Honeywell F-BO-AFE70, F-BO-AFE70-3, F-BO-AFE70-2 Installation, Connection, Commissioning, Maintenance

Page 1

FIRE ALARM ASPIRATION SENSING TECHNOLOGY™

Automatic Purging Units for

Aspirating Detectors

F-BO-AFE70

Description

Installation - Connection - Commissioning - Maintenance

SYSTEM SENSOR EUROPE

Pittway Tecnologica S.r.l.

Via Caboto 19/3

34147 TRIESTE

Italy

www.systemsensoreurope.com

Page 2

Page 3

User Manual Series F-BO-AFE70

Important information for the installer for the use of a Purging unit

in a fire detection system

Fire detection systems are designed to protect people and property from the dangers of a fire.

Therefore, they have to be planned, installed and put into operation very carefully by trained personnel.

For the handling of compressed air or for the installation of a compressed-air system, country-specific qualifying examinations or approvals may be required. In addition, for the installation, commissioning and maintenance of the Automatic Purging Units F-BO-AFE70, you must follow the

special precautions listed below.

Before starting any work on the Purging unit, the supply voltage of the Purging unit as well

as the compressed-air supply must be reliably interrupted, and measures must be taken to

ensure that they are not switched back on!

Only turn on the compressed-air supply after finishing all mounting, installation, connection and parameterisation work in the course of commissioning, as described starting on

page 40 in Chapter 10: „Commissioning and function test“. Turning on the compressed-air

supply at an earlier time can result in serious personal injuries or damage to property,

depending on the condition of the system and the environment.

When carrying out any work, do wear suitable personal protective gear, for example, wear

eye protection and hearing protection when working with compressed air.

3

Take care that fingers, other parts of the body, and objects never get into the pipe connection openings. During the Purging process, the valve that is integrated into the Automatic

Purging Units F-BO-AFE70 is closed with high velocity and great force. As a result, parts of

the body or objects, which are in the valve body, can be seriously injured or even severed or

destroyed respectively! In addition, the Purging unit can be severely damaged or destroyed

as a result.

Only expert service specialists and trained employees are allowed to plan, install, modify, maintain and service a fire detection system.

Fire detection and/or extinguishing systems must be checked and serviced regularly by trained

personnel in order to maintain their functionality, on the one hand, and to avoid false alarms to

the greatest extent possible on the other.

Parts of a fire detection or extinguishing system that are experiencing a fault, are not able to perform their functions efficiently or can not do so at all. Therefore, faults must be repaired immediately by a trained and authorized specialised company.

In addition to the careful and expert manipulation, the safe operation of aspirating smoke detectors

requires, above all, the proper transport, storage, installation and commissioning.

The special requirements for the installation of a fire detection system are not described in this User

Manual.

Safety instructions

Before installing, commissioning, servicing or using the product described in this User

Manual, you have to read the User Manual carefully and, in particular, you have to

note and subsequently follow the information given on pages 3 and 4 as well as in

Chapter 1.5: „Important tips“ from page 8 onwards.

Furthermore, the pictographs that are described in Chapter 1.3: „Types of symbols“

from page 8 onwards are very important for you – these pictographs are used frequently throughout the User Manual to remind you of dangers that may arise in case

of improper use of the product, as well as to point to valuable tips.

I56-4252-010

D200-104-00

Page 4

4

User Manual Series F-BO-AFE70

Pressure Equipment / CE-labelling / Construction Products Regulation

Within the EU, pressure equipment is subject to the Directive 2014/68/EU of the European Parliament and of the Council of 15 May 2014 on the harmonisation of the laws of the member states

regarding making pressure equipment available on the market. In Austria the guideline has been

implemented with the Druckgeräteverordnung (DGVO), in Germany it has been implemented with

the „Vierzehnte Verordnung zum Produktsicherheitsgesetz (Druckgeräteverordnung –

14. ProdSV)“.

According to §8 of the DGVO, the Automatic Purging Units F-BO-AFE70 are pressure equipment

with low risk potential, and according to article 4, paragraph 3 of the Directive 2014/68/EU they

are „Pressure equipment and assemblies below or equal to the limits set out in points (a), (b) and

(c) of paragraph 1 and in paragraph 2 respectively (...)“ and are designed and manufactured in

accordance with the engineering practice of a Member State.

The CE-labelling results from a guideline from the board of the European Community for the equivalency of the laws of its member states, including the mutual approval of laws. By means of the

CE-label that is affixed to the device, the manufacturer confirms the conformity of the product with

the following standards and guidelines:

Electromagnetic Compatibility Directive: 2014/30/EU, EN 55022:2010, EN 50130-4:2011 +

A1:2014.

The CE-labelling of the device expressly does not result from the guideline 2014/68/EU.

You must not exceed the values specified in the project planning guidelines of the

aspirating smoke detector. Please observe the respective national standards and

guidelines for planning aspirating smoke detectors.

However, the Automatic Purging Units F-BO-AFE70 do not represent an additional air resistance in the sampling pipe network, and therefore they do not have

to be additionally included in the calculation of the sampling pipe network.

I56-4252-010

D200-104-00

Page 5

User Manual Series F-BO-AFE70

Contents

1 Introduction..........................................................................................................................7

1.1 General............................................................................................................................................7

1.2 Intended use.................................................................................................................................... 7

1.3 Types of symbols............................................................................................................................8

1.4 Abbreviations, special terms...........................................................................................................8

1.5 Important tips..................................................................................................................................8

1.6 Scope of delivery............................................................................................................................9

2 Manner of operation of a Purging unit............................................................................10

2.1 General..........................................................................................................................................10

2.2 Characteristic features of the Automatic Purging Unit F-BO-AFE70............................................11

3 Displaying of the operating conditions and operation....................................................12

3.1 Operating conditions indicated by the status LED........................................................................12

3.2 Operation by the user....................................................................................................................13

3.3 Operation by the installer..............................................................................................................13

4 Pneumatic components – dimensioning...........................................................................14

4.1 Purging unit...................................................................................................................................14

4.2 Compressed-air supply..................................................................................................................15

5

5 Final assembly, mechanical structure and dimensions...................................................19

5.1 Final assembly..............................................................................................................................19

5.2 Mechanical structure.....................................................................................................................20

5.3 Dimensions...................................................................................................................................21

6 Safety devices......................................................................................................................22

7 Special notes on using the F-BO-AFE70-3 in refrigeration areas..................................23

8 Mounting and connection of pneumatic components.....................................................24

8.1 Location of installation.................................................................................................................24

8.1.1 Permissible mounting positions..................................................................................................24

8.1.2 Installation of the Automatic Purging Unit F-BO-AFE70..........................................................25

8.2 Connection to the sampling pipe and to the aspirating smoke detector.........................................25

8.2.1 Loosening the pipe connection...................................................................................................26

8.2.2 Use of filters............................................................................................................................... 26

8.2.3 Use of check valves....................................................................................................................27

8.2.4 Connection diagram for a double pipe system............................................................................27

8.2.5 Connection diagram for far-flung pipe systems with master-slave mode of the Purging units. . .28

8.3 Connection of the compressed air.................................................................................................29

9 Connection and parameterisation.....................................................................................30

9.1 General instructions......................................................................................................................30

9.2 Power supply................................................................................................................................31

9.3 Location of the display and operating elements and terminals on the control board of the

Automatic Purging Unit F-BO-AFE70..........................................................................................31

9.4 Connection of and interaction between Purging unit, aspirating smoke detector and fire detection

control panel.................................................................................................................................31

9.4.1 Standard connection with indirect actuation through the fire detection control panel (in

accordance with EN 54-13)........................................................................................................33

9.4.1.1 Output „Slave activation“ ...................................................................................................... 33

9.4.1.2 Synchronisation of the internal clock of the F-BO-AFE70 .................................................... 34

9.4.2 Connection of Purging units in the master-slave mode with direct actuation through the fire

detection control panel (in accordance with EN 54-13)..............................................................34

9.5 Parameterisation of the Purging unit.............................................................................................36

9.5.1 Setting the Purging program.......................................................................................................36

9.5.2 Internal clock..............................................................................................................................37

9.5.2.1 Displaying and manually setting the time .............................................................................. 37

I56-4252-010

D200-104-00

Page 6

6

User Manual Series F-BO-AFE70

9.5.2.2 Automatically synchronising the time .................................................................................... 38

9.5.3 Setting and displaying the device number..................................................................................38

9.6 Label showing the parameterisation options and connection possibilities.....................................39

10 Commissioning and function test......................................................................................40

11 Inspection............................................................................................................................42

12 Specifications......................................................................................................................43

13 Set parameters....................................................................................................................45

14 Appendix A..........................................................................................................................46

14.1 EU declaration of conformity........................................................................................................46

14.2 Supplier's declaration of conformity.............................................................................................47

I56-4252-010

D200-104-00

Page 7

User Manual Series F-BO-AFE70 Chapter 1 • Introduction

1 Introduction

1.1 General

This User Manual of the Automatic Purging Units F-BO-AFE70 provides the expert installer with

the information necessary for planning, configuration, installation, connection, parameterisation,

commissioning and maintenance of the Automatic Purging Units Series F-BO-AFE70.

The manner of operation of Purging units in general and of the Automatic Purging Units

F-BO-AFE70 in particular are described from page 10 onwards in Chapter 2: „Manner of operation of a Purging unit“.

