Page 1

Storey

Controller

HCE 40

Installation and Operation

Page 2

Page 3

Contents

Contents

Overview 3

Application 3

Installation procedure 4

Creating zoning plan 4

Installing 4

Configuring and making electrical connections 4

Start-up 4

Creating zoning plan 5

Determining temperature zones 5

Filling out zoning plan 6

Installation 10

Wall installation 11

Installation on DIN rails 12

Installing storey controller components 12

Description 13

Layout of circuit board 13

LED indicators on storey controller 14

Operating modes of storey controller 15

Buttons on storey controller 17

Configuration and electrical connection 19

Opening housing 19

Branching out time programs 20

1

Page 4

Contents

Setting actuator 22

Switching between heating/cooling 23

Cabling connections 24

Start-up 35

Starting up storey controller 35

Start-up with central operating device 36

Assigning setpoint adjusters of type HCU 23 or HCW 23

to a zone 40

Removing assignment 40

Saving settings at central operating device 43

Checking installation 43

Completing start-up 44

Resetting storey controller to state of delivery 45

Appendix 46

Glossary 46

Help with problems 47

Overview of heating components 50

Zoning plan 51

2

Page 5

Overview

Overview

For your information

Technical terms are explained in the glossary (Page 46). They are

identified in the text by an *.

Application

The storey controller HCE 40 receives information on the temperature

of the room from the setpoint adjusters*, room temperature sensors of

type RF 20 or from the central operating device* HCM 100. The storey

controller uses this information to control the boiler feedback*, the

pump relay and the thermal actuators* (see "Overview of heating

components" Page 50).

The storey controller HCE 40 is hard-wired to setpoint adjusters of

type HCU 23 or HCW 23, room temperature sensors of type RF 20 or

the central operating device HCM 100.

It has a self-learning controller (fuzzy logic), which automatically

adjusts the control parameter according the installation conditions.

The desired room temperature is reached quickly and then

maintained.

3

Page 6

Overview

Installation procedure

Creating zoning plan

• Determining which heating circuits* are controlled by the storey

controller.

Installing

• Installing the components of the storey controller HCE 40.

Configuring and making electrical connections

• Setting the storey controller to the actuator type, attaching cables to

the respective connections and connect components together.

Start-up

• Assigning room names to the temperature-zones with the central

operating device HCM 100 if applicable.

4

Page 7

Creating zoning plan

Creating zoning plan

A temperature zone is an area of the building, e.g. a room, in which

the setpoint temperature* is set with a setpoint adjuster. The storey

controller controls all thermal actuators of a temperature zone

identically.

5 temperature zones can be set up for each storey controller.

3 actuators can be connected in each of 3 zones, and 2 actuators can

be connected in each of the remaining 2 zones.

The total number of actuators which can be controlled by a signal

storey controller is limited to 10.

Determining temperature zones

Damage caused by equipment from other manufacturers!

Caution!

► Group actuators (by type and location) which are controlled with the

storey controller.

► Group together all actuators which are controlled by a setpoint

adjuster in a temperature zone.

5

The storey controller was designed for use with

components from Honeywell only!

► Use only H 200 AG (normally closed) or H 200 AO

(normally open)-type actuators.

Page 8

Creating zoning plan

If more than 5 temperature zones or 10 actuators are present:

► Determine the number of additional storey controllers required using

the following table:

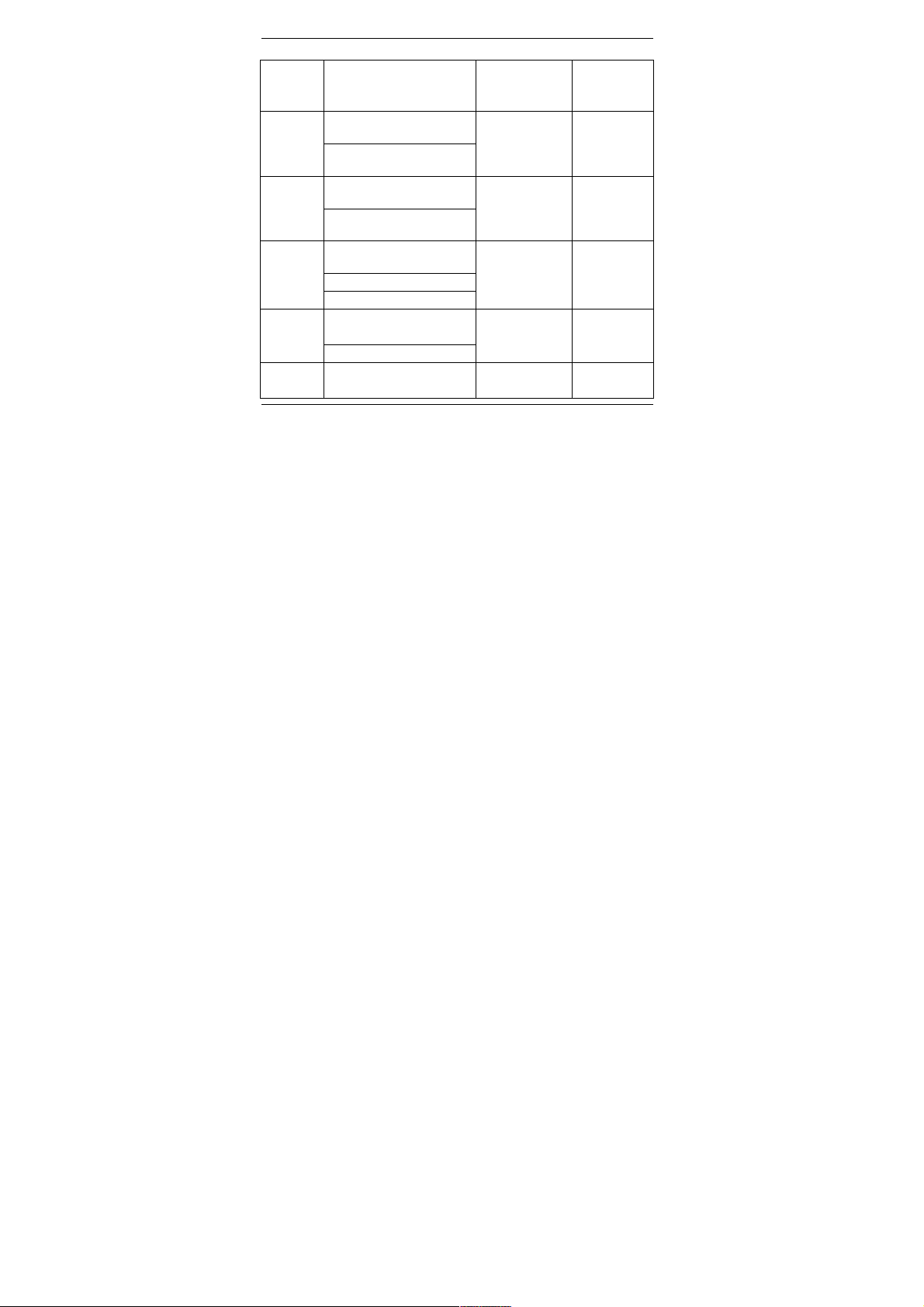

Temperature

zones (maximum)

Actuators

(maximum)

No. of storey

controller

5 10 1

10 20 2

15 30 3

Hint: The example at the end of this section shows zone divisions with

corresponding zoning plan.

