Page 1

EXPERION PKS

RELEASE 516

UOC User Guide

EPDOC-X512-en-516A

August 2020

Page 2

Disclaimer

This document contains Honeywell proprietary information. Information contained herein is to be

used solely for the purpose submitted, and no part of this document or its contents shall be

reproduced, published, or disclosed to a third party without the express permission of Honeywell

International Sàrl.

While this information is presented in good faith and believed to be accurate, Honeywell disclaims

the implied warranties of merchantability and fitness for a purpose and makes no express

warranties except as may be stated in its written agreement with and for its customer.

In no event is Honeywell liable to anyone for any direct, special, or consequential damages. The

information and specifications in this document are subject to change without notice.

Copyright 2020 - Honeywell International Sàrl

- 2 -

Page 3

Contents 3

Chapter 1 - About this guide 12

1.1 Revision history 12

1.2 Related documents 12

1.3 Terms and definitions 15

Chapter 2 - Overview of UOC features 19

2.1 Native Experion Integration 19

2.2 ControlEdge 900 Form Factor 19

2.3 FTE Uplink Connectivity 20

2.4 Ethernet I/O Connectivity 20

2.5 ControlEdge 900 21

2.6 Field Device Manager 22

2.7 EtherNet/IP Connectivity to I/O, Devices, and Controllers 22

2.8 CEE Control Processing 22

2.9 Control Builder Strategy Configuration 22

2.10 I/O Points and I/O Reference Blocks 23

2.11 Simulation 23

2.12 Control Redundancy 23

2.13 Peer-To-Peer Communication 24

2.14 Alarms and Events 25

2.15 Time Synchronization 25

2.16 Security 25

2.17 Licensing 25

2.18 vUOC 26

Chapter 3 - Networking 29

3.1 Uplink FTE Network 29

3.2 Downlink I/O Network Topology 30

3.2.1 HSR Ring Topology with 900 I/O 31

3.2.2 Redundant Star (PRP) Topology with 900 I/O 34

3.2.3 DLR Ring Topology with EtherNet/IP and 900 I/O devices 35

3.2.4 Non-Redundant Star to 900 I/O and EIP Devices 38

3.2.5 EtherNet/IP in Experion 40

- 3 -

Page 4

Chapter 4 - Installation 43

4.1 Hardware Considerations 43

4.2 Firmware Considerations 43

4.2.1 Converting PLC CPM to UOC CPM 44

4.2.2 Upgrading UOC CPM to New Firmware Version 48

4.2.3 Upgrading UOC EPM to new Firmware Version 48

4.2.4 Upgrading UOC UIOM to new Firmware Version 50

4.2.5 Firmware and Software Upgrade Considerations for vUOC 51

4.2.6 Additional Maintenance Activities in Firmware Manager 51

Chapter 5 - Configuration 52

5.1 Configuration Studio 52

5.2 Define and add assets in your enterprise model 52

5.3 Control Building 52

5.4 Specifying a Time Server 52

5.5 FTE Device Index 52

5.6 Creating UOC Platform block 53

5.6.1 Method 1: Using the File Menu 53

5.6.2 Method 2: Using the Project Assignment Panel 53

5.7 UOC Platform Block 54

5.8 Secondary UOC Platform Block 69

5.9 CEE Function Block 70

5.10 Configure UOC for Retention Startup 80

5.10.1 Introduction 80

5.10.2 Configure RETENTIONTRIG block 80

5.10.3 Loading Retention Trigger Block 97

5.11 Configure ControlNet for UOC 103

5.12 Configure ProfiNet for UOC 104

5.13 Configuring DLR for UOC 104

5.14 Convert a non-redundant UOC to a redundant controller 106

5.14.1 Prerequisites: 106

5.14.2 To convert a non-redundant UOC to a redundant controller 106

5.15 Convert a redundant UOC to a non-redundant controller 107

5.15.1 Prerequisites 107

5.15.2 To convert a redundant UOC to a non-redundant controller 107

- 4 -

Page 5

5.16 Licensing Model 107

5.16.1 I/O Analog/Digital point(s) license 107

5.16.2 Composite Device Point(s) License 108

5.16.3 License Matrix 108

Chapter 6 - Load Configuration 110

6.1 About load operations 110

6.1.1 Loaded versus project database versions 110

6.1.2 Load initiation and load dialog box 110

6.1.3 Load action with Compare Parameters function 111

6.1.4 Load options for server history and server displays configuration 111

6.2 Initial load order guidelines 112

6.2.1 Component deletion considerations 112

6.3 Load components from Project 113

6.3.1 Loading UOC 113

6.3.2 Loading CEE 115

6.3.3 Loading I/OMs and CMs 117

6.4 Load With Contents command 117

6.5 Reloading components from project 117

6.6 Upload to the Monitoring database 118

Chapter 7 - ControlEdge 900 I/O Device Connectivity 119

7.1 CE900 IO in UOC 119

7.1.1 Model numbers 120

7.1.2 ControlEdge 900 IO Version Compatibility Matrix 120

7.2 UOC Configuration 121

7.3 Controller Rack 123

7.3.1 Rules 123

7.3.2 Creating Controller Rack 123

7.3.3 Method 1: Using the CE900_I/O library 123

7.3.4 Controller Rack Configuration 125

7.3.5 I/OM Status Summary 125

7.4 I/O Rack (EPM) 126

7.4.1 Rules 126

7.4.2 Creating I/O Rack 127

7.4.3 Hardware Information 127

7.4.4 Soft Failures and Alarms 127

7.5 I/O Module 128

- 5 -

Page 6

7.5.1 Rules 128

7.5.2 I/O Module Creation 128

7.6 Channel 130

7.6.1 Rules and Behaviors 130

7.6.2 Channel Type Configuration 130

7.6.3 Channel Configuration and Status 133

7.6.4 Soft Failures and Alarms 135

7.7 I/O Module Configuration 139

7.7.1 Maintenance 139

7.7.2 Module Configuration/Monitoring Tabs 140

7.7.3 Common CE900 Module Configuration/Monitoring Tabs 141

7.7.4 CE900 UIO DI Channel NAMUR Configuration/Monitoring Tabs 145

7.7.5 CE900 UAI Module Configuration/Monitoring Tabs 146

7.7.6 CE900 DI32-24VDC Module Configuration/Monitoring Tabs 149

7.7.7 CE900 DO32-24VDC Module Configuration/Monitoring Tabs 151

7.7.8 CE900 DI16-VAC Module Configuration/Monitoring Tabs 153

7.7.9 CE900 DO08-VAC Module Configuration/Monitoring Tabs 155

7.7.10 CE900 DI16-DRYCT Module Configuration/Monitoring Tabs 156

7.7.11 CE900 DO08-RELAY Module Configuration/Monitoring Tabs 158

7.7.12 CE900 AO04 Module Configuration/Monitoring Tabs 160

7.7.13 CE900 AI16-100MS Module Configuration/Monitoring Tabs 162

7.7.14 CE900 AO08 Module Configuration/Monitoring Tabs 164

7.7.15 CE900 DI16-VACDC Module Configuration/Monitoring Tabs 166

7.7.16 UIO Namur Support 168

Chapter 8 - EtherNet/IP Device Connectivity 170

8.1 EtherNet/IP Device Configuration in UOC 170

8.1.1 Slot 0 Diagnostic Information 171

8.1.2 Slot 0 Configuration 172

8.1.3 Configuring the EtherNet/IP GenAdapter Block 173

8.1.4 Configuring the IP address of an EtherNet/IP device 179

8.1.5 Configuring I/O module blocks 179

8.1.6 Assigning EtherNet/IP devices to the CEE 181

8.1.7 Configuring I/O Ref blocks in CMs to access data from EtherNet/IP devices 181

8.2 Configuration Parameters for arrayed custom parameters 182

8.3 Configuration Parameters for scalar (non-arrayed) custom

parameters 186

8.4 Scaling support for Generic Device 187

- 6 -

Page 7

8.4.1 Scaling Configuration Tab 187

8.4.2 Configuration 188

8.4.3 To view and modify the scaling parameters in EtherNet/IP generic device

instances 188

8.5 UOC and ControlLogix integration 189

Chapter 9 - UOC Node Redundancy Operation 191

9.1 Redundancy configuration restrictions 191

9.1.1 FTE Device Index 191

9.2 Partner controller compatibility 191

9.2.1 Redundancy compatibility result - RDNCMPT 192

9.3 UOC 1-slot I/O rack 194

9.4 Redundancy synchronization 194

9.4.1 Synchronization states - RDNSYNCSTATE 194

9.4.2 Enable Synchronization - ENBLSYNCCMD 195

9.4.3 Disable Synchronization - DSBLSYNCCMD 195

9.4.4 Auto-Synchronization State - RDNAUTOSYNC 195

9.4.5 Inhibit Sync Reason - RDNINHIBITSYNC 196

9.4.6 Initial Sync Progress - RDNSYNCPROG 198

9.4.7 Maximum Initial Synchronization Time - RDNISTIMEMAX 198

9.4.8 Last Synchronization Time - SYNCTIMEBEG 198

