Page 1

F100

Media Air Cleaner

PRODUCT DATA

FEATURES

• High efficiency media filter (included with some

models) captures particles as small as 0.3 micron.

• FC100A Efficiency and arrestance ratings based on

the American Society of Heating, Refrigerating and Air

Conditioning- Engineers Standard 52.2-1999.

• Applicable to all gas, oil, and electric forced warm air

furnaces and to compressor cooling up to 5 tons.

• Mounts in the return air duct.

• Cabinet can support weight of residential furnace and

evaporator coil.

• Requires no electrical connections.

• Mounts in any position.

APPLICATION

The F100 Media Air Cleaner captures a significant amount of

the air-borne particles from the air circulated through the unit.

SPECIFICATIONS

IMPORTANT

The specifications in this publication do not include

normal manufacturing tolerances; therefore, an

individual unit may not exactly match the listed

specifications. This product is tested and calibrated

under closely controlled conditions, and some minor

differences in performance can be expected if those

conditions are changed.

Models:

F100F Media Air Cleaner includes cabinet, access door and

pleated media filter. Some units include a W8600A

AirWatch™ Indicator. F100B Media Air Cleaner includes

cabinet and access door.

Application:

Use with gas, oil, and electric forced warm air furnaces and

with compressor cooling. Can be used with heat pumps if

filter is changed regularly to prevent excessive pressure drop.

Not recommended for applications where pressure drop may

be critical.

• Requires no maintenance except periodic media filter

replacement.

• Quick and easy media filter replacement.

• Later upgrade to higher performing media or

electronic air cleaner is easy. (Note that 25 x 20 in. and

25 x 22 in. models cannot be upgraded to an electronic

air cleaner.)

FC100A Efficiency:

Efficiency Ratings: Based on American Society of Heating,

Refrigerating and Air-Conditioning Engineers Standard

52.2-1999.

Initial Efficiency: 25 percent (0.3 micron particles).

Minimum Efficiency Reporting Valve (MERV): 10 at 492 fpm.

Filter Media:

Pleated for greater media capacity.

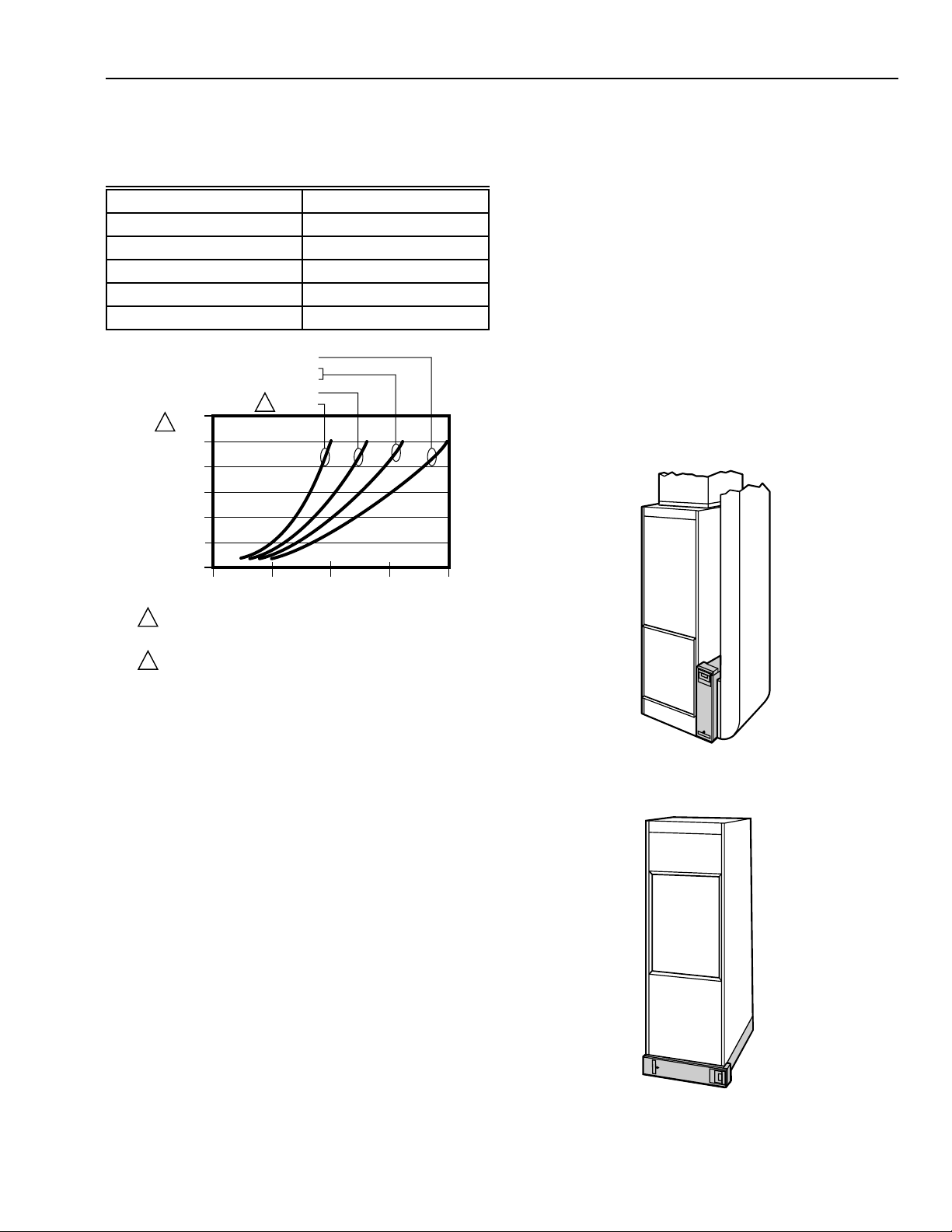

Capacity And Pressure Drop:

See Fig 2.

Initial Pressure Drop: 0.233 in. wc at 492 fpm.

Temperature Rating:

-40° to +140°F (-40° to +60°C).

