Page 1

APPLICATION

Humidity Control

Régulateur d'humidité

-

2

0

°

F

-

1

0

°

F

0

°

F

+

1

0

°

F

+

2

0

°

F

O

v

e

r

2

0

°

F

1

5

%

2

0

%

2

5

%

3

0

%

3

5

%

4

0

%

H

U

M

I

D

I

T

Y

S

E

T

T

IN

G

O

U

T

D

O

O

R

T

E

M

P

E

R

A

T

U

R

E

-

3

0

°

C

-

2

5

°

C

-

2

0

°

C

-

1

0

°

C

-

5

°

C

O

v

e

r

0

°

C

M13371

CASE REMOVAL

SLOT

HOLE FOR WIRING

THE DUCT MOUNTING

INSTALLATIONS

The H8908B Humidistat and H8908C Deh um idi stat

(humidity controllers) provide automatic low voltage

control of humidifiers and dehumidifiers or venti lator s,

respectively, in central heating and air conditioning systems. They have a spst, snap-acting, dust-proof switch

and are designed for wall or surface duct mounting.

INSTALLATION

When Installing this Product...

Read these instructions carefully. Failure to follow

1.

them could damage the product or cause a hazardous condition.

Check the ratings given in the instructions and on

2.

the product to make sure the product is suitable

for your application.

Installer must be a trained, experienced service

3.

technician.

After installation is complete, check out product

4.

operation as provided in these instructions.

CAUTION

Personal Injury Hazard.

Power supply can cause electrical shock.

Disconnect power supply before beginning

installation.

Location and Mounting

The styling of the H8908 is designed to blend with the

latest T8600 family of Honeywell Chronother m ® IV

Deluxe Programmabl e Thermostat s . A mounting template is included for mounting the H8908 next to the

T8600. The H8908 can also be mounted at any other

convenient location in the living area or equipment

room. See Fig 1.

NOTE: The H8908 electrical connections are not

shared with the thermostat.

H8908B Humidistat

H8908C Dehumidistat

INSTALLATION INSTRUCTIONS

Fig. 1. H8908B Humidistat.

Wall Mounting

IMPORTANT

Mount the control in an area with average

room temperature and average relative

humidity.

The following mounting instructions are for mounting

the H8908 on the wall next to the T8600. When installing the H8908 at another location, modify the procedure

to fit the installation.

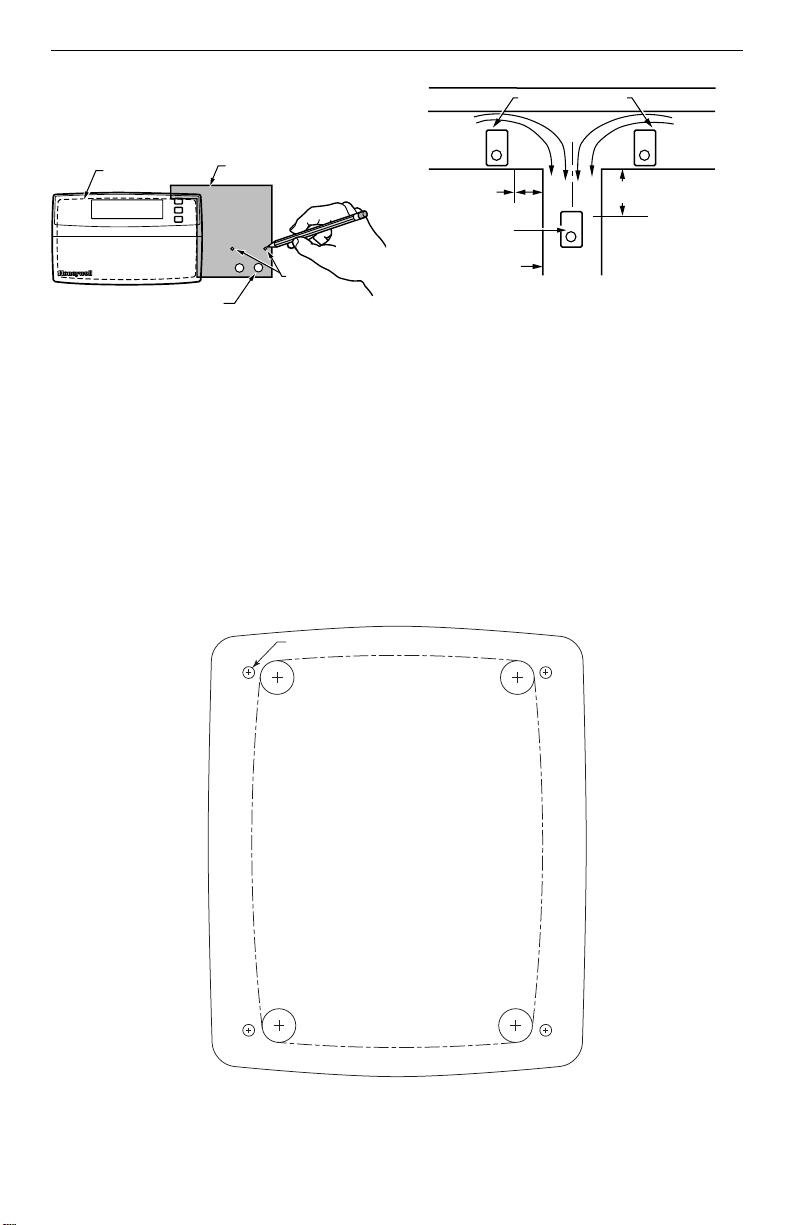

Hold the mounting template (included) next to the

1.

