Page 1

Honeywell Process Solutions

Experion PKS

Series A Fieldbus Interface

Module

User's Guide

EP-DCX166

R400

July 2010

Release R400

Honeywell

Page 2

Notices and Trademarks

Copyright 2010 by Honeywell International Sárl.

Release R400 July 2010

While this information is presented in good faith and believed to be accurate, Honeywell disclaims

the implied warranties of merchantability and fitness for a particular purpose and makes no

express warranties except as may be stated in its written agreement with and for its customers.

In no event is Honeywell liable to anyone for any indirect, special or consequential damages. The

information and specifications in this document are subject to change without notice.

Honeywell, PlantScape, Experion PKS, and TotalPlant are registered trademarks of Honeywell

International Inc.

Other brand or product names are trademarks of their respective owners.

Honeywell Process Solutions

1860 W. Rose Garden Lane

Phoenix, AZ 85027 USA

1-800 822-7673

ii Experion PKS Series A Fieldbus Interface Module User's Guide R400

Honeywell July 2010

Page 3

About This Document

Provides guidelines and procedures for interf aci ng fi el d bu s devi ces with an Experion system. It

includes module installation, configuration, operation, maintenance, and FOUNDATION

Fieldbus reference data.

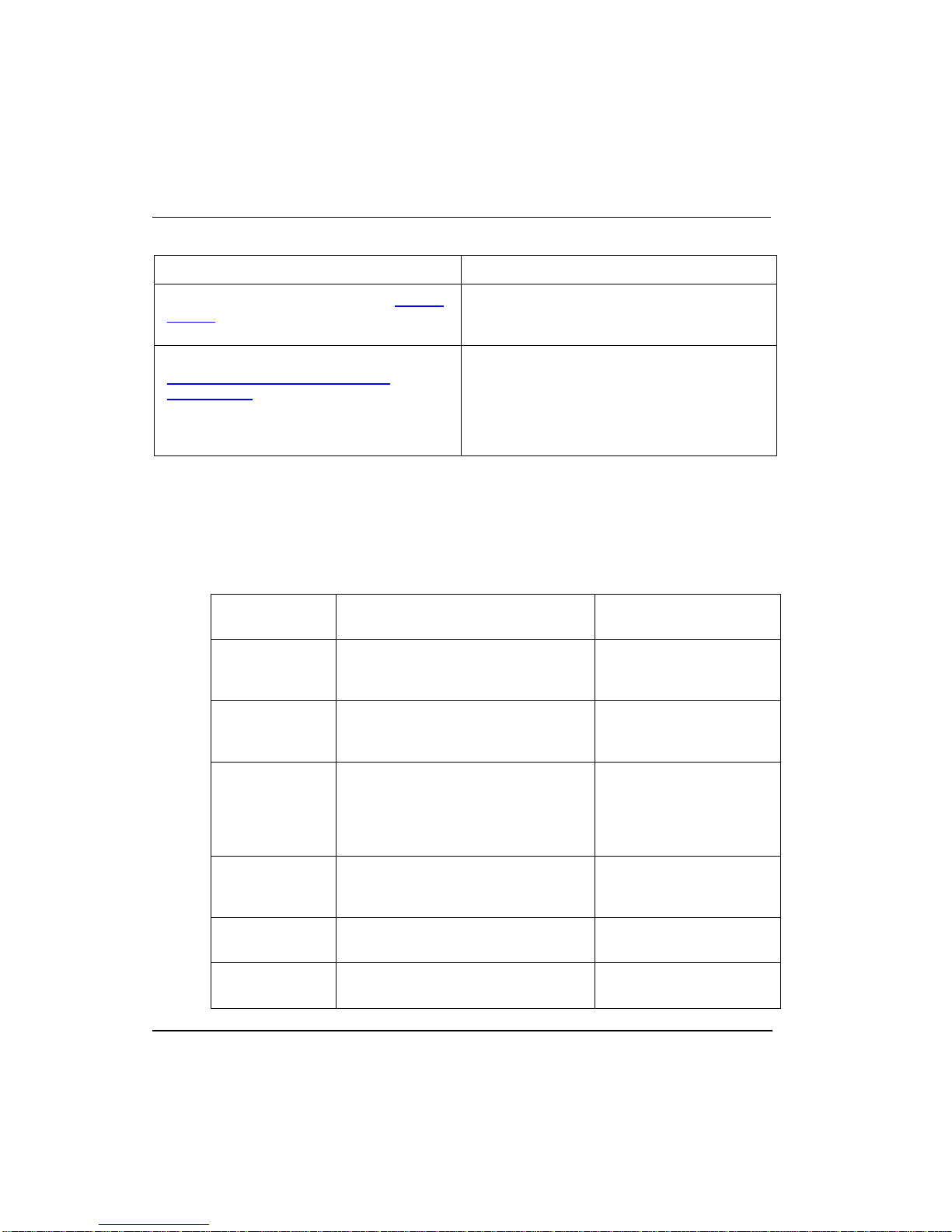

Release Information

Document Name Document ID

Release

Number

Publication

Date

Series A Fieldbus Interface Module User's

Guide - figd

Document Category

Purpose

EP-DCX166 R400 July 2010

R400 Experion PKS Series A Fieldbus Interface Module User's Guide iii

July 2010 Honeywell

Page 4

Support and Other Contacts

Support and Other Contacts

United States and Canada

Europe, Middle East, and Africa (EMEA)

Contact:

Phone:

Fascimile:

Mail:

Contact:

Phone:

Fascimile:

Mail:

Honeywell Solution Support Center

1-800-822-7673

Calls are answered by dispatcher between 6:00 am and 4:00 pm

Mountain Standard Time. Emergency calls outside normal working hours

are received by an answering service and returned within one hour.

1-973-455-5000

Honeywell TAC, MS L17

1860 W. Garden Lane

Phoenix, AZ, 85027 USA

Honeywell TAC-EMEA

+32-2-728-2345

+32-2-728-2696

TAC-BE02

Hermes Plaza

Hermeslaan, 1H

B-1831 Diegem, Belgium

Pacific

Contact:

Phone:

Fascimile:

Mail:

Email:

Honeywell Global TAC – Pacific

1300-364-822 (toll free within Australia)

+61-8-9362-9559 (outside Australia)

+61-8-9362-9564

Honeywell Limited Australia

5 Kitchener Way

Burswood 6100, Western Australia

GTAC@honeywell.com

India

iv Experion PKS Series A Fieldbus Interface Module User's Guide R400

Honeywell July 2010

Contact:

Phone:

Fascimile:

Mail:

Email:

Honeywell Global TAC – India

+91-20- 6603-9400

+91-20- 6603-9800

Honeywell Automation India Ltd

56 and 57, Hadapsar Industrial Estate

Hadapsar, Pune –411 013, India

Global-TAC-India@honeywell.com

Page 5

Korea

Contact:

Phone:

Fascimile:

Mail:

Email:

Honeywell Global TAC – Korea

+82-2-799-6317

+82-2-792-9015

Honeywell Co., Ltd

4F, Sangam IT Tower

1590, DMC Sangam-dong, Mapo-gu

Seoul, 121-836, Korea

Global-TAC-Korea@honeywell.com

People’s Republic of China

Contact:

Phone:

Mail:

Email:

Honeywell Global TAC – China

+86- 21-2219-6888

800-820-0237

400-820-0386

Honeywell (China) Co., Ltd

33/F, Tower A, City Center, 100 Zunyi Rd.