9.4.9 Last Lost of Sync Time - SYNCTIMEEND 198

9.4.10 Redundancy Traffic Rate 198

9.4.11 Conditions that result in loss of sync 199

9.4.12 Conditions that do not result in loss of sync 199

9.5 Switchover and secondary readiness 199

9.5.1 Become Primary command - BECMPRICMD 200

9.5.2 Initiate Switchover - SWITCHCMD 200

9.5.3 Max Switchover Time - RDNSOTIMEMAX 200

9.5.4 Conditions that result in switchover 200

9.5.5 Conditions that do not result in a switchover 201

9.5.6 Network switchover considerations 202

9.6 Redundancy history 202

Chapter 10 - Operation 203

10.1 UOC States And Transitions 203

10.2 UOC Front Panel Indications 206

10.2.1 Ethernet Port LEDs 206

10.2.2 Behaviors of Status and Redundancy Role LEDs 206

- 7 -

Page 8

10.2.3 Status LED 207

10.2.4 Redundancy Role LED 211

10.3 UOC Startup 212

10.3.1 Actions During Boot 212

10.3.2 Restart After Power Loss 214

10.3.3 vUOC States and Startup Behaviors 214

10.4 Using Station displays 214

10.4.1 Identifying UOC 215

10.4.2 UOC Controller Point Detail Display (Redundant) 215

10.4.3 UOC Controller Point Detail displays (Non- Redundant) 219

10.4.4 vUOC Controller Point Detail displays 223

10.4.5 UOC-CPM (Local I/O) Racks 226

10.4.6 UOC-EPM Racks 227

10.4.7 UIO Racks 228

Chapter 11 - Troubleshooting 230

11.1 What to do when faults occur 230

11.2 Initial checks 230

11.3 Checking Control Builder error code reference 230

11.3.1 Checking faceplate LEDs 230

11.3.2 Using Firmware Manager to capture diagnostic data 231

11.3.3 Viewing release information log 231

11.3.4 Checking server point build log 231

11.3.5 Checking server point build error log 232

11.3.6 Checking error log 232

11.4 Fixing common problems 232

11.4.1 Loss of power 232

11.4.2 Power-On Self Test (POST) does not complete 232

11.4.3 Module does not complete startup 233

11.4.4 One or both FTE LEDs are OFF 234

11.4.5 FTE receive fault diagnostic 234

11.4.6 Controller does not synchronize with backup 236

11.4.7 Fatal ECC error 236

11.4.8 Isolated (lonely) Node 237

11.4.9 Duplicate Device Index detection 238

11.5 UOC Controller soft failures 239

11.6 Additional status and fault messages 245

11.6.1 Redundancy-related notifications 245

- 8 -

Page 9

11.6.2 OPM-related notifications - RDNOPMSTATUS parameter 245

11.7 Online diagnostics 245

11.8 Fault classifications 246

11.8.1 Hard/Severe Failures 248

11.8.2 UOC Redundancy Communication Issues if CPM is not securely connected

to the rack 249

11.8.3 Soft Failures 249

11.8.4 Installation-Startup Failures 250

11.8.5 Hardware Watchdog Timer Expired 250

11.8.6 Communications Failure 250

11.9 Communications and system time faults during startup 250

11.9.1 Non-redundant UOC Controller 251

11.9.2 Redundant Primary UOC Controller 252

11.9.3 Secondary UOC Controller 254

11.10 Gathering information for reporting problems to

Honeywell 257

11.11 Guidelines for requesting support 257

Chapter 12 - Control Execution Environment 258

12.1 Functional Highlights 259

Chapter 13 - vUOC 260

13.1 Introduction 260

13.1.1 vUOC controllers with Private Path and Downlink I/O adapters 260

13.1.2 Flat Network Downlink I/O Topology 261

13.1.3 VLAN Tagged Network Downlink I/O Topology 262

13.1.4 Network Downlink I/O Topology 263

13.2 Guidelines for integration of virtual controllers 264

13.3 Creating Network Connections 265

13.3.1 Creating a Standard vSwitch 266

13.4 Defining Port Groups 272

13.4.1 Adding a Port Group to a Standard vSwitch 272

13.5 Physical network support for VLAN topologies 276

13.5.1 First level Switch configurations 276

13.5.2 Downstream Switch configurations 278

13.5.3 I/O Device Port configurations 280

13.5.4 Control Edge 900 IO and Switch Configurations 281

13.6 Download 282

- 9 -

Page 10

13.7 vUOC Deployment 282

13.7.1 Reconfigure Network Assignments 289

13.8 vUOC Provisioning (first-time start up only) 290

13.9 vUOC Configuration and Usage 293

13.10 vUOC and Virtualization Host Maintenance 293

13.11 vUOC and Virtualization Host Availability 296

13.11.1 Turning on Fault Tolerance protection for vUOC 296

13.11.2 Disabling Fault Tolerance protection for vUOC 298

Chapter 14 - Performance and Capacity Considerations 300

14.1 Key Specifications 300

14.2 Managing Processing Load 302

14.2.1 Relevant Parameters 302

14.2.2 Overall Load Limits 303

14.2.3 Cycle Overruns 304

14.2.4 CPU Free 304

14.2.5 Redundancy Throughput 305

Chapter 15 - Security Guidelines for UOC 306

15.1 General 306

15.2 Organizational Security 306

15.3 Physical Security 306

15.4 Communication Hardening 307

15.5 Securing Connection to Uplink Network 307

15.6 Securing Connection to Downlink Network 307

15.7 Maintenance, Configuration and Operation 308

15.8 Third Party Configuration Files 308

15.9 Third Party Firmware Files 308

15.10 Private Redundancy Network Path 308

15.11 Patch Management 309

15.12 Backup/Recovery Capability 309

Chapter 16 - Configuring a Secure Connection for Experion Integration 310

16.1 Secure Communications 310

16.1.1 Secure Communication System Planning 312

16.1.2 Configure and Setup Steps 312

16.1.3 Advanced Technical Information 313

- 10 -

Page 11

16.1.4 Certificate Management 313

16.1.5 Secure Communications using IPSec 313

16.1.6 Secure Commuincations Using TLS 314

16.1.7 Secure Boot 314

16.2 Obtaining and Installing the software 314

16.3 Overview of an IPSec deployment 315

16.4 Set Enrollment Information 316

16.5 Creating the Certificate Authority 316

16.6 Creating a certificate for Engineering Station and Console 320

16.6.1 Creating a certificate 321

16.6.2 Importing certificate and private key on target machine 322

16.7 Configure ControlEdge UOC for use with IPSec 329

16.7.1 Installing Certificate Manager Configuration Console 329

16.7.2 Setup certificates and IPSec policy in UOC 338

16.8 Configuring IPSec to secure traffic to the UOC 347

16.8.1 Configure and Activate Security Policies 347

16.8.2 Enable IPSec policy on PCs 347

16.8.3 Disable IPSec policy on Engineering Station/Console 351

16.8.4 Enable IPSec policy rules in the UOC 351

16.8.5 Disable IPSec policy rules in the UOC 353

16.9 Backup and Restore of CA 355

16.9.1 Backup 355

16.9.2 Restore 361

16.10 Renewal and revocation of certificates 365

16.10.1 CA Root certificate 365

16.10.2 Renewing the CA Root certificate 366

16.10.3 PC certificates 367

16.10.4 Revocation 367

16.10.5 UOC certificates 370

16.10.6 Revocation 370

16.11 Troubleshooting 370

16.11.1 How to reset UOC for IPSec configuration? 370

16.11.2 How to reset IPSec configuration on Windows? 371

16.11.3 Diagnosing IPSec with Network Analysis Software 371

16.11.4 If CMCC upload a large number of policies, the read data from the

transport connection can not be received 371

- 11 -

Page 12

CHAPTER

1

ABOUT THIS GUIDE

1.1 Revision history

Revision Date Description

A August 2020 Initial release of the document.

1.2 Related documents

The following list identifies publications that may contain information relevant to the information

in this document. You can find these documents on https://www.honeywellprocess.com/en-

US/support/pages/all-documentation.aspx.

- 12 -

Page 13

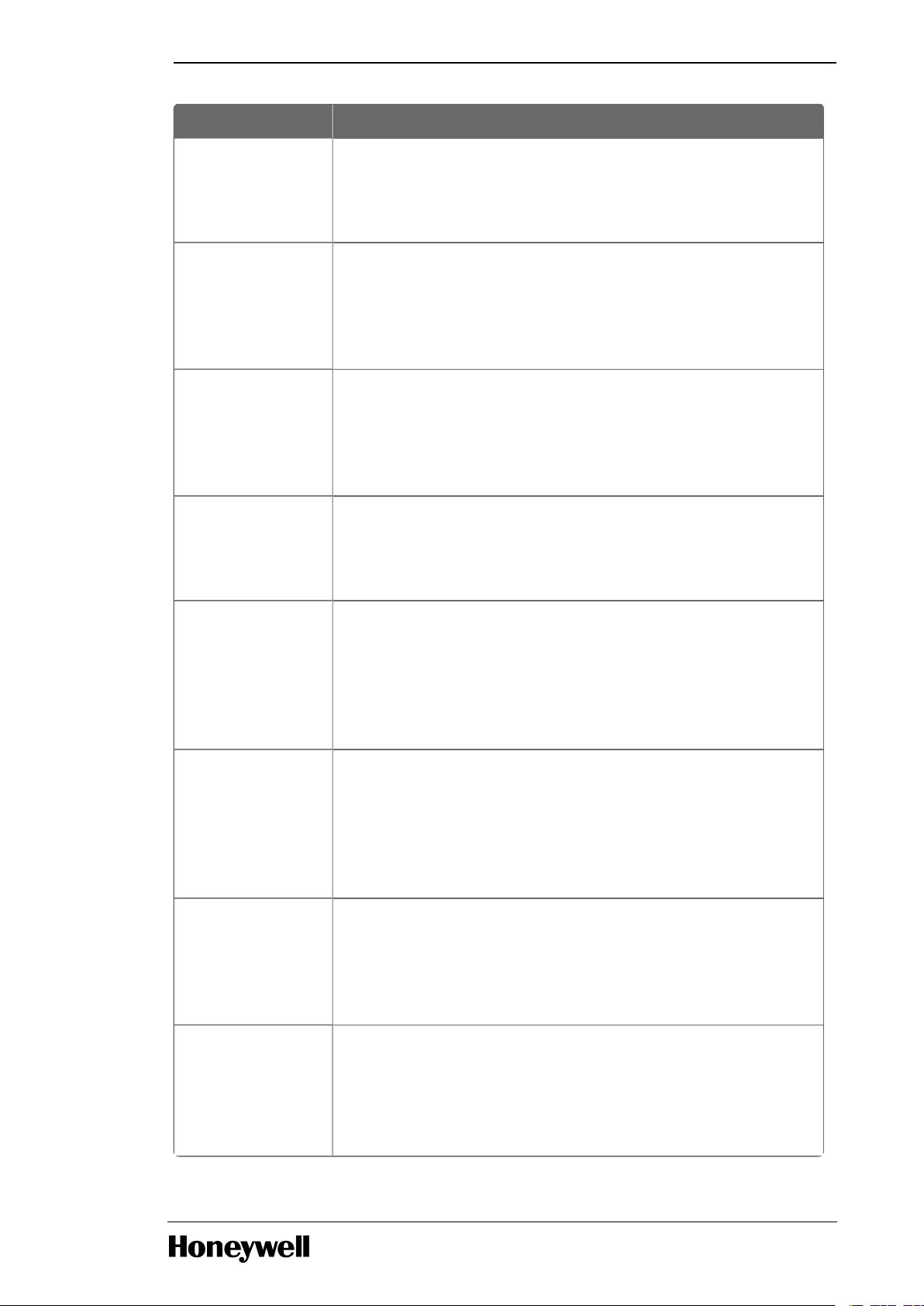

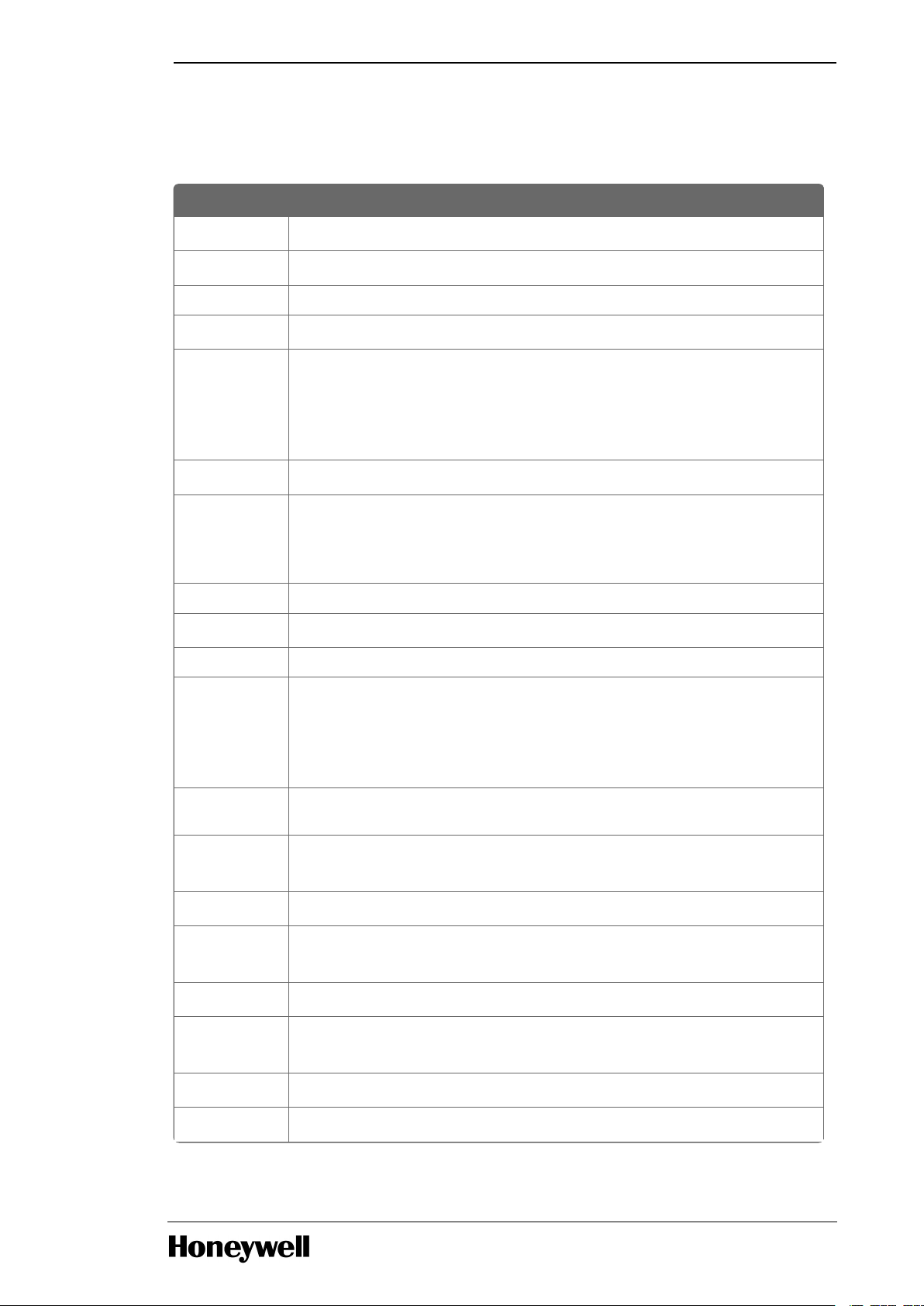

Document Description

Firmware

Manager User

Guide_EPDOCX470.pdf

This document describes the tool used for loading

firmware to hardware modules of the UOC system and for

uploading diagnostics information from them.