Filling out zoning plan

► Copy the sample zoning plan ("Zoning plan" Page 51) (archive it).

► Enter the type and installation location of the respective actuator in

each temperature zone.

► Assign a setpoint adjuster or room temperature sensor to each

temperature zone.

► Assign room names if necessary.

► Hand over the zoning plan to the customer after installation.

6

Page 9

Creating zoning plan

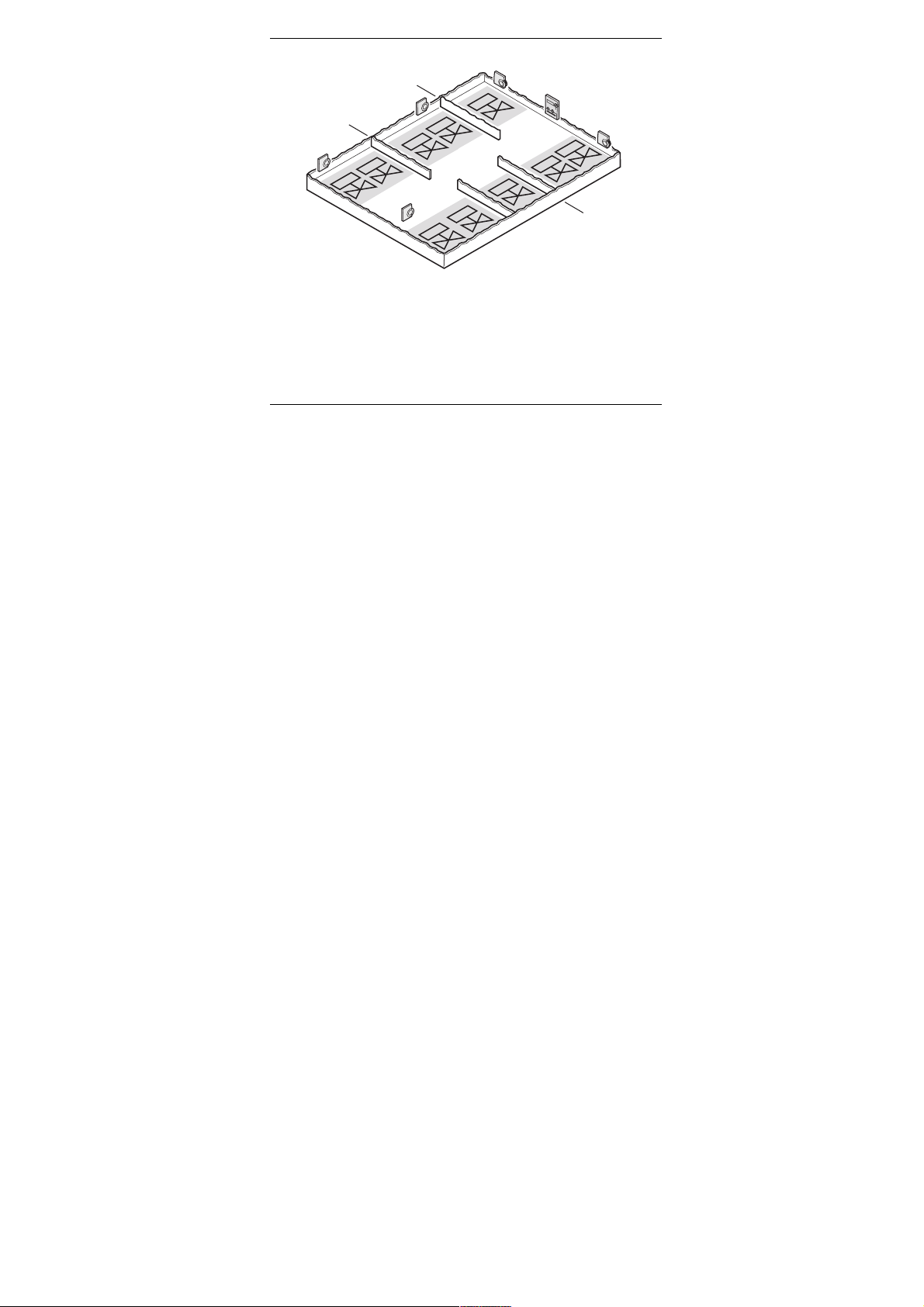

Example of zone divisions

Zone 5

Zone 1

Zone 2

Dining

Living

Bathroom

WC

Kitchen

Bedroom

Hall

Zone 4

Zone 3

This example shows:

• A home divided into five temperature zones.

• Bathroom and WC are controlled by one setpoint adjuster. One

temperature zone is sufficient for three actuators.

• The maximum number of actuators (10 per storey controller) is used

to the full with the storey controller.

7

Page 10

Creating zoning plan

The example yields the following zoning plan:

Temperature zone

Zone 1

Actuator

(type, location)

Heating loop 1

(living room)

Heating loop 2

Setpoint

adjuster

(location)

Room name

at operating

device

Living room "Living"

(living room)

Zone 2

Heating loop 1 (dining

room)

Heating loop 2 (dining

Dining room "Dining"

room)

Zone 3

Heating loop 1 (bathroom) "Bathroom/

Heating loop 2 (bathroom)

Heating loop 3 (WC)

Bathroom and

WC

WC"

Heating loop 1 (bedroom) Bedroom "Bedroom"

Zone 4

Heating loop 2 (bedroom)

Zone 5 Heating loop 1 (kitchen) Kitchen "Kitchen"

8

Page 11

Creating zoning plan

9

Page 12

Installation

Installation

The storey controller is sensitive to excessive

temperatures!

Caution!

► When selecting the location for operation, ensure

that the ambient temperature in that area does not

The storey controller was designed for installation in a distributor box.

exceed 50 °C.

If insufficient space is available there, select a location free of humidity

and moisture.

The storey controller can be installed in one of two ways:

• on the wall

• on DIN rails

Note the 82 mm installation height of the storey controller!

If the storey controller is installed at a severe angle, the

transformer must be on top to allow for better ventilation.