Shanghai 200051, People’s Republic of China

Global-TAC-China@honeywell.com

Singapore

Contact:

Phone:

Fascimile:

Mail:

Email:

Honeywell Global TAC – South East Asia

+65-6580-3500

+65-6580-3501

+65-6445-3033

Honeywell Private Limited

Honeywell Building

17, Changi Business Park Central 1

Singapore 486073

GTAC-SEA@honeywell.com

Support and Other Contacts

Taiwan

R400 Experion PKS Series A Fieldbus Interface Module User's Guide v

July 2010 Honeywell

Contact:

Phone:

Fascimile:

Mail:

Email:

Honeywell Global TAC – Taiwan

+886-7-536-2567

+886-7-536-2039

Honeywell Taiwan Ltd.

17F-1, No. 260, Jhongshan 2nd Road.

Cianjhen District

Kaohsiung, Taiwan, ROC

Global-TAC-Taiwan@honeywell.com

Page 6

Support and Other Contacts

Japan

Contact:

Phone:

Fascimile:

Mail:

Email:

Honeywell Global TAC – Japan

+81-3-6730-7160

+81-3-6730-7228

Honeywell Japan Inc.

New Pier Takeshiba, South Tower Building,

20th Floor, 1-16-1 Kaigan, Minato-ku,

Tokyo 105-0022, Japan

Global-TAC-JapanJA25@honeywell.com

Elsewhere

Call your nearest Honeywell office.

World Wide Web

Honeywell Solution Support Online:

http://www.honeywell.com/ps

Training Classes

Honeywell Automation College:

