Page 1

In Ceiling Media Air Cleaner

APPLICATION

The F111 (Series 1,2,3) Ceiling Media Air Cleaner is a media

air cleaner that uses either a single-speed or three-speed

direct drive forward curve blower motor with particle filter.

When equipped with CPZ™ modules (2), gases and odors are

adsorbed from the air passing through the unit. The air

cleaner removes airborne particles such as dust, soot, mold

spores, pollen and some cooking smoke from the air

circulated through the filter.

F111 (Series 1,2,3)

PRODUCT DATA

FEATURES

• High Efficiency Particulate Air (HEPA) filter models are

99.97% efficient and the hospital grade particle filter

models are 95% efficient at 0.3 micron particles. Both

models are more efficient on particles smaller and

larger. There is also a 95% ASHRAE model.

• Circulates up to 1250 cfm.

• Designed to overcome the increase in air flow

resistance normally caused by filter loading.

• White or black color cover to complement the ceiling.

• CPZ™ module removes up to 95% of the space odors

for up to 24 months.

• 3-Speed remote wall switch ( 3-speed models only)

• READ AND SAVE THESE

INSTRUCTIONS

Application.........................................................................1

Features............................................................................1

Specifications....................................................................2

Ordering Information .........................................................2

Planning the Installation ....................................................3

Installation.........................................................................4

Operation...........................................................................7

Service ..............................................................................8

Parts List .......................................................... ... ... ...........9

Limited Two-Year Warranty...............................................12

The Honeywell Trademark is used under license from Honeywell International

Inc. by Air-Pure Systems.

Honeywell International Inc. makes no representations or warranties with

respect to this product.

Contents

68-0198-2

Page 2

F111 (SERIES 1,2,3) IN CEILING MEDIA AIR CLEANER

SPECIFICATIONS

IMPORTANT

The specifications given in this publication do not

include normal manufacturing tolerances. Therefore,

this unit may not exactly match the listed specifications. Also, this product is tested and calibrated

under closely controlled conditions, and some minor

differences in performance can be expected if those

conditions are changed.

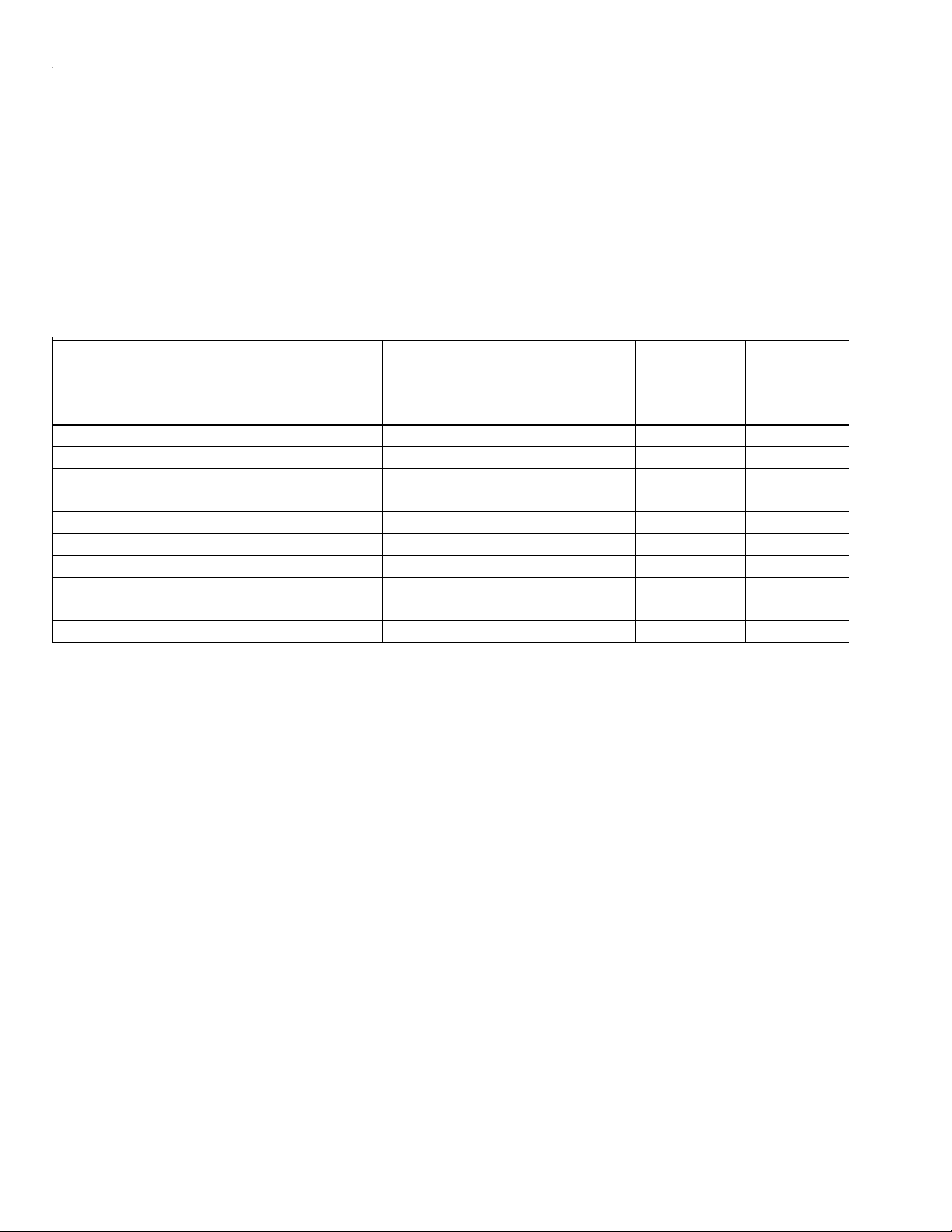

Table 1. F111 (Series 3) Description.

