Page 1

208414, 208415 Replacement

Power Supply Kit for Electronic Air Cleaner

INSTALLATION INSTRUCTIONS

APPLICA TION

These kits replace the power supplies with W8600E solidstate performance indicators (SSPI) used in the F50F and

F58F Electronic Air Cleaners. See Table 1.

NOTE: The W8600E Remote Performance Indicator

driver circuit board has been calibrated with the

power supply in this kit. False wash indications

will occur if used with a different power supply.

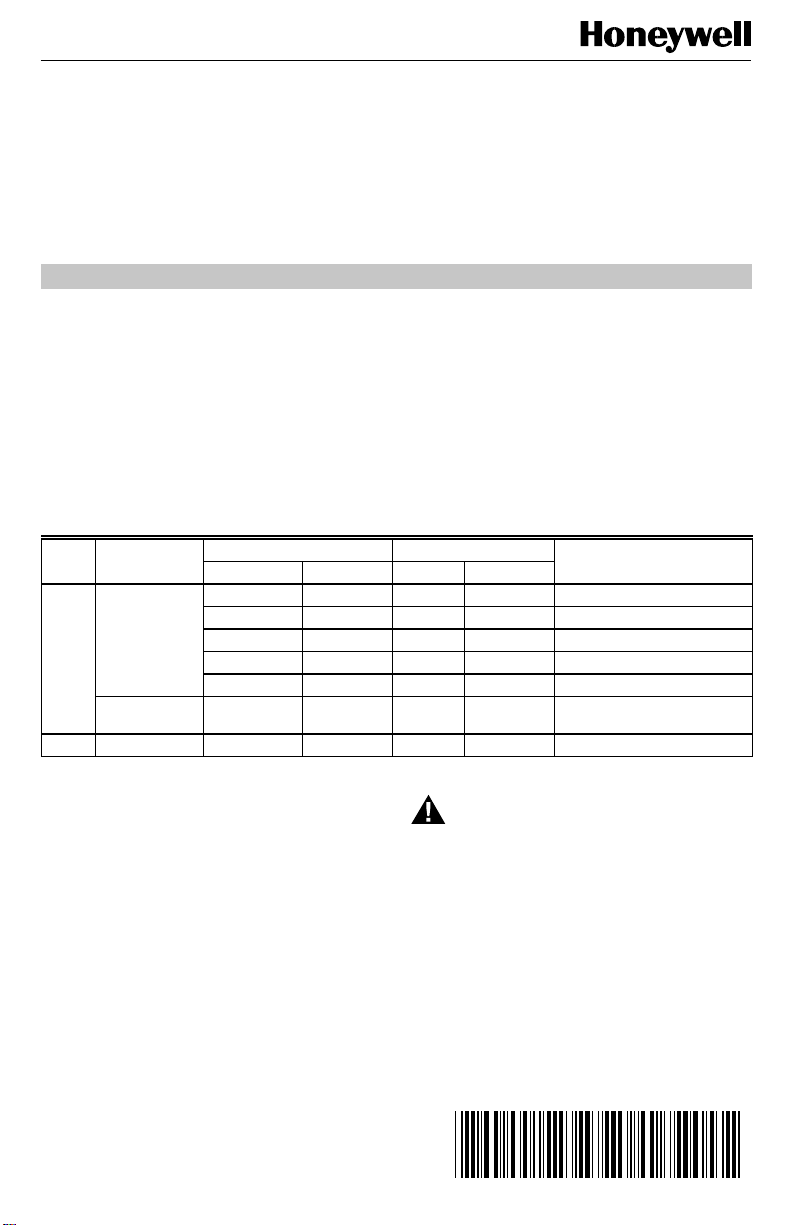

Table 1. Power Supply Replacement Guide.

