Honeywell GENT S4 Data And Installation

Data and Installation

by Honeywell

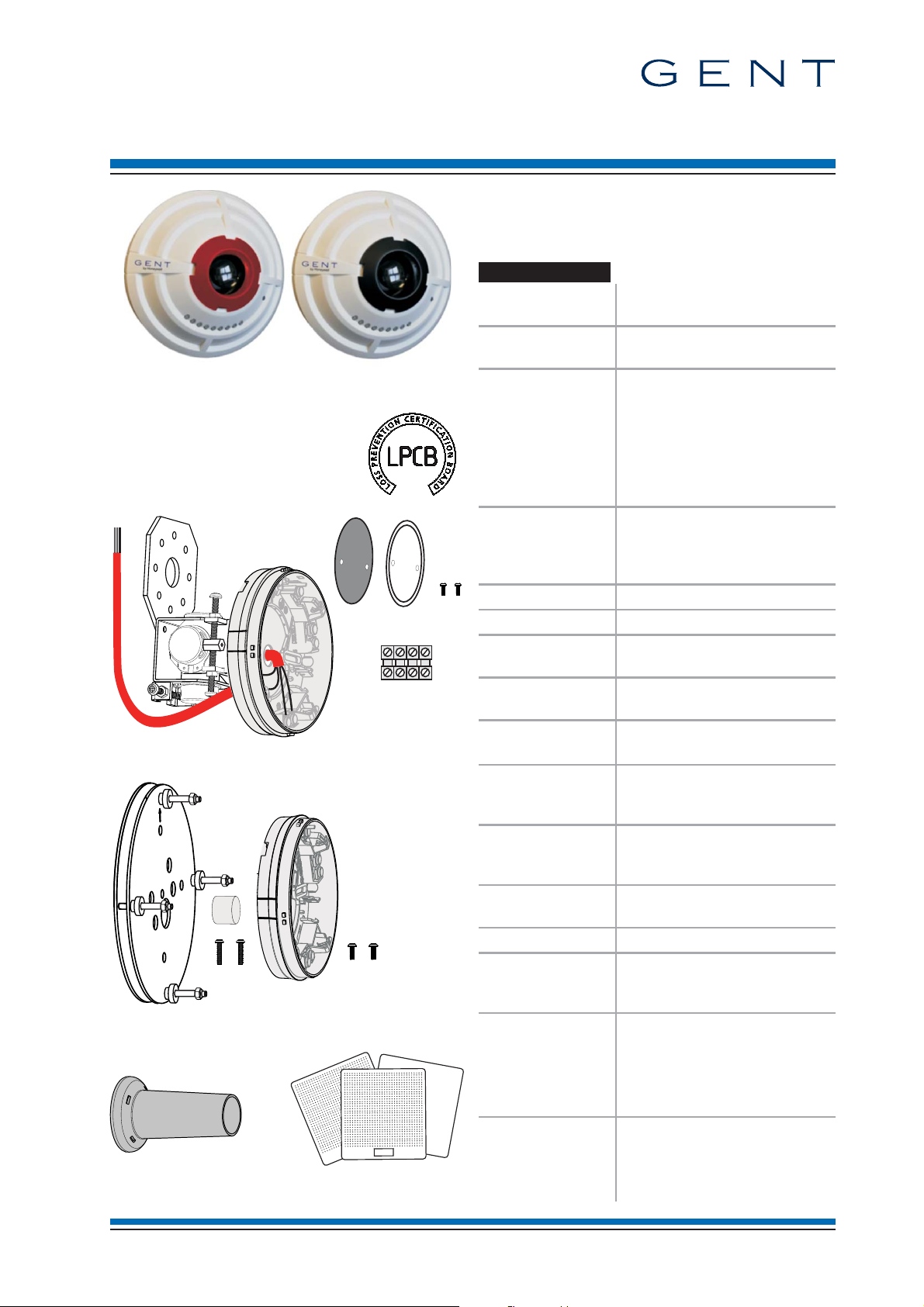

Base

Sleeve

042bh/01

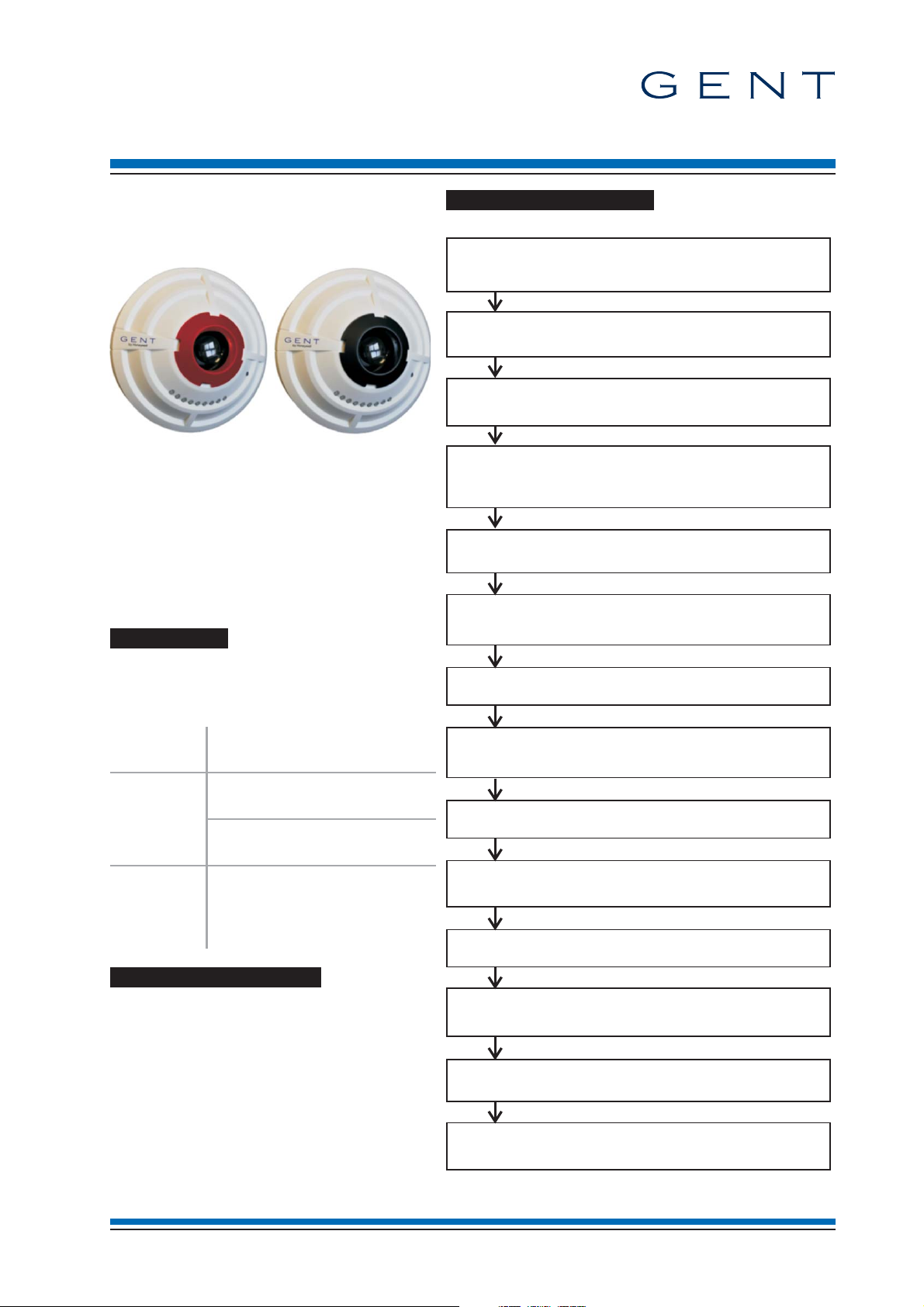

S4 Beam Sensor & brackets

(for Vigilon and Nano Systems)

The Beam Sensor pair allows the detection of

smoke over distances from2mto100m,using a

'beam transmitter' and a 'beam receiver', each

mounted on a base fixed to either bracket.

Technical Data

Standards designed to meet

Approvals LPCB Approved

Transmitter (red retainer) Receiver (black retainer)

Beam sensor pair (Transmitter & Receiver)

¨

S4-34740

Beam Transmitter only

¨

S4-34741

Beam Receiver only

¨

S4-34742

¨

Angle bracket with base

S4-34741-01

¨

Parallel bracket with base

S4-34741-03

¨

Light Shield (5 per pack) Test Cards

S4-34741-99 S4-34741-50

Overall

assembled

dimensions in mm

Assembled weight

(approximate)

Enclosure ABS

Colour (Sensor) RAL9010

Storage

temperature

Ambient operating

temperature

Relative Humidity

(Non condensing)

Emission BS EN61000-6-3: 2007 EMC

Immunity BS EN50130-4: 1996 +

Ingress Protection

(estimated)

Operating voltage 35-41V

Indicators Two Red and Seven Green

EN54-17 : 2005

(section 4.8)

data:

Compatible

Backward compatibility

is possible, refer to

your supplier

EN54 : Part 12 : 2002

EN54 : Part 17 : 2005

STATES 0, 1, 2 and 3

Transmitter or receiver:

Æ 117xd54

Angle bracket with base:

h145xw106xd130

Parallel bracket with base:

Æ 152xd27

Light shield: Æ 50x75

Transmitter or receiver:105g

Angle bracket + base: 620g

Parallel bracket + base: 600g

Light shield: 14g

-20 to +70ºC

-10 to +50°C

up to 95%

Temperature +5 to +45°C

for residential, commercial &

light Industry.