http://www.automationcollege.com

vi Experion PKS Series A Fieldbus Interface Module User's Guide R400

Honeywell July 2010

Page 7

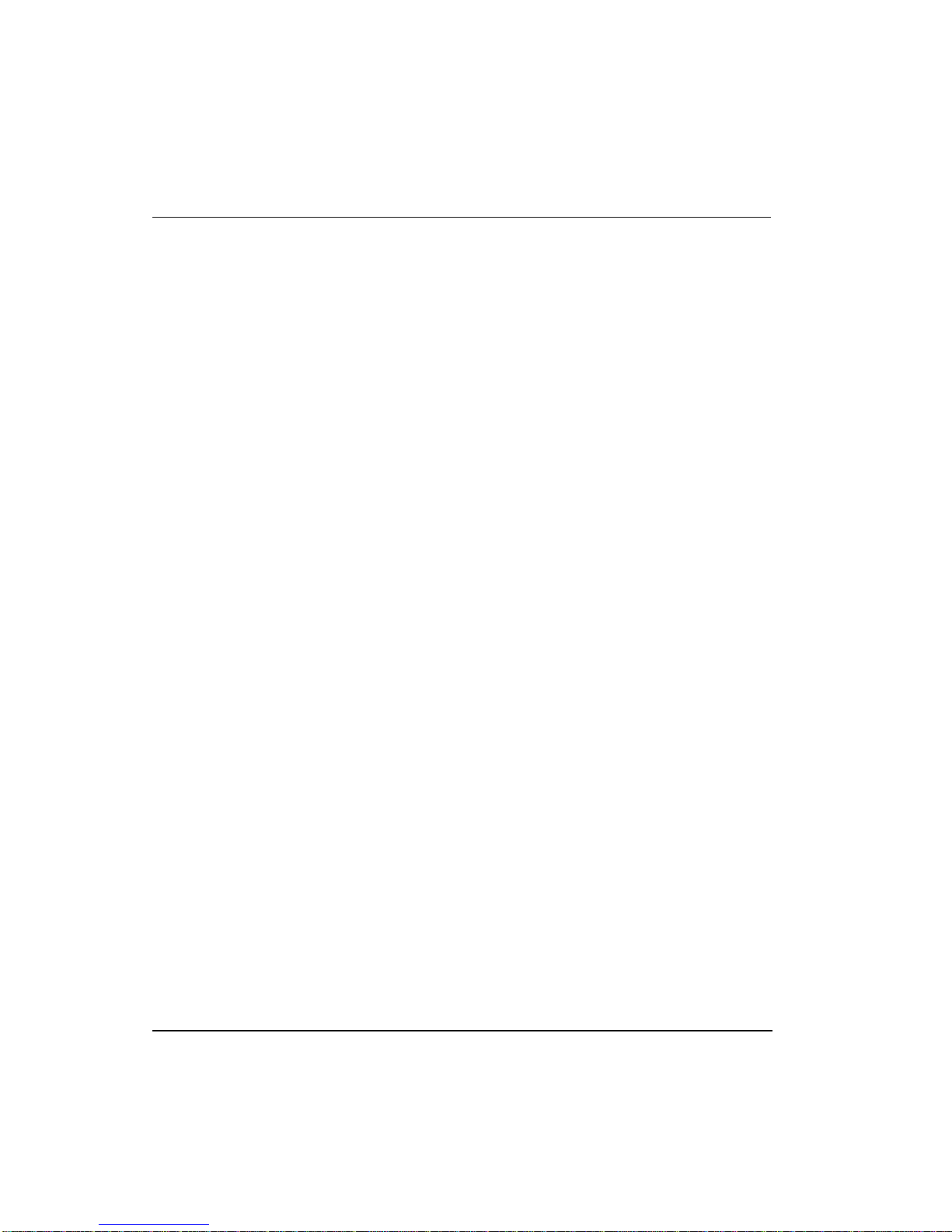

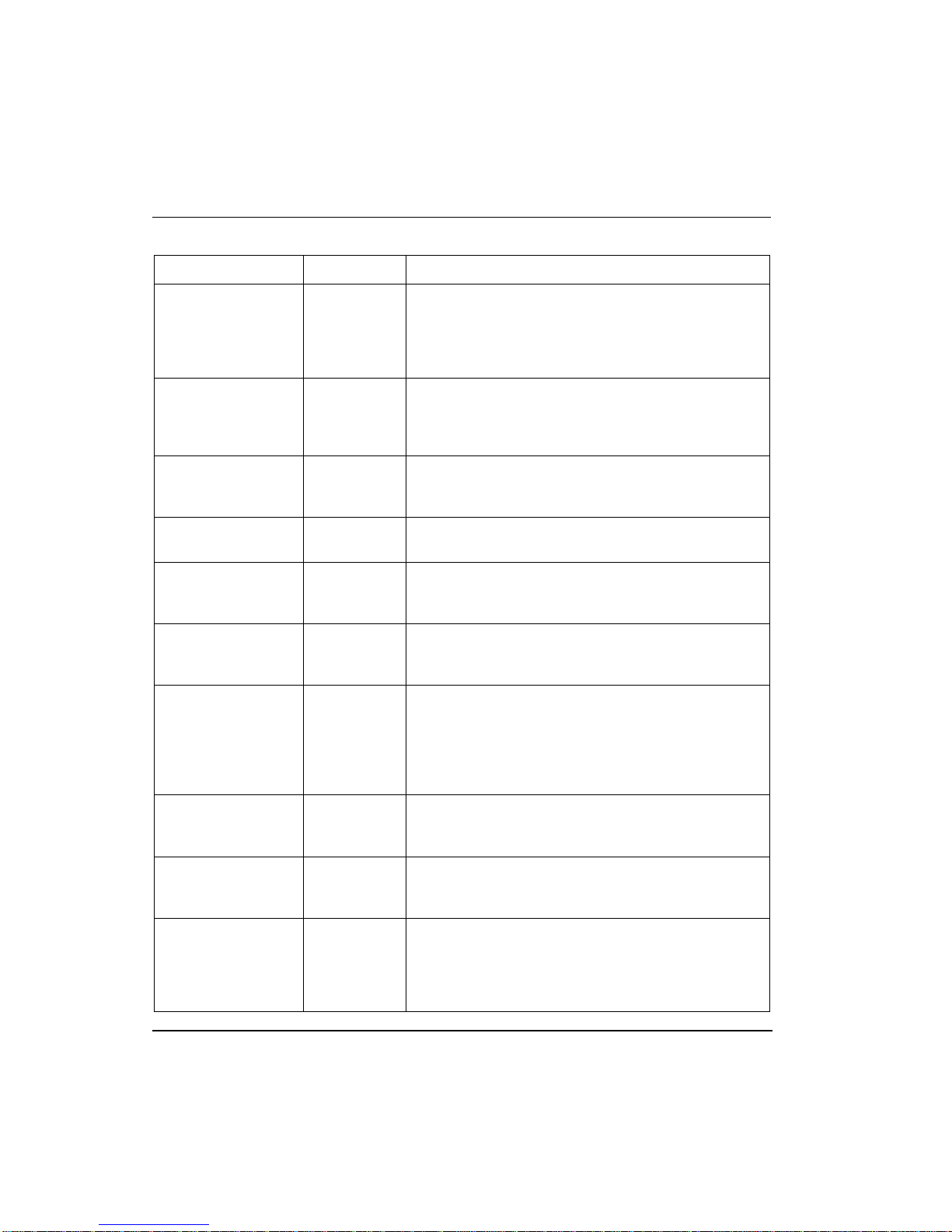

Symbol Definitions

Symbol Definitions

The following table lists those symbols used in this document to denote certain conditio ns.

Symbol Definition

CAUTION

ATTENTION: Identifies information that requires special

consideration.

TIP: Identifies advice or hints for the user, often in terms of

performing a task.

REFERENCE -EXTERNAL: Identifies an additional source of

information outside of the bookset.

REFERENCE - INTERNAL: Identifies an additional source of

information within the bookset.

Indicates a situation which, if not avoided, may result in equipment

or work (data) on the system being damaged or lost, or may result in

the inability to properly operate the process.

CAUTION: Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also be used

to alert against unsafe practices.

CAUTION symbol on the equipment refers the user to the product

manual for additional information. The symbol appears next to

required information in the manual.

WARNING: Indicates a potentially hazardous situation, which, if not

avoided, could result in serious injury or death.

WARNING symbol on the equipment refers the user to the product

manual for additional information. The symbol appears next to

required information in the manual.

R400 Experion PKS Series A Fieldbus Interface Module User's Guide vii

July 2010 Honeywell

Page 8

Symbol Definitions

Symbol Definition

WARNING, Risk of electrical shock: Potential shock hazard where

HAZARDOUS LIVE voltages greater than 30 Vrms, 42.4 Vpeak, or

60 VDC may be accessible.

ESD HAZARD: Danger of an electro-static discharge to which

equipment may be sensitive. Observe precautions for handling

electrostatic sensitive devices.

Protective Earth (PE) terminal: Provided for connection of the

protective earth (green or green/yellow) supply system conductor.

Functional earth terminal: Used for non-safety purposes such as

noise immunity improvement. NOTE: This connection shall be

bonded to Protective Earth at the source of supply in accordance

with national local electrical code requirements.

Earth Ground: Functional earth connection. NOTE: This

connection shall be bonded to Protective Earth at the source of

supply in accordance with national and local electrical code

requirements.

Chassis Ground: Identifies a connection to the chassis or frame of

the equipment shall be bonded to Protective Earth at the source of

supply in accordance with national and local electrical code

requirements.

viii Experion PKS Series A Fieldbus Interface Module User's Guide R400

Honeywell July 2010

Page 9

Contents

1. INTRODUCTION ..........................................................................23

1.1 Where to look for information......................................................................23

Contents guide.....................................................................................................................23

1.2 Conventions...................................................................................................24

Terms and type representations...........................................................................................24

2. WHAT IS FIELDBUS?..................................................................27

2.1 Fieldbus Organization ..................................................................................27

About the Fieldbus Foundation ............................................................................................27

Want more information?.......................................................................................................27

2.2 Fieldbus Technology .................................................................................... 27

Reference.............................................................................................................................27

2.3 Fieldbus Terms..............................................................................................27

Description...........................................................................................................................27

3. FIELDBUS INTEGRATION WITH EXPERION SYSTEM.............33

3.1 Overview ........................................................................................................33

Background..........................................................................................................................33

CIOM-A FIM versus Series C FIM........................................................................................33

Non-Redundant Fieldbus integrated architecture for CIOM-A FIM.......................................34

Redundant Fieldbus integrated architecture for CIOM-A FIM ..............................................35

Fieldbus Interface Module (FIM) - the key to integration......................................................37

Redundancy Module - the key to redundant operation.........................................................37

Control Builder serves as common configuration tool ..........................................................37

Parameter Definition Editor serves as key interoperability tool ............................................39

Parameter Definition Editor supports Fieldbus Methods......................................................40

Station provides centralized operator interface....................................................................41

3.2 Control Integration........................................................................................42

FIM handles data integration................................................................................................42

About link object...................................................................................................................42

Network Management description ........................................................................................42

System Management description.........................................................................................43

About device objects............................................................................................................43

About VFD objects...............................................................................................................43

Type creation makes integration possible............................................................................44

R400 Experion PKS Series A Fieldbus Interface Module User's Guide ix

July 2010 Honeywell

Page 10

Contents

Fieldbus device Analog Input integration............................................................................. 44

Fieldbus Analog Input data manipulation ............................................................................ 45

Fieldbus device Analog Output or PID integration............................................................... 46

Fieldbus Analog Output or PID data manipulation............................................................... 48

Fieldbus device Discrete Input integration........................................................................... 50

Fieldbus Discrete Input data manipulation .......................................................................... 51

Fieldbus device Discrete Output data integration................................................................ 52

Fieldbus Discrete Output data manipulation........................................................................ 53

Interface Connections Summary......................................................................................... 54

A word about SCM parameter interaction ........................................................................... 54

Fieldbus status data details................................................................................................. 55

Fieldbus status indications .................................................................................................. 57

3.3 Control Mode Interaction..............................................................................57

Fieldbus block modes versus control modes....................................................................... 57

Control mode priorities and indications ............................................................................... 59

Rotary Switch Model versus Toggle Switch Model.............................................................. 61

Display indications and mode calculation............................................................................ 62

Access control through GRANT_DENY parameter............................................................. 63