10

Page 13

Installation

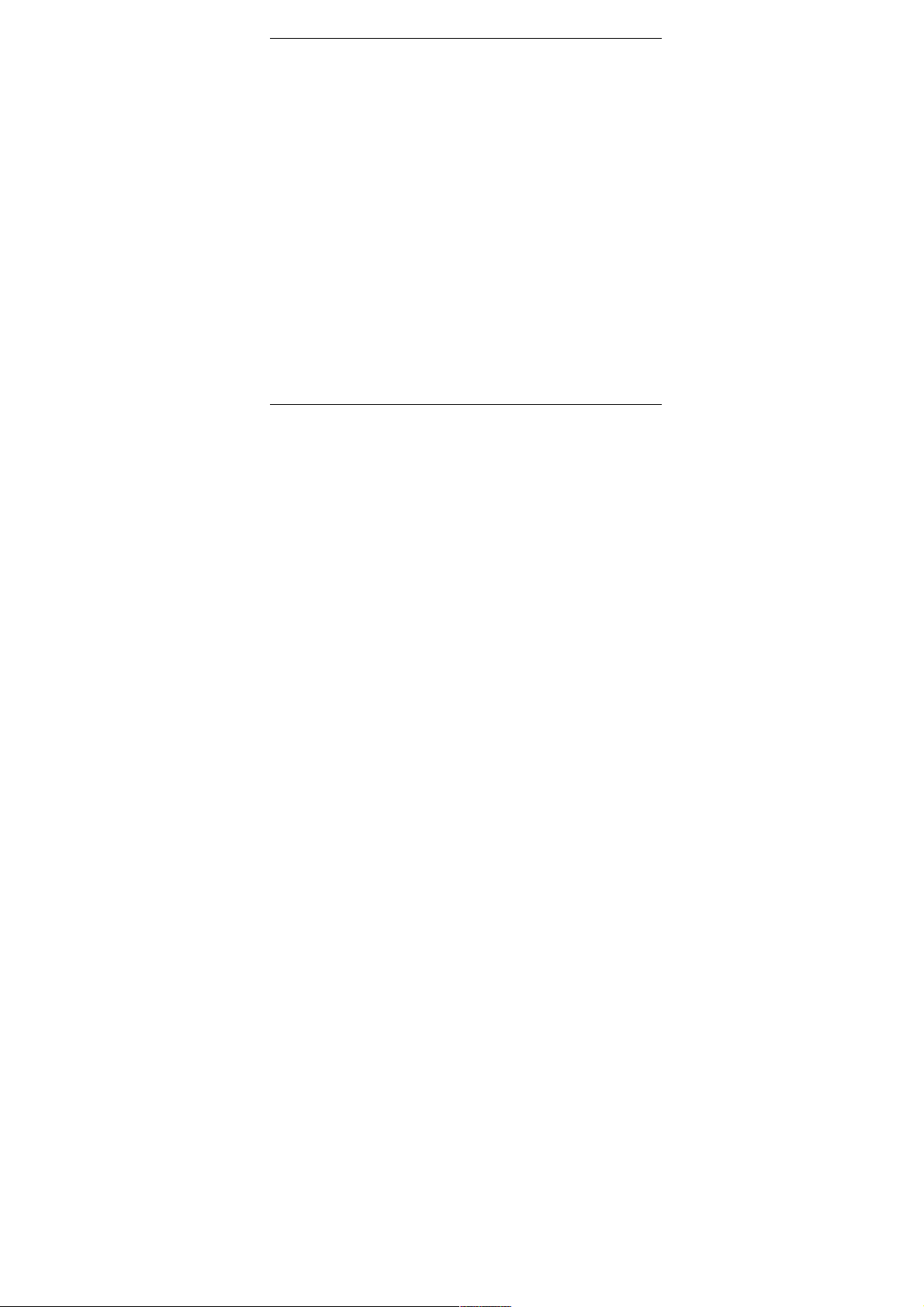

Wall installation

Four 4.2-mm holes for installation are located on the storey controller.

Dimensions of storey controller in mm

ø4.2

50

82

65

82

324

335

► Mark, drill and insert plugs into fastening holes.

► Screw on the storey controller.

11

Page 14

Installation

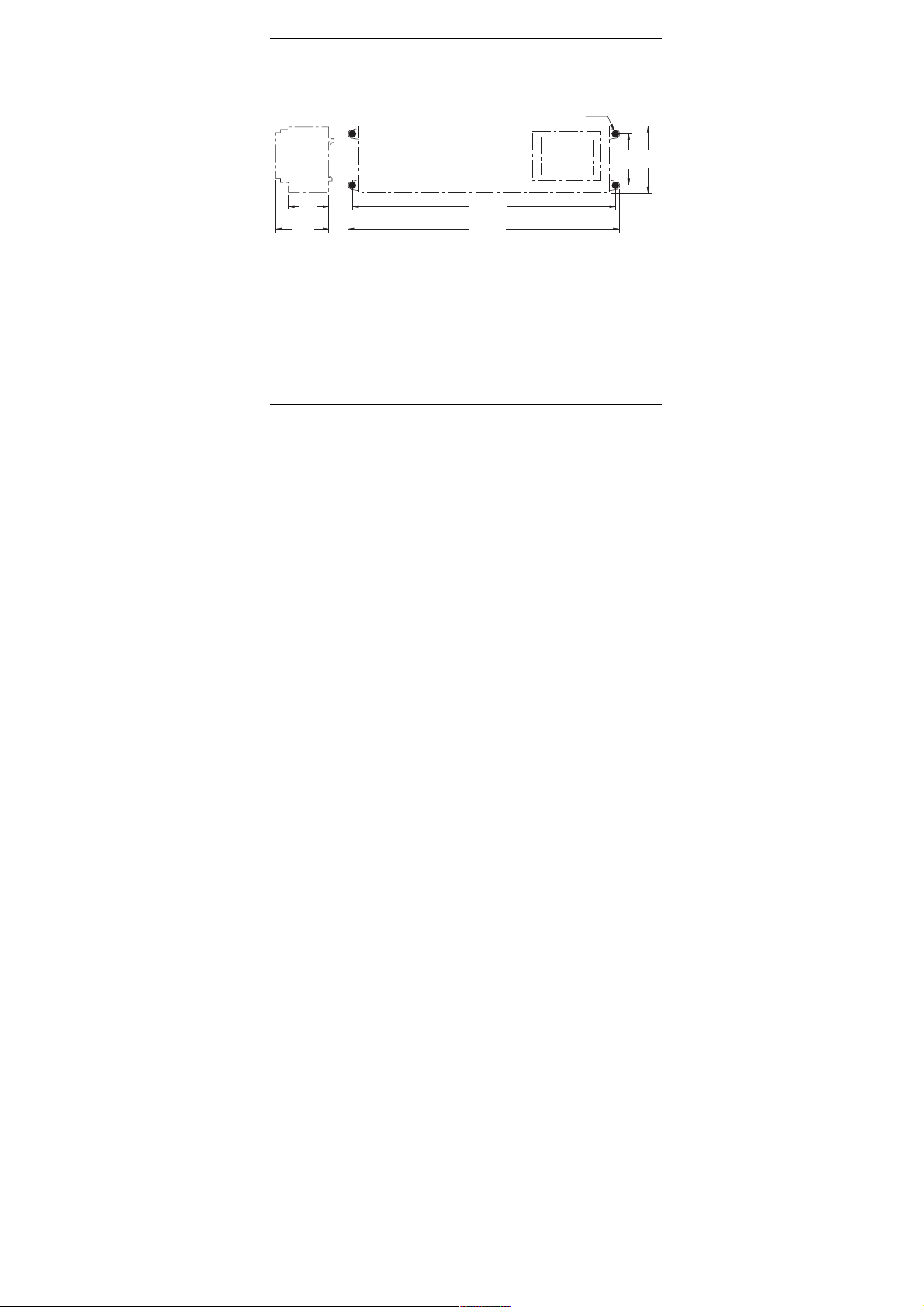

Installation on DIN rails

► Place housing on the

DIN rail from below (1).