A1:1998 +A2 2003

for alarm systems

IP30

IP20 mounted on bracket

LEDs visible at 500LUX

ambient light levels 5m

max 42V IC max 0.4A

V

nom 40V IS max 1A

V

min 24V IL max 20mA

V

SO max 16V VSO min 8V

V

C max 0.130W

Z

Vigilon : MCC ³ V4.41 / V3.96

LPC ³ V4.39 / V3.96

Nano : MC ³ V1.39

LD ³ V1.03

4188-969 issue 3_Part 1_07-11_S4 Beam & brackets 1

Data and Installation S4 Beam Sensor & brackets

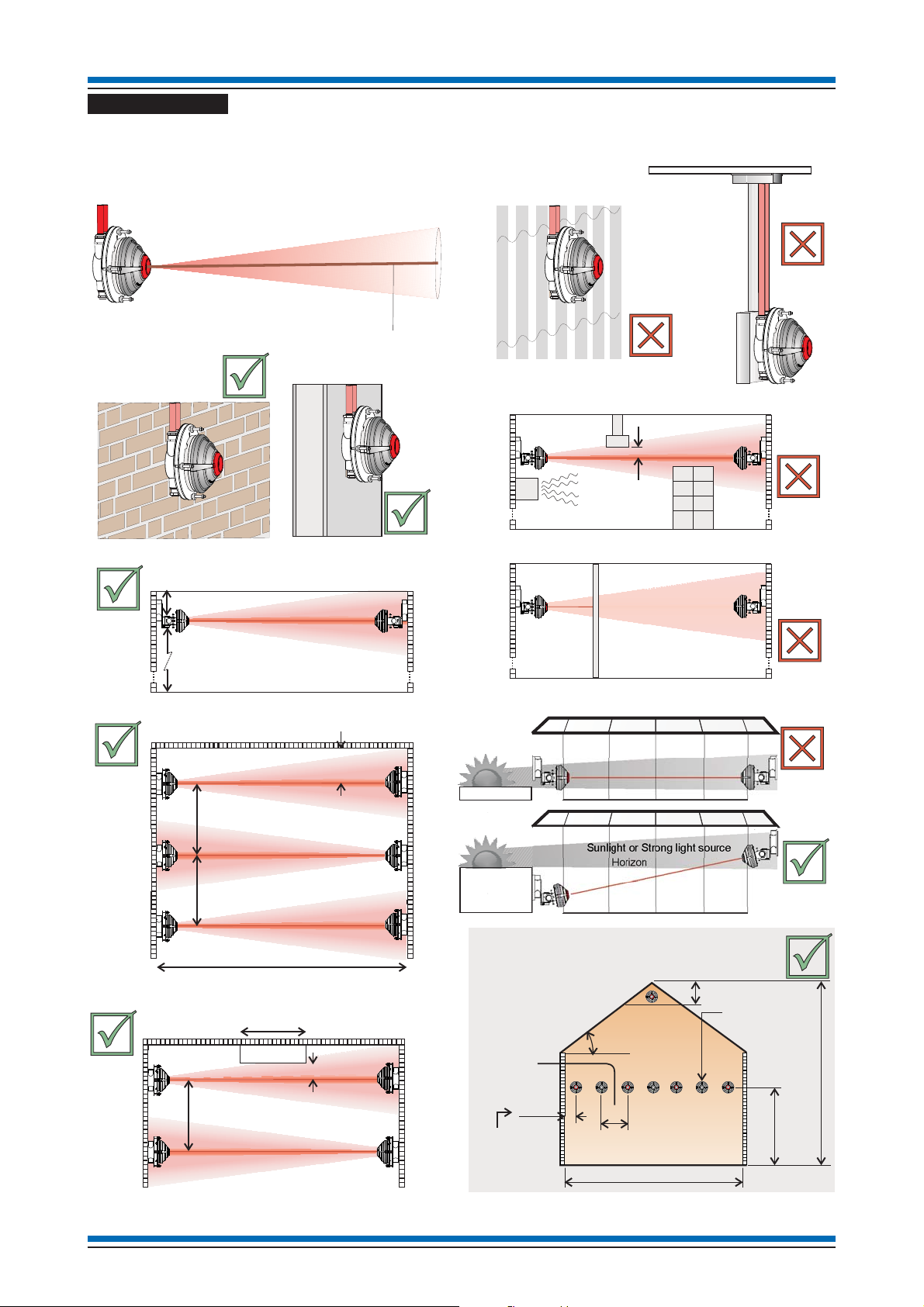

IR Beam

(invisible)

Solid Wall

Floor level

IR Beam projection

Solid Walls

Plan view (flat ceiling)

Receiver

Receiver

Transmitter

Transmitter

Transmitter

Receiver

Shelves and Storage boxes

Solid Wall

Floor level

Ceiling

Building structure support

Solid Wall

Floor level

Ceiling

Ventilation duct

0.3m - 0.6m

15m

> 0.15m

Metal Ceiling

Unistrut

25m maximum

15m

2m to 100m maximum

1m minimum

7m maximum

Solid Walls

Plan view (flat ceiling)

Receiver

Receiver

Transmitter

Transmitter

15m

3m max.

>0.5m

Receiver

Transmitter

Receiver

Transmitter

Receiver

Transmitter

Metal beam

Solid Wall

2.5 m

17.5 m width

17.5 m width covered by one beam sensor pair within 600mm

vertical of the apex, using the extra coverage of 25% given

by the roof angle of 25

o

25

o

1.25 m

10 m mounting

height

20 m

600mm

Calculated from

12.5% of 10m

mounting height

Seven beam sensor

pair required

at this height

2.5 m calculated from

twice 12.5% of 10m

mounting height

ATRIUM

Side view (flat ceiling)

Obstructions

Cladding panels / Plaster board

Transmitter

Transmitter

Receiver

Glass Atrium

Heat Source

Receiver

Horizon

Sunlight or Strong light source

Horizon

Sunlight or Strong light source

Do's and Dont's

A general guidance on Do's and Dont's is illustrated here, however for full information on siting beam sensor

pair refer to BS5839 Part 1.

