Page 1

F50F

Duct Mounted Electronic Air Cleaner

INSTALLATION INSTRUCTIONS

APPLICATION

The high efficiency F50F Electronic Air Cleaner is

mounted in the return air duct of a forced air heating,

cooling, or ventilating system. It captures a significant

amount of airborne particles 0.5 microns and larger from

the air circulated through it. All models have an internal

airflow switch to operate the F50F when the system

blower is on.

PLANNING THE INSTALLATION

Review Installation Requirements

The air cleaner should be installed where all the air

passing through the system circulates through it. The best

location is in the return air duct next to the blower compartment so the air cleaner can help keep the blower motor

and evaporator coils clean.

IMPORTANT

Do not mount in the discharge air duct.

For most efficient air cleaning, airflow must be spread

evenly across the face of the air cleaner. If the duct is a

different size than the air cleaner cabinet, gradual transitions are recommended. If the duct turns sharply just

before the air cleaner, turning vanes are recommended.

Applications with Air Conditioning

The air cleaner should be installed upstream from the

evaporator coil. The air cleaner will help keep the coil

clean, reducing maintenance.

Applications with a Humidifier

An evaporative humidifier can be mounted upstream from

the air cleaner. An atomizing humidifier should be mounted

downstream from the air cleaner, even though hard water

salts will be blown into the living space and deposited as

dust. If an atomizing humidifier must be mounted upstream

from the air cleaner:

1. Mount it as far upstream as possible from the

air cleaner.

2. Install a standard disposable furnace filter between

the humidifier and the air cleaner to trap water

droplets and hard water salts.

3. Frequently clean the air cleaner to prevent a hard

water salt buildup.

NOTE: The volume of water that passes through an

atomizing humidifier can overload the air cleaner,

resulting in hard water salts being deposited as

dust in the living space.

Applications with an Activated Carbon Filter

An activated carbon (charcoal) filter can be used to remove

odors or other gaseous contaminants (not particle-based) that

are not removed by the air cleaner. Locate the carbon filter:

• Downstream from the air cleaner. This means that dust

from the carbon filter will not be collected by the air

cleaner and will be deposited in the living space.

• Outside the air cleaner cabinet. Some carbon filters are

combustible and contact with high voltage could result

in smoke or fire.

• Where carbon granules cannot fall into the electronic

cell. If necessary, use a disposable furnace filter

between the carbon filter and the electronic cell.

• With proper transitions, if the activated carbon filter

requires a differently size duct than the air cleaner.

Allow 20 degrees expansion per side, per fitting.

NOTE: Honeywell does not offer carbon filters. Refer to

an activated carbon filter manufacturer for sizing

and application.

Applications with Outdoor Air Intake

Return air temperature must be at least 40°F (4°C). Lower

temperatures can cause ionizer wire failure. If outdoor air is

used, warm it upstream from the air cleaner by:

• Making sure the outdoor intake is far enough upstream

from the air cleaner so the return and outdoor air is

thoroughly mixed. Stratified air can dump a stream of

very cold air into one section of the air cleaner.

• Adding baffles upstream from the air cleaner to force

thorough air mixing.

• Installing a preheater if large amounts of outdoor air are

used. The preheater, which could be an electric strip

heater or hot water coil, should be controlled by a

thermostat. Hot water or steam coils should be

protected by a freeze-up control.

Optional W8600F

The F50F terminal board is recessed slightly so it or the wires

will not interfere with installation. The entire power supply box

can be unplugged and removed to provide access to the

terminals. The W8600F air cleaner monitor can be mounted in

the living area or in the furnace room. It should be located in a

convenient location to observe the display.

®U.S. Registered Trademark

Copyright © 1998 Honeywell Inc. • All Rights Reserved

X-XX UL

69-0754B-1

Page 2

F50F DUCT MOUNTED ELECTRONIC AIR CLEANER

Choose Location

Choose a location that is readily accessible for regular

inspection and cleaning. Allow at least 13 in. [330 mm] in

front of the access door for removing the prefilter and

electronic cell. Allow enough room above the power supply

so it can be serviced without removing pipes, ducts, or

other heating system components.

The air cleaner

will not exceed 40°F to 125°F (4°C to 52°C).

must

be installed where the temperature

Choose Mounting Position

WARNING

Heavy Equipment.

Can cause injury or equipment damage.

Do not mount the air cleaner with the access door

facing down. If the access door faces down, the

latch may not hold, and the cell and prefilter can

fall unexpectedly. Also, nothing holds the cell and

prefilter in place when the access door is opened.

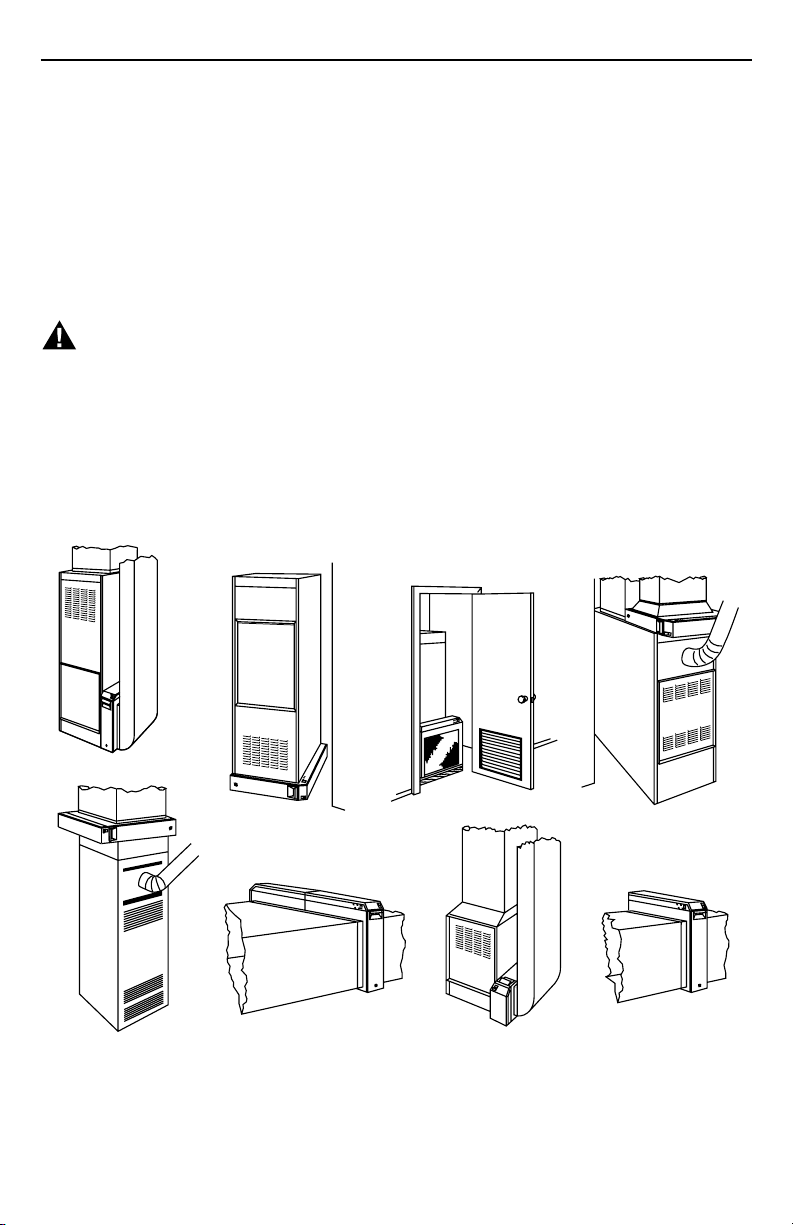

The air cleaner can be mounted in any position except with

the access door facing down. Following is a list of air cleaner

mounting positions for a variety of furnace installations.

A

B

NOTE: At least 13 in. [330 mm] clearance is required

between the access door and any obstructions

for cell and prefilter maintenance.

—

Upflow “Highboy” furnace:

cleaner is mounted vertically where return enters side

inlet of furnace. See Fig. 1A.

—

Downflow “Highboy” furnace

furnace (air cleaner cabinet can easily support weight

of furnace and air conditioner coil). Air cleaner is

mounted horizontally where return enters from below.

See Fig. 1B.

—

Upflow “Highboy” furnace:

cleaner is mounted vertically on furnace between

furnace and louvered return air opening in closet door.

See Fig. 1C.

—

“Lowboy” furnace:

in return plenum just above furnace, opposite supply

plenum. See Fig. 1D.

—

Downflow “Counterflow” furnace:

mounted horizontally in return duct or plenum just

above furnace. See Fig. 1E.

—

High capacity system:

be used together. See Fig. 1F.

—

Electric furnace or heat pump:

is mounted with access door on top. See Fig. 1G.

—

Horizontal furnace:

where return enters. See Fig. 1H.

C

Side installation; air

: Installation beneath

Closet installation. Air

Air cleaner is mounted horizontally

Air cleaner is

Two or more air cleaners can

Single cell air cleaner

Air cleaner is mounted vertically

D

69-0754B—1

E

G

F

Fig. 1. Mounting positions with a variety of furnace installations.

2

H

M11973

Page 3

F50F DUCT MOUNTED ELECTRONIC AIR CLEANER

Determine Duct Design Requirements

The air cleaner is adaptable to all new or existing forced air

heating, cooling and ventilating systems used in residential

applications. Transitions, turning vanes, or offsets may be

needed in some applications for effective operation.

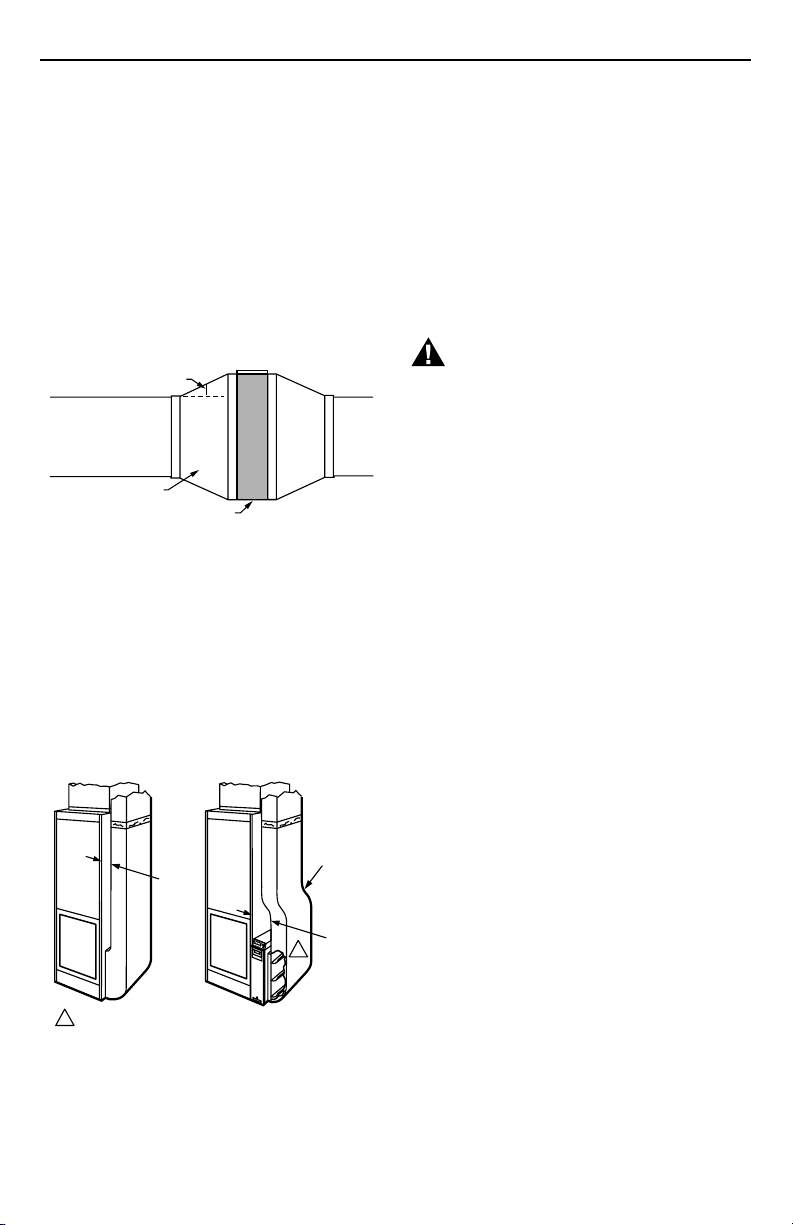

Transitions

Transitions are needed when the duct is a different size

than the air cleaner cabinet. Gradual transitions reduce air

turbulence and increase efficiency. Limit expansion to no

more than 20 degrees (about 4 in. per running foot

[100 mm per 300 linear mm]) on each side of a transition

fitting. See Fig. 2.