3.4 Link and Block Schedules............................................................................64

Link Active Scheduler (LAS) and Link Master ..................................................................... 64

Link Schedule...................................................................................................................... 66

Function block execution schedule...................................................................................... 67

3.5 Tags, Addresses, and Live List....................................................................69

Tag and address assignments ............................................................................................ 69

A word about fieldbus address assignments in Control Builder........................................... 70

Live List and Uncommissioned Devices.............................................................................. 70

3.6 Notification Scheme......................................................................................71

Fieldbus versus Experion Alarm Priorities........................................................................... 71

Advanced Alarming............................................................................................................. 73

Fieldbus Alarm Conditions .................................................................................................. 73

Loading alarm conditions .................................................................................................... 77

Alarm server operation........................................................................................................ 77

3.7 CIOM-A FIM Redundancy Functionality......................................................78

About CIOM-A FIM redundancy.......................................................................................... 78

CIOM-A FIM versus C200 CPM redundancy....................................................................... 79

Switchover and Secondary readiness................................................................................. 80

Switchover behavior considerations.................................................................................... 81

Failure conditions and switchover ....................................................................................... 82

Fieldbus network switchover considerations....................................................................... 83

Switchover versus fieldbus network activities...................................................................... 84

Switchover events............................................................................................................... 86

3.8 Block Instantiation Support..........................................................................86

About instantiable blocks..................................................................................................... 86

Control Builder supports block instantiation ........................................................................ 86

x Experion PKS Series A Fieldbus Interface Module User's Guide R400

Honeywell July 2010

Page 11

Contents

Instantiable block implementation considerations ................................................................87

4. INSTALLATION ...........................................................................99

4.1 Planning Considerations..............................................................................99

Experion system references.................................................................................................99

Installation declaration .........................................................................................................99

CIOM-A FIM and I/O module allowance...............................................................................99

CIOM-A FIM only chassis configuration considerations.....................................................100

Fieldbus component references.........................................................................................101

Fieldbus network references..............................................................................................102

Fieldbus wiring selection and calculation...........................................................................103

Intrinsically safe applications..............................................................................................104

4.2 Installing CIOM-A Fieldbus Interface Module TC-FFIF01........................104

Front View..........................................................................................................................104

Inserting module in chassis................................................................................................105

Connecting RTP cable to module.......................................................................................107

Loading FIM firmware ........................................................................................................108

4.3 Installing Fieldbus RTP TC-FFRU01/TC-FFRP02 or RRTP TC-FFSU01/TC-

FFSP02....................................................................................................................109

Front view...........................................................................................................................109

Mounting on a DIN rail .......................................................................................................110

Mounting Dimensions.........................................................................................................111

Wiring.................................................................................................................................112

5. CONFIGURATION .....................................................................117

5.1 Before You Start..........................................................................................117

What do you know about Control Builder?.........................................................................117

Do you know how to configure a Control Processor Module?............................................117

Can you configure a Control Module?................................................................................117

Are you familiar with your system architecture?.................................................................117

Do you understand and have experience with fieldbus?....................................................117

Are you Ready? .................................................................................................................118

5.2 Non-Experion Interface Precautions.........................................................118

5.3 Free VCR Recommendation....................................................................... 119

5.4 Configuring Fieldbus Components In a Control Strategy ...................... 120

About control strategy configuration...................................................................................120

Example Application and Control Strategy for Procedural Reference................................120

Configuration considerations only for redundant CIOM-A FIM applications.......................122

Adding CIOM-A FIM block to Project .................................................................................123

Checking link configuration ................................................................................................133

Creating a Fieldbus device type from vendor DD...............................................................141

R400 Experion PKS Series A Fieldbus Interface Module User's Guide xi

July 2010 Honeywell

Page 12

Contents

Editing device block parameters........................................................................................ 145

Adding a fieldbus device to Project ................................................................................... 146

Assigning a device to a Link in Project.............................................................................. 151

Checking device configuration........................................................................................... 154

Making fieldbus block template and assigning function block to device............................ 164

Creating Control Module for sample PID loop - Optional................................................... 172

5.5 Loading Components Online......................................................................202

About load operations ....................................................................................................... 202

About Load Dialog box...................................................................................................... 204

Load order guidelines........................................................................................................ 205

General load considerations.............................................................................................. 206

Fieldbus device states....................................................................................................... 206

Fieldbus device matching rules......................................................................................... 207

Loading a CIOM-A FIM and its Links................................................................................. 208

Matching uncommissioned device to project device or vice versa .................................... 211

Loading Link contents or fieldbus device........................................................................... 219

5.6 Configuring Advanced Alarming ...............................................................225

Overview........................................................................................................................... 225

Opening the Configuration dialog box............................................................................... 226

Configuring/creating a condition........................................................................................ 227

Managing the conditions ................................................................................................... 230

Enabling or disabling a condition ....................................................................................... 230

Assigning criticalities and priorities.................................................................................... 232

Editing an existing condition.............................................................................................. 233

5.7 Block Offnet Diagnostic Alarm...................................................................234

Behavior of the Block Offnet and Device Offnet System alarms in various communication loss

scenarios........................................................................................................................... 235

Behavior of the Block Offnet and Device Offnet System alarms in various operational

scenarios........................................................................................................................... 236

5.8 Configuring non-cache parameters...........................................................238

5.9 Summary ......................................................................................................240

6. OPERATION..............................................................................243

6.1 Monitoring Fieldbus Functions Through Station Displays.....................243

Using Station Detail displays............................................................................................. 243

6.2 Foundation Fieldbus Detail Displays/Faceplates.....................................244

Detail Displays contents based on FF control points loading............................................ 245

Naming conventions for Detail Displays............................................................................ 245

Tabs of FF Detail Displays................................................................................................ 246

Detail Displays tabs of the different Foundation Fieldbus blocks....................................... 247

Common functionalities of faceplates................................................................................ 250

FF Detail Displays example templates for Control Builder ................................................ 252

xii Experion PKS Series A Fieldbus Interface Module User's Guide R400

Honeywell July 2010

Page 13

Contents

Using Station Event Summary display...............................................................................252

6.3 Monitoring Fieldbus Functions Through Monitoring Tab.......................253

Inactivating/Activating a Link..............................................................................................253

Monitoring/Interacting with given component/block............................................................256

Checking/changing fieldbus device functional class...........................................................257

Checking live list and interacting with uncommissioned devices........................................264

Viewing and optimizing Link schedule configuration..........................................................267

CheckingCIOM-A FIM redundancy status and initiating manual switchover ......................273

Using Controller menu functions........................................................................................275

7. FIELDBUS DEVICE COMMISSIONING.....................................277

7.1 Getting Started ............................................................................................277

Read this first.....................................................................................................................277

Initial checks and operations..............................................................................................279

7.2 Connecting Devices....................................................................................280

7.3 Checking Device..........................................................................................282

7.4 Checking Control Strategy.........................................................................283

7.5 Flowchart Summary....................................................................................284

8. MAINTENANCE, CHECKOUT, AND CALIBRATION................287

8.1 Adding, Removing and Replacing Components......................................287

About removal and insertion under power (RIUP)..............................................................287

General procedure .............................................................................................................287

Guidelines for adding fieldbus device to "live"/operating Link ............................................288

