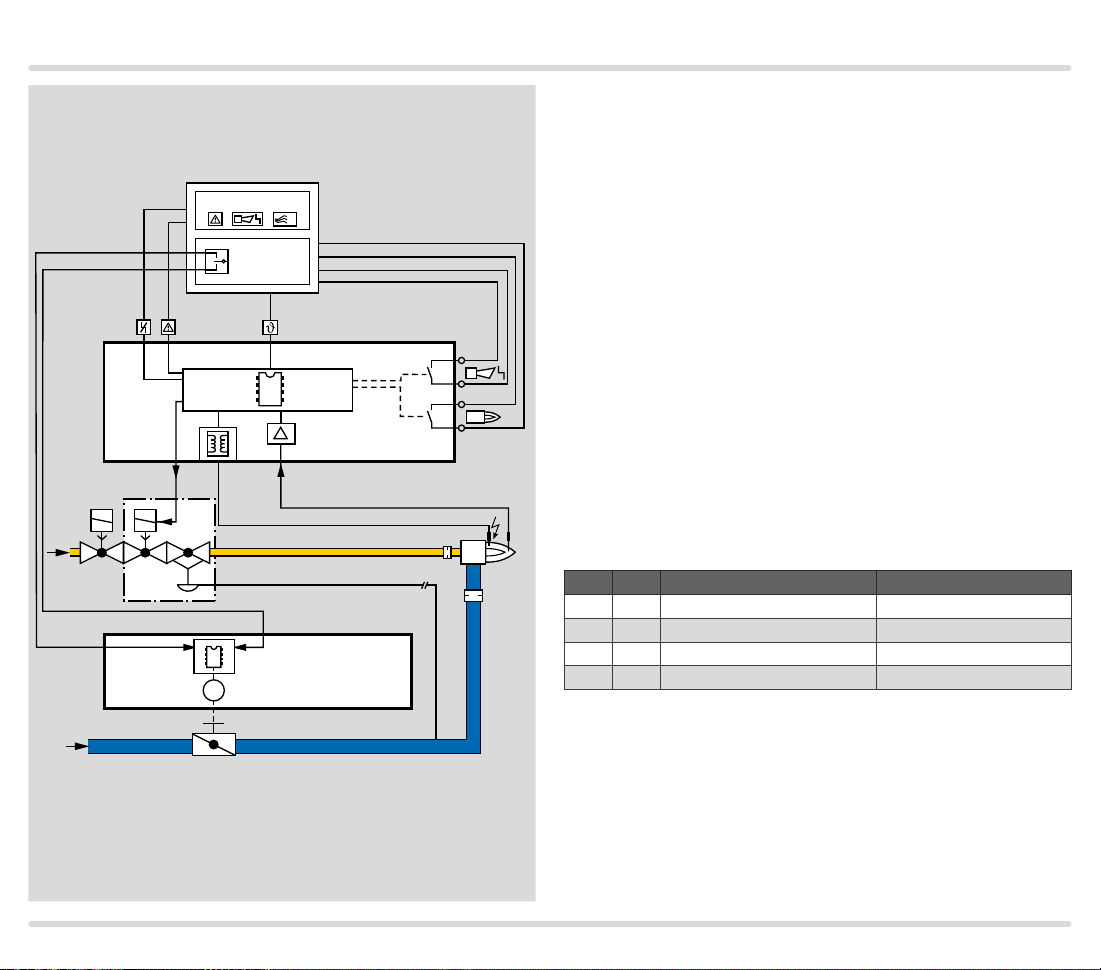

1.1.3 Continuous control by three-point step signal

The actuator IC 40 is controlled by the three-point step

controller 3PS and moves the butterfly valve BVA to the

ignition position. The burner starts.

L1, N, PE

3PS

P

PLC

Once the burner is operating, the operation signalling

contact of the burner control unit BCU 460 closes. The

BCU issues the controller enable signal to the temperature controller. The butterfly valve opens or closes between the low-fire and high-fire rate positions depend-

5 3

12

V1

4

µC

9

BCU 460

18

19

16

17

ing on the capacity demand of the burner. When the

three-point step signal is disconnected, the butterfly

valve stops at its current position.

If both inputs on the IC 40 (DI 1 and DI 2) are activated

after the burner has been shut down, the butterfly valve

closes further than the low-fire rate position (see Operating mode 12, 3-point step operation with low position).

µC

M

DI 2

7

BIO/

BIC

DI 1 DI 2 IC 40 position Valve position

Off Off Idle/Stop Idle

On Off Open to high position Open to high-fire rate

Off On Close to middle position Close to low-fire rate

On On low Valve closes further

BVA

IC 40 · Edition 07.18 7

Page 8

Application

VAGVAS

VAG

L1, N, PE

PLC

P

22

A

23

5 3

12 26

V1

DI 1 DI 2

4 7

4

µC

9

P

BCU 460..L

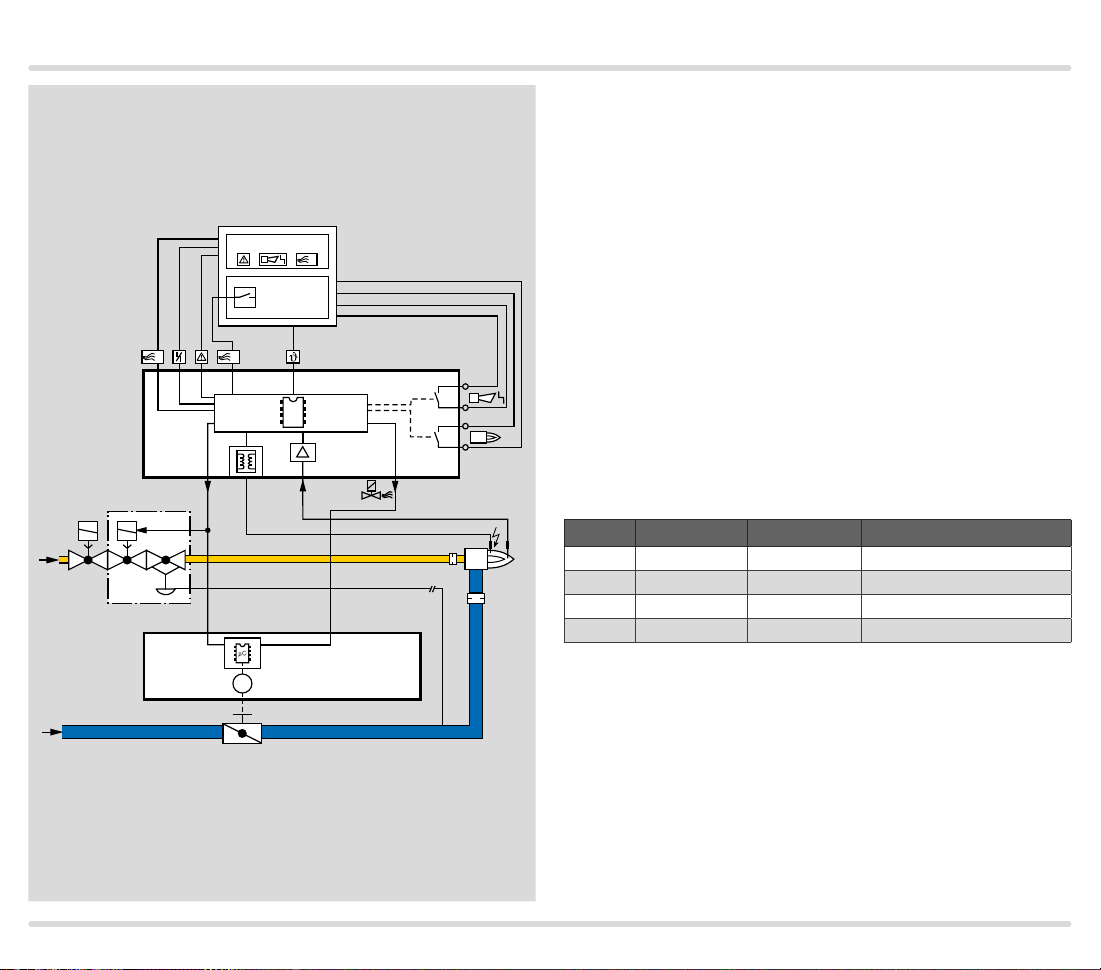

1.1.4 Staged control with pre-purge

The central control system starts the pre-purge. Input

DI 2 is activated via the air valve output of the BCU and

the butterfly valve BVA is set to the pre-purge position.

In the event of a temperature demand, the burner control unit BCU activates input DI 1 via the valve output

V1 and moves the butterfly valve to the ignition position

(precondition: the IC 40 must have reached the ignition

position on the instant of ignition). The burner starts.

To activate the high-fire rate, DI 2 is actuated via the air

18

19

16

17

valve output on terminal 26 of the BCU.

The butterfly valve moves cyclically between the high-

fire rate position and the low-fire rate position (see

Operating mode 11, 2-stage operation with two digital

inputs).

DI 1/ V1 DI 2/air valve IC 4 position Valve position

BIO/

BIC

Off Off closed Closed

On Off low Ignition position/low-fire rate

On On middle High-fire rate

Off On high Pre-purge

IC 40

M

BVA

IC 40 · Edition 07.18 8

Page 9

Application

VAGVAS

VAG

P

22

5 3

12 26

V1

DI 1 DI 2

IN

18

4 7

IC 40

mA

µC

M

L1, N, PE

PLC

µC

4

9

P

BCU 460..L

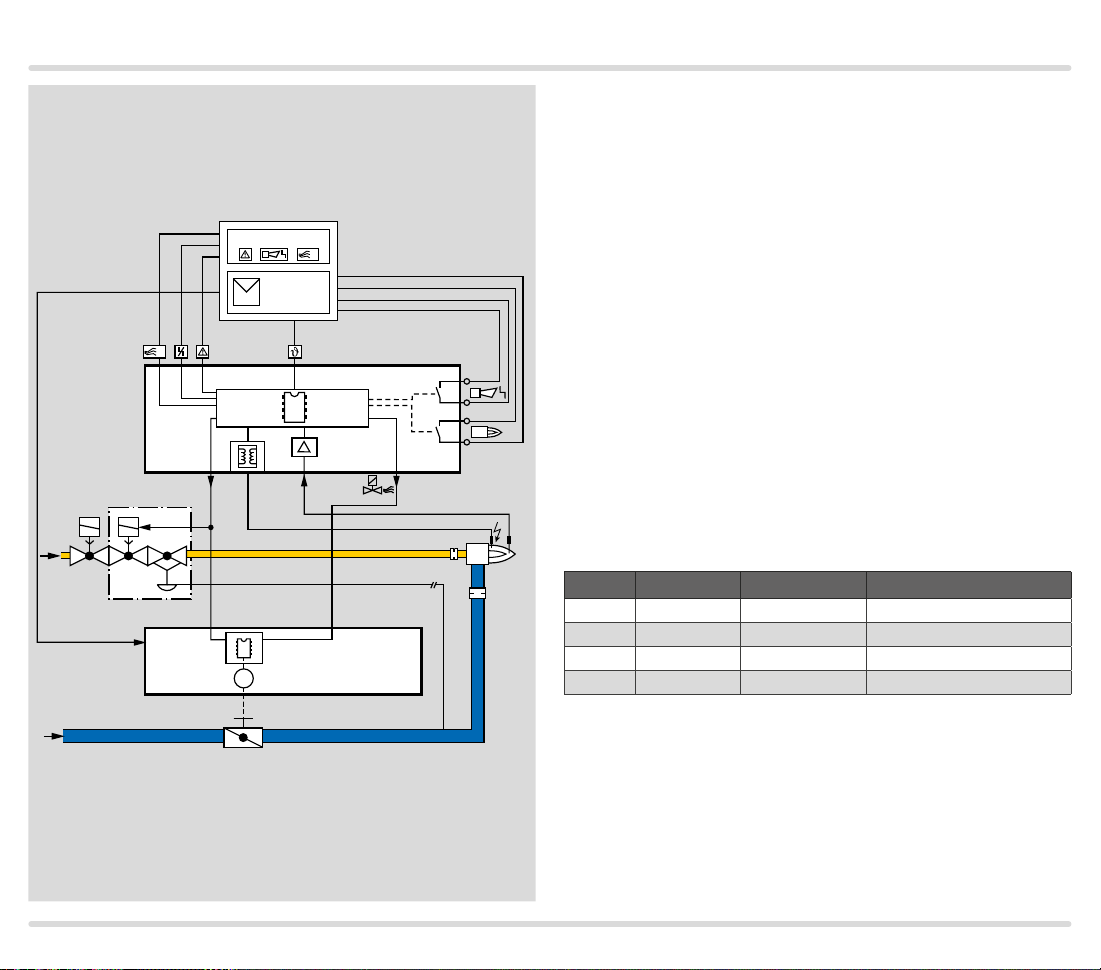

1.1.5

Continuous control with defined ignition position

The central control system starts the pre-purge. Input

DI 2 is activated via the air valve output of the BCU and

the butterfly valve BVA is set to the pre-purge position.