CHANGE DUCT SIZE GRADUALLY TO MINIMIZE TURBULENCE.

20 DEGREE EXPANSION PER SIDE PER

FITTING (4 in. PER LINEAR FOOT

[100 mm PER 300 LINEAR mm]).

RETURN

AIR DUCT

TRANSITION FITTING

ELECTRONIC AIR CLEANER CABINET

Fig. 2. Change duct size gradually to

minimize turbulence.

Turning Vanes

If the air cleaner is installed close to an elbow or angle

fitting, install turning vanes inside the angle to distribute

airflow more evenly across the face of the cell. See Fig. 3

Offsets

If the duct connection to the furnace in a side installation

allows less than 7 in. (178 mm) for mounting the air

cleaner cabinet, add an offset to the elbow. See Fig. 3.

TYPICAL USE OF DUCT OFFSET TO ALLOW

SPACE FOR ELECTRONIC AIR CLEANER.

M5626A

INSTALLATION

When Installing this Product…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

WARNING

Electric Shock Hazard.

Can cause electrical shock or

equipment damage.

Do

not

connect to power before installation

is complete.

Unpack Electronic Air Cleaner

J Check that all components are included. The electronic

air cleaner is shipped assembled. The unit consists of a

galvanized steel cabinet, power supply with on-off

switch and neon light, one or two electronic cells and

prefilters, access door with test button, and homeowner

literature package.

J W8600F (optional), mounting hardware and installation

literature must be ordered separately.

Clean Blower Compartment

J Remove and discard the existing furnace filter.

J Thoroughly clean the blower compartment.

J If possible, power vacuum the ductwork to remove

accumulated dust in an existing home, or construction

dirt in a new home. The electronic air cleaner cannot

remove dust that has settled in the blower compartment

and distribution ducts.

J Check the edges of the furnace fan blades for dirt

buildup and clean as necessary. The fan will not deliver

the rated cfm if the blades are dirty.

LESS

THAN

7 in.

[178 mm]

E

L

E

C

T

R

O

N

I

C

A

I

R

C

L

E

A

N

E

R

1 TURNING VANES HELP DISTRIBUTE AIRFLOW EVENLY.

Fig. 3. Typical use of duct offset to allow space for

electronic air cleaner.

OFFSET

AT LEAST

7 in.

1

[178 mm]

M5627A

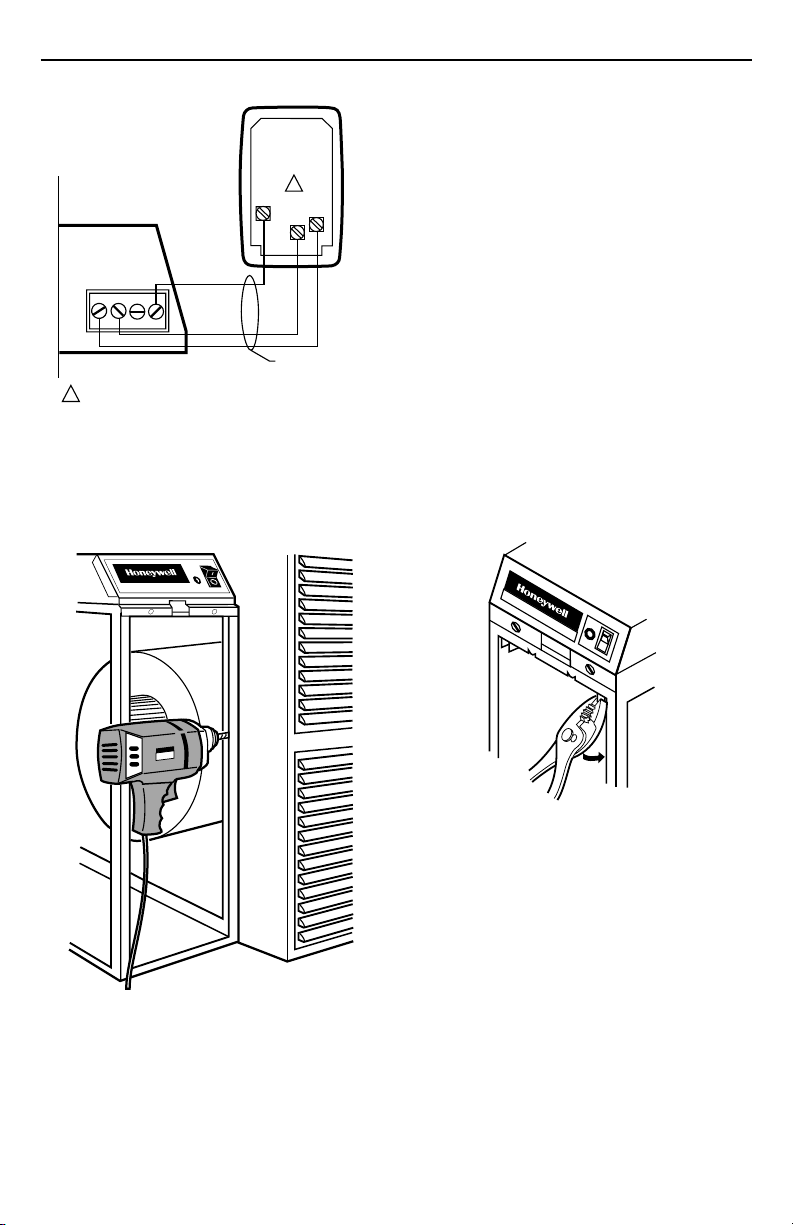

Fasten Cabinet To Furnace

NOTE: This procedure shows a side installation on a

typical highboy furnace. You may need to alter

the procedure to fit your application.

J Remove and set aside the access door, electronic

cell(s) and prefilter(s).

J Align the cabinet with the return air opening.

J Create opening in furnace to match air cleaner

cabinet opening.

J Install a transition if the furnace and air cleaner

openings are different sizes. See Fig. 2.

J Place blocks under the cabinet so the unit is firmly

supported and level. The 5/8 in. (16 mm) mounting foot

on the cabinet hinge plate provides the minimum

clearance required for the access door hinge.

J If a W8600F is used, first attach the wires to the

W8600F and then attach the wires to the air cleaner

power box terminal board. See Fig. 4 and the W8600F

installation literature, form 69-1200.

3

69-0754B—1

Page 4

F50F DUCT MOUNTED ELECTRONIC AIR CLEANER

W8600F

1

1

ELECTRONIC AIR CLEANER

TERMINAL STRIP

ON POWER BOX

4

2

3

R

B

1 CONNECT TO W8600F TERMINALS BEFORE CONNECTING TO

POWER BOX.

GREEN

1

G

Y

RED

BLUE

4

3

THREE-WIRE

THERMOSTAT CABLE

M11974

Fig. 4. Schematic for wiring W8600F to F50F.

J Attach the cabinet securely to the furnace. The unit can

be attached directly, as shown, or a starting collar can

first be fitted in the furnace opening. Either drill holes

and fasten with sheet metal screws or rivets, or use slip

joints. If drilling holes, use locking pliers to help hold the

unit in place during drilling. See Fig. 5.

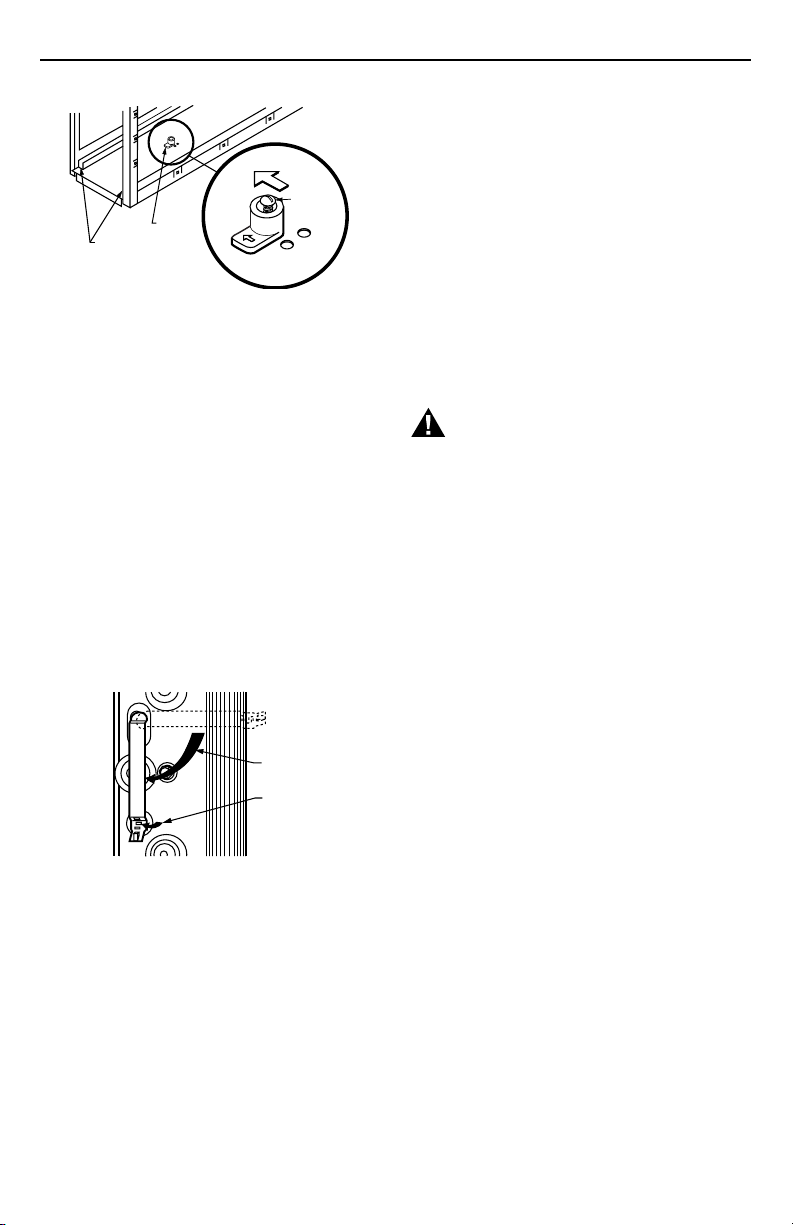

Fasten Cabinet To Ductwork

J Install a transition if the opening in the air cleaner

cabinet and the duct are different sizes. See Fig. 2.

J Fasten the other side of the cabinet to the elbow using

sheet metal screws, rivets, or slip joints as appropriate.

See Fig. 6.

Install Optional W8600F Air Cleaner Monitor

Choose a location for the W8600F if it is part of the

installation. The W8600F is designed to mount next to your

thermostat, or in any convenient visible area (such as

utility room) where it can be seen as it monitors the air

cleaner performance. It shares no electrical connections

with the thermostat. To install the W8600F, see Fig. 4 and

refer to the Installations Instructions, form 69-1200,

included with the air cleaner monitor.

Seal Joints

J Seal all joints in the return air system between the air

cleaner and the furnace to prevent dust from entering

the clean airstream.

Disable Unused Prefilter Guide

J Crimp the end of the downstream (closest to the

furnace) prefilter guide to prevent incorrect prefilter

installation following cleaning. See Fig. 6.

ELECTRONIC AIR CLEANER

M3678

Fig. 5. Fasten cabinet to furnace.

Install Turning Vanes

J Mount turning vanes inside the elbow or angle fitting

that is directly against the air cleaner cabinet.

69-0754B—1

M5640A

Fig. 6. Crimping the prefilter guide.

Position Cell Key

The electronic cell must always be installed so the ionizer

section is on the upstream side. A factory-installed cell key

on the bottom of the cabinet allows the cell to be inserted

in only one direction. As long as the arrow molded into the

plastic key points in the same direction as the airflow, the

ionizer will always be on the upstream side.

If the position of the key must be reversed, proceed as

follows:

1. Re

move electronic cell.

2. Remove the screw holding the cell key in place.

See Fig. 7.