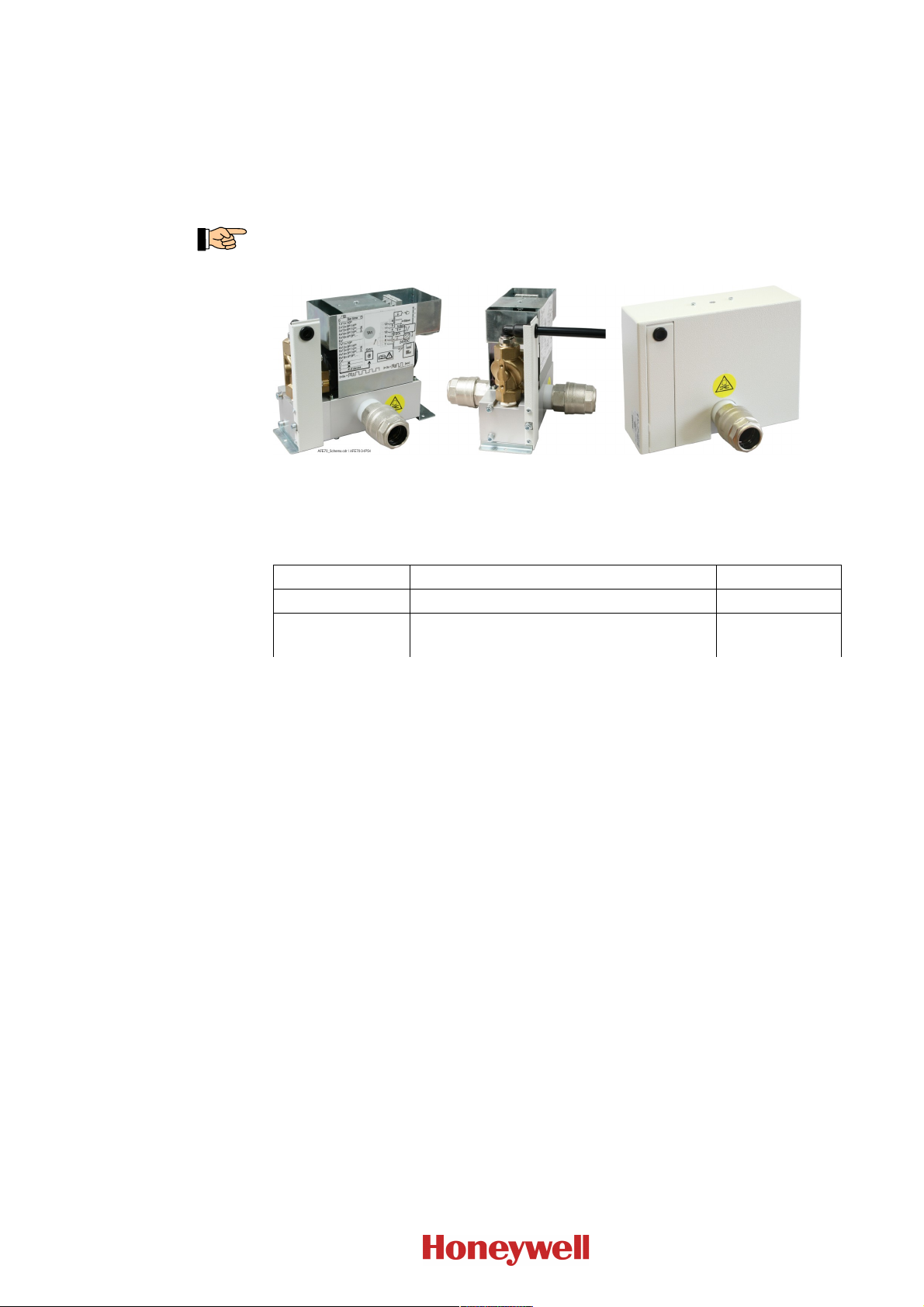

Fig. 1: View of the Automatic Purging Unit F-BO- AFE70

Left: Automatic Purging Unit F-BO-AFE70-3 without cover

Centre: Automatic Purging Unit F-BO-AFE70-3 view of the solenoid valve

Right: Automatic Purging Unit F-BO-AFE70-3 with cover

7

The following types of the Automatic Purging Units F-BO-AFE70 are available:

Type Name Art. No.

F-BO-AFE70-2 Automatic Purging Unit/3500L/IP54

F-BO-AFE70-3 Automatic Purging

Unit/5000L/DF/IP54

1) IP54 means: protected against dust in harmful quantities, complete protection against contact,

protection against water splashed from all directions

2) DF ... refrigeration area down to -20°C

Table 1: Type code of the Automatic Purging Units Series F-BO- AFE70

1) 2)

1)

F-BO-AFE70-2

F-BO-AFE70-3

The Automatic Purging Units F-BO-AFE70-2 and F-BO-AFE70-3 have outer dimensions and functionality in common, they essentially differ in the built-in solenoid valves which allow different air

flow rates and/or extended operating temperatures. The Automatic Purging Unit F-BO-AFE70-2

with a typical air flow rate of the solenoid valve of approx. 3,500 l/min (ANR) at 0.7MPa (7bar) is

designed both for small as well as for larger pipe systems with a large number of aspiration holes.

Thanks to the solenoid valve's typical air flow rate of approx. 5,000 l/min (ANR) at 0.7MPa (7bar),

the Automatic Purging Unit F-BO-AFE70-3 is suitable for even larger and further-flung pipe systems, and in addition it allows use in environments with low temperatures (down to -20°C). Notes

with regard to dimensioning can be found from page 14 onwards in Chapter 4: „Pneumatic components – dimensioning“. The functions of the Purging units are described starting on page 10 in

Chapter 2: „Manner of operation of a Purging unit“.

The information in this User Manual relates to the firmware release number PL0200_V_1.00 of the

control board. In Fig. 11 the position of the label is indicated where the version of the firmware

used can be read. Devices using firmware with another release number can differ in their function

from the range of functions described in this document.

1.2 Intended use

The Automatic Purging Units F-BO-AFE70 are designed and intended exclusively for purging

pipes of aspirating smoke detectors for fire detection systems in buildings, within the limits

described in this User Manual. Any other use of the devices is expressly not intended and forbidden.

I56-4252-010

D200-104-00

Page 8

8

Chapter 1 • Introduction User Manual Series F-BO-AFE70

The improper use of the Automatic Purging Unit F-BO-AFE70 can endanger life and health

or lead to damage to property. The manufacturer does not accept any responsibility for

improper use.

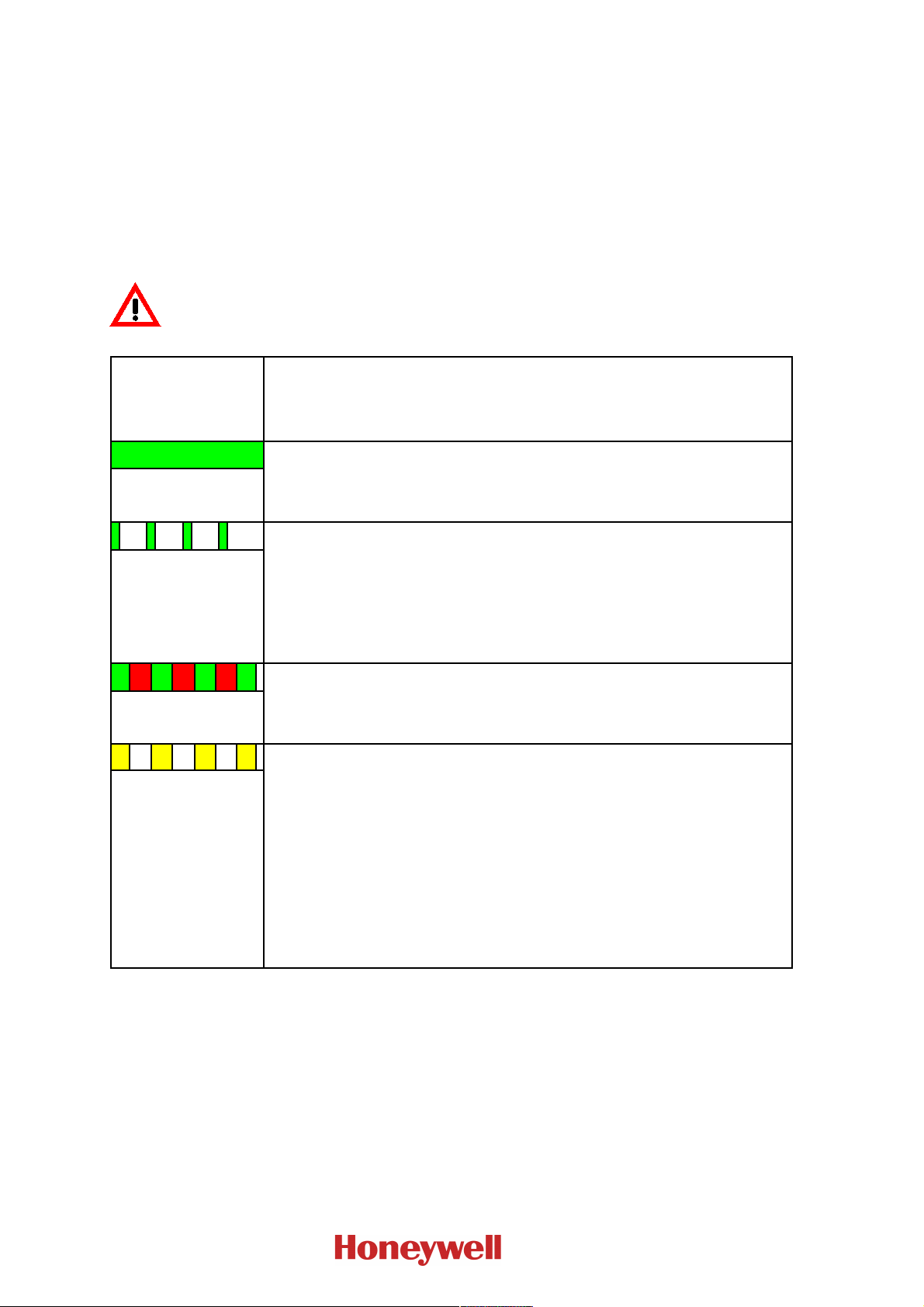

1.3 Types of symbols

Especially important sections of text in this User Manual are indicated with symbols. The following symbols are used:

Means DANGER! Ignoring these directions can result in danger to life and health.

Means ATTENTION! Ignoring these tips can result in system malfunctions or damage to prop-

erty.

Means TIP! Here the text contains tips for easier operation.

Means that the country-specific and/or the site-specific requirements of the DEVICE and/or

SYSTEM APPROVALS of the fire detection system must be observed.

1.4 Abbreviations, special terms

In order to improve the readability of this User Manual, the generic terms „Purging unit“ and

„F-BO-AFE70“ are used, and the exact type F-BO-AFE70-2 or F-BO-AFE70-3 is specified only if

it is necessary.

The terms „control board“ and AFS70-1 refer to the built-in electronic control of the Purging unit.

The term „overpressure“ refers to the difference between the static absolute pressure of the com-

pressed air and the static absolute pressure of the ambient air. In colloquial language, this is usually

referred to as „pressure“.

„ANR“ means that the specification applies to standard reference atmosphere (at a pressure of

0.1MPa (1bar), a temperature of 20°C and a relative air humidity of 65%).

In this User Manual, the term „aspirating smoke detector“ (which is also abbreviated as „ASD“)

refers both to

the actual evaluation unit of an ASD

as well as sometimes also to

the combination of the essential components of which an ASD consists, namely, the evaluation

unit, the ASD, the sampling pipe system and sometimes the compressed-air supply, etc.

