Page 1

F74C

Construction

The fine filter comprises:

• Housing with pressure gauge

• Threaded connections

• Rotatable connector piece (F74C only)

• Fine filter in clear filter bowl

• Ball valve with drain connection

• Double wring wrench

Materials

• High quality synthetic material housing

• Brass threaded connections

• Red bronze connector piece (F74C only)

• Stainless steel fine filter

• Shock-resistant, clear transparent synthetic material filter

bowl

• NBR seals

FN74C

F74C/FN74C

Reverse rinsing fine filter

Product specification sheet

Application

F74C/FN74C reverse rinsing filters ensure a continuous supply of

filtered water. The fine filter prevents the ingress of foreign bodies,

for example rust particles, strands of hemp and grains of sand.

F74C/FN74C fine filters are used in systems where an existing

pressure reducing valve is fitted or where one is not required.

Both horizontal and vertical installation is possible.

Special Features

• DIN/DVGW approved

• Filtered water supplied even during reverse rinsing

• Patented reverse rinsing system - fast and thorough cleaning

of the filter with small amount of water

• Memory ring indicates when next manual reverse rinsing is

due

• Automatic reverse rinsing actuator with bayonet connector

can be retrofitted

• Large filter surface

• Shock resistant clear synthetic material filter bowl enables

easy checking of filter contamination

• Filter and complete filter bowl are replaceable

• Very simple operation

• Standardised discharge connection

• Meets KTW recommendations for potable water

Range of Application

Medium Water

The filter is constructed for drinking water installations. In case of

a process water application the filter has to be proven individually.

Technical Data

Installation position Vertical or horizontal,

with filter bowl downwards

Operating pressure Minimum 1.5 bar

Maximum 16.0 bar

Operating temperature Maximum 30 °C

Connection size

3

/4", 1", 11/4"

EN0H-1148GE23 R1009 • Subject to change without notice

www.honeywell.com 27

Page 2

F74C/FN74C Reverse rinsing fine filter

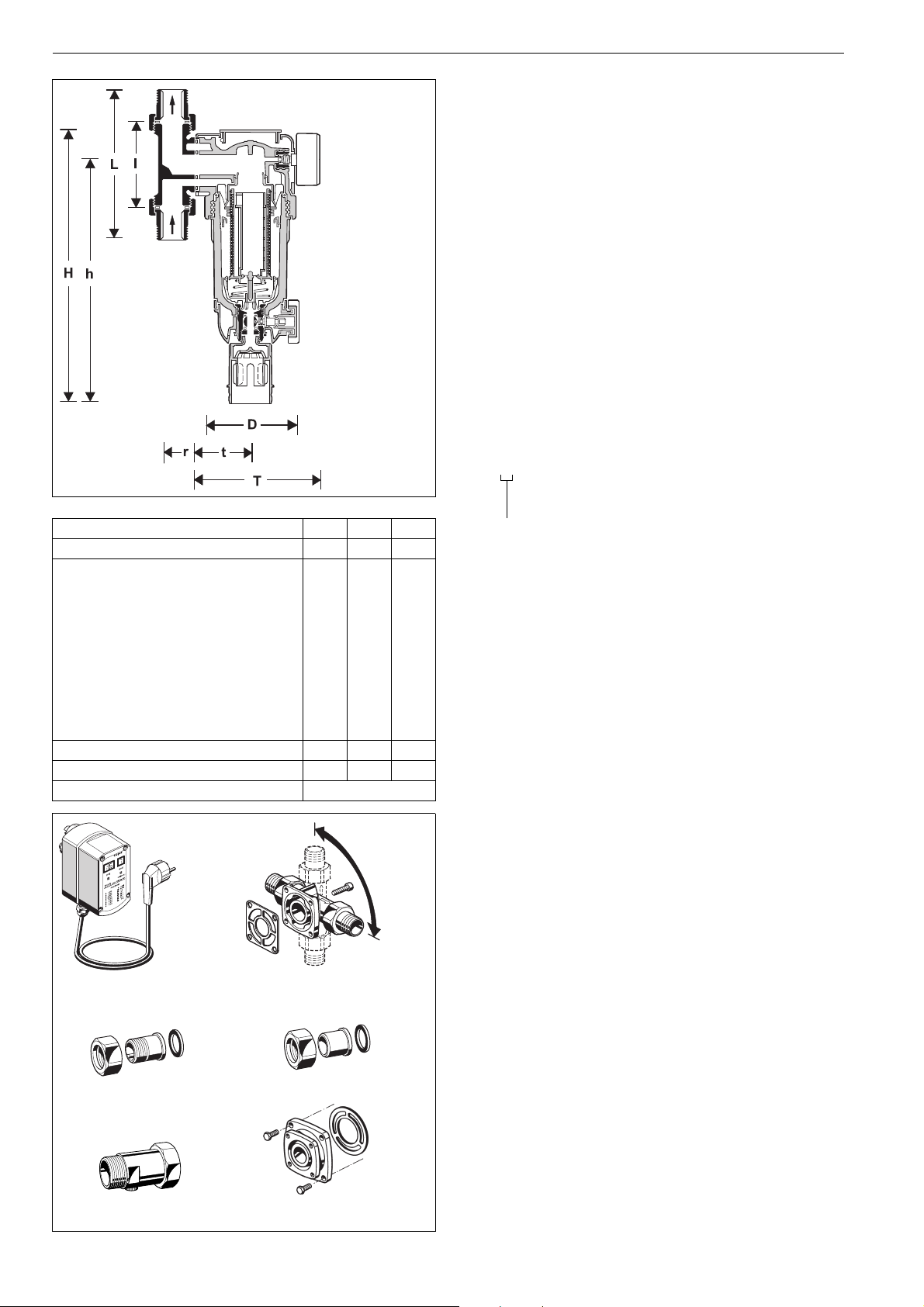

Connection size DA74C R3/4"1"11/4"