4

Page 5

DOWNSTREAM

AIRFLOW

CELL

PREFILTER GUIDES

M5639

Fig. 7. Position of cell key determines orientation of

cell (arrow on key must point downstream).

3. Turn the key around and place it over the opposite

holes. The tab on the bottom fits into the larger hole,

and the screw into the smaller hole. Make sure the

arrow on the key points in the direction of the air flow

(downstream).

4. Tighten the screw into the new hole.

5. Insert the electronic cell. The ionizer section will now

be on the air-entering (upstream) side of the cabinet.

Attach Cell Handle(s)

The cell handles are packed int the installers bag

assembly. They must be installed on the end of the cell

closest to the access door. To install:

1. Orient the cell as it will be when installed. The gray

contact board must be up and the airflow arrow

stamped into the cell must point downstream.

2. Hold the handle sideways and insert the solid tab on

the back of the handle into the slot in the cell. Turn

the handle 90 degrees clockwise to align the divided

tab with the square hole. See Fig. 8.

CELL KEY

INSTALL HANDLE ON END OF CELL

CLOSEST TO ACCESS DOOR.

Fig. 8. Install handle on end of cell

closest to access door.

KEY

CELL KEY

SCREW

ALTERNATE

HOLES FOR

KEY

ROTATE 90

DEGREES

FOLD TAB

TO LOCK

HANDLE

IN PLACE

M6047A

F50F DUCT MOUNTED ELECTRONIC AIR CLEANER

3. Insert the divided tab into the square hole.

4. Fold up the wedge and insert it into the divided tab

to lock the handle in place. If necessary, press with

a blunt instrument like the end of a pliers.

Reassemble Air Cleaner

J Insert the electronic cell with the gray contact board up

and the airflow arrow pointing downstream. If the cell

does not slide easily in to the cabinet, check the

orientation of the cell key.

J Insert the prefilter on the upstream side of the cabinet

in the guide provided.

J Replace the access door. Insert the tab on the bottom

of the door into the slot in the cabinet, then swing it

closed and press into place. The door must be firmly in

place or the air cleaner will not operate.

Complete Wiring

WARNING

Electric shock hazard.

Can cause personal injury.

Do

not

use an extension cord.

• All wiring must comply with local codes and ordinances.

•The line voltage power source must match the voltage and

frequency printed on the label inside the access door.

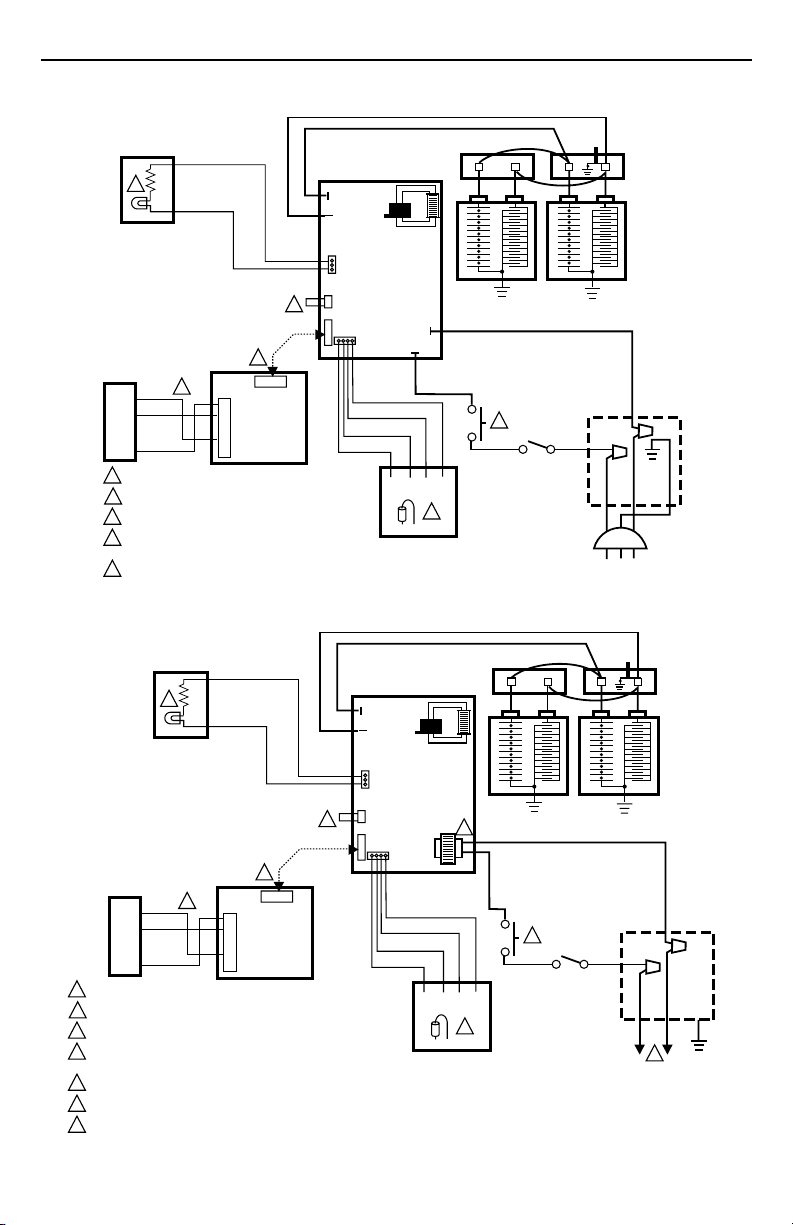

J

Plug the F50F directly into the correct voltage and

frequency outlet. See Fig. 9 through 12 for internal

schematic. The F50F will operate properly at any fan

speed on a multispeed or modulated speed system

wired with conduit or plugged in.

NOTE: To reduce the risk of electric shock, this product

has a grounding type plug that has a third

(grounding) pin. This plug will only fit into a

grounding type power outlet. If the plug does not

fit into the outlet, contact a qualified electrician to

install the proper outlet. Do

in any way.

not

change the plug

5

69-0754B—1

Page 6

F50F DUCT MOUNTED ELECTRONIC AIR CLEANER

BLACK

5

BLACK

4

4

BLUE

B4

R3

Y2

G1

1 INTERLOCK SWITCH.

2 SHORTING BAR.

3 AIRFLOW SWITCH DISABLE JUMPER.

4 OPTIONAL W8600F AIR CLEANER MONITOR. DRIVER

BOARD AND CABLE PROVIDED WITH W8600F.

5 NEON LIGHT.

RED

GREEN

6

5

J2

2

Fig. 9. Internal schematic for F50F with W8600F.

BLACK

7

BLACK

P3

P4

J4

J5

2

J3

J1

J1

ORANGE

GRAY

VIOLET

BLACK

W4 W2 W1 W3

AIRFLOW SWITCH BOARD

P3

P4

J4

BLACK COLLECTOR

RED IONIZER

POWER

SUPPLY

BROWN

P2

P1

BLACK

3

BLACK COLLECTOR

1

BLACK

RED IONIZER

RED

BLACK

RED

TEST

BUTTON

BLACK

BLACK

BLACK

TEST

BUTTON

CONTACT

BOARD

WHITE

M11975

GREEN

CONTACT

BOARD

J5

2

J3

4

B4

R3

Y2

G1

1 INTERLOCK SWITCH.

2 SHORTING BAR.

3 AIRFLOW SWITCH DISABLE JUMPER.

4 OPTIONAL W8600F AIR CLEANER MONITOR. DRIVER BOARD AND

CABLE PROVIDED WITH W8600F.

5 TOP TERMINAL ON TRANSFORMER

6 INPUT POWER. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

7 NEON LIGHT.

RED

GREEN

6

5

2

4

BLUE

J1

J2

J1

ORANGE

GRAY

VIOLET

BLACK

AIRFLOW SWITCH BOARD

Fig. 10. Internal schematic for 220/240V F50F models.

69-0754B—1

6

5

W4 W2 W1 W3

3

BROWN

BLACK

BLACK

1

BLACK

GREEN

WHITE

BLACK

6

L1 L2

220/240V

50/60 Hz

M11976

Page 7

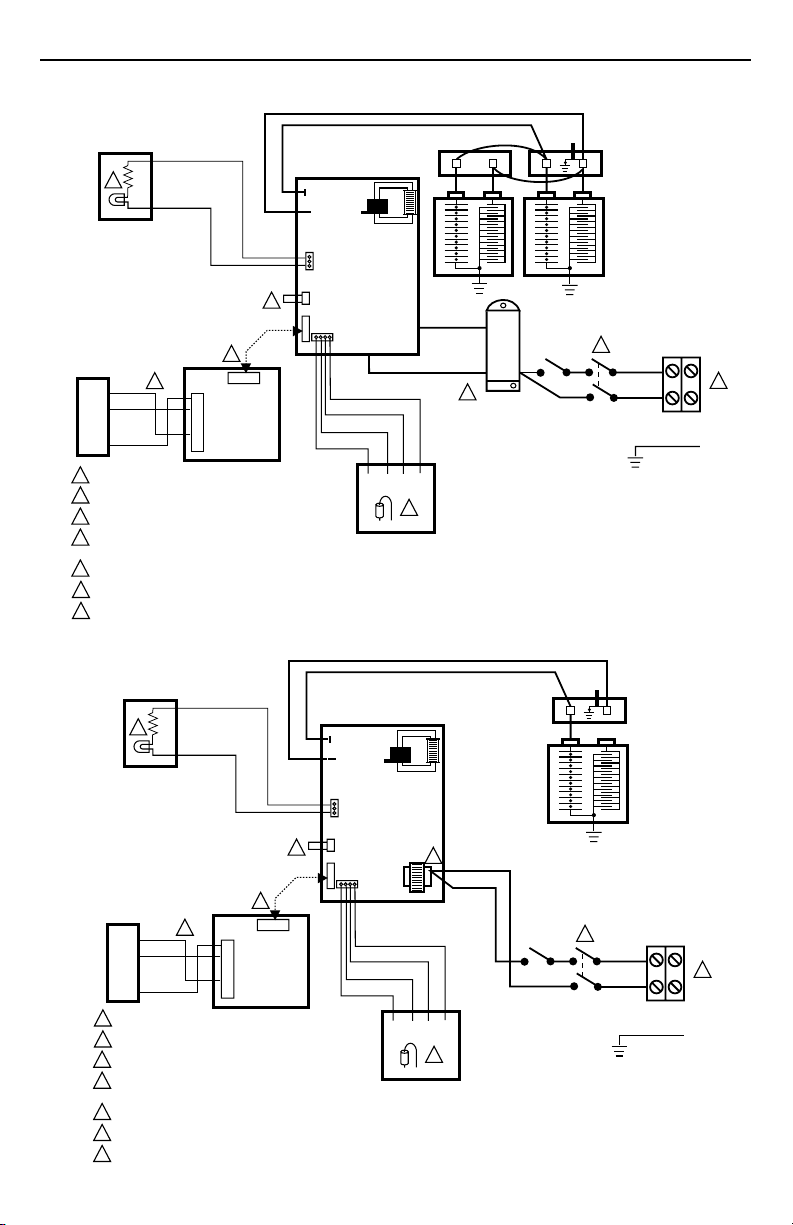

F50F DUCT MOUNTED ELECTRONIC AIR CLEANER

BLACK COLLECTOR

RED IONIZER

BLACK

5

BLACK

4

B4

R3

Y2

G1

1 INTERLOCK SWITCH.

2 SHORTING BAR.

3 AIRFLOW SWITCH DISABLE JUMPER.

4 OPTIONAL W8600F AIR CLEANER MONITOR. DRIVER

BOARD AND CABLE PROVIDED WITH W8600F.

5 NEON LIGHT.

6 TRANSFORMER.

7 INPUT POWER. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

RED

GREEN

6

5

2

4

BLUE

J1

J2

Fig. 11. Internal schematic for CE compliant 230V, 2 cell F50F models.