Particulates at

Model Voltage

F111A1253W-3S 120 Vac, 60 Hz, 8.5A 95% ASHRAE N/A N/A 1250 (2120)

F111A1063W-3S 120 Vac, 60 Hz, 7.2A 99.97% HEPA N/A N/A 950 (1610)

F111C1073W-3S 120 Vac, 60 Hz, 7.5 A 95% ASH RAE 85% CPZ™ modules 1150 (1950)

F111C1003W-3S 120 Vac, 60 Hz, 7.0A 99.9 7% HEPA 85% CPZ™ modules 825 (1400)

F111C1012W-3S 120 Vac, 60 Hz, 8.0A 95% at 0.3 micron 85% CPZ™ modules 1125 (1910)

F111A2253W-3S 230 Vac, 50 Hz, 4.2A 95% ASHRAE N/A N/A 1125 (1910)

F111A2007W-3S 230 Vac, 50 Hz, 3.5A 99.97% HEPA N/A N/A 900 (1530)

F111C2073W-3S 230 Vac, 50 Hz, 4.0 A 95% ASH RAE 85% CPZ™ modules 1025 (1740)

F111C2003W-3S 230 Vac, 50 Hz, 3.2A 99.9 7% HEPA 85% CPZ™ modules 825 (1400)

F111C1053W-3S 230 Vac, 50 Hz, 3.5A 95% at 0.3 micron 85% CPZ™ modules 950 (1610)

F111C1061

b

same as F111C1012B-3S

0.3 Micron

(DOP Test)

Models: Refer to Table 1 for model descriptions.

Grill Color: White (standard) or Black (add ‘B’ to end of

model number).

Blower/Motor: Single speed (standard) or three speed ( add

‘-3S’ to the end of the model number) direct drive forward

curve.

Dimensions: See Fig. 1 for dimensions.

Efficiency

V.O.C./Odor

(Most Gases/

Odors First Pass

Average)

Gas, V .O.C. and

Odor Control

Modules (2)

Air Volume

in cfm

3

/hr)

(m

a

N/A = not applicable.

a

For single-speed and three-speed systems (set to High)

b

F111C1061 has a new model number : F111C1012B

To Order F111 with a Black Grill

Replace the ‘W’ with a ‘B’ to any model number in Table 1.

ORDERING INFORMATION

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Commercial Air Products Distributor.

2. Air-Pure Systems

16873 Fish Point Rd. SE

Prior Lake, MN 55372

www.cleanairfacility.com

Phone: (800) 998-1919

Fax: (800) 221-3248

68-0198-2 Release 5-09 2

Page 3

F1 11 (SERIES 1,2,3) IN CEILING MEDIA AIR CLEANER

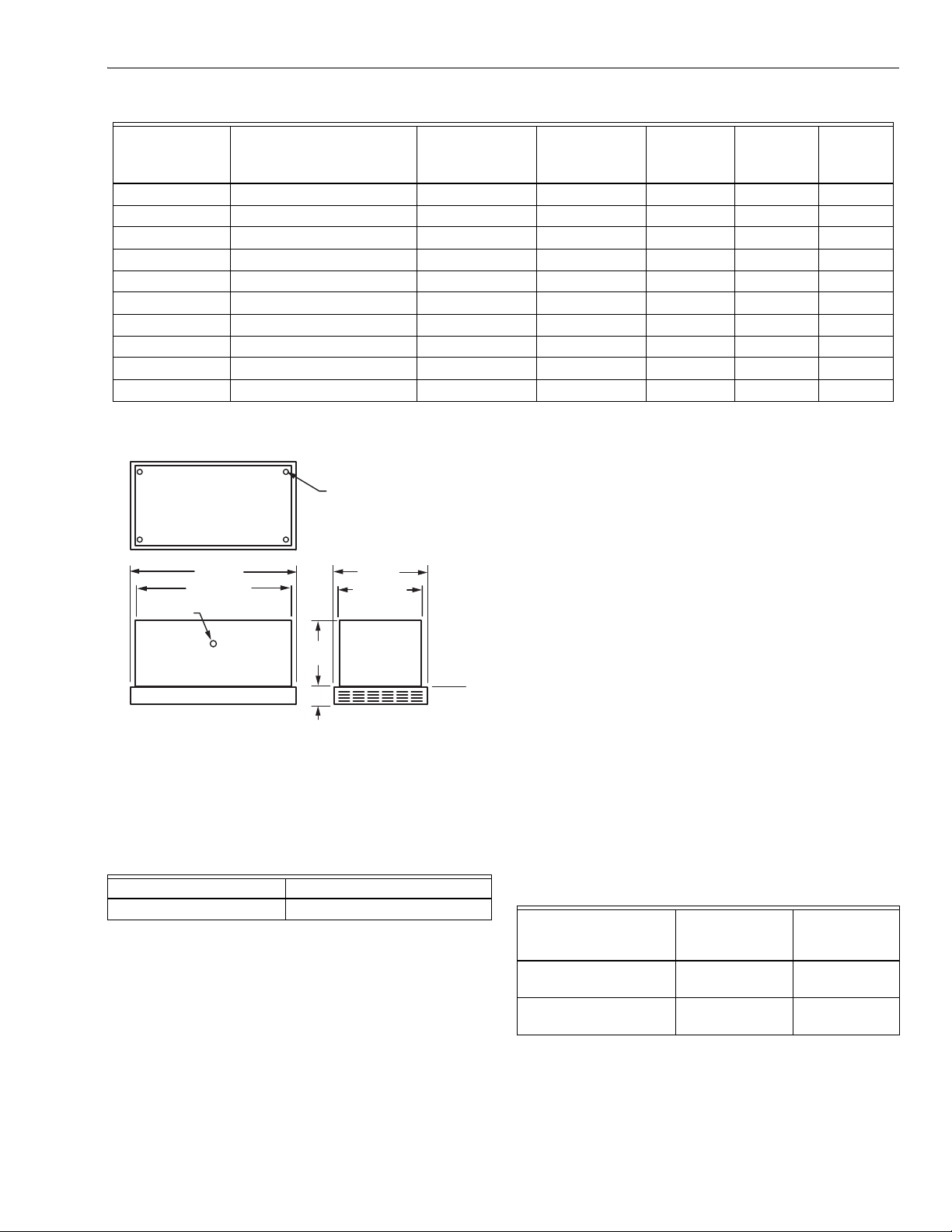

Table 2. F111 Air Volume Specifications for 3 Speed Models (Series 3).

a

Model Voltage

Particulates at

0.3 Micron

(DOP Test)

Gas, V .O.C. and

Odor Control

Modules (2)

High

in cfm

(m3/hr)

Medium

in cfm

(m3/hr)

Low

in cfm

(m3/hr)

F111A1253W-3S 120 Va c, 60 Hz, 8.5 A 95% ASHRAE N/A 1250 (2120) 800 (1360) 450 (760)

F111A1063W-3S 120 Vac, 60 Hz, 7.2A 99.97% HEPA N/A 950 (1610) 775 (1310) 450 (760)

F111C1073W-3S 120 Vac, 60 Hz, 7.5A 95% ASHRAE CPZ™ modules 1150 (1950) 825 (1400) 450 (760 )