In the event of a temperature demand, the burner control unit BCU activates input DI 1 via the valve output

V1 and moves the butterfly valve to the ignition position

(precondition: the IC 40 must have reached the ignition

position on the instant of ignition). The burner starts.

The BCU activates DI 2 via the air valve output. This

18

19

16

17

enables the analogue input IN on the actuator IC 40.

Depending on the capacity demand of the temperature

controller, the butterfly valve BVA moves steplessly to

the position between the low-fire rate and the high-fire

rate as specified by the analogue input IN (see Operating mode 27, 2-stage operation with two digital inputs

and variable adjustment angle for the open position).

BIO/

BIC

DI 1/ V1 DI 2/air valve IC 40 position Valve position

Off Off closed Closed

On Off low Ignition position/low-fire rate

On On analogue chart 1 In acc. with chart 1

Off On high Pre-purge/high-fire rate

BVA

IC 40 · Edition 07.18 9

Page 10

Application

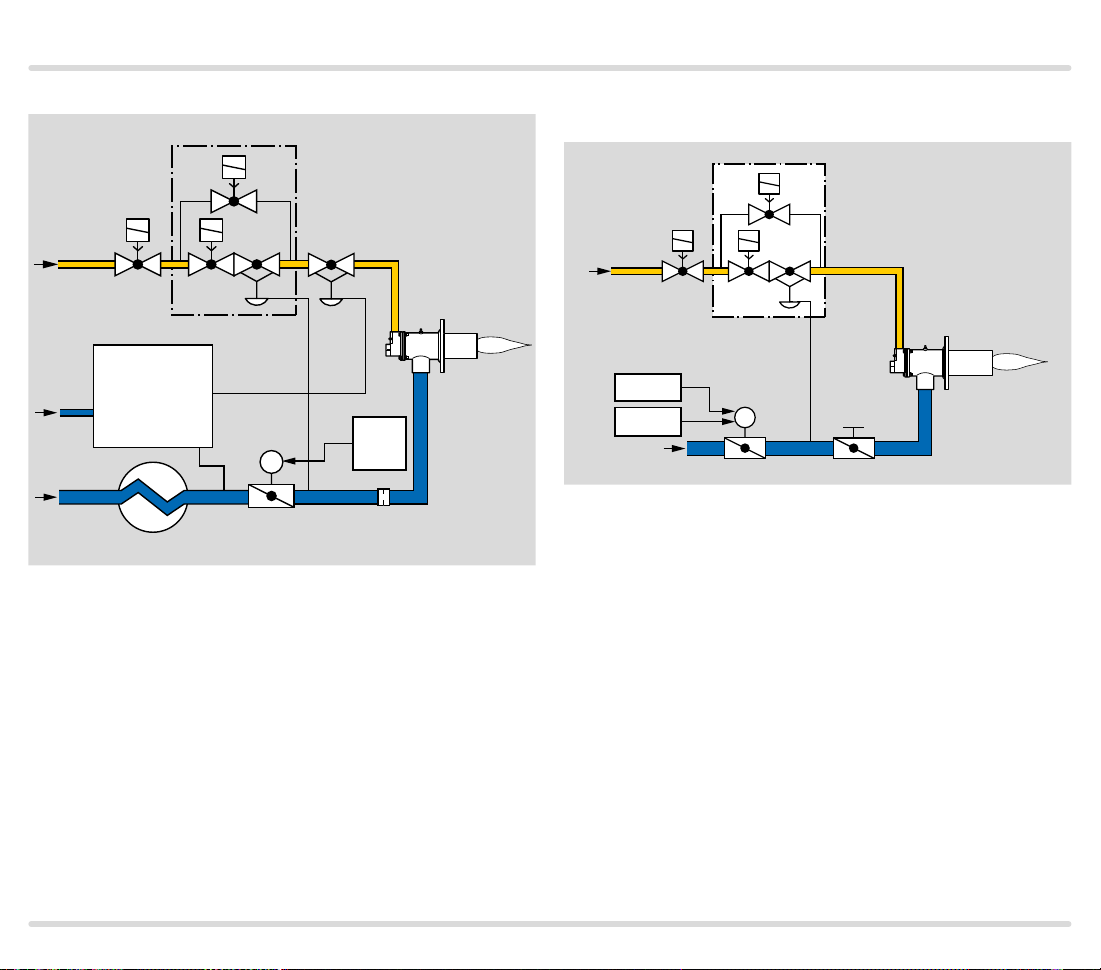

1.1.6 Hot-air compensation

VAG +VAS 1

VAS

GIK

WPS

Two

M

IC 40 +

BVH

point

For processes in which preheated combustion air at a

temperature of up to 450°C must be controlled. In this

example, the actuator IC 40 is controlled by a two-point

controller to adjust the burner capacity. It runs in High/

Low intermittent mode. The running time can be adjusted between 5 and 25 seconds.

Staged control with online adjustment of the burner

1.1.7

capacity

VAG +VAS 1

VAS

4–20 mA

PLC

M

IC 40 + BVA BVA

For processes that require a homogeneous temperature distribution and high temperature accuracy in the

furnace.

If only a low heat output is required, for example to

maintain the temperature in the furnace, the burner can

continue to be operated in intermittent mode. The adjustment angle of the valve is reduced via the analogue

input (4–20 mA) of the actuator and the burner capacity is therefore lowered. This ensures uniform temperature distribution even with a low heat output.

This function of the actuator IC 40 can also be used in

the ceramics industry to correct the lambda value or for

temperature compensation purposes in hot-air applications.

IC 40 · Edition 07.18 10

Page 11

Certification

2 Certification

Certificates–see Docuthek.

EU certified

Meets the requirements of the

– Low Voltage Directive (2014/35/EU)

– EMC Directive (2014/30/EU)

Standards:

– EN 60730214

Eurasian Customs Union

The product IC 40 meets the technical specifications of

the Eurasian Customs Union.

ANSI/CSA approved

Directive on the restriction of the use of hazardous

substances (RoHS) in China

Scan of the Disclosure Table China RoHS2 – see certificates at www.docuthek.com

UL listed

Underwriters Laboratories–UL 607301 “Automatic

Electrical Controls for Household and Similar Use”,

UL 60730214 “Automatic Electrical Controls for

Household and Similar Use; Part 2: Particular Requirements for Electric Actuators”, File No. E4436.

American National Standards Institute/Canadian

Standards Association–ANSI/UL 429 and CSA C22.2.

Class number: C322102, Class number: C322182

www.csagroup.org.

IC 40 · Edition 07.18 11

Page 12

Function

3 Function

The actuator IC 40 moves the butter fly valve towards 0°

or 90°. There are 4 possible positions which the actuator can approach in steps. Any intermediate position is

possible in continuous three-point step mode. Optionally, the actuator can also approach any intermediate

position via an additional current input.

The slow flashing blue LED indicates that the motor of

actuator IC 40 is moving. The position indicator on the

housing indicates the opening angle. Further visualization and operation are performed on a PC using the

BCSoft software.

BCSoft

The sequence of opening and closing is programmed

using the BCSoft software and can be adapted individually to any application.

All settings for the actuator IC 40 are made using

BCSoft. Commissioning and calibration of the “closed”

position are performed conveniently using the software.

BCSoft offers the option of moving and adjusting the

butterfly valve in Manual mode via the actuator, see

page 51 (Manual mode).

A detailed manual is available for the BCSoft PC software:

ww w.docuthek.com Home Elster Thermal Solu-

tions Products 03 Valves and butterfly valves

Actuators IC BCSoft (D, GB)

IC 40 · Edition 07.18 12

Page 13

Function

▼

3.1 Operating modes

The operating mode is responsible for the setting prop-

erties of the IC 40.

The running times and dwell positions of the actuator

are stored in the various operating modes but can be

reprogrammed at any time using BCSoft (if mounted on

butterfly valve BV..).

The actuator operates in continuous and intermittent

mode with various adjustment angles for the “open”

position. The adjustment angles for the “open” position

indicate the approached position of the actuator in the

case of intermittent operation. They can be changed in

BCSoft.

The corresponding operating modes are displayed in

BCSoft as flowcharts by way of example to visualize the

opening/closing behaviour of the actuator.

3.2 Standard and analogue operating modes

In the standard operating modes, two digital inputs

(DI 1 and DI 2) of the actuator are pre-assigned at the

works as universal inputs. If a voltage of 24 V DC or

100–230 V AC is applied to the input, this is recog-

nized as “On” signal (positive logic). It is not necessary

to set or readjust the voltage magnitude or voltage type.

In the analogue operating modes, an additional input

(IN) is assigned for the actuator. If an actuator IC 40..A

with 4–20 mA analogue input is connected (option),

further operating modes are available in addition to the

standard operating modes. The actuator can approach

corresponding intermediate positions via a current signal to the additional input, see page 49 (Priority and

running time in operating modes 1–10).

3.3

Closed, low-fire rate, intermediate and open

position

Depending on the set operating mode, there are 4 positions which the actuator can approach:

Closed = 0° = 0%,

Low = low-fire rate position,

Middle = intermediate position,

High = open position.

The positions not used by the operating mode are

barred.

The “closed position” is always the calibrated zero posi-

tion of the device and cannot be readjusted. The other

positions can be defined on site.

IC 40 · Edition 07.18 13

Page 14

Function

Basically, the following parameter limits must be noted.

Ascending sequence of positions:

0% = closed –>

low –>

middle –>

high ≤ 100%

The “high position” must not be selected less than

10 %.

If the positions have been changed in the software,

BCSoft checks the new values for compliance with the

limits and adapts the positions.

3.4 Running times

Up to 6 running times (t1 to t6), each between 0 and

max. 25.5 seconds, can be set dependent on the operating mode.

A minimum running time is required for each change in

position.

Minimum actuator running time t

t

4.5 s x change in position%

=

min

100 %

Times which are too short are automatically corrected

by the IC 40 to the minimum possible value. If the actuator is to operate as fast as possible, a time of 0 seconds can be preset.