EAC Electrical

Model Rating

F50F 120 Vac, 60 Hz 16 x 20 406 x 508 1.33 N/A 208414G

220/240 Vac,

50/60 Hz

F58F 120 Vac, 60 Hz 20 x 25 508 x 635 2.10 3 208414H

Nominal Size Ionizer Current

(in.) (mm) (mA) J6 Position

16 x 25 406 x 635 1.65 2 208414H

20 x 20 508 x 508 1.65 2 208414H

20 x 25 508 x 635 2.10 3 208414H

20 x 12-1/2 508 x 318 1.05 N/A 208414C

20 x 12-1/2 508 x 318 1.05 N/A 208415C

NOTE: Use the 120 Vac replacement power supply in

Table 1 when servicing the F50F or F58F

Electronic Air Cleaners that were modified with

the 203365A Transformer Kit to operate at 220/

240 Vac.

The power supply board in the 208414H Kit has been

calibrated to provide a selectable ionizer current output.

Select the correct ionizer current by moving the J6 shorting

bar to the correct position. See Tables 1 and 2. See Fig. 8

for location of J6. All other kits have single-current output.

Replacement Power Supply

(OS No.)

INST ALLATION

When Installing this Product…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition such as electrical shock.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

®U.S. Registered Trademark

Copyright © 1999 Honeywell Inc. • All Rights Reserved

W ARNING

ELECTRICAL HAZARD.

Can Cause Electrical Shock or Equipment

Damage.

Disconnect power before removing old power

supply board and installing replacement power

supply board.