F111C1003W-3S 12 0 Vac, 60 Hz, 7.0A 99.97% HEPA CPZ™ modules 825 (1400) 700 (1190) 450 (760)

F111C1012W-3S 120 Vac, 60 Hz, 8.0A 95% at 0.3 micron CPZ™ modules 1125 (1910) 825 (1400) 450 (760)

F111A2253W-3S 230 Va c, 50 Hz, 4.2 A 95% ASHRAE N/A 1125 (1910) 700 (1190) 475 (810)

F111A2007W-3S 230 Vac, 50 Hz, 3.5 A 99.97% HEPA N/A 900 (1530) 600 (1020) 400 (680)

F111C2073W-3S 23 0 Vac, 50 Hz, 4.0A 95% ASHRAE CPZ™ modules 1025 (1740) 675 (1150) 450 (760)

F111C2003W-3S 23 0 Vac, 50 Hz, 3.2A 99.97% HEPA CPZ™ modules 825 (1400) 550 (930) 375 (640)

F111C1053W-3S 23 0 Vac, 50 Hz, 3.5A 95% at 0.3 micron CPZ™ modules 950 (1610) 625 (1060) 425 (720)

a

Same for Single Speed Models (Series 1 & 2).

.

Accessories:

TOP VIEW

Black Color Grill

Remote 3-Speed Wall Switch

3/8 X 16

INTERNAL

THREAD (4)

48 (1219)

46-3/4 (1187)

POWER CONNECTION

POINT

17-1/4

(438)

4-1/2

(114)

24 (610)

22-1/2 (572)

CEILING

LINE

M11996A

Fig. 1. Approximate dimensions of F111

(Series 1,2,3) in in. (mm).

Installation Weight:

Approximately 115 lb to 155 lb (kg) depending on the filter

configuration. Refer to Table 3.

Table 3. Sorbent Module Weight.

Media Weight in lb (kg)

CPZ™ modules (2) 43 (20)

Sound Level at 3.3 ft (1m):

Low speed: 53 dBA (3 speed models only).

Medium speed: 57 dBA (3 speed models only)

High speed: 61 dBA.

Grille Type: Perforated metal.

Replacement Parts See Parts List, Table 5.

PLANNING THE INSTALLATION

The number of F11 1 (series 1,2,3) air cleaners that are needed

is determined by taking into account the number of occupants

and the volume of the space. Type of contamination, outdoor

air quality and use of the area are also factors. Refer to Table

3 for general guidelines when determining how many air

cleaners are needed.

EXAMPLE: One air cleaner can provide 2.5 air changes per

If any questions should arise concerning determining the

number of air cleaners needed for an area, consult your

distributor or local Honeywell Commercial Air Cleaner

Distributor.

Space Volume

(L x W x H) in Cubic

Feet (Cubic Meter)

12000 to 18000

18001 to 35000

hour in a 24,000 cubic feet (720 cubic meters) no

smoking area. Table 3 suggests two air cleaners

for a 24,000 cubic feet area because most areas

have contaminants that require more units to

provide quality air.

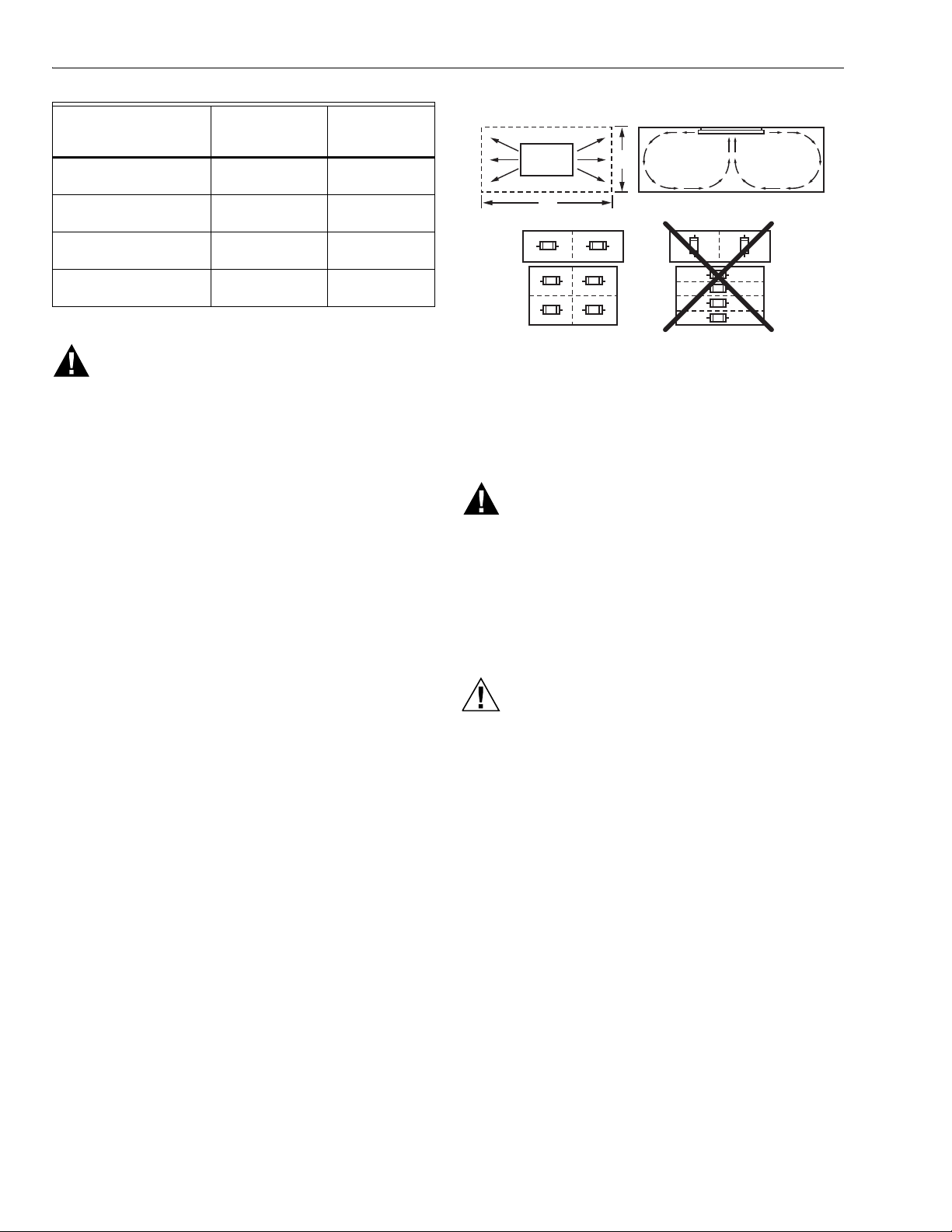

Table 4. Determining the Minimum Number of

Air Cleaners Needed for a Space.