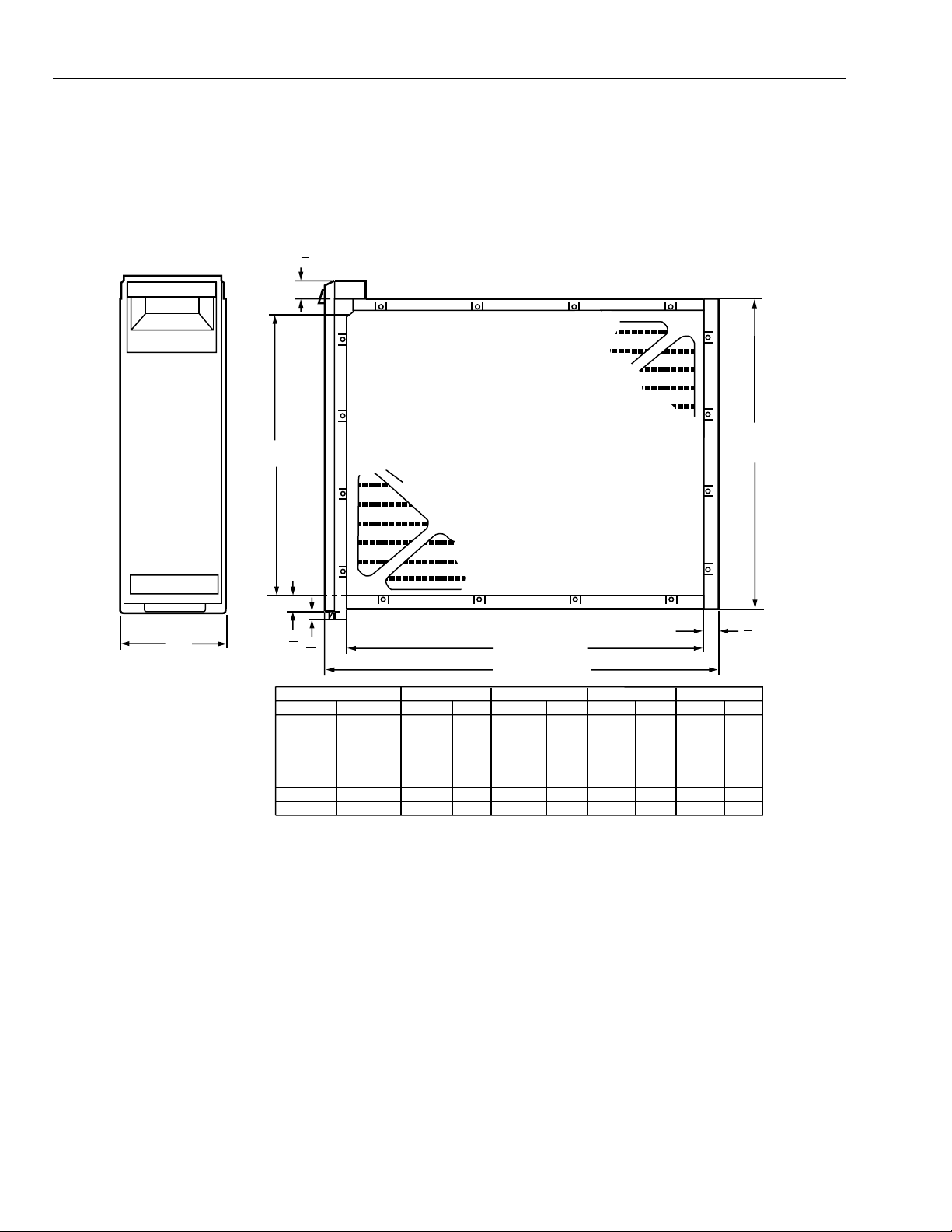

Dimensions:

See Fig. 1.

® U.S. Registered Trademark

Copyright © 2004 Honeywell International Inc. • All Rights Reserved

68-0239EF-4

Page 2

F100 MEDIA AIR CLEANER

Mounting:

Mounts in any position in the return air duct, usually next to

the furnace blower compartment. Cabinet is sturdy enough to

support weight of a residential furnace and evaporator coil.

Approvals:

Underwriters Laboratories, Inc.:

Listed to UL 900, Class 2.

1

(29)

1

8

DIM. A

(SEE TABLE)

Upgrade Path:

The F100 uses the same cabinet as the F50 Electronic Air

Cleaner. Upgrade may require installing the cell key,

electronic cells, protective screens and installation and wiring

of the power box, depending on model. (Note that 25 x 20 in.

and 25 x 22 in. models cannot be upgraded to an electronic

air cleaner.)

Accessory:

W8600A AirWatch™ Indicator (optional with some models).

DIM. B

(SEE TABLE)

DIM. D

7

8

(22)

648

521

648

521

333

524

572

M14710A

6

(171)

3

4

7

5

8

8

(22)

(16)

F100 SIZE

IN.

16 X 25

16 X 20

20 X 25

20 X 20

20 X 12 1/2

25 X 20

25 X 22

MM

406 X 635

406 X 508

508 X 635

508 X 508

508 X 318

635 X 508

635 X 559

DIM. C (SEE TABLE)

DIM. D (SEE TABLE)

DIM. A

IN. MM IN. MM

14 7/16

14 7/16

18 7/16

18 7/16

18 7/16

23 5/16

23 5/16

367

367

468

468

468

592

592

DIM. B

16 3/16

16 3/16

20 3/16

20 3/16

20 3/16

25 1/8

25 1/8

411

411

513

513

513

638

638

DIM. C

IN. MM IN. MM

23 1/4

591

457

591

457

276

467

514

25 1/2

20 1/2

25 1/2

20 1/2

13 1/8

20 5/8

22 1/2

18 1/4

23 1/4

18 1/4

10 7/8

18 3/8

20 1/4

Fig. 1. Installation dimensions in in. (mm) of air cleaner.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Home and Building Control Sales Office (check white pages of your phone directory).

2. Home and Building Control Customer Relations

Honeywell Inc., 1885 Douglas Drive North, MN10-1461

Golden Valley, Minnesota 55422-4386

3. Website: www.honeywell.com/yourhome/

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

68-0239EF–4

2

Page 3

F100 MEDIA AIR CLEANER

M939A

Replacement Media:

For optimum system performance, replace the filter every six

months (before heating season and before cooling season).

Adjust the schedule to you needs, but replace the filter at

least annually.

Filter Size (in.) Part Number

12.5 x 20 FC100A1052

16 x 25 FC100A1029

16 x 20 FC100A1003

20 x 25 FC100A1037

20 x 20 FC100A1011

FILTER SIZE

20 X 25

16 X 25

20 X 20

16 X 20

12.5 X 20

0.300

1

0.250

0.200

0.150

0.100

0.050

PRESSURE DROP (IN. WC)

0.000

0

WHEN FIRST INSTALLED. PRESSURE DROP INCREASES AS FILTER

1

BECOMES LOADED. REPLACE FILTER WHEN PRESSURE DROP

REACHES 0.5 IN. WC. (0.1 kPa).

2

AVAILABLE ONLY IN UNITED STATES.

2

500 1000 1500

AIRFLOW (CFM)

2000

M14709

Applications With Air Conditioning

Mount the media air cleaner upstream of the evaporator coil

in a cooling system. The filter will help to keep the coil clean

and reduce maintenance.