Weight approx. kg 2.7 3.2 3.6

Dimensions mm

H 324 324 324

h 285 285 285

T 150 150 150

t666666

r272731

D 105 105 105

I 90 100 105

L 162 184 203

3

Flow value at ∆p=0.2bar m

-value 5.5 6.0 6.5

k

vs

DIN/DVGW Approval No. NW-9301 BO 0224

/h 3.5 4.0 4.5

Method of Operation

The filter insert comprises an upper part and a lower combination

section. When in the „filtering“ position, the small upper filter is

closed so that the water can only pass through the main filter

from outside to inside. When the ball valve is opened for reverse

rinsing, the filter is pushed downwards until the water supply to

the outer side of the main filter is stopped. Simultaneously, the

water flow is opened to the upper part of the filter. The water

needed for cleaning the filter passes through the upper sieve, the

rotating impeller and the main filter from inside to outside. By this

means, the filter is fully cleaned over its whole surface area at the

full inlet pressure. The filter automatically switches over to the

operating position when the ball valve is closed again.

Options

F74C-...AA = Filter mesh size 100 µm, incl. rotatable

connector piece DA74C with threaded male

connections

F74C-...AC = Filter mesh size 50 µm, incl. rotatable connector

piece DA74C with threaded male connections

F74C-...AD = Filter mesh size 200 µm, incl. rotatable

connector piece DA74C with threaded male

connections

Connection size

FN74C-1A = Filter mesh size 100 µm; rotatable connector

piece DA74C has to be ordered separately - see

accessories

FN74C-1C = Filter mesh size 50 µm; rotatable connector

piece DA74C has to be ordered separately - see

accessories

Z11S

VST06-A

RV277

28 www.honeywell.com

DA74C

VST06-B

ZA76C

Accessories

Z11S Automatic reverse rinsing actuator

For automatic filter cleaning at presettable intervals

DA74C Rotatable connector piece

For connection of retrofit filters and filter combinations

VST06-B Connection set

Solder connections

VST06-A Connection set

Threaded connections

RV277 Inlet check valve

1

Available in sizes R

/2" - 2"

ZA76C Connector piece

For conversion of the fine filters with rotatable

connector pieces (1 1/4" and 1 1/2") into retrofit filter

combinations (Converts 63 mm hole centres to 45 mm

hole centres)

EN0H-1148GE23 R1009 • Subject to change without notice

Page 3

Installation Example

F74C/FN74C Reverse rinsing fine filter

Installation Guidelines

• Install in horizontal or vertical pipework with filter bowl

downwards

o This position ensures optimum filter efficiency

• Install shutoff valves

• Ensure good access

o Pressure gauge can be read off easily

o Degree of contamination can be seen with clear filter bowl

o Simplifies maintenance and inspection

• The installation location should be protected against frost

• Fit immediately after water meter

o Corresponds to DIN 1988, Part 2

Flow Diagram

Typical Applications

Fine filters of this type are suitable for supplies to buildings of all

types. They can also be used for commercial and industrial applications within the limits of their specifications.

Fine filters of this type are installed:

• Where there is existing metal or plastics pipework

• If the downstream system includes appliances which must be

protected against dirt

• For installation in horizontal or vertical pipework

• As replacement for an existing filter

• Where space is limited

EN0H-1148GE23 R1009 • Subject to change without notice

www.honeywell.com 29

Page 4

F74C/FN74C Reverse rinsing fine filter

F74C

3

Spare Parts

F74C/FN74C Fine Filters (From 1995 onwards)

No. Description Dimension Part No.

1 Filter insert complete

Filter mesh 100 µm3/4" - 11/4" AF74-1A

Filter mesh 50 µm

Filter mesh 200 µm

2 Clear filter bowl

1

complete

3

/4" - 11/4" AF74-1C

3

/4" - 11/4" AF74-1D

3

/4" - 11/4"KF74-1A

3 Pressure gauge M07M-A16

(0 - 16 bar)

4 Double ring wrench

for removing filter

bowl (no fig.)

3

/4" - 11/4" ZR10K-3/4

2

FN74C

3

1

2

Automation and Control Solutions

Honeywell GmbH

Hardhofweg

D-74821 Mosbach

Phone: (49) 6261 810

Fax: (49) 6261 81309

http://europe.hbc.honeywell.com

www.honeywell.com

Manufactured for and on behalf of the

Environmental and Combustion Controls Division

of Honeywell Technologies Sàrl, Rolle, Z.A. La

Pièce 16, Switzerland by its Authorised Representative Honeywell GmbH

EN0H-1148GE23 R1009

Subject to change without notice

© 2009 Honeywell GmbH

Loading...

Loading...