Minimum

Number of

Persons Present

Number of Air

Cleaners

30 to 60 1

(360 to 540)

61 to 90 2

(540 to 1050)

Mounting: Recesses into opening on the ceiling.

Approvals:

Underwriters Laboratories Inc.: Listed.

Canadian Standards Association: Listed.

3 68-0198-2

Page 4

F111 (SERIES 1,2,3) IN CEILING MEDIA AIR CLEANER

Space Volume

(L x W x H) in Cubic

Feet (Cubic Meter)

35001 to 51000

(1050 to 1530)

51001 to 65000

(1530 to 1950)

65001 to 80000

(1950 to 2400)

80001 to 95000

(2400 to 2850)

Number of

Persons Present

91 to 120 3

121 to 180 4

181 to 240 5

241 to 300 6

Minimum

Number of Air

Cleaners

WARNING

TO REDUCE THE RISK OF FIRE,ELECTRICAL

SHOCK, OR INJURY TO PERSONS,OBSERVE THE

FOLLOWING:

1. Installation Work And Electrical Wiring Must Be Done

By Qualified Person(s) In Accordance With All Applicable Codes And Standard, Including Fire Rated Constructions.

2. When Cutting Or Drilling Into The Wall Or Ceiling, Do

Not Damage Electrical Wiring And Other Hidden Utilities.

3. Never Place A Switch Where It Can Be Reached From

A Tub Or Shower.

4. Use This Unit Only In The Manner Intended By The

Manufacturer. If You have Questions, Contact The Manufacturer.

5. Before Servicing Or Cleaning Unit, Switch Power Off At

Service Panel And Lock Service Panel To Prevent

Power From Being Switched on Accidentally.

6. If This Unit Is To Be Installed Over A Tub Or Shower, It

Must Be Marked As appropriate For The Application

and be connected to a GFCI (Ground Fault Circuit Interrupter) - protected branch circuit.

Choose Location

Choosing the correct location for the air cleaner affects the

overall performance of the unit. The bidirectional airflow

pattern must flow into the longest reaches of the zone being

cleaned. See Fig. 2

CLEANING FOOTPRINT

(SERIES

IMPORTANT

Never hang the air cleaner higher than 16 ft (5m)

above the floor.

F111

11000)

2

CORRECT

1

INSTALLATION

WARNING

Explosion Hazard Possible.

Can cause personal injury or equipment damage.

Do not install or use the F111 (series 11000) air

cleaner where there is any danger of gas, vapor or

dust explosion.

IMPORTANT

This air cleaner has not been investigated for use in

the ceilings of fire-resistant assemblies.

CAUTION

Electrical Hazard.

Can cause personal injury or equipment damage.

Turn off power before installing or servicing the air

cleaner.

IMPORTANT

Stand on a stable platform when working with the air

cleaner.

CEILING

FLOOR

INCORRECT

M12652A

NOTE: The F1 1 1 Has Not Been Investigated

For Use In Fire Resistance Rated

Construction.

Fig. 2. Correct positioning of the air cleaner

for optimum cleaning.

The air cleaner is designed to be suspended centrally in a

space and mounted into or on a ceiling. The cleaning footprint

of the air cleaner is rectangular with air patterns that move

clean air to the corners of the area while drawing contaminated

air up from the center of the area. See Fig. 2.

When multiple air cleaners are installed, the allotted areas to

be cleaned should be equal. The air throw in one direction is

approximately 55 ft (17m). Air velocity at 90 ft per minute

(27m per minute) is considered end of throw.

68-0198-2 Revised 5-09 4

When Installing this Product…

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service technician.

4. After installation is complete, check out product operation as provided in these instructions.

Unpack the Air Cleaner

Check that all components are included. The unit consists of:

• cabinet and grille/door assembly,

• media modules,

• literature.

Page 5

• latches (2)

• 3-speed switch module ( 3 Series only)

Make Opening (if Mounting in a Drop Ceiling)

1. Size the opening to fit the air cleaner cabinet as closely

as possible.

2. Frame the opening to provide adequate support for the

cabinet. The cabinet must fit snugly in the opening;

allow no more than 1/4 in. (6 mm) from the opening to

each side of the cabinet.

3. Cover the framing and any unused portion of the opening with wallboard, plywood, or other material and finish

to match the ceiling.

F1 11 (SERIES 1,2,3) IN CEILING MEDIA AIR CLEANER

FACTORY WIRING

EXTERNAL

WIRING BY

INSTALLER

CAPACITOR

BLACK

BROWN

WHITE

GREEN

MOTOR

A100002

BLACK

RED

BLUE

VIOLET

SWITCH

REMOTE 3-SPEED

Fig. 4. Typical F111 Series 3 only 120V, 60 Hz or

230V, 50 Hz wiring diagram.

Electrical Hookup

All wiring must comply with applicable codes and ordinances.

The power source must agree with the model type: 120V,

60 Hz or 230V, 50 Hz.

1. Locate the prepunched hole in the side of the cabinet.

2. Remove the air cleaner lid.

3. For Series 1 and 2 only.

Remove the connection box

cover plate in the center cavity of the air cleaner.

4. For Series 3 only. Remove the connection box cover

plate on the bottom, underneath the tray.

5. Refer to Fig. 3 and 4 for typical electrical diagrams.

WARNING

Risk of Fire or Electric Shock.

Can cause personal injury or equipment damage.

Use only Honeywell 190097C Remote Speed Switch

(3-speed models only) to regulate air cleaner speed.

Using a different speed switch may void the warranty.

IMPORTANT

• Be sure the air cleaner is grounded for correct

operation and safety.

• Canadian installation: NEVER install in ceilings with

thermal insulation value greater than R-40.

FACTORY WIRING

BLACK

EXTERNAL

WIRING BY

INSTALLER

BROWN

CAPACITOR

WHITE

GREEN

MOTOR

M12657

Mount Air Cleaner Cabinet

The air cleaner can be mounted in a drop ceiling system or

hung in an open area. Both mounting methods require the air

cleaner to be level and positioned facing downward for correct

operation.

1. Remove the door/grille from the carton and set it aside.

2. Remove all filters.

3. Fit the cabinet into the prepared ceiling opening or

position on the ceiling.

4. Use the four 3/8 x 16T internal nuts (one at each corner)

to fasten the cabinet to a structural support (bar joist,

concrete slab or timber framing). See Fig. 5.