Applications With A Humidifier

The media air cleaner is compatible with humidifiers. Avoid

applications where water mist will reach the media. If an

atomizing humidifier is used, the filter media will require

replacement more often because of minerals in the water.

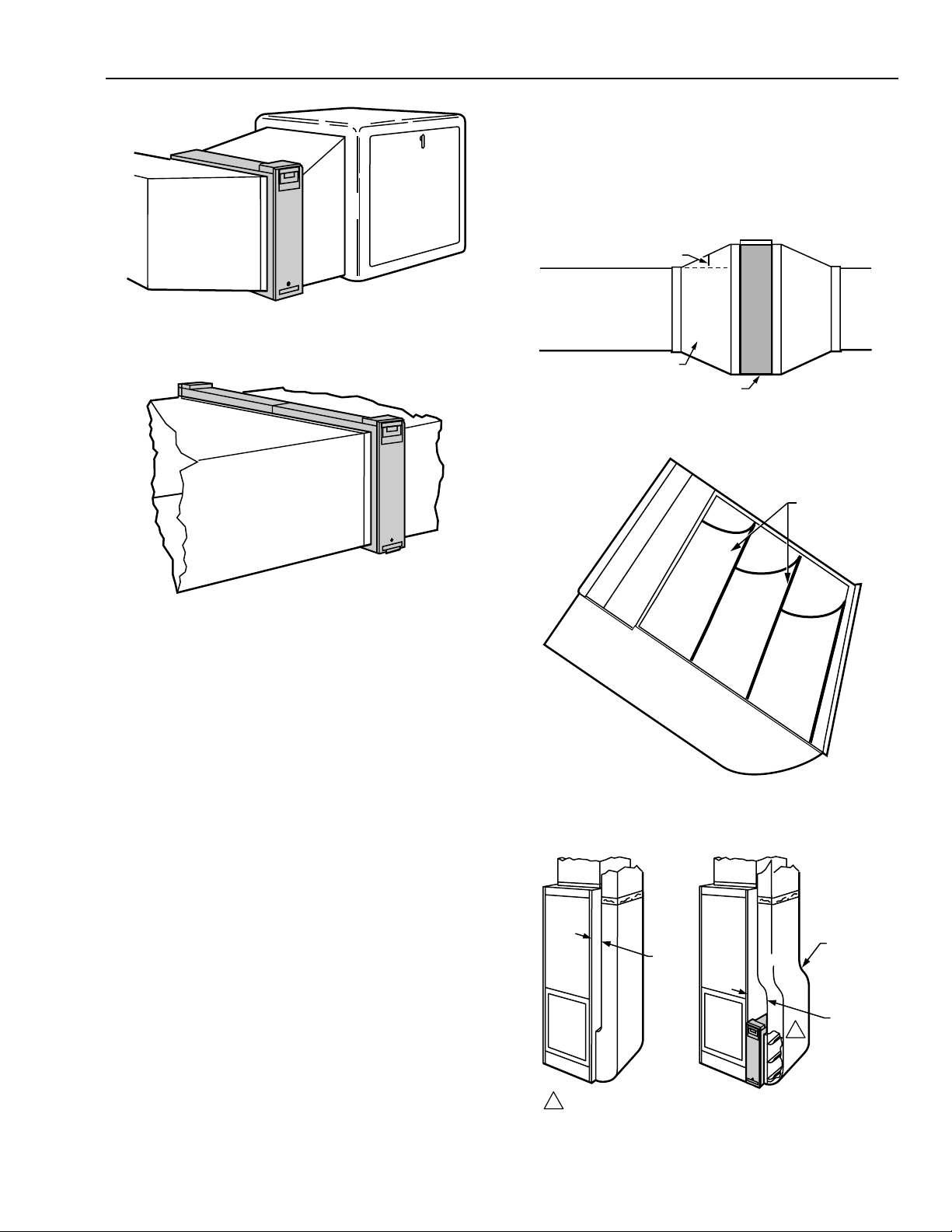

Choose Mounting Position

The media air cleaner can be mounted in any position, but the

arrow on the cartridge must point in the same direction as the

airflow. See Figs. 3-10 for proper location of the media air

cleaner for a variety of furnace installations. Note that the

media air cleaner cabinet is sturdy enough to easily support

the weight of the furnace and evaporator coil. See Fig. 4.

Fig. 2. Capacity, Pressure Drop and Area of

FC100A Filter Media.

PLANNING THE INSTALLATION

Location

The media air cleaner should be installed where all the air

passing through the system is circulated through it. The best

location is in the return air duct next to the blower

compartment so the media air cleaner can help to keep the

blower motor and evaporator coils clean. Do not mount in the

supply air duct.

For most efficient air cleaning, spread airflow evenly across

the face of the media. If the duct is a different size than the

media air filter cabinet, gradual transitions are required. If the

duct turns sharply just before the air filter, turning vanes are

required.

Choose a location that is readily accessible for checking and

replacing the filter. Allow at least 26 in. (660 mm) clearance in

front of the unit for removal of the cartridge.

Install the media air filter where the temperature will not

exceed the ratings in the Specifications.

Fig. 3. Highboy furnace, with side installation.

Media air filter is mounted vertically where return

enters side inlet of furnace.

M940A

Fig. 4. Highboy furnace, with installation beneath furnace.

Media air cleaner is mounted horizontally where return

enters from below.

3

68-0239EF–4

Page 4

F100 MEDIA AIR CLEANER

M941A

Fig. 5. Highboy furnace, with closet installation. Media air

cleaner is mounted vertically on furnace between furnace

and louvered return air opening in closet door.

M943A

Fig. 7. Counterflow furnace, with media air cleaner

mounted horizontally in return duct or plenum just

above furnace.

M942A

Fig. 6. Lowboy furnace, with media air cleaner mounted

horizontally in return plenum just above furnace and

opposite heating plenum.

68-0239EF–4

M944A

Fig. 8. Central fan installation, with media air cleaner

mounted horizontally in central return duct.

4

Page 5

M945A

20 DEGREE EXPANSION PER SIDE PER

FITTING (4 IN. PER RUNNING FOOT

[100 MM PER 300 LINEAR MM])

RETURN AIR

DUCT

TRANSITION FITTING

MEDIA AIR CLEANER CABINET

M947B

DUCT SIZE CHANGED GRADUALLY TO PREVENT TURBULENCE.

M948A

LESS

THAN

7 in.

(178 mm)

OFFSET

AT LEAST

7 in.

(178 mm)

1

1 REQUIRED TURNING VANES HELP DISTRIBUTE AIRFLOW EVENLY.

Fig. 9. Horizontal furnace, with media air filter mounted

vertically in return duct near furnace.