Using optional safe handling of new devices......................................................................289

Replacing a failed device with a like device having the same model name and device revision

...........................................................................................................................................290

Replacing a failed device with a different device using a different block type ....................297

8.2 Unlike Device Replacement Report...........................................................317

8.3 Replacing Device Template with a Different One ....................................320

Prerequisites......................................................................................................................320

Considerations...................................................................................................................321

Using Unlike Template Replacement wizard to make device replacements......................321

8.4 Correcting Some Common UTR errors.....................................................328

8.5 Upgrading Firmware in Uncommissioned Device...................................328

8.6 Changing or Clearing Tag and/or Address of Uncommissioned Device332

8.7 Using Fieldbus Device Simulate Function ...............................................334

R400 Experion PKS Series A Fieldbus Interface Module User's Guide xiii

July 2010 Honeywell

Page 14

Contents

8.8 Preparing Fieldbus Device for a Move or Software Migration................343

Migrating Fieldbus device type to a release supporting Enable Block Offnet Diagnostic Alarm

.......................................................................................................................................... 347

8.9 Interpreting Component LED Indications .................................................348

CIOM-A FIM LED indications ............................................................................................ 348

8.10 FIM Self-Test Diagnostic Codes .............................................................349

8.11 Checking Fieldbus Device Calibration...................................................358

8.12 Using Fieldbus Methods Manager..........................................................359

Prerequisites ..................................................................................................................... 359

Launching Methods Manager............................................................................................ 360

Interacting with Methods Manager .................................................................................... 360

9. EXPERION PKS HOST REGISTRATION ................................. 365

9.1 Overview.......................................................................................................365

New features..................................................................................................................... 365

Conditional support for FF devices.................................................................................... 367

EDDL................................................................................................................................. 368

DD View tab ...................................................................................................................... 368

Following are some of the considerations for FF blocks with DD View. ............................ 373

Persistent data handling.................................................................................................... 375

10. APPENDIX A.............................................................................377

10.1 Fieldbus Technology ...............................................................................377

Open communications architecture................................................................................... 377

Communication layer description ...................................................................................... 378

10.2 Standard Function Blocks.......................................................................381

Overview........................................................................................................................... 383

About modes of operation................................................................................................. 384

Analog Input block............................................................................................................. 386

Analog Output block.......................................................................................................... 388

Bias/Gain block ................................................................................................................. 390

Control Selector block ....................................................................................................... 393

Discrete Input block........................................................................................................... 396

Discrete Output block........................................................................................................ 397

Manual Loader block......................................................................................................... 400

Proportional/Derivative block............................................................................................. 402

Ratio block ........................................................................................................................ 412

10.3 Device Descriptions and Block Parameters..........................................416

About Device Descriptions ................................................................................................ 416

Device Description Language ........................................................................................... 416

Device Description infrastructure....................................................................................... 416

xiv Experion PKS Series A Fieldbus Interface Module User's Guide R400

Honeywell July 2010

Page 15

Contents

Block parameter definitions................................................................................................417

10.4 Fieldbus Foundation Documents...........................................................418

Reference Data..................................................................................................................418

11. APPENDIX B..............................................................................419

11.1 Standard Function Block Parameters ...................................................419

ACK_OPTION....................................................................................................................419

ALARM_HYS .....................................................................................................................419

ALARM_SUM .....................................................................................................................419

ALERT_KEY ......................................................................................................................420

BAL_TIME..........................................................................................................................421

BIAS...................................................................................................................................421

BKCAL_HYS......................................................................................................................422

BKCAL_IN ..........................................................................................................................422

BKCAL_OUT......................................................................................................................423

BKCAL_OUT_D .................................................................................................................423

BKCAL_SEL_1...................................................................................................................424

BKCAL_SEL_2...................................................................................................................424

BKCAL_SEL_3...................................................................................................................425

BLOCK_ALM......................................................................................................................425

BLOCK_ERR .....................................................................................................................426

BLOCK_ERR.DISABLED...................................................................................................427

BYPASS.............................................................................................................................428

CAS_IN..............................................................................................................................428

CAS_IN_D..........................................................................................................................429

CHANNEL..........................................................................................................................429

CLR_FSTATE....................................................................................................................430

CONFIRM_TIME................................................................................................................430

CONTROL_OPTS..............................................................................................................431

CYCLE_SEL ...................................................................................................................... 432

CYCLE_TYPE....................................................................................................................432

DEV_REV ..........................................................................................................................433

DEV_TYPE ........................................................................................................................433

DD_RESOURCE................................................................................................................434

DD_REV.............................................................................................................................434

DISC_ALM.........................................................................................................................435

DISC_LIM...........................................................................................................................435

DISC_PRI...........................................................................................................................436

DV_HI_ALM.......................................................................................................................436

DV_HI_LIM.........................................................................................................................437

DV_HI_PRI.........................................................................................................................437

DV_LO_ALM......................................................................................................................438

DV_LO_LIM .......................................................................................................................439

DV_LO_PRI .......................................................................................................................439

FAULT_STATE..................................................................................................................439

FEATURES........................................................................................................................440

R400 Experion PKS Series A Fieldbus Interface Module User's Guide xv

July 2010 Honeywell

Page 16

Contents

FEATURE_SEL................................................................................................................. 440

FF_GAIN........................................................................................................................... 441

FF_SCALE........................................................................................................................ 441

FF_VAL............................................................................................................................. 442

FIELD_VAL ....................................................................................................................... 442

FIELD_VAL_D................................................................................................................... 443

FREE_SPACE................................................................................................................... 444

FREE_TIME...................................................................................................................... 444

FSTATE_TIME.................................................................................................................. 445

FSTATE_VAL.................................................................................................................... 445

FSTATE_VAL_D............................................................................................................... 446

GAIN .................................................................................................................................446

GRANT_DENY.................................................................................................................. 446

HARD_TYPES ..................................................................................................................447

HI_ALM ............................................................................................................................. 447

HI_HI_ALM........................................................................................................................ 448

HI_HI_LIM......................................................................................................................... 449

HI_HI_PRI......................................................................................................................... 449

HI_LIM............................................................................................................................... 450

HI_PRI............................................................................................................................... 450

IO_OPTS........................................................................................................................... 451

IN....................................................................................................................................... 452

IN_1................................................................................................................................... 452

LIM_Notify......................................................................................................................... 453

L_TYPE............................................................................................................................. 453

LO_ALM............................................................................................................................ 454

LO_LIM ............................................................................................................................. 455

LO_LO_ALM ..................................................................................................................... 455

LO_LO_LIM....................................................................................................................... 456

LO_LO_PRI....................................................................................................................... 456

LO_PRI ............................................................................................................................. 457

LOW_CUT......................................................................................................................... 457

MANUFAC_ID................................................................................................................... 458

MAX_NOTIFY ................................................................................................................... 458

MEMORY_SIZE................................................................................................................ 459

MIN_CYCLE_T.................................................................................................................. 459

MODE_BLK....................................................................................................................... 460

NV_CYCLE_T................................................................................................................... 460

OFFNETALM_ENABLED.................................................................................................. 461

OUT................................................................................................................................... 461

OUT_D.............................................................................................................................. 462