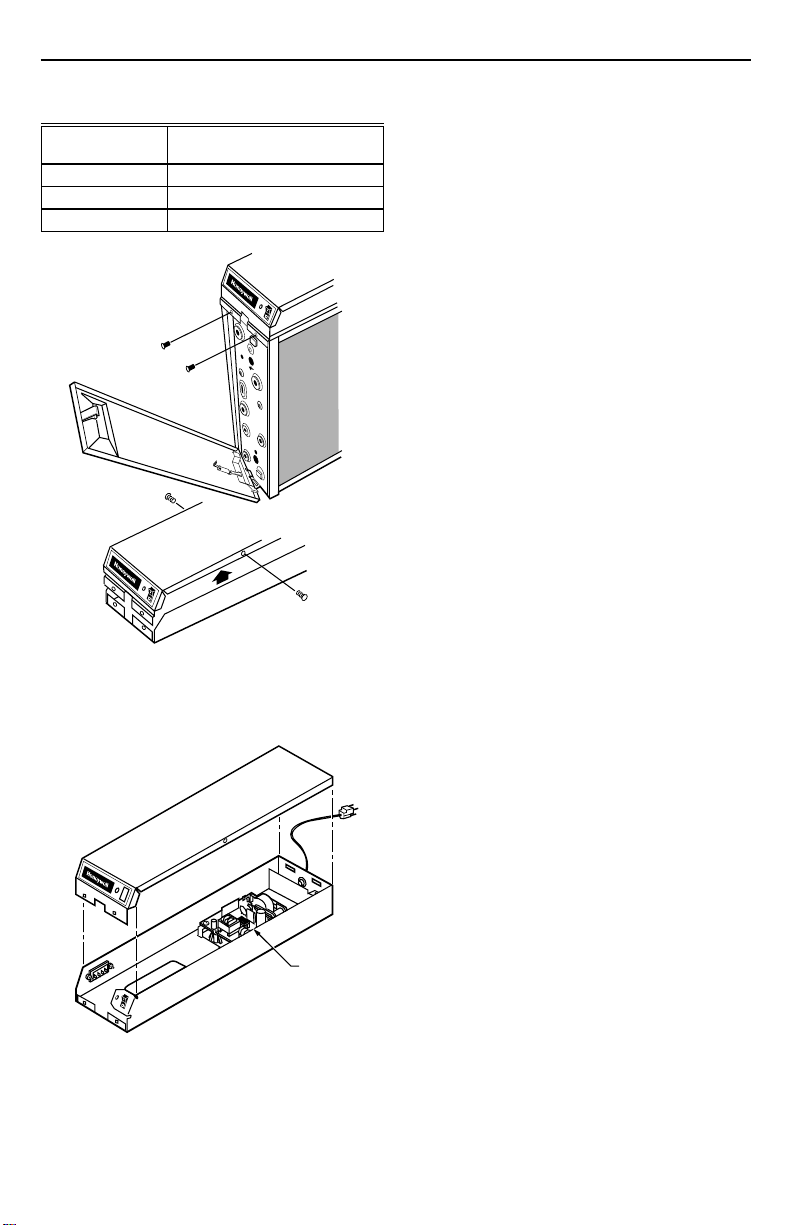

T o Remove Old Power Supply Board

NOTE: Observe the location of leadwires to be replaced

on the power supply. Label the leadwires to

identify them for reconnecting later.

■ Open access door. See Fig. 1.

■ Open power box.

X-XX UL

69-1136-2

Page 2

208414, 208415 REPLACEMENT POWER SUPPLY KIT FOR ELECTRONIC AIR CLEANER

Table 2. Ionizer Current Output Guide

J6 Shorting Bar

Position Ionizer Current Output (mA)

32.10

21.65

11.05

REMOVING COVER

FROM POWER BOX.

2

1

3

M5676A

Fig. 1. Remove cover from power box.

■ Disconnect the leads from 1, 2, 3, 4, P1, P2, P3, P4,

P5, P12, P14, P17, P18 and P21 on the old power

supply. See Fig. 2 through 5.

POWER

SUPPLY

M5764

Fig. 2. Power supply location on F50F and F58F.

■ Remove and discard W8600E terminal block and

wiring. Set aside screws for later use.

■ Remove and set aside the sheetmetal screws holding

the board in place.

■ Discard the old power supply.

Install New Power Supply

■ When replacing the power supply, reuse the remain-

ing leadwires in the air cleaner when removing the old

power supply.

■ Install W8600E terminal block and wiring supplied

with this kit using screws previously removed.

■ Align the mounting holes and mount the new power

supply in the air cleaner, using the sheetmetal screws

removed earlier. Orient the power supply so P1 and

P2 are toward the front (closest to the switch and

neon light).

■ Route the remaining leads so the P3 and P4 leads

are separate from the low voltage leads. Route all

high voltage leads around, rather than over, the power

supply board. Low voltage leads can go over the

power supply board.

■ Connect leads to the terminals on the new power supply.

IMPORTANT

Do not splice ionizer and collector leads. These

leads must be unbroken to avoid electrical shock

through the connector or tape covering the splice.

■ Plug the electronic air cleaner directly into the correct

voltage and frequency outlet or reconnect power for

directly wired devices. See Fig. 3 or 4 for internal

schematic. The air cleaner operates correctly at any

fan speed on a multispeed or modulated speed

system wired with conduit or plugged in.

NOTE: To reduce the risk of electric shock, this product

has a grounding type plug with a third (grounding) pin. This plug fits only into a grounding type

power outlet. If the plug does not fit into the

outlet, contact a qualified electrician to install the

proper outlet. Do

not

change the plug in any way.

CHECKOUT

IMPORTANT

The following instructions are for use only by

qualified personnel.

With all components in place, turn on the air cleaner switch

and energize the system blower. Check the following

points of operation:

1. The neon light next to the on-off switch is on. If a

W8600E is part of the installation, check the wall

panel and make sure the ON LED is lighted. The

W8600E CHECK LED comes on if there is a

problem with the high voltage power supply.

2. Turn off the system blower. The neon light should go

off after a few seconds. The neon light shows that

the air cleaner is energized and the high voltage

power supply is working properly.

3. Turn on the system blower. With the air cleaner

energized, push the test button. A snapping sound

indicates that the collector voltage is present on the

cell. The W8600E CHECK LED comes on when the

test button is held down.

4. With a multispeed blower, repeat steps 1 through 3

for each fan speed.