BLACK

7

BLACK

P3

P4

J4

2

J3

J1

POWER

SUPPLY

J5

E1/B2

ORANGE

GRAY

VIOLET

BLACK

W4 W2 W1 W3

AIRFLOW SWITCH BOARD

P3

P4

J4

BLACK

E2/B4

BLACK

3

BLACK COLLECTOR

RED IONIZER

6

RED

BLACK

TEST

BUTTON

TEST

BUTTON

CONTACT

BOARD

1

BLACK

BROWN

CONTACT

BOARD

230V ac

50 Hz

GROUND

M11977

L

7

N

J5

2

J3

4

B4

R3

Y2

G1

1 INTERLOCK SWITCH.

2 SHORTING BAR.

3 AIRFLOW SWITCH DISABLE JUMPER.

4 OPTIONAL W8600F AIR CLEANER MONITOR. DRIVER

BOARD AND CABLE PROVIDED WITH W8600F.

5 BROWN WIRE TO TOP TERMINAL.

6 INPUT POWER. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

7 NEON LIGHT.

6

RED

5

2

GREEN

Fig. 12. Internal schematic for CE compliant 230V, 1 cell F50F models.

4

BLUE

J1

J2

J1

ORANGE

GRAY

VIOLET

BLACK

5

BROWN

BLACK

W4 W2 W1 W3

3

AIRFLOW SWITCH BOARD

7

1

BLACK

BROWN

230V ac

50 Hz

GROUND

M11978

L

6

N

69-0754B—1

Page 8

F50F DUCT MOUNTED ELECTRONIC AIR CLEANER

J Alternatively, the F50F can be wired with conduit.

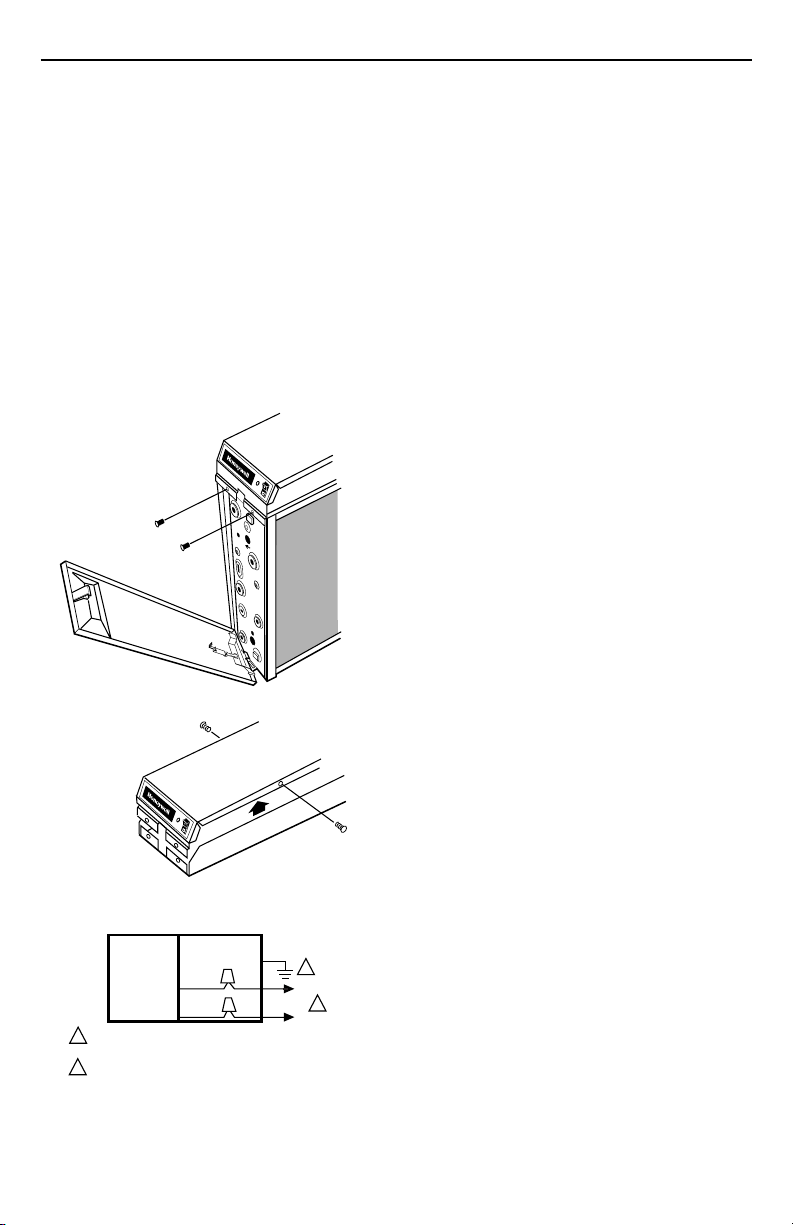

1. Open access door.

2. Remove and retain the (2) screws from the front of

the power box and the (2) screws from the sides of

the power box. See Fig. 13.

3. In the power box, remove and retain (2) wire nuts that

connect the line cord leads to the power box wiring.

4. Remove the green lead from the green grounding

screw on the wiring compartment barrier.

5. Remove the power cord and the strain relief.

6. Install plug (provided in bag assembly) in the hole

left by the power cord.

7. Attach conduit through a power box side knockout.

8. Wire the air cleaner directly to line voltage using wire

nuts. See Fig. 14. Secure ground connection to the

green ground screw on the wiring compartment

barrier.

9. Replace power supply cover and access door.

REMOVING COVER FROM POWER BOX.

2

1

OPERATION

Large particles (lint, hair) are caught by the prefilter. As the

dirty air passes through the intense high voltage electric

field surrounding the ionizer wires, all particles are given

an electrical charge. The air then moves through the

collector part of the cell where alternate parallel plates are

charged positively and negatively, creating a uniform

electrostatic field. The charged particles are attracted to

and collect on the plates having the opposite electrical

charge. The air leaving the air cleaner has fewer particles.

Each time the air circulates through the F50F, more

particles are removed.

CHECKOUT

Inspect The Installation

Make sure:

• Turning vanes and transitions, as needed, are

properly installed.

• Sheet metal joints between air cleaner and furnace

are sealed.

• All sheet metal connections are complete.

• Original furnace filter has been removed and the blower

compartment cleaned.

• If an atomizing humidifier is installed upstream from the

air cleaner, a disposable furnace filter is installed

between the humidifier and the air cleaner.

• Outside air, if used, is mixed with return air or heated,

as necessary, before it can reach the air cleaner.

• The airflow arrows on the electronic cell point

downstream.

• The prefilter is on the upstream side of the cell.

• The cell handle faces outward.

• The electronic cell and prefilter are clean and dry.

• That W8600F (if included) wiring connections are

properly made.

Fig. 13. Removing cover from power box.

WIRING

ELECTRONIC

AIR CLEANER

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQUIRED.

2

THE AIR CLEANER CAN BE COMPLETELY ISOLATED FROM

THE ELECTRICAL CIRCUIT OF THE HVAC SYSTEM UNLESS

REQUIRED BY LOCAL CODE TO USE SAME CIRCUIT. ANY

CONVENIENT HOUSE CIRCUIT CAN POWER AIR CLEANER,

REGARDLESS OF ELECTRICAL RATING OF HVAC SYSTEM.

COMPARTMENT

BLACK

BROWN

Fig. 14. Conduit connection for F50F.

69-0754B—1

3

M5676A

2

L1 (HOT)

1

L2

M5707

Check Air Cleaner Operation

With all components in place, turn on the air cleaner switch

and energize the system blower. Check the following

points of operation:

1. The neon light next to the on-off switch is on. If a

W8600F is part of the installation, also check the

wall panel and make sure ON is indicated. The

W8600F FAULT indicator will come on if there is a

problem with the high voltage power supply.

2. Turn off the system blower. The neon light should go

off after a few seconds. The neon light shows that

the air cleaner is energized and the high voltage

power supply is working properly.

3. Turn on the system blower. With the air cleaner

energized, push the test button. A snapping sound

indicates that the collector voltage is present on the

cell. On air cleaner with a W8600F, the FAULT

indicator will come on when the test button is held

down.

4. With a multispeed blower, repeat steps 1-3 for each

fan speed.

5. If operation is not as described, refer to the Trouble-

shooting and Service section.

8

Page 9

F50F DUCT MOUNTED ELECTRONIC AIR CLEANER

TROUBLESHOOTING AND SERVICE

WARNING

Electrical Shock Hazard.

Can cause personal injury or

equipment damage.

The following procedures expose hazardous live

parts. Disconnect from power between checks and

proceed carefully. The instructions are for use by

only qualified personnel.

Tools And Equipment

Troubleshooting the electronic air cleaner requires:

• Needle nose pliers for stringing ionizer wires and

inserting edge connectors.

• Test meter.

The electronic air cleaner troubleshooting charts show how

to quickly isolate a problem in the air cleaner. Although a

meter is needed for some steps, the primary diagnostic

tools are the

Neon Light (On Power Box)

The neon light is powered through the power supply and is

on when the power supply output voltage is normal.

Test Button

When pushed, the

to ground. The resulting arcing sound indicates that high

voltage is being supplied to the collector. The solid state

power supply controls current flow to the collector. On air

cleaners with a W8600F, the FAULT indicator will activate

when the

FAULT Indicator (Air Cleaners with W8600F)

The FAULT indicator is on the W8600F. It indicates the

following problems: excessive dirt loading, partial shorting

of the collector, continuous ionizer or collector arcing,

power supply failure, excessive ionizer current, or any

condition causing a major reduction in high voltage.

neon light

test button

and the

test button

is held down.

test button

shorts from collector voltage

. See Fig. 15.

Modification To Reduce Ozone Odor

The electronic air cleaner generates a small amount of

ozone in normal operation. During the first week or two of

operation, the amount may be higher because of sharp

edges on some of the new high voltage metal parts.

Normal use dulls these edges in a short time.

The average person can detect the odor of ozone in

concentrations as low as 0.003 to 0.010 parts per million

(ppm). The electronic air cleaner contributes 0.005 to

0.010 ppm of ozone to the indoor air. The U.S. Food and

Drug Administration and Health and Welfare Canada

recommend that indoor ozone concentration should not

exceed 0.050 ppm. As a comparison, the

level in major cities is sometimes as high as 0.100 ppm.

However, if desired, the ozone generated by the air

cleaner can be reduced in one of two ways:

1. Install an activated carbon filter downstream from

2. Move J5 shorting bar. This will reduce ozone

Power Box

WARNING

Electric shock hazard.

Can cause personal injury.

Always turn off power and remove access door

before removing power supply or its cover.

The solid state power supply within the power supply box

can be replaced. If troubleshooting indicates a power

supply problem, replace the entire power box or replace

the power supply within the box. See form 69-1136. See

Fig. 16 for power box removal.

WARNING

Electric shock hazard.

Can cause personal injury.

Always disconnect power and open the access

door before opening the power supply cover.

outdoor

ozone

the air cleaner. Make sure particles from the air filter

cannot fall into the air cleaner.

WARNING

Electric shock hazard.

Can cause personal injury.

Only a trained service technician should perform

the following procedure.

production about 20-25 percent and reduce efficiency about 7-10 percent depending on actual

airflow delivered by the furnace blower.

a. Unplug or disconnect power to the air cleaner.

b. Open the access door.

c. Remove the power box cover. See Fig. 16.

d. Locate J5 shorting bar on the power supply.

See Fig. 17. Remove the shorting bar and

reinstall so it is on only one pin.

NOTE: The ozone will be reduced, but the shorting

bar is available for reinstallation if needed.

e. Replace the power supply cover and access

door. Turn on the power.

f. Repeat the checkout procedure before leaving

the job.

9

69-0754B—1

Page 10

F50F DUCT MOUNTED ELECTRONIC AIR CLEANER

START

MAKE SURE ELECTRONIC

CELL(S) ARE CLEAN, DRY

AND PROPERLY INSTALLED.

MAKE SURE PREFILTER(S)

ARE IN CABINET SLOT

FARTHEST FROM FURNACE.

TURN ON ELECTRONIC AIR

CLEANER AND SYSTEM

FAN.

CHECK NEON LIGHT.

3 Vdc

OR MORE

OFF

OFF

YES

PUSH TEST BUTTON AND

LISTEN FOR SNAPPING

SOUND.

CHECK ON INDICATOR

ON W8600F

DEPRESS AND HOLD DOWN

TEST BUTTON. FAULT

INDICATOR ON W8600F

SHOULD COME ON

ELECTRONIC AIR CLEANER

AND W8600F ARE OK.

CORRECT

WIRING.

WIRING

CHECK WIRING BETWEEN

W8600F AND AIR CLEANER.

USE MAX NO. 18 3-WIRE

THERMOSTAT CABLE

CONNECTED 1(G) TO 1(G),

3(R) TO 3(R), AND 4(B)

TO 4(B).