F100 MEDIA AIR CLEANER

Offsets

If the duct connection to the furnace in a side installation

allows less than 7 in. (178 mm) for mounting media air

cleaner cabinet, attach an offset to the elbow. See Fig. 13.

Fig. 11. Duct size changed gradually to prevent

turbulence.

TURNING

VANES

Fig. 10. Two or more media air cleaners used in a high

capacity system.

Determining Sheetmetal Requirements

The media air cleaner is adaptable to all new or existing

forced air heating and cooling systems used in residential

applications. Transitions or turning vanes may be required in

some applications for effective media air cleaner operation.

Transitions

Tr ansitions are needed when the duct is a different size than

the media air cleaner cabinet. Follow these guidelines when

fabricating:

1. Use gradual transitions to reduce air turbulence and

increase efficiency. See Fig. 11.

2. Use no more than 20 degrees (about 4 in. per running

ft. (100 mm per 300 linear mm)) of expansion on each

side of a transition fitting.

Turning Vanes

If the media air cleaner is installed next to an elbow or angle

fitting, add turning vanes inside the angle to distribute airflow

more evenly across the face of the media. See Fig 12.

M946A

M5651

Fig. 12. Turning vanes installed in bend help distribute

airflow evenly over face of media.

Fig. 13. Typical use of duct offset to make room for

media air cleaner.

5

68-0239EF–4

Page 6

F100 MEDIA AIR CLEANER

INSTALLATION AND CHECKOUT

When Installing this Product…

1. Read these instructions carefully. Failure to follow them

could damage the media air filter or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

media air cleaner to make sure the product is suitable

for your application.

3. Installer must be a trained, experienced service

technician.

Remove Furnace Filter And Clean Blower

Compartment

Before starting the installation, remove and discard the

existing furnace filter (if used). Thoroughly clean the blower

compartment. If possible, power vacuum the ductwork to

remove accumulated dust in an occupied home or remove

construction dirt in a new home. The media air cleaner cannot

remove dirt that has settled in the blower compartment and

distribution ducts.

Install The Cabinet

The following procedure describes a typical side installation

on an existing highboy furnace. Alternate procedures are

noted as appropriate. Other changes in installation

procedures may be necessary to complete your installation.

Fasten Cabinet To Ductwork

Fasten side of cabinet to the ductwork using sheet-metal

screws, rivets, or slip joints, as appropriate.

Connect Ductwork

Connect the vertical duct section to the elbow. If the vertical

drop of the duct is less than 7 in. (178 mm) from the side of

the furnace, shorten the horizontal trunk or attach an offset

fitting to the elbow. See Fig. 12. When ductwork is properly

aligned, connect the vertical duct to the horizontal trunk.

Seal Joints

Seal all joints in the return air system between the media air

filter and the furnace to prevent dust from entering the clean

airstream.

Install Filter Cartridge

Slide the filter cartridge into the cabinet, making sure the

arrow on the cartridge points in the direction of air flow.

Replace access door. Insert the tab on the bottom of the door

into the slot in the cabinet. Swing the door closed and press it

into place.

Install W8600A AIRWATCH™ Indicator

(Included with some models)

Review The Installation Plan

Temporarily place the cabinet on the floor, oriented as it will

be when installed. Insert and remove the cartridge to make

sure the plan allows adequate clearance for easy removal

and replacement of the cartridge.

Make sure that shop-fabricated sheetmetal components, such

as turning vanes, are available.

Fasten The Cabinet To The Furnace

Align the cabinet with the return air opening. Place blocks

under the cabinet, as necessary, to make sure the unit sits

securely. Create an opening in the furnace to match the

cabinet opening. Attach the cabinet securely to the furnace.

Attach the unit directly or fit a starting collar in the furnace

opening. Either drill holes and fasten with sheetmetal screws

or rivets, or use slip joints. If you are drilling holes, use a

locking pliers to help hold the unit in place during drilling.

Install Turning Vanes

Install turning vanes to help distribute air equally over the full

surface of the upstream side of the media. Install them

whenever an abrupt 90 degree elbow is installed directly

against the media air cleaner cabinet.

Mount the W8600A next to the thermostat or any other

convenient location in the living area of the home. The device

is battery-operated so has no electrical requirements.

Remove the device from the base and mark the mounting

holes, using the base as a template. Drill the holes. Position

the base over the holes and install the mounting screws

provided. Tighten the screws until the base is mounted firmly

on the wall. Replace the device onto the base.

Set the DIP switches on the back of the W8600A according to

the equipment installed in the home. Use the default settings

when all devices (air cleaner, UV air treatment system, and

humidifier) are installed. Or move the DIP switch to off (left)

when a device is not installed.

NOTE: The UV air treatment system and the humidifier

settings are set for one year. The air cleaner settings

are selectable according to homeowner activities

and schedule.

Set the air cleaner filter time DIP switches for 3, 6, 9 or 12

months according to the information on the back of the

device. Leave the factory default DIP switch settings to

change the filter every three months. If no air cleaner filter is

installed, move DIP switch 4 and 5 settings to off (left).

68-0239EF–4

6

Page 7

F100 MEDIA AIR CLEANER

Install two AAA alkaline batteries (provided) in the harness on

the back of the device. Observe that the device performs a

self-test, beeping and flashing the LC display individually for

each device (air cleaner, UV air treatment system, humidifier)

installed in the home. Then press and hold the black reset

button on the bottom of the device for five seconds or until the

display stops flashing to start the timers. Observe the battery

LCD: on solidly means that the unit is correctly powered;

flashing indicates that the battery requires replacing.

Checkout

Visually check the installation. Make sure:

• Airflow is in the direction of the arrow on the media air filter

cartridge.

•Turning vanes and transitions, if used, are properly

installed.

• Joints in sheetmetal between media fir filter and fur-nace

are sealed.

• All sheetmetal connections are complete.

•Original furnace filter has been removed and blower

compartment is cleaned.

Replace any access doors removed during the Installation or

Checkout.

Run the furnace or cooling system through one complete

cycle to make sure the system operates as desired.

Maintenance

The W8600A beeps every fifteen minutes when an LCD is

flashing. Replace the part in the system that corresponds with

the flashing LCD.

NOTE: When batteries need replacing, replace them within

30 seconds of removal to maintain the correct

indicator time. After 30 seconds of replacing the

batteries, if the LCD is blank, remove and install new

batteries. For other parts, press and hold the black

button on the bottom of the device to reset the timer

after replacing parts.

