Page 1

Refer to Supplemental Information (next page) for complete descriptions of these installation steps

5-051-739-00B Page 1

FlexGuard

®

FG-1625SN V-Plex Glassbreak Detector Installation Instructions

FG1625SN V-Plex Glassbreak Detector

1625SN_001-V0

Tamper Switch

Rear Tamper

Terminal Block

Wire Entry Hole

Mounting Hole

Mounting Hole

Microphone

LED Indicators

Test Mode Pads

Front Cover

Cover Screw Location

21

O

N

DIP Switch

Bar Code

(serial no.)

1234567891234

Select Mounting Location

Wall Mount

(T op View)

1625_wall_mnt-V0

1625_ceiling_mnt-001-V0

Ceiling Mount: (Side View)

Test Location w/ 9V Battery

1625SN_009-V0

21

ON

9V

Set Sensitivity Configuration

21

ON

1

O

N

2

SENS1

SENS2

1625SN_004-v0

SENS1 & SENS2 configure sensitivity

SENSITIVITY APPROXIMATE

RANGE

SENS1 SENS2

MAX 25 ft (7.6m)

OFF OFF

MEDIUM 15 ft (4.6m)

ON OFF

LOW 10 ft (3m)

OFF ON

LOWEST 5 ft (1.5m)

ON ON

Note: Ranges are approximate and vary with each

room's acoustic properties. Always verify range with a

FG-701 Glassbreak Simulator.

Enable Wall Tamper

• Remove plastic tab from rear of detector.

• Install wall tamper screw as shown.

• Set screw depth to make contact w/ bottom of

tamper cavity when device is installed

1625_005-V0

4.2 mm or 4.8 mm

(#8 or #10)

9.7 mm (.38”)

Max. screw head size

Wire Channel

Breakout Tabs

Wire Channel

Breakout Tabs

Connect Detector

Connect detector to the polling loop using 18 to 22 AWG

wire, with ends stripped approximately 6mm (1/4 inch).

Be sure to observe proper polarity!

1625Wiring_004-V0

21

ON

FG1625SN V-Plex (Polling Loop) Wiring

Prepare Housing for Surface Wiring (Optional)

The back of the housing has four wire channels to

accommodate surface wiring. If surface wiring is to be

used, select the appropriate wire channel and remove

the breakout tab by inserting a flathead screwdriver

under the tab and prying upward.

1625SN_WireChan-V0

Wire Channel

Breakout Tabs

Wire Channel

Breakout Tabs

Wire Channel

Breakout Tabs

Mount Detector

• Place unit over wall tamper screw, if used.

• Use mounting holes as template to mark ceiling or

wall.

• Mount detector using appropriate hardware.

NOTE: A screw retention feature designed to

make ceiling mounting easier will cause some

resistance when inserting the screw into the plastic.

1625_006-V00

3.5 mm or 4.2 mm

(#6 or #8)

*

*

3.5 mm (#6) screws

work best with the screw

retention feature.

21

ON

Test Detector Installation

Enter Test Mode using FG-701 (see Testing the

Detector on the next page) or manually by shorting

Test Mode pads (as below). Test Mode will

automatically time out after five minutes.

TEST

1625SN_007-V0

21

ON

IMPORTANT NOTE: Close Cover while testing.

Install Cover Screw (optional)

1625_008-V1

2.9 mm (#4) screw,

6 mm (1/4”) long

Page 2

Refer to Installation Instructions and diagrams (next page) when installing this product

©2003 Honeywell International Inc. All rights reserved.

Honeywell, FlexGuard and V-Plex are registered trademarks of

Honeywell International Inc. - All other brands mentioned are the

trademarks or registered trademarks of their respective owners.

Specifications subject to change without prior notice.

P/N 5-051-739-00 Rev B

FlexGuard® FG-1625SN V-Plex Glassbreak Detector Supplemental Information

1. General Information

The FG1625SN glassbreak detector senses the sound of

breaking plate, tempered, laminated, wired, coated, and

sealed insulating glass. This device is designed for use only

with controls supporting V-Plex (polling loop) technology.