CHECK W8600F BATTERY

LESS THAN

3 Vdc

REPLACE W8600F

BATTERY

TYPE BR2082

CHECK W8600F PER

INSTRUCTIONS PACKED

WITH UNIT. OK?

REPLACE W8600F

NOT OK

WIRING OK

NO

1

FOR POWER SUPPLY REPLACEMENT, SEE FORM 69-1136.

2

W8600F HAS A LCD DISPLAY WITH FOUR INDICATORS: ON,

BATTERY, SERVICE, FAULT.

3

W8600F OPERATION CAN BE CHECKED SEPARATELY.

SEE W8600F INSTRUCTIONS.

TO USE THIS CHART:

1.

FOLLOW THE STEPS IN ORDER; DO NOT SKIP AROUND.

2.

EACH TIME YOU ISOLATE AND FIX A PROBLEM, GO BACK TO START.

3.

REPEAT ALL THE STEPS UNTIL THE AIR CLEANER CHECKS OUT OK.

WARNING

THESE SERVICING INSTRUCTIONS ARE FOR USE BY QUALIFIED PERSONNEL

ONLY. TO REDUCE RISK OF ELECTRIC SHOCK, DO NOT PERFORM ANY

SERVICING OTHER THAN CONTAINED IN THE OPERATING INSTRUCTIONS

UNLESS YOU ARE QUALIFIED TO DO SO.

PUSH TEST BUTTON

OFF

AND LISTEN FOR

NO

2

2

SNAPPING SOUND.

NO

TURN OFF AIR CLEANER

AND REMOVE CELL(S)

ONLY (NOT PREFILTERS).

CLOSE ACCESS DOOR

AND TURN ON

AIR CLEANER.

CHECK NEON LIGHT.

INSPECT CELL(S) FOR:

BENT COLLECTOR

•

PLATES

BROKEN IONIZER

•

WIRES

DIRT ON INSULATORS

•

DAMAGED IONIZER

•

OR COLLECTOR

CONTACT TABS

YES

REPAIR OR

REPLACE

CELL(S).

WITH OHMMETER,

CHECK FOR SHORT

BETWEEN:

••CELL FRAME AND

IONIZER SECTION

CELL FRAME AND

COLLECTOR SECTION

CELL

SHORTED

REPLACE

CELL.

CELL OK.

ON

YES

ON

ON

RISK OF ELECTRIC SHOCK

ON

NO

INFINITE

RESISTANCE

YES

REPLACE LIGHT ASSEMBLY.

THIS STEP EXPOSES

DANGEROUSLY HIGH

OFF

VOLTAGE. ONLY A

QUALIFIED SERVICE

TECHNICIAN SHOULD

ATTEMPT THIS STEP.

REMOVE POWER BOX COVER.

CHECK FOR CORRECT INPUT

VOLTAGE ACROSS:

120V MODELS: P1 AND P2

TERMINALS ON POWER

SUPPLY.

220/240V MODELS:

QUICK CONNECT TERMINALS

ON POWER SUPPLY

TRANSFORMER.

NO

FIX

WIRING.

SHORT AIRFLOW SWITCH

DISABLE JUMPER TO GROUND.

POWER SUPPLY FUNCTIONS

NORMALLY.

YES

REPLACE

AIRFLOW

SWITCH.

WARNING

YES

NO

REPLACE

POWER

SUPPLY.

1

M11979

69-0754B—1

Fig. 15. Troubleshooting electronic air cleaners.

10

Page 11

F50F DUCT MOUNTED ELECTRONIC AIR CLEANER

REMOVE POWER BOX FROM AIR CLEANER AND REMOVE THE COVER.

2

1

Fig. 16. Removing the power box.

P3

3

4

M6168A

P4

J4

J5

J3

J1

Fig. 17. Move J5 shorting bar to reduce ozone production about 20-25 percent.

11

P1

P2

M10609

69-0754B—1

Page 12

F50F DUCT MOUNTED ELECTRONIC AIR CLEANER

Automation and Control Solutions

Honeywell Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

69-0754B—1

69-0754B—1 G.H. Rev. 6-98 www.honeywell.com

Honeywell Limited-Honeywell Limitée

35 Dynamic Drive

Scarborough, Ontario M1V 4Z9

Printed in U.S.A. on recycled

paper containing at least 10%

12

post-consumer paper fibers.

Page 13

F50F DUCT MOUNTED ELECTRONIC AIR CLEANER

Filtre à air électronique pour montage

en gaine F50F

INSTRUCTIONS D’INSTALLATION

APPLICATION

Le filtre à air électronique à haut rendement F50F s’installe

dans la gaine de reprise d’air dans un système de

chauffage, de refroidissement ou de ventilation à air pulsé.

Il capte un très grand nombre de particules en suspension

dans l’air, de 0,5 micron et plus, qui le traversent. Tous les

modèles ont un interrupteur interne à débit d’air commandant le F50F lorsque le ventilateur est sous tension.

PLANIFICATION DE L’INSTALLATION

Vérifier les exigences relatives à

l’installation

Installer le filtre à air de manière que tout l’air qui passe

dans le système puisse circuler dans le filtre. Le meilleur

endroit est la gaine de retour d’air, à côté du compartiment

de ventilation car le filtre à air gardera le moteur du

ventilateur et les serpentins de l’évaporateur plus propres.

IMPORTANT

Ne pas installer le filtre à air dans la gaine d’air

pulsé.

L’épuration de l’air sera plus efficace si le débit d’air est

réparti uniformément sur la surface du filtre. Si la gaine et

le boîtier du filtre à air n’ont pas les mêmes dimensions, il

est préférable d’installer des raccords de transition. Si la

gaine présente un angle aigu juste avant le filtre à air, il est

recommandé d’utiliser des déflecteurs.

Applications appareil de refroidissement

Le filtre à air devrait être installé en amont du serpentin de

l’évaporateur. Le filtre à air aidera à garder le serpentin

propre et permettra de réduire la fréquence de la maintenance.

Applications humidificateur

Un humidificateur à évaporation peut être installé en

amont du filtre à air. Un humidificateur atomiseur devrait

être installé en aval du filtre à air même si des sédiments

d’eau dure s’introduiront dans les pièces sous forme de

poussière et se déposeront. Dans le cas d’un

humidificateur atomiseur en amont du filtre à air :

1. Monter l’humidificateur le plus loin possible en

amont du filtre à air.

2. Installer un filtre jetable standard pour appareil de

chauffage entre l’humidificateur et le filtre à air pour

retenir les gouttes d’eau et les sédiments d’eau

dure.

3. Nettoyer le filtre à air fréquemment pour empêcher

l’accumulation de sédiments d’eau dure.

REMARQUE : Le volume d’eau qui passe dans

Applications filtre à charbon actif

Un filtre à charbon actif peut servir à éliminer les odeurs ou

autres polluants gazeux (c.-à-d. les polluants non formés

de particules), que le filtre à air n’élimine pas. Placer le

filtre à charbon actif :

• En aval du filtre à air. Dans ce cas, la poussière du filtre

à charbon ne sera pas amassée par le filtre à air et elle

se déposera dans les pièces.

•À l’extérieur du boîtier du filtre à air. Certains filtres à

charbon sont combustibles. En contact avec une

source de tension élevée, ils peuvent provoquer de la

fumée ou des incendies.

•À un endroit où les granules de charbon ne peuvent

pas tomber dans la cellule électronique. S’il y a lieu,

utiliser un filtre jetable pour appareil de chauffage entre

le filtre à charbon et la cellule électronique.

• Installer des raccords de transition, si le filtre à charbon

nécessite l’utilisation d’une gaine dont le diamètre est

différent de celui du filtre à air. Prévoir une expansion

de 20 degrés de chaque côté, pour chaque raccord.

REMARQUE : Honeywell n’offre pas de filtres à

Applications apport d’air extérieur

La température de l’air repris doit être d’au moins 4 °C (40

°F). Des températures plus basses peuvent endommager

les fils de l’onisateur. L’air extérieur doit être réchauffé

avant qu’il n’atteigne le filtre à air. Il faut donc :

• S’assurer que l’apport d’air extérieur est suffisamment

en amont du filtre à air pour que l’air repris et l’air

extérieur soient parfaitement mélangés. Si l’air est

stratifié, un jet d’air très froid pourrait circuler dans une

section du filtre à air.

• Ajouter des déflecteurs en amont du filtre à air pour

assurer le mélange complet de l’air.

l’humidificateur atomiseur peut

surcharger le filtre à air. Par conséquent,

les sédiments d’eau dure pourraient

s’introduire dans les pièces sous forme

de poussière.

charbon. Consulter un fabricant de filtre à

charbon actif pour obtenir des

renseignements sur l’encombrement et

les applications.

Copyright © 1998 Honeywell Inc. • Tous droits réservés

X-XX UL

13

69-0754B-1

69-0754B—1

Page 14

F50F DUCT MOUNTED ELECTRONIC AIR CLEANER

FILTRE À AIR ÉLECTRONIQUE POUR MONTAGE EN GAINE F50F

• Installer un appareil de préchauffage, si l’apport d’air

extérieur est important. Cet appareil, par exemple un

élément chauffant ou un serpentin d’eau chaude,

devrait être commandé par un thermostat. Les

serpentins d’eau chaude ou à vapeur devraient être

protégés par un dispositif antigel.

Ajout du W8600F (en option)

Le bornier du F50F est un peu en retrait pour éviter que la

plaque à bornes ou les fils ne nuisent à l’installation. Il est

possible de déconnecter le bloc d’alimentation en entier et

de l’enlever pour avoir accès aux bornes. Le moniteur de

filtre à air W8600F peut être monté dans une pièce ou

dans la salle où est l’appareil de chauffage. Il doit être

installé à un endroit permettant de bien voir les voyants.

Choisir l’emplacement du F50F

Choisir un emplacement permettant de faire facilement la

vérification et le nettoyage normaux du filtre. Prévoir un

dégagement d’au moins 330 mm (13 po) à l’avant de la

porte d’accès pour retirer le préfiltre et la cellule. Prévoir

suffisamment d’espace au-dessus du bloc d’alimentation

pour faire la maintenance sans avoir à enlever les tuyaux,

les gaines ou d’autres composants du système de

chauffage.

Le filtre doit être installé à un endroit où la température se

situe entre 4 °C et 52 °C (40 °F à 125 °F).

Choisir la position d’installation du filtre

AVERTISSEMENT

Équipement lourd.

Peut causer des blessures ou endommager

l’équipement.

Ne pas installer le filtre à air de sorte que la porte

d’accès soit dirigée vers le plancher. Si la porte

d’accès fait face au plancher, le verrou pourrait se

détacher et la cellule et le préfiltre pourraient

tomber brusquement. De plus, la cellule et le

préfiltre ne sont pas retenus lorsque la porte est

ouverte.

Le filtre à air peut être monté dans n’importe quelle

position, sauf la porte d’accès dirigée vers le bas. Les

positions du filtre à air sur divers types d’appareils de

chauffage sont énumérées ci-après :

REMARQUE : Prévoir un dégagement d’au moins 330

mm (13 po) entre la porte d’accès et tout

obstacle pour faciliter la maintenance du

préfiltre et de la cellule.

—

Appareil de chauffage à caissons superposés, à

circulation ascendante.

à air est installé à la verticale à l’endroit où entre l’air

repris, sur le côté de l’appareil de chauffage. Voir Fig.

1A.

—

Appareil de chauffage à caissons superposés, à

circulation descendante

chauffage (le boîtier du filtre à air peut facilement

soutenir l’appareil de chauffage et le serpentin du

système de refroidissement). Le filtre à air est installé

à l’horizontale à l’endroit où entre l’air repris, au bas

de l’appareil de chauffage. Voir Fig. 1B.

—

Appareil de chauffage à caissons superposés, à

circulation ascendante.

Le filtre est installé à la verticale sur l’appareil de

chauffage entre celui-ci et l’ouverture à persiennes

pour l’air repris dans la porte de l’armoire. Voir Fig.

1C.

—

Appareil de chauffage à caissons juxtaposés

à air est installé à l’horizontale dans le plenum d’air

repris juste au-dessus de l’appareil de chauffage, face

au plenum d’alimentation. Voir Fig. 1D.