In the case of position changes < 16.2%, the maximum

running time is reduced from 25.5 s percentage-wise.

min

:

The IC 40 corrects the time to the maximum possible

value.

After they have been entered, the valid parameters are

automatically read out and displayed in BCSoft.

We recommend switching to Manual mode when commissioning in order to establish the right positions

and running times for the application, see page 51

(Manual mode).

Outputs

In addition to feedback signals, it is also possible to

assign freely adjustable position ranges to the two outputs, RO 1 and RO 2, see page 50 (Outputs).

Statistics

The statistical data stored in the unit, such as faults

which have occurred, various counter readings and

measured values, are displayed and read out in BCSoft,

see page 52 (Statistics).

Emergency closing function

A pre-tensioned spiral spring moves the drive shaft with

valve disc to the closed position in the event of faults or

if the continuous supply voltage is interrupted, within

the closing time < 1 s, see page 43 (Emergency closing function).

IC 40 · Edition 07.18 14

Page 15

Function

t

1

high

low

closed

DI 1

Operating mode 1

3.5 Standard operating modes 1 – 12

General description, see page 13 (Operating modes).

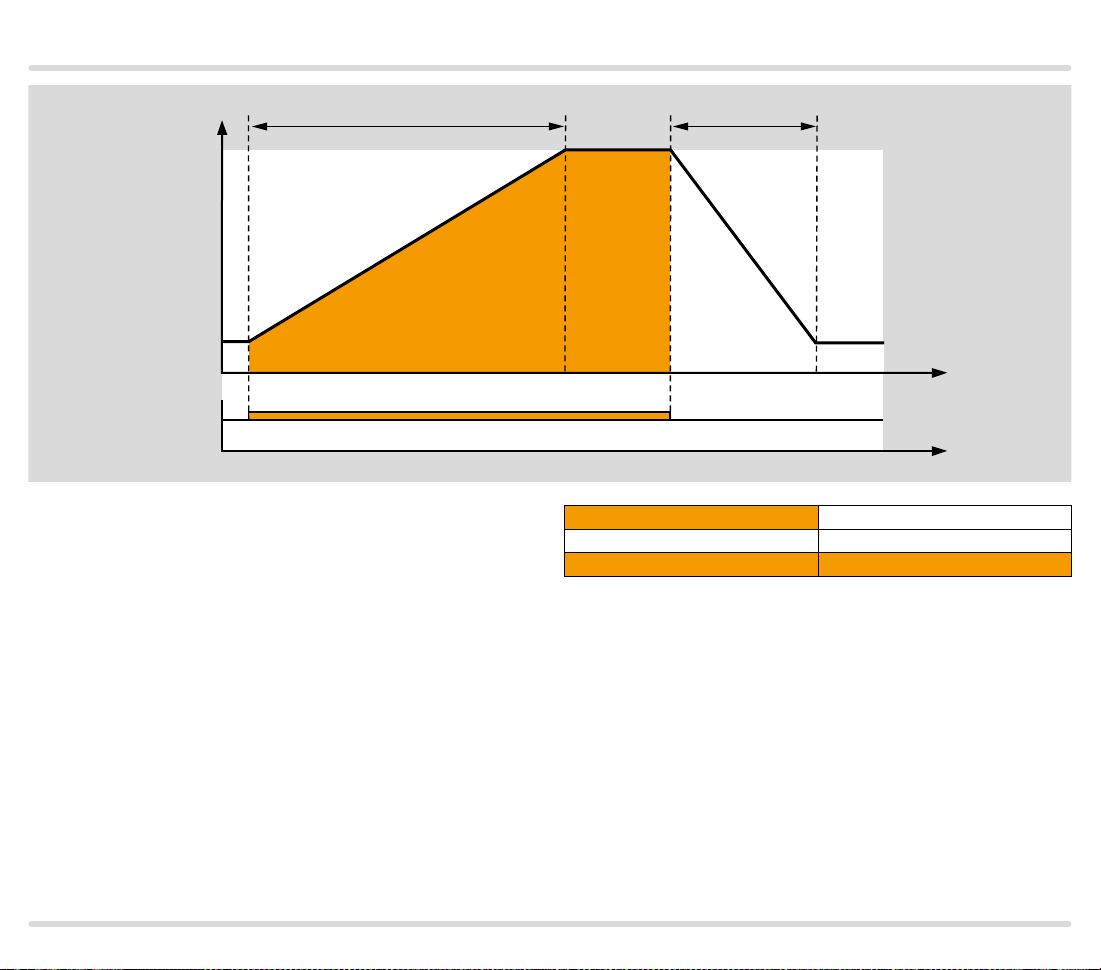

3.5.1 2-point operation

Operating mode 1

In idle state (DI 1 with no signal), the actuator is in “low”

position (“low” position may also be 0° = “closed” position).

If a signal is applied to digital input DI 1, the actuator moves to “high” position within running time t

When the signal at digital input DI 1 drops, the actuator

moves back to “low” position within running time t2.

.

1

t

2

t [s]

t [s]

DI 1 Position

Off low/closed

On high

If the signal at digital input DI 1 is deactivated before

“high” position is reached, the actuator moves directly to

“low” position within the percentage time of t2.

The actuator operates in high/low (high/closed) inter-

mittent mode.

Possible parameter sets for this operating mode:

P68017, P68018 and P68019, see page 45 (Parameter sets).

IC 40 · Edition 07.18 15

Page 16

Function

t

1

t

2

t

3

high

middle

low

closed

DI 1

Operating mode 2

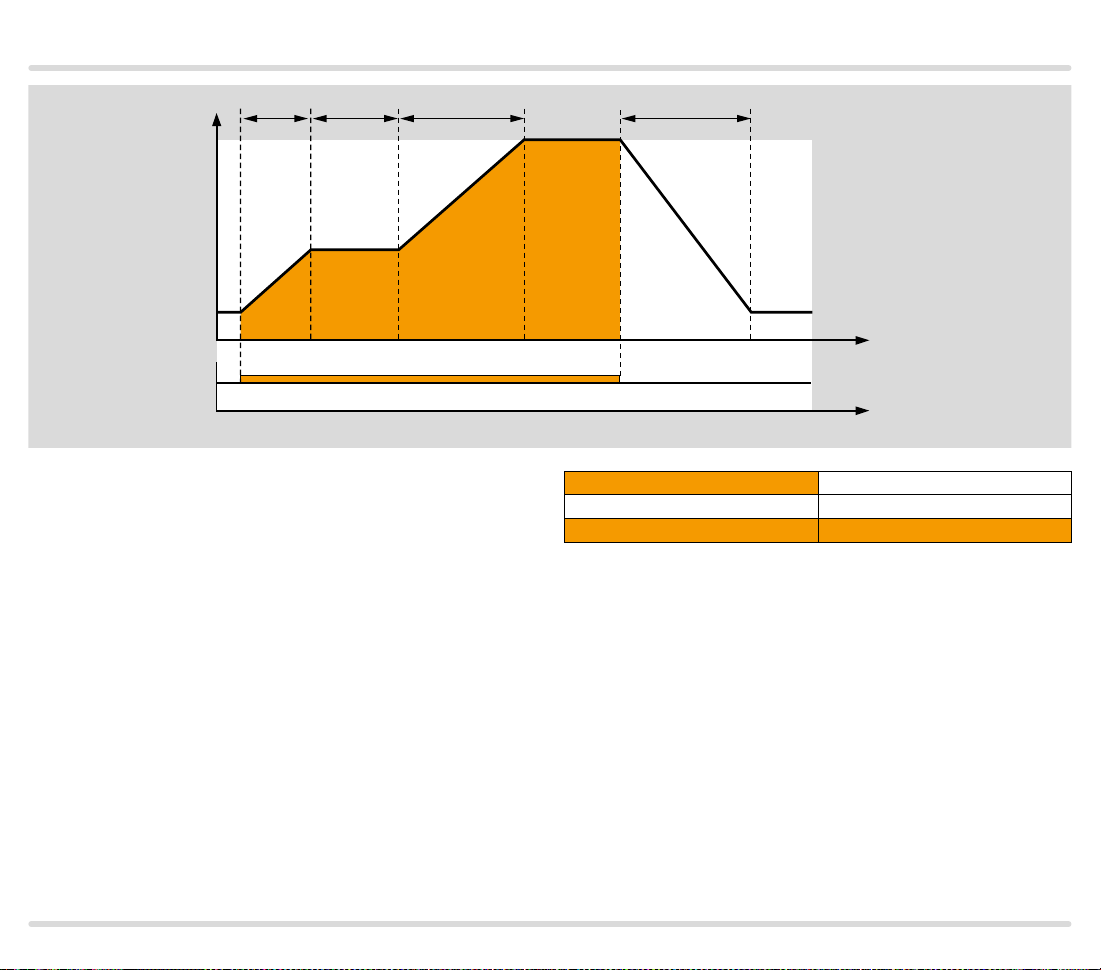

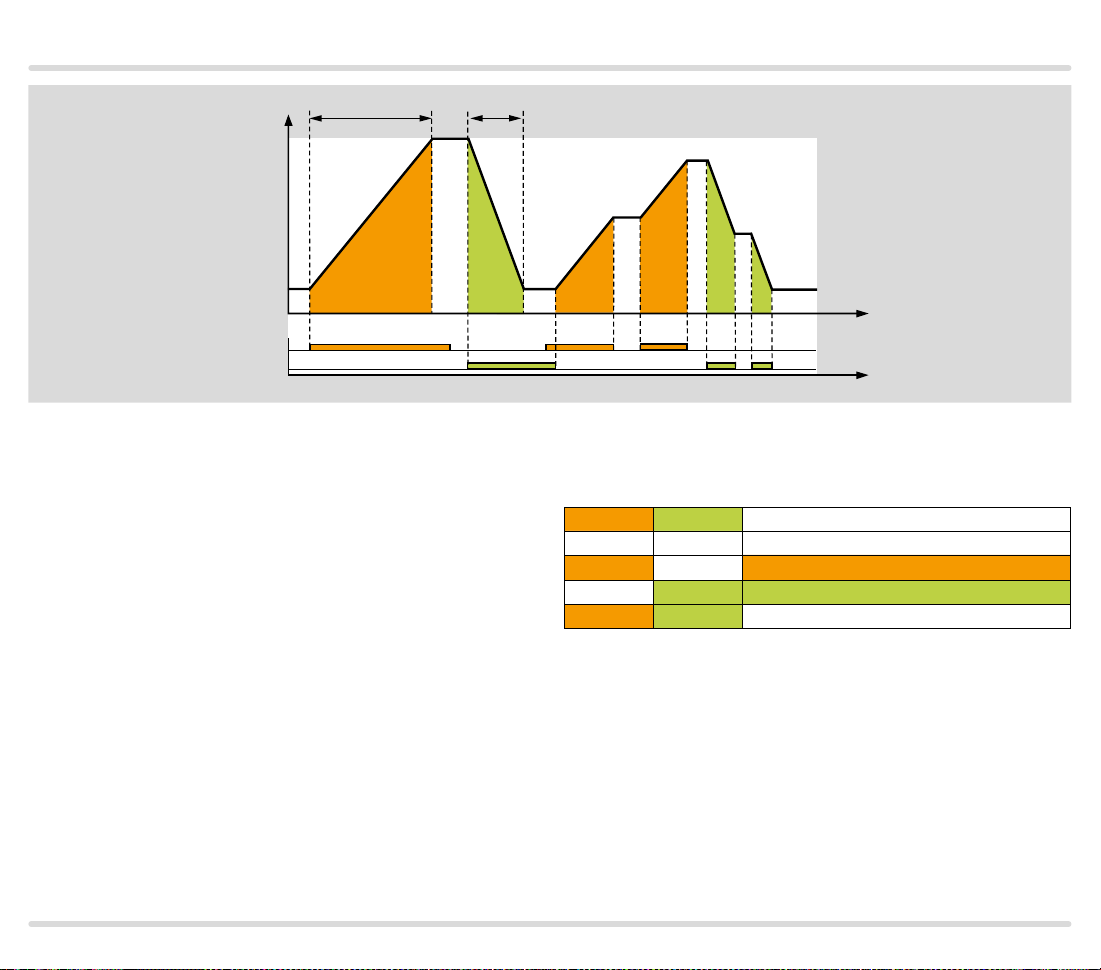

3.5.2 2-point operation with flame proving period

Operating mode 2

In idle state (DI 1 with no signal), the actuator is in “low”

position (“low” position may also be 0° = “closed” position).