Control units for use in Canada utilizing polling loops require

compatibility analysis by Underwriters' Laboratories of

Canada for glass break detec tors that are intended to be

connected to these control units. Refer to the Installation

Instructions for the control unit before installi ng burglar

alarm equipment.

NOTE: The FG1625SN does NOT illuminate its LEDs on

power-up. LEDs operate only in Tes t Mode.

2. Choosing Mounting Location

The preferred mounting location for the device is on a wall

or ceiling, opposite the pr otected glass.

For the best detector perfor m ance, select a mounting

location that is:

• within 7.6 m (25 feet) of the protected glass;

• within clear view of the protected glass;

• at least 2 m (6.5 feet) from the floor;

• at least 1 m (3.3 feet) fr om forced air ducts;

• at least 1 m (3.3 feet) fr om sirens or bells greater than

5 cm (2 inches) in diameter.

• between the protected glass and any heavy window

coverings that may be present. Alternatively, when

heavy window coverings are present, the detector can

be mounted on the frame of the window.

Avoid mounting the detector on the same wall as the

protected glass, on free- standing posts or pillars, or in

rooms with noisy equipment (air compressors, bells,

power tools, etc.), if this equipment is operated when the

detector is armed.

3. Testing Mounting Location

You can test the detector in t he desired mounting location

before drilling/wiring by connecting a 9V battery to the

polling loop terminal block . Observe the polarity marked

on the PC board. After applying power, allow ten seconds

for the unit to stabilize before testing. Follow the

procedure described in “Tes ting the Detector” (next

column) to confirm proper operation.