2 4188-969 issue 3_Part 1_07-11_S4 Beam & brackets

S4 Beam Sensor & brackets Data and Installation

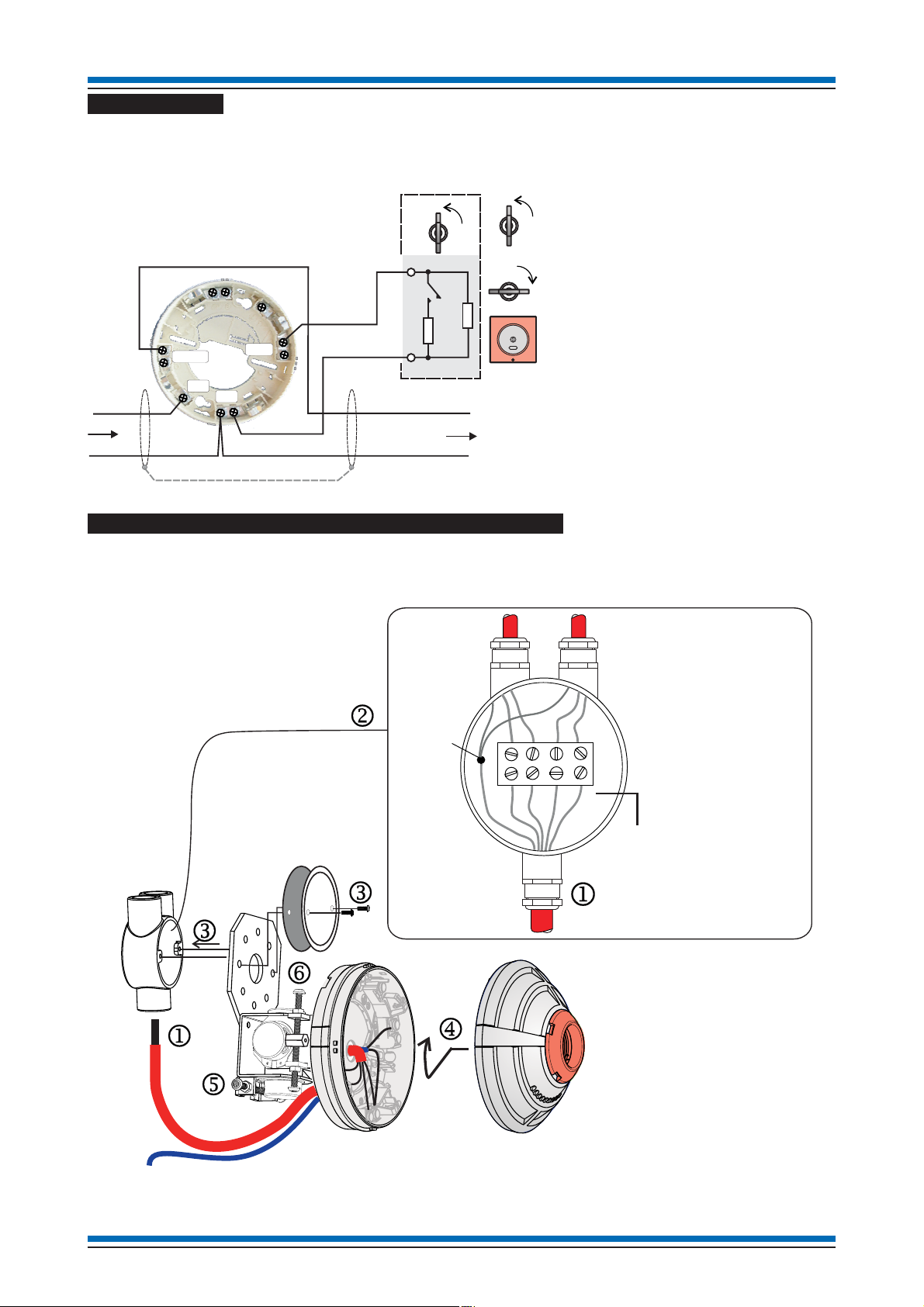

EM2

OUT5

IN4

C3

L1

0V

L2

470 W

10 KW

Input

Beam Transmitter base

FIRE

14115-08

or any suitable

keyswitch

O

I

Active

O

I

Normal

O

I

L1

0V

L2

0V

L1 (1)

0V (4)

0V(2)

L2 (3)

EARTH(5)

The numbers in brackets

refer to alternative cable

sleeve markings which may

be used to denote wires.

Metal box

Earth

Cable from the sensor base

Loop - In cable

Loop - Out cable

Angle bracket with base

Metal box

mounted on

a solid wall

Beam Sensor

Keyswitch wiring if used

The Test Keyswitch

connects to terminals

EM2 and C3 in the

base.