► Press upper edge of

housing toward the

wall until it snaps into

place (2).

Á

À

Installing storey controller components

► Install components as described in the accompanying installation

instructions.

12

Page 15

Description

Description

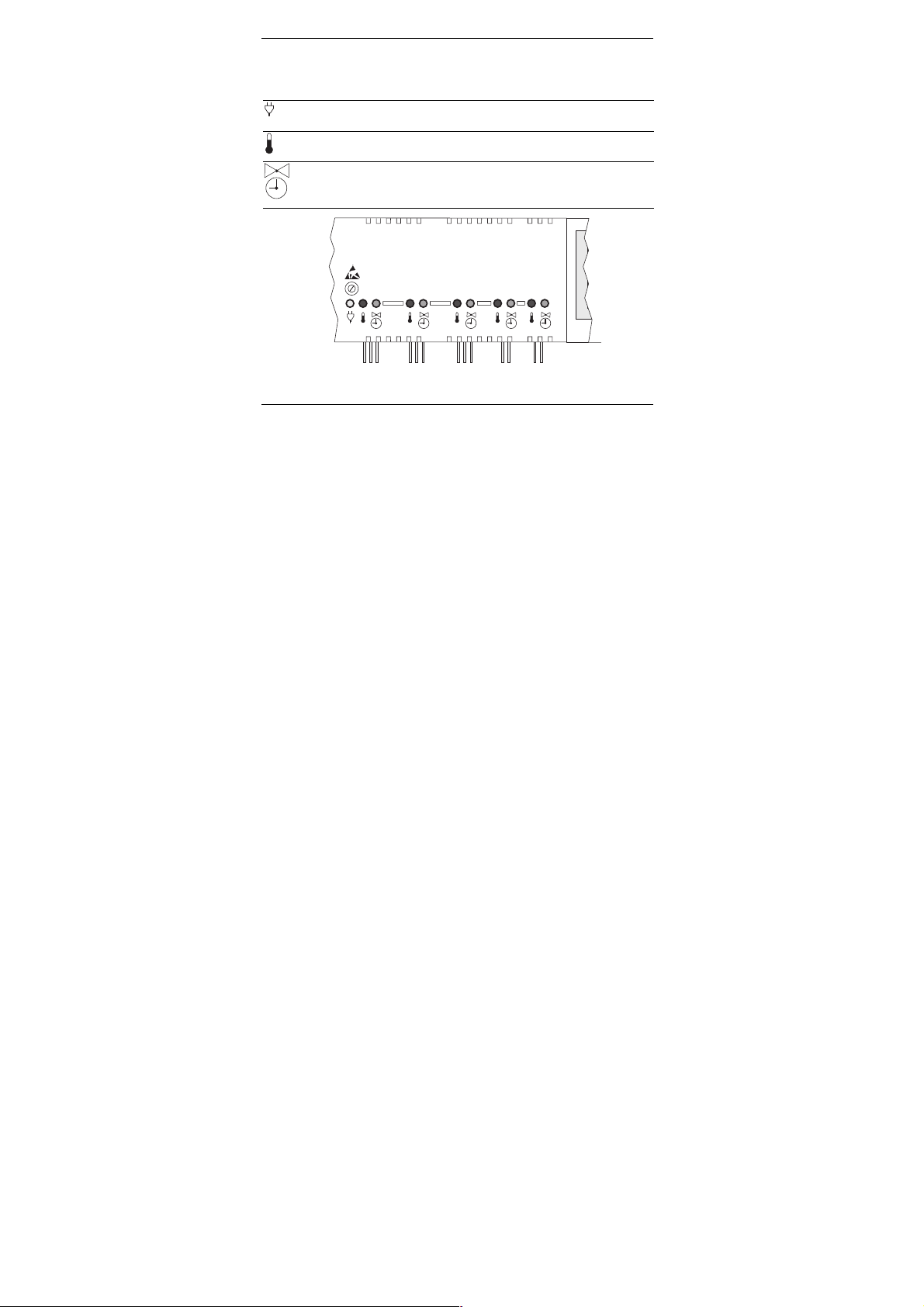

Layout of circuit board

1. Connector (1 to 12)

2. Connector (13 to 25)

3. Switch used to branch out

temperature zones (Page 20)

4. Switch used to configure the

actuators (Page 22)

5. Connection for temperature zone 5

6. Connection for temperature zone 4

7. Connection for temperature zone 3

8. Connection for temperature zone 2

9. Connection for temperature zone 1

10. Plug-in terminal for connection of a

potential-free heating/cooling

contact (Page 23)