Hardware

Planning and

Installation

Guide_HWDOCX430-en-H.pdf

This document describes hardware components and

related installation practices for the ControlEdge 900

family of controller hardware.

Virtualization

Planning and

Implementation

Guide_EPDOCX147-en-A.pdf

This guide provides high-level guidance on how to

implement a virtualized Experion environment.

EtherNet_IP_

Users_Guide_

EPDOC-X399en-511A.pdf

This document provides an overview of the use of

EtherNet/IP™ communications with level 1 Experion

control systems and offers practical guidance to perform a

successful integration of EtherNet/IP with Experion.

Fault_Tolerant_

Ethernet_

Overview_and_

Implementation_

Guide_EPDOCXX37-en-511.pdf

This guide contains basic installation instructions and

configuration requirements for an FTE network and its

components. Detailed network planning and requirements

information is not included as this type of information is

site-specific.

Fault_Tolerant_

Ethernet_

Installation_and_

Service_Guide_

EPDOC-XX36en-511A.pdf

This document provides instructions for installing and

servicing the Fault Tolerant Ethernet Mux driver.

Network_and_

Security_

Planning_Guide_

EPDOC-XX75en-511B.pdf

This document contains networking and security-related

information applicable to Experion. It provides information

about the recommendations to assist you in planning,

setting up, and maintaining a secure environment for your

system.

Switch_

Configuration_

Tool_Users_

Guide_EPDOCX246-en-

This guide describes the user interface of the Switch

Configuration Tool and provides an overview for

configuring switches using the tool. It describes the tasks

to create new switch configuration, open an existing switch

configuration, generate text files from the switch

Chapter 1 - About this guide

- 13 -

Page 14

Document Description

511A.pdf configuration, and load the new switch configurations to

the switches. It also briefly describes creating and saving

projects using the tool.

Control Builder

Components

Theory_EPDOCXX16-en511A.pdf

This guide provides detailed information on the

functionality of Control Builder and the function block

libraries it is used to configure. It does not cover

ControlEdge hardware modules such as the Control

Processor Module (CPM) or Input / Output Modules

(I/OMs).

Control Building

User’s Guide_

EPDOC_XX19_

en-511A.pdf

The procedures in this guide are intended to give you the

ability to perform basic tasks within the Control Builder

application such as configuring hardware devices,

continuous control strategies, and sequential control

strategies. Only representative forms are shown to

illustrate a procedure/concept.

Control Builder

Parameter

Reference

Guides_EPDOCXX18-en511A.pdf

This guide provides information about parameters

associated with configuration forms of function blocks in

Control Builder.

Control_Builder_

Components_

Reference_

EPDOC-XX15en-511.pdf

This document provides a brief technical reference of

function blocks configured through Control Builder.

Engineering Data

Builder (EDB)

User’s GuideEPDOC-X417en-511A.pdf

The Engineering Data Builder (EDB) add-in is a

productivity enhancement tool integrated with the Control

Builder.

EDB add-in deploys customized, reusable, and extensible

spreadsheets, allowing project engineers to save time in

updating configuration.

Virtualization

with the

Premium

Platform

EPDOC-X455en-B.pdf

This guide gets you started with the Honeywell Premium

Platform for Experion Virtualization Solutions.

Chapter 1 - About this guide

- 14 -

Page 15

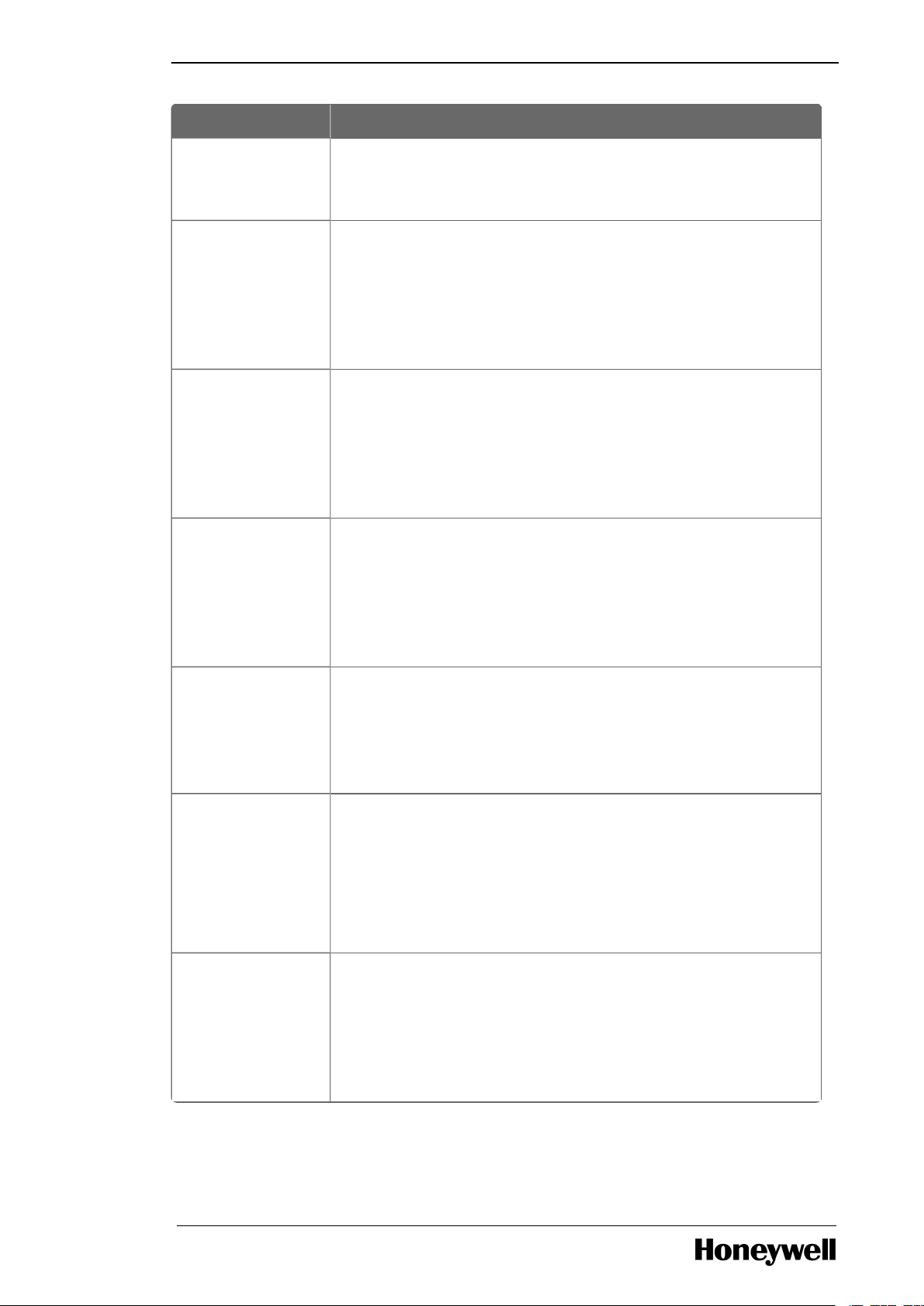

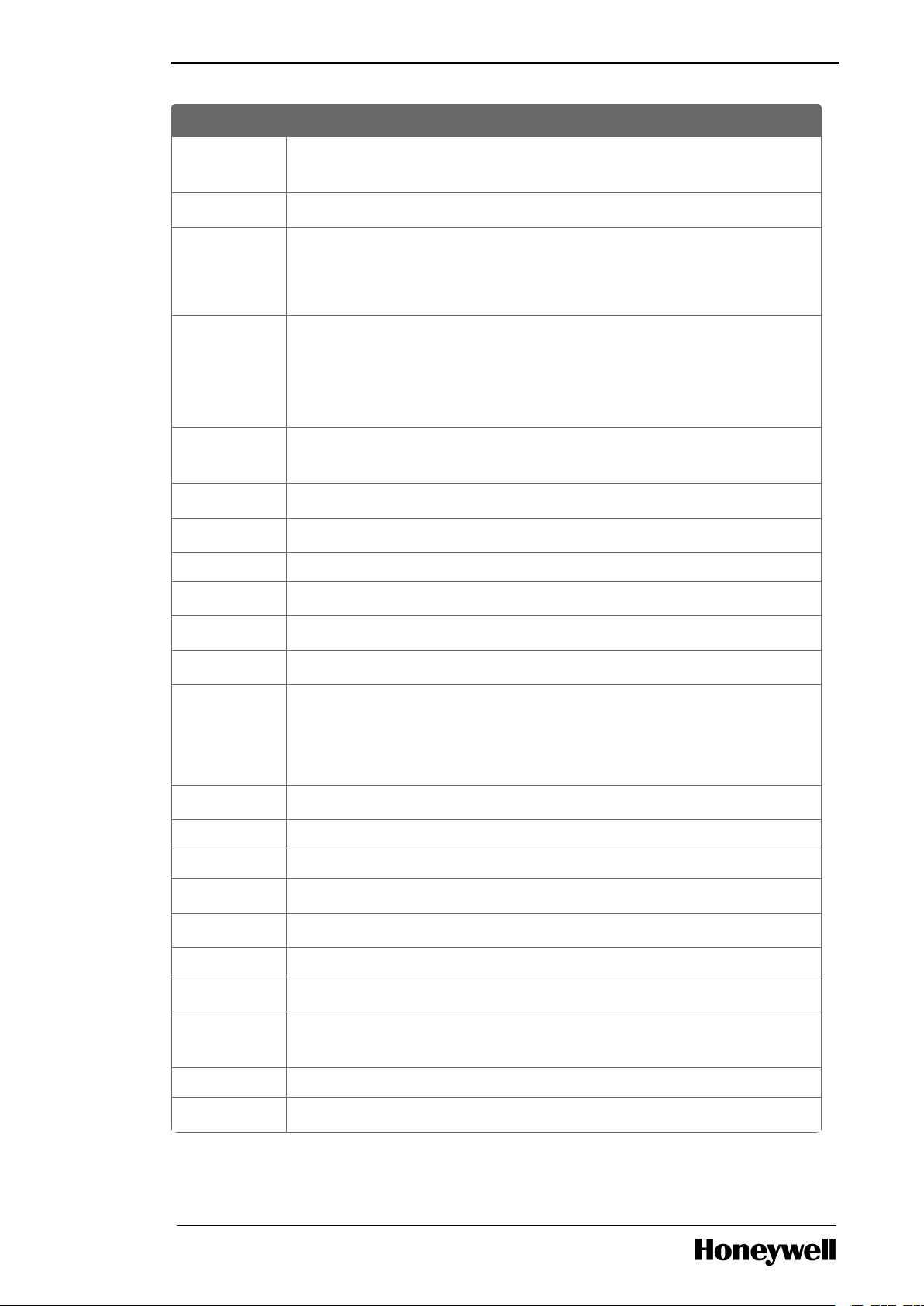

Term Definition

AI Analog Input

AO Analog Output

CA Certificate Authority

CBR Class Based Recipe

CDA Control Data Access

It is the Experion system communication infrastructure and data

access interface schema that provides application integration

with Experion system objects.

CEE Control Execution Environment

CIP Common Industrial Protocol

An industrial communication protocol now maintained as a

standard by the Open Device Venders Association (ODVA).

Cleartext Data that is stored or transmitted unencrypted

CM Control Module

CMCC Certificate Manager Configuration Console

Consolidate

Connections

A single connection used to group multiple I/O modules, instead

of one connection per I/O module.

Also referred to as Assembly connections, Rack connections,

Gateway connections.

ControlEdge

900

A family of controller hardware which can be assembled to create PLC or UOC

systems.

CPM Control Processor Module (also commonly referred to as

controller)

DI Digital Input

DLR DLR is a link layer protocol for establishing a form of ring

redundancy on an Ethernet network.

DO Digital Output

Downlink Shorthand term use to refer to one of two possible types of I/O

and device network that a UOC controller connects to.

EDB Engineering Data Builder

EDS Electronic Data Sheets

Chapter 1 - About this guide

1.3 Terms and definitions

- 15 -

Page 16

Term Definition

Files which define the communication properties of devices

capable of connecting to EtherNet/IP networks.