Test Keyswitch

A test keyswitch unit can be connected to the 'beam transmitter' to facilitate simulation of a test fire condition.

The test keyswitch function is supported on Vigilon system only. The keyswitch unit is required to have a

series resistor of value 470W coupled with an end-of-line 10KW resistor wired as illustrated below.

There is a maximum cable length

limit of 15 metres from the 'beam

transmitter' base to the external

Keyswitch Unit.

A keyswitch input at the 'beam

transmitter' must be enabled

during commissioning.

The wiring is monitored for open

and short circuit failure.

On operating the keyswitch it will

cause a ramp down signal to

generate a test fire condition.

How to install an Angle bracket and fit a Beam sensor

The installation of the angle bracket and beam sensor are illustrated by steps j to o. Note steps n and

o require setting of adjusters for sensor to face the opposite sensor assembly, which is normally done

during commissioning.

4188-969 issue 3_Part 1_07-11_S4 Beam & brackets 3

Data and Installation S4 Beam Sensor & brackets

by Honeywell

At the end of their useful life, the packaging,

product and batteries should be disposed of

via a suitable recycling centre and in

accordance with national or local legislation.

Do not dispose of with your normal household waste.

Do not burn.

WEEE Directive:

At the end of their useful life, the packaging,

product and batteries should be

disposed of via a suitable recycling centre.

0832

Gent by Honeywell

Hamilton Industrial Park,

140 Waterside Road,

Leicester LE5 1TN, UK

Product EC Certification

No. of Conformity No.

S4-34741 0832-CPD-1365

S4-34742 0832-CPD-1365

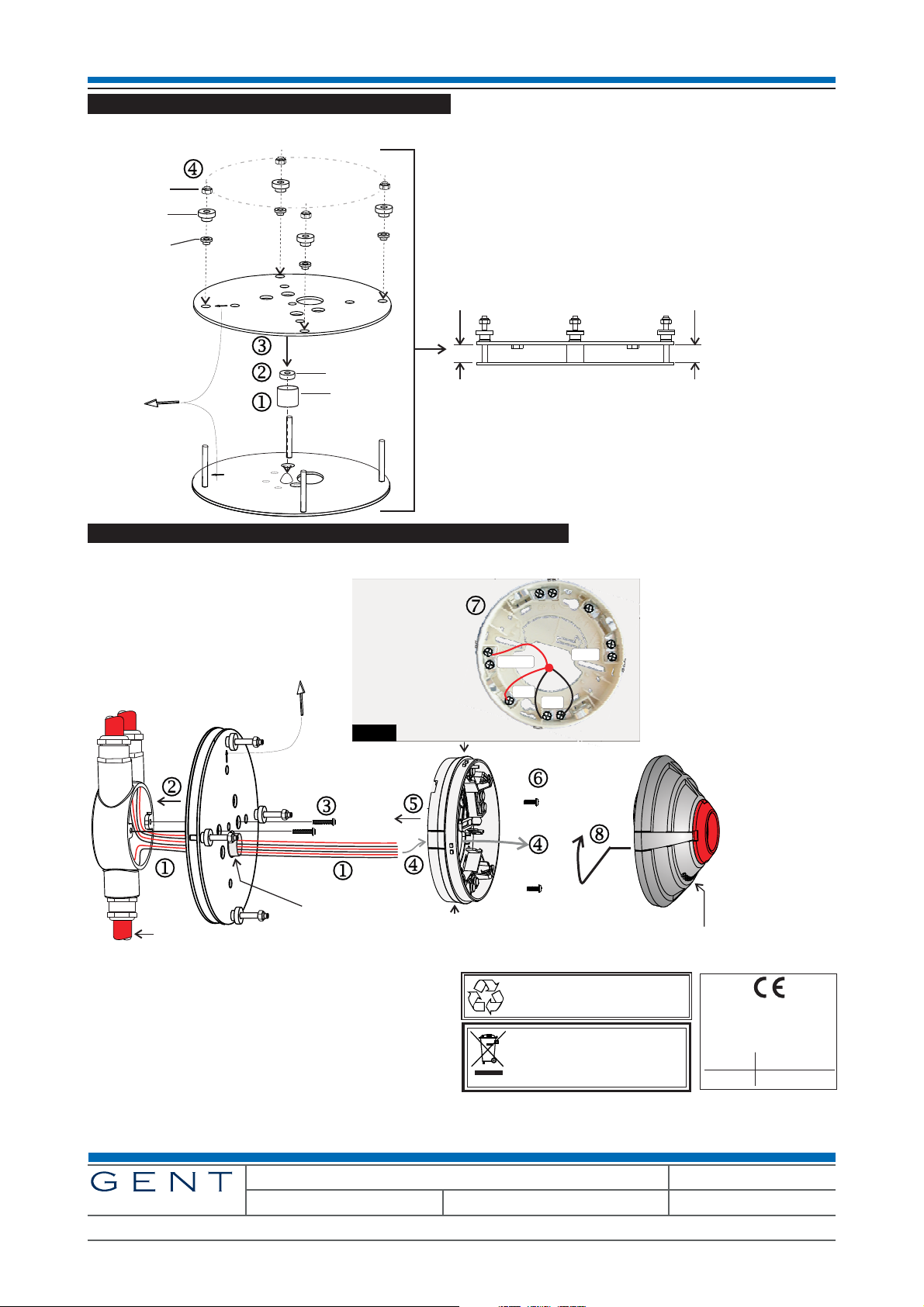

ARROW

Fixed plate

Adjustable plate

Adjuster

Bush

Lock nut

Bush

Spring

8mm

8mm

Ensure the adjusters are set to provide an 8mm

gap all around between the adjustable and fixed plates.