In the context it is always clear what is meant in the particular case.

The fire detection control panel is also abbreviated as „FDCP“.

„PLC“ is the abbreviation for programmable logic controller.

Further abbreviations that are not familiar in everyday usage are avoided in this User Manual.

1.5 Important tips

Fire detection systems and their components must always be planned, installed and put into operation by specialists who are trained on a continuous basis. The specific specialist training on the

functions of the aspirating smoke detectors must be provided by the respective manufacturer or by

persons expressly authorized by the manufacturer for this purpose. Since the Purging unit will be

integrated directly into the pipe system of the ASD, the guidelines of the manufacturer of the ASD,

with regard to the construction and length of the pipe system, must be observed.

The devices that are used in addition to the ASD, such as the fire detection control panel, the power

supply, etc., are only mentioned as examples in this User Manual. The present manual does not

provide any information concerning the expert planning or design of a fire detection system. It

replaces neither the installer's required technical qualification nor his or her specific training.

I56-4252-010

D200-104-00

Page 9

User Manual Series F-BO-AFE70 Chapter 1 • Introduction

Pay attention to the danger notices given on page 3.

Beware of static charges! The electronic components used in the Automatic Purging Units

F-BO-AFE70 can be destroyed by static charges when the device is open. Before and during the

work being performed on printed circuit boards, static charges from your body must be reliably

discharged by touching an earthed piece of metal.

1.6 Scope of delivery

The Automatic Purging Units F-BO-AFE70 are assembled at the factory and supplied 100% function-tested. Only the pipe connecting parts have been enclosed for reasons of safe transport and still

have to be installed. Please check the delivery for completeness and transport damage before

assembling the equipment.

The delivery scope of the Automatic Purging Unit F-BO-AFE70 includes:

the valve block (with flange-mounted solenoid valve) that has been mounted on the bottom

plate and has been completely assembled and tested, including the mounted control board

AFS70-1, with protection cover (i.e., the housing) and cover.

two 25mm push-in fittings for the connection to the sampling pipe

two pipe nipples G3/4“×34mm

two plastic gaskets Ø32mm×10mm

this User Manual

an end-of-line resistor 5.6kOhm (for the line-monitoring of the fault output of the evaluation

unit of the aspirating smoke detector)

mounting material (three screws and three 6mm plugs for wall mounting)

three cable ties

transport packaging.

9

The Purging unit weighs approx. 3.2kg – the sturdy transport packaging has been designed to

avoid transport damage to any part. If the packaging has been damaged, you must inspect the

Purging unit especially thoroughly.

I56-4252-010

D200-104-00

Page 10

10

Chapter 2 • Manner of operation of a Purging unit User Manual Series F-BO-AFE70

2 Manner of operation of a Purging unit

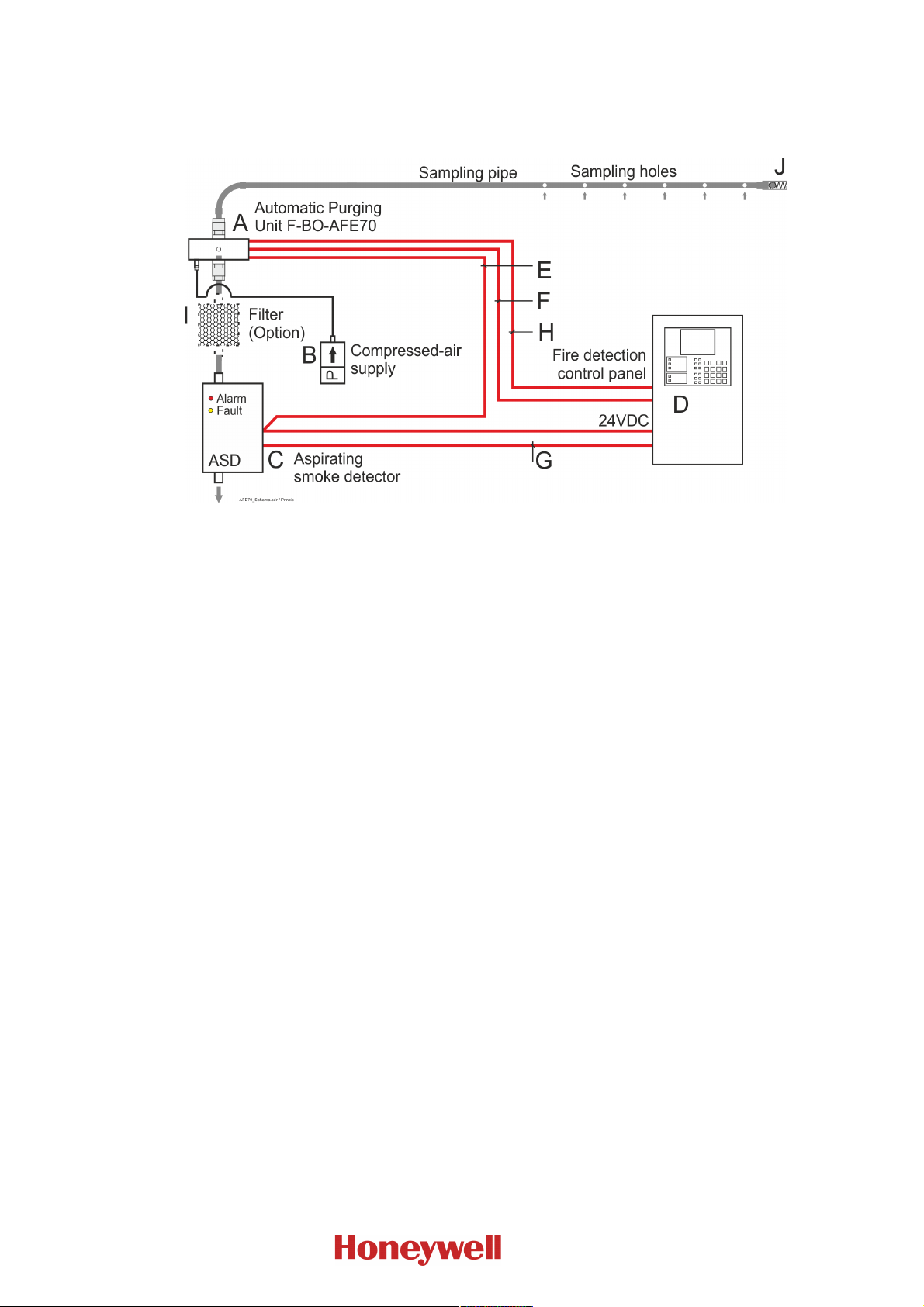

Typical structure of a system, consisting of fire detection control panel, aspirating smoke detector,

Purging unit, compressed-air supply and sampling pipe.

Fig. 2: Depiction of the structure of a system with an Automatic Purging Unit F-BO- AFE70 as well as

2.1 General

Aspirating smoke detectors use a low negative pressure to continuously sample air through aspiration holes of a sampling pipe that is laid in a room or building, and direct the air samples to a central measuring element (the evaluation unit) in order to examine the sample for various characteristics (e.g., the smoke concentration).

the required components and connections

A … Automatic Purging Unit F-BO- AFE70

B … Compressed-air supply

C … Aspirating smoke detector; in the above diagram an ASD with one pipe is shown, note that

for each pipe system a separate Purging unit is needed.

D … Fire detection control panel

E … Power supply line. Both the Purging unit as well as the ASD must be supplied with 24VDC.

F … Transmission of the fault message of the ASD to the fire detection control panel

G … Transmission of the fire alarm of the ASD to the fire detection control panel. The connection

can be established – as shown in the figure above – by means of a conventional line or via

loop modules.

H … The fire detection control panel actuates or activates the F-BO- AFE70

I … Air filter (optional), which can be located before the Purging unit. As a result, on the one

hand the Purging unit is protected against contamination, and on the other hand every Pur-

ging process also cleans the filter. If this is not possible (for example, because the filter case

is not pressure-resistant), the filter must be located between the Purging unit and the aspir-

ating smoke detector.

J … Check valve

Over the operating time, continuously aspirating the ambient medium through the relatively small

aspiration holes and a pipe network with a relatively small cross-sectional area leads to an accumulation of contaminations which can change the aspirated air flow and can even result in the measurement failing completely. In order to prevent this contamination, dirty pipe networks and filter

systems should be regularly cleaned („purged“) by means of compressed air.

For this purpose, clean compressed air is manually or automatically led into the pipe network

and/or the filter system at intervals. In order to protect the evaluation unit of the aspirating smoke

detector against damage caused by exposure to compressed air, in conventional Purging units first a

valve isolates the evaluation unit from the pipe network, and then compressed air is led into the

pipe network through a second valve that is connected to a T-piece.

I56-4252-010

D200-104-00

Page 11

User Manual Series F-BO-AFE70 Chapter 2 • Manner of operation of a Purging unit

2.2 Characteristic features of the Automatic Purging Unit F-BO-AFE70

In contrast to the structure of conventional Purging units, the Automatic Purging Unit F-BO-AFE70

only needs one (built-in) solenoid valve; furthermore, thanks to its thoughtful design, the Automatic Purging Unit F-BO-AFE70 ensures completely unhindered air flow from the sampling pipe

through the Purging unit to the evaluation unit of the ASD. The unit is controlled by an integrated

control board which has been developed for this special task and which replaces the PLC that is

normally used.

Thanks to the use of high-quality materials and the high-precision processing, the Automatic Purging Unit F-BO-AFE70 is designed to ensure flawless operation for many years.

The trouble-free operation can be affected by various environmental influences, such as temperature, humidity and air that is polluted by gases and aerosols, which can cause increased need for

maintenance and reduce the life span due to wear and tear or contamination.

The following features distinguish the Automatic Purging Unit F-BO-AFE70:

6 Purging programs, each with short or long Purging cycle

they can be manually controlled by means of an external push-button

internal clock for up to 6 daily timed, preventive Purging processes

automatic start if fault message is received from aspirating smoke detector

remote-controlled start (e.g., based on external calendar of factory or office hours)

if there are several F-BO-AFE70's, a time delay can be used so as not to stress the com-

pressed-air system

master-slave mode with actuation of one or more „slaves“

monitoring of the supply voltage

they can be used in a wide pressure range, F-BO-AFE70-2 up to 0.7MPa (7bar) and

F-BO-AFE70-3 up to 1.0MPa (10bar)

they are prepared for connection to all usual fire detection control panels, either via conven-

tional lines or via loop modules.