EtherNet/IP EtherNet/IP™

EPM Expansion Processor Module

Ethernet communications module connecting distributed racks

of ControlEdge 900 I/O modules to the CPM.

ETAP EtherNet/IP™ Tap

A type of switch that allows a device incapable of supporting the

DLR redundancy protocol to form a non-redundant connection

into a DLR ring.

Expansion

I/O rack

I/O rack with EPM installed

FDM Field Device Manager

FTE Fault Tolerant Ethernet

GTAC Global Technical Assistance Center

HART Highway Addressable Remote Transducer

HMI Human Machine Interface

HPS Honeywell Process Solutions

HSR HSR (High Availability Seamless Redundancy) is a link layer

protocol for establishing a form of ring redundancy on an

Ethernet network. HSR is referred to as “Ring-HSR” in the UOC

platform block configuration form.

HW Hardware

IIS Internet Information Services

IKE Internet Key Exchange

I/O Input/Output

IP Internet Protocol

IPSec Internet Protocol Security

LEAP Lean Engineering of Automation Projects

Local I/O

rack

I/O rack with Control Processor Module installed (nonredundant)

NIC Network Interface Controller

NTP Network Time Protocol

Chapter 1 - About this guide

- 16 -

Page 17

Term Definition

NVS Non-Volatile Storage

ODVA Open Device Venders Association

OTP One Time Password

OWD Open Wire Detected

PC Personal computer

PCCC Programmable Controller Communications and Commands

PCDI Peer Control Data Interface

PLC Programmable Logic Controller

Peer Server

Responder

Data sourcing service provided by the Experion Process Server

node which allows controllers like the UOC to access any data

presented by the Server’s data points via peer communication

over the supervisory network.

PRP Parallel Redundancy Protocol is a link layer protocol for

establishing a form of dual-path redundancy on an Ethernet

network.PRP is also referred to as “Star-PRP”.

PSM Power Status Module

PSU Power Supply Unit

PTP Precision Time Protocol PTP

IEEE-1588

It is a standardized internet networking protocol used for

synchronizing computer clock times in a distributed network of

computers. PTP provides higher precision than NTP. The UOC

supports time synchronization by either NTP or PTP on its uplink,

FTE network.

P&ID

Diagram

A diagram representing the Process and Instrumentation Design

of a plant or plant unit.

PWA Printed Wiring Assembly

RCM Recipe Control Module

Redundancy

Box

A network switch that allows another device to connect into a

ring topology even if the device itself cannot natively handle the

ring redundancy protocol.

Redundant

Controller

Rack

ControlEdge 900 rack capable of hosting a redundant pair of

CPMs.

Redundancy Module used with a CPM within a 1 I/O Slot Rack to implement

Chapter 1 - About this guide

- 17 -

Page 18

Chapter 1 - About this guide

Term Definition

Module

(RM)

Dual Rack Redundancy.

SCM Sequence Control Module

SD Card Secure Digital Card

SW Software

TCP Transport Control Protocol

TLS Transport Layer Security

UI/O Universal Input/Output Module

UCM Unit Control Module

It is a container that represents a piece of or logical grouping of

physical equipment. A Recipe may be configured to acquire a

UCM before its procedure can be executed. A UCM can also be

used as an auxiliary resource.

UOC Unit Operations Controller

This is a term used to refer to the CPM when used as a controller

in the Experion PKS Distributed Control System.

Uplink Shorthand term used to refer to the supervisory Ethernet

network that the UOC controller connects to within an Experion

system.

UPS Uninterruptable Power Supply

Users Human Actors

User Goals What users are hoping to achieve at a high level and why. Independent of

system implementation. Should be able to be linked to stakeholder business

goals and SRS use cases.

User Scenarios Specific examples that elaborate on user goals in a context. Told in the form of

stories. Independent of system implementation.

vUOC Virtual Unit Operations Controller

- 18 -

Page 19

CHAPTER

2

The Unit Operations Controller (UOC) is a high value, low cost, rack-based process controller that

can be applied to any process control application in any industry. Its form factor, cost profile and

licensing model make it especially well-suited to industries that prefer to limit the scope of a single

controller to a single process unit, and to industries that require powerful batch enablers.

The UOC is paired with a virtualized controller called the virtual Unit Operations Controller

(vUOC).The vUOC provides a set of functions parallel to those of the UOC except that they are

deployed within a server hosted virtual machine.

Summary descriptions of UOC and vUOC features are presented within this section. Additional

details may be found elsewhere within this document and within the overall Experion document

set.

OVERVIEW OF UOC FEATURES

2.1 Native Experion Integration

UOC integrates natively into the Experion DCS in a fashion parallel to that of existing controllers

such as the C300 and C200E. It uses the same CEE (Control Execution Environment) control

solver as those controllers. Experion Fault Tolerant Ethernet provides redundant, level 2

communications to the UOC. Engineering Station, Direct Station and Flex Station nodes all

provide view of UOC parameter and alarm data via Experion native Control Data Access (CDA)

protocol. Communication, monitoring, displays, trending, historizing, advanced applications, batch

applications, configuration and field device management all work with the UOC controller in a

fashion equivalent to that of existing CEE controllers.

2.2 ControlEdge 900 Form Factor

UOC control algorithms and I/O communications processing run in a family of rack-resident

modules called ControlEdge 900. ControlEdge can be used to deploy high density control and I/O

installations meeting all environment and agency certification requirements with no restriction as

to cabinet type.

In addition to the UOC, components of the ControlEdge HW family can be used to deploy the

ControlEdge PLC, without the need to deal with a completely different component family.

The main components of UOC HW are listed here.

- 19 -

Page 20

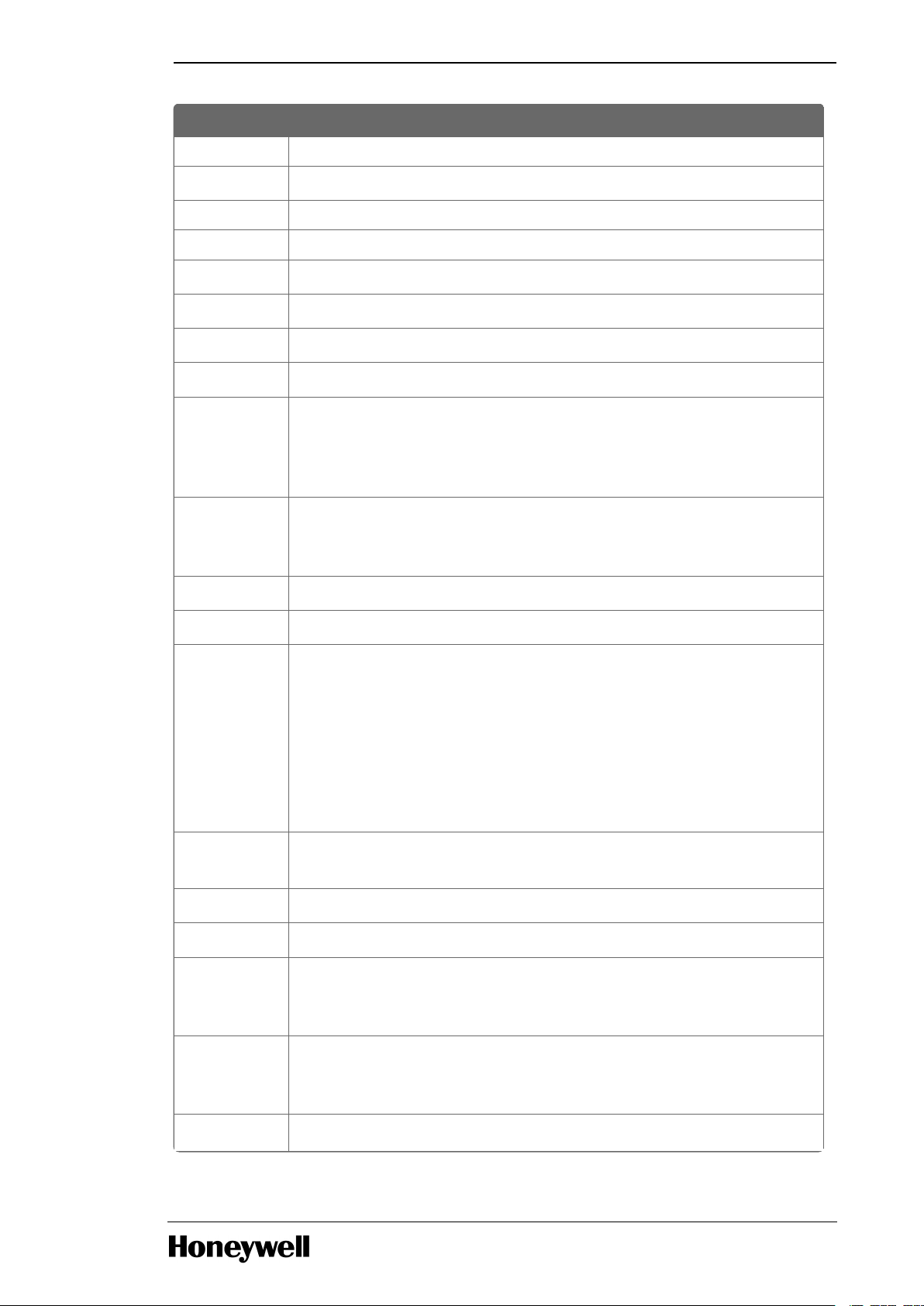

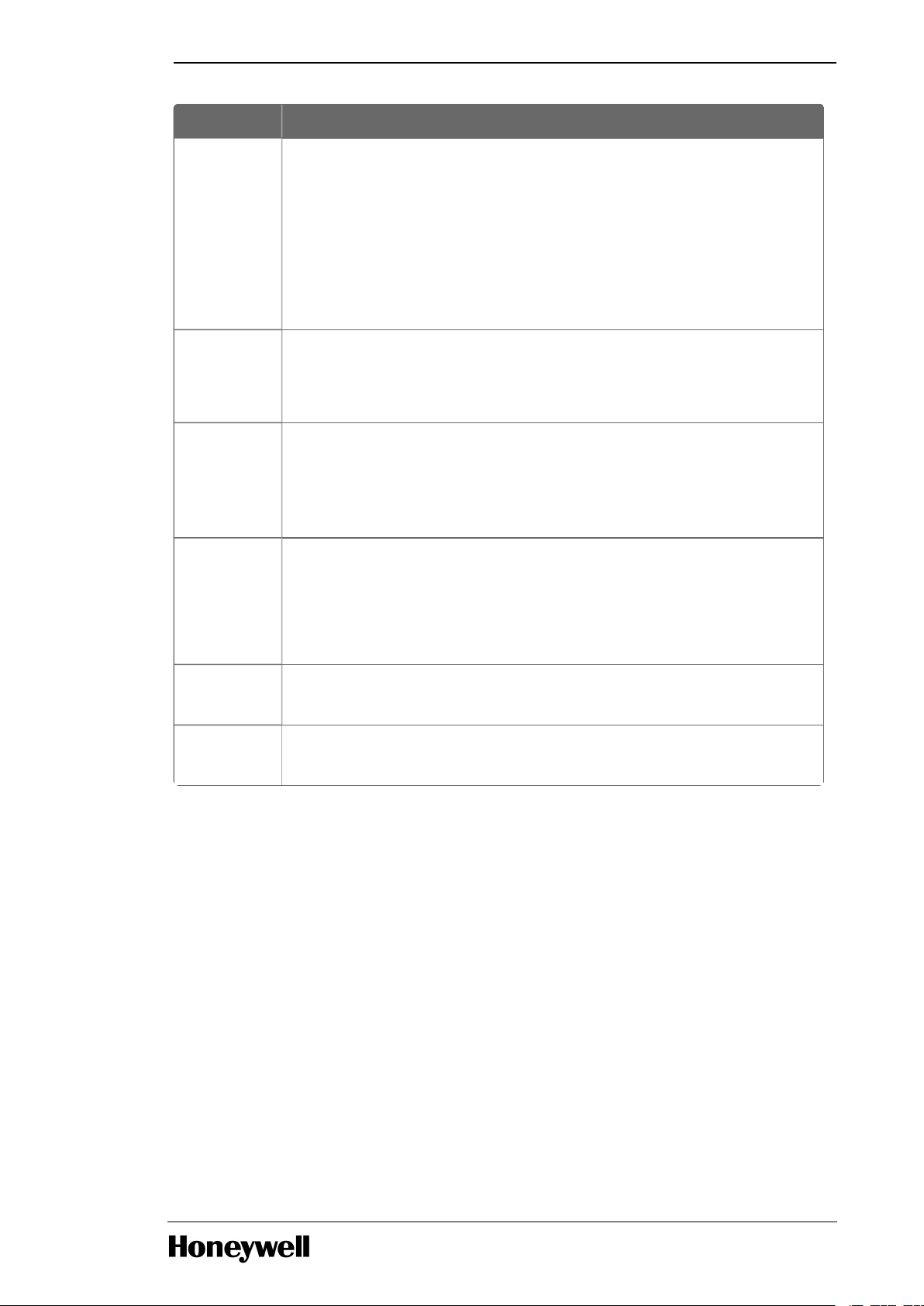

Component Description

CPM Control Processor Module

Referred to as UOC-CPM.