If digital input DI 1 is activated, the actuator moves to

“middle” position within running time t

After waiting time t

, the actuator automatically moves

2

.

1

further to “high” position within running time t3.

As the voltage at digital input DI 1 drops, the actuator

closes to “low” position within running time t

.

4

t4

t [s]

t [s]

DI 1 Position

Off low/closed

On high

If the signal at digital input DI 1 is deactivated before

“high” position is reached, the actuator moves directly to

“low” position within the percentage time of t4.

The actuator operates in high/middle/low (high/mid-

dle/closed) intermittent mode.

On burners which must ignite during opening of the

butterfly valve, waiting time t

is appropriate for flame

2

proving.

Possible parameter set for this operating mode:

P 68021, see page 45 (Parameter sets).

IC 40 · Edition 07.18 16

Page 17

Function

▼

t

1

t

2

high

middle

low

closed

DI 1

DI 2

Operating mode 3

3.5.3 2-stage operation with one or two digital inputs

Operating mode 3

In idle state (DI 1 and DI 2 with no signal), the actuator is in “low” position (“low” position may also be 0° =

“closed” position).

Control via two digital inputs

If digital input DI 2 is activated, the actuator moves

from “low” position to “middle” position within running

time t

.

1

If, in addition, digital input DI 1 is activated, the actuator

approaches “high” position within running time t

.

2

When the signal at DI 1 drops, the actuator moves back

to “middle” position within running time t

and closes

3

the control element to “low” position within running

t

3

t4

t

1

t

2

t [s]

t [s]

time t

if the signal is also disconnected from DI 2.

4

The actuator operates in high/middle/low (high/mid-

dle/closed) intermittent mode.

DI 1 DI 2 Position

Off Off low/closed

On Off high (DI 1 has priority)

Off On middle

On On high

In this operating mode, digital input DI 1 has priority

and its signal always leads to opening of the actuator to

“high” position.

IC 40 · Edition 07.18 17

Page 18

t [s]

t

t

Function

high

middle

low

closed

DI 1

DI 2

Operating mode 3

This may prove to be practical in order to purge a fur-

nace or kiln via DI 1 (independently of DI 2), for instance.

It is then possible to operate with both inputs in high/

middle/low intermittent mode.

Possible parameter sets for this operating mode:

P 68015, P68016, see page.45 (Parameter sets).

Control via one digital input

If digital input DI 1 is activated (DI 2 with no signal), the

actuator moves to “high” position. The running times t

1

and t2 run directly in succession.

Likewise, the actuator closes within the successive running times t

and t4 if signal DI 1 drops. The “middle”

3

position serves as an interpolation point and can be

freely programmed.

1

2

t [s]

Owing to the two successive running times, the opening characteristic of the butterfly valve can be changed.

For example, the characteristic of the air circuit can be

adapted to that of the gas circuit.

Running times up to 51 s (2 x 25.5 s) are possible in this

operating mode. If the signal at digital input DI 1 is deactivated before “high” position is reached, the actuator

moves directly to “low” position within the percentage

times of t

and t4.

3

The actuator operates in high/low (high/closed) inter-

mittent mode.

DI 1 DI 2 Position

Off Off low/closed

On Off high

IC 40 · Edition 07.18 18

Page 19

Function

t

1

t

2

high

middle

low

closed

DI 1

DI 2

Operating mode 4

3.5.4 2-stage operation with two digital inputs

Operating mode 4

The function corresponds to operating mode 3 with dif-

ferent priority of the digital inputs.

Digital input DI 2 has priority over DI 1. This means that

a signal at DI 1 has no effect unless a signal is also applied to DI 2.

t

3

t

4

t [s]

t [s]

DI 1 DI 2 Position

Off Off low/closed

On Off low/closed (DI 2 has priority)

Off On middle

On On high

Possible parameter set for this operating mode:

P 68022, see page 45 (Parameter sets).

IC 40 · Edition 07.18 19

Page 20

Function

Operating mode 5

high

low

closed

DI 1

DI 2

t

1

t

2

3.5.5 3-point step operation

Operating mode 5

If only digital input DI 1 is active, the actuator opens. If

only digital input DI 2 is active, the actuator closes.

If neither of the digital inputs or both digital inputs are

active simultaneously, the actuator stops in its position.

This means that it can be stopped in any position.

The actuator operates in continuous mode and is con-

trolled via a 3-point step signal. The setting function is

limited by the “low” and “high” positions (“low” position

may also be 0° = “closed” position).

The opening speed is preset via the time t

for the entire

1

“low” to “high” setting travel. Accordingly, the closing

speed is set with t2 for the entire “high” to “low” setting

travel.

t [s]

t [s]

Possible parameter sets for this operating mode:

P68012, P68013, P68014, see page 45 (Parameter

sets).

DI 1 DI 2 Reaction

Off Off Idle/Stop

On Off

Off On Close to “low” position (“closed” position) at min.

On On Idle/Stop

Open to “high” position at max.

This method of control is frequently used on furnaces

and kilns in the sector of ceramics, steel and aluminium.