NOTES:

5. Level the air cleaner.

6. Turn the air cleaner power on and check for proper

7. Turn off the power.

8. Install the particle filter. Note airflow direction arrows if

9. For Series 1 and 2 only.

10. For Series 3 only.

• All external hardware is furnished by the installer.

• When using the suspension system of mounting,

be sure to include a means for leveling adjustment after installation.

• Never rest the air cleaner on the T-bar.

operation for 2 to 3 minutes. There should be a smooth,

powerful blower sound and air discharging from both

ends of the air cleaner.

present. Install the filter with the direction arrow pointing

towards the motor.

Fasten the filter tabs. Be sure

there is a snapping sound when fastened. The tabs are

commercial Velcro and require more force than lightly

pushing them together.

Lock and secure the particle filter

into place by closing both latches.

Fig. 3. Typical F111 (series 1 & 2) 120V, 60 Hz or

208/230V, 50/60 Hz wiring diagram.

5 68-0198-2

Page 6

F111 (SERIES 1,2,3) IN CEILING MEDIA AIR CLEANER

TOP OF METAL CABINET

THREADED

ROD

JAM

NUT

CHAIN

EYEBOLT

JAM NUT

3/8 IN. X 16T

OR USING OPTIONAL "Z"

TOP OF METAL CABINET

BOTTOM FLANGE AGAINST

UNDERSIDE OF TEES

BRACK

ETS

"Z" BRACKET (4)

NOTE:

FASTEN SECURELY TO STRUCTURAL

SUPPORT SYSTEM, I.E. BAR JOIST,

CONCRETE SLAB OR TIMBER FRAMING.

HEX BOLT

LOCK

WASHER

CEILING

TEE

CAUTION

• This installation to be performed only by a qualified

installer.

• All wiring to comply with local electrical codes.

• Disconnect power to air cleaner at fuse or breaker

before beginning work. Failure to do so can result in

shock hazard endangering equipment and personal

safety of installer.

• Only one air cleaner can be connected to a remote

switch

1. Disconnect power to air cleaner.

2. Mount 4” x 4” outlet box at desired remote location.

3. Attach 3/4” extension ring to outlet box.

4. Run five conductor, color-coded, 18-gauge wires from

the remote switch location to the air cleaner.

5. Use three wire nuts to connect three color-coded, lead

wires on the remote switch to three color-coded wires

from the air cleaner. (Red, Blue, Violet)

6. Use one wire nut to connect white color-coded, lead

wire from the air cleaner to single color-coded wire from

the power supply. (White)

BOTTOM VIEW OF

UNIT WITHOUT

LID ASSEMBLY

M10892

Fig. 5. Fasten cabinet to a structural support.

IMPORTANT

Do not touch the pleated filter media. Handle only the

filter frame to prevent damage to the filter media.

11. Remove CPZ™ sorbent modules (select models) from

their packaging and install one module into each cavity.

12. For Series 1 only

. Be sure the fastener tabs are facing

downward and fasten them.

13. For Series 2 and 3 only.

Be sure both catches are

turned down and filter rests firmly on catches.

14. Install the prefilter in the air cleaner lid. Position the

metal screen mesh so it is facing upward when the lid is

closed.

Remote 3 Speed Wall Switch (3 Speed Models only)

The 190097C Remote Wall Switch Assembly allows control of

the F111 model air cleaners from a a location separate from

the air cleaner. The assembly includes a remote switch with

an outlet box cover, outlet box, extension ring, and a wire

harness. Wiring to connect the remote switch and air cleaner

must be furnished separately.

BLACK

A100001

Fig. 6. Wiring 3-Speed Remote Switch

7. Connect the ground wire from the power supply to a

ground stud of the outlet box.(Green)

8. Connect the ground wire from the air cleaner to the

ground stud of the outlet box.(Green)

9. Use one wire nut to connect the black color-coded, lead

wire on the remote switch to the black color-coded wire

from the power supply.

10. Fold wires into box and mount remote switch on outlet

box. Leave switch in OFF position.

11. On the air cleaner remove two screws on wiring compartment cover and open

12. Run five conductor, color coded, 18 gauge wires from

the remote switch through the air cleaner access opening into the wiring compartment. Strip ends of remote

switch lead wires

13. Connect three wires on air cleaner to remote switch

lead wires with wire nuts following color code used at

remote switch. (Red, Blue, Violet)

68-0198-2 Revised 5-09 6

Page 7

F1 11 (SERIES 1,2,3) IN CEILING MEDIA AIR CLEANER

14. Connect one wire on air cleaner to power supply wire

with a wire nut following color code used at remote

switch. (White)

15. Connect the ground wire from the remote switch to a

ground stud of the wiring compartment cover.(Green)

16. Fold wires into wiring compartment. Replace wiring

compartment cover .

17. Turn on power to air cleaner at fuse or breaker.

18. Check operation by turning air cleaner at HIGH,

MEDIUM, and LOW. Note

that only the remote switch

will operate the air cleaner.

Lid Assembly

The F111 lid is held in place by two separable hinges and two

spring loaded plungers. To install the spring loaded plungers

on the lid follow these steps:

1. Pull the plunger back and twist a quarter turn to reveal

the wrench flat on the body of the spring loaded plunger

(see Fig 7.)

2. Turn the threaded barrel out of the spring plunger.

3. Insert the threaded barrel through the hole in the lid and

turn the spring loaded plunger onto it.

4. Tighten the assembly with wrenches.

5. Repeat steps 1 through 4 for the second plunger.

WRENCH FLAT

THREADED

BARREL

WRENCH

FLAT

Removing /Replacing the Lid

IMPORTANT

The lid is heavy. Make sure that it is supported

before removing.

To remove the lid, swing it into the open position. Slide safety

catch to off position. Move the lid to the side to disengage the

hinge pins. Reverse the procedure to replace the lid. Make

sure safety catch is in safe position.

OPERATION

The F111 (series 1,2,3) in Ceiling Media Air Cleaner has been

engineered to improve indoor air quality for commercial and

industrial applications. The filters are the most practical and

effective filtering system for removing atmospheric dust,

pollens, bacteria, viruses, mold spores, smoke, fumes, mists

and aerosols. Refer to Fig. 8.

AIR IN

CPZ™

SORBENT

FILTER

MODULE

CEILING LINE

CLEAN AIR

DISCHARGE

M12651A

CPZ™

SORBENT

FILTER

MODULE

CEILING LINE

CLEAN AIR

DISCHARGE

BLOWER

MOTOR

INTAKE

PARTICLE FILTER

AIR IN

AIR VENTS

PREFILTER

Fig. 8. F111 (series 1,2,3) air cleaner operation.