Ã

Â

Á

À

13

14

15

16

17

18

19

20

21

1

22

2

23

3

24

4

25

5

6

7

8

9

10

11

12

13

É

È

0

Ç

C

Ä

Å

Æ

Page 16

Description

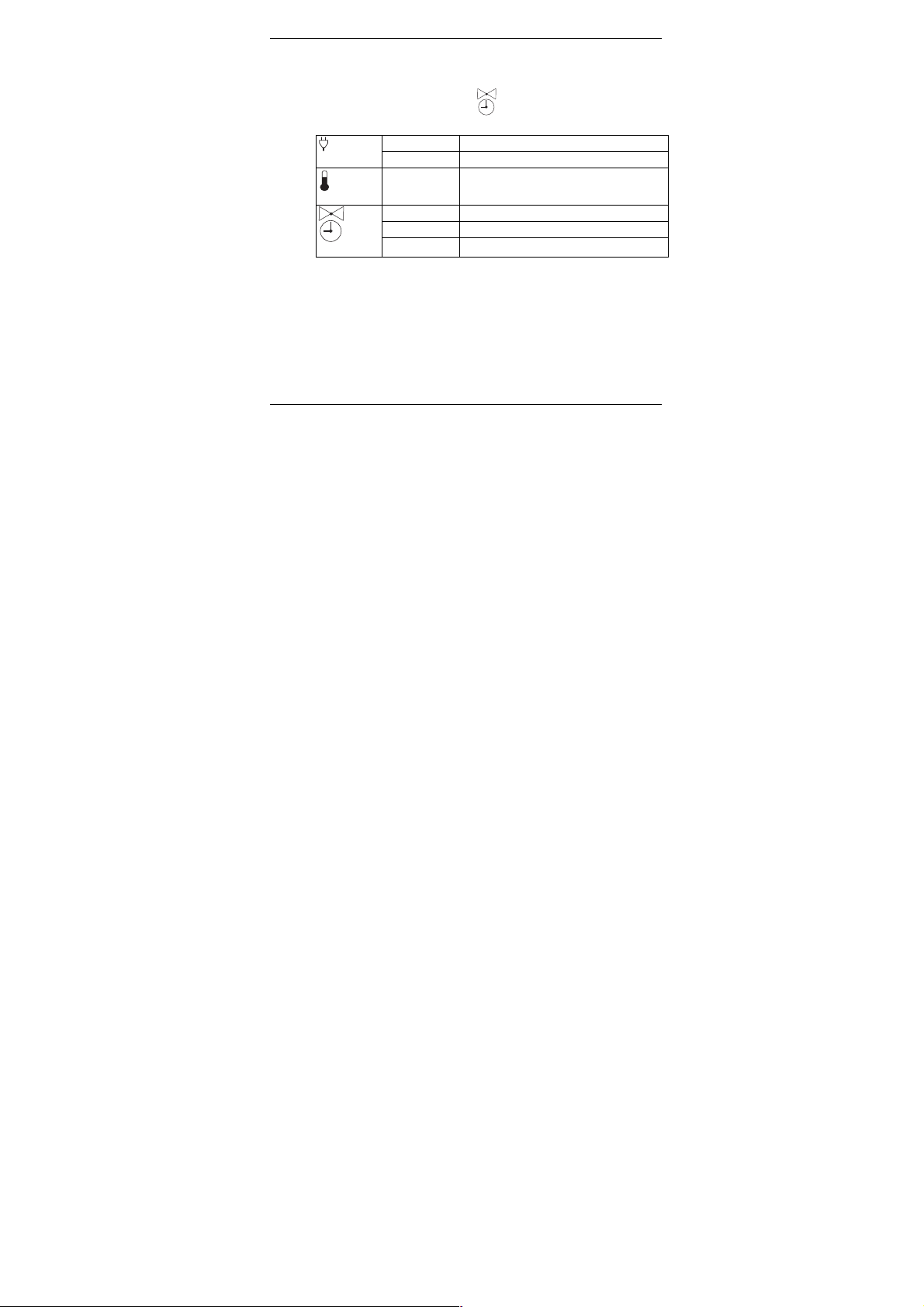

LED indicators on storey controller

The LEDs on the storey controller indicate the operating mode of the

storey controller and the installed temperature zones.

(green)

(red)

(green)

Normal mode /

Power-on indicator

Connected setpoint adjuster /

Fault indication: wire break or short circuit

Position of the actuators /

Assignment of temperature zones /

Fault indication: Faulty communication with HCM 100

14

Zone 1 Zone 2 Zone 3 Zone 4 Zone 5

Page 17

Description

Operating modes of storey controller

Normal mode

In normal mode the green LEDs

position of the actuators:

(green)

(red)

Illuminating Mains voltage connected

Off Mains voltage not connected

Flashing Room sensor or setpoint adjuster

provide information on the

connection faulty.

Illuminating Thermal actuator opened

Flashing Faulty communication with HCM 100

(green)

Off Thermal actuator closed

The setpoint adjusters HCW 23 or HCU 23 are clearly assigned via

the wiring of the temperature zones. The respective red LEDs do not

illuminate. If the red LED flashes anyway, the connection to the

setpoint adjuster has been interrupted, short circuited or an incorrect

resistance value was detected.

15

Page 18

Description

Installation mode

• In installation mode, temperature zones are assigned to the central

operating device.

Refer to Section "Start-up with central operating device" on

Page 36.

Device display (configuration button 1)

• The device display informs you of the configuration of your storey

controller system, i.e. the assignment of setpoint adjusters to the

temperature zones of room names at the central operating device.

Refer to Section "Checking installation" on Page 43.

16

Page 19

Description

Buttons on storey controller

• Configuration button (1):

Display of the assignment of

temperature zones to the central

operating device.

Selection of the temperature zone

which is to be assigned to the

central operating device or a

setpoint adjuster (see Button

check

installation

functions on Page 18).

• Delete button (2):

Removing the temperature zone

Button 2

Button 1

from the central operating device

or a setpoint adjuster (see Button

functions on Page 18).

17

Page 20

Description

Button functions

► Press the configuration

button (1) briefly.

The assignment of the storey

controller to the central operating

device, setpoint adjusters and room

temperature sensors is displayed.

The storey controller shows up in the

device display.

► Press the configuration

button (1) briefly once

more.

► Press the delete

button (2).

18

The green LED

illuminates if a

temperature zone is assigned to the

central operating device.

The red LED

illuminates if an RF

20, HCU 23 or HCW 23 is connected.

The display returns to normal mode

after 60 seconds.

The red LED

of temperature zone 1

flashes.

Installation mode is active.

The selected temperature zone is

removed (the LED flashes).

Page 21

Configuration and electrical connection

Configuration and electrical connection

► Unplug the power plug before opening the housing.

Damage to exposed components!

Caution!

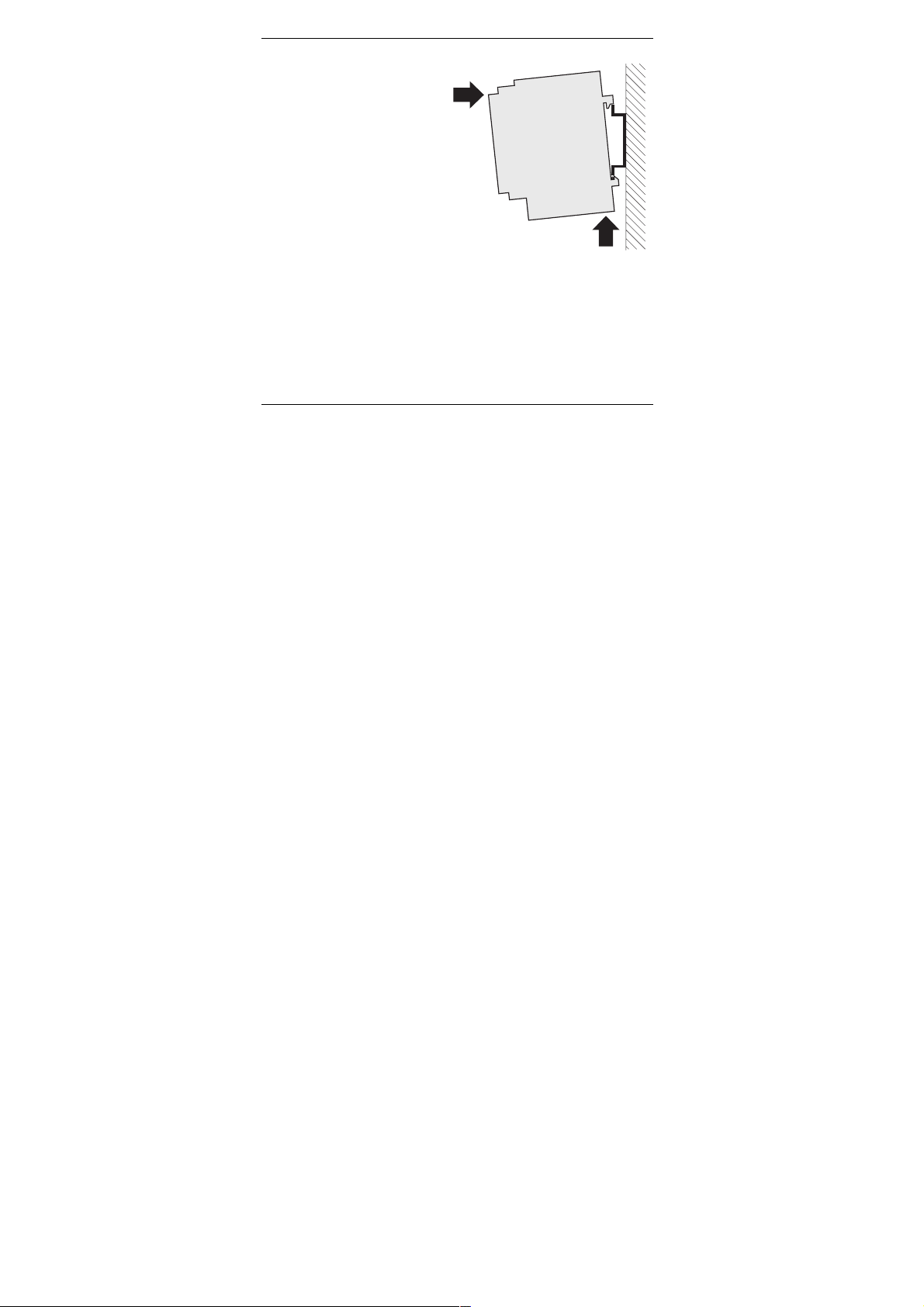

Opening housing

► Loosen the screw on the

front (1).