11

I56-4252-010

D200-104-00

Page 12

YYY

Y

12

Chapter 3 • Displaying of the operating conditions and operation User Manual Series F-BO-AFE70

3 Displaying of the operating conditions and operation

This chapter describes how the individual operating conditions of the Purging unit are indicated

and explains the respective operational features.

3.1 Operating conditions indicated by the status LED

The control board of the Purging unit continuously checks the status and indicates it in red, yellow

and green, by means of the status LED (see Fig. 5 on page 21).

The conditions that are indicated by the status LED are explained below in Table 2.

If the status LED is dark it is very likely that the Purging unit experiences a power failure or, if it

has been proven that the supply voltage is available, the componentry itself experiences a fault.

In any case you must assume that the Purging unit is inoperable. The fault must be removed as

soon as possible.

Condition of the

status LED

G = green, R = red

Y = yellow

G Condition: Normal condition

illuminates green

Condition of the control board / response time / effect / removal

Response time: Immediately

Effect: Componentry is in normal operation

Removal: Not necessary

↑=G flashing green

G R G R G R G

alternately green and

red

blinking yellow

Condition: No valid Purging program selected

Response time: Immediately

Effect: The componentry is all right, however it will not carry out an automatic

Purging process.

HINT: Switch position 0 allows you to set the time, switch position F allows you to

set the device number.

Removal: Select a valid Purging program.

Condition: The solenoid valve has been activated.

Response time: Immediately

Effect: The Purging process is currently running.

Removal: Not necessary

Condition: Either the aspirating smoke detector reports a fault, or a wire breakage

on the connection line from the Purging unit (terminals 3 and 4) to the aspirating

smoke detector has been detected.

Response time: Immediately

Effect: If the aspirating smoke detector reports a fault, the selected Purging process

will be started.

The aspirating smoke detector could be partly or completely out of order and therefore must be checked.

If the connection line is broken, this will be evaluated like a fault message from the

aspirating smoke detector.

Removal: If there is no fault of the aspirating smoke detector, the connection line

must be checked for freedom from faults.

I56-4252-010

D200-104-00

Page 13

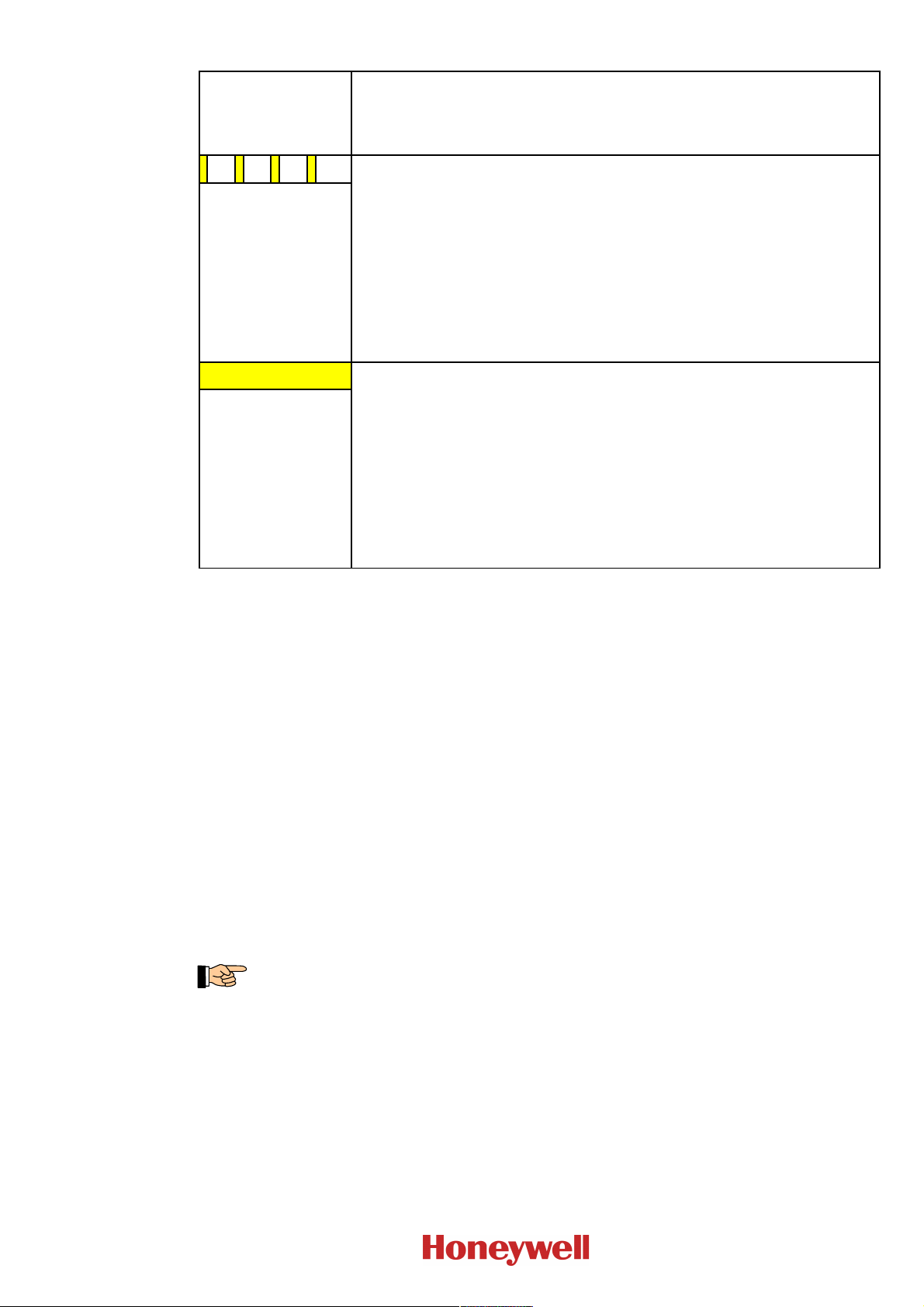

User Manual Series F-BO-AFE70 Chapter 3 • Displaying of the operating conditions and operation

Condition of the

status LED

G = green, R = red

Y = yellow

flashing yellow

Y Condition: There is a fault.

illuminates yellow

Condition of the control board / response time / effect / removal

Condition: A short circuit on the connection line to the fault contact of the aspirat-

ing smoke detector has been detected.

Response time: Immediately

Effect: If the Purging unit is synchronised by an external timer and the short circuit

exists for approx. 60 seconds, the internal clock will be synchronised to 00:00.

If the short circuit exists for less than 50 seconds, this will be indicated by the

status LED, but apart from that it will not be evaluated. If the short circuit exists

for more than 70 seconds, this will be evaluated as fault, the condition of the status

LED will change to illuminating yellow.

Removal: If the time has not been synchronised, the connection line must be

checked.

Response time: Immediately

Effect: Maybe the aspirating smoke detector is partly or completely out of order

and must be checked.

Removal: If an air flow fault of the aspirating smoke detector exists, further

manual Purging processes should be carried out in order to remove the clogging

(see on page 31 in Chapter 9.3: „Location of the display and operating elements

and terminals on the control board of the Automatic Purging Unit F-BO-AFE70“).

If there is another fault, it must be removed on the aspirating smoke detector.

If there is no fault of the aspirating smoke detector, the connection line must be

checked for freedom from faults.

13

Table 2: Possible conditions of the componentry status display

3.2 Operation by the user

If a valid Purging program has been set on the Purging unit, the unit operates in the automatic mode

and the status LED indicates the current condition.

In this case the Purging processes will be carried out automatically. If additional Purging processes

are needed, you can carry them out by pressing the external push-button „Manual activation“,

provided that this feature has been prepared by the installer of the system. In this case, the compressed air will be blown into the pipe network for as long as the push-button is being pressed, but

the maximum duration for one press of the push-button is limited to 2 minutes.

3.3 Operation by the installer

If a valid Purging program (Purging program „1“ … „C“) has been set on the Purging unit, additional Purging processes can be started manually.

A manual Purging process can be started by briefly pressing the button TA1; depending on the Purging program that has been set with the rotary switch „Purging program“ SW1, this will carry out a

long or short Purging process.

The button TA1 will only be accessible after removing the cover (see Fig. 4 on page 20).