The media filter must be replaced when pressure drop across

the media filter reaches 0.5 in. w.c. (0.1 kPa). or at least

annually. If the media air cleaner is installed downstream from

an atomizing humidifier or if the installation includes both

heating and cooling, more frequent replacement may be

necessary. Clogged media must be replaced promptly to

avoid restricting airflow and reducing efficiency of the heatingcooling system. Record the replacement date in the space

provided on the replacement media filter.

LCD If arrow is flashing or

unit is beeping

Battery Batteries need changing. Changing batteries within 30 seconds of removing

old batteries to maintain correct indicator time.

Air Cleaner Media filter needs replacing. Pressing and holding reset button for 10 seconds or

until arrow is no longer displayed.

UV Air Treatment UV lamps need replacing in UV air

treatment system.

Humidifier Humidifier pad needs replacing.

Reset by

7

68-0239EF–4

Page 8

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

68-0239EF–4 G.H. Rev. 7-04

Honeywell Limited-Honeywell Limitée

35 Dynamic Drive

Scarborough, Ontario

M1V 429

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

M18621A

Page 9

Filtre à air à élément filtrant à fibres F100

APPLICATION

Le filtre à air à élément filtrant à fibres F100 retient une importante

quantité de particules contenues dans l’air qui le traverse.

FICHE TECHNIQUE

IMPORTANT

Les caractéristiques techniques indiquées dans la

présente publication ne comprennent pas les tolérances

normales de fabrication. Par conséquent, il se peut que

l’appareil ne corresponde pas exactement aux

caractéristiques indiquées. De même, le produit a été

mis à l’essai et étalonné dans des conditions entièrement

contrôlées et on peut s’attendre à de légères différences

de fonctionnement si ces conditions sont modifiées.

Modèles :

F100F filtre à air à élément filtrant à fibres avec boîtier, porte

d’accès, médium filtrant en papier accordéon. Certaines

modèles comprennent un indicateur AirWatch

F100B filtre à élément filtrant à fibres avec boîtier et porte

d’accès.

Application :

Convient aux appareils de chauffage à air pulsé au gaz, au

mazout et à l’électricité et aux compresseurs de

refroidissement. Peut être utilisé dans un système à pompe à

chaleur si le filtre est remplacé à intervalle régulier pour éviter

une trop grande chute de pression. Non recommandé dans

les systèmes ou une chute de pression peut nuire.

MD

W8600A.

DONNÉES TECHNIQUES

CARACTÉRISTIQUES

• Filtre à fibres à haut rendement (compris avec certains

modèles) qui retient des particules dont la taille fait

aussi peu que 0,3 micron.

• Efficacité et capacité de rétention du FC100A établies

d’après la norme 52.2-1999 de l’American Society of

Heating, Refrigerating and Air-Conditioning Engineers.

• Convient à tous les systèmes de chauffage à air pulsé

au gaz, au mazout ou à l’électricité et aux

compresseurs de refroidissement allant jusqu’à 5

tonnes.

• S’installe dans la gaine de reprise d’air.

• Le boîtier résistant peut recevoir le poids d’un

appareil de chauffage résidentiel et d’un serpentin

d’évaporation.

• Ne requiert aucun raccordement électrique.

• S’installe dans n’importe quelle position.

• N’exige aucun entretien à l’exception du

remplacement périodique du filtre à fibres.

• Remplacement simple et rapide du filtre à fibres.

• Peut par la suite être remplacé facilement par un

modèle à rendement plus élevé ou par un filtre à air

électronique. (Prendre note que les modèles 25 x 20 po

et 25 x 22 po ne peuvent pas être remplacés par un

filtre à air électronique.)

Efficacité du FC100A :

Efficacité établie d’après la norme 52.2-1999 de l’American

Society of Heating, Refrigerating and Air-Conditioning

Engineers.

Efficacité initiale : 25 % (particules de 0,3 micron).

Rendement minimum rapporté : 10 à 492 pi

Médium filtrant :

Papier plié en accordéon pour une plus grande capacité.

Capacité et chute de pression :

Voir la Fig. 2.

Chute de pression initiale : 0,233 po c.e. à 492 pi

Température ambiante nominale :

-40 à 60 oC (-40 à 140 oF).

Encombrement :

Voir la Fig. 1.

3

/min.

3

/min.

® Marque de commerce enregistrée aux États-Unis

Copyright © 2004 Honeywell International Inc. * Tous droits réservés

68-0239EF-4

Page 10

FILTRE À AIR À ÉLÉMENT FILTRANT À FIBRES F100

Installation :

S’installe dans n’importe quelle position dans la gaine de

reprise d’air, habituellement près du compartiment du

ventilateur de l’appareil de chauffage. Le boîtier est

suffisamment résistant pour recevoir le poids d’un appareil de

chauffage résidentiel et d’un serpentin d’évaporation.

Homologation :

Underwriters Laboratories Inc., répertorié selon la norme

UL900, classe 2.

1

(29)

1

8

DIM. A

(SEE TABLE)

Possibilité de mise à niveau :

Le F100F fait appel au même boîtier que le filtre à air

électronique F50. La mise à niveau peut nécessiter

l’installation d’un clavette de cellule, de cellules électroniques,

d’écrans protecteurs; selon les modèles, il faudra également

installer et raccorder le bloc d’alimentation. (Prendre note que

les modèles 25 x 20 po et 25 x 22 po ne peuvent pas être

remplacés par un filtre à air électronique.)

Accessoire :

Indicateur AirWatch

MD

W8600A (en option avec certaines

modèles).

DIM. B

(SEE TABLE)

DIM. D

(22)

25 1/2

20 1/2

25 1/2

20 1/2

13 1/8

20 5/8

22 1/2

MF14710A

7

8

6

(171)

3

4

7

5

8

8

(22)

(16)

MM

406 X 635

406 X 508

508 X 635

508 X 508

508 X 318

635 X 508

635 X 559

F100 SIZE

IN.

16 X 25

16 X 20

20 X 25

20 X 20

20 X 12 1/2

25 X 20

25 X 22

DIM. C (SEE TABLE)

DIM. D (SEE TABLE)

DIM. A

MM IN. MM IN.

367

14 7/16

367

14 7/16

468

18 7/16

468

18 7/16

468

18 7/16

592

23 5/16

592

23 5/16

DIM. B

411

411

513

513

513

638

638

16 3/16

16 3/16

20 3/16

20 3/16

20 3/16

25 1/8

25 1/8

DIM. C

MM IN. MM IN.

591

457

591

457

276

467

514

23 1/4

18 1/4

23 1/4

18 1/4

10 7/8

18 3/8

20 1/4

648

521

648

521

333

524

572

Fig. 1. Encombrement du filtre à air en mm (po).