5. If operation is not as described, refer to the Troubleshooting and Service section.

69-1136—2

2

Page 3

208414, 208415 REPLACEMENT POWER SUPPLY KIT FOR ELECTRONIC AIR CLEANER

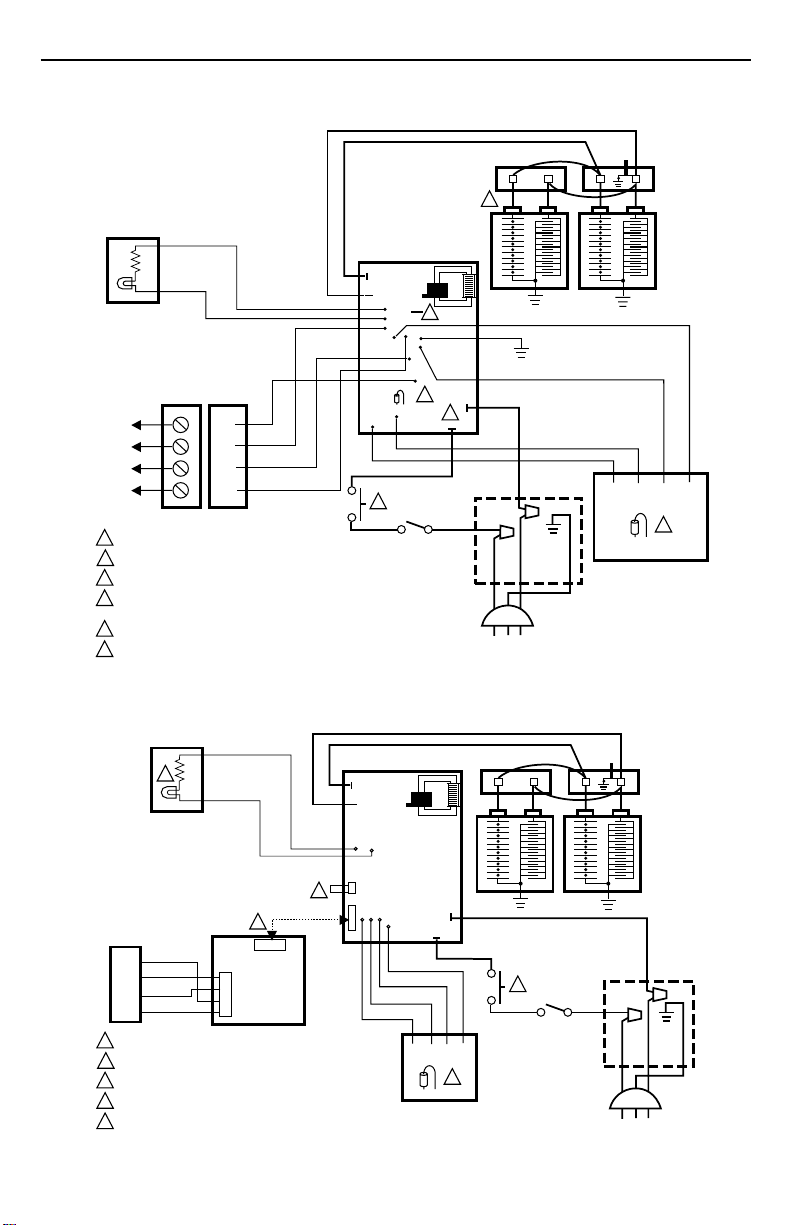

INTERNAL SCHEMATIC FOR ELECTRONIC AIR CLEANER WITH W8600E.

BLACK

BLACK

TERMINAL STRIP

FRONT BACK

1

1

TO

W8600E

WALL

PANEL

1 INTERLOCK SWITCH.

2 OUTPUT REDUCTION JUMPER.

3 AIRFLOW SWITCH DISABLE JUMPER.

4 RESISTOR FOR W8600 WASH INDICATION THRESHOLD. PRESENT ON POWER

SUPPLIES MANUFACTURED WITH DATE CODE 9430 AND EARLIER.

5 ONE-CELL UNIT SIMILAR, BUT WITH JUST ONE CELL.

6 P1, P2 TERMINALS ON 120V MODELS ONLY. POWER CONNECTIONS ON 240V MODELS ARE TO QUICK-CONNECTS ON POWER

SUPPLY TRANSFORMER. BROWN LEAD GOES TO TOP TERMINAL AND BLACK LEAD TO BOTTOM TERMINAL.