I56-4252-010

D200-104-00

Page 14

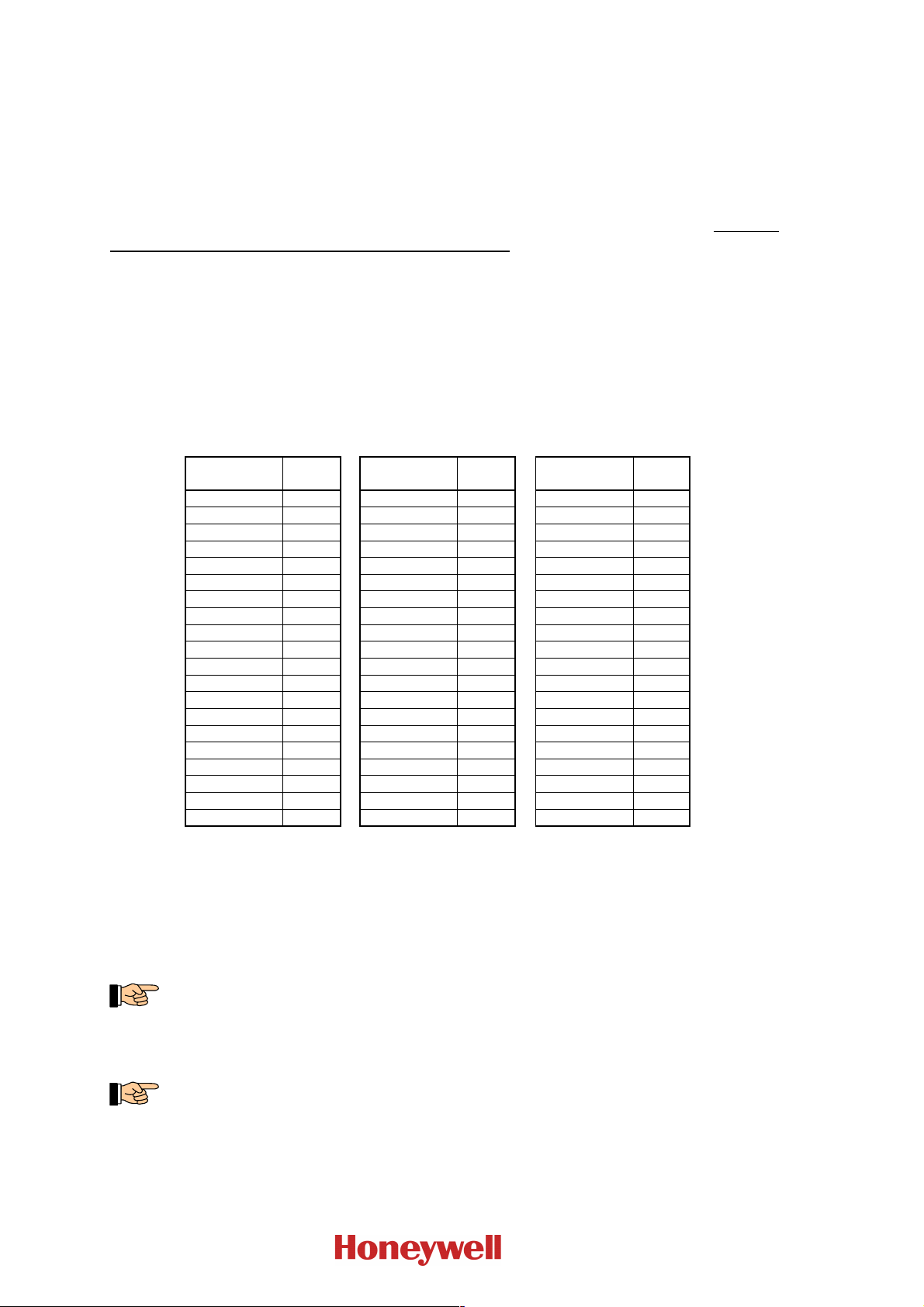

2.00 3.15 4.00 12.57 6.00 28.28

2.10 3.47 4.10 13.21 6.10 29.23

2.20 3.81 4.20 13.86 6.20 30.20

2.30 4.16 4.30 14.53 6.30 31.18

2.40 4.53 4.40 15.21 6.40 32.17

2.50 4.91 4.50 15.91 6.50 33.19

2.60 5.31 4.60 16.62 6.60 34.22

2.70 5.73 4.70 17.35 6.70 35.26

2.80 6.16 4.80 18.10 6.80 36.32

2.90 6.61 4.90 18.86 6.90 37.40

3.00 7.07 5.00 19.64 7.00 38.49

3.10 7.55 5.10 20.43 7.10 39.60

3.20 8.05 5.20 21.24 7.20 40.72

3.30 8.56 5.30 22.07 7.30 41.86

3.40 9.08 5.40 22.91 7.40 43.01

3.50 9.63 5.50 23.76 7.50 44.18

3.60 10.18 5.60 24.64 7.60 45.37

3.70 10.76 5.70 25.52 7.70 46.57

3.80 11.35 5.80 26.43 7.80 47.79

3.90 11.95 5.90 27.34 7.90 49.02

Diameter

[mm]

Area

[mm²]

Diameter

[mm]

Area

[mm²]

Diameter

[mm]

Area

[mm²]

14

Chapter 4 • Pneumatic components – dimensioning User Manual Series F-BO-AFE70

4 Pneumatic components – dimensioning

4.1 Purging unit

The geometry of the sampling pipe and the number and size of the aspiration holes depends on the

size and geometry of the room as well as the technical possibilities of the aspirating smoke detector

used. Thanks to the special construction of the Automatic Purging Unit F-BO-AFE70, it does not

cause an additional air resistance in the piping that is worth mentioning, and therefore it does not

have to be taken into consideration when dimensioning the pipe system.

Through intensive tests and experiments, the recommended values for dimensioning that are stated

below, have been established. Please note that the specified values are only approximate values

because a huge number of components (the length and the geometry of the pipe, the position of the

aspiration holes along the piping, the opening pressure of a check valve that may exist, etc.) affect

the Purging process. Therefore you can only make sure that the Purging unit is working properly by

carrying out a final test on the individual system.

First calculate the total aperture area of the aspiration holes that exist in the pipe network. In order

to keep the calculation simple, the table below shows the area of a circular hole, depending on its

diameter.

Table 3: Calculation aid for the determination of the total aperture area of the aspiration holes in the

sampling pipework; add up the stated values for the holes in the piping that is to be connected to

the Purging unit. The diameters that have been marked in bold in the table are the predetermined

standard values for the Series FAAST and VESDA.

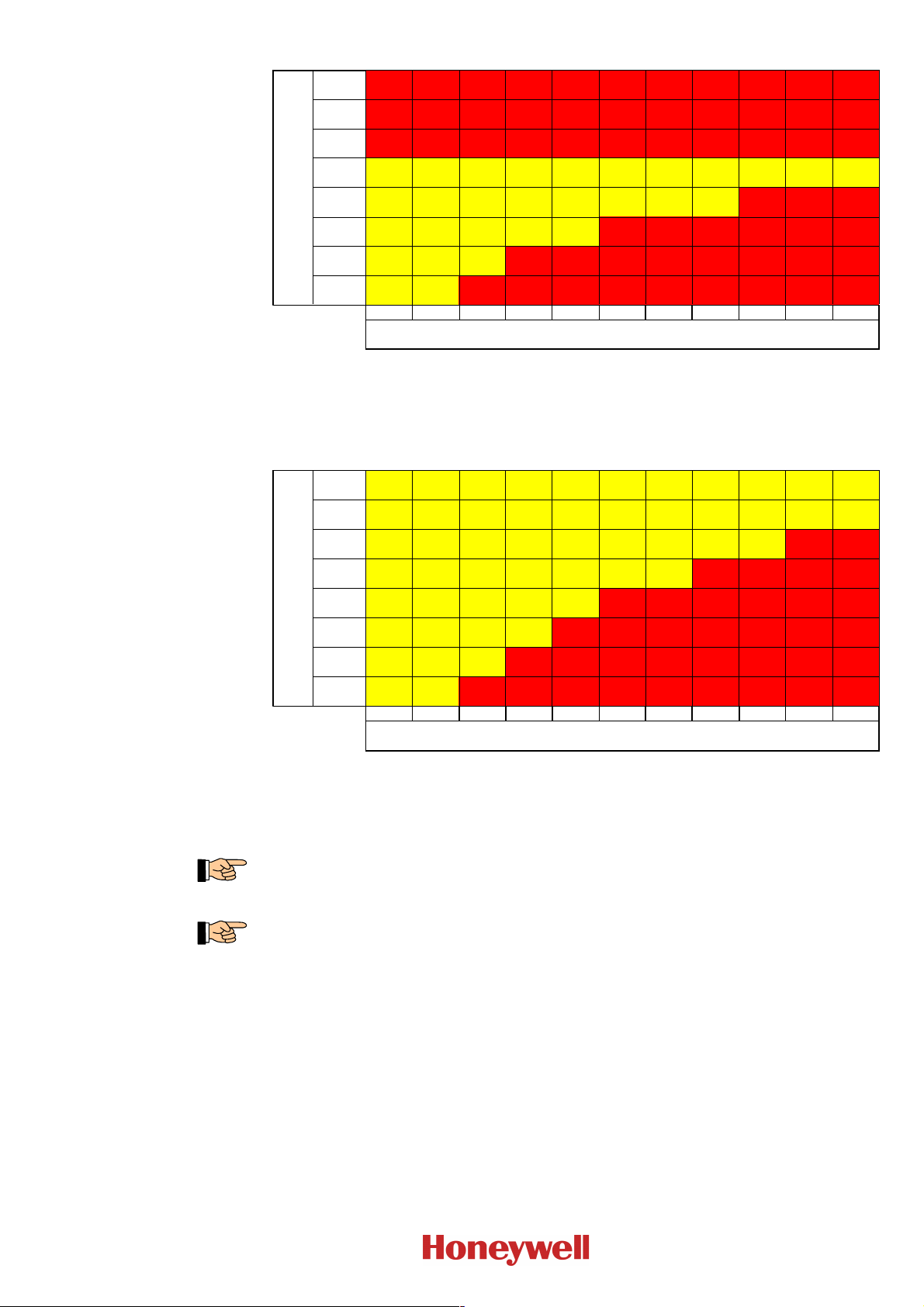

The tables below show the operation limits of the Automatic Purging Units F-BO-AFE70-2 and

F-BO-AFE70-3, depending on the input overpressure during the Purging process and on the sum of

the aperture area of the aspiration holes of the piping that is connected to the Purging unit.

The data is based on a DN25 pipe network that has been realised as straight branch, and on a

check valve with an opening pressure of 25kPa (0.25bar) that has been installed at the end of the

pipe network. A safety factor has been added to the data and therefore it can be regarded as

approximate value for normal system configurations, but the proper functioning of the respective

system must always be verified in a test!

During the Purging process, the input overpressure decreases, depending on the quality of the

compressed-air supply and the air volume that is consumed. The input overpressure value listed

in the table is the value when air is being consumed, i.e., the decreased value!

I56-4252-010

D200-104-00

Page 15

User Manual Series F-BO-AFE70 Chapter 4 • Pneumatic components – dimensioning

- - - - - - - - - - -

- - - - - - - - - - -

- - - - - - - - - - -

- - -

- - - - - -

- - - - - - - -

- - - - - - - - -

40mm² 60mm² 80mm² 100mm² 120mm² 140mm² 160mm² 180mm² 200mm² 220mm² 240mm²

Eingangsüberdruck

input overpressure

1.00MPa

(10bar)

0.90MPa

(9bar)

0.80MPa

(8bar)

0.70MPa

(7bar)

AFE70-2

(3500L)

AFE70-2

(3500L)

AFE70-2

(3500L)

AFE70-2

(3500L)

AFE70-2

(3500L)

AFE70-2

(3500L)

AFE70-2

(3500L)

AFE70-2

(3500L)

AFE70-2

(3500L)

AFE70-2

(3500L)

AFE70-2

(3500L)

0.60MPa

(6bar)

AFE70-2

(3500L)

AFE70-2

(3500L)

AFE70-2

(3500L)

AFE70-2

(3500L)

AFE70-2

(3500L)

AFE70-2

(3500L)

AFE70-2

(3500L)

AFE70-2

(3500L)

0.50MPa

(5bar)

AFE70-2

(3500L)

AFE70-2

(3500L)

AFE70-2

(3500L)

AFE70-2

(3500L)

AFE70-2

(3500L)

0.40MPa

(4bar)

AFE70-2

(3500L)

AFE70-2

(3500L)

AFE70-2

(3500L)

0.30MPa

(3bar)

AFE70-2

(3500L)

AFE70-2

(3500L)

gesamte Öffnungsfläche

total aperture area

- -

- - - -

- - - - - -

- - - - - - -

- - - - - - - -

- - - - - - - - -

60mm² 90mm² 120mm² 150mm² 180mm² 210mm² 240mm² 270mm² 300mm² 330mm² 360mm²

Eingangsüberdruck

input overpressure

1.00MPa

(10bar)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

0.90MPa

(9bar)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

0.80MPa

(8bar)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

0.70MPa

(7bar)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

0.60MPa

(6bar)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

0.50MPa

(5bar)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

0.40MPa

(4bar)

AFE70-3

(5000L)

AFE70-3

(5000L)

AFE70-3

(5000L)

0.30MPa

(3bar)

AFE70-3

(5000L)

AFE70-3

(5000L)

gesamte Öffnungsfläche

total aperture area

Table 4: Operation limits of the Automatic Purging Unit F-BO- AFE70-2, depending on the input pres-

sure that is available during the Purging process („input overpressure“) and the sum of the aperture areas of the piping that is to be connected to the Purging unit („total aperture area“). The

Automatic Purging Unit F-BO-AFE70-2 must not be operated with input overpressures of more

than 0.7MPa (7bar)!