OUT_HI_LIM..................................................................................................................... 463

OUT_LO_LIM.................................................................................................................... 463

OUT_SCALE..................................................................................................................... 463

OUT_STATE..................................................................................................................... 464

PV .....................................................................................................................................465

PV_D................................................................................................................................. 465

PV_FTIME......................................................................................................................... 466

xvi Experion PKS Series A Fieldbus Interface Module User's Guide R400

Honeywell July 2010

Page 17

Contents

PV_SCALE.........................................................................................................................466

PV_STATE.........................................................................................................................467

RA_FTIME .........................................................................................................................467

RATE .................................................................................................................................468

RCAS_IN............................................................................................................................468

RCAS_IN_D.......................................................................................................................469

RCAS_OUT........................................................................................................................469

RCAS_OUT_D...................................................................................................................470

READBACK .......................................................................................................................471

READBACK_D...................................................................................................................471

RESET...............................................................................................................................472

RESTART ..........................................................................................................................472

ROUT_IN ...........................................................................................................................473

ROUT_OUT .......................................................................................................................474

RS_STATE.........................................................................................................................474

SEL_1 ................................................................................................................................475

SEL_2 ................................................................................................................................475

SEL_3 ................................................................................................................................476

SEL_TYPE.........................................................................................................................477

SET_FSTATE ....................................................................................................................477

SHED_OPT........................................................................................................................478

SHED_RCAS.....................................................................................................................478

SHED_ROUT.....................................................................................................................479

SIMULATE.........................................................................................................................479

SIMULATE_D.....................................................................................................................480

SP......................................................................................................................................481

SP_D..................................................................................................................................482

SP_HI_LIM .........................................................................................................................482

SP_LO_LIM........................................................................................................................483

SP_RATE_DN....................................................................................................................483

SP_RATE-UP.....................................................................................................................484

ST_REV.............................................................................................................................484

STATUS_OPTS.................................................................................................................484

STRATEGY........................................................................................................................486

TAG_DESC........................................................................................................................486

TEST_RW..........................................................................................................................487

TRK_IN_D..........................................................................................................................488

TRK_SCALE......................................................................................................................488

TRK_VAL...........................................................................................................................489

UPDATE_EVT....................................................................................................................490

WRITE_ALM......................................................................................................................490

WRITE_LOCK....................................................................................................................491

WRITE_PRI........................................................................................................................491

XD_SCALE ........................................................................................................................492

XD_STATE.........................................................................................................................493

12. APPENDIX C..............................................................................495

R400 Experion PKS Series A Fieldbus Interface Module User's Guide xvii

July 2010 Honeywell

Page 18

Contents

12.1 Fieldbus Status Display Indications ......................................................495

12.2 Substatus Definitions for Quality Status...............................................502

13. APPENDIX D.............................................................................507

13.1 Mode Change Conditions........................................................................507

14. APPENDIX E ............................................................................. 511

14.1 Fieldbus Wiring Considerations.............................................................511

Fieldbus topologies ........................................................................................................... 511

Power Conditioning........................................................................................................... 512

Power distribution.............................................................................................................. 513

Signal degradation limitations............................................................................................ 513

Cable guidelines summary................................................................................................ 514

Cable Attenuation.............................................................................................................. 515

Signal distortion versus capacitance................................................................................. 515

Attenuation calculation summary....................................................................................... 516

Cable test.......................................................................................................................... 516

15. APPENDIX F..............................................................................517

15.1 About Parameter Definition Editor for Fieldbus Device Block............517

16. APPENDIX G.............................................................................519

16.1 Loading CIOM-A FIM firmware................................................................519

Checking CIOM-A FIM firmware status............................................................................. 519

Checking firmware version................................................................................................ 520

Loading Boot code ............................................................................................................525

Loading Personality image................................................................................................ 529

17. APPENDIX H.............................................................................533

17.1 Important Functional Considerations....................................................533

General ............................................................................................................................. 533

18. APPENDIX I...............................................................................539

18.1 Link Parameters Reference.....................................................................539

Background....................................................................................................................... 539

More detailed information.................................................................................................. 540

xviii Experion PKS Series A Fieldbus Interface Module User's Guide R400

Honeywell July 2010

Page 19

Contents

18.2 Description...............................................................................................540

Parameters for Link Configuration in Project Mode............................................................540

Parameters for Link Configuration in Monitor Mode...........................................................551

Some term abbreviations ...................................................................................................555

19. APPENDIX J ..............................................................................557

19.1 Load Interactions for Fieldbus Related Operations.............................557

Summary............................................................................................................................557

R400 Experion PKS Series A Fieldbus Interface Module User's Guide xi x

July 2010 Honeywell

Page 20

Contents

Tables

Tables

Table 1 CIOM-AFIM LED Interpretations....................................................................348

Table 2 CONTROL_OPTS Bit Selections...................................................................431

Table 3 IO_OPTS Bit Selections.................................................................................451

Table 4 STATUS_OPTS Bit Selections ......................................................................485

xx Experion PKS Series A Fieldbus Interface Module User's Guide R400

Honeywell July 2010

Page 21

Contents

Figures

Figures

Figure 1 Sample system architecture for non-redundant Fieldbus integration for CIOM-A

FIM..........................................................................................................................34

Figure 2 Sample system architecture for redundant Fieldbus integration for CIOM-A FIM.

................................................................................................................................36

Figure 3 Project tab in Control Builder has new icons for fieldbus components..........39

Figure 4 Typical Parameter Definition Editor view for selected fieldbus device block.40

Figure 5 Sample Fieldbus Methods view in Parameter Definition Editor.....................41

Figure 6 Integration of fieldbus device analog input signal with Control Builder control

strategy...................................................................................................................45

Figure 7 Integration of fieldbus device analog output signal with Control Builder control

strategy...................................................................................................................47

Figure 8 Integration of fieldbus device PID control with Control Builder control strategy48

Figure 9 Integration of fieldbus device digital input signal with Control Builder control

strategy...................................................................................................................51

Figure 10 Integration of fieldbus device digital output signal with Control Builder control

strategy...................................................................................................................53

Figure 11 Block mode calculation summary.................................................................63

Figure 12 Algorithm execution phase sequence..........................................................69

Figure 13 Summary of address allocations for fieldbus devices..................................70

Figure 14 Typical RCP setup in 10-slot chassis...........................................................79

Figure 15 Double-Wide CIOM-A Fieldbus Interface Module TC-FFIF01...................105

Figure 16 RTP model TC-FFRU01 is unpowered and can be used in Division 2

hazardous locations; model TC-FFRP02 is powered and can be used to power

fieldbus devices in Intrinsically Safe applications.................................................109

Figure 17 Redundant RTP model TC-FFSU01 is unpowered and can be used in Division

2 hazardous locations; model TC-FFSP02 is powered and can be used to power

fieldbus devices in Intrinsically Safe applications.................................................110

Figure 18 Simplified wiring schematic for RTP model TC-FFRU01, unpowered. Users

must provide conditioned 24 Vdc power for the Links - Not shown.....................114

Figure 19 Simplified wiring schematic for RRTP model TC-FFXXXX, unpowered. Users

must provide conditioned 24 Vdc power for the Links - Not shown.....................115