POUR COMMANDER

Au moment d’acheter des produits de modernisation et de remplacement auprès de votre grossiste ou distributeur TRADELINE©,

consultez le catalogue TRADELINE ou les tarifs pour obtenir le numéro de pièce.

Prière d’adresser toute question additionnelle, demande d’information ou commentaires sur les produits et services par écrit ou par

téléphone :

1. Aux services à la clientèle de Honeywell

Honeywell 1885 Douglas Drive North, MN10-1461

Golden Valley, MN 55422-4386

2. Ou visiter notre site Web à www.honeywell.com/yourhome/

Au Canada : Honeywell Limited-Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9

Points de vente et de service dans toutes les grandes villes du monde. Usines en Allemagne, en Australie, au Canada, en

Espagne, aux États-Unis, en Finlande, en France, au Japon, au Mexique, aux Pays-Bas, au Royaume-Uni et à Taiwan.

68-0239EF–4

2

Page 11

FILTRE À AIR À ÉLÉMENT FILTRANT À FIBRES F100

M939A

Médium filtrant de rechange :

Pour assurer au système un fonctionnement optimal,

remplacer le filtre tous les six mois (avant la saison de

chauffage et avant la saison de refroidissement). Modifier le

calendrier selon les besoins, mais remplacer le filtre au moins

une fois l’an.

Taille du filtre (en po) Numéro de pièce

12.5 x 20 FC100A1052

16 x 25 FC100A1029

16 x 20 FC100A1003

20 x 25 FC100A1037

20 x 20 FC100A1011

TAILLE DU FILTRE

0.300

1

0.250

0.200

0.150

0.100

0.050

0.000

CHUTE DE PRESSION (PO C.E.)

0

APRÈS L’INSTALLATION, LA CHUTE DE PRESSION AUGMENTE À MESURE

1

QUE LE FILTRE SE CHARGE DE PARTICULES. REMPLACER LE FILTRE

LORSQUE LA CHUTE DE PRESSION ATTEINT 1 kPa (0,5 po c.e.).

2

OFFERT AUX ÉTATS-UNIS SEULEMENT.

20 X 25

16 X 25

20 X 20

16 X 20

2

12.5 X 20

500 1000 1500

DÉBIT D’AIR (EN pi3/min)

2000

MF14709A

Applications – appareil de refroidissement

Le filtre à air devrait être installé en amont du serpentin de

l’évaporateur. Le filtre à air aidera à garder le serpentin propre

et permettra de réduire la fréquence de l’entretien.

Applications – humidificateur

Le filtre à air convient aux systèmes avec humidificateurs.

Éviter les installations où l’eau vaporisée peut atteindre le

médium filtrant. Dans le cas d’une installation avec

humidificateur atomiseur, il faudra remplacer le médium

filtrant plus souvent en raison des sédiments que contient

l’eau.

Choisir la position d’installation du filtre

Le filtre à air à élément filtrant à fibres peut être installé dans

n’importe quelle position, mais les flèches figurant sur la

cartouche doivent pointer dans le même sens que celui de

l’écoulement de l’air. Voir les figures 3 à 10 pour observer

l’emplacement adéquat du filtre à air à élément filtrant à fibres

selon le type d’appareil de chauffage. Il est à noter que le

boîtier du filtre à air à élément filtrant à fibres est robuste et

qu’il peut facilement recevoir le poids de l’appareil de

chauffage et du serpentin d’évaporation. Voir la Fig. 4.

Fig. 2. Efficacité du filtre à air, chute de pression à divers

débits d’air.

PLANIFICATION DE L’INSTALLATION

Emplacement

Installer le filtre à air de manière que tout l’air qui passe dans le

système puisse circuler dans le filtre. Le meilleur endroit est la

gaine de retour d’air, à côté du compartiment de ventilation; à

cet endroit, le filtre à air contribuera en effet à garder le moteur

du ventilateur et les serpentins de l’évaporateur plus propres.

Ne pas installer le filtre dans la gaine de soufflage.

Le filtrage de l’air sera plus efficace si le débit d’air est réparti

uniformément sur la surface du filtre. Si la gaine et le boîtier du

filtre à air n’ont pas les mêmes dimensions, il est préférable

d’installer des raccords de transition. Si la gaine présente un

angle aigu juste avant le filtre à air, il est recommandé d’utiliser

des déflecteurs.

Choisir un emplacement facile d’accès pour la vérification et le

remplacement du filtre. Prévoir un dégagement d’au moins

660 mm (26 po) sur le devant de l’appareil pour le retrait de la

cartouche.

Installer le filtre à air à élément filtrant à fibres à un endroit où

la température ne dépasse pas les limites indiquées dans la

fiche technique.

Fig. 3. Appareil de chauffage à caissons superposés.

Filtre à air installé sur le côté à la verticale, à l’endroit où

entre l’air repris, sur le côté de l’appareil de chauffage.

M940A

Fig. 4. Appareil de chauffage à caissons superposés.

Filtre à air installé sous l’appareil de chauffage à

l’horizontale, à l’endroit où entre l’air repris, au bas de

l’appareil de chauffage.

3

68-0239EF–4

Page 12

FILTRE À AIR À ÉLÉMENT FILTRANT À FIBRES F100

M941A

Fig. 5. Appareil de chauffage à caissons superposés,

dans une armoire. Filtre à air installé sur le côté à la

verticale sur l’appareil de chauffage, entre l’appareil de

chauffage et la grille de reprise d’air placée dans

l’ouverture de la porte de l’armoire.

M943A

Fig. 7. Appareil de chauffage à contre-courant. Filtre à air

installé à l’horizontale dans la gaine de reprise d’air ou

dans le plénum juste au-dessus de l’appareil de

chauffage.

M942A

Fig. 6. Appareil de chauffage à caissons juxtaposés. Filtre

à air installé à l’horizontale dans le plénum d’air repris

juste au-dessus de l’appareil de chauffage, face au

plénum d’alimentation.

68-0239EF–4

4

M944A

Fig. 8. Appareil de ventilation centrale. Filtre à air installé

à l’horizontale dans une gaine de reprise centrale.

Page 13

M945A

MF5651

DÉFLECTEURS

MF947C

MODIFICATION GRADUELLE DE LA TAILLE DE LA GAINE D’AIR

EN VUE DE RÉDUIRE LA TURBULENCE.

EXPANSION DE 20 DEGRÉS DE CHAQUE CÔTÉ,

PAR RACCORD (100 mm par 300 mm linéaires)

(4 po par pied linéaire).

GAINE DE REPRISE D’AIR

RACCORD DE TRANSITION

BOÎTIER DU FILTRE À AIR À ÉLÉMENT

FILTRANT À FIBRES

Fig. 9. Appareil de chauffage horizontal. Le filtre à air est

monté à la verticale à l’endroit où entre l’air repris près

de l’appareil de chauffage.