—

Appareil de chauffage à contre-courant, à circulation

descendante

dans la gaine de reprise d’air ou dans le plenum juste

au-dessus de l’appareil de chauffage. Voir Fig. 1E.

—

Système à haut rendement.

combiner deux ou plusieurs filtres à air. Voir Fig. 1F.

—

Appareil de chauffage électrique ou thermopompe

filtre à air à une cellule est installé de sorte que la

porte d’accès soit sur le dessus. Voir Fig. 1G.

—

Appareil de chauffage horizontal.

monté à la verticale à l’endroit où entre l’air repris.

Voir Fig. 1H.

Raccords de gaines requis

Le filtre à air se combine à tout système résidentiel de

chauffage, de refroidissement et de ventilation à air pulsé

neuf ou en place. Des raccords de transition ou de

dérivation et des déflecteurs peuvent être nécessaires

pour assurer un meilleur rendement dans certaines

applications.

Raccords de transition

Des raccords de transition sont nécessaires lorsque les

dimensions de la gaine et du boîtier du filtre à air sont

différentes. Les raccords de transition réduisent la

turbulence et augmentent l’efficacité. L’expansion

maximale doit être de 20 degrés (environ 100 mm par 300

mm linéaires [4 po par pied linéaire]) de chaque côté du

raccord de transition. Voir Fig. 2.

Installation sur le côté. Le filtre

. Installation sous l’appareil de

Installation dans une armoire.

. Le filtre

. Le filtre à air est installé à l’horizontale

Il est possible de

. Le

Le filtre à air est

69-0754B—1

69-0754B—1

2

14

Page 15

FILTRE À AIR ÉLECTRONIQUE POUR MONTAGE EN GAINE F50F

F50F DUCT MOUNTED ELECTRONIC AIR CLEANER

A

B

E

F

Fig. 1. Les positions du filtre à air sur divers types d’appareils de chauffage.

MODIFIER L’ENCOMBREMENT DE LA GAINE AVEC DES RACCORDS

DE TRANSITION POUR MINIMISER LA TURBULENCE.

EXPANSION DE 20 DEGRÉS DE

CHAQUE CÔTÉ, PAR RACCORD

(100 mm par 300 mm linéaires)

(4 po par pied linéaire).

C

D

G

H

UTILISATION TYPIQUE DU RACCORD DE DÉRIVATION

DE LA GAINE POUR ASSURER UN DÉGAGEMENT

SUFFISANT POUR LE FILTRE À AIR ÉLECTRONIQUE.

M11973

GAINE DE

REPRISE D’AIR

RACCORD

DE TRANSITION

BOÎTIER DU FILTRE À AIR ÉLECTRONIQUE

Fig. 2. Modifier l’encombrement de la gaine avec des

raccords de transition pour minimiser la turbulence

Déflecteurs

Si le filtre à air est installé près d’un raccord coudé (à

angle), installer les déflecteurs à l’intérieur du raccord pour

assurer une distribution d’air plus uniforme à la surface de

la cellule. Voir Fig. 3.

Raccords de dérivation

Si le raccord entre la gaine et l’appareil dans le cas d’une

installation sur le côté avec dégagement inférieur à 178

mm (7 po) pour le boîtier du filtre à air, ajouter un raccord

de dérivation au raccord coudé. Voir Fig. 3.

MF5626A

MOINS DE

178 mm

[7 po]

E

L

E

C

T

R

O

N

I

C

A

I

R

C

L

E

A

N

E

R

1

1 LES DÉFLECTEURS ASSURENT UNE MEILLEURE RÉPARTITION D’AIR.

Fig. 3. Utilisation typique du raccord de dérivation de

la gaine pour assurer un dégagement suffisant pour le

3

15

filtre à air électronique.

69-0754B—1

69-0754B—1

RACCORD DE

DÉRIVATION

AU MOINS

178 mm

[7 po]

MF5627A

Page 16

F50F DUCT MOUNTED ELECTRONIC AIR CLEANER

FILTRE À AIR ÉLECTRONIQUE POUR MONTAGE EN GAINE F50F

INSTALLATION

Pour Installer Ce Produit...

1. Lire attentivement les instructions. Le fait de ne pas

les suivre risque d’endommager le produit ou de

constituer un danger.

2. Vérifier les caractéristiques nominales indiquées

dans les instructions et sur le produit, et s’assurer

que celui-ci correspond bien à l’application prévue.

3. L’installateur doit être un technicien d’expérience

ayant reçu la formation pertinente.

4. Une fois l’installation terminée, vérifier le

fonctionnement du produit comme indiqué dans les

présentes instructions.

AVERTISSEMENT

Risque de choc électrique.

Peut causer un choc électrique ou

endommager l’équipement.

Ne pas brancher l’appareil avant d’avoir terminé

l’installation.

Déballer le filtre à air électronique

J S’assurer qu’il ne manque aucun composant. Le filtre à

air électronique est expédié assemblé. L’appareil

comprend un boîtier en acier galvanisé, un bloc

d’alimentation avec un interrupteur et une lampetémoin, une ou deux cellules et un ou deux préfiltres

selon le modèle, une porte d’accès munie d’un bouton

d’essai et la documentation nécessaire.

J Le W8600F (en option), les pièces de montage et la

notice d’installation doivent être commandés

séparément.

Nettoyer le compartiment du ventilateur

J Retirer et mettre de côté le filtre actuel de l’appareil de

chauffage.

J Nettoyer à fond le compartiment du ventilateur.

J Si cela est possible, passer l’aspirateur dans le

système de gaines pour éliminer la poussière

accumulée dans une maison déjà construite ou la

saleté due à la construction dans une maison neuve.

Le filtre à air électronique ne peut éliminer la poussière

accumulée dans le compartiment du ventilateur et les

gaines de distribution.

J Vérifier s’il n’y a pas de la poussière sur les bordures

des lames du ventilateur de l’appareil de chauffage.

Les nettoyer au besoin. Le rendement du ventilateur

(pi3/min) sera inférieur au rendement prévu si les

lames sont sales.

Fixer le boîtier à l’appareil de chauffage

REMARQUE : L’installation d’un filtre sur le côté d’un

J Retirer et mettre de côté la porte d’accès, la (les)

cellule(s) et le(s) préfiltre(s).

J Aligner le boîtier sur l’ouverture pour la reprise d’air.

J Percer une ouverture dans l’appareil de chauffage

correspondant à celle du boîtier du filtre à air.

appareil de chauffage à caissons

juxtaposés est décrite ci-dessous. Des

modifications peuvent s’avérer

nécessaires dans le cas d’un autre

système.

J Installer un raccord de transition si les ouvertures de

l’appareil de chauffage et du filtre sont de dimensions

différentes. Voir Fig. 2.

J Placer des blocs sous le boîtier pour que l’appareil soit

bien soutenu et de niveau. Le pied de fixation de 16

mm (5/8 po) sur la plaque de la charnière du boîtier

assure le dégagement suffisant de la charnière

d’articulation de la porte d’accès.

J Si le W8600F est intégré au système, raccorder tout

d’abord les fils au W8600F, puis relier les fils au bornier

du bloc d’alimentation du filtre à air. Voir la Fig. 4 et la

notice d’installation, publication no 69-1200.

W8600F

1

1

FILTRE À AIR ÉLECTRONIQUE

BORNIER SUR

LA BOÎTE

D’ALIMENTATION

4

2

3

R

B

1 EFFECTUER LES RACCORDS AUX BORNES DU W8600 AVANT

DE BRANCHER À LA BOÎTE D’ALIMENTATION.

VERT

1

G

Y

ROUGE

BLEU

4

3

CÂBLE TRIFILAIRE

DU THERMOSTAT

MF11974

Fig. 4. Schéma de raccordement du W8600F au F50F.

J Fixer solidement le boîtier à l’appareil de chauffage soit

directement (voir illustration), soit à l’aide d’un collier de

démarrage dans l’appareil de chauffage. Percer des

trous et fixer l’appareil à l’aide de rivets ou de vis pour

tôle ou utiliser des joints coulissants. Percer les trous à

l’aide d’une pince-étau pour maintenir l’appareil en

place pendant l’installation. Voir Fig. 7

Installer les déflecteurs

J Installer les déflecteurs à l’intérieur du raccord coudé (à

angle) monté directement sur le boîtier du filtre à air.

Fixer le boîtier au système de gaines

J Installer un raccord de transition si les ouvertures du

boîtier du filtre à air et de la gaine sont de dimensions

différentes. Voir Fig. 2.

J Fixer l’autre côté du boîtier sur le raccord coudé à l’aide

de rivets, de vis pour tôle, ou de joints coulissants, au

besoin. Voir Fig. 6.

Installer le moniteur W8600F (en option)

Installer le moniteur W8600F (en option) à l’endroit désiré.

Le W8600F est conçu pour être monté près du thermostat,

ou à tout autre endroit commode, comme la salle de

l’appareil de chauffage, car il permet de surveiller le

rendement du filtre. L’emplacement choisi doit permettre

de vérifier l’état des voyants de l’appareil. Toutes ses

connexions électriques sont indépendantes de celles du

thermostat. Pour installer le W8600F, voir la Fig. 4 et la

notice d’installation fournie, publication 69-1200.

69-0754B—1

69-0754B—1

4

16

Page 17

FILTRE À AIR ÉLECTRONIQUE POUR MONTAGE EN GAINE F50F

F50F DUCT MOUNTED ELECTRONIC AIR CLEANER

Installer la clavette de la cellule dans la

bonne direction.

La cellule électronique doit toujours être installée de façon

que la section d’ionisation soit du côté amont. Une clavette

de cellule installée en usine au bas du boîtier permet

d’insérer la cellule dans une seule direction. Tant que la

flèche moulée dans la clavette en plastique pointe dans la

même direction que le débit d’air, l’ionisateur restera du

côté amont.

Si la position de la clavette doit être inversée :

1. Retirer la cellule électronique.

2. Desserrer la vis qui tient la clavette de la cellule en

place. Voir Fig. 7.

M3678

Fig. 5. Fixer le boîtier à l’appareil de chauffage.

Sceller les joints

J Sceller tous les joints du système de reprise d’air entre

le filtre à air et l’appareil de chauffage pour empêcher la

poussière de pénétrer dans le courant d’air propre.

Fig. 7. La position de la clavette de la cellule détermine

l’orientation de la cellule. La flèche de la clavette doit

3. Changer la clavette de position et la placer par-

Mettre hors service le guide de préfiltre non

utilisé

J Sertir l’extrémité du guide du préfiltre en aval (la plus

près de l’appareil de chauffage) pour éviter d’installer le

préfiltre de façon incorrecte après le nettoyage. Voir

Fig. 6.

ELECTRONIC AIR CLEANER

M5640A

Fig. 6. Sertir l’extrémité du guide du préfiltre non

utilisé.

4. Serrer la vis dans le nouveau trou.

5. Insérer la cellule électronique. La section

Fixer les poignées des cellules

Les poignées de la cellule sont comprises dans

l’emballage. Elles doivent être installées à l’extrémité de la

cellule qui est la plus près de la porte d’accès. Installation :

1. Orienter la cellule dans la direction désirée pour

2. Tenir la poignée par les côtés et insérer la languette

3. Insérer la languette divisée dans le trou carré.

4. Plier la cale et l’insérer dans la languette divisée

CLAVETTE DE

LA CELLULE

GUIDES DU PRÉFILTRE

CLAVETTE

DE LA

CELLULE

EN AVAL

DÉBIT

D’AIR

VIS POUR

LA CLAVETTE

AUTRES

TROUS POUR

LA CLAVETTE

pointer vers l’aval.

dessus les trous opposés. La languette du bas

s’insère dans le grand trou et la vis, dans le plus

petit trou. S’assurer que la flèche sur la clavette

pointe dans la direction de l’écoulement de l’air (en

aval).

d’ionisation sera maintenant du côté de l’entrée d’air

(en amont) du boîtier.

l’installation. Le panneau de contacts gris doit

pointer vers le haut et la flèche indiquant le débit

d’air de la cellule doit pointer vers l’aval.

rigide sur le dos la poignée dans la fente de la

cellule. Tourner la poignée 90° en sens horaire pour

aligner la languette divisée sur le trou carré. Voir

Fig. 8.

pour verrouiller la poignée en place. Si cela est

nécessaire, exercer une pression avec un instrument émoussé comme une paire de pinces.