► Push both snap locks

inward (2).

► Remove the housing cover

from above (3).

19

The electronic components of the storey controller can

be damaged by static electricity discharge!

► Do not touch such components.

► Touch an earthed piece of metal to discharge static

electricity from your body.

Á

À

Â

Á

Page 22

Configuration and electrical connection

Branching out time programs

You can use the setpoint and temperature input* of zone one

as source for other zones. The branching is be done by the

selector switch (1).

1. Switch used to assign temperature zones to setpoint

and temperature inputs.

À

► Set the switch according to the following table.

20

Page 23

Configuration and electrical connection

Switch

position

Property

A setpoint and temperature input is assigned to each

temperature zone.

The setpoint and temperature input of temperature

zone 1 is also valid for temperature zone 2.

The setpoint and temperature input of temperature

zone 1 is also valid for temperature zones 2 and 3.

The setpoint and temperature input of temperature

zone 1 is also valid for temperature zones 2, 3 and 4.

The setpoint and temperature input of temperature

zone 1 is also valid for temperature zones 2, 3, 4 and

5.

If a room temperature sensor is not connected to a branched

out temperature zone, the actual value of temperature zone 1

is used for this area.

21

Page 24

Configuration and electrical connection

Setting actuator

Only one type of actuator can be connected to a storey

controller at a time. If actuators which are open with current

and actuators which are closed with current are to be used,

two storey controllers with the respective suitable controller

are required.

1. Switch used to configure

the actuators

(O = Open, C = Closed)

À

► Check the type of actuator being used.

22

Page 25

Configuration and electrical connection

► Set the switch according to the following table.

Switch

Actuator type Property

position

Normally closed

H 200 AG

Normally open

H 200 AO

Opens the heating circuit

when the actuator is

supplied with current.

Opens the heating circuit

when the actuator is not

supplied with current.

Switching between heating/cooling

You can switch between the cooling and heating functions of the

storey controller.

1. Terminal for the connection of a

potential-free switch.

Switches between heating/cooling

(open = heating, closed = cooling)

► Set the potential-free switch in accordance with the desired function.

23

3

1

4

1

5

1

6

1

7

1

8

1

9

1

0

2

1

2

2

2

1

3

2

2

4

2

5

3

2

4

5

6

7

8

9

0

1

1

1

2

1

À

Page 26

Configuration and electrical connection

Cabling connections

Permissible cable types and lengths

Cable (designation) Connection: Storey

controller HCE 40 and -

JE-Y(St)Y 2×2×0.8

Central operating device

HCE 100

Setpoint adjuster HCU 23 100 m

MCR pre-regulator 100 m

Pump relay HREL 1 100 m

JE-LiYCY 2×2×0.8

Central operating device

HCE 100

Setpoint adjuster HCU 23 100 m

CY 2×2×0.14

Central operating device

HCE 100

Setpoint adjuster HCU 23 100 m

Prefabricated cable Thermal actuators

H200 AO and H200 AG

Two-lead cable Switch used to switch

between heating/cooling

The prefabricated cable of the thermal actuators can be

extended from 1 to 3 metres. This cable is available plug-inready as type HCV 2.

24

Max. permissible length

56 m

35 m

10 m

1 m

(3 m)

100 m

Page 27

Configuration and electrical connection

Use only cables with wire diameters up to 1.5 mm2. We

recommend the cable type JE-Y(St)Y 2×2×0.8. Use the

accompanying connector types and cables of sufficient length.

Connecting actuators

3 actuators can be connected in temperature zones 1 to 3, and

2 actuators can be connected in temperature zones 4 and 5.

► Unplug the power plug before connecting the actuators.

If more than 10 actuators are connected, additional storey

controllers must be installed (see Page 6).

25

Page 28

Configuration and electrical connection

► Insert the connectors of the

actuators into the sockets of

the respective temperature

zones.

Zone ...

► Squeeze the cables into the

stress relief clamp.

► Break out the openings for

the cables on the housing

using a diagonal cutter.

26

H 200XX

Page 29

Configuration and electrical connection

Zone Allocation

For device connections, the following zone allocation must be applied:

27

Page 30

Configuration and electrical connection

Connecting central operating device

The storey controller HCE 40 can control up to 10 actuators. However,

no more than 3 actuators may be connected in any one temperature

zone.

► Use cables in accordance with the table on Page 24.

► Attach the connector of the central operating device to the connector

of the storey controller as shown in the following diagram.

If several storey controllers (max. 3) are to be connected to the

central operating device, they are to be connected to each

other via the bus cable as shown in the diagram on the next

page.

28

Page 31

Configuration and electrical connection

1. Central operating

device HCM 100

2. Storey controller 1

(connector 13 to 25)

3. Storey controller 2

(connector 13 to 25)

4. Storey controller 3

(connector 13 to 25)

5. Temperature zone 5

6. Boiler feedback

7. Voltage supply

13.8 V AC

8. Bus

9. Pump relay

TW Temperature

selector input

RF Room temperature

Storey controller 1

13 14 15 16 17 18 19 20 21 22 23 24

Á

TW RCKR B- B-B+B+

RF

Storey controller 2

13 14 15 16 17 18 19 20 21 22 23 24

Â

TW RCKR B- B-B+B+

RF

Storey controller n

13 14 15 16 17 18 19 20 21 22 23 24

Ã

TW RCKR B- B-B+B+

RF

ÄÅÆ Ç È

234

1

P2

P1

P2

P1

P2

P1

À

5

B-

B+P2P1

25

PR

25

PR

25

PR

sensor input

⊥ Ground

29

Page 32

Configuration and electrical connection

Connecting setpoint adjusters HCU 23 and HCW 23

Setpoint adjusters of type HCU 23 and HCW 23 are hard-wired.

► Use cables in accordance with the table on Page 24.

► Attach the connectors of the setpoint adjusters to the connector of the

storey controller as shown in the following diagram.

One setpoint adjuster (max.) can be used with the central

operating device HCM 100.

If you are using only one four-lead cable for the setpoint

adjuster HCU 23, you must place a jumper between terminal

19 and a ground connection (e.g. terminal 17). You can

connect it to the ground connection of the storey controller

(terminal 5).