IC 40 · Edition 07.18 20

Page 21

Function

▼

t

1

t

2

t

3

high

middle

low

closed

DI 1

DI 2

Operating mode 6

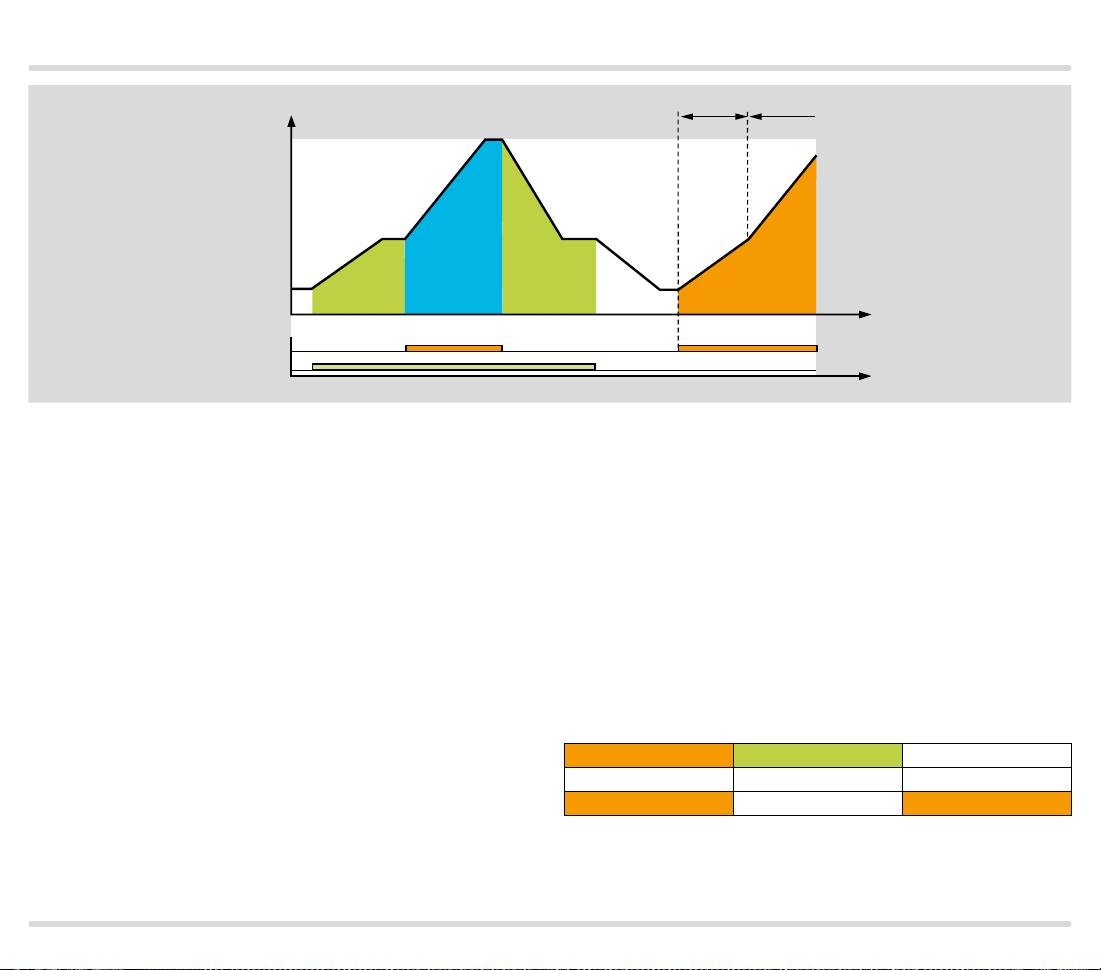

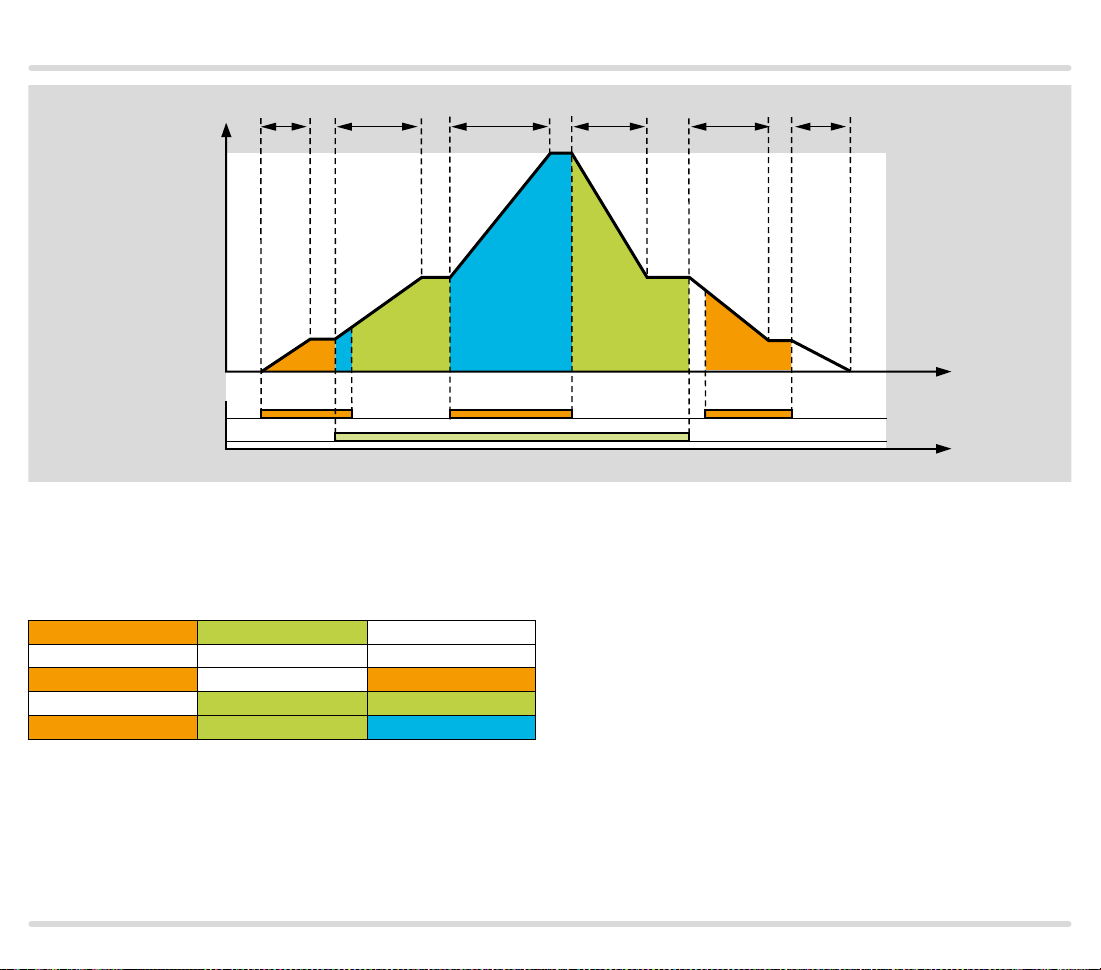

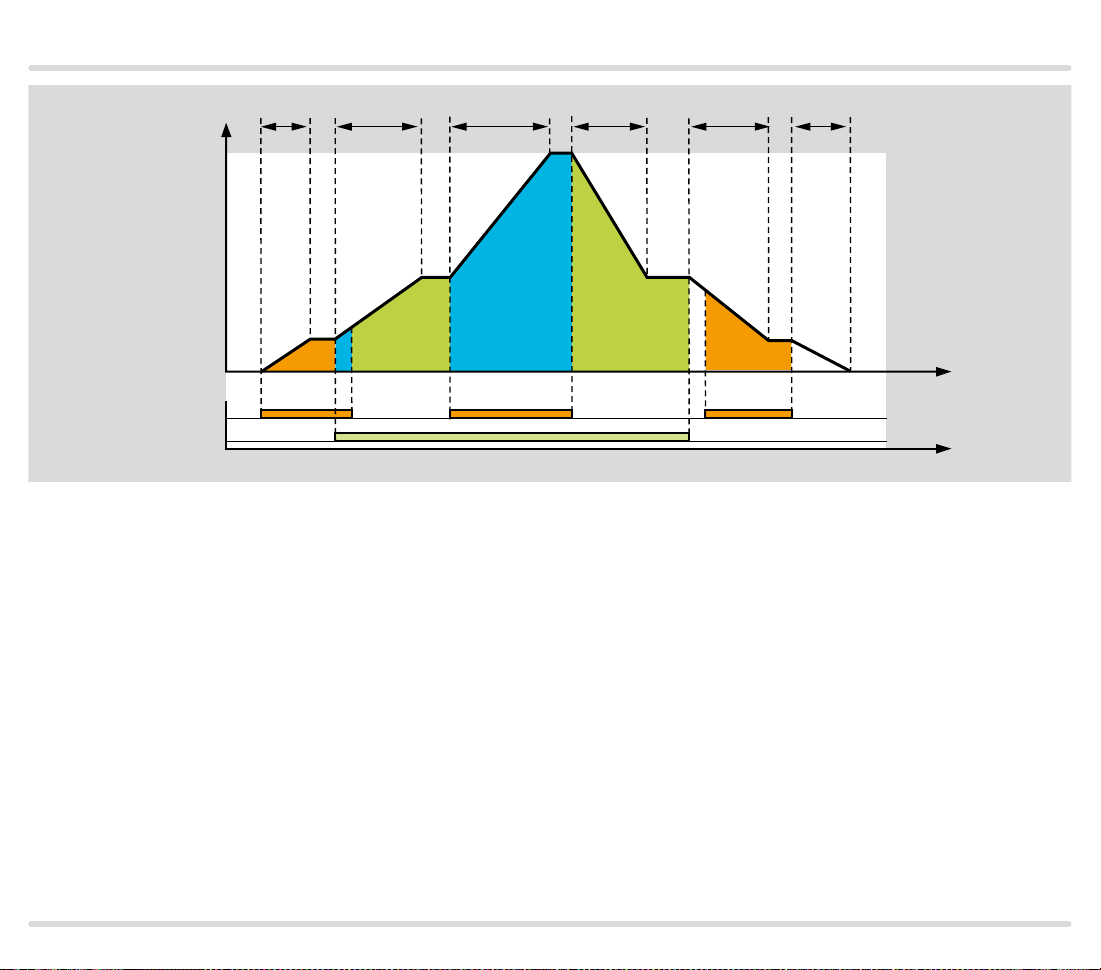

3.5.6 3-stage operation with one or two digital inputs

Operating mode 6

Each of the 4 circuit combinations resulting from DI 1

and DI 2 determines precisely one actuator position:

DI 1 DI 2 Position

Off Off closed

On Off low

Off On middle

On On high

Each signal change results in a new position setpoint

for the actuator. If the signals overlap (see t2), the actuator moves towards “high”. If the signals do not overlap

(see t5), the actuator moves towards “closed”.

t

4

t

5

t

6

t [s]

t [s]

Various modes of operation can be implemented with

this operating mode.

Control via one digital input

DI 2 with no signal:

The actuator operates in low/closed intermittent mode

via digital input DI 1.

DI 1 with no signal:

The actuator operates in middle/low intermittent mode

via digital input DI 2.

IC 40 · Edition 07.18 21

Page 22

Function

t

1

t

2

t

3

high

middle

low

closed

DI 1

DI 2

Operating mode 6

DI 1 with continuous signal, for instance resulting from

inversion of the logic, see page 48 (Switching logic):

The actuator operates in high/low (high/closed) inter-

mittent mode via digital input DI 2 with two successive

running times up to 51 s (2 x 25.5 s).

DI 1 and DI 2 are connected in parallel:

The actuator operates with one signal in high/closed

intermittent mode with three successive running times

up to 76.5 s (3 x 25.5 s).

With three successive running times via interpolation

points, it is possible to change the opening characteristic of the butterfly valve. For example, the characteristic of the air circuit can be adapted to that of the gas

circuit.

t

4

t

5

t

6

t [s]

t [s]

Control via two digital inputs

If all possible combinations of the two inputs are used,

for instance by a PLC control system, it is possible to

implement high/middle/low/closed intermittent mode

(3 stages plus the “closed” position).

Possible parameter set for this operating mode:

P 68001, see page 45 (Parameter sets).

IC 40 · Edition 07.18 22

Page 23

t [s]

Function

▼

t

1

t

2

high

middle

low

closed

DI 1

DI 2

Operating mode 7

3.5.7

2-point operation with switchover o f the adjustment

angle for the “open” position

Operating mode 7

In idle state (DI 1 and DI 2 with no signal), the actuator is in “low”

position (“low” position may also be 0° = “closed” position).

Digital input DI 1 functions as a pulse input.

DI 2 has no signal:

The actuator operates in high/low (high/closed) inter-

mittent mode via digital input DI 1.

Signal at DI 2:

The actuator can switch over its intermittent mode be-

tween high/low (high/closed) and middle/low (middle/

closed) during ongoing operation.

The adjustment angle for the “open” position is then ap-

proached with signal at DI 1 and switched over via DI 2.

t [s]

The actuator now operates in middle/low (middle/

closed) intermittent mode via digital input DI 1.

The heat output can now be reduced and it is never-

theless possible to continue operation in intermittent

mode so as to ensure a uniform temperature distribution. High/low may also be used for purging and middle/low may also be used for heating mode in order to

reduce the pre-purge time, for instance.

DI 1 DI 2 Position

Off Off low/closed

On Off high

Off On low/closed (DI 1 has priority)

On On middle

IC 40 · Edition 07.18 23

Page 24

Function

t

1

t

2

high

middle

low

closed

DI 1

DI 2

Operating mode 7

The opening speed is preset via the running time t1 for

the entire “low” to “high” setting travel. Accordingly, the

closing speed is set with t2 for the entire “high” to “low”

setting travel. The speeds are retained when switching

with reduced capacity (signal at DI 2). The running time

is shortened in accordance with the reduced position.

Alternative function (2-stage operation with constant

speed):

DI 1 DI 2 Position

Off Off low/closed

On Off high

Off On low/closed (DI 1 has priority)

On On middle

t [s]

t [s]

For as long as a signal is applied to DI 1, DI 2 switches

to and fro between “high” and “middle” position. In this

case, it may be practical to invert the logic of digital input DI 2, see page 48 (Switching logic).

This mode of operation ensures that the actuator al-

ways opens or closes at constant speed.

Possible parameter set for this operating mode:

P 68023, see page 45 (Parameter sets).

IC 40 · Edition 07.18 24

Page 25

Function

t

1

t

2

high

middle

low

closed

DI 1

DI 2

Operating mode 8

3.5.8 2-point operation with input-dependent adjustment angle for the “open” position

Operating mode 8

The function corresponds to operating mode 7 apart

from the fact that both digital inputs function as pulse

inputs.

The actuator operates in high/low (high/closed) inter-

mittent mode via digital input DI 1 and operates in middle/low (middle/closed) mode via DI 2.

A signal at DI 1 (priority) always leads to approaching

“high” position which can be used to purge the furnace

or kiln, for instance.

t [s]

t [s]

DI 1 DI 2 Position

Off Off low/closed

On Off high

Off On middle

On On high (DI 1 has priorit y)

Alternative function: 2-stage operation with constant

speed.

For as long as a signal is applied to DI 2, DI 1 switches

to and fro between “high” and “middle” position.

This mode of operation ensures that the actuator al-

ways opens or closes at constant speed.

Possible parameter set for this operating mode:

P68024, see page 45 (Parameter sets).

IC 40 · Edition 07.18 25

Page 26

Function

t

1

t

2

high

low

closed

DI 1

DI 2

Operating mode 9

3.5.9

2-point operation with switchover of the running

times

Operating mode 9

Digital input DI 1 functions as a pulse input.

The actuator operates in high/low (high/closed) inter-

mittent mode via digital input DI 1.

In idle state (DI 1 with no signal), the actuator is in “low”

position (“low” position may also be 0° = “closed” position).

DI 1 Position

Off low/closed

On high

t

3

t

4

t [s]

t [s]

The running times are switched over via DI 2.

DI 2 Opening time Closing time

Off t

On t

1

3

Switchover of the running times may also occur during

movement of the actuator.

This function can also be used for fast movement to the

pre-purge position, for instance, with correspondingly

slow running time for burner operation.