2

2

3

3

4

4

P3

P4

P21

P17

BLACK

1

BLACK

P5

P12

2

P18

BLACK COLLECTOR

POWER

SUPPLY

J2

2

J7

4

P14

3

1

4

R43

BLACK

6

P2

P1

RED IONIZER

5

GREEN

BROWN

BLACK

WHITE

RED

VIOLET

BLACK

TEST

BUTTON

BLACK

ORANGE

GRAY

GREEN

AIRFLOW SWITCH BOARD

W4 W2 W1 W3

Fig. 3. Internal schematic for F50F and F58F Electronic Air Cleaner with W8600E.

CONTACT

BOARD

3

M15096

BLACK COLLECTOR

BLACK

5

BLACK

2

4

BLUE

B4

RED

YELLOW

GREEN

5

3

2

1

R3

Y2

G1

1 INTERLOCK SWITCH.

2 SHORTING BAR.

3 AIRFLOW SWITCH DISABLE JUMPER.

4 W8600E REMOTE PERFORMANCE INDICIATOR DRIVER.

5 NEON LIGHT.

J1

J2

P3

P4

E5

E4 E3

J1

E6

J5

BLACK

E2

GRAY

VIOLET

E1

ORANGE

AIRFLOW SWITCH BOARD

POWER

SUPPLY

P2

P1

BLACK

W4 W2 W1 W3

3

RED IONIZER

BROWN

BLACK

RED

BLACK

1

BLACK

Fig. 4. Retrofitted schematic for F50F and F58F Electronic Air Cleaner with W8600E.

3

TEST

BUTTON

BLACK

CONTACT

BOARD

WHITE

GREEN

M15097

69-1136—2

Page 4

208414, 208415 REPLACEMENT POWER SUPPLY KIT FOR ELECTRONIC AIR CLEANER

BLACK

7

BLACK

4

BLUE

B4

RED

YELLOW

GREEN

5

3

2

1

R3

Y2

G1

1 INTERLOCK SWITCH.

2 SHORTING BAR.

3 AIRFLOW SWITCH DISABLE JUMPER.

4 W8600E REMOTE PERFORMANCE INDICIATOR DRIVER.

5 TOP TERMINAL ON TRANSFORMER

6 INPUT POWER. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

7 NEON LIGHT.

J1

J2

P3

P4

E5

2

J1

Fig. 5. Retrofitted schematic for 220/240 Vac F50F Electronic Air Cleaner with W8600E.

TROUBLESHOOTING AND SERVICE

W ARNING

ELECTRIC SHOCK HAZARD.

Can Cause Personal Injury or Equipment

Damage. Instructions are Only for Use by

Qualified Personnel.

The following procedures expose hazardous live

parts. Disconnect from power between checks and

proceed carefully.

Tools and Equipment

Troubleshooting the electronic air cleaner requires:

• Needle-nose pliers for stringing ionizer wires and

inserting edge connectors.

• Test meter.

Although a meter is needed for some steps, the primary

diagnostic tools are the

See Fig. 6.

neon light

and the

test button

.

BLACK COLLECTOR

RED IONIZER

E6

J5

E4 E3

BLACK

E2

VIOLET

5

BROWN

E1

ORANGE

GRAY

W4 W2 W1 W3

AIRFLOW SWITCH BOARD

Test Button

When pushed, the

to ground. The resulting arcing sound indicates that high

voltage is being supplied to the collector. The solid state

power supply controls current flow to the collector. On air

cleaners with a W8600E, the CHECK LED comes on

when the

BLACK

1

BLACK

3

test button

test button

TEST

BUTTON

RED

BLACK

BLACK

BLACK

L1 L2

shorts from collector voltage

is held down.