15

Table 5: Operation limits of the Automatic Purging Unit F-BO- AFE70-3, depending on the input pres-

sure that is available during the Purging process („input overpressure“) and the sum of the aperture areas of the piping that is to be connected to the Purging unit („total aperture area“). The

Automatic Purging Unit F-BO-AFE70-3 must not be operated with input overpressures of more

than 1.0MPa (10bar)!

The Automatic Purging Unit F-BO-AFE70 still works perfectly at and below an input overpressure of 0.1MPa (1bar), but perhaps the resulting pressure built up in the pipe network will not

suffice to open the check valve and to clean the pipe network completely.

If the sum of the area of the aspiration holes of the piping exceeds the specified values, branches

can also be purged, by means of the master-slave mode (see from page 34 onwards in Chapter

9.4.2: „Connection of Purging units in the master-slave mode with direct actuation through the

fire detection control panel (in accordance with EN 54-13)“), through separate Automatic Purging Units F-BO-AFE70. This also applies analogously to the areas marked with „-“ in the

Tables 4 and 5.

4.2 Compressed-air supply

I56-4252-010

D200-104-00

The required size of the air vessel as well as the air delivery volume of the compressed-air supply

essentially depend on the following factors:

positive operating pressure of the compressed-air supply (air vessel overpressure)

chosen input overpressure of the Purging unit

total opening time of the solenoid valve during the Purging process.

Page 16

16

Chapter 4 • Pneumatic components – dimensioning User Manual Series F-BO-AFE70

There is a tool based on a spreadsheet which makes this dimensioning easier. In order to use it,

you need the following parameters:

- Ambient temperature

- Number of aspiration holes

- Diameter of aspiration holes

- Air vessel overpressure

- Actual input overpressure

The compressed air must always be clean and free from oil and water or other contamination. If

compressed air is used which is not sufficiently purified, these contaminations can result in malfunctions of the Purging unit or of the aspirating smoke detector. For example, the valve piston

system of the Purging unit can ice up or the measuring device of the aspirating smoke detector

can become oily, and therefore can become useless or can even be destroyed. This can also lead

to false alarms or increased contamination of the aspirating smoke detector as a result of particles

in the compressed air, which are again drawn in by the evaluation unit of the aspirating smoke

detector after a Purging process.

Metal shavings, other foreign particles or liquids in compressed-air lines must not get into the

Purging unit because otherwise the Purging unit can be damaged.

As recommended value for the purity of compressed air, Class 2 according to ISO8573-1:2010

should be used, which for oil permits a limit value of max. 0.1mg/m³ of compressed air. This

value also makes sense with regard to the durability of the compressed-air lines.

During the Purging process the Automatic Purging Units Series F-BO-AFE70 briefly need a very

large amount of air which is withdrawn from the compressed-air vessel of the compressed-air supply. The air output capacity of a compressor is only of secondary importance for the dimensioning

of the compressed-air supply of the Purging unit because usually the time between two Purging

processes is very long and therefore the compressor has sufficient time for charging the compressed-air vessel. Therefore, only the dimensioning of the compressed-air vessel is dealt with

below.

Fig. 3: Typical construction of a compressed-air system for providing the required compressed-air

volume of an Automatic Purging Unit Series F-BO- AFE70, and explanation of the terms used in

this chapter and by the calculation tool.

A … Air vessel overpressure: This is the pressure that prevails in the compressed-air vessel – as

well as the reference value that has been set on the compressor and at which the compressor

should turn itself on again.

B … Input overpressure: This is the pressure at the Purging unit's input (compressed-air connec-

tion) that results from the number and size of aspiration holes, from the flow rate of the

solenoid valve that has been installed in the Purging unit, as well as from the pressure

losses in the compressed-air supply pipe.

C … Pressure regulator (option): The pressure regulator SHOULD be used whenever the avail-

able air vessel overpressure is markedly higher than the recommended input overpressure,

and MUST be used whenever the air vessel overpressure is higher than the maximum input

overpressure of the F-BO- AFE70 used.

If several Purging units are supplied by the same compressed-air vessel, it is also possible

to use one pressure regulator for several Purging units. But in this case, please note the

maximum possible flow rate of the pressure regulator.

Tables 6 and 7 contain approximate values for the calculation of the minimum size of the compressed-air vessel of the compressed-air system, depending on the air vessel overpressure and the

chosen input overpressure of the respective Purging unit. The result of the table is given in litres

per second of operation of the solenoid valve, and therefore it still has to be multiplied by the

I56-4252-010

D200-104-00

Page 17

User Manual Series F-BO-AFE70 Chapter 4 • Pneumatic components – dimensioning

solenoid valve's operation time during a Purging process, in order to obtain the size of the air vessel.

The prerequisite for the validity of the tables in this chapter is a constant input overpressure of

the Purging unit during the Purging process; to ensure this an appropriately dimensioned pressure-limiting valve is required.

The calculation of the stated values is based on a pipe between compressed-air vessel and Purging unit that is very short and has a low velocity loss. Therefore, if the distances are large, see to

it that the compressed-air supply pipe is generously dimensioned in order to keep the pressure

losses low.

In order to estimate the required size of the compressed-air vessel, proceed as follows:

First determine on the basis of the specifications in Chapter 4.1 the required input overpressure of

the Purging unit.

Now use Table 6 or 7 to determine the air vessel's required sub volume (in litres per second of the

Purging process) at the intersection of the Purging unit's required input overpressure and the available air vessel overpressure. For the required total vessel volume you have to multiply the determined size by the solenoid valve's planned total opening time during the Purging process.

An example should explain the approach:

For your system you need an F-BO-AFE70-2 with an input overpressure of at least 0.5MPa (5 bar).

Furthermore, your planned air vessel overpressure of the compressor is 1.0MPa (10bar).

17

So, to determine the size of the compressed-air tank for an Automatic Purging Unit F-BO-AFE70-2

you use Table 6. The Purging unit's required input overpressure of 0.5MPa (5bar) and the air vessel

overpressure of the compressor of 1.0MPa (10bar) result in a vessel sub volume of 9.4 litres per

second of opened solenoid valve.

Depending on the Purging process that is to be set according to Chapter 9.5.1 in the course of commissioning, the solenoid valve's total opening time during the Purging process amounts to 3×3=9

seconds (for the short Purging process) or 5×5=25 seconds (for the long Purging process).

So in the case of the short Purging process and an air vessel overpressure of 1.0MPa (10bar), an air

vessel volume of at least 9.4×9=84.6 litres is needed, in the case of the long Purging process an air

vessel volume of at least 9.4×25=235 litres is needed.

I56-4252-010

D200-104-00

Page 18

1.4 2.4 3.4 4.8 6.7 9.2 12.4

- - -

1.5 2.6 3.8 5.5 7.8 11.0 15.5 - - -

1.7 3.0 4.3 6.4 9.4 13.8 20.6

- - -

1.9 3.4 5.0 7.7 11.7 18.4 30.9 - - -

2.2 3.9 6.0 9.6 15.6 27.5 61.7

- - -

2.5 4.7 7.5 12.8 23.4 55.0 - - - -

3.0 5.9 10.0 19.2 46.7

- - - - -

3.8 7.8 15.0 38.4 - - - - - -

5.0 11.7 30.0

- - - - - - -

7.5 23.4 - - - - - - - -

15.0

- - - - - - - - -

- - - - - - - - - -

Kesselüberdruck

air vessel overpressure

1.2MPa

(12bar)

1.1MPa

(11bar)

1.0MPa

(10bar)

0.9MPa

(9bar)

0.8MPa

(8bar)

0.7MPa

(7bar)

0.6MPa

(6bar)

0.5MPa

(5bar)

0.4MPa

(4bar)

0.3MPa

(3bar)

0.2MPa

(2bar)

0.1MPa

(1bar)

0.1MPa

(1bar)

0.2MPa

(2bar)

0.3MPa

(3bar)

0.4MPa

(4bar)

0.5MPa

(5bar)

0.6MPa

(6bar)

0.7MPa

(7bar)

0.8MPa

(8bar)

0.9MPa

(9bar)

1.0MPa

(10bar)

Eingangsüberdruck F BO AFE70‑ ‑ ‑2

input overpressure F BO AFE70‑ ‑ ‑2

1.7 2.5 4.1 6.3 8.8 12.5 17.7 25.0 37.8 62.5

1.8 2.8 4.6 7.1 10.3 15.0 22.1 33.3 56.7 125.0

2.0 3.1 5.2 8.3 12.3 18.8 29.4 50.0 113.3 -

2.3 3.6 6.1 10.0 15.4 25.0 44.2 100.0 - -

2.6 4.2 7.3 12.5 20.6 37.5 88.3 - - -

3.1 5.0 9.2 16.7 30.8 75.0 - - - -

3.7 6.3 12.2 25.0 61.7 - - - - -

4.6 8.3 18.3 50.0 - - - - - -

6.1 12.5 36.7 - - - - - - -

9.2 25.0 - - - - - - - -

18.3 - - - - - - - - -

- - - - - - - - - -

Kesselüberdruck

air vessel overpressure

1.2MPa

(12bar)

1.1MPa

(11bar)

1.0MPa

(10bar)

0.9MPa

(9bar)

0.8MPa

(8bar)

0.7MPa

(7bar)

0.6MPa

(6bar)

0.5MPa

(5bar)

0.4MPa

(4bar)

0.3MPa

(3bar)

0.2MPa

(2bar)

0.1MPa

(1bar)

0.1MPa

(1bar)

0.2MPa

(2bar)

0.3MPa

(3bar)

0.4MPa

(4bar)

0.5MPa

(5bar)

0.6MPa

(6bar)

0.7MPa

(7bar)

0.8MPa

(8bar)

0.9MPa

(9bar)

1.0MPa

(10bar)

Eingangsüberdruck F-BO-AFE70-3

input overpressure F-BO-AFE70-3

18

Chapter 4 • Pneumatic components – dimensioning User Manual Series F-BO-AFE70

Table 6: Estimate of the minimum size of the compressed-air vessel, depending on the air vessel overpres-

sure and the required input overpressure of the Automatic Purging Unit F-BO- AFE70- 2. The

values are given in litres per second of operation of the solenoid valve.