THIS WAY UP

Pre-assembled

Parallel bracket

Metal

box

Beam Sensor

Base

EM2

OUT5

IN4

C3

L1

0V

L2

LOOP IN

LOOP OUT

Loop Cable

In - Out

Test Keyswitch wiring if used

The Test Keyswitch

connects to EM2 and

C3, see page 3.

Sleeve

Ensure the base is mounted to the bracket such

that the Beam sensor LEDs can be seen from floor level.

How to pre-assemble the parallel bracket

The parallel bracket may be pre-assembled as illustrated by steps j to m.

How to install a Parallel Bracket and fit a Beam sensor

The installation of the parallel bracket and beam sensor are illustrated by steps j to q.

Further information about this product can be found in Part 2

of this document available on Gent Expert website.

Gent by Honeywell reserves the right to revise this publication from time to time and make changes to the content hereof without

obligation to notify any person of such revisions of changes.

4 4188-969 issue 3_Part 1_07-11_S4 Beam & brackets

Hamilton Industrial Park, Waterside Road, Leicester LE5 1TN, UK Website: www.gent.co.uk

Telephone: +44 (0) 116 246 2000 Tech. Support: www.gentexpert.co.uk Fax (UK): +44 (0)116 246 2300

Commissioning information

by Honeywell

Light shield

A light shield is only required to be fitted onto a beam receiver where

direct sunlight or strong light is likely to fall in the path of the ‘beam

receiver’. Where necessary fit the light shield.

Find Beam

Finding the device address of the ‘beam transmitter’ and

‘beam receiver’ on the loop.

Normal indications

Check the operational indications given by the red LEDs on the

beam sensor.

Laser tool

Read the instructions supplied with the recommended laser tool

and roughly align the beam sensor using the tool.

Compatibility

Check the control panel in the system has compatible software for

the S4 beam sensors installed on its loop circuit.

Brackets

If necessary, check the method of adjusting the parallel and angle

brackets.

Select a STATE

Program the required Beam sensor STATE, the factory default

is STATE 0.

Alignment indications

Interpreting the alignment indications given at a beam device.

Align beam sensor pair

Align the ‘beam transmitter’ with ‘beam receiver’.

Time averages

Reading the time averages during beam sensor alignment.

Gain and STATE

Check the Beam STATE selected is applicable.

Check the Gain value after alignment is within the distance range.

Tests

Perform tests on the installed beam sensor pair.

Commissioning tool

Where required, configure the monitored input and working

indication features.

Beam STATES

Determine which Beam sensor STATE is required.

S4 Beam Sensor & brackets

(for Vigilon and Nano Systems)

This document describes how to adjust the

beam sensor using adjusters on the angle or

parallel bracket, align beam sensor pairs and

test the installation.

Transmitter (red retainer) Receiver (black retainer)

A beam sensor pair consist of a:

'beam transmitter' that can be identified by

¨

a red lens retainer and a

'beam receiver' that can be identified by a

¨

black lens retainer.

each sensor is fitted onto a base that is a

¨

part of an angle or parallel bracket.

Compatibility

The S4 Beam Sensor pair are compatible for

use in Vigilon and Nano systems having the

following panel firmware.

Commissioning checks

Control

Panel

having card and firmware

Vigilon Main Controller Card

³ V4.41 / V3.96

Loop Processor Card

Nano Main Controller

³ V4.39 / V3.96

³ V1.39

Loop Driver

³ V1.03

Backward Compatibility

An S4 Beam sensor pair can be converted to

be a BACKWARD COMPATIBLE Beam

Sensor pair.

The conversion is done using a Programming

base interface for S4 beam sensor pair, see

section headed 'Backward Compatibility'.

4188-968 issue 4_Part 2_07-12_S4 mains interface 1

Commissioning information S4 Beam Sensor & brackets

[Align] the ‘beam sensor pair’

[Autogain] the ‘beam receiver’

Adjust the ‘beam transmitter’

[Autogain] at the device

Adjust the ‘beam receiver’

[Autogain] the ‘beam receiver’

at the panel.

Check Gain value matches the distance

as stated on page 13.