COLLECTOR

TERMINAL

IONIZER

TERMINAL

COLLECTOR

TERMINAL

CONTACT

BOARD

6

220/240V

50/60 Hz

WHITE

GREEN

M15098

Neon Light (On Power Box)

The neon light is powered through the power supply and is

on when the power supply output voltage is normal.

69-1136—2

M6155

Fig. 6. Use an ohmmeter to check

the electronic cells for short circuits.

4

Page 5

208414, 208415 REPLACEMENT POWER SUPPLY KIT FOR ELECTRONIC AIR CLEANER

Check Led (Air Cleaners With W8600E)

The CHECK LED on the W8600E lights to indicate the

following problems: excessive dirt loading (beyond that

required to activate the WASH LED), partial shorting of

the collector, continuous ionizer or collector arcing,

power supply failure, excessive ionizer current, or any

condition causing a major reduction in high voltage.

Power Supply

W ARNING

ELECTRIC SHOCK HAZARD.

Can Cause Personal Injury.

Always turn off power and remove access door

before removing the power box or its cover.

The solid state power supply assembly has no field

serviceable components. If troubleshooting indicates a

power supply or solid state performance indicator problem,

replace the entire power supply assembly.

Troubleshooting Procedure

The electronic air cleaner Troubleshooting chart shows

how to quickly isolate an air cleaner problem. The primary

diagnostic tools are the

Some steps require a meter. See Fig. 7.

TROUBLESHOOTING AIR CLEANERS WITH SOLID STATE PERFORMANCE INDICATOR.

START

MAKE SURE ELECTRONIC

CELL(S) ARE CLEAN, DRY

AND PROPERLY INSTALLED.

MAKE SURE PREFILTER(S)

ARE IN CABINET SLOT

FARTHEST FROM FURNACE.

TURN ON ELECTRONIC AIR

CLEANER AND SYSTEM

FAN.

CHECK NEON LIGHT.

CORRECT

WIRING.

WIRING

CHECK WIRING BETWEEN

W8600E AND AIR CLEANER.

USE MAX NO. 18 4-WIRE

THERMOSTAT CABLE

CONNECTED 1(G) TO 1(G),

2(Y) TO 2(Y), 3(R) TO 3(R),

AND 4(B) TO 4(B).

1

2

3

NOT OK

WIRING OK

REPLACE

3

W8600E.

FOR POWER SUPPLY REPLACEMENT, SEE FORM 69-0776.

W8600E HAS THREE LIGHT-EMITTING DIODES (LEDS):

ON, WASH, AND CHECK.

W8600E OPERATION CAN BE CHECKED SEPARATELY.

SEE W8600E INSTRUCTIONS.

PUSH TEST BUTTON AND

LISTEN FOR SNAPPING

SOUND.

OFF

CHECK ON LED IN

W8600E

OFF

DEPRESS AND HOLD DOWN

TEST BUTTON. CHECK

LED IN W8600E

SHOULD COME ON

TURN OFF AIR CLEANER

AND REMOVE CELL(S)

ONLY (NOT PREFILTERS).

CLOSE ACCESS DOOR

AND TURN ON AIR CLEANER.

WASH LED IN W8600E

SHOULD COME ON.

OFF

ELECTRONIC AIR CLEANER

AND W8600E ARE OK.

ON

ON

ON

YES

2

ON

2

2

TO USE THIS CHART:

1.

FOLLOW THE STEPS IN ORDER; DO NOT SKIP AROUND.

2.

EACH TIME YOU ISOLATE AND FIX A PROBLEM, GO BACK TO START.

3.

REPEAT ALL THE STEPS UNTIL THE AIR CLEANER CHECKS OUT OK.

THESE SERVICING INSTRUCTIONS ARE FOR USE BY QUALIFIED PERSONNEL

ONLY. TO REDUCE RISK OF ELECTRIC SHOCK, DO NOT PERFORM ANY

SERVICING OTHER THAN CONTAINED IN THE OPERATING INSTRUCTIONS

UNLESS YOU ARE QUALIFIED TO DO SO.

PUSH TEST BUTTON

OFF

AND LISTEN FOR

SNAPPING SOUND.