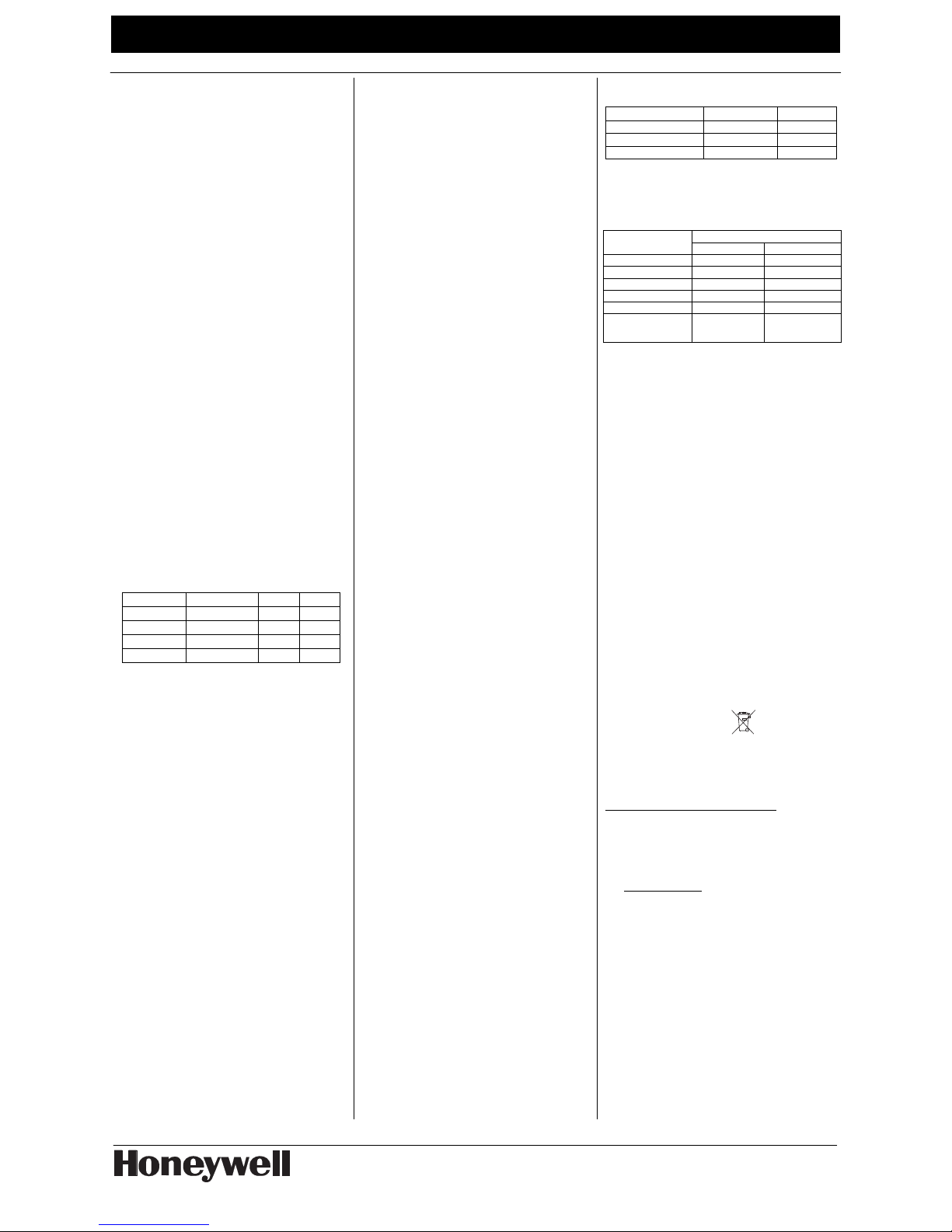

4. Configuring Sensitivity (Range)

DIP switches SENS1 and SENS2 set det ector sensitivity

(range), as shown:

SENSITIVITY RANGE * SENS1 SENS2

MAX 25 ft (7.6m)

OFF OFF

MEDIUM 15 ft (4.6m)

ON OFF

LOW 10 ft (3m)

OFF ON

LOWEST 5 ft (1.5M)

ON ON

*In order to maximize false alarm immunity, Sensitivity must be

set to match the distance between the detector and the

protected glass, as verified using the FG-701 (or GBS-7)

Glassbreak Simulator (see next page).

5. Enabling Rear Tamper

The FG1625SN is equipped with normall y-closed (NC)

cover and wall tamper switches. Each unit is shipped with

the cover tamper operational, and the wall tamper disabled.

To enable the rear tamper, remove the plastic tab on the

back of the detector, using needle-nose pliers. The wall

tamper arm will extend through the hole. Proceed with the

mounting instructions to install the wall tamper screw.

6. Mounting the Detector

Note: If ceiling mounted, the end with the hole (microphone

end) should face the glass being protected.

1. If using optional Wall Tamper: Mark the

mounting location for the wall tamper screw

based on the final location of the detector. Then,

install the wall tamper screw so that it will just

make contact with the bottom of the tamper

cavity when the unit is mounted. Use a flat head

4.2 mm or 4.8 mm screw (#8 or #10).

2. Position the unit over the wall tamper screw (if

used), then mark the mounting sc rew and wire

openings. If required by the location, install wall

anchors for the mounting screws.

3. Secure the unit to the wall or c eiling, oriented so

the microphone has the best line of sight to the

protected glass. Use 3.5 mm (#6) f lat or pan

head screws.

4. NOTE: A screw capture feature des igned to

make ceiling mounting easier will cause some

resistance when inserting the screw into the

plastic.

7. Wiring the Detector

Refer to the wiring diagram on page 1. Pul l the polling loop

wires through the center wire entry hole and connect them

to the terminal block, observing the polarity marked on the

PC board. After connecting the polling loop, allow ten

seconds for the unit to stabilize before testing.

NOTE: Accidental reverse polarity will not harm the detector

or the control.

NOTE: This sensor must be connected to a UL or ULC

Listed power supply or UL or ULC Listed control unit

capable of supplying a minimum of four hours of

standby power.

8. Address/Serial Number ID

This detector's unique, fac tory-assigned serial number can

be found on the bar code label on the PC board (see figure).