Repeat the process if required.

k

j

l

m

n

o

[Autogain] at the device

Move on to align the next beam

sensor pair

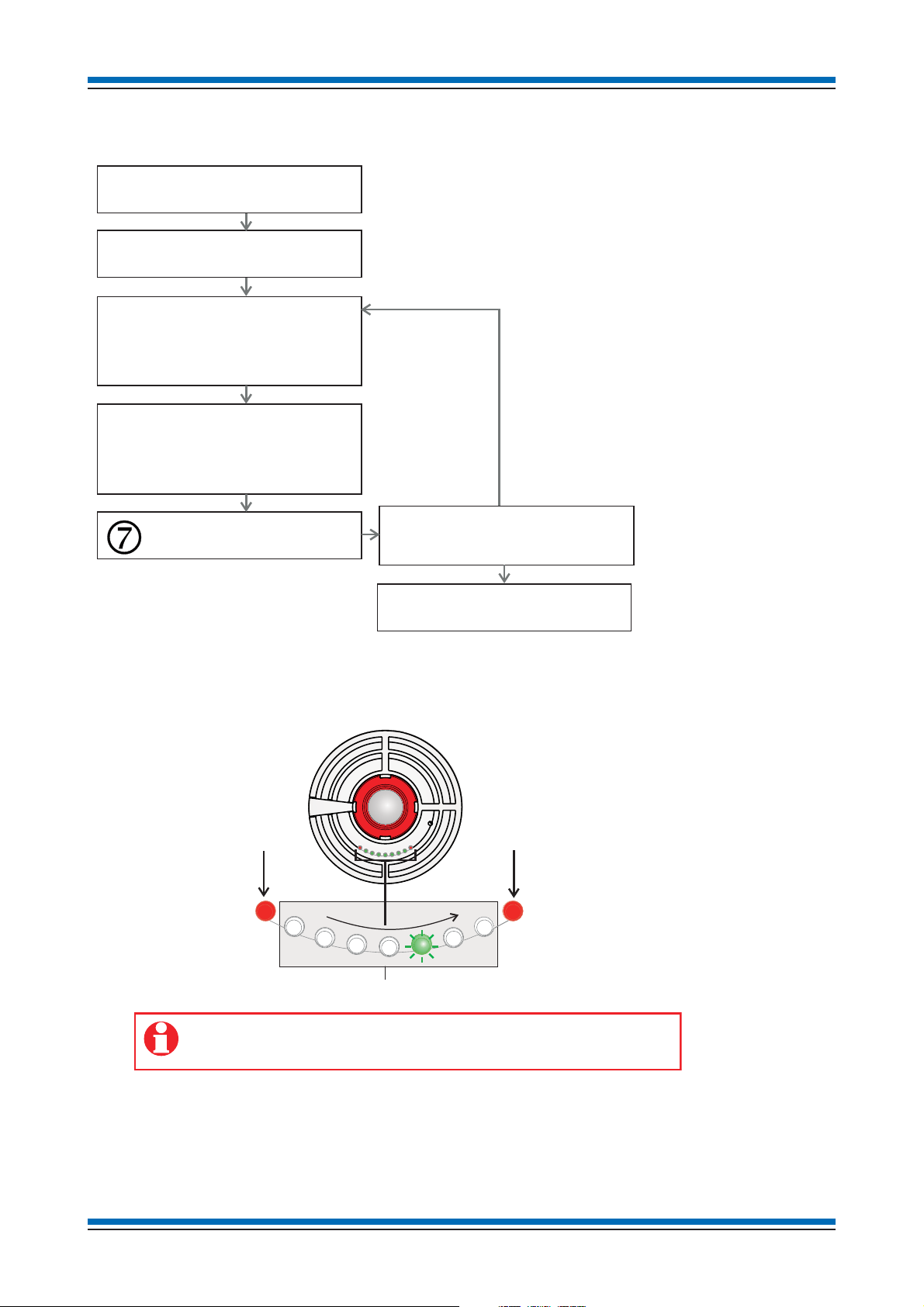

This Red LED illuminates during

alignment to indicate the sensor

has reached Saturation.

This Red LED illuminates during

alignment to indicate a low level

signal, which means the sensor

is Out of Specification.

These Green LEDs are lit during the alignment process to indicate the ADC bit level.

140 bits

180 bits

Less than 140 bits

More than 180 bits

Make adjustments in the X axis and Y axis, using adjusters on the beam sensor

bracket to let the highest Green LED to illuminate. The LEDs update

every 2 seconds, so make small adjustments and wait for the indication to refresh.

How to align a Beam Sensor pair

Overall process to align Beam sensor pair

During the alignment process all the LEDs on the 'beam transmitter' and 'beam receiver' act as a simple level

meter to indicate the ADC bit level. An increase in level causes the intensity of the particular LED to

increase, until the level is enough to turn on the next LED to the right.

The illumination of red LEDs on a beam sensor will indicate the level is either too low or too high and it is

important to carry out a sensor [Auto Gain] after adjustment of the bracket.