SPRING

LOADED

PLUNGER

M11994

Fig. 7. Lid assembly.

Opening/Closing the Lid

To open the lid, pull the spring loaded plungers back to

disengage the plunger. Carefully swing the lid open on the

hinges while supporting the filter and/or adsorbent modules as

required. To close, swing the lid into the closed position and

engage the plungers.

The air cleaner is either operating (power on) or off (power

off). There are no other operational options available. Even

when the area is unoccupied, the air cleaner can be operated

continuously to prevent buildup of airborne contaminants.

Operate the air cleaner only when the area is occupied when

specific activities produce contaminants.

The CPZ™ sorbent module has the ability to collect and hold

gas-phase compounds and vapors typically found in

commercial and light industrial facilities. These gases and

vapors frequently appear as odors that, at times, can be

annoying and irritating. The modules become saturated after

collecting 25% to 50% of their weight in gaseous odors. The

quantity of CPZ™ material provides adequate dwell time to

ensure up to 95% collection efficiency in the first pass. This

also provides a long maintenance-free service life.

The minimum recommended air exchange rate is 2.5 times

per hour. In a heavily contaminated area, up to 15 air

exchanges per hour can be necessary. The factors that

determine what the rate of air exchange should be are:

• generation rates of the various pollutants;

• concentration level of the pollutants;

• desired contamination reduction level.

Airborne contaminants will always be present in the air where

contaminant generations take place. Air cleaning systems and

ventilators do not eliminate airborne contaminants, they

reduce the excessive accumulation of the contaminants. To

eliminate the contamination, the source of contamination must

be removed.

7 68-0198-2

Page 8

F111 (SERIES 1,2,3) IN CEILING MEDIA AIR CLEANER

Local, Federal and professional ventilation engineering

standards and codes prescribe minimum ventilation rates to

dilute air contamination in specific applications. The

ventilation rates usually assume the injection of outdoor air

measured as air exchange rate. The use of the F1 11 (series

1,2,3) air cleaner to comply with ventilation requirements is an

acceptable alternative to ventilation with outdoor air. However,

at least 20% of a specified ventilation rate or code must be

derived from outdoor air. The F111 (series 1,2,3) air cleaner

filtered and recirculated air can be the remaining 80%.

SERVICE

CAUTION

Electrical Hazard.

Can cause personal injury or equipment damage.

Turn off power before installing or servicing the air

cleaner.

IMPORTANT

Be sure to change filters as recommended to prevent

reduced airflow in the air cleaner.Stand on a stable

platform when working with the air cleaner.

The useful life of the CPZ™ sorbent mo dules may vary from 4

to 24 months, depending on the application. In most

applications, the sorbent media life ranges from 12 to 18

months. The particle filter life ranges from 6 to 24 months with

12 to 24 months as an average. The modules and filters need

to be changed more frequently in facilities that operate 24

hours a day.

Prefilter

The disposable prefilter collects large dust particulates and

lint- type airborne fibers. Check the filter every two weeks to

determine the replacement frequency:

1. Slowly open the lid, supporting the lid so the filters do

not fall out.

2. Remove the dirty prefilter.

3. Install the new prefilter in the air cleaner lid. Position the

metal screen mesh so it is facing upward when the lid is

closed.

4. Close and latch the lid.

Particle Filter

The particle filter collects particulates that pass through the

prefilter. The filter life is typically from 1 to 2 years. There is

decreased air quality and a pulsing sound when the filter is

filled with contaminants. The filter must be replaced when the

pulsing sound is noticed.

3. Place spent filter in a plastic trash bag and dispose of

properly.

4. Inspect the motor brackets for loose fasteners and

tighten as necessary.

5. Install the new filter noting the direction of airflow arrow.

6. For Series 1 and 2 only

there is a snapping sound when they are fastened. The

tabs are commercial Velcro and require more force to

fasten.

7. For Series 3 only.

into place by closing both latches

IMPORTANT

Do not touch the pleated filter media. Handle only the

filter frame to prevent damage to the filter media.

8. Close and latch the lid.

. Fasten the filter tabs. Be sure

Lock and secure the particle filter

CPZ™ Adsorbent Module

The CPZ™ adsorbent module is used to collect gases,

vapors, odors and volatile organic compounds (V.O.C.) from

the air that passes through the air cleaner. Adsorbents collect

and hold 25% to 50% of their weight in odorous gases and

vapors. The impurities are collected until the adsorbents reach

saturation. At saturation, the adsorbents emit a continuous

strong pungent odor. If the air cleaner is turned off for 8 to 10

hours, there will a temporary odor when it is turned back on. If

the odor persists for 30 minutes, it is time to replace the filters.

NOTE: When tobacco smoke is a contaminant, both the

particle filter and the adsorbent filter will need to be

serviced at the same time.

1. Slowly open the lid, supporting the lid so the filters do

not fall out.

2. For Series 1 only.

one hand and release the fastener.

3. For Series 2 and 3. Support the adsorbent module with

one hand and turn open the catches.

4. Use two hands and slide the filter from the housing.

IMPORTANT

The module weighs about 26 lb (12 kg) and can be

hard to handle.

5. Place the spent module in a plastic trash bag and

dispose of properly.

6. Remove CPZ™ sorbent modules from their packaging

and install.

7. For Series 1 only

downward and fasten them.

8. For Series 2 and 3 only.

turned down and filter rests firmly on catches.

9. Install 1 startup-filter in each end of grill.

10. Close and latch the lid.

Support the adsorbent module with

. Be sure the fastener tabs are facing

Be sure both catches are

NOTE: The filter must be replaced. Washing, vacuuming or

reverse air blasting does not clean it.

1. Slowly open lid, supporting it so the filters do not fall out.

2. Open the securing strips and with both hands. Slide the

filter toward you.

68-0198-2 Revised 5-09 8

On initial startup, a small amount of dust can blow from the air

cleaner. This is normal and stops a few minutes after startup.

The startup-filters will catch all the dust. The startup-filters are

placed in the two exit outlets on the grill. After running the unit

for 5 minutes, turn off the unit. Remove and discard the two

start-up filters.