The serial number can be entered by one of the following

methods:

1. Downloading (Zone Definition screen of Compass

downloading software). Recommended for large

installations and installations where foot traffic cannot

be controlled.

2. Manually, at the "learn" prompt duri ng manual zone

programming (see Important not e below).

3. Entered by operating the detector tamper switch

twice while at the "learn" prompt during manual zone

programming.

IMPORTANT: If you are programming manually, be sure

that other polling loop sensor s are not activated so that

they cannot send a signal to the control while the

FG1625SN is being programmed (mask PIRs, don’t

open/close doors, etc.).

To enter the serial number, refer to the control’s

programming instructions, noting the following:

• Input Type = 6 (SL: Serial Number Polling Loop

Device)

• Loop Number = 1

To fault the detector when prompted, follow the

instructions under “Testing the Detector”.

9. Testing the Detector

The detector should be tested at least once each year. Test

the detector with the FG-701 (or GBS- 7) Glassbreak

Simulator. No other simulators should be used with the

FG1625SN. The detector must first be placed in Test Mode

(and you must close the cover .)

NOTE: In Test Mode, the LEDs are enabled an d detector

current can be as high as 5 mA. Be sure to exit Test Mode

on completion of testing.

To enter Test Mode manually:

1. Open the front cover.

2. Use a screwdriver to short the Test Mode pads

on the PC board (see diagram on next page).

3. Close the front cover.

The detector’s green LED blinks approximately once per

second to indicate that it has entered Test Mode.

To enter the Test Mode with the FG-701:

1. Stand within 4.6 m (15 feet) of the detec tor.

2. Switch the FG-701 to ACTIVATE and MANual

modes.

3. Point the front speaker of the glassbreak

simulator towards the detector. Press the red

START button to send a short activ ation code.

When the detector enters Tes t Mode, the green LED on

the detector flashes about once per second. If the green

LED does not flash, move closer to the detector and

repeat the procedure. Close the cover during test!

Testing the Detector (flex and audi o signals):

To test the FG1625SN:

1. Place the detector in Test Mode.

2. Set the tester switches to the TEST and FLEX

positions.

3. Position the tester near t he farthest point of the

protected glass, and point the speaker directly at

the detector. If window cover ings are present,

close them fully and hold the tester between the

coverings and the protected glass.

4. Press the red START button. The sim u la to r clicks

on and starts an 8-second armed period.

5. Generate a flex signal by c arefully striking the

glass with a cushioned tool. The tester responds

with a burst of glassbreak audi o.

If the detector receives bot h the flex and audio signals

properly, its red Alarm LED lights for five seconds.

Testing the Detector (audio signals only):

The FG-701 can also be used to test the detector’s ability

to receive audio signals only. In Test Mode, when the

detector receives the audio s ignal from the simulator, the

green Event LED flickers.

Exiting Test Mode:

Test mode will automatically time out after five minutes.

If you need to exit Test Mode sooner, exit by following

the same procedure used to enter Test Mode. The FG1625SN will automatically exit test mode 5 minutes after

the last event is detected.

10. LED Indicators

The detector is equipped with two LEDs: a green Event

LED and a red Alarm LED. Both LEDs are normally

disabled, but they are automatically enabled in Test Mode.

The following table summarizes the LED messages in

Test Mode.

CONDITION GREEN LED RED LED

Test Mode Flash once per sec OFF

Test Mode, event detected Flicker OFF

Test Mode, alarm Flash once per sec ON 5 seconds

11. Cover Screw

The front cover can be secured af ter installation. To do so,

pierce the cover breakout flash and secure the front cover

with a 2.9 mm x 6 mm (#4 x ¼”) screw.

12. Nominal Glass Thickness Chart

Nominal Thickness

Glass Type*

Minimum Maximum

Plate 3a

2mm (3/32 in.) 10mm (3/8 in.)

Tempered

3mm (1/8 in.) 10mm (3/8 in.)

Laminated1

3mm (1/8 in.) 14mm (9/16 in.)

Wired

6mm (1/4 in.) 6mm (1/4 in.)