FILTRE À AIR À ÉLÉMENT FILTRANT À FIBRES F100

Fig. 11. Modification graduelle de la taille de la gaine d’air

en vue de réduire la turbulence.

Fig. 10. Deux filtres à air à élément filtrant à fibres ou

plus installés dans un système à haut rendement.

Raccords de gaines requis

Le filtre à air se combine à tout système résidentiel de

chauffage, de refroidissement et de ventilation à air pulsé

neuf ou en place. Des raccords de transition ou de dérivation

et des déflecteurs peuvent être nécessaires pour assurer un

meilleur rendement dans certaines applications.

Raccords de transition

Des raccords de transition sont nécessaires lorsque les

dimensions de la gaine et du boîtier du filtre à air sont

différentes.

1. Les raccords de transition réduisent la turbulence et

augmentent l’efficacité. Voir la Fig. 11.

2. L’expansion maximale doit être de 20 degrés (environ

100 mm par 300 mm linéaires [4 po par pied linéaire])

de chaque côté du raccord de transition.

Déflecteurs

Si le filtre à air est installé près d’un coude (raccord à angle),

installer les déflecteurs à l’intérieur du coude pour assurer

une distribution d’air plus uniforme à la surface du filtre. Voir la

Fig. 12.

Raccords de dérivation

Si le raccord entre la gaine et l’appareil dans le cas d’une

installation sur le côté offre un dégagement inférieur à 178

mm (7 po) pour le boîtier du filtre à air, ajouter un raccord de

dérivation au coude. Voir la Fig. 13.

M946A

Fig. 12. Utilisation de déflecteurs pour contribuer à

assurer une distribution d’air plus uniforme à la surface

du filtre.

1

RACCORD

DE DÉRIVATION

AU MOINS

178 mm

(7 po)

MF948A

MOINS DE

178 mm

(7 po)

1 LES DÉFLECTEURS ASSURENT UNE MEILLEURE RÉPARTITION D’AIR.

Fig. 13. Utilisation typique d’un raccord de dérivation

pour assurer un dégagement suffisant au filtre à air à

élément filtrant à fibres.

5

68-0239EF–4

Page 14

FILTRE À AIR À ÉLÉMENT FILTRANT À FIBRES F100

INSTALLATION

AVANT D’INSTALLER CE PRODUIT...

1. Lire attentivement les instructions. Le fait de ne pas les

suivre risque d’endommager le produit ou de constituer

un danger.

2. Vérifier les caractéristiques nominales indiquées dans

les instructions et sur le produit, et s’assurer que celuici correspond bien à l’application prévue.

3. L’installateur doit être un technicien d’expérience ayant

reçu la formation pertinente.

4. Une fois l’installation terminée, vérifier le

fonctionnement du produit comme l’indiquent les

présentes instructions.

Retirer le filtre de l’appareil de chauffage et

nettoyer le compartiment du ventilateur

Avant de procéder à l’installation, retirer et mettre de côté le

filtre actuel de l’appareil de chauffage (s’il existe). Nettoyer à

fond le compartiment du ventilateur. Si c’est possible, passer

l’aspirateur dans le système de gaines pour éliminer la

poussière accumulée dans une maison déjà construite ou la

saleté due à la construction dans une maison neuve. Le filtre

à air à élément filtrant à fibres ne peut éliminer la poussière

accumulée dans le compartiment du ventilateur et les gaines

de distribution.

Installer les déflecteurs

Installer les déflecteurs pour assurer une distribution uniforme

de l’air sur toute la surface amont du médium filtrant. Il faut

les installer à l’intérieur du coude à 90 degrés, montés

directement sur le boîtier du filtre à air.

Fixer le boîtier au système de gaines

Fixer l’autre côté du boîtier sur le coude à l’aide de rivets, de

vis pour tôle, ou d’écrous coulissants, au besoin.

Raccorder le filtre à la gaine

Raccorder la section verticale de la gaine au coude. Si la

portion verticale de la gaine est à moins de 178 mm (7 po) du

côté de l’appareil de chauffage, raccourcir la portion

horizontale ou fixer un raccord de dérivation au coude. Voir la

Fig. 13. Lorsque la gaine d’air est correctement alignée,

raccorder la partie verticale à la partie horizontale.

Sceller les joints

Sceller tous les joints du système de reprise d’air entre le

filtre à air et l’appareil de chauffage pour empêcher la

poussière de pénétrer dans le courant d’air propre.

Installer la cartouche du filtre

Faire glisser la cartouche du filtre dans le boîtier et vérifiant

que la flèche figurant sur la cartouche correspond bien au sens

d’écoulement de l’air.

Installer le boîtier

Remettre la porte d’accès en place, insérer la languette au bas

L’installation d’un filtre sur le côté d’un appareil de chauffage

à caissons juxtaposés est décrite ci-dessous. D’autres

explications sont fournies au besoin. Des modifications

peuvent s’avérer nécessaires dans le cas d’un autre système.

de la porte dans la fente pratiquée sur le boîtier. Refermer la

porte et appuyer pour qu’elle soit solidement en place.

Installation de l’indicateur AIRWATCH

W8600A (compris avec certaines modèles

Passer en revue le plan de l’installation

Déposer le boîtier sur le sol, orienté comme il le sera une fois

l’installation terminée. Insérer et retirer la cartouche pour

vérifier que les plans offrent un dégagement suffisant au

retrait et au remplacement de la cartouche.

S’assurer d’avoir sous la main des éléments de tôle

préfabriqués, comme des déflecteurs.

F100)

L’indicateur W8600A peut être installé près du thermostat ou à

tout autre endroit pratique dans la maison. C’est un appareil

alimenté par pile qui n’exige aucun raccord électrique.

Retirer l’appareil de sa base et marquer l’emplacement des

trous de fixation en utilisant la base comme gabarit. Percer les

trous. Placer la base vis-à-vis des trous et installer les vis de

fixation fournies. Serrer les vis jusqu’à ce que la base soit

fermement fixée au mur. Remettre l’appareil sur sa base.

MD

Fixer le boîtier à l’appareil de chauffage

Aligner le boîtier sur l’ouverture pour la reprise d’air. Placer

des blocs sous le boîtier pour que l’appareil soit bien soutenu

et de niveau. Percer une ouverture dans l’appareil de

chauffage correspondant à celle du boîtier du filtre à air. Fixer

solidement le boîtier à l’appareil de chauffage soit

directement (voir illustration), soit à l’aide d’un collier de

démarrage dans l’appareil de chauffage. Percer des trous et

fixer l’appareil à l’aide de rivets ou de vis pour tôle ou utiliser

des écrous coulissants. S’il faut percer des trous, utiliser une

pince-étau pour maintenir l’appareil en place pendant cette

opération.