Setpoint adjuster HCW 23

Example: Connection to temperature zone 5

1. Setpoint adjuster HCW 23

2. Storey controller HCE 40

(connector 13 to 25)

3. Temperature zone 5

30

À

Á

TW KR

321

13 14 15 16 17 18

Â

P1RF

Page 33

Configuration and electrical connection

Setpoint adjuster HCU 23

1. Setpoint adjuster HCU 23

2. HAC 30 (window contact)

3. Connection of the

temperature zones 1 to 5

4. Power supply for the

setpoint adjuster HCU 23

5. Storey controller HCE 40

(connector 13 to 25)

6. Temperature zone 5

TW Temperature selector input

RF Room temperature sensor

input

⊥ Ground

À

Á Â

456

321

RF TW

Ã

78

13 14 15 16 17 18 19 20 21 22 23 24

Ä

TW RCKR B- B-B+B+

RF

Å

P2

P1

25

PR

31

Page 34

Configuration and electrical connection

Connecting boiler feedback and pump relay

Boiler feedback is possible with controllers MCR 200, MCR 35,

MCR 40 and ZG 252N:

Depending on the design, the temperature selector and ground inputs

are found on different terminals of the controller MCR 200.

► Connect the inputs in accordance with the accompanying

instructions.

With controllers MCR 35 and MCR 40, the temperature selector and

ground inputs are found on the following terminals:

1. MCR 35

Low-voltage side

2. Ground input

HCE 40 terminal 17

3. Temp. selector input

HCE 40 terminal 16

4. MCR 40

Low-voltage side

5. ZG 252N

Low-voltage side

TW: Temperature selector

input

À

Á

Ã

Á Â

Ä

TW

78910456123

Â

TW

78910456123

78910456123

Á

TW

11

12

Â

32

Page 35

Configuration and electrical connection

If control cables for heating ("boiler feedback") and for the pump relay

are available:

► Use cables in accordance with the table on Page 24.

► Connect boiler feedback and pump relay to storey controller as

shown in the following diagram.

Connections of storey controller and pump relay

HREL 1

Storey controller 1

Connector 13-25

13

TW RCKR B- B-B+B+

Storey controller 2

Connector 13-25

13

TW RCKR B- B-B+B+

Storey controller 3

Connector 13-25

13

TW RCKR B- B-B+B+

17 18 19 20 21 22 23 24 25

14 15 16

RF

14 15 16

RF

14 15 16

RF

P1

17 18 19 20 21 22 23 24 25

P1

17 18 19 20 21 22 23 24 25

P1

24V AC

P2

P2

P2

230V AC

1

A1

A2

2

PR

PR

PR

You can connect up to 3 storey controllers. The PR

connection of the other storey controllers remains open.

33

Page 36

Configuration and electrical connection

Connecting setpoint adjuster and room temperature sensor

Setpoint adjusters of type HCW 23 and HCU 23 and room

temperature sensors of type RF 20 are hard-wired.

► Connect the setpoint adjuster and room temperature sensor in

accordance with the accompanying installation instructions.

Inserting connectors

► Insert connectors into the

connector strip of the storey

controller.

13

14

5

1

16

17

18

19

20

21

1

2

3

22

3

2

24

4

5

6

25

7

8

9

10

1

1

12

Closing housing of storey controller

► Place cover on housing.

► Snap left and right snap locks into place.

► Tighten screw on the front.

34

Page 37

Start-up

Start-up

Setpoint adjusters, room temperature sensors or the central operating

device are assigned to the temperature zones of the storey controller

at start-up. A room name is defined at the central operating device (if

present) for each temperature zone.

Starting up storey controller

► Plug in power plug.

The mains voltage LED

► Start up setpoint adjuster if applicable

(see setpoint adjuster instructions).

► Start up central operating device if applicable

(see central operating device instructions).

► Assign temperature zones if a central operating device is used

(see central operating device HCM 100 instructions).

► Check configuration.

35

illuminates.

Page 38

Start-up

Start-up with central operating device

This section covers start-up with the central operating device. Setpoint

adjusters and room names are assigned to the individual zones. This

section can be ignored if you have not installed a central operating

device.

Dial button (1)

► Press

► Turn

Back button (2)

► Press

36

Activates the cursor

or confirms input.

Places the cursor on

a name or value in

the display.

Jumps back one

menu level.

Input is discarded if

it was not confirmed

with the Dial button.

arrive leave holiday party

À

Á

Page 39

Start-up

Assigning temperature zones

Setpoint adjusters or room temperature sensors which are

used are already assigned (fixed) via their wiring.

Example: Assigning room name LIVING to zone 1

► Press the configuration button (1) on the storey controller.

Assignment of the storey controller to the central operating device

is displayed. The green LED illuminates if a temperature zone is

already assigned to the central operating device. The red LED

illuminates if a setpoint adjuster or room temperature sensor is

connected.

If temperature zone 1 is already assigned to the central

operating device, the existing assignment is overwritten by a

new assignment.

► Press the configuration button (1) on the storey controller twice.

The green LED of the first zone flashes. The storey controller waits

for a signal from the central operating device.

37

Page 40

Start-up

The central operating device is in

automatic mode. The display on the

central operating device shows the

standard display, for example:

► Press the Dial button.

The following text is displayed:

► Turn the Dial button to the right until

"Programming" is selected.

► Press the Dial button.

The following text is displayed:

38

Works setting

WE 28.07.97 11:15

No Lifestyle active

LIVING 20.0 C

Please check the clock

TU 29.05.01 11:15

No Lifestyle active

LIVING 20.0 C

PROGRAMMING

TU 29.05.01 11:15

No Lifestyle active

LIVING 20.0 C

LIFESTYLES

TIME PROGRAMS

SETTINGS

VERSION

Page 41

Start-up

► Select the "Settings" submenu and

press the Dial button.

The following text is displayed:

INSTALLATION

DE-INSTALLATION

SUMMER TIME

► Select the "Installation" submenu

and press the Dial button.

The following text is displayed:

PARAMETERS

LIVING

DINING

KITCHEN

► Turn the Dial button until "LIVING" is

selected.

► Press the Dial button.

An * appears after "LIVING".

The LED on the storey controller in temperature zone 1 is

BEDROOM

LIVING *

DINING

KITCHEN

BEDROOM

extinguished. The name "LIVING" has been assigned to

temperature zone 1.

► Enter room name in zoning plan.

► Repeat these steps until a room name is assigned to all temperature

zones.

39

Page 42

Start-up

► Press the configuration button (1) repeatedly until the last LED goes

out.

The storey controller is back in normal mode.

If the configuration button is not pressed for longer than three

minutes, the storey controller changes to normal mode. The

assigned temperature zones remain stored in the storey

controller, even after a power failure.

Assigning setpoint adjusters of type HCU 23 or HCW 23 to a zone

Setpoint adjusters and room sensors are assigned (fixed) to the

temperature zones due to their wiring. Refer to "Connecting setpoint

adjusters HCU 23 and HCW 23" on Page 28.

If the setpoint adjuster and room sensor are removed, the

assignment must be removed as well. See "Removing

assignment".