Host processor of control and communications supporting

redundant and non-redundant configurations. Provides two

uplink Ethernet ports for connectivity to FTE. Provides two

downlink Ethernet ports for connectivity to an I/O and device

network.

EPM Expansion Processor Module

Ethernet communications module connecting distributed racks

of ControlEdge 900 I/O modules to the CPM.

UI/OM Universal Input / Output Module

16 channel I/O module with universal channels which can be

configured as AO, DI or DO. Channels configured as AO support

HART protocol.

I/O Racks Five possible non-redundant racks which hold an EPM or a non-

redundant CPM together with 1, 4, 8 or 12 I/O Modules. Three of

the racks accommodate non-redundant power supplies. The 8

and 12 slot racks are available with redundant power supplies

and a power status module.

Redundant

CPM Rack

Redundant controller racking supporting two power supplies and

two CPM slots.

Power

System

AC or DC power supply modules and power status module.

Chapter 2 - Overview of UOC features

2.3 FTE Uplink Connectivity

Detailed information on the installation, planning and general characteristics of ControlEdge 900

HW components can be found in ControlEdge 900 Platform Hardware Planning and Installation

Guide_HWDOC-X430.pdf.

UOC connects to a redundant FTE supervisory network via its uplink Ethernet ports (port #1& port

#2). UOC hosts a full featured firewall allowing it to securely connect directly to level 2, FTEqualified, third party switches. UOC deployments do not require connectivity to FTE through a

separate firewall.

Beginning with Experion R510.2, the vUOC connects to a redundant FTE supervisory network via

its uplink Ethernet ports (virtual switches). A software-based firewall is included allowing a secured

connection directly to Level 2, FTE- qualified, third party switches.

2.4 Ethernet I/O Connectivity

UOC connects to an I/O and device network via its two downlink Ethernet ports (port #3 & 4).

- 20 -

Page 21

Multiple application-dependent typologies are supported with two configurable options:

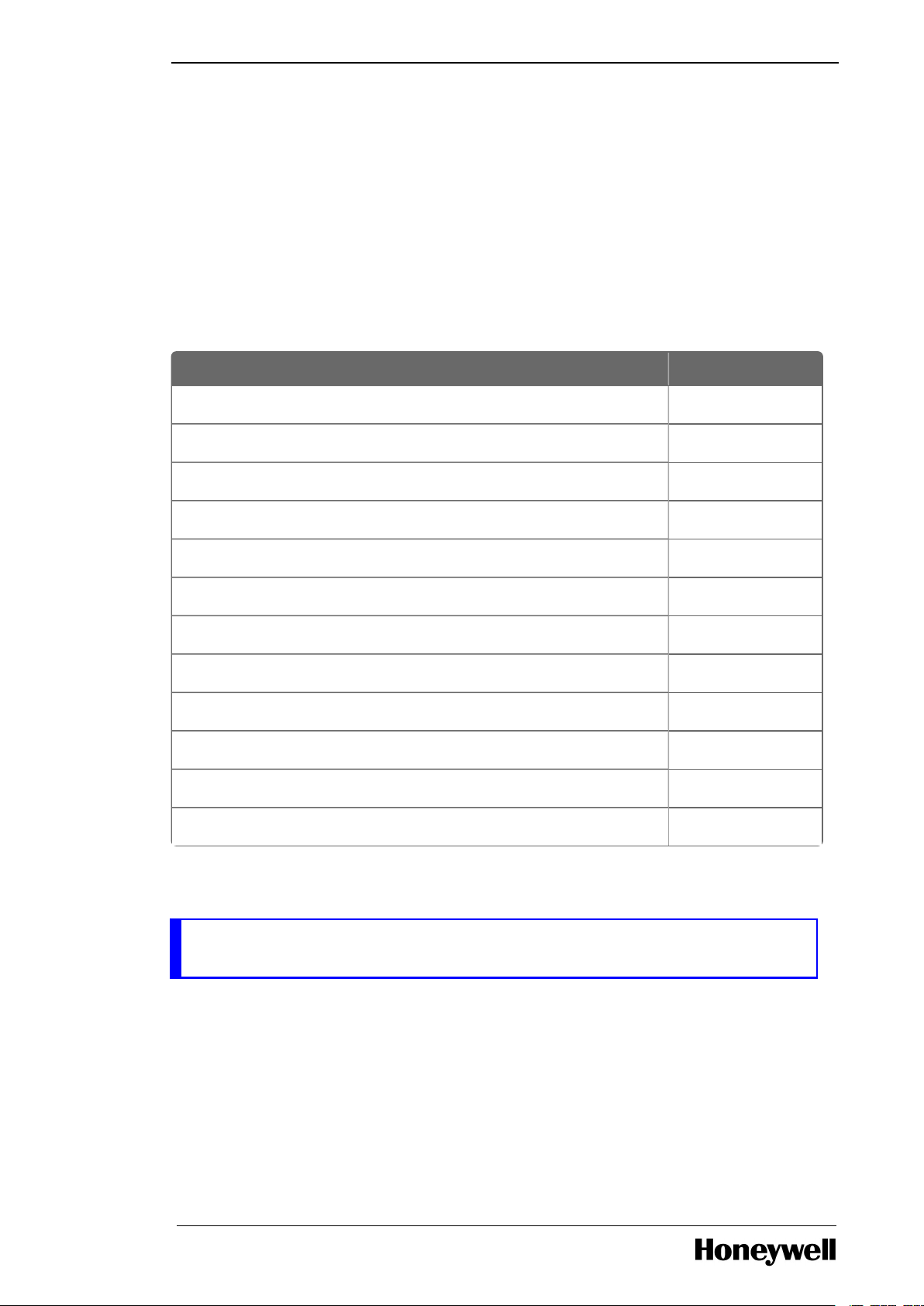

Module Type Model Number

UI/O module 900U01-0100

UAI module 900A01-0102

DI 24VDC module 900G32-0001

DO 24VDC module 900H32-0102

DI High Voltage AC 900G03-0102

DO High Voltage AC 900H03-0102

AI16-100MS (High Level Analog Input, 16 Channels) 900A16-0103

AO04-500MS (Analog Output, 4 Channels) 900B01-0101

AO08-500MS (Analog Output, 8 Channels) 900B08-0202

DI16-DRYCT (DI - 16ch Dry Contact Type) 900G01-0102

DI16-VACDC (DI - 120/240 VAC, 125 VDC (16ch-Iso)) 900G04-0001

DO08-RELAY (Digital Output Relays, 8 Channels) 900H01-0102

l When only ControlEdge 900 I/O racks are connected, a native ring redundancy based on the

High Availability Seamless Redundancy (HSR) protocol may be used, a star redundancy based

the Parallel Redundancy Protocol (PRP) may be used or a non-redundant star may be used.

l When ControlEdge 900 I/O racks are used together with 3rd party EtherNet/IP devices, a ring

redundancy based on Device Level Ring (DLR) may be used or a non-redundant star may be

used.

2.5 ControlEdge 900

ControlEdge PLC supports various input/output modules. The following I/O modules are included:

Chapter 2 - Overview of UOC features

Additional I/O modules will be made available in future releases of the Experion PKS.

NOTE : For Module AI16-100MS, the Model Number should be 900A16-0103 and the

firmware version should be 1.39 for the 100 ms scan rate support.

For below IO modules, there can be Model number mismatch between the IO module hardware

and the IO module reports.

- 21 -

Page 22

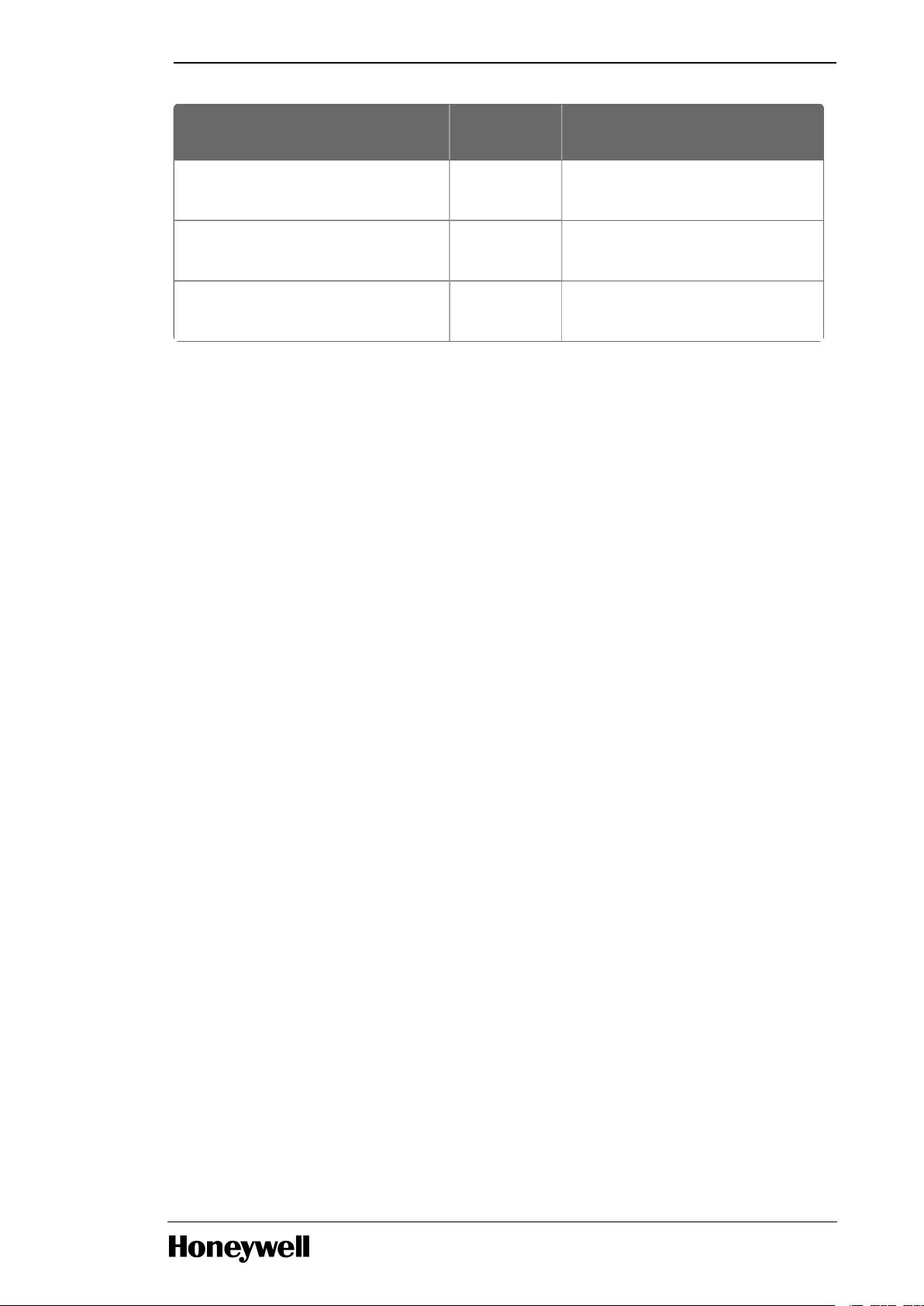

Module Description

Model

Number

Module Number report by the IO

Module

Analog Output, 0 to 20mA, (4

channel)

900B010301

900B01-0101

Digital Input, Contact type, (16

channel)

900G010202

900G01-0102

Digital Output, Relays (8

channel)

900H010202

900H01-0102

Chapter 2 - Overview of UOC features

2.6 Field Device Manager

UOC supports integration with Experion Field Device Manager (FDM) for management of smart

field instruments. The FDM can view and manipulate the digital HART variables of field

instruments through the analog channels of UOC’s UI/OM.