Figure 20 Simplified wiring schematic for RTP model TC-FFRP02, powered. Users must

provide 24 Vdc power supply for the GI/IS power supplies..................................116

Figure 21 Sample Application and Control Strategy Integrating Fieldbus Devices with an

Experion System. .................................................................................................121

Figure 22 Completed CM101 for sample loop............................................................197

Figure 23 Sample CM with Device Control block for pump control in sample loop. ..198

Figure 24 Completed CM102 with parameter connections for sample loop interlocks.201

Figure 25 Overview of load operations used to initiate components online...............203

Figure 26 Load Dialog box provides more load choices. ...........................................204

Figure 27 Typical FIM Detail display in Station. .........................................................244

R400 Experion PKS Series A Fieldbus Interface Module User's Guide xxi

July 2010 Honeywell

Page 22

Contents

Figures

Figure 28 FF PID Main Tab Detail Display when loaded in CEE Environment..........249

Figure 29 FF PID Main Tab Detail Display when loaded to FFLINK. .........................250

Figure 30 Event Summary display includes fieldbus related details...........................252

Figure 31 Sample Link Schedule configuration display in Project..............................270

Figure 32 Sample Link Schedule configuration display in Monitoring. .......................271

Figure 33 FIM front panel indicators. ..........................................................................348

Figure 34 Typical Tune tab for fieldbus device's Transducer block............................358

Figure 35 Typical Other tab for fieldbus device's Transducer block...........................359

Figure 36 OSI versus Fieldbus communication model. ..............................................377

Figure 37 User Application (or Function Block Application Process) based on blocks.381

Figure 38 Using Function Blocks in fieldbus devices to form a control loop...............384

Figure 39 Functional schematic for Analog Input function block. ...............................386

Figure 40 Functional schematic for Analog Output function block..............................389

Figure 41 Functional schematic for Bias/Gain function block.....................................391

Figure 42 Functional schematic for Control Selector function block...........................394

Figure 43 Functional schematic for Discrete Input function block. .............................396

Figure 44 Functional schematic for Discrete Output function block............................398

Figure 45 Functional schematic for Manual Loader function block.............................400

Figure 46 Functional schematic for Proportional/Derivative function block................403

Figure 47 Functional schematic for Proportional/Integral/Derivative function block...408

Figure 48 Functional schematic for Ratio function block. ...........................................412

Figure 49 Device Descriptions infrastructure..............................................................417

Figure 50 Overview of fieldbus wiring topologies........................................................511

Figure 51 Communications entity architecture............................................................539

xxii Experion PKS Series A Fieldbus Interface Module User's Guide R400

Honeywell July 2010

Page 23

1. Introduction

1.1 Where to look for information

Contents guide

Read this section, If you,

What is Fieldbus? - Fieldbus Organization

Have no idea what the Fieldbus Foundation

is or what constitutes the F

Fieldbus technology. This section lists some

common fieldbus terms for reference. It also

references, which includes descriptions of

some standard fieldbus function blocks and

describes the role of Device Descriptions and

block parameters for general reference.

OUNDATION

TM

TM

Fieldbus Integration With Experion

System - Control Integration

Installation - Planning Considerations

Configuration- Configuring Fieldbus

Components In a Control Strategy

Operation - Monitoring Fieldbus Functions

Through Monitoring Tab

Want some insight on what functional

relationships result from the integration of

fieldbus devices with an Experion system. The

information in this section will be helpful

background for planning and configuring your

control strategy.

Will be responsible for setting up the hardware

infrastructure to support fieldbus devices. This

section identifies the things you should

consider before installing any equipment and

provides detailed procedures for how to install

the Fieldbus Interface Module (FIM) and its

companion Remote Termination Panel (RTP).

Will be configuring the control strategy through

Control Builder. This section provides detailed

procedures for including fieldbus functional

components in your overall control strategy. It

includes creating hardware blocks, making

block types, associating blocks, assigning

modules, assigning devices, and loading

components

Will be monitoring system operation. This

section provides an overview of functions you

can monitor through Station displays and the

Monitoring tab in Control Builder.

R400 Experion PKS Series A Fieldbus Interface Module User's Guide 23

July 2010 Honeywell

Page 24

1. Introduction

1.2. Conventions

Read this section, If you,

Fieldbus Device Commissioning - Getting

Started

Maintenance, Checkout, and Calibration -

Adding, Removing and Replacing

Components

1.2 Conventions

Terms and type representations

The following table summarizes the terms and type representation conventions used in

this Guide.

Term/Type

Representation

Click

Double-click

Click left mouse button once.

(Assumes cursor is positioned on

object or selection.)

Click left mouse button twice in quick

succession. (Assumes cursor is

positioned on object or selection.)

Will be commissioning the fieldbus loop. This

section provides a suggested process to follow

for fieldbus device commissioning.

Will be responsible for maintaining and trouble

shooting system operation. This section

provides information about replacing

components, upgrading firmware in

uncommissioned devices, and checking device

calibration.

Meaning Example

Click the Browse button.

Double click the Station

icon.

Drag

Right-click

<F1>

<Ctrl>+<C>

24 Experion PKS Series A Fieldbus Interface Module User's Guide R400

Honeywell July 2010

Press and hold left mouse button

while dragging cursor to new screen

location and then release the button.

(Assumes cursor is positioned on

object or selection to be moved.)

Click right mouse button once.

(Assumes cursor is positioned on

object or selection.)

Keys to be pressed are shown in

angle brackets.

Keys to be pressed together are

shown with a plus sign.

Drag the PID function

block onto the Control

Drawing.

Right-click the AND

function block.

Press <F1> to view the

online Help.

Press <Ctrl>+<C> to

close the window.

Page 25

1. Introduction

1.2. Conventions

File->New

>D:\setup.exe<

Shows menu selection as menu name

followed by menu selection

Data to be keyed in at prompt or in an

entry field.

Click File->New to start

new drawing.

Key in this path location

>D:\setup.exe<.

R400 Experion PKS Series A Fieldbus Interface Module User's Guide 25

July 2010 Honeywell

Page 26

1. Introduction

1.2. Conventions

26 Experion PKS Series A Fieldbus Interface Module User's Guide R400

Honeywell July 2010

Page 27

2. What is Fieldbus?

2.1 Fieldbus Organization

About the Fieldbus Foundation

The Fieldbus Foundation is a not-for-profit corporation made up of over 160 leading

suppliers and customers of process control and manufacturing automation products.

Since its inception in 1994, it is totally dedicated to developing one standard, "open,"

interoperable field communication model known as F

is a founding and supporting member of the found a tion.

Want more information?

ou have Internet access, please visit the Fieldbus Foundation web site at

If y

http://www.fieldbus.org/

9005 Mountain Ridge Drive

Bowie Building - Suite 190

Austin, Texas 78759-5316 USA

2.2 Fieldbus Technology

for more information. Alternatively, their mail address is:

OUNDATION Fieldbus. Honeywell

Reference

REFERENCE - INTERNAL

Please refer to Appendix A, if you are interested in more information about

this topic.