Table 7: Estimate of the minimum size of the compressed-air vessel, depending on the air vessel overpres-

sure and the required input overpressure of the Automatic Purging Unit F-BO- AFE70- 3. The

values are given in litres per second of operation of the solenoid valve.

I56-4252-010

D200-104-00

Page 19

User Manual Series F-BO-AFE70 Chapter 5 • Final assembly, mechanical structure and dimensions

5 Final assembly, mechanical structure and dimensions

5.1 Final assembly

For reasons of safe transport, the pipe connecting components are enclosed and still have to be

installed.

Figure 4 gives an overview of the structure of a Purging unit after final assembly.

In order to assemble the device, proceed as follows:

Remove the two M3 screws from the cover and lift the cover of the Purging unit.

Screw a pipe nipple G3/4“×34mm by hand into the thread of the 25mm push-in fitting as far as it

will go and completely push the plastic gasket Ø32mm×10mm onto the pipe nipple.

Remove the protective cover from an opening of the housing; keep the protective cover for later

use.

Now screw the part of the pipe nipple's thread that protrudes from the plastic gasket by hand into

one of the two fitting threads of the Purging unit's body as far as it will go.

Use a wrench of the right size (wrench size 32mm) to turn the 25mm push-in fitting by approxim-

ately another 30° until it seats tightly and seals perfectly.

19

Repeat the procedure described above for the other side of the Purging unit.

Cover the openings of the 25mm push-in fittings with the protective covers and only remove the

protective covers just before connecting the sensor pipe network.

By carrying out this step, the final assembly has been completed.

It must be ensured that after final installation of the Purging unit, no push-in fitting can be

loosened by hand, and that all push-in fittings are perfectly sealed. Therefore, check the

tight seat of the push-in fittings after final assembly and prior to commissioning.

You must never use any glue for the connections of the sampling pipes on the Purging unit and

on the aspirating smoke detector.

The warranty claims shall terminate in case of violation of this rule.

I56-4252-010

D200-104-00

Page 20

20

Chapter 5 • Final assembly, mechanical structure and dimensions User Manual Series F-BO-AFE70

5.2 Mechanical structure

Fig. 4: View of the Automatic Purging Unit F-BO- AFE70 with cover taken off

Left: Automatic Purging Unit F-BO-AFE70-3 without cover

Right: Cover that has been removed from the Purging unit

A … Valve block

B … Compressed-air connection

C … Piping to the aspirating smoke detector

D … Control board AFS70-1

E … Cover of the Purging unit

F … Opening for the cable entry

G … Button TA1

I56-4252-010

D200-104-00

Page 21

User Manual Series F-BO-AFE70 Chapter 5 • Final assembly, mechanical structure and dimensions

5.3 Dimensions

21

Fig. 5: Dimensions of the Automatic Purging Unit F-BO- AFE70

A … Front view

B … View from below

C … View from the left side

D … Piping to the monitored area

E … Piping to the aspirating smoke detector

F … Position of the opening for the cable entry

G … Compressed-air connection F-BO-AFE70- 2

H … Compressed-air connection F-BO-AFE70- 3

I … Status LED

I56-4252-010

D200-104-00

Page 22

22

Chapter 6 • Safety devices User Manual Series F-BO-AFE70

6 Safety devices

By installing the Automatic Purging Unit F-BO-AFE70 in the customer's pipe network, and

through the connection to the other components also provided by the customer, namely the aspirating smoke detector, the fire detection control panel, the electrical power supply as well as the compressed-air supply, a machine in the sense of the Directive 2006/42/EC is created.

Therefore the adherence to this directive must be ensured during the whole installation; therefore

corresponding measures have to be taken which depend on the system construction, the installed

components as well as the use of the building, and which can also exceed the minimum requirements listed below. Therefore a corresponding danger evaluation is required in any case.

The following basic minimum requirements must always be fulfilled in any case and at any time:

A protection against contact with the movable valve piston of the Purging unit must be in place;

this requirement is fulfilled if both 25mm push-in fittings have been installed as described in

Chapter 5.1: „Final assembly“ and suitable pipes of the customer's pipe system have been inserted in such a way that it is not possible to enter and touch the valve piston without a tool, also

compare Chapter 8.2: „Connection to the sampling pipe and to the aspirating smoke detector“.

The possibility that the compressed air that is introduced into the pipe system during the Pur-

ging process can eject parts which can cause injuries or damage to property, must have been

prevented altogether. This can be done, for example, by altogether preventing such parts from

entering the compressed-air system or the piping, or by making sure that at the time of the Purging process nobody can stay in the danger zone, or by implementing other suitable protective

measures (e.g., deflectors) in the system.

All parts that will be pressurised during operation (for example, pipes, fittings, valves, hoses,

pressure regulators and filters) must have been approved for the application of compressed air

within the pressure range that is to be expected.

A device must be installed by means of which the system can be easily shut down both in the

event of an emergency as well as during normal operation. This is ensured, for example, if the

compressed-air supply to the Automatic Purging Unit F-BO-AFE70 can be interrupted easily

and quickly by means of a hand-actuated pneumatic valve. This valve must be freely accessible

and has to be appropriately labelled or signposted with „EMERGENCY STOP“.

If, in spite of all the safety precautions and protective measures that have been taken, unavoidable

risks still exist, the necessary warnings and warning devices have to be put up.

A failure to meet the requirements described here can have serious consequences for life,

limb and property; therefore make sure that all required devices are in place and function

flawlessly.

I56-4252-010

D200-104-00

Page 23

User Manual Series F-BO-AFE70 Chapter 7 • Special notes on using the F-BO-AFE70-3 in refrigeration areas

7 Special notes on using the F-BO-AFE70-3 in refrigeration areas

The problem in refrigeration areas is that due to condensation and ice formation, ice crystals can

form on aspiration holes and in the sampling pipe and have to be blown out regularly.

The place of installation of the Purging unit must be chosen such that condensation is precluded at

all times.

After installing the Purging unit at the place where it will be used, you have to wait until the Purging unit has become acclimatised to the ambient temperature of the refrigeration area before you

connect it. For this purpose it is recommended that the cover of the Purging unit be removed and

the two protective covers of the 25mm push-in fittings be removed (if they have been installed).

Take care that contaminants or foreign objects can not get into the push-in fittings.

After acclimatisation to the final ambient temperature, the two 25mm push-in fittings have to be

checked for tight seat and, if necessary, they have to be tightened up. Only after that is the Purging

unit to be electrically connected and mechanically connected to the sensor pipe network and to the

compressed-air system, according to the instructions provided in the chapters that follow.

In particular, make sure that only dried compressed air is used for the operation of the Purging unit,

because residual humidity in the compressed air can lead to icing of the Purging unit.

Please note the demands on the compressed air, see Chapter 4.2: „Compressed-air supply“ from

page 15 onwards.

23

The sampling pipe must have the same temperature as the refrigeration area.

I56-4252-010

D200-104-00

Page 24

24

Chapter 8 • Mounting and connection of pneumatic components User Manual Series F-BO-AFE70

8 Mounting and connection of pneumatic components

This chapter describes the mounting of the Purging unit, the connection to the sampling pipe system as well as the aspirating smoke detector and the compressed-air connection.

Pay attention to the danger notices given on page 3.

Beware of static charges! The electronic components used in the Automatic Purging Unit

F-BO-AFE70-2 can be destroyed by static charges when the device is open. Before and during

the work being performed on printed circuit boards, static charges from your body must be reliably discharged by touching an earthed piece of metal.

8.1 Location of installation

The Purging unit must be installed in a clean room on a stable wall surface. The room temperature

must range between +5°C and +50°C in the immediate vicinity of the Automatic Purging Unit

F-BO-AFE70-2, and between -20°C and +40°C in the immediate vicinity of the F-BO-AFE70-3;

the relative humidity of the air must not exceed 95% at 40°C.

Within certain limits, the temperature range can be extended; please ask your supplier or the manufacturer about it.

Bear in mind that the life span of the components may be reduced by high temperature and

humidity. Therefore, it is recommended to install the Purging unit in an environment with a normal indoor climate (i.e., up to a maximum of +40°C), if it is possible.

The pipe connection between the Automatic Purging Unit F-BO-AFE70 and the evaluation unit of

the aspirating smoke detector should be as short as possible. Please note that this connecting piece

is not cleaned during the „Purging process“!

8.1.1 Permissible mounting positions

Fig. 6: Schematic illustration of the permissible wall mounting positions of the Automatic Purging

Unit F-BO- AFE70 together with the evaluation unit and the pipe system of the aspirating smoke

detector.

A … Mounting position with downward air flow in the direction of aspiration (compressed-air

connection at the bottom)

B … Mounting position with upward air flow in the direction of aspiration (compressed-air con-

nection at the top)

C … Mounting position with air flow from the left to the right in the direction of aspiration (com-

pressed air connection at the bottom right)

However, the mounting position with air flow from the right to the left in the direction of

aspiration (compressed-air connection at the top left) is not permissible!

I56-4252-010

D200-104-00

Page 25

User Manual Series F-BO-AFE70 Chapter 8 • Mounting and connection of pneumatic components

8.1.2 Installation of the Automatic Purging Unit F-BO-AFE70

Remove the two M3 screws from the cover and lift the cover of the Purging unit.

Position the Purging unit at a suitable place on the wall, so that later it can be easily connected to

the pipe system, the aspirating smoke detector and the compressed air. While doing so, note the

permissible mounting positions of the Purging unit and the mounting examples shown above in

Fig. 6.