MF5639

69-0754B—1

5

17

69-0754B—1

Page 18

F50F DUCT MOUNTED ELECTRONIC AIR CLEANER

FILTRE À AIR ÉLECTRONIQUE POUR MONTAGE EN GAINE F50F

INSTALLER LES POIGNÉES AU BOUT DE LA CELLULE

QUI EST LA PLUS PRÈS DE LA PORTE D’ACCÈS

TOURNER À

90 DEGRÉS

PLIER LA LANGUETTE

POUR VERROUILLER

LA POIGNÉE EN PLACE

MF6047A

Fig. 8. Installer les poignées au bout de la cellule qui

est la plus près de la porte d’accès.

Réassembler le filtre à air

J Insérer la cellule électronique de façon que le panneau

de contacts gris soit orienté vers le haut et que la flèche

de débit d’air pointe vers l’aval. Si la cellule ne glisse

pas facilement dans le boîtier, vérifier l’orientation de la

clavette de la cellule.

J Insérer le préfiltre du côté amont du boîtier dans le

guide fourni.

J Remettre la porte d’accès en place. Insérer la languette

au bas de la porte dans la fente du boîtier, refermer la

porte, en exerçant une pression. La porte doit être bien

en place sinon le filtre à air ne fonctionnera pas.

NOIR

5

NOIR

P3

P4

J4

Terminer le raccordement

AVERTISSEMENT

Risque de choc électrique.

Peut causer des blessures.

Ne pas utiliser un fil prolongateur.

• Tous les raccordements doivent être conformes aux

règlements et aux codes locaux.

• L’alimentation tension secteur doit correspondre à la

tension et à la fréquence indiquées sur l’étiquette dans

la porte d’accès.

J Brancher le F50F directement dans la prise ayant la

tension et la fréquence indiquées. Voir les schémas de

raccordement interne, Fig. 9 à 12. Le F50F

fonctionnera efficacement quelle que soit la vitesse du

ventilateur d’un système à vitesses multiples ou à

action modulante relié par des conducteurs ou branché.

REMARQUE: Afin d’éviter les risques de chocs

COLLECTEUR NOIR

IONISATEUR ROUGE

ALIMENTATION

électriques, le filtre possède une fiche à

trois broches (la troisième broche sert de

mise à la terre). Cette fiche ne peut être

utilisée qu’avec une prise de mise à la

terre. Si la prise doit être changée, faire

installer la prise appropriée par un

électricien qualifié. Ne pas le faire soimême.

BOUTON

D’ESSAI

ROUGE

NOIR

PANNEAU DE

CONTACTS

69-0754B—1

69-0754B—1

2

4

B4

R3

Y2

G1

1 INTERRUPTEUR DE VERROUILLAGE.

2 TIGE DE COURT-CIRCUIT.

3 CAVALIER DE COUPURE DE L’INTERRUPTEUR

À DÉBIT D’AIR.

4 MONITEUR DE FILTRE À AIR W8600F EN OPTION.

PANNEAU DE COMMANDE ET CÂBLE FOURNIS

AVEC LE W8600F.

5 LAMPE-TÉMOIN.

ROUGE

VERT

6

5

2

4

BLEU

J1

J2

Fig. 9. Schéma interne du F50F avec le W8600F.

J5

J3

J1

ORANGE

GRIS

VIOLET

NOIR

W4 W2 W1 W3

TABLEAU DE L’INTERRUPTEUR

À DÉBIT D’AIR

18

6

P2

P1

NOIR

BRUN

1

NOIR

3

NOIR

NOIR

BLANC

VERT

MF11975

Page 19

F50F DUCT MOUNTED ELECTRONIC AIR CLEANER

FILTRE À AIR ÉLECTRONIQUE POUR MONTAGE EN GAINE F50F

COLLECTEUR NOIR

NOIR

ROUGE

NOIR

NOIR

BOUTON

D’ESSAI

BOUTON

D’ESSAI

NOIR

L1 L2

220/240V

50/60 Hz

PANNEAU

DE CONTACTS

IONISATEUR ROUGE

NOIR

7

NOIR

4

B4

R3

Y2

G1

1 INTERRUPTEUR DE VERROUILLAGE.

2 TIGE DE COURT-CIRCUIT.

3 CAVALIER DE COUPURE DE L’INTERRUPTEUR À DÉBIT D’AIR.

4 MONITEUR DE FILTRE À AIR W8600F EN OPTION. PANNEAU

DE COMMANDE ET CÂBLE FOURNIS AVEC LE W8600F.

5 BORNE SUPÉRIEURE SUR LE TRANSFORMATEUR.

6 ALIMENTATION D’ENTRÉE. FOURNIR UN DISPOSITIF DE COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES AU BESOIN.

7 LAMPE-TÉMOIN.

5

ROUGE

VERT

6

5

2

Fig. 10. Schéma interne des modèles F50F 220/240 V.

NOIR

NOIR

4

BLEU

J1

J2

P3

P4

J4

J5

2

J3

J1

ORANGE

GRIS

VIOLET

NOIR

P3

P4

ALIMENTATION

J4

5

BRUN

NOIR

1

NOIR

W4 W2 W1 W3

3

TABLEAU DE L’INTERRUPTEUR

À DÉBIT D’AIR

COLLECTEUR NOIR

IONISATEUR ROUGE

ROUGE

PANNEAU DE

CONTACTS

BLANC

6

MF11976

VERT

J5

2

J3

E1/B2

4

B4

R3

Y2

G1

1 INTERRUPTEUR DE VERROUILLAGE.

2 TIGE DE COURT-CIRCUIT.

3 CAVALIER DE COUPURE DE L’INTERRUPTEUR À DÉBIT D’AIR.

4 MONITEUR DE FILTRE À AIR W8600F EN OPTION.

PANNEAU DE COMMANDE ET CÂBLE FOURNIS AVEC LE W8600F.

5 LAMPE-TÉMOIN.

6 TRANSFORMATEUR.

7 ALIMENTATION D’ENTRÉE. FOURNIR UN DISPOSITIF DE COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES AU BESOIN.

ROUGE

VERT

6

5

2

4

BLEU

J1

J2

J1

ORANGE

GRIS

VIOLET

NOIR

W4 W2 W1 W3

TABLEAU DE L’INTERRUPTEUR

À DÉBIT D’AIR

E2/B4

NOIR

NOIR

6

3

Fig. 11. Schéma interne des modèles F50F à deux cellules, 230 V.

7

19

1

NOIR

BRUN

MISE À LA TERRE

69-0754B—1

69-0754B—1

230V ac

50 Hz

MF11977

L

7

N

Page 20

F50F DUCT MOUNTED ELECTRONIC AIR CLEANER

FILTRE À AIR ÉLECTRONIQUE POUR MONTAGE EN GAINE F50F

COLLECTEUR NOIR

NOIR

7

NOIR

4

4

BLEU

B4

R3

Y2

G1

1 INTERRUPTEUR DE VERROUILLAGE.

2 TIGE DE COURT-CIRCUIT.

3 CAVALIER DE COUPURE DE L’INTERRUPTEUR À DÉBIT D’AIR.

4 MONITEUR DE FILTRE À AIR W8600F EN OPTION.

PANNEAU DE COMMANDE ET CÂBLE FOURNIS AVEC LE W8600F.

5 FIL BRUN À LA BORNE SUPÉRIEURE.

6ALIMENTATION D’ENTRÉE. FOURNIR UN DISPOSITIF DE COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES AU BESOIN.

7 LAMPE-TÉMOIN.

ROUGE

VERT

6

5

J2

2

P3

P4

J4

J5

2

J3

J1

J1

IONISATEUR ROUGE

5

BRUN

NOIR

ORANGE

GRIS

VIOLET

NOIR

W4 W2 W1 W3

3

TABLEAU DE L’INTERRUPTEUR

À DÉBIT D’AIR

Fig. 12. Schéma interne pour les modèles F50F à une cellule électronique, 230 V.

BOUTON

D’ESSAI

1

PANNEAU

DE CONTACTS

NOIR

BRUN

MISE À LA TERRE

230V ac

50 Hz

MF11978

L

6

N

J Le F50F peut aussi être raccordé à l’aide d’un fil

conducteur.

1. Ouvrir la porte d’accès.

2. Enlever les deux vis sur le devant et les deux vis

sur le côté du bloc d’alimentation. Voir Fig. 13.

3. Dans le bloc d’alimentation enlever les

capuchons qui raccordent le cordon

d’alimentation au câblage du bloc d’alimentation.

4. Retirer le fil vert de la vis de mise à la terre verte

dans le compartiment de câblage.

5. Enlever le cordon d’alimentation et le serre-câble.

6. Placer le bouchon (fourni dans l’emballage) sur le

trou laissé par le cordon d’alimentation.

7. Relier le fil conducteur par l’ouverture défonçable

sur le côté du bloc d’alimentation.

8. Raccorder le filtre à air directement au fil tension

secteur à l’aide des capuchons. Voir Fig. 14.

Replacer le fil de mise à la terre sur la vis de

mise à la terre verte sur le guide-fils.

9. Replacer le couvercle du bloc d’alimentation et la

porte d’accès.

69-0754B—1

69-0754B—1

RETRAIT DU COUVERCLE

DU BLOC D’ALIMENTATION.

2

1

3

Fig. 13. Retrait du couvercle du bloc d’alimentation.

20

8

MF5676A

Page 21

FILTRE À AIR ÉLECTRONIQUE POUR MONTAGE EN GAINE F50F

F50F DUCT MOUNTED ELECTRONIC AIR CLEANER

COMPARTIMENT

FILTRE À AIR

ÉLECTRONIQUE

ALIMENTATION. FOURNIR UN DISPOSITIF DE COUPURE ET UNE

1

PROTECTION CONTRE LES SURCHARGES AU BESOIN.

2

LE FILTRE À AIR PEUT ÊTRE ISOLÉ ENTIÈREMENT DU CIRCUIT

DU SYSTÈME DE CONDITIONNEMENT D’AIR À MOINS QUE LES CODES

LOCAUX EXIGENT L’UTILISATION DU MÊME CIRCUIT. TOUT CIRCUIT

ÉLECTRIQUE RÉSIDENTIEL PEUT ALIMENTER LE FILTRE À AIR,

PEU IMPORTE LES CARACTÉRISTIQUES NOMINALES DU SYSTÈME

DE CONDITIONNEMENT D’AIR.

DE CÂBLAGE

NOIR

BRUN

2

L1 (SOUS TENSION)

1

L2

MF5707

Fig. 14. Connexion des conducteurs du F50F.

FONCTIONNEMENT

Les grosses particules (charpie, poils) sont captées par le

préfiltre. L’air pollué passe dans le champ électrique haute

tension autour des fils ionisants. Toutes les particules

reçoivent une décharge électrique. L’air passe par ensuite

dans les plaques collectrices, qui sont simultanément

positives et négatives, ce qui crée un champ

électrostatique uniforme. Les particules ionisées sont

attirées par les plaques ayant une charge contraire,

auxquelles elles achèrent. À la sortie du filtre à air, l’air

propre contient très peu de particules. Chaque fois que

l’air circule dans le F50F, la quantité de particules dans

l’air diminue.

VÉRIFICATION

Vérifier l’installation

S’assurer que :

• les déflecteurs et les raccords de transition sont bien

installés;

• les joints en tôle entre le filtre à air et l’appareil de

chauffage sont scellés;

• tous les raccords en tôle ont été posés;

• le filtre original a été retiré et que le compartiment du

ventilateur a été nettoyé;

• si un humidificateur atomiseur est installé en amont du

filtre à air, un filtre jetable pour appareil de chauffage

est installé entre l’humidificateur et le filtre à air;

• l’air extérieur, s’il y a lieu, est mélangé avec l’air repris

ou chauffé au besoin avant d’atteindre le filtre à air;

• les flèches de débit d’air sur la cellule électronique

pointent vers l’aval;

• le préfiltre est du côté amont de la cellule électronique;

• la poignée de la cellule fait face vers l’extérieur;

• la cellule électronique et le préfiltre sont propres et

secs;

• les raccordements du W8600F (s’il y a lieu) sont bien

faits.

Vérifier le fonctionnement du filtre à air

Une fois tous les composants en place, mettre sous

tension le filtre à air et le ventilateur du système. Vérifier

les points suivants :

1. La lampe-témoin près de l’interrupteur est allumée.

Si le filtre comprend un W8600F, vérifier également

le panneau mural et s’assurer que le voyant ON est

allumé. Le voyant FAULT du W8600F s’allumera, s’il

y a un problème d’alimentation haute tension.