Possible parameter set for this operating mode:

P 68025, see page 45 (Parameter sets).

t

2

t

4

IC 40 · Edition 07.18 26

Page 27

Function

▼

high

t

t

1

2

t

t

3

4

middle

{

low

closed

DI 1

DI 2

Operating mode 10

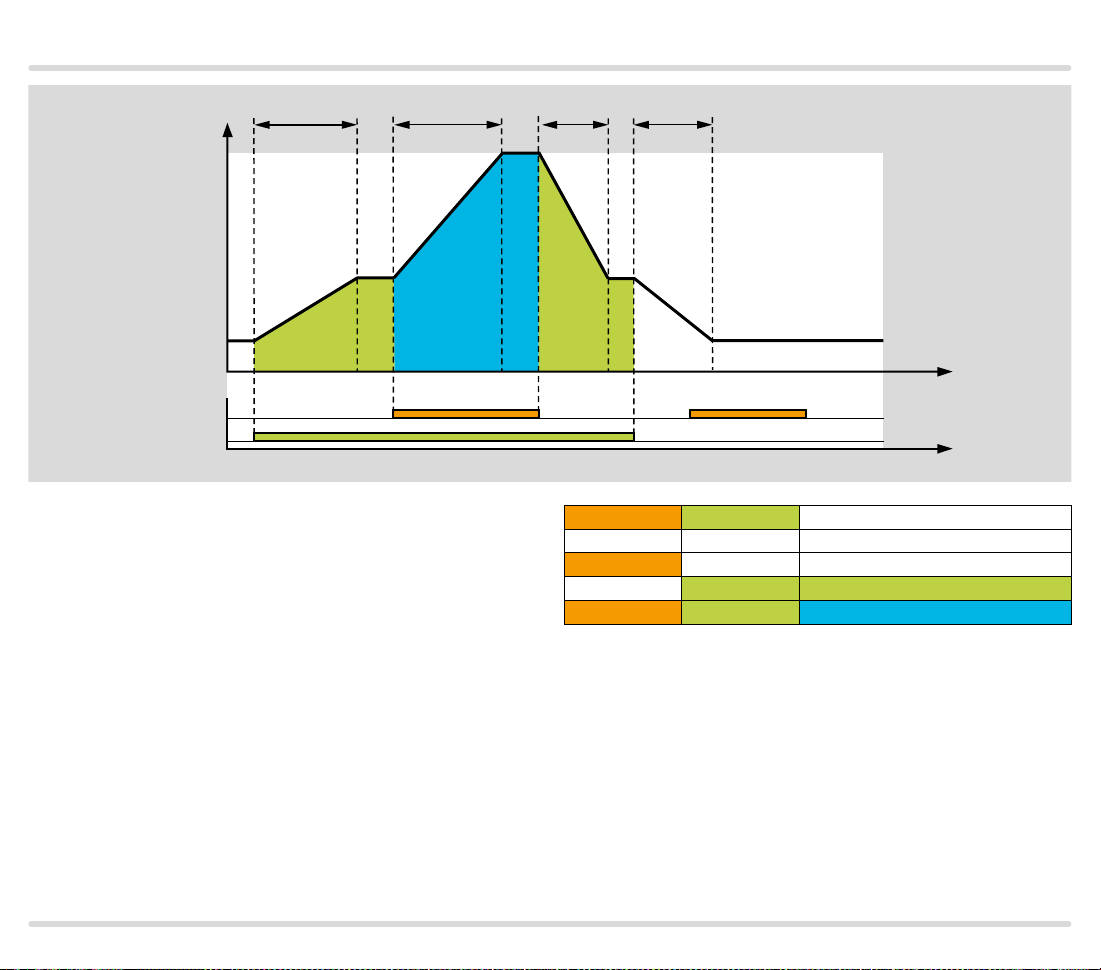

3.5.10 3-point step operation with running time fractions

Operating mode 10

If only digital input DI 1 is active, the actuator opens. If

only digital input DI 2 is active, the actuator closes.

If neither of the digital inputs or both digital inputs are

active simultaneously, the actuator stops in its position.

The actuator can be stopped in any position.

The actuator operates in continuous mode and is con-

trolled via a 3-point step signal.

The setting function is limited by the “low” and “high”

positions (“low” position may also be 0° = “closed” position).

t [s]

t [s]

DI 1 DI 2 Reaction

Off Off Idle/Stop

On Off Open to “high” position at max.

Off On Close to “low” position (“closed” position) at min.

On On Idle/Stop

IC 40 · Edition 07.18 27

Page 28

Function

high

t

t

1

2

t

t

3

4

middle

{

low

closed

DI 1

DI 2

Operating mode 10

The opening time results from the two successive run-

ning times t1 and t2.

The closing time results accordingly from running times

t

and t4. “Middle” position is used as an interpolation

3

point. This can be defined individually.

Owing to the two successive running times, the opening characteristic of the butterfly valve can be changed.

For example, the characteristic of the air circuit can be

adapted to that of the gas circuit.

Running times up to 51 s (2 x 25.5 s) are possible in this

operating mode.

t [s]

t [s]

Possible parameter sets for this operating mode:

P68010, P68011 and P68020, see page 45 (Parameter sets).

IC 40 · Edition 07.18 28

Page 29

Function

t

1

t

2

t

3

high

middle

low

closed

DI 1

DI 2

Operating mode 11

3.5.11 3-stage operation with two digital inputs

Operating mode 11

In idle state (DI 1 and DI 2 with no signal), the actuator

is in “closed” position and the butterfly valve is closed.

If a signal is applied to DI 1 (DI 2 with no signal), the

butterfly valve moves to “low” position (ignition position

and low-fire rate position).

If a signal is applied to DI 2 (DI 1 with no signal), the

butterfly valve moves to “high” position for pre-purge.

If a signal is applied to DI 1 and DI 2, the butterfly valve

moves to “middle” position (high-fire rate).

t

4

t

5

t

6

t [s]

t [s]

DI 1/ V1 DI 2/air valve IC 40 Position Valve position

Off Off closed Closed

On Off low Ignition position/low-fire rate

On On middle High-fire rate

Off On high Pre-purge

Example of application, see page 8 (Staged control

with pre-purge).

IC 40 · Edition 07.18 29

Page 30

Function

t

1

t

2

high

middle

low

closed

DI 1

DI 2

Operating mode 12

3.5.12 3-point step operation with low position

Operating mode 12

If a three-point step signal is applied to DI 1 (DI 2 with

no signal), the butterfly valve moves to “high” position.

If a three-point step signal is applied to DI 2 (DI 1 with

no signal), the butterfly valve moves to “middle” position.

If no three-point step signal is applied to the inputs

(DI 1 and DI 2 with no signal), the actuator stops and

the butterfly valve remains in its current position.

If a three-point step signal is applied to inputs DI 1 and

DI 2, the actuator moves from the low-fire rate position

to “low” position.

t

1

t [s]

t [s]

DI 1 DI 2 IC 40 position Valve position

Off Off Idle/Stop Idle

On Off Open to high position Open to high-fire rate

Off On Close to middle position Close to low-fire rate

On On low Valve closes further

Example of application, see page 7 (Continuous

control by three-point step signal).

IC 40 · Edition 07.18 30

Page 31

t

t

Function

▼

1

high

analogue

low

closed

DI 1

Operating mode 21

3.6 Analogue operating modes 21 – 27

General description, see page 13 (Operating modes).

3.6.1 2-point operation

Operating mode 21

In idle state (DI 1 with no signal), the actuator is in “low”

position (“low” position may also be 0° = “closed” position).

If a signal is applied to digital input DI 1, the actuator moves to the position preset via analogue input

4–20 mA. When the signal at DI 1 drops, the actuator

moves back to “low” position.

The actuator operates in analogue/low (analogue/

closed) intermittent mode, whereby the analogue signal

determines the adjustment angle for the “open” posi-

2

t [s]

t [s]

tion (= setpoint). The adjustment angle for the “open”

position, which can be varied via the analogue signal, is

set in BCSoft.

Example: 4 mA for 60% opening and 20 mA for 100%

opening. If no analogue value is preset, the actuator remains in “low” position (“closed” position).

DI 1 Position

Off low/closed

On analogue

The opening speed is preset via the time t1 for the entire

“low” to “high” setting travel. Accordingly, the closing

speed is set with t2 for the entire “high” to “low” setting

travel.

IC 40 · Edition 07.18 31

Page 32

t [s]

Function

T

t

t

1

2

analogue

high

low

closed

DI 1

Operating mode 21 with prolonged running time

The “high” position can be selected correspondingly

lower in order to obtain longer running times (> 25.5 s).

The “high” position does not limit the adjustment angle

for the “open” position but defines only the speeds here.

Consequently, the “high” position may also be lower

than the “analogue” position. The magnitude of the current signal is crucial as regards the “analogue” position.

t [s]

Example for double running time T:

The “high” position is set to 50%.

1

100 %

high

100 %

50%

T = t

T = 25.5 s

T = 51 s

Possible parameter set for this operating mode:

P68026, see page 45 (Parameter sets).

Note:

The running time can be prolonged up to max. 150 s for

the full adjustment range 0–90°. Running times outside of this permitted range are adapted automatically

by BCSoft.

IC 40 · Edition 07.18 32

Page 33

Function

▼

t

1

t

2

high

analogue

{

low

closed

DI 1

DI 2

Operating mode 22

3.6.2 2-point operation with switchover of the adjustment angle for the “open” position

Operating mode 22

In idle state (DI 1 and DI 2 with no signal), the actuator

is in “low” position independently of the analogue signal

(“low” position may also be 0° = “closed” position).

Signal at DI 1, DI 2 with no signal:

The actuator operates in high/low (high/closed) inter-

mittent mode via digital input DI 1.

Digital input DI 1 functions as a pulse input.

Signal at DI 2:

Intermittent mode can switch in ongoing operation

between high/low (high/closed) and analogue/low

(analogue/closed). The adjustment angle for the “open”

t [s]

t [s]

position is then approached with signal at DI 1 and

switched over via DI 2. The actuator now operates in

analogue/low (analogue/closed) intermittent mode via

digital input DI 1.

The adjustment angle for the “open” position, which can

be varied via the analogue signal (position setpoint), is

set in BCSoft.

Example: 4 mA for 60% opening and 20 mA for 100%

opening.

IC 40 · Edition 07.18 33

Page 34

Function

t

1

t

2

high

analogue

{

low

closed

DI 1

DI 2

Operating mode 22

Depending on the adjustment angle for the “open”

position, the heat output can be reduced and a uniform

temperature distribution in the furnace or kiln can be

achieved nevertheless owing to intermittent operation

of the burner.

DI 1 DI 2 Position

Off Off low/closed

On Off high

Off On low/closed

On On analogue

t [s]

t [s]

The speeds are retained in both intermittent modes.

The running times are changed accordingly if the “ana-

logue” position (current signal) is moved. The “analogue”

position may also be higher than the “high” position in

this operating mode.

Possible parameter set for this operating mode:

P 68027, see page 45 (Parameter sets).

The opening speed is preset via the time t1 for the entire

“low” to “high” setting travel.

Accordingly, the closing speed is set with t

tire “high” to “low” setting travel.

IC 40 · Edition 07.18 34

for the en-

2

Page 35

Function

Operating mode 23

high

analogue

low

closed

DI 1

DI 2

t

1

{

t

2

3.6.3 2-point operation with input-dependent adjustment angle for the “open” position

Operating mode 23

The function corresponds to operating mode 22 apart

from the fact that both digital inputs function as pulse

inputs.

The actuator operates in high/low (high/closed) inter-

mittent mode via digital input DI 1.

The actuator operates in analogue/low (analogue/

closed) intermittent mode via digital input DI 2.

A signal at DI 1 (priority) always leads to approaching

“high” position. This application can be used for purging

a furnace or kiln, for instance.

The adjustment angle for the “open” position, which can

be varied via the analogue signal, is set in BCSoft.