Coated

2,3b

3mm (1/8 in.) 6mm (1/4 in.)

Sealed

Insulating

1,3b, 4

3mm (1/8 in.)

[13mm (1/2 in.)

overall]

6mm (1/4 in.)

[19mm (3/4 in.)

overall]

* Minimum size for all types is 28cm (11 in.) square; glass must be

framed in the wall or mounted in a barrier at least 0.9m (36 in.) wide.

1

Protected only if both plates in the unit are broken

2

Coated glass with security films up to 0.3mm (12 mils) thi ck (inc luding f ilms for

solar protection) may be used. Film Technologie s International , Inc. ’s

GLASS-GARD GGLL 1200 has been evaluated with this product b y

Underwriters Laboratories, Inc. at Honeywel l’s req uest

3

In compliance with Underwriters Laboratories of Canada’s Standard

for Intrusion Detection Units (CAN/ULC-S306-M89):

a. Plate glass 3mm (1/8 in.) to 10mm (3/8 in.) can be protected.

b. ULC recognizes a maximum range for protecti ng seal ed ins ulati n g

glass and coated glass of 3.8 m (12.5 ft).

4

UL recognizes a maximum range for protecting sealed insulating

glass of 6.1m (20 ft.) with sensitivity set at maximum.

13. Specifications

Range:

7.6 m (25 ft.) maximum, omni

directional

No minimum range

Operating Temper atu re:

-10° C to 55° C (14° F to

131° F)

(Indoor use environment)

Storage: -20° C to 55° C

(-4° F to 131° F)

Tamper Switch:

Combination cover/ wall

tamper

RFI Immunity:

10 V/m,

10 MHz - 1000 MHz

Power Requirements:

Input Voltage:

7 – 16 V peak-to-peak at the

polling loop terminals

Current:

1 mA max, w/ LEDs disabled

5 mA max, w/ LEDs enabled

ESD Immunity:

10 kV discharges of either

polarity to exposed surfaces

Dimensions:

115 mm x 72 mm x 27 mm

(4.5 in. H x 2.8 in. W x 1.05 in.

D)

Weight:

98 g (3.5 oz.)

Packaged Product: 126 g (4.5

oz.)

Approvals / Listings:

FCC and IC verified,

UL listed, ULC listed,

CE, C-Tick,

EN 50131-1; Security Grade 2,

Environmental Class II

Suitable for connection to an

EN60950 Limited Power

Source

Customers in

European Union

countries are

advised to dispose

of this product, at the end of

its useful life, as per

applicable local laws,

regulations and procedures.

To obtain applicable EU compliance Declaration of Conformities for this product,

please refer to our Website

http://www.security.honeywell.com/hsce/international/index.html.

For any additional information regarding the compliance of this product to any EU

specific requirements, please contact –

Quality Assurance Department,

Honeywell Security & Custom Electronics,

Newhouse Industrial Estate,

Motherwell,

Lanarkshire ML1 5SB,

Scotland,

United Kingdom

Tel: +44(0)1698 738200

Email: UK64Sales@Honeywell.com

NOTICES

FCC NOTICE: This device complies with Part 15 of the FCC Rule s. Operation is subject

to the following two conditions: (1) This deice may not cause harmful interference, and (2)

this device must accept any interference received, including interference that may cause

undesired operation.

The user is cautioned that changes or modifications not expre ssl y appro ved by H oney well

could void the user’s authority to operate this equipment.

Note: This equipment has been tested and found to comply with the lim its for a Class B

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures: 1) Reorient or relocate the receivin g antenna, 2) Increase the separation

between the equipment and receiver, 3) Connect the equipment into an ou tlet on a cir cuit

different from that to which the receiver is connected. The instal ler can also consult an

experienced radio/television technician for additional suggestions, if necessary.

IC Notice: This Class B digital apparatus complies with the Canadian ICES-003.

Cet appareil numérique de la Classe B est conforme à la norme NMB-003 du Canada.

Loading...

Loading...