Page 9

F1 11 (SERIES 1,2,3) IN CEILING MEDIA AIR CLEANER

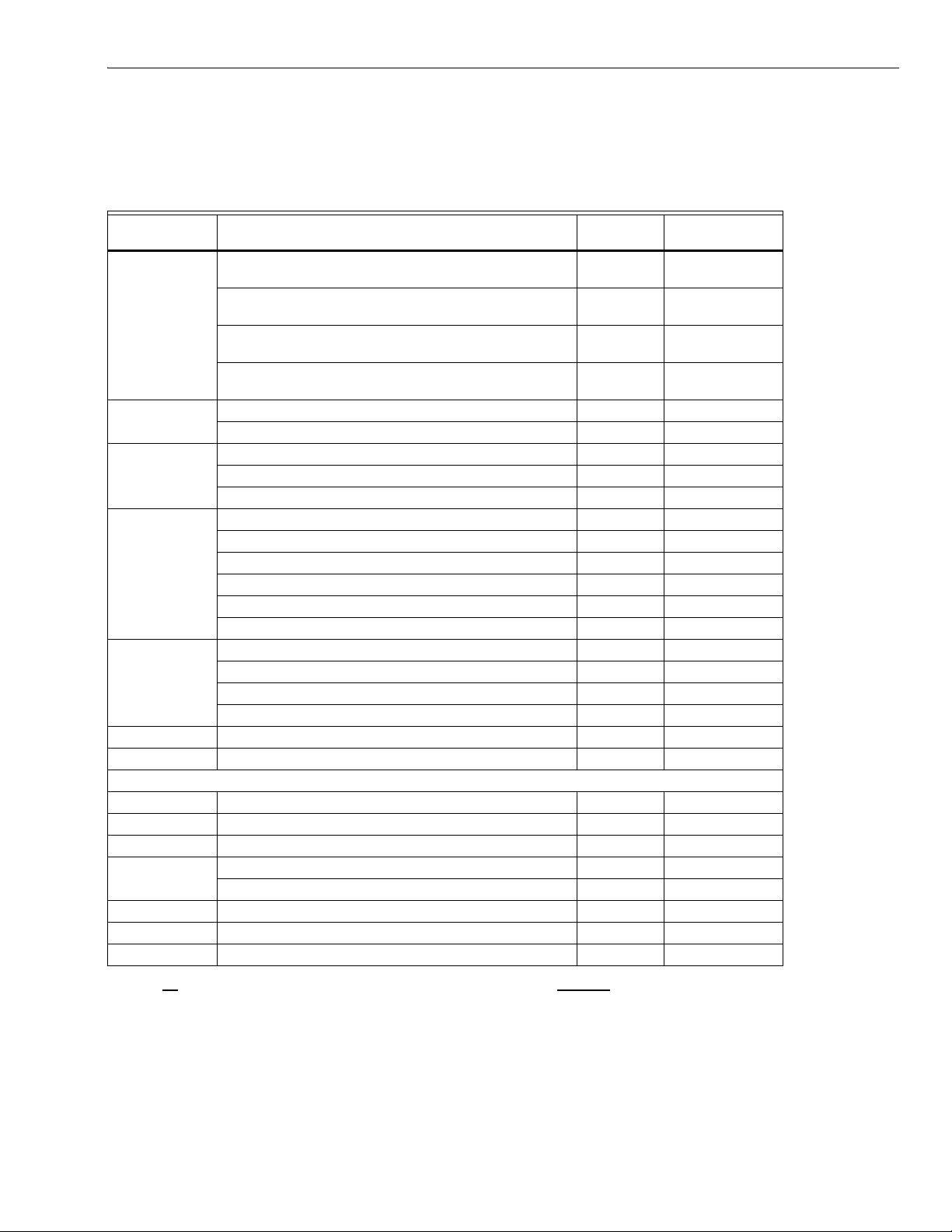

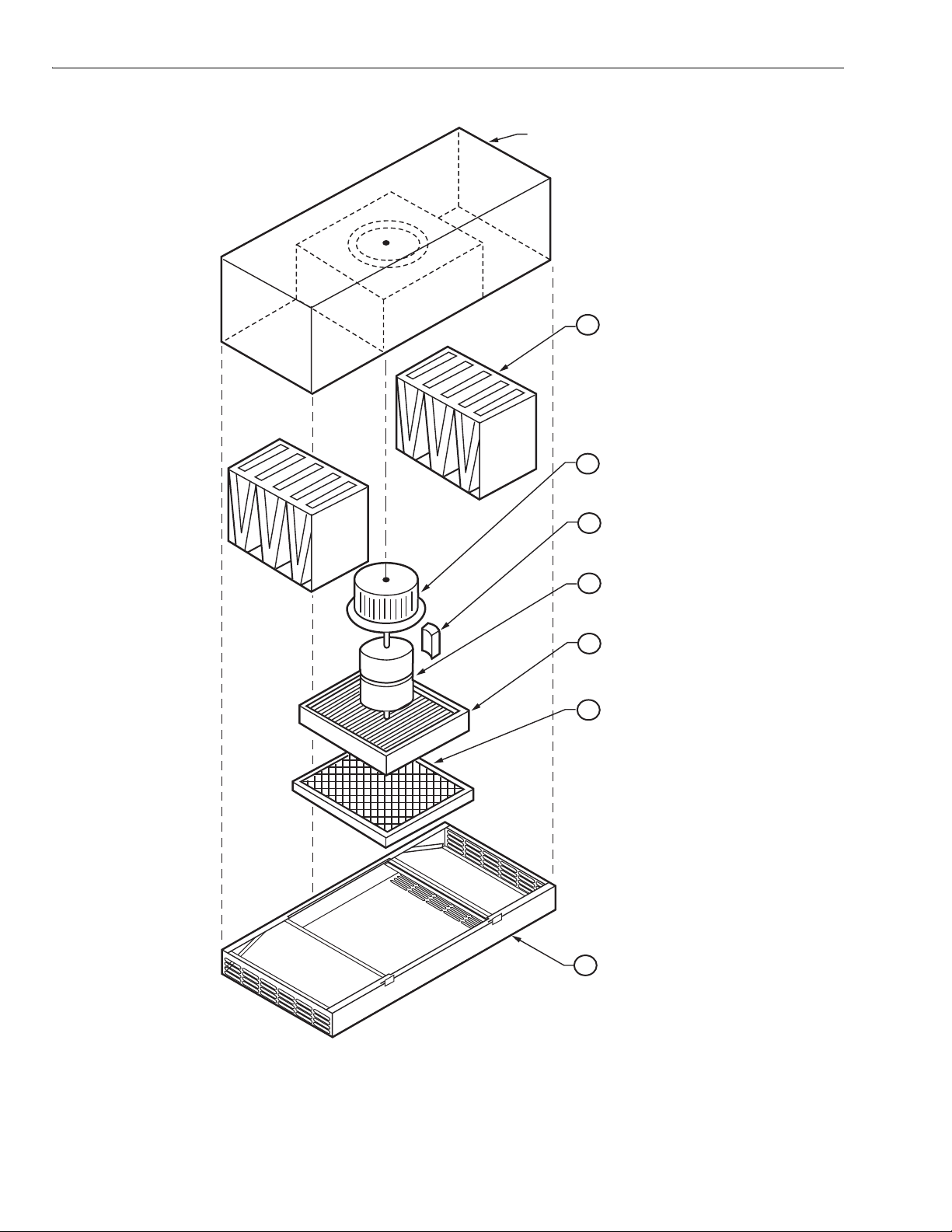

PARTS LIST

Refer to Fig. 9 and Table 5 for replacement part information.