Example: 4 mA for 60% opening and 20 mA for 100%

opening.

t [s]

t [s]

Depending on the adjustment angle for the “open” position, the heat output can be reduced and a uniform

temperature distribution in the furnace or kiln can be

achieved nevertheless owing to intermittent operation

of the burner. The “high” position may also be lower

than the “analogue” position in this case.

DI 1 DI 2 Position

Off Off low/closed

On Off high

Off On

On On high (DI 1 has priority)

analogue

Possible parameter set for this operating mode:

P68028, see page 45 (Parameter sets).

IC 40 · Edition 07.18 35

Page 36

Function

▼

t

1

t

2

high

analogue

{

low

closed

DI 1

DI 2

Operating mode 24

3.6.4

2-point operation with switchover of the running

times

Operating mode 24

Digital input DI 1 functions as a pulse input. The actuator operates in analogue/low (analogue/closed) intermittent mode via DI 1.

In idle state (DI 1 with no signal), the actuator is in “low”

position (“low” position may also be 0° = “closed” position).

The adjustment angle for the “open” position, which can

be varied via the analogue signal, is set in BCSoft.

Example: 4 mA for 60% opening and 20 mA for 100%

opening.

t

3

t

4

t [s]

t [s]

Depending on the adjustment angle for the “open” position, the heat output can be reduced and a uniform

temperature distribution in the furnace or kiln can be

achieved nevertheless owing to intermittent operation

of the burner.

DI 1 Position

Off low/closed

On analogue

IC 40 · Edition 07.18 36

Page 37

Function

t

1

t

2

high

analogue

{

low

closed

DI 1

DI 2

Operating mode 24

The running times are switched over via DI 2.

DI 2 Opening time Closing time

Off t

On t

The running times can also be switched over in ongoing

operation.

The “high” position can be selected correspondingly

lower in order to obtain longer running times (> 25.5 s).

The “high” position does not limit the adjustment angle

for the “open” position but only defines the speeds.

Consequently, the “high” position may also be lower

than the “analogue” position. The magnitude of the current signal is crucial as regards the “analogue” position.

1

3

t

2

t

4

t

3

t

4

t [s]

t [s]

Possible parameter set for this operating mode:

P68029, see page 45 (Parameter sets).

IC 40 · Edition 07.18 37

Page 38

Function

▼

t

1

high

analogue

chart 1

analogue

chart 2

low

closed

DI 1

DI 2

Operating mode 25

3.6.5 2-point operation with characteristic curve switchover I

Operating mode 25

In idle state (DI 1 and DI 2 with no signal), the actuator is in “low” position (“low” position may also be 0° =

“closed” position).

DI 1 functions as a pulse input. The analogue characteristic curve (analogue chart 1/analogue chart 2)

is switched over via DI 2 and the adjustment angle for

the “open” position is preset by this. This angle is approached with signal at DI 1.

DI 2 with no signal:

The actuator operates in analogue chart 1/low (ana-

logue chart 1/closed) intermittent mode via digital input DI 1.

t

2

t [s]

t [s]

Signal at DI 2:

The actuator operates in analogue chart 2/low (ana-

logue chart 2/closed) intermittent mode via digital

input DI 1.

This function allows the actuator to switch over its in-

termittent mode in ongoing operation. The adjustment

angle for the “open” position is preset via two characteristic curves (charts), each with 5 interpolation points,

see page 48 (Inputs). This allows the same current

signal to be used for running through two different capacity ranges, for example for lambda adjustment or for

hot-air compensation.

IC 40 · Edition 07.18 38

Page 39

Function

t

1

t

2

high

analogue

chart 1

analogue

chart 2

low

closed

DI 1

DI 2

Operating mode 25

The adjustment angles for the “open” position of the

characteristic curves chart 1 and chart 2 can be set

mutually independently. The adjustment angle for the

“open” position of chart 2 may thus also be higher than

that of chart 1.

The burner continues to be operated in intermittent

mode so as to ensure a uniform temperature distribution even with low heat output.

DI 1 DI 2 Position

Off Off low/closed

On Off analogue chart 1

Off On

On On analogue chart 2

low/closed

The opening speed is preset via the time t1 for the entire

“low” to “high” setting travel.

t [s]

t [s]

Accordingly, the closing speed is set with t

for the en-

2

tire “high” to “low” setting travel.

The speeds are retained in both intermittent modes.

The “high” position can be selected correspondingly

lower in order to obtain longer running times (> 25.5 s).

The “high” position does not limit the adjustment angle

for the “open” position but only defines the speeds. The

adjustment angles for the “open” position are preset by

the current signal.

Consequently, “high” position may also be lower than

the “analogue chart” positions. If no analogue value is

preset, the actuator remains in “low” position (“closed”

position).

Possible parameter set for this operating mode:

P68030, see page 45 (Parameter sets).

IC 40 · Edition 07.18 39

Page 40

Function

▼

t

1

t

2

high

analogue

chart 1

analogue

chart 2

low

closed

DI 1

DI 2

Operating mode 26

3.6.6 2-point operation with characteristic curve switchover II

Operating mode 26

In idle state (DI 1 with no signal), the actuator is in “low”

position (“low” position may also be 0° = “closed” position).

Each circuit combination of DI 1 and DI 2 determines

precisely one actuator position:

DI 1 DI 2 Position

Off Off low/closed

On Off analogue chart 1

Off On high

On On analogue chart 2

t [s]

t [s]

“High” position may also be lower than the “analogue

chart” positions in this case. The opening speed is preset via the running time t

for the entire “low” to “high”

1

setting travel. Accordingly, the closing speed is set with

t2 for the entire “high” to “low” setting travel. The speeds

are independent of the digital inputs and the analogue

input in this case.

Two characteristic curves, each with 5 interpolation

points, are available, see page 48 (Inputs).

A change in the circuit combination directly triggers approach to the new position.

IC 40 · Edition 07.18 40

Page 41

Function

t

1

t

2

high

analogue

chart 1

analogue

chart 2

low

closed

DI 1

DI 2

Operating mode 26

This allows the same current signal to be used for run-

ning through two different capacity ranges, for example

for lambda adjustment or for hot-air compensation.

Intermittent operation

DI 2 with no signal:

The actuator operates in analogue chart 1/low (ana-

logue chart 1/closed) intermittent mode via digital input DI 1.

DI 1 with no signal:

The actuator operates in high/low (high/closed) inter-

mittent mode via digital input DI 2.

DI 1 and DI 2 simultaneously with ON or OFF signal:

The actuator operates in analogue chart 2/low (ana-

logue chart 2/closed) intermittent mode.

t [s]

t [s]

If all possible combinations of the two inputs are used,

for instance by a PLC control system, this allows high/

analogue chart 1/analogue chart 2/low (closed) intermittent mode to be implemented.

Continuous operation

The actuator may also operate in continuous mode via

the 4–20 mA current input. In this case, it is possible to

switch over between two characteristic curves via the

digital inputs, see page 48 (Inputs).

As with operating mode 25, this allows lambda adjustment or hot-air compensation to be implemented.

Possible parameter set for this operating mode:

P 68031, see page 45 (Parameter sets).

IC 40 · Edition 07.18 41

Page 42

Function

middle

closed

Operating mode 27

high

low

DI 1

DI 2

t

1

t

2

t

3

3.6.7 2-stage operation with two digital inputs and variable adjustment angle for the “open” position

Operating mode 27

In idle state (DI 1 and DI 2 with no signal), the actuator

is in “closed” position and the butterfly valve is closed.

If a signal is applied to DI 1 (DI 2 with no signal), the

butterfly valve moves to “low” position (ignition position

and low-fire rate position).

If a signal is applied to DI 2 (DI 1 with no signal), the

butterfly valve moves to “high” position for pre-purge

(high-fire rate).

If a signal is applied to DI 1 and DI 2, the butterfly valve

can be moved steplessly via the analogue input. The

possible adjustment range is between 0% and 100%.

The adjustment angle for the “open” position, which can

t

4

t

5

t

6

analogue

t [s]

t [s]

be varied via the analogue signal, is set in BCSoft.

Example: 4 mA for 60% opening and 20 mA for 100%

opening.

DI 1 DI 2 IC 40 position Valve position

Off Off closed Closed

On Off low

On On analogue chart 1 In acc. with chart 1

Off On high Pre-purge/high-fire rate

Ignition position/low-fire rate

Example of application, see page 9 (Continuous

control with defined ignition position).

IC 40 · Edition 07.18 42

Page 43

t [s]

t

t

t

Function

high

low

closed

DI 1

Power

Emergency closing function

1

2

S

t [s]

3.6.8 Emergency closing function

The emergency closing function cuts in in the event of

a fault or interruption of the continuous supply voltage

(power) or, for instance, in the event of a motor defect.

A pre-tensioned spiral spring turns the drive shaft with

valve disc to the “closed” position within the closing

time t

Fast and reliable closing prevents air being able to flow

into the furnace or kiln chamber in uncontrolled manner if the installation is disconnected from the electrical power supply or in the event of a device defect. The

penetration of air may also lead to damage to the material in the furnace or kiln in extreme cases, besides

changing the furnace or kiln atmosphere.

IC 40 · Edition 07.18 43

< 1 s.

S

In order to maximize the service life of the parts subject

to wear in the actuator and in the butterfly valve, the

emergency closing function should be used only for the

intended closing function and not for controlled shutdown or for intermittent switching of the burner.

The emergency closing function is available as an op-

tion on the actuator IC 40S and can be implemented

only in combination with the butterfly valve BVHS. Both

actuator and butterfly valve must feature this function,

see page 59 (Selection).

Page 44

Function

3.7 Parameters

Various parameter sets are saved in the BCSoft software to assist programming. Selecting a parameter set

preselects the corresponding operating mode and assigns practical values to all parameters which can be

set. Each parameter can be tailored to the individual

requirements of the installation

IC 40 · Edition 07.18 44

Page 45

Function

▼

3.7. 1 Parameter sets

Parameter set Operating mode Function

P68001 6 3-stage operation with one or two digital input s, running time: 6 s

P68010 10 3-point step operation with running time fractions, running time: 51 s

P68011 10 3-point step operation with running time fractions, running time: 30 s

P68012 5 3-point step operation, running time: 15 s

P68013 5 3-point step operation, running time: 7.5 s

P6 8014 5 3-point step operation, running time: 4.5 s

P68015 3 2-stage operation with one or two digital inputs, running time: 51 s

P68 016 3 2-stage operation with one or t wo digital inputs, running time: 30 s

P6 8017 1 2-point operation, running time: 15 s

P68018 1 2-point operation, running time: 7.5 s

P68019 1 2-point operation, running time: 4.5 s

P68020 10 3-point step operation with running time fractions , running time: 15 s

P68021 2 2-point operation with flame proving period, running time: 4.5 s

P68022 4 2-stage operation with two digital inputs, running time: 5 s

P68023 7 2-point operation with switchover of the adjustment angle for the “open” position, running time: 4.5 s

P6 8024 8 2-point operation with input-dependent adjustment angle for the “open” position, running time: 4.5 s

IC 40 · Edition 07.18 45

Page 46

Function

Parameter set Operating mode Function

P68025 9 2-point operation with switchover of the running times, running time: 4.5 s/15 s

P68026 21 2-point operation, running time: 7.5 s

P68027 22 2-point operation with switchover of the adjustment angle for the “open” position, running time: 7.5 s

P68028 23 2-point operation with input-dependent adjustment angle for the “open” position, running time: 7.5 s

P68029 24 2-point operation with switchover of the running times, running time: 4.5 s/15 s

P68030 25 2-point operation with characteristic curve switchover I, running time: 7.5 s

P68031 26 2-point operation with characteristic curve switchover II, running time: 7.5 s

IC 40 · Edition 07.18 46

Page 47

Function

3.7. 2 Factory default parameters

Factory default parameters are data saved permanently

in the unit. This includes motor data and calibration

data.