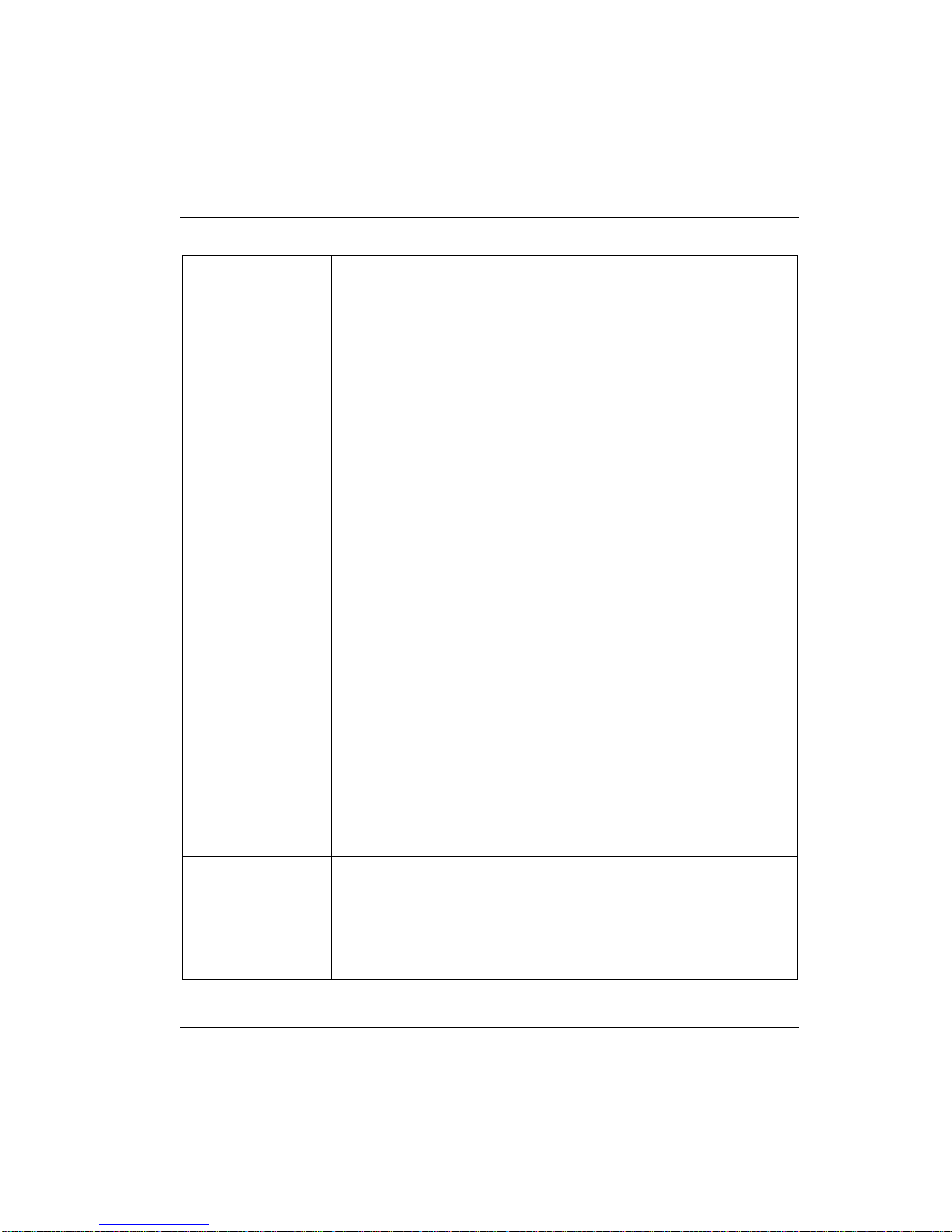

2.3 Fieldbus Terms

Description

The following table lists some fieldbus terms and abbreviations for general reference.

Term Abbreviation Description

Capability File

R400 Experion PKS Series A Fieldbus Interface Module User's Guide 27

July 2010 Honeywell

The Capability file contains some or all of the given

fieldbus device's information that can be read from a

device online. It consists of both resource information

(what the device can potentially do) and value

information (how the device should actually be set up).

Page 28

2. What is Fieldbus?

2.3. Fieldbus Terms

Term Abbreviation Description

Common File

CFF

Format

Connection

Manager

Device Description DD

The format of a Capability file is a readable text

document based on a Windows Initialization (INI) file

type.

A Fieldbus Foundation service to manage connection

information about device types, devices, and blocks

that are actively communicating with a host

application.

A binary file that provides the definition for parameters

in the FBAP of a device. For example, what Function

Blocks a device contains, and what parameters are in

those blocks.

28 Experion PKS Series A Fieldbus Interface Module User's Guide R400

Honeywell July 2010

Page 29

2. What is Fieldbus?

2.3. Fieldbus Terms

Term Abbreviation Description

Device Description

Item

DD Item

Item is a fundamental concept of the Device

Description Language (DDL). It makes up the

description of the device and can be any of the

following constructs:

Array*

Block*

Collection

Domain

Edit Display

Item Array

Menu

Method

Program

Record*

Refresh Relation

Response Code

Variable*

Variable List*

WAO Relation

* These items are of the most interest to Block Type

templates.

Device Description

Language

Device Description

Object

DDL

DDO

The language that vendors use to define their device's

Function blocks and parameters.

The suffix name for incremental DD binary files

supplied by vendors that are to be converted to full and

complete DD binary files by the Fieldbus Foundation

Synthesizer.

Device Description

Service

DDS

A software library developed by the Fieldbus

Foundation that provides a generic access to a DD.

R400 Experion PKS Series A Fieldbus Interface Module User's Guide 29

July 2010 Honeywell

Page 30

2. What is Fieldbus?

2.3. Fieldbus Terms

Term Abbreviation Description

DD Synthesizer

Enhanced Device

Description

Enhanced Device

Description

Language

Fieldbus Foundation

Object

Fieldbus Foundation

Tokenizer

H1 Fieldbus

Segment

H1 Fieldbus Link

A tool supplied by the Fieldbus Foundation. It

combines incremental DDs, with unresolved

references, with Fieldbus Foundation standard DDs to

produce a complete/full DD that can be used with

DDS.

EDD

A newer version of the binary file (*.ff5) that provides

the definition for parameters in the FBAP of a device.

For example, what Function Blocks a device contains,

and what parameters are in those blocks.

EDDL

The language that vendors use to define their device's

Function blocks and parameters.

FFO or FF5 The suffix name for the complete/full DD binary file.

A Fieldbus Foundation tool that converts an ASCII text

file written in conformance with the Device Description

Language specification into a DD binary file.

An independent electrical environment consisting of

wire, terminators and a power source per IEC 611581/ISA S50.1 for supporting fieldbus devices.

The logical medium by which H1 Fieldbus devices are

interconnected. It is composed of one or more physical

segments interconnected by bus Repeaters or

Couplers. All of the devices on a link share a common

schedule, which is administered by that link's current

LAS.

Object Dictionary OD

Production Rules

Release Directory

30 Experion PKS Series A Fieldbus Interface Module User's Guide R400

Honeywell July 2010

Contains the Object Descriptions for communication

objects such as DataType,

DataTypeStructureDescription, and SimpleVariable.

The grammar, in BNF format, used to describe a

language. The Common File Format used to construct

the Resource file follows specific production rules.