Removing assignment

Removing temperature zone on HCE 40

If you would like to remove a temperature zone, e.g. if it was assigned

accidentally or a setpoint adjuster has been uninstalled and is no

longer required, proceed as follows:

40

Page 43

Start-up

► Press the configuration button (1) repeatedly until the red or green

LED of the relevant temperature zone flashes.

The red LED of the temperature zone flashes.

► Press the delete button (2) until the red or green LED goes out.The

temperature zone is removed.

41

Page 44

Start-up

Deleting assignment of a room name at central operating device

► Change to submenu "Settings", as

described on Page 39.

The following text is displayed:

INSTALLATION

DE-INSTALLATION

SUMMER TIME

► Select the "De-Installation" submenu

and press the Dial button.

A list of the assigned room names

(temperature zones) appears in the

display:

► Select room name (in this case,

LIVING) and press the Dial button.

The * symbol after the room name

disappears:

PARAMETERS

LIVING *

DINING *

KITCHEN *

BEDROOM *

LIVING

DINING *

KITCHEN *

BEDROOM *

The assignment is deleted and can be reassigned.

42

Page 45

Start-up

Saving settings at central operating device

Before start-up is completed, the settings at the central operating

device must be saved.

The method for saving settings is described in the operating

instructions of the central operating device.

Checking installation

Configuration

► Press the configuration button (1) briefly.

The green LED illuminates if a temperature zone is assigned to

the central operating device.

The storey controller shows up in the device display.

The colours of LEDs 1 to 10 indicate the configuration of the

temperature zones.

(red)

(green)

43

Illuminating Setpoint adjuster or room temperature

sensor connected

Off No setpoint adjuster or room temperature

sensor assigned

Illuminating Room assigned to HCM 100

Off No assignment to HCM 100

Page 46

Start-up

Checking assignment of room names

► Maximise setpoint temperature at the central operating device (see

operating instructions of central operating device).

The green LED of the assigned temperature zone illuminates.

Actuators which are normally closed may experience a delay

of 15 minutes.

► Minimise setpoint temperature at the central operating device (see

operating instructions of central operating device).

The green LED of the assigned temperature zone goes out.

The assignment is correct.

Actuators which are normally open may experience a delay of

15 minutes.

Completing start-up

Closing open setpoint adjusters

► Replace cover and snap in both snap locks.

Handing over zoning plan

► Hand over the completed zoning plan and the installation instructions

to the customer. Both documents are important, as changes to the

system may be made in future.

44

Page 47

Start-up

Resetting storey controller to state of delivery

All current assignments are lost if the storey controller is reset

to the state of delivery.

► Press the configuration button (1) twice briefly.

► Press and hold the delete button (2) for approx. 20 seconds until all

LEDs illuminate briefly.

The storey controller is reset to the state of delivery.

Note to installer

After the storey controller has been started up, you should inform your

customer about the storey controller system:

► Familiarise your customer with the operation of the installed

components.

► Explain the manual operation of the components.

► Point out particular features and extension possibilities of the

respective customer installation.

45

Page 48

Appendix

Appendix

Glossary

Setpoint adjuster

Senses the actual temperature

and changes the setpoint

temperature. Installed in a userfriendly location in each zone.

Heating circuit

Area controlled by an actuator.

Central operating device

Central operating device HCM 100

of the storey controller HCE 40.

Boiler feedback

The storey controller HCE 40

controls the boiler feedback via

an analogue control device from

Honeywell. The boiler feedback to

Honeywell controllers MCR 200,

MCR 35, MCR 40 and ZG 252

could be done via an analogue

signal.

46

Setpoint temperature

Room temperature which is to be

reached.

Setpoint and temperature input

Function of the setpoint adjuster

in manual mode.

Thermal actuator

Opens and closes a heating

circuit. Controlled by the storey

controller.

Time program

Defined combination of setpoints

and switching points at the central

operating device.

Zoning plan

Overview of the temperature

zones of the storey controller.

Page 49

Appendix

Help with problems

Problem Cause/Solution

does not

LED

illuminate when power

plug is plugged in.

Red LED flashes in

normal mode.

Mains voltage not connected.

► Check whether electricity is available at

outlet.

Connection of setpoint adjuster or room

temperature sensor faulty.

► Ensure correct cabling to setpoint adjuster

or room temperature sensor.

► Check for broken cables or short circuits.

Green LED flashes in

normal mode.

Communication with central operating device

HCM 100 faulty.

► Check whether or not central operating

device is installed.

► Check whether or not a room name is

assigned to zone.

► Reassign zone if applicable.

► Ensure correct cabling between central

operating device HCM 100 and storey

controller.

47

Page 50

Appendix

Problem Cause/Solution

Not all rooms are

heated.

► Check heating and inlet temperature.

► Check adjuster on thermal actuator (see

"Setting actuator" on Page 22).

► Check actuator for correct operation.

All rooms to cold or all

rooms to warm.

Room name cannot be

assigned at central

operating device.

Room controlled

incorrectly.

► Check fuse (4 A, fast) inside of the

controller.

► Ensure correct cabling between central

operating device HCM 100 and storey

controller.

► Check whether adjusting ring of setpoint

adjuster is at position 0.

► Check whether adjusting ring can be

turned between –12 and +12 with housing

cover removed.

► Check whether or not a setpoint adjuster is

assigned to room.

► Ensure correct position of selector switch.

► Ensure correct setting (normally open/

closed) and connection of actuators.

48

Page 51

Appendix

(D)

49

Page 52

Appendix

Overview of heating components

A Setpoint adjuster HCW 23

Controls the setpoint temperature in each temperature zone via

an adjusting ring and integrated room temperature sensor

B Setpoint adjuster HCU 23

Controls the setpoint temperature in each temperature zone via

the adjusting ring, integrated room temperature sensor and time

program

C Central operating device HCM 100

Central operating device of the storey controller system

D Storey controller HCE 40

Controls actuators of floor heating/radiators; communicates with

setpoint adjusters and room temperature sensors

E Room temperature sensor RF 20 for storey controller

Transmits room temperature information to the storey controller

F Boiler feedback

G Pump relay HRel 1

H Thermal actuators

50

Page 53

Appendix

Zoning plan

Zone Actuator

(type, location)

1

2

3

4

5

Setpoint adjuster

(location)

Room name

51

Page 54

Appendix

Distribution limitation

• max. 5 zones per storey controller

• max. 3 connections per zone

• max. 10 actuators per storey controller

• only one type of thermal actuator per storey controller (open with

current or closed with current)

• max. 3 storey controllers of type HCE 40 can be connected to one

central operating device HCM 100.

• If a central operating device HCM 100 is installed, maximum one

setpoint adjuster HCU 23 can be connected to the storey connector

HCE 40.

52

Page 55

Page 56

Honeywell AG

Böblinger Straße 17

D – 71101 Schönaich

Tel. (+49) (0) 1801 466 390

The right is reserved to make modifications. This document is definitive for

the enclosed product and replaces all previous publications.

No. 7157588 EN1H-0186 GE51 R1002

This company is certificated to

Loading...

Loading...