Fig. 7: Schematic illustration of the mounting holes and of the location of the connections for the

sampling pipes and for the compressed air on the Automatic Purging Unit F-BO- AFE70

Mark the three mounting points of the bottom plate of the Purging unit, as shown above in Fig. 7,

on the wall and drill the mounting holes with a diameter of 6mm. Insert the plugs into the holes and

use the mounting screws to screw the bottom plate with the assembled valve block to the wall.

25

Since the installation of an aspirating smoke detector (laying the piping, making the electrical

connections, etc.) can extend over a longer period, it is recommended that the cover be reinstalled

immediately after completion of the work on the Purging unit, and that the free openings of the

25mm push-in fittings as well as of the compressed-air connection be kept closed until the pipe

network is connected, in order to protect the Purging unit.

8.2 Connection to the sampling pipe and to the aspirating smoke detector

For safety reasons and in order to allow easy connection, the Automatic Purging Units

F-BO-AFE70 are delivered with two 25mm push-in fittings which have to be installed as described

in Chapter 5.1.

Using other fittings or other components instead of the supplied 25mm push-in fittings can

lead to severe injuries or damage and therefore has to be refrained from!

The connection between the Purging unit and the sampling pipe must be airtight and pressure-resistant, the connection between the Purging unit and the aspirating smoke detector must be airtight,

but it does not have to be pressure-resistant. Therefore make sure you choose the suitable material.

You must never use any glue for the connections of the sampling pipes on the Purging unit and

on the aspirating smoke detector.

In order to make the connections on the Purging unit, please note the instructions in this chapter;

to make the connections on the aspirating smoke detector, please note the instructions of the manufacturer of the ASD.

The 25mm push-in fittings are designed to allow insertion of pipes with an outside diameter of

25mm and to let claws hinder the pipes from gliding out. The pipe is hermetically enclosed by a

gasket.

I56-4252-010

D200-104-00

For this purpose, the pipe that is to be inserted must be cut at a right angle and the cut surface must

be perfectly deburred on the inside and on the outside. Furthermore, the outer surface has to be

provided with a 30° chamfered edge, so as not to damage the gasket when inserting the pipe.

It is recommended that the pipes from the Purging unit to the sampling pipe as well as to the aspirating smoke detector should be constructed in such a way that, even after completed installation,

the pipes can still be pulled out from the 25mm push-in fittings by approximately 45mm in order to

make commissioning and maintenance easier.

Page 26

26

Chapter 8 • Mounting and connection of pneumatic components User Manual Series F-BO-AFE70

The pipe is connected by carefully inserting the pipe, which has been prepared as described above,

into the 25mm push-in fitting as far as it will go, the insertion depth is approximately 39mm. After

completing these activities, check the correct fit of the pipe.

The pipe system that is connected to the Automatic Purging Unit F-BO-AFE70, including all

components installed in the pipe, such as filters, must be designed such that it withstands the

static overpressure of the connected compressed-air supply with sufficient safety. Although usually this pressure is never reached during normal operation, this pressure can be reached in case

of severe clogging of the piping. Therefore you absolutely have to contact the suppliers of the

components and make sure that the components meet the requirements.

If the piping and the components connected to it have not been laid professionally or if

components are used which do not withstand the maximum pressure that is available,

severe injuries or damage can occur!

It is recommended that, if possible, the aspirating smoke detector should only be installed in the

course of commissioning the Purging unit, because the pneumatic connection between the Purging unit and the aspirating smoke detector has to be interrupted when commissioning starts.

8.2.1 Loosening the pipe connection

The Purging unit's connection to a 25mm pipe can also be loosened again by unscrewing the 25mm

push-in fittings.

Make absolutely sure that, before starting this activity, both the supply line of the compressed air as well as the supply voltage are reliably turned off or disconnected and that

they can not be turned on or connected again by mistake.

To unscrew the 25mm push-in fitting you need a suitable wrench for applying a counteracting force

on the hexagon surface of the push-in fitting (wrench size 32mm), as well as a suitable open-end

wrench (or, if necessary, a suitable pair of pliers) for unscrewing the push-in fitting via the octagon

surface (wrench size 35mm). It is not necessary to disassemble the push-in fitting, it only has to be

unscrewed as far as necessary to easily pull out the pipe by hand. When unscrewing the connection,

also make sure that the push-in fitting is not screwed off from the valve body by mistake.

Before the 25mm push-in fitting can be used again after pulling out the pipe, it must be screwed

together again (3Nm torque) and checked for flawless condition of all components.

After finishing the work, make sure that the fit of the push-in fittings is correct and safe.

8.2.2 Use of filters

If it must be expected that the air that is drawn in by the aspirating smoke detector will be particularly dirty, it is recommended that an air filter should be installed between the pipe system and the

Purging unit. Without appropriate prefiltering of the intake air, the accumulation of dust inside the

housing of the Purging unit can cause increased abrasion or even result in the valve piston getting

stuck.

In the event of a fault in the purification of the compressed air, solid or liquid particles in the compressed air which are aspirated again by the aspirating smoke detector after the Purging process has

been carried out, can cause deceptive alarms or result in the rapid contamination of the aspirating

smoke detector. As a precaution it is therefore recommended that a prefilter should be used between

the Purging unit and the aspirating smoke detector.

Many types of aspirating smoke detectors already have prefilters built into their evaluation unit,

therefore a separate prefilter between Purging unit and evaluation unit is not needed.

In any case, filters must comply with the system approval of the aspirating smoke detector used.

Pay attention to the project planning instructions of the manufacturer of the aspirating smoke

detector.

I56-4252-010

D200-104-00

Page 27

User Manual Series F-BO-AFE70 Chapter 8 • Mounting and connection of pneumatic components

8.2.3 Use of check valves

It is recommended that a check valve should be mounted at the end of every branch of the pipe system. Mounting a check valve ensures that the dirt particles and ice particles will be blown out of

the pipe in the best possible way. In addition, the check valve also serves to limit the pressure in the

piping, thereby relieving the aspiration holes during the Purging process. Ideally, the opening overpressure of the check valve should be around 25kPa (0.25bar).

The cleaning of the aspiration holes is also ensured without a check valve, but it is not ensured

that the dirt particles will be blown out along the whole length of the pipe in the best possible

way.

8.2.4 Connection diagram for a double pipe system

The following figure shows the schematic connection of the components needed for purging two

separate pipe systems of an aspirating smoke detector.

27

I56-4252-010

D200-104-00

Fig. 8: Aspirating smoke detector with two separate pipe systems. As a supplement to Fig. 2 (page 10),

electrical connection cables are not shown here in order to provide a clearer overview.

A … Aspirating smoke detector with two separate pipe systems

B … F-BO-AFE70 for the first pipe system

C … Filter before the Purging unit of pipe system 1 (option)

D … F- BO-AFE70 for the second pipe system

E … Filter before the Purging unit of pipe system 2 (option)

If the aspirating smoke detector used has separate fault outputs for each individual pipe network,

the Purging units can be actuated individually. As a result, the pipes can also be purged independently of each other in the event of a fault.

If the aspirating smoke detector used does not have separate fault outputs for each individual pipe

network, but has only one common fault output for all pipe networks, the Purging units must be

connected and operated in the master-slave mode. In this case, the pipes will always be purged

together.

Page 28

28

Chapter 8 • Mounting and connection of pneumatic components User Manual Series F-BO-AFE70

8.2.5 Connection diagram for far-flung pipe systems with master-slave mode of the Purging units

If the needed air flow rate exceeds the value of one Purging unit, two Purging units have to be

interconnected in the master-slave mode. The following diagram shows the schematic connection

of the components needed for purging far-flung pipe systems, using the example of a double-U

pipe system in the master-slave mode, in which both U pipe segments are purged together.

Fig. 9: ASD with one pipe network and two F-BO- AFE70's in master-slave arrangement. In the

example, two F-BO- AFE70's are needed because of the total aperture area of the aspiration

holes.

As a supplement to Fig. 2 (page 10), the electrical connection cables are not shown here in order

to provide a clearer overview; however, the logical sequence of the Purging process has been

drawn in with red dotted arrows.

A … Aspirating smoke detector with pipe networks in double-U design

B … F-BO-AFE70 (master) for the first U pipe network

C … F-BO- AFE70 (slave) for the second U pipe network

D … Filter for the entire pipe network. Since most aspirating smoke detectors only permit one

external filter per pipe system, in the example above the filter must be located before the two

Purging units (option).

E … A pressure regulator must be used if the compressed-air supply used can exceed the per-

missible pressure.

Which one of the two Purging units works as master unit and which one as slave unit is only

determined by the order in which they are cabled. The unit which receives the fault message from

the ASD is the master unit, the unit that is actuated by the master unit is the slave unit.

I56-4252-010

D200-104-00

Page 29

User Manual Series F-BO-AFE70 Chapter 8 • Mounting and connection of pneumatic components

8.3 Connection of the compressed air

The Automatic Purging Unit F-BO-AFE70 is provided with a commercial push-in fitting for easily

connecting the compressed air via a hose with an outer diameter of 10mm.

The push-in fitting of the Automatic Purging Unit F-BO-AFE70 may only be connected and disconnected by applying a counteracting force on the pipe elbow on the input of the valve in order

to avoid excessive strain. Connection and disconnection without applying an adequate counteracting force can cause damage to the solenoid valve, the cover of the Purging unit and the pushin fitting.

It is recommended that a shut-off device for the compressed air should be installed before the

compressed-air connection of the Purging unit; this makes installation, commissioning and any

maintenance jobs easier.

Only turn on the compressed-air supply after finishing all mounting, installation, connection and parameterisation work in the course of commissioning, as described starting on

page 40 in Chapter 10: „Commissioning and function test“. Turning on the compressed-air

supply at an earlier time can result in severe damage or injuries, depending on the condition of the system and the environment.

The compressed-air supply must be engineered in such a way that the maximum permissible input overpressure of the Purging unit will not be exceeded, see from page 43 onwards

in Chapter 12: „Specifications“.

If the used compressed-air supply can exceed the permissible pressure, a pressure regulator must be

used. This pressure regulator must be constructed in such a way that it does not limit the air flow

rate in an inadmissible way. The maximum permissible positive operating pressure as well as the

recommended air flow rate for the Purging unit that you are using can be found from page 43

onwards in Chapter 12: „Specifications“.

29

Furthermore, the compressed-air supply must be engineered such that the compressor and the compressed-air vessel as well as the supply line up to the Purging unit are sufficiently dimensioned, so

that during the Purging process the pressure that is available at the input of the Purging unit does

not decrease to an insufficient value, in which case the required air flow rate would no longer be

ensured for the duration of the Purging process.

The compressed air must always be clean and free from oil and water or other contamination. If