68-0239EF–4

6

Il faut régler les microrupteurs situés au dos du W8600A en

fonction des systèmes installés dans la maison. Utiliser les

positions par défaut réglées en usine lorsque tous les appareils

(filtre à air, système de traitement de l’air aux ultraviolets,

humidificateur) sont installés dans la maison. Déplacer les

microrupteurs à la position de gauche (en position d’arrêt OFF) lorsqu’un des appareils n’est pas installé dans la maison.

REMARQUE. Les réglages du système de traitement de l’air

aux ultraviolets et de l’humidificateur sont valables

pour une année. Les réglages du filtre à air peuvent

être modifiés en fonction des activités et des

besoins du propriétaire.

Page 15

FILTRE À AIR À ÉLÉMENT FILTRANT À FIBRES F100

Suivre les réglages qui figurent au dos du W8600A pour régler

les microrupteurs pour 3, 6, 9, ou 12 mois. Utiliser les réglages

de l’usine pour remplacer le filtre à fibres tous les trois mois,

selon le nombre de mois désirés. S’il n’y a pas de filtre à air,

placer les microrupteurs 4 et 5 vers la gauche (en position

d’arrêt – OFF).

Placer deux piles alcalines AAA (fournies) dans le porte-piles

au dos de l’appareil. Observer l’appareil procéder à un test

automatique : les indicateurs à cristaux liquides

correspondant à chacun des appareils installés dans la

maison (filtre à air, système de traitement de l’air aux

ultraviolets, humidificateur) clignotent à tour de rôle. Pour

Indication Si la flèche clignote ou si

l’appareil émet un bip…

Battery (pile) Il faut changer les piles. Changer les piles 30 secondes après avoir retiré les

Air Cleaner (filtre à air) Il faut remplacer le filtre à fibres ou

nettoyer le filtre à air électronique.

UV Air Treatment (traitement

de l’air aux ultraviolets)

Humidifier (humidificateur) Il faut remplacer les tampons de

Il faut remplacer les lampes UV du

système de traitement de l’air aux

ultraviolets.

l’humidificateur.

remettre la minuterie à zéro, il faut ensuite appuyer sur le

bouton de réarmement et le maintenir enfoncée pendant cinq

secondes ou jusqu’à ce que l’affichage cesse de clignoter.

Observer l’indicateur à cristaux liquides des piles. S’il reste

allumé, l’appareil est correctement alimenté. S’il clignote, il

faut remplacer les piles.

REMARQUE.

Le W8600A émet un signal sonore lorsqu’une des

flèches clignote pour avertir l’utilisateur qu’il faut vérifier

quel appareil doit être nettoyé. Après l’entretien, appuyer

sur le bouton de réarmement au bas du W8600A et le

retenir pendant 10 secondes pour réarmer la minuterie.

Ce qu’il faut faire

anciennes piles pour que l’intervalle d’avertissement

reste le bon.

Appuyer sur le bouton de réarmement et le retenir

pendant 10 secondes ou jusqu’à ce que la flèche ne

soit plus allumée.

VÉRIFICATION

Vérifier l’installation visuellement comme suit :

•L’air circule dans le sens indiqué par la flèche figurant

sur la cartouche du filtre à air à élément filtrant à fibres.

• Les déflecteurs et les raccords de transition, le cas

échéant, sont bien installés

• Les joints en tôle entre le filtre à air et l’appareil de

chauffage sont scellés.

•Tous les raccords en tôle ont été posés.

• Le filtre original a été retiré et le compartiment du

ventilateur a été nettoyé.

Remettre en place toutes les portes d’accès retirées au

moment de l’installation.

Faire fonctionner l’appareil de chauffage ou de refroidissement

pendant un cycle complet pour vérifier que le système

fonctionne comme il se doit.

Maintenance

Le W8600A émet un signal sonore toutes les quinze minutes

lorsqu’un des indicateurs à cristaux liquides clignote. Il faut à

ce moment remplacer la pièce du système qui correspond à

l’indicateur qui clignote.

REMARQUE. Lorsqu’il faut remplacer les piles, les

remplacer en moins de 30 secondes après leur

retrait pour conserver le bon intervalle

d’avertissement. Si l’écran à cristaux liquides reste

vide 30 secondes après le remplacement des piles,

retirer les piles et en installer de nouvelles. Pour les

autres pièces, appuyer sur le bouton de

réarmement situé sur la partie inférieure de

l’indicateur et le maintenir enfoncé pour remettre la

minuterie à zéro après avoir remplacé les pièces.

Le filtre à air à élément filtrant à fibres doit être remplacé

lorsque la chute de pression dans le filtre atteint 0,5 po c.e.

(1 kPa); il faut à tout le moins le remplacer une fois par

année. Si le filtre à fibres est installé en aval d’un

humidificateur atomiseur, des remplacements plus fréquents

pourront être nécessaires. Il faut remplacer un filtre obstrué

le plus rapidement possible pour éviter d’empêcher

l’écoulement de l’air et de réduire l’efficacité du système de

chauffage-refroidissement. Inscrire la date du remplacement

dans l’espace prévu à cet effet sur le filtre à fibres de

rechange.

7

68-0239EF–4

Page 16

Honeywell

Offrez à votre famille un air ambiant de

meilleure qualité en faisant appel aux

solutions Honeywell. Confort et

tranquillité d’esprit seront au rendez-vous.

Système de traitement d’air aux ultraviolets

Éliminez les microbes contenus dans l’air et

empêchez les spores de moisissures de croître

sur les serpentins de refroidissement

Filtre à air pour toute la maison

Emprisonnez une bonne partie des particules

contenues dans l’air

Humidificateur pour toute la maison

Humidifiez l’air trop sec, maintenez l’humidité

ambiante pour réduire les effets

négatifs sur la santé

Solutions de régulation et d’automatisation

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

68-0239EF–4 G.H. 7-04

Honeywell Limited – Honeywell Limitée

35, Dynamic Drive

Scarborough (Ontario)

M1V 4Z9

Système de régulation par zones

Réglez la température ambiante par zones pour

plus de commodité et un confort accru

Échangeur d’air PerfectWindow®

Aérez la maison pour que l’air soit plus sain

tout en réduisant la perte d’énergie

Thermostat programmable

Économisez jusqu’à 30 % du coût annuel de

l’énergie grâce à ce thermostat d’installation facile*

* selon l’emplacement géographique et l’utilisation

Imprimé aux États-Unis sur du

papier recyclé composé d’au moins

10 % de fibres post-consommation.

Loading...

Loading...