2 4188-968 issue 4_Part 2_07-12_S4 mains interface

S4 Beam Sensor & brackets Commissioning information

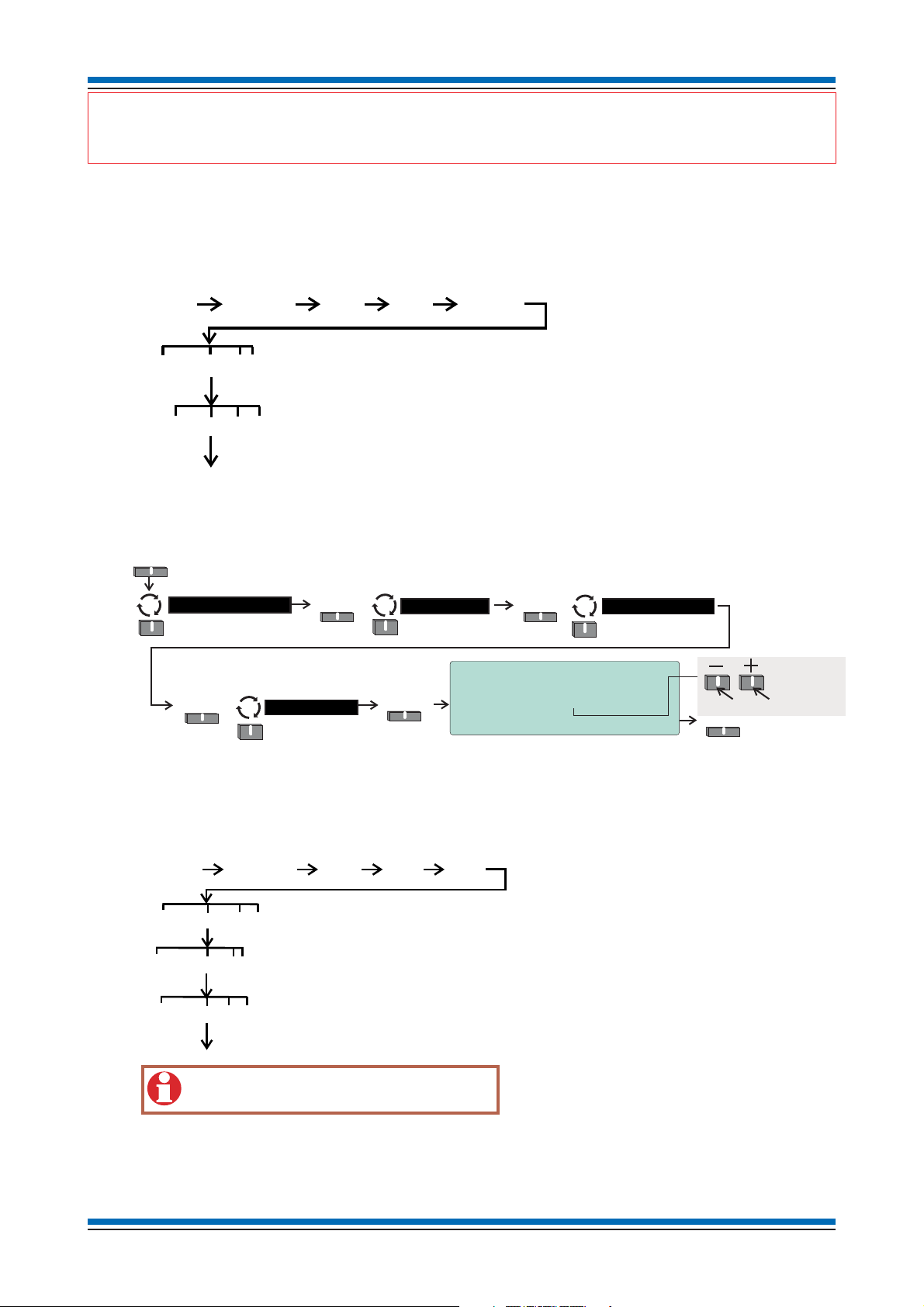

{}

Params

1-207

[Device]

{}

Params

1-207

[Loop]

{}

Params

1-8

[C] [Q]

[E]

[Align]

<etc>

[Test/Eng]

[UserCode]

[Loop]

Enter the ‘ device addressBeam receiver’

Enter the on which the Beam sensor pair are installedloop number

The Alignment function is activated.

Enter the ‘ device addressBeam transmitter’

The alignment function will timeout after 1 hour.

Select Select

Engineering

Menu

Beams >

Select

16:15 Mon 16/02/09

Warning! Selecting this option will

initiate the beam autogain procedure.

Enter Beam RX Address [ 1]

Accept Quit

Autogain

Select

Accept

To scroll the range 1-127

Loop >

Enter the ‘beam

receiver’ device

address

Enter the on which

the ‘beam receiver’ is installed

loop number

[AutoGain]

[Loop]

{}

Params

1-207

{}

Params

1-8

[C] [Q]

[E]

<etc>

[Test/Eng]

[UserCode]

[Loop]

Enter the ‘beam receiver’ device address

Enter the on which the ‘beam receiver’ is installedloop number

An ‘Auto Gain’ is carried out at the ‘beam receiver’.

"

On first power up of the system having beam sensors a light indication of 'Sensor out of Specification' is

given at each beam sensor, with the left most Red LED on the beam sensor lit.

jAssuming the beam sensor pair are in rough alignment at the control panel activate the [Autogain]

function on the 'beam receiver' of the beam sensor pair to be commissioned. You will need to know the

device address of the 'beam receiver' and the loop number on which it resides.

Procedure for Vigilon panel (Access level 3)

Procedure for Nano panel (Access level 4)

kUsing the options in [Test/Eng] menu put the required beam pair into [Align] mode.

Procedure for Vigilon panel (Access level 3)

4188-968 issue 4_Part 2_07-12_S4 mains interface 3

Loading...

Loading...