Table 5. Replacement Parts.

Fig.

Reference No. Description Pack Qty Order Number

1 CPZ™ sorbent module (requires 2)—used with only

95% HEPA or 95% ASHRAE particle filters

Charcoal sorbent module (requires 2)—used with only

95% HEPA or 95% ASHRAE particle filters

Zeolite sorbent module (requires 2)—used with only

95% HEPA or 95% ASHRAE particle filters

Permanganate sorbent module (requires 2)—used with

only 95% HEPA or 95% ASHRAE particle filters

2 Blower wheel, Series 1 1 32000236

Blower wheel, Series 2, and 3 1 32002285

3 Motor capacitor; 120V, 60 Hz, Series 1,2, and 3 1 32000265

Motor capacitor; 208/230V, 50/60 Hz, Series 1, 2 1 32000549

Motor capacitor; 230V, 50 Hz, Series 3 1 32000265

4 Motor; 120 V, 60 Hz, Series 1 1 32000270

Motor; 208/230V, 50/60 Hz, Series 1 1 32000263

Motor; 120 V, 60 Hz, Series 2 1 32002415-001

Motor; 208/230V, 50/60 Hz, Series 2 1 32002415-002

Motor; 120 V, 3-Speed, 60 Hz, Series 3 1 32002415-004

Motor; 230V , 3-Speed, 50Hz, Series 3 1 32002415-005

5 99.97% HEPA media filter, 3”, Series 1 and 2 1 32000204-001

99.97% HEPA media filter, 4.5”, Series 3 1 32000204-002

95% hospital grade filter 1 32000203

95% ASHRAE particle filter 1 50004739-001

6 Prefilter (disposable) 1 32002307

7 Lid assembly with hinges and latches in White Color 1 32002308-002

OPTIONAL Parts not shown in Fig. 9.

Remote Wall 3-Speed Switch, Series 3 1 190097C

Motor mount bracket 1 32000260

Motor maintenance grommet set 3 32000261

Snap-loc Tabs; Series 1 1 32000262-001

Snap-loc Tabs; Series 2 1 32000262-002

Z Sidemount Bracket Kit 4 32002353

Spring Loaded Plunger 2 32002278

Lid assembly with hinges and latches in Black Color 1 32002308-003

1 32004078-001

1 32004078-002

1 32004078-003

1 32004078-004

NOTE: All replacement filters must be provided by Air-Pure Systems to maintain U.L. Certification and Warranty.

9 68-0198-2

Page 10

F111 (SERIES 1,2,3) IN CEILING MEDIA AIR CLEANER

CABINET

ASSEMBLY

SORBENT MEDIA MODULE

1

(2 REQUIRED)

BLOWER WHEEL

2

MOTOR CAPACITOR

3

MOTOR

4

MEDIA FILTER

5

PREFILTER

6

LID ASSEMBLY WITH

7

HINGES AND LATCHES

Fig. 9. Exploded view of F111 (series 1,2,3) in Ceiling Media Air Cleaner components.

68-0198-2 Revised 5-09 10

M11995E

Page 11

NOTES

F1 11 (SERIES 1,2,3) IN CEILING MEDIA AIR CLEANER

11 68-0198-2

Page 12

LIMITED TWO-YEAR WARRANTY

Air-Pure Systems warrants its air cleaner products to be free from defects in workmanship or materials under normal use and service, for a period

of two (2) years from the date of purchase by the original end-user. If at anytime during the warranty period the product is defective or malfunctions, Air-Pure Systems, through the distributor or dealer, from which the product was purchased, or through an authorized warranty repair

station, shall at Air-Pure Systems option, replace or repair the defective product or component.

This warranty does not cover removal or installation costs. This warranty shall not apply if it is shown that the defect or malfunction was caused

by damage which occurred during handling or shipment, improper electrical connections, improper use of the product or abuse.

Air-Pure Systems sole responsibility shall be to repair or replace the product within the terms stated above. AIR-PURE SYSTEMS SHALL NOT

BE LIABLE FOR ANY LOSS OR DAMAGE OF ANY KIND, INCLUDING ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING,

DIRECTLY OR INDIRECTLY, FROM ANY BREACH OF WARRANTY, EXPRESS OR IMPLIED, OR ANY OTHER FAILURE OF THIS PRODUCT. (Some states do not allow the exclusion or limitation of incidental or consequential damages, so this limitation may not apply to you.) THE

WARRANTIES SET FORTH HEREIN ARE EXCLUSIVE AND AIR-PURE SYSTEMS’ EXPRESSLY DISCLAIMS ALL OTHER WARRANTIES,

WHETHER WRITTEN OR ORAL, IMPLIED OR STATUTORY, INCLUDING BUT NOT LIMITED TO ANY WARRANTIES OF MERCHANTABILITY, WORKMANSHIP, OR FITNESS FOR A PARTICULAR USE.

This warranty gives you specific legal rights and you may have other rights which vary from state to state.

How to make a warranty claim or have questions answered:

Should you have a warranty claim or questions about the warranty policy, contact the distributor or dealer from which you purchased the product

or the authorized warranty repair stations nearest your location.

NOTE: Do not return any products or parts to the factory without a factory issued “Returned Warranty Goods Label” issued by Air Pure Sys-

In the event you or other persons, have any questions concerning the use and care of this product or this warranty please call or write the factory.

Air-Pure Systems

16873 Fish Point Rd. SE

Prior Lake, MN 55372-1714

Phone: (800) 998-1919

Fax: (800) 221-3248

tems.

Air-Pure Systems

16873 Fish Point Rd. SE

Prior Lake, MN 55372-1714

Phone (800) 998-1919

Fax: (800) 221-3248

68-0198-2 Revised 5-09 www.cleanairfacility.com

Loading...

Loading...