The ability of UOC itself to access digital HART variables via a Field Device Server hosted on the

Engineering Station will be introduced in a future release.

2.7 EtherNet/IP Connectivity to I/O, Devices, and Controllers

UOC supports control through third party I/O and devices connected by the EtherNet/IP protocol

on its Ethernet downlink.

A set of EtherNet/IP devices come preinstalled and ready for instantiation within Experion Control

Builder. This includes Rockwell Allen Bradley’s ArmorPoint I/O, ArmorBlock I/O, PowerFlex Drive

and E3 Relay.

Support for other EtherNet/IP I/O and EtherNet/IP device types can be integrated by projects

personnel without dependence on a new Experion release through the use of Experion Control

Builder’s Parameter Definition Editor (PDE).

Also supported are User Defined Type (UDT) blocks which enable UOC to communicate over its

downlink via EtherNet/IP with Rockwell Allen Bradley’s ControlLogix.

2.8 CEE Control Processing

UOC hosts the well-proven Control Execution Engine (CEE) strategy solver used in existing

Experion controllers. CMs (Control Modules) are fully supported for continuous control strategies.

SCMs (Sequential Control Modules), UCMs (Unit Control Modules), RCMs (Recipe Control Modules)

and CBRs (Class Based Recipes) are fully supported for batch control strategies.

2.9 Control Builder Strategy Configuration

Like all CEE controllers, UOC’s control strategies are configured using Experion Control Builder.

Control Builder offers a rich set of tools for the creation of strategies to control continuous,

discrete and batch processes. Strategies may be created as individual instances or as replicable

templates. Bulk creation of UOC control strategies is supported through Experion’s Engineering

Data Builder (EDB) add-on to Control Builder. EDB allows application engineers to create large

configurations using an efficient, spreadsheet-driven workflow.

- 22 -

Page 23

2.10 I/O Points and I/O Reference Blocks

UOC supports binding of I/O to control through a mechanism that allows the configuration of one

to be independent of the other. UOC I/O points may be introduced into the system independent of

UOC control strategies. UOC control strategies may be configured and tested independent of their

corresponding I/O.

This independence is achieved through two kinds of function blocks supported by Control Builder

and by CEE.

l I/O Points

o

I/O Points are Experion tagged blocks representing the device connected to the UOC

through an input or output channel of an I/O module.

o

They are typically tagged with the same name (up to 40 characters) that labels the

device in a P&ID diagram.

o

They serve as a connection target that binds a control strategy to an I/O channel.

o

They allow the binding to be made by name, without constraining the strategy to work

with the particular channel of a particular I/O Module.

o

They allow the configuration of the I/O Module to be separated from the configuration

of the control strategy.

o

They can be created before or after the corresponding control strategy.

o

In addition to I/O channels, they can be used to represent key parameter data which

do not correspond to actual I/O channels.

Chapter 2 - Overview of UOC features

l I/O Reference Blocks

o

I/O Reference Blocks are basic blocks instantiated in Control Modules to make an I/O

signal available for connection to algorithm blocks.

o

They are bound to I/O Points though named references independent of particular

channels in particular I/O Modules.

o

They support a simulation mode that allows for strategy checkout to be done in the

absence of I/O Modules.

o

They complement I/O Points by serving as the reference end of the connection to the

I/O Point.

o

In addition to referencing I/O channels, they can be used to reference key parameter

data which do not correspond to actual I/O channels.

UOC’s I/O Points and I/O Reference Blocks provide key enablers of the Lean Execution of

Automation Projects (LEAP) methodology supported by Experion.

2.11 Simulation

UOC may be used for both control and strategy-check-out simulation without the need to deploy a

special purpose simulation application. Simulation behaviors of strategies are controlled through

the SIMMODE parameter of I/O Reference blocks within the Control Module under test.

2.12 Control Redundancy

UOC optionally supports redundant control operation. Single Rack Redundancy is provided

through a single rack scheme where the partner CPMs are placed in the same rack along with

power supplies. The power supplies in a single rack scheme do not provide REDUNDANT power:

The left power supply provides power to the CPM mounted in the left slot. Likewise, the right power

- 23 -

Page 24

Responding Node

Initiating Node

UOC vUOC

C300

C200E C200

UOC

ü ü ü ü ü

vUOC

ü ü ü ü ü

C300

ü ü ü ü ü

ACE

ü ü ü ü ü

C200E

ü ü ü ü ü

C200 Note

1

Note

1

ü ü ü

Chapter 2 - Overview of UOC features

supply provides power to the CPM mounted in the right slot.

Switchover from the active primary to the backup controller may be commanded manually. If a

fault occurs, the failed primary is detected automatically by virtue of comprehensive diagnostics,

leading toautomatic switchover. Switchover occurs within 500 milliseconds in order to ensure a

seamless transition, preserving all configuration data and live data, and with no disturbance to

outputs.

Dual Rack Redundancy is provided through 2 separate 1 I/O slot racks each with a power supply

and a Redundancy Module . Refer to the ControlEdge 900 Platform Hardware Planning and

Installation Guide_HWDOC-X430.pdf for additional information.

2.13 Peer-To-Peer Communication

UOC supports multiple forms of peer-to-peer communication across its uplink FTE connection.

l Control Data Access (CDA)

UOC uses Experion native CDA protocol for communication with peer partners as well as level 2

server and station nodes. Parameter reads are supported under a cyclic publication paradigm.

Parameter writes are supported under an acyclic store paradigm.

Within CMs and SCMs, the configuration of peer references is transparent to the application

engineer. They are specified by configuring fully qualified parameter names such as

“TT101.DATAACQ.PV” in expressions, inputs pins or selected output pins, without concern as to

whether the parameter is in the same UOC or in a different controller.

UOC’s CDA peer connections may also be used to reference data from SCADA points by virtue of

Experion Peer Server Responder capability.

The Experion node types with which UOC supports CDA peer-to-peer communication are listed in

the following table. This set will be expanded in future releases.

NOTE1: The C200 controller can respond to CDA peer communications from a UOC or vUOC

but cannot initiate them.

l Exchange Blocks

- 24 -

Page 25

UOC supports a library of blocks which enable communication with third party PLCs and devices

via protocols which were originated by Rockwell Allen Bradley and now support transport over

Ethernet. Blocks within the EXCHANGE library allow initiation of and response to read and write

requests for flags, numeric and string arrays. EXCHANGE blocks support two protocols: the

Common Industrial ProtocolTM(CIP) and Programmable Controller Communication Commands

(PCCC).

l PCDI Blocks

UOC supports a library of blocks called Peer Control Data Interface (PCDI) which enable

communication with third party PLCs and devices via the Modbus TCP/IP protocol. Blocks within

the PCDI library allow initiation of read and write requests through a device proxy block to flag,

numeric and string arrays in a Modbus-capable peer controller.

2.14 Alarms and Events

UOC supports a comprehensive set of alarm and event reporting capabilities that integrate

seamlessly with Experion enablers for the display and historization of alarms and events.

Supported notification types include high, low and rate of change process alarms, state change

process alarms, state change system events, diagnostic events and batch events.

Chapter 2 - Overview of UOC features

2.15 Time Synchronization

UOC maintains an internal clock which is synchronized with external wall clock time.

Synchronization can be maintained over the uplink network using either the Network Time

Protocol (NTP) or the Precision Time Protocol (PTP). All alarms and events reported by UOC are

issued with synchronized time stamps.

2.16 Security

UOC has built in enablers to provide for the secure and robust operation of its control and I/O

configurations. This includes an uplink firewall that limits message types to those appropriate to

the mission of the FTE network. It includes a downlink firewall that limits message types to those

appropriate to the missions of 900 I/O and EtherNet/IP communication. UOC also supports

mechanisms of signed firmware and secure boot which insure only Honeywell authorized

firmware to be executed within the device.

2.17 Licensing

UOC systems are delivered under a licensing model which allows HW and SW components to be

deployed in the manner that most naturally fits the process control problem to be solved. Indirect

cost penalties for good design practices are avoided. The bulk of the cost associated with deploying

a UOC system is proportional to the count of Analog and Digital I/O points put into service. There is

little additional cost if a good design dictates the deployment of small, per unit controllers. Similarly,

there is little additional cost if the design dictates the deployment of small, modularized control

strategies.

For more information on Licensing refer to Licensing Model section.

- 25 -

Page 26

Chapter 2 - Overview of UOC features

2.18 vUOC

As noted above, the virtual UOC provides a set of functions nearly equivalent to those provided by

the ControlEdge 900 based UOC. It is well suited to supervisory batch applications, lab applications

and control strategy checkout before strategies are deployed to a ControlEdge UOC

Differences between the two are driven by the nature of their hosting platforms and, to a certain

extent, by particular strengths that their respective deployments provide. Key differences are

highlighted by the following table.