2. Fermer le ventilateur du système. La lampe-témoin

devrait s’éteindre après quelques secondes. La

lampe-témoin indique que le filtre à air est en

marche et que l’alimentation haute tension

fonctionne normalement.

3. Mettre en marche le ventilateur du système. Une

fois le filtre à air sous tension, appuyer sur le bouton

d’essai. Le déclic indique que la tension du

collecteur se rend à la cellule. Dans le cas du filtre à

air avec un W8600F, le voyant FAULT s’allumera si

le bouton est enfoncé.

4. Avec un ventilateur à vitesses multiples, répéter les

étapes 1 à 3 pour chaque vitesse.

5. Si le filtre ne fonctionne pas de la façon décrite ci-

dessus, consulter la section Dépannage.

DÉPANNAGE ET ENTRETIEN

AVERTISSEMENT

Risque de choc électrique

Peut causer des blessures ou endommager

l’équipement.

Les étapes suivantes exposent des pièces sous

tension. Couper l’alimentation entre les

vérifications et procéder avec soin. Les directives

s’adressent au personnel qualifié seulement.

Outils et équipement

Pour effectuer le filtre à air électronique, il faut :

• des pinces à bec effilé pour relier les fils de l’ionisateur

et pour insérer les connecteurs plats;

• un multimètre.

Les tableaux de vérification du filtre à air électronique

montrent comment déceler rapidement une défectuosité.

Bien qu’un multimètre soit nécessaire pour certaines

étapes, les principaux outils de diagnostic sont la lampetémoin et le bouton d’essai. Voir Fig. 15.

Lampe-témoin (sur le bloc d’alimentation)

La lampe-témoin est alimentée par le bloc d’alimentation

et elle est allumée lorsque la tension à la sortie est

normale.

Bouton d’essai

Lorsqu’il est enfoncé, le bouton d’essai provoque un courtcircuit entre la tension du collecteur et la mise à la terre. Le

bruit d’arc qui en résulte indique que le collecteur est

alimenté par du courant haute tension. Le bloc

d’alimentation à semi-conducteurs règle l’apport du

courant au collecteur. Sur les filtres à air avec un W8600F,

le voyant FAULT s’allume lorsqu’on le bouton d’essai est

enfoncé.

VOYANT FAULT

(filtres à air muni d’un W8600F)

Le voyant FAULT est situé sur le W8600F. Il indique les

problèmes suivants : accumulation de saleté, court-circuit

partiel du collecteur, formation continue d’arcs dans

l’ionisateur ou le collecteur, panne de courant, tension

excessive dans l’ionisateur ou tout autre condition pouvant

abaisser considérablement la haute tension.

9

21

69-0754B—1

69-0754B—1

Page 22

F50F DUCT MOUNTED ELECTRONIC AIR CLEANER

FILTRE À AIR ÉLECTRONIQUE POUR MONTAGE EN GAINE F50F

DÉBUT

S’ASSURER QUE LA OU LES

CELLULES SONT PROPRES

ET BIEN INSTALLÉES.

S’ASSURER QUE LE OU LES

PRÉFILTRES SONT DANS

L’ESPACE DU BOÎTIER LE

PLUS ÉLOIGNÉ DE

L’APPAREIL DE CHAUFFAGE.

METTRE EN MARCHE LE

FILTRE À AIR ÉLECTRONIQUE

ET LE VENTILATEUR.

VÉRIFIER LA LAMPE-TÉMOIN.

À L’ARRÊT

À L’ARRÊT

OUI

VÉRIFIER LE VOYANT ON

SUR LE W8600F.

APPUYER SUR LE BOUTON

D’ESSAI. LE VOYANT FAULT

DU W8600F DEVRAIT

S’ALLUMER.

LE FILTRE À AIR

ÉLECTRONIQUE ET LE

W8600F SONT CORRECTS.

APPUYER SUR LE BOUTON

D’ESSAI, IL DEVRAIT Y AVOIR

UN DÉCLIC.

RÉPARER LE CÂBLAGE.

CÂBLAGE

VÉRIFIER LE CÂBLAGE ENTRE

LE FILTRE À AIR ET LE W8600F.

UTILISER UN CÂBLE À 3 FILS

(THERMOSTAT) D’UN CALIBRE

MAXIMAL DE 18 RACCORDÉ

1G À 1G, 2Y À 2 Y, 3R À 3R

ET 4B À 4B.

VÉRIFIER LA PILE DU W8600F.

REMPLACER LA PILE

DU W8600F

(TYPE BR2082).

VÉRIFIER LE W8600F EN

SUIVANT LES INSTRUCTIONS

FOURNIES. OK?

REMPLACER LE W8600F.

1

2

3

INCORRECT

CÂBLAGE

CORRECT

MOINS DE

3 V c.c.

POUR REMPLACER LE BLOC D’ALIMENTATION, CONSULTER

LA PUBLICATION 69-1136.

LE W8600F COMPREND QUATRE DIODES ÉLECTROLUMINESCENTES :

ON, BATTERY, SERVICE, FAULT.

ON PEUT VÉRIFIER LE FONCTIONNEMENT DU W8600F SÉPARÉMENT.

VOIR LES DIRECTIVES DU W8600F.

NON

3 V c.c.

OU PLUS

EN MARCHE

OUI

EN MARCHE

Fig. 15. Dépannage des filtres à air électronique.

EN MARCHE

POUR UTILISER CE DIAGRAMME :

1. SUIVRE LES ÉTAPES DANS L’ORDRE, NE PAS SAUTER D’ÉTAPE.

2. CHAQUE FOIS QUE VOUS TROUVEZ UN PROBLÈME ET QUE VOUS LE RÉPAREZ,

RETOURNEZ AU DÉBUT.

3. RÉPÉTER TOUTES LES ÉTAPES JUSQU’À CE QUE LE FILTRE À AIR

FONCTIONNE BIEN.

AVERTISSEMENT

SEUL UN TECHNICIEN QUALIFIÉ PEUT DEVRAIT EFFECTUER CES VÉRIFICATIONS.

POUR RÉDUIRE LES RISQUES DE CHOC ÉLECTRIQUE, LES PERSONNES NON

QUALIFIÉES DOIVENT EFFECTUER SEULEMENT LES VÉRIFICATIONS INDIQUÉES

DANS LE MANUEL D’UTILISATION.

APPUYER SUR LE BOUTON

À L’ARRÊT

D’ESSAI ET ATTENDRE

LE DÉCLIC.

NON

2

2

NON

FERMER LE FILTRE À AIR ET

RETIRER LA OU LES CELLULES

(ET NON LE(S) PRÉFILTRE(S)),

FERMER LA PORTE D’ACCÈS

ET METTRE LE FILTRE À AIR

EN MARCHE.

VÉRIFIER LA LAMPE-TÉMOIN.

AD INSPECTER LA OU LES

CELLULES POUR VOIR S’IL Y A :

• DES PLAQUETTES

COLLECTRICES PLIÉES

• DES FILS D’IONISATEUR

BRISÉS

• DE LA SALETÉ SUR LES

ISOLANTS

• DES LANGUETTES SUR LE

COLLECTEUR OU DE

L’IONISATEUR

ENDOMMAGÉES.

OUI

RÉPARER OU

REMPLACER LA

OU LES CELLULES.

À L’AIDE D’UN OHMMÈTRE,

VÉRIFIER S’IL Y A UN

COURT-CIRCUIT ENTRE :

LE CADRE DE LA OU DES

•

CELLULES ET LA SECTION

DE L’IONISATEUR.

LE CADRE DE LA OU DES

•

CELLULES ET LA SECTION

DU COLLECTEUR.

CELLULE

COURTCIRCUITÉE

REMPLACER

LA OU LES

CELLULES

CELLULE CORRECTE.

RISQUE DE CHOC ÉLECTRIQUE

OUI

À L’ARRÊT

EN MARCHE

NON

RÉSISTANCE

INFINIE

REMPLACER L’ENSEMBLE

VOYANT/INTERRUPTEUR.

CETTE ÉTAPE EXPOSE À DES

TENSIONS ÉLEVÉES. ELLE

DOIT ÊTRE EFFECTUÉE

SEULEMENT PAR UN

TECHNICIEN QUALIFIÉ.

ENLEVER LE COUVERCLE DU

BLOC D’ALIMENTATION

VÉRIFIER SI LA TENSION

D’ENTRÉE EST ADÉQUATE :

MODÈLES 120V : BORNES P1 ET

P2 SUR LE BLOC D’ALIMENTATION.

MODÈLES 220/240V : BORNES À

ACTION RAPIDE SUR LE

TRANSFORMATEUR DU BLOC

D’ALIMENTATION

NON

RÉPARER

LE CÂBLAGE.

RELIER LE CAVALIER DE COUPURE

DE L’INTERRUPTEUR À DÉBIT D’AIR

À LA MISE À LA TERRE. LE BLOC

D’ALIMENTATION FONCTIONNE

NORMALEMENT.

OUI

REMPLACER

L’INTERRUPTEUR

À DÉBIT D’AIR.

AVERTISSEMENT

REMPLACER

LE BOC

D’ALIMENTATION.

OUI

NON

1

MF11979

Bloc d’alimentation

AVERTISSEMENT

Risque de choc électrique

Peut causer des blessures.

Toujours couper le courant et enlever la porte

d’accès avant de retirer le bloc d’alimentation ou

son couvercle.

L’alimentation à semi-conducteurs à l’intérieur du bloc

d’alimentation se remplace. Si au cours de la vérification

un problème d’alimentation est décelé, remplacer le bloc

d’alimentation en entier ou l’alimentation à l’intérieur du

bloc. Consulter la publication 69-1136. Se reporter à la

Fig. 16 pour enlever le bloc d’alimentation.

69-0754B—1

69-0754B—1

Réduction de l’odeur d’ozone

AVERTISSEMENT

Risque de choc électrique

Peut causer des blessures

Toujours couper l’alimentation et ouvrir la porte

d’accès avant de soulever le couvercle du bloc

d’alimentation.

Le filtre à air produit une petite quantité d’ozone lorsqu’il

fonctionne normalement. Pendant les deux premières

semaines de fonctionnement, la quantité d’ozone est

parfois plus élevée à cause des extrémités tranchantes

des nouvelles pièces métalliques haute tension. Si elles

fonctionnement normalement, les pièces seront rodées en

peu de temps.

10

22

Page 23

FILTRE À AIR ÉLECTRONIQUE POUR MONTAGE EN GAINE F50F

F50F DUCT MOUNTED ELECTRONIC AIR CLEANER

En général, on peut déceler l’odeur d’ozone dans des

concentrations aussi faibles que 0,003 à 0,010 partie par

millions (ppm). Le filtre à air électronique produit de 0,005

à 0,010 ppm d’ozone à l’intérieur. La U.S. Food and Drug

Administration et Santé et bien-être social Canada

recommandent que la concentration d’ozone à l’intérieur

ne dépasse pas 0,050 ppm. À titre indicatif, la concentration d’ozone dans la plupart des grandes villes atteint

parfois 0,100 ppm.

Toutefois, il est possible de réduire la quantité d’ozone

produite par le filtre à air de deux façons :

1. En installant un filtre à charbon actif en aval du filtre

à air. S’assurer que les particules provenant de

l’élément filtrant ne tombent pas dans le filtre à air.

AVERTISSEMENT

Risque de choc électrique

Peut causer des blessures

Seul un technicien qualifié devrait effectuer les

étapes suivantes.

RETIRER LE BLOC D’ALIMENTATION DU FILTRE À AIR ET ENLEVER LE COUVERCLE.

2. Déplacer la tige de court-circuit J2 pour réduire la

2

production d’ozone d’environ 20 à 25 % et diminuer

l’efficacité d’environ 7 à 10 % selon le débit d’air réel

du ventilateur de l’appareil de chauffage.

a. Débrancher le filtre à air ou en couper

l’alimentation.

b. Ouvrir la porte d’accès.

c. Retirer le couvercle du bloc d’alimentation.

Voir Fig. 16.

d. Repérer la tige de court-circuit J5 sur le bloc

d’alimentation. Voir Fig. 17. L’enlever et la

raccorder à une seule broche.

REMARQUE : La production d’ozone diminuera;