In addition, information on which parameter set was

preset in the condition as delivered is also saved in the

factory default parameters, see page 45 (Parameter

sets).

IC 40 · Edition 07.18 47

Page 48

Function

3.8 Inputs

3.8.1 Digital

In the basic setting, the two digital inputs operate as universal inputs. If a voltage of 24 V DC or

100–230 V AC is applied to the input, this is recog-

nized as “On” signal (positive logic).

Switching logic

The switching logic can be inverted for each individual

digital input. An applied voltage is then recognized as

“Off” signal while no voltage results in an “On” signal

(negative logic). Inversion of the input switching logic

in conjunction with the operating modes provides new

options for defining the behaviour of the actuator.

3.8.2 Analogue

The actuator can approach corresponding intermedi-

ate positions via a current signal to the additional input.

This function can be used only if an actuator IC 40 with

4–20 mA analogue input is connected (option). The

switch-on and switch-off threshold of the analogue input is defined at approx. 3 mA.

The assignment of current value to position can be free-

ly defined via 5 pairs of values (interpolation points).

Each of the interpolation points at 4, 8, 12, 16 and 20

mA can be assigned a position which the actuator approaches when the corresponding current signal is

applied. The position is interpolated on the basis of a

linear function in each case between the interpolation

points.

In the case of operating modes 25 and 26, 2 characteristic curves, each with 5 interpolation points, can be defined. In this case, the digital inputs define which characteristic curve currently applies. This allows the same

current signal to be used to run through two different

capacity ranges, for example for lambda adjustment

or for hot-air compensation, see page 38 (2-point

operation with characteristic curve switchover I) and

page 40 (2-point operation with characteristic curve

switchover II).

IC 40 · Edition 07.18 48

Page 49

Function

Filtering and hysteresis of the current signal

In order to suppress noise of the current signal, the analogue input is sampled equidistantly every millisecond

and a mean value is generated over 0.1 s. This filtering

can be prolonged up to 1 s in the case of a very poor

input signal. However, this also prolongs the response

time to a change at the analogue input.

The current input (4–20 mA) operates internally with a

resolution of 10 bit (corresponding to 0.1% of the actuator). This allows the analogue input to detect a change

of 0.02 mA (hysteresis).

If the input signal fluctuates too greatly (owing to noise,

for instance), this high resolution results in constant

corrections of the actuator and butterfly valve (when

mounted onto butterfly valve BV..).

Consequently, the hysteresis may be increased to up to

0.2 mA. The resolution in this case is reduced down to

1% of the actuator accordingly. The maximum resolu-

tion is always set in each case as the basic setting.

Priority and running time in operating modes 1 – 10

In operating modes 1 to 10, the actuator is positioned

(0–100%) by both digital inputs DI 1 and DI 2. Alternatively, on the IC 40A..A, there is the option of positioning

the actuator with a 4–20 mA current signal. Simultaneous presets via the analogue input and via the digital

inputs necessitate defining a priority in BCSoft. The

digital inputs have priority by default.

Opening speeds and closing speeds between 0 and

25.5 s can be set for analogue mode. The time always

relates to the distance between the positions at 4 and

20 mA. If the current signal changes more slowly than

the set running time, the actuator follows more slowly

accordingly through to step-by-step movement, see

page 14 (Running times).

IC 40 · Edition 07.18 49

Page 50

Function

3.9 Outputs

Various, independent signalling functions can be assigned to the two outputs RO 1 and RO 2: closed position, low position, middle position and high position,

fault signals and freely programmable positions.

2 relays with change-over contacts are available for signalling. The contacts are floating and are thus referred

to as dry contacts. They can be integrated in automation processes.

For instance, reaching the preset position can be signalled back as a signal function. The range in which the

output switches can be defined in BCSoft using the

relational operator. The range may be =, ≥ or ≤ the set

position. Thus, for instance, the behaviour of a cam disk

can be simulated.

Example for output 1 (RO 1): if the condition is met, the

output relay is energized. Terminals 10 and 12 are connected, see page 53 (Connection diagram).

The switching range can also be set individually via one

minimum value and one maximum value. These settings are independent of the selected low position, middle position or high position.

A feedback signal can also be used as a fault signal. In

BCSoft, it is possible to select what status is to lead to

setting of the output (relay energized).

Device defective:

An internal error, such as a fault in the memory chip,

leads to failure of the device.

Internal warning (reference switch):

Internal monitoring of the motor position has detected

a fault. Recalibrate!

Internal temperature > 90°C:

Warning! Attach heat deflectors.

Service note:

Number of cycles, changes of direction or relay switching operations greater than limit.

“Fault signals” also covers a “Device in Manual mode”

signal even though the signal is not actually a fault signal.

The precise cause of the signal is displayed in BCSof t

and saved in the statistics, see page 52 (Statistics).

The feedback signal of the IC 40 must not be used on

its own for fail-safe signalling of a status or a fail-safe

position, see page 60 (Project planning information).

IC 40 · Edition 07.18 50

Page 51

Function

3.10 Manual mode

For simplified commissioning, the actuator can be operated “by hand” via the BCSoft sof tware. Manual mode

is activated via BCSoft.

A distinction is made between two types of Manual

mode: Direct position preset and Simulate inputs. The

related setting options are enabled after the required

Manual mode is selected.

The exterior, applied input signals have no effect on

the control element in both Manual operating modes.

Instead, the device responds to the presets from the

software.

Fast flashing of the blue LED indicates that the actuator is in Manual mode.

Only one Manual mode may be activated at any one

time. If the Manual mode is to be changed, the existing

Manual mode must first be deactivated before the other

Manual mode can be activated.

3.10.1 Direct position preset

This Manual mode serves to determine the operating

positions for the process, such as the low-fire rate (low)

position, the ignition (middle) position and the high-fire

rate (high) position.

For this purpose, the actuator can be moved to any position, regardless of the input signal. The position can

be entered or changed directly in BCSoft. The resolu-

tion is defined in ranges fine/medium/coarse, whereby

“fine” allows any step of the step motor (< 0.05%).

After transfer of the values from BCSoft to the actuator,

the actuator responds accordingly to the new presets.

The new position is always approached at maximum

speed in this case.

The operating position determined can be assigned in

BCSoft to a position, for example ignition position.

3.10.2 Simulate inputs

When this Manual mode is activated, the external inputs are deactivated. Instead, the signals of the two

digital inputs can be preset “manually”. If the actuator

has a 4–20 mA analogue input (option), this can also

be simulated.

Switching the inputs allows the behaviour of the actuator to be tested. This allows the set running times to be

checked and optimized in BCSoft.

IC 40 · Edition 07.18 51

Page 52

Function

3.11 Statistics

The statistical data stored in the unit, such as fault sig-

nals which have occurred, various counter readings and

measured values, is displayed in statistics in BCSoft.

The counters and measured values ranges are each

split into overall data and customer data. The customer

data is used for recording information over a specific

period.

3.11.1 Counters

Actuating cycles (0–100–0%), changes of direction

(Open/Close), switching of the output relays, “Power

On” switching operations and mains operating hours

are added in the statistics. Besides the total counters,

there are customer counters for recording information

over a specific period.

3.11.2 Measured values

The minimum and maximum internal housing tempera-

tures are saved in statistics. In addition, the current internal temperature is displayed. Here as well, there is a

customer memory for viewing a period.

3.11.3 Resetting statistics

All signals and customer data can be reset. The reset

date is saved automatically and displayed together with

the customer data.

Total counter and measured values cannot be reset or

deleted.

3.11.4 Resetting a signal

A fault signal is signalled by the red LED on the actuator.

The detailed cause of the signal is displayed in BCSoft.

The cause must be remedied. The signal can then be

acknowledged and reset with BCSoft.

IC 40 · Edition 07.18 52

Page 53

Function

3.12 Connection diagram

For detailed information on the

electrical connections, see page

see page 60 (Project planning

information). or on the technical data, see page 66 (Technical data).

IC 40 · Edition 07.18 53

Page 54

Function

▼

3.13 Display

3.13.1 During operation

Blue LED Red LED Operating state

Moderately flashing

Slow flashing

Lit Off Device in Standby mode

Moderately flashing

Fast flashing

Fast flashing

Lit Flashing depending on fault message Fault

Flashing alternately for 2 s

1)

Fast: 5 times per second, 2) moderately: 3 times per second,

3.13.2 Warnings and faults

2)

3)

2)

1)

1)

1)

Off Zero position

Slow flashing3) Calibration

Off Device in motion

Off Manual mode

Off Moving in Manual mode

Parameters accepted

3)

slow: once per second

Blue LED Red LED

According to

operating state

According to

operating state

According to

operating state

Flashing light (1×) 1 Warning Internal temperature > 90°C - High ambient temperature

Flashing light (2×) 4 Warning Drift > 5%

Flashing light (3×) 7 Warning Drift > 10%

BCSoft fault

code

Warning/fault Description Cause

- Mechanical valve offset

- Valve moving against its stop

- Mechanical valve offset

- Valve moving against its stop

- Valve blocked

According to

operating state

Flashing light (4×) 8 Warning Reference switch does not open

- Large mechanical offset

- Internal error

- Actuator offset

According to

operating state

According to

operating state

IC 40 · Edition 07.18 54

Flashing light (5×) 9 Warning Reference switch does not close

Flashing light (6×) 10 Warning Analogue input IN < 4 mA

- Valve blocked

- Internal error

- Actuator offset, mechanical offset

- Signal interrupted

- Signal not connected

- Input defective

Page 55

Function

Blue LED Red LED

According to

operating state

According to

operating state

According to

operating state

Flashing light (1×) Permanent light 5 Fault Internal fault - e.g. EEPROM reading or writing error

Flashing light (2×) Permanent light 11 Fault

Flashing light (3×) Permanent light 12 Fault

Flashing light (6×) Permanent light 30 Fault

Flashing light (7×) Permanent light 31 Fault Saving error: factory default parameters

Flashing light (8×) Permanent light 32 Fault Saving error: user calibration

Flashing light (9×) Permanent light 15 Fault Low voltage Check actuator mains voltage supply

Flashing light (7×) 21 Warning

Flashing light (8×) 22 Warning

Flashing light (9×) 23 Warning

BCSoft fault

code

Warning/fault Description Cause

Service note: number of OPEN/CLO SE

Service note: number of relay output RO

1 or RO 2 switching operations > limit

Saving error for adjustable parameters,

cycles > limit value

Service note: number of changes of

direction > limit value

value

Zero position check: reference switch

does not close

Zero position check: reference switch

does not open

etc.

- Valve blocked

- Internal error

- Actuator offset

- Valve not closed (BVHS)

- Valve blocked

- Internal error

- Actuator offset

IC 40 · Edition 07.18 55

Page 56

Function

3.14 Relay outputs RO 1 and RO 2 function

The function of digital outputs RO 1 and RO 2 can be adjusted using BCSoft.

Signal at RO 1 or RO 2 Further setting options Remarks

CLOSED position

Low-fire rate position (low)

Intermediate position (middle)

OPEN position (high)

Freely programmable position Minimum and maximum value [°,%]

Reference switch drift > 5%

Reference switch drift > 10%