- 26 -

Page 27

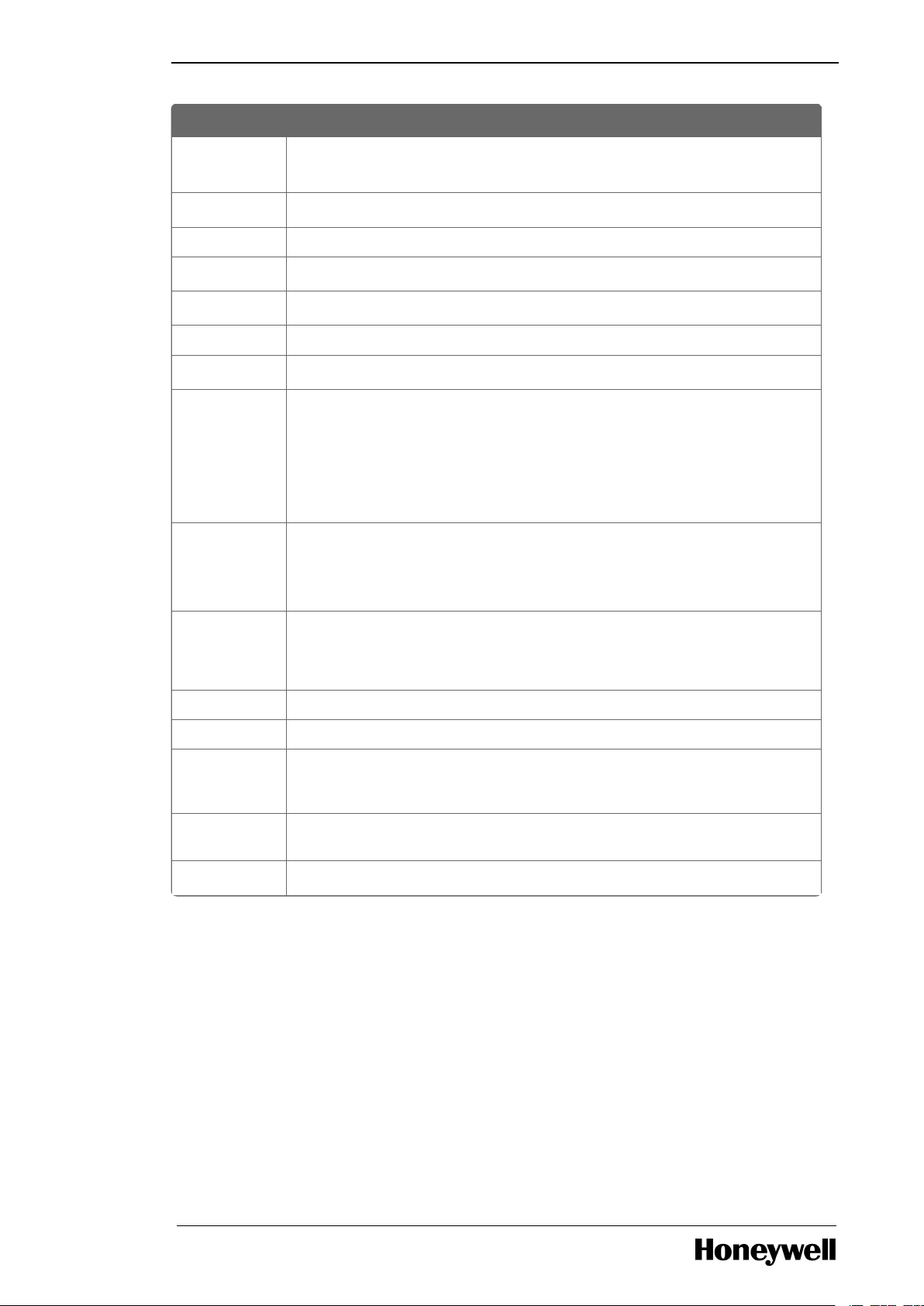

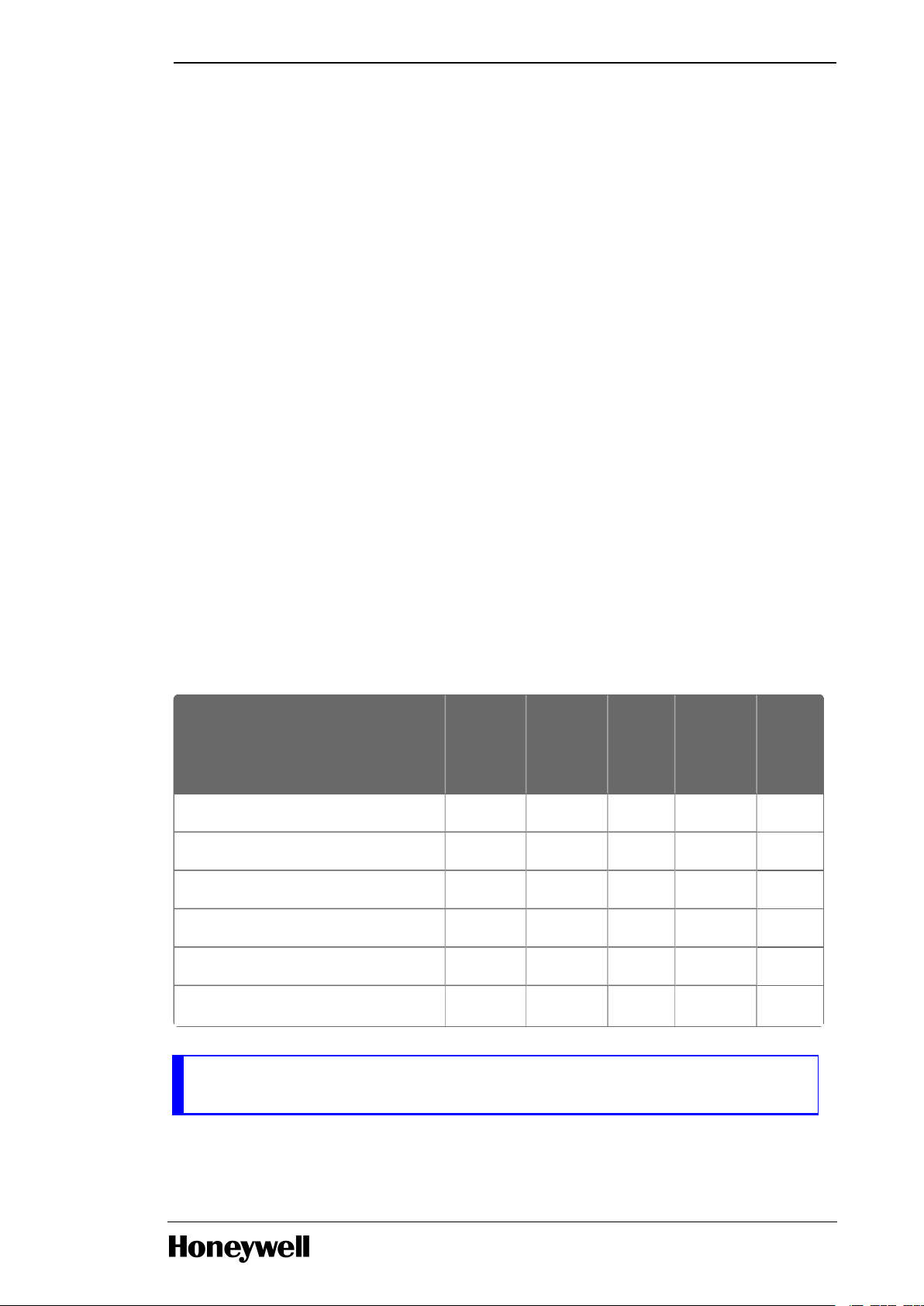

Attribute UOC vUOC Comment

Host

Platform

l Runs on the

purposebuilt,

industry

hardened,

ControlEdge

CPM

l Runs as a

virtual

machine on

general

purpose PC

servers

Base Period l 50 ms l 50 ms or

500 ms

A second vUOC variant

supports a slower base

cycle in addition to the

50 ms base cycle

parallel to the UOC.

The slower variant

allows the vUOC to be

applied as a very large

batch supervisor

managing UOCs or

C200Es serving as

equipment controllers.

User

Memory

Capacity

l 32 MB l 32 MB in

the 50 ms

variant

l 128 MB in

the 500 ms

variant

The 500 ms variant of

the vUOC supports a

user memory database

4 X that of the UOC as

an additional enabler

of large supervisory

batch configurations.

Control

Redundancy

l Transparent

redundancy

support

based on

proprietary

enablers

l Not

currently

supported

The vUOC has no

native redundancy

enablers, but as an

alternative, it can

optionally be deployed

in virtual platforms

that provide high

availability solutions.

Support In

VEP

l Runs on

purposebuilt HW and

cannot run

within HPS’

Virtual

Engineering

Platform

l Can run

within HPS’

Virtual

Engineering

Platform

One of the key

deployments of the

vUOC is as a simulator

within VEP to support

early application

development.

Chapter 2 - Overview of UOC features

- 27 -

Page 28

Attribute UOC vUOC C300

SIMC300

ACE

SIMACE

Hosting on Server No Yes No Yes Yes Yes

Direct I/O Connectivity Yes Yes Yes No No No

Deployment as Controller Yes Yes Yes No Yes No

Deployment as Simulator Yes Yes No Yes No Yes

Simultaneous Control and

Simulation

Yes Yes No No No No

Chapter 2 - Overview of UOC features

Users familiar with the Experion portfolio of controllers and simulators may be tempted to interpret

the vUOC in terms of things they are already familiar with. There are indeed similarities that can be

noted.But there are also significant differences which prevent vUOC from being equated with

previous offerings. This point is highlighted by the following table.

- 28 -

Page 29

CHAPTER

3

NETWORKING

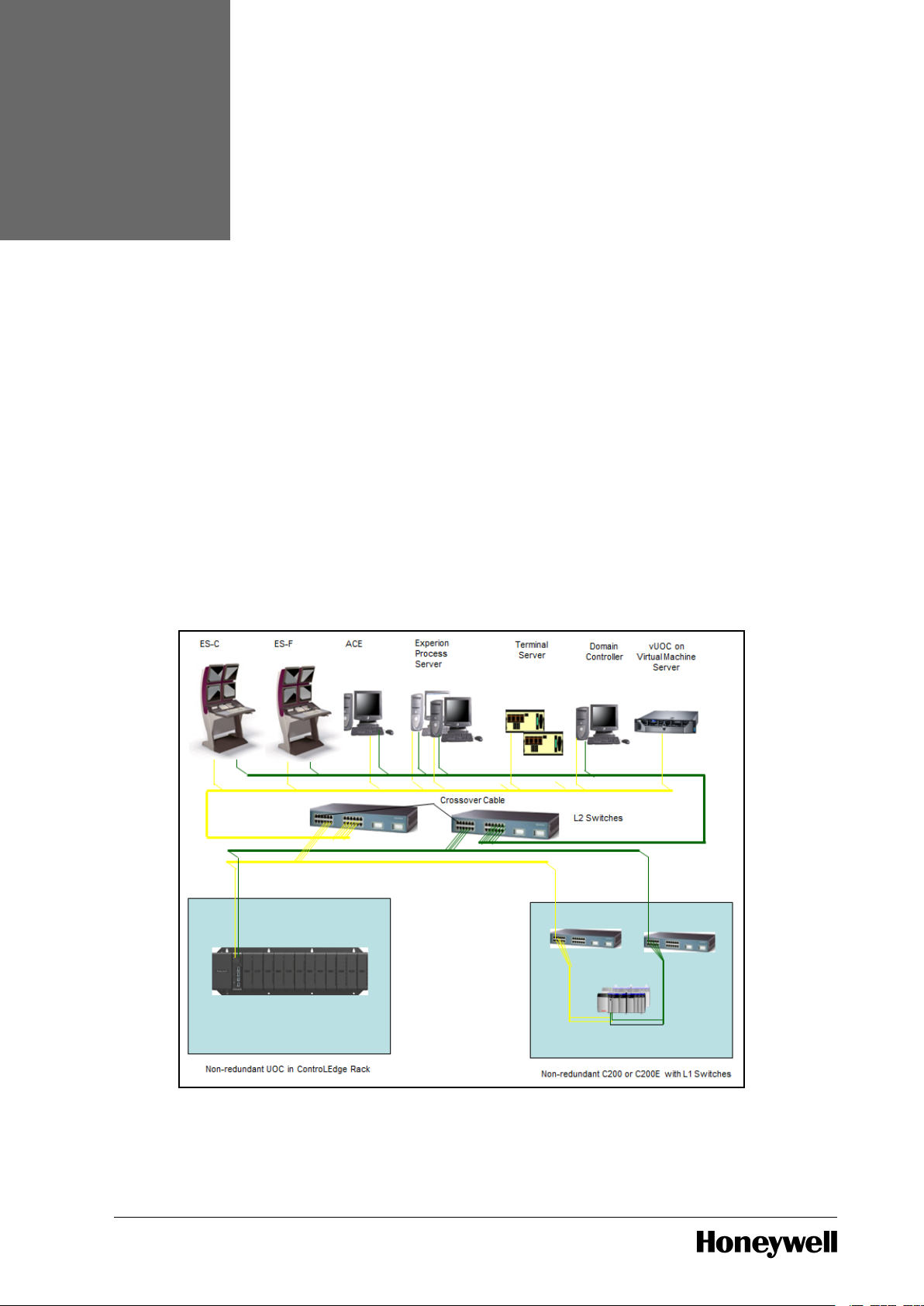

3.1 Uplink FTE Network

UOC and vUOC are deployed within Experion systems by connecting their uplink Ethernet ports to

a Level 2 FTE network. Of the two parallel tree networks that comprise an Level 2 FTE installation,

the ETH1 port connects to the A or Yellow tree while ETH2 connects to the B or Green tree.

FTE connectivity is summarized in the following diagram which shows a non-redundant UOC rack

and a virtual machine server for a vUOC in the context of the following Experion nodes.

l Experion Process Server

l Experion Direct Station (ES-C)

l Experion Flex Station (ES-F)

l ACE

l Terminal Server

l Domain Controller

Figure 3.1 UOC Network Connectivity (Uplink FTE Network)

- 29 -

Page 30

Chapter 3 - Networking

UOC utilizes an existing FTE network, native to Experion PKS. It has a dual connection to Level 2

Yellow and Green FTE switches. No third party firewalls are required.

The number of levels of FTE switches above the UOC may be one, as shown in the diagram above,

two or three.

vUOC’s deployment within an FTE network follows Experion guidance for virtual machines. For

further information, see the vUOC section in this document.

Like existing CEE controllers, UOC requires the presence of a Process Server to function within an

Experion system.

When connecting to FTE, the UOC CPM gets its IP address from the Experion BOOTP service

running on the Engineering Station node. Its IP address is constructed by combining the CPM’s

FTE Device Index with the subnet base address configured through Control Builder and known to

the BOOTP server. Rotary switches of the UOC CPM are located on the module and are used to set

the FTE Device Index. They must be set before the module is inserted into its slot.

ATTENTION

Ensure that the Device Index is set before you place a module in a rack.

Note that, in the special circumstance that a PLC CPM received from the factory is being converted

to a UOC CPM, considerations on IP addressing are different initially. For further information on

converting a PLC CPM to a UOC, see the Converting PLC CPM to UOC CPM section.