NO

NO

TURN OFF AIR CLEANER

AND REMOVE CELL(S)

ONLY (NOT PREFILTERS).

CLOSE ACCESS DOOR

AND TURN ON

AIR CLEANER.

CHECK NEON LIGHT.

INSPECT CELL(S) FOR:

BENT COLLECTOR

•

PLATES

BROKEN IONIZER

•

WIRES

DIRT ON INSULATORS

•

DAMAGED IONIZER

•

OR COLLECTOR

CONTACT TABS

YES

REPAIR OR

REPLACE

CELL(S).

WITH OHMMETER,

CHECK FOR SHORT

BETWEEN:

••CELL FRAME AND

IONIZER SECTION

CELL FRAME AND

COLLECTOR SECTION

CELL

SHORTED

REPLACE

CELL.

Fig. 7. Troubleshooting air cleaners with solid-state performance indicator.

ON

CELL OK.

WARNING

RISK OF ELECTRIC SHOCK

YES

OFF

CHECK FOR CORRECT INPUT

VOLTAGE ACROSS P1 AND P2

TERMINALS ON POWER SUPPLY.

TURN OFF AIR CLEANER,

REPLACE CELLS(S) AND

DISCONNECT FOUR W8600E

LEADS AT AIR CLEANER.

REPLACE ACCESS DOOR.

NO

TURN ON AIR CLEANER. PUSH

TEST BUTTON AND LISTEN

FOR SNAPPING SOUND.

REPLACE

POWER

BOX OR

POWER SUPPLY.

INFINITE

RESISTANCE

AIR CLEANER OK. TURN OFF

AIR CLEANER AND RECONNECT

W8600E LEADS 1(G) TO 1(G),

2(Y) TO 2(Y), 3(R) TO 3(R), AND

4(B) TO 4(B).

neon light

REPLACE LIGHT ASSEMBLY.

FIX

WIRING.

and the

WARNING

THIS STEP EXPOSES

DANGEROUSLY HIGH

VOLTAGE. ONLY A

QUALIFIED SERVICE

TECHNICIAN SHOULD

ATTEMPT THIS STEP.

NO

YES

NO

YES

1

test button

M5609E

.

5

69-1136—2

Page 6

208414, 208415 REPLACEMENT POWER SUPPLY KIT FOR ELECTRONIC AIR CLEANER

Modification To Reduce Ozone Odor

W ARNING

ELECTRIC SHOCK HAZARD.

Can Cause Personal Injury

Always disconnect power before opening power

supply cover.

The electronic air cleaner generates a small amount of

ozone in normal operation. During the first or second week

of operation, the amount may be higher because of sharp

edges on some of the new high voltage metal parts.

Normal use quickly dulls these edges.

The average person can detect the odor of ozone in

concentrations as low as 0.003 to 0.010 parts per million

(ppm). The electronic air cleaner contributes 0.005 to

0.010 ppm of ozone to the indoor air. The U.S. Food and

Drug Administration and Health and Welfare Canada

recommend that indoor ozone concentration does not

exceed 0.050 ppm. As a comparison, the

level in major cities is sometimes as high as 0.100 ppm.

However, if desired, the ozone generated by the air

cleaner can be reduced in one of two ways:

1. Install an activated carbon filter downstream from

the air cleaner. Make sure particles from the air filter

cannot fall into the air cleaner.

W ARNING

ELECTRIC SHOCK HAZARD.

Can Cause Personal Injury.

Only a trained service technician should perform

the following procedure.

outdoor

ozone

2. To reduce ozone production about 20 to 25 percent

and reduce efficiency about seven to ten percent,

depending on actual airflow delivered by the furnace

blower:

a. Unplug or disconnect power supply to the air

cleaner.

b. Open the access door.

c. Remove the power box cover. See Fig. 1.

d. Locate J5 shorting bar on the power supply.

See Fig. 8. Remove the shorting bar and

reinstall on only one pin.

NOTE: The ozone will be reduced, and the

shorting bar is available for reinstallation, if

needed.

e. Replace the power supply cover and access

door. Turn on the power.

f. Repeat the checkout procedure before leaving

the job.

J4 SHUNT

IN POSITION

TO DISABLE

NEON LIGHT

OUTPUT

J4

P3

J4 SHUNT

IN POSITION

TO ENABLE

NEON LIGHT

OUTPUT

J5 SHUNT

IN NORMAL

POSITION

J5 SHUNT

IN OZONE

REDUCED

POSITION

P4

J4

E5

E6

J4

3 2 1

J6

J5

J5

E4 E3

J5

Fig. 8. Move J5 shorting bar to reduce ozone

production about 20 to 25 percent.

E2

E1

J3

J1

P1

P2

M14200

69-1136—2

6

Page 7

208414, 208415 REPLACEMENT POWER SUPPLY KIT FOR ELECTRONIC AIR CLEANER

LIMITED TWO-YEAR WARRANTY

Honeywell warrants this product to be free from defects in the workmanship or materials, under normal use and service,

for a period of two (2) years from the date of purchase by the consumer. If, at any time during the warranty period, the

product is defective or malfunctions, Honeywell shall repair or replace it (at Honeywell’s option) within a reasonable period

of time.

If the product(s) is defective, please contact:

a) the dealer from whom you purchased it, or

b) the local Honeywell Authorized Repair Station, or

c) the local Honeywell Home and Building Control Office, or

d) the Honeywell Customer Assistance Center toll free at 1-800-468-1502, or

e) package the defective cell, power supply or other component with care, along with a bill of sale, receipt, or other

dated proof of purchase, and a short description of the malfunction, and ship it, prepaid, to the following address:

Honeywell, Inc.

Return Goods Department

1050 Berkshire Lane

Plymouth, MN 55441-4437

This warranty does not cover removal or reinstallation costs. This warranty shall not apply if it is shown by Honeywell that

the defect or malfunction was caused by damage that occurred while the product was in the possession of a consumer.

Honeywell sole responsibility shall be to repair or replace the product within the terms stated above. HONEYWELL SHALL

NOT BE LIABLE FOR ANY LOSS OR DAMAGE OF ANY KIND, INCLUDING ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES RESULTING, DIRECTLY OR INDIRECTLY, FROM ANY BREACH OF ANY WARRANTY, EXPRESS OR

IMPLIED, OR ANY OTHER FAILURE OF THIS PRODUCT. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so this limitation may not apply to you.

THE WARRANTIES SET FORTH HEREIN ARE EXCLUSIVE, AND HONEYWELL EXPRESSLY DISCLAIMS ALL

OTHER WARRANTIES, WHETHER WRITTEN, ORAL, IMPLIED OR STATUTORY, INCLUDING BUT NOT LIMITED TO

ANY WARRANTIES OF MERCHANTABILITY, WORKMANSHIP, OR FITNESS FOR A PARTICULAR PURPOSE.

This warranty gives you specific legal rights, and you may have other rights which vary from state to state.

If you have any questions concerning this warranty, please write our Customer Assistance Center, Honeywell Inc.,

P.O. Box 524, MN27-2164, Minneapolis, Minnesota 55440-0524 or call toll-free at 1-800-468-1502, Monday-Friday,

7:00 a.m.-5:30 p.m. Central time. In Canada, Honeywell Limited/Honeywell Limitee, 155 Gordon Baker Road, North

York, Ontario M2H 3N7.

7

69-1136—2

Page 8

208414, 208415 REPLACEMENT POWER SUPPLY KIT FOR ELECTRONIC AIR CLEANER

Home and Building Control

Honeywell Inc.

Honeywell Plaza

P.O. Box 524

Minneapolis, MN 55408-0524

69-1136—2

69-1136—2 G.H. Rev. 12-99 Printed in Mexico

Home and Building Control

Honeywell Limited-Honeywell Limitée

155 Gordon Baker Road

North York, Ontario

M2H 3N7

8

Loading...

Loading...