T8600. Select the mounting side for the H8908.

The template is rever sib le f o r moun ting on either

the left or right side of the T8600. See Fig. 2.

Mark the holes for the two mounting screws

2.

(included). Then mark the hole for the low voltage

wiring on the template that corresponds with the

side sel ected in st ep 1.

Remove the te mplate and dr ill the holes.

3.

Run low voltage wiring to the location and pull

4.

about 6 in. (152 mm) of wire through the hole.

Plug the hole with nonflammable insulation to

5.

prevent drafts from affecting the control operation.

® U.S. Registered Trademark

Copyright © 1999 Honeywell Inc. • •All Rights Reserved

69-1341

Page 2

H8908B HUMIDISTAT H8 908C DEHUMIDISTAT

Remove the H8908 case from the base. See

6.

Fig. 1.

Position the base on the wall with the arrow up.

7.

Use the two 1 in. (25 mm) mounting screws to

8.

secure the base to the wall.

THERMOSTAT

WALLPLATE

MOUNTING

TEMPLATE

RETURN

AIR

6 in. (152 mm)

MINIMUM

BEST

LOCATION

ALTERNATE LOCATION

15 in. (381 mm)

MINIMUM

RETURN

AIR

MOUNTING

WIRING HOLES FOR MOUNTING ON RIGHT.

USE LEFT HOLES FOR MOUNTING ON LEFT.

HOLES (2)

Fig. 2. Positioning mounting template.

IMPORTANT

Use 18- to 22-gauge wire for proper wiring.

Connect the low voltage wires to the leads on the

9.

H8908.

Replace the H8908 case.

10.

Duct Mounting

IMPORTANT

When mounting near an elbow area, locate the

control 6 in. (152 mm) upstream from the

elbow so the element is exposed to the normal

airflow (Fig. 3).

4X DRILL 7/64 IN. DIAMETER

PERCER 4 X 7/64 PO.

CAUTION

Equipment Damage Hazard.

Be careful when selecting control

location and cutting hole in ductwork.

Do not cut or drill into air conditioning

or electrical accessories.

Do not install control on supply (hot air) ductwork.

To use template:

1. Remove backing and apply template to duct.

2. Cut along template dotted line and drill the

MISE EN GARDE

Risque d'endommager le matériel.

Faire attention au moment de choisir

l'emplacement du régulateur et de percer les

trous dans la gaine.

Ne pas couper ou percer les accessoires

électriques ou de climatisation.

Ne pas installer le régulateur sur la gaine

d'alimentation (air chaud).

Utilisation du gabarit:

1. Retirer l'endos du gabarit et placer le gabarit

2. Couper le long de la ligne pointillée du gabarit

M13370

1.

2.

3.

4.

5.

6.

7.

8.

9.

IMPORTANT

DUCT TEMPLATE

GABARIT DE GAINE

mounting holes.

sur la gaine.

et percer les trous de fixation.

RETURN AIR DUCT

M13369

Fig. 3. Selecting duct location for control.

Locate the control at least 8 in. (203 mm)

upstream from the humidifier (or dehumidi fier /

ventilator supply) in the return air duct. See Fig. 3.

Apply the duct template to the duct location.

Use the duct template, Fig. 4, to make the opening and mounting holes for the H8908.

Remove the H8908 case from the base. See

Fig. 1.

Position the foam gasket on the H8908 base.

Position the base on the duct with the arrow up.

Use the four 1 in. (25 mm) mounting screws to

secure the base to the duct.

Connect the low voltage wires to the leads on the

H8908.

Replace the H8908 case.

Use 18- to 22-gauge wire for proper wiring.

Fig. 4. Positioning return air duct template.

69-1341 2

M13373

Page 3

WIRING

M13386

L1

(HOT)

L2

1

2

1

2

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

24V WIRING.

HUMIDIFIER

TRANSFORMER

WATER

SOLENOID

LEAD WIRE

CURRENT

SENSING

RELAY

C

LO

HI

H8908B

M13385

L1

(HOT)

L2

1

2

1

2

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

24V WIRING.

HUMIDIFIER

TRANSFORMER

H8908B

SAIL

SWITCH

CAUTION

Personal Injury Hazard.

Power supply can cause electrical shock and

injury.

Disconnect power supply before installation or

servicing.

All wiring must c o mply with applica ble local codes , ordinances and regulations. Make wiring connect ion s

according to humidifier (or dehumidifier/ventilator)

instructions, if available; otherwise, see typical wirin g

diagrams in Fig. 5 through 12.

IMPORTANT

Select models of fan centers include humidifer

taps so the current sensing relay or sail switch

is not needed.

If not using a current sensing relay or sail

switch, the humidifier must be energized during blower motor cycles for proper operation.

On multispeed blower applications, do not wire

the high voltage side of the transformer to the

same power source that services the furnace

blower. Premature transformer burnout can

occur.

On HE360 fan powered humidifier models,

only the two yellow wires are connected to the

control. The remaining two red wires are only

used with electronic humidity controls.

L1

POWER

(HOT)

L2

1

2

1

FAN CONTROL

SUPPLY

FURNACE

FAN

PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION

AS REQUIRED.

24 VAC WIRING.

MOTOR

Fig. 5. Typical wiring diagram for

system with fan interlock.

H8908B

TRANSFORMER

HUMIDIFIER

2

M13368

H8908B HUMIDISTAT H8908C DEHUMIDISTAT

Fig. 7. Typical wiring diagram of current

sensing relay with humidifier.

Fig. 8. Typical wiring diagram

of sail switch with humidifier.

FAN WIRING

H8908B

1

NOTE:

TERMINALS

1

HUMIDISTAT

TERMINALS

24V WIRING.

FOLLOW THE INSTALLATION INSTRUCTIONS

INCLUDED WITH THE STEAM HUMIDIFIER

TO WIRE THE SYSTEM FAN.

1

HUMIDIFIER

TO

SYSTEM

FAN

M13387

Fig. 9. Typical wiring diagram for steam humidifiers.

H8908C

CHRONOTHERM® IV THERMOSTAT

L1

POWER

(HOT)

SUPPLY

L2

1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

2

24 VAC WIRING.

Fig. 6. Typical wiring diagram for system

DPST

SWITCHING

RELAY

2-SPEED

HL

FAN

MOTOR

C

with 2-speed fan motor.

2

TRANSFORMER

HUMIDIFIER

B

O

HEATING

RELAY OR

VALVE COIL

COOLING

CONTACTOR

COIL

WY

FAN

RELAY

COIL

H8908BFAN CONTROL

1

PROVIDE OVERLOAD PROTECTION AND

M13384

DISCONNECT MEANS AS REQUIRED.

Fig. 10. T ypical par allel wirin g of humidity con troller

with Chronotherm® IV Thermostat for

dehumidification and mildew control.

R

G

1

M13366

3 69-1341

Page 4

H8908B HUMIDISTAT H8908C DEHUMIDISTAT

CHRONOTHERM® IV THERMOSTAT

BO

1

Fig. 11. Typical series wiring of humidi t y c ont r ol ler

W

Y

HEATING

RELAY OR

VALVE COIL

COOLING

CONTACTOR

COIL

PROVIDE OVERLOAD PROTECTION

AND DISCONNECT MEANS AS REQUIRED.

with Chronotherm® IV Therm ost at fo r

dehumidification and m i ldew control.

H8908C

Fig. 12. Typical wiring diagram for HR150,

HR200, ER150 and ER200 Ventilator

or HD220 Dehumidifier appli cat io ns.

FAN

RELAY

COIL

VENTILATOR/DEHUMIDIFIER

G

DEHUMIDISTAT

TERMINALS

R

H8908C

1

M13383

M13367

ADJUSTMENTS

Humidity Control Adjustment

To maintain optimum humidity control without causing

condensation on cold surfaces such as windows, the

homeowner must adjust the setpoint as the outdoor

temperature changes.

To reduce the relative humidity, reduce the setpoint

approximately three percent relative humid it y ever y 24

hours. To increase the relative humidity, increase the

sepoint approximately three percent re lative humidity

every 24 hours.

Setpoint Adjustment

Set the humidity setpoint according to the prevailing

outdoor temperature. See Table 1 for recommended

settings.

Table 1. Recommended Humidity

Controller Settings.

Outdoor Temperature Recommended

-20 -29 15

-10 -23 20

0-18 25

+10 -12 30

+20 -7 35

>+20 >-7 40

Controller Setting°F °C

Humidity

OPERATION AND CHECKOUT

Place the system in operation and observe through at

least one complete cycle to make certain that all components are functioning properly.

Home and Building Control Home and Building Control

Honeywell Inc. Honeywell Limited-Honeywell Limitée

Honeywell Plaza 155 Gordon Baker Road

P.O. Box 524 North York, Ontario

Minneapolis, MN 55408-0524 M2H 3N7

69-1341 G.H. 10-99 Printed in Taiwan R.O.C. www.honeywell.com

Loading...

Loading...