Care must be taken in the assignment of FTE device indices to a UOC’s rotary switches. In a

redundant controller rack, the left hand UOC must be assigned an odd numbered device index

while the right hand UOC must be assigned an odd + 1 device index. The odd + 1 position is

reserved and must not be used for other than redundant partner. Non-redundant UOCs must

always be assigned odd numbered device indices. For more information on how to set the FTE

device index see the FTE Device Index section.

The L2 FTE switches to which UOC connects are managed switches which must be configured

using the FTE Switch Configuration Tool. Any ports to which UOCs connect must be configured as

“Other Auto” using this tool. For further information on the FTE Switch Configuration Tool, see the

Switch Configuration Tool Users Guide_EPDOC-X246-EN-511A.pdf.

Except for specific considerations noted within this document, all FTE installation and

maintenance practices for the UOC and vUOC must be done in a fashion consistent with Experion

and FTE guidelines. For further information, see Fault Tolerant Ethernet Overview and

Implementation Guide EPDOC-XX37-en-511A.pdf, Fault Tolerant Ethernet Installation and Service

Guide EPDOC-XX36-en-511A.pdf, and Network and Security Planning Guide EPDOC-XX75-en511A.pdf.

3.2 Downlink I/O Network Topology

UOC supports direct connectivity to an I/O network through its downlink Ethernet ports, ETH3 and

ETH4.

The table below provides a description of various downlink topologies supported.

- 30 -

Page 31

Chapter 3 - Networking

Topology Type Description Switch Types

Topology 1 HSR ring to 900 I/O. None

Topology 2 Non-redundant star to 900 I/O Generic

Topology 3 Redundant star (via PRP) to 900 I/O Generic

Topology 4 DLR direct connection to 900 I/O and

EIP devices

None

Topology 5 Non-redundant star to 900 I/O and EIP

devices

Generic and

Stratix

TM

ATTENTION

Uplink and downlink subnets must be unique. The Downlink subnet mask must be limited to

the number of addresses expected in that subnet.

For example, if a max of 64 addresses is expected, you could use a mask of 255.255.255.192.

Below sections provides detailed description of downlink topologies .

3.2.1 HSR Ring Topology with 900 I/O

High Availability Seamless Redundancy Protocol (HSR) is an industrial redundancy communication

protocol standardized by the International Electrotechnical Commission as IEC 62439-3 edition 2.

It allows system to overcome single network failure without affecting data transmission. It can be

applied to industrial Ethernet applications since it is independent of the protocols and provides

seamless failover.

HSR realizes active network redundancy by packet duplication over two independent networks that

operate in parallel.

When connecting to ControlEdge 900 I/O only, a redundant ring topology may be used. The ring

type is HSR (High Availability Seamless Redundancy). In this topology no third party redundancy

boxes are required. The UOC CPM connects directly, using its two downlink Ethernet ports.

Similarly, EPM modules connect directly using their two Ethernet ports. When a UOC downlink is

constructed in this fashion, it is not possible to connect third party I/O, Devices or PLCs. Only 900

I/O racks may be connected.

When connecting CPMs and EPMs into an I/O network ring, the numbered ports must be

connected so that odd numbered ports always connect to even numbered ports. This is shown in

the following diagram for the case of a redundant UOC rack with two UOC CPMs connecting to two,

4-I/O slot, non-redundant racks, each with its own EPM. Also shown are the CPM’s connection of

ETH1 to the A, Yellow FTE network tree and ETH2 to the B, Green FTE network tree. Note that

incorrect cabling will result in LAN ID Errors and reduced robustness. To clear the LAN ID errors

and the associated software, reset statistics.

- 31 -

Page 32

Chapter 3 - Networking

Figure 3.2 Downlink I/O Network

Considerations for components that connect to a UOC’s downlink HSR ring network are

summarized in the following table.

- 32 -

Page 33

Chapter 3 - Networking

Component

Type

Comments

ControlEdge

UOC CPM

The UOC CPM must be connected to the downlink I/O ring

such that even numbered ports always connect to odd

numbered ports. Important properties of UOC CPM

communications on the downlink network are configured on

the UOC Platform Block in Control Builder. This includes

configuration of the UOC DHCP server for assigning EPM IP

addresses. It also includes setting the Downlink Network

Configuration to Ring-HSR. For complete information on

configuring the downlink network properties on the UOC

Platform Block, see the UOC Platform Block section.

ControlEdge

900 I/O

Racks with

EPMs

An EPM must be connected to the downlink I/O ring such that

even numbered ports always connect to odd numbered ports.

Before it is inserted into its slot, the 100X rotary switch on the

EPM board must be set to indicate I/O network connectivity.

This is done by setting it to position 3. The IP address of the

EPM is assigned by the UOC CPM based on the module

number set on the 10X and 1X rotary switches. Ensure that the

values within the range of 1-12 are used, as these are the valid

values. This too must be set before the EPM is inserted into its

slot. For complete information see the ControlEdge 900 I/O

Device Connectivity section.

- 33 -

Page 34

Chapter 3 - Networking

3.2.2 Redundant Star (PRP) Topology with 900 I/O

ATTENTION

The UOC does not support downlink network topologies containing both PRP and nonredundant connected devices. If your UOC downlink network connection type is configured

for redundant star, you should only connect PRP-capable devices to the downlink network.

Parallel Redundancy Protocol (PRP) is a data communication network standardized by the

International Electrotechnical Commission as IEC 61850 edition 2. It allows systems to overcome

single network failure without affecting data transmission. It can be applied to industrial Ethernet

applications since it is independent of the protocols and provides seamless failover.

PRP provides redundancy by sending two copies of the same frame over two independent

networks. A Redundancy Control Trailer (RCT) is added to each frame (which includes a sequence

number to support detection of duplicate messages so that one may be discarded.) It supports zero

failover time.

When connecting to ControlEdge 900 I/O only, either a non-redundant or redundant star topology

may be used. The network redundancy type is PRP (Parallel Redundancy Protocol). In this topology

no third party redundancy boxes are required. The UOC CPM connects directly, using its two

downlink Ethernet ports. Similarly, EPM modules connect directly using their two Ethernet ports.

When a UOC downlink is constructed in this fashion, it is not possible to connect third party I/O,

Devices or PLCs. Only 900 I/O racks may be connected.

An example of a UOC and two 900 I/O racks on a downlink, redundant, star network is shown in

the following diagram. Also shown are the CPM’s connection of ETH1 to the A, Yellow FTE network

tree and ETH2 to the B, Green FTE network tree.

Figure 3.3 Redundant Star Network

The UOC does not support star topologies which mix redundant and non-redundant connectivity.

Downlink star networks must be set up as exclusively redundant or exclusively non-redundant.

- 34 -

Page 35

Chapter 3 - Networking

Component

Type

Comments

ControlEdge

UOC CPM

Important properties of UOC CPM communications on the

downlink network are configured on the UOC Platform Block in

Control Builder. This includes configuration of the UOC DHCP

server for assigning EPM IP addresses. It also includes setting

the Downlink Network Configuration to “Non-redundant” in the

case of a non-redundant star network or “Star-PRP” in the case

of a redundant star network. For complete information on

configuring the downlink network properties on the UOC

Platform Block, see the UOC Platform Block section.

ControlEdge

900 I/O

Racks with

EPMs

Before it is inserted into its slot, the 100X rotary switch on an

EPM board must be set to indicate I/O network connectivity.

For a non-redundant or redundant star network, this is done by

setting it to position 4. The IP address of the EPM is assigned

by the UOC CPM based on the module number set on the 10X

and 1X rotary switches. Ensure that the values within the range

of 1-12 are used, as these are the valid values. This too must be

set before the EPM is inserted into its slot. For complete

information see the ControlEdge 900 I/O Device Connectivity

section.

Unmanaged

Switches

900 I/O racks with EPM gateways have been qualified to

communicate with UOC through unmanaged switches.

Managed switches may not be used. For information on

qualified switches see the ControlEdge 900 Hardware and

Installation Guide.

Considerations for components that connect to a UOC’s downlink non-redundant or redundant

star network are summarized in the following table.

3.2.3 DLR Ring Topology with EtherNet/IP and 900 I/O devices

Device Level Ring (DLR) is layer 2 data link layer protocol that provides media redundancy, faster

network fault detection, and network fault resolution in a ring topology.

Advantages:

l DLR reduces the number of external components and associated cabling, which eases design

and installation. It also reduces the cost.

l When a ring breaks, DLR detects it and provides alternate routing of the data to help recover

the network at extremely fast rates.

l Line faults of bidirectional rings can be reconfigured quickly, as switching happens at a high

level, and thus the traffic does not require individual rerouting.

On network with only DLR devices, one device act as an active ring supervisor and other devices

form ring nodes. DLR network contain a maximum 50 IP address nodes(This is Honeywell

specification).

DLR network should have at least one node configured as ring supervisor. If there are multiple

nodes configured as supervisor, then the node with highest supervisor precedence value becomes

active supervisor, others will be backup Supervisors.

- 35 -

Page 36

Chapter 3 - Networking

The active ring supervisor cyclically sends out Beacon Frames and Announce Frames on both

ports. They are received on one port of a ring node, processed and passed on to the next ring node

via the other port.

DLR ring topology which provides redundancy protection against a single network ring fault.

Installation and maintenance of a downlink EtherNet/IP network must be done in accordance with

the best practices of Ethernet networking in general and EtherNet/IP in particular.

In this topology, UOC connects directly to the ring through downlink ports ETH3 and ETH4. EPM

connects through their ETH1 port and ETH2 port directly to ring networks.

An example of a DLR Ring network is shown in the following diagram.

Figure 3.4 Downlink DLR Network

Installation and maintenance practices for the UOC’s downlink EtherNet/IP network generally

follow those described in the EtherNet IP User's Guide. Additional considerations for components

that connect to the EtherNet/IP network are summarized in the following table.

- 36 -

Page 37

Chapter 3 - Networking

Component

Type

Comments

ControlEdge

UOC CPM

The UOC CPM connects to a downlink EtherNet/IP network

through its ETH3 and ETH4 ports. Important properties of

UOC CPM communications on the downlink network are

configured on the UOC Platform Block in Control Builder. This

includes configuration of the UOC DHCP server for assigning

EPM IP addresses. It also includes Downlink Network

Configuration to Non-redundant.

ControlEdge

900 I/O

Racks with

EPMs

When 900 I/O is used, the EPM in the I/O rack serves the role

of communication gateway into the I/O rack. When an EPM is

connected, ETH1 port and ETH2 port are directly connected to

an EtherNet/IP network. Before it is inserted into its slot, the

100x rotary switch on the EPM board must be set to indicate

the type of network connectivity in use. This is done by setting

it to position 4.

The IP address of the EPM is assigned by the UOC CPM based

on the module number set on the 10X and 1x rotary switches.

These switches must also be set before the EPM is inserted

into its slot.

For complete information on the use of ControlEdge EPM and

900 I/O, see ControlEdge 900 I/O section.

ControlLogix

PLC

UOC can communicate with Rockwell Allen Bradley

ControlLogix PLCs by passing instances of User Defined Types

(UDTs). References to ControLogix data are created in

Experion Control Builder with the aid of tag names provided by

the Matrikon Allen Bradley OPC server or by export of

ControlLogix tag names from the Rockwell Allen Bradley

Studio 5000 designer tool. ControlLogix PLCs on a UOC’s

downlink EtherNet/IP network must always use static IP

address assignments. For information on the configuration of

ControlLogix communications, see EtherNet IP User's Guide_

EPDOC-X399-en-511A.pdf.

EtherNet/IP

I/O and

Devices

UOC supports a set of EtherNet/IP devices with pre-populated

CEE block types in Experion Control Builder (CB). In addition,

CB provides the Parameter Definition Editor (PDE) tool which

allows for the integration of new EtherNet/IP I/O and devices

independent of Experion release. Although some third party

EtherNet/IP devices support IP address assignment from a

network resident DHCP server, this feature cannot be used

when the EtherNet/IP network connects to UOC. All device IP

addresses must be statically assigned. For further information,

see EtherNet IP User's Guide_EPDOC-X399-en-511A.pdf.

- 37 -

Page 38

Component

Type

Comments

Allen Bradley

OPC Server

from

MatrikonOPC

The Rockwell Allen Bradley OPC Server from MatrikonOPC can

be installed on the Engineering Station in systems which

incorporate UOC. The Matrikon OPC Server enables one of two

methods whereby ControlLogix tag names can be used to

make UDT references in a UOC strategy. For further

information, see EtