Page 1

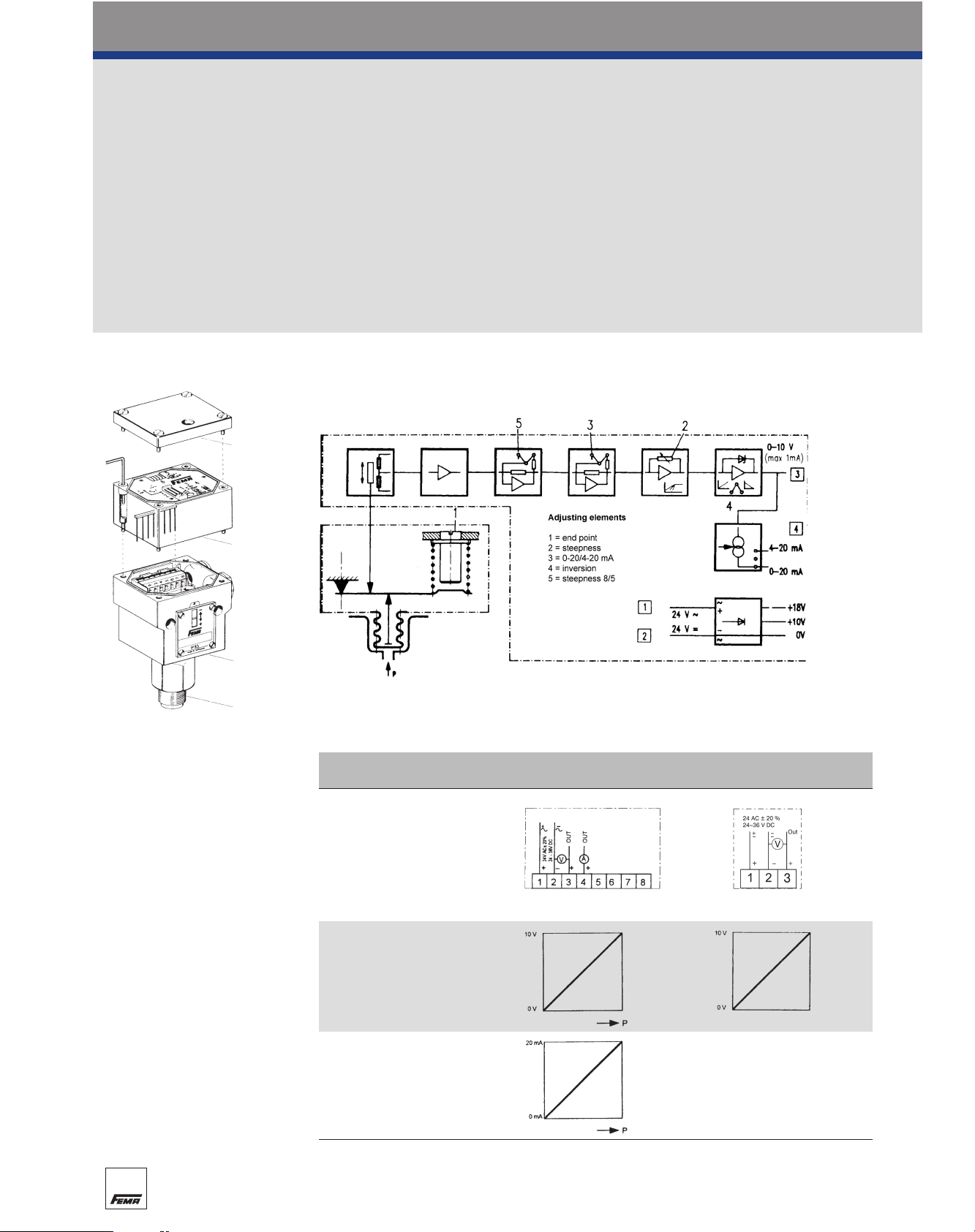

Type series F…+ ED 1 F…+ ED 3

Electrical connection Terminal connection Plug connection

Output signal Output signal

0–10 V and 0–20 mA 0–10 V

Voltage output characteristic

Current output characteristic

Operating method

Pressure transmitters are used to convert overpressure, vacuum or differential pressure into a

proportional electrical signal of 0–10 V, 0–20 mA

(4–20 mA). A metal bellows or diaphragm is

exposed to the occurring pressure. The pressure-dependent movements of the metal bellows

are transmitted free of play to an inductive displacement sensor. The electronic system converts the position of the displacement sensor

into a proportional electrical signal (voltage and

injected current).

Type series F

Pressure transmitters, mechanical-inductive

General technical information

Operating principle

Pressure transmitters

Pressure transmitters

A complete transmitter consists

of a sensor module with pressure and electrical connections,

an evaluation module and a

cover.

Additional evaluation modules can

be plugged in.

Cover

Evaluation

module

ED 1

Sensor

module

with terminal box

Pressure

connection

67

Page 2

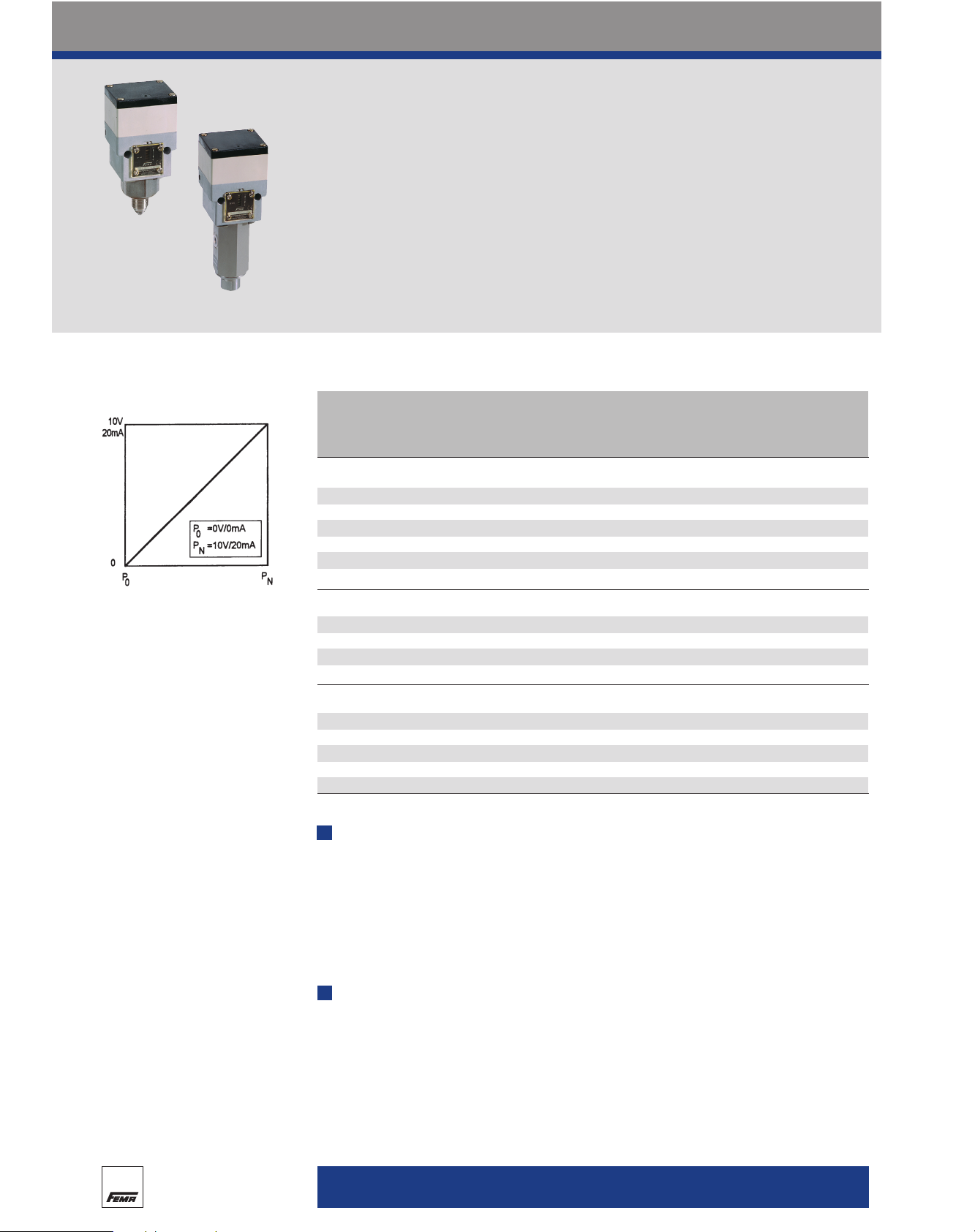

Pressure transmitters

for overpressure, vacuum, differential pressure

Pressure transmitter with 3 conductors

· with 2 output signals 0–10 V and 0–20 mA

· Switchable to 2–10 V and 4–20 mA

and invertible

· Plug-in display module AZ 331

Pressure transmitters of the F series produce

0–10 V / 0–20 mA. Both signals are applied to

the terminal strip and can be used in parallel. A

complete transmitter consists of a sensor parts

and the plug-in evaluation module ED 1.

Removing the cover gives access to an operator

interface for adjusting the operating range.

A plug-in digital display AZ 331 is available to

display the output signal in any units

(voltage / current / pressure / differential

pressure). For further details see Datasheet AZ.

Type series F…+ ED 1

with terminal connection

Pressure FN… + ED 1

Differential pressure FHBN…+ ED 1

Product Summary

Operating range Smallest Max. Sensor Type

(nominal range) adjustable permissible material

P

0–PN

operating range pressure

(approx. values)

Overpressure

0 – 50 mbar 20 mbar 2.5 bar FN 505 + ED 1

0 – 100 mbar 25 mbar 5 bar FN 510 + ED 1

0 – 250 mbar 65 mbar 6 bar 1.4104 FN 025 + ED 1

0 – 500 mbar 125 mbar 6 bar + FN 05 + ED 1

0 – 1 bar 250 mbar 6 bar 1.4571 FN 1 + ED 1

0 – 2.5 bar 0.7 bar 16 bar FN 3 + ED 1

Vacuum

–1 to 0 bar 250 mbar 6 bar 1.4104 FVN 111 + ED 1

–1 to 1 bar 500 mbar 6 bar + FVN 112 + ED 1

–1 to 5 bar 1.5 mbar 25 bar 1.4571 FVN 105 + ED 1

–250 to+250 mbar 125 mbar 3 bar FVN 125 + ED 1

Differential pressure

0 – 500 mbar 125 mbar 10 bar FHBN 05 + ED 1

0 – 1 bar 250 mbar 15 bar 1.4305 FHBN 1 + ED 1

0 – 2.5 bar 0.7 bar 15 bar + FHBN 3 + ED 1

0 – 5 bar 1.25 mbar 15 bar 1.4571 FHBN 5 + ED 1

0 – 10 bar 2.5 mbar 25 bar FHBN 10 + ED 1

Degree of protection:

IP 65

s

Characteristic of a transmitter

(nominal range)

Accessories

· Plug-in display module AZ 331

· Programmable display APV 630

For differential pressure

· Valve combination VKD 3, VKD 5

· Threaded joint with male adapter union MAU 8

Note

· If measured values diverge due to higher static (system) pressure, observe the adjustment instructions on page 71.

i

+

68

Page 3

Pressure transmitters

Type series F

Technical data

Supply voltage 24 V AC ± 20% or 24–36 V DC

Signal and supply voltage is connected to the sensor module.

Power consumption max. 1 W

Outputs (short-circuit proof) 0–10 V, 2–10 V (± 1 mA),

0–20 mA, 4–20 mA (3-conductor system)

All outputs are invertible.

Load impedance max. 750 Ohm.

Direction of action Rising pressure produces a rising output signal (default setting).

Invert with slide switch 4.

Output signal Voltage and current output can also be picked up and used

0–10 V and 0–20 mA simultaneously. Terminals 5–8 are reserved for later expansions

and must not be connected as this would destroy the device.

Operating mode mechanical, inductive

Sensor element Pressure bellows or diaphragm

Pressure connection G 1/2 external and G 1/4 internal.

On FH types: G 1/4 internal.

Cable entry 2 x M 16 x 1.5

Degree of protection IP 65

Installation Directly on the pressure line or mounted on wall with two 4 mm ø

screws.

Materials see Product Summary.

Linearity The maximum linearity error is approx. 1% of full scale.

Hysteresis approx. 0.5% nominal range, related to full output

0–10 V or 0–20 mA.

Long-term drift 0.2% FS / year

Repetition accuracy approx. 0.2%

Accuracy class 1.0

Temperature drift Range from 20–45°C approx. 0.02%/K

Range from 0–20°C approx. 0.05%/K

Influence of static pressure < = 3%/bar (see adjusting instructions, page 72)

Mounting position Vertical. With other mounting positions, the degree of protection

and accuracy are different.

Ambient temperature 0 to 45°C

Max. medium temperature 70°C. Temperatures may reach 85°C for short periods. Higher

medium temperatures are possible if the above limit values for the

switching device are ensured by suitable measures (e.g.siphon).

Storage temperature –20 to +70°C

All plugged-in modules are powered via the terminal strip of the

sensor module (on ED 1) or via the

plug connection. The output signal

is sent from each module for further evaluation via the same route.

The power consumption increases

by approx. 1 W for each additional

module plugged in.

Connection schemes

Terminal connection

Plug connection

ED 3 output signal 0–10 V

Important:

When connecting to control systems

with a common AC supply, the ground

conductor must be looped through. That

is to say, on all devices in the system,

the same reference potential must be

present at the corresponding ground terminal (terminal 2). In the case of a DC

supply, ensure correct polarity.

!

70

Page 4

Type series F

Adjustment and operation

Operating ranges and output signals are adjustable

over a wide range.

An outstanding characteristic of the pressure transmitters is the variability of the characteristic curve,

which means that the pressure range and output signal can be adapted to any subsequent control

system.

P

0

= starting pressure of nominal range

P

N

= nominal pressure (end point of nominal range)

P

A

= starting pressure of set range

P

E

= end pressure of set range

Output signals for module ED 1

Basic setting

The factory default setting covers the nominal range P

0

(usually 0 bar) to PN.

Altering the range

The range can easily be altered by shifting the end point and

adjusting the steepness of the characteristic curve.

Inversion

The output signal can be inverted by means of a slideswitch.

Output signals for module ED 3

Range alteration and inversion as above.

The current signal can be reduced below 4 mA (down to approx.

2.5 mA). If the installation has a fault alarm system, the response

threshold should be set below 2.5 mA.

Pressure transmitters

Operator interface ED 1

1 = Setting spindle for setting

the final value P

E

2 = Setting potentiometer for set-

ting the initial value P

A

3 = Slide switch for selecting the

output signal 0–20 mA (0–10 V)

or 4–20 mA (2–10 V)

4 = Slide switch for inverting the

output signal

5 = Slide switch for changing the

steepness of the characteristic

in a ratio of 8:5.

Normal position: 8

For smaller operating ranges

(< approx. 70% of the nominal

range), select position 5

6 = Plug connector for further eval-

uation modules

Operator interface ED 3

1 = Setting spindle for setting

the final value P

E

2 = Setting potentiometer for set-

ting the initial value P

A

4 = Slide switch for inverting the

output signal

6 = Plug connector for further eval-

uation modules

71

Page 5

Pressure transmitters

Type series F

Setting and testing

Altering the operating range

To check functioning or change the settings from outside the system, a test set-up is required which

meets the following requirements:

1. It must be possible to apply pressure to the pressure transmitter up to the desired final value. The

pressure must be displayed by a sufficiently accurate pressure gauge.

2. To display the output signal a voltmeter with a measuring range of 0–10 V (preferably 0–15 V) or an

ammeter with a measuring range of 0–20 mA (preferably 0–25 or 0–30 mA) are required.

3. To supply power to the transmitter, a 24 V AC or 24 V DC voltage source is needed.

Setting operations must be carried out in the correct sequence

1. Remove the plastic cover

2. Set the slide switches (3) and (4) to the correct position (switch 3 is only present on ED 1)

Switch (3): Output signal 0–10 V / 0–20 mA or 4–20 mA / 2–10 V (only on ED 1)

Switch (4): Direction of action

Switch up rising pressure = rising output signal

Switch down (INV): rising pressure = falling output signal

3. Loosen the locking screw above the cover glass (approx. 2 turns anticlockwise)

4. Apply final pressure P

E

5. Using a screwdriver, turn the setting spindle (1) to the desired output signal (depending on position

of slide switches (3) and (4): 10 V, 20 mA, 0 V, 0 mA, 4 mA)

6. Apply starting pressure P

A

With the potentiometer (2), adjust the output signal to the desired value (depending on position of

slide switches: 0 V, 0 mA, 10 V, 20 mA, 4 mA)

7. Check the setting again and then retighten the locking screw for the setting spindle.

Important: Always set the upper final value P

E

with the setting spindle (1) first, and then the

lower initial value P

A

with the potentiometer (2).

Generating an output signal without pressure

It can often be very useful to generate an output signal before commissioning the system, in order to

check electrical operation, the direction of action and the functioning of downstream control elements.

The procedure is as follows:

1. Loosen the four screws on the scale window and remove the cover glass, scale plate

and rubber seal.

2. In the lower, wide part of the cut-out in the housing, insert the tip of a small screwdriver

underneath the bridge.

3. Carefully move the bridge up and down. When the supply voltage is applied, the output signal

should change depending on the movements of the bridge.

4. Check the direction of action. Upward movement of bridge corresponds to rising pressure.

5. Once you have finished testing, carefully screw the parts back on again in the following order:

rubber seal, scale plate, cover glass.

Caution: In the event of incorrect assembly, IP 65 protection is no longer assured.

Adjustment instructions: Correction of effect with static pressure

· The system in which the FHBN is installed must be filled and exposed to the usual static pressure.

· A differential pressure must not be active, i.e. no pump operation and no flow.

· Remove the plastic cover and check slide switches 3 + 4.

· The FHBN is supplied with the correct voltage and the output voltage is displayed.

· Loosen the spindle locking screw above the inspection window.

· Adjust setting spindle “1” with a screwdriver until the output signal is “0”.

· Retighten the spindle with the spindle locking screw.

72

Page 6

Type series F

Dimensioned drawings

Pressure transmitters

Dimensioned drawings

Dimensioned drawing no. Types A

1 FN 025-FN 3 55.5

FVN…

2 FHBN… 90

3 FN 505, FN 510 82

Height of evaluation module = 1 Module height = 34 mm.

The dimensions are for the basic device, consisting of sensor and

evaluation module.

Each further plug-in module increases the overall height by one

module unit = 34 mm.

1

2

3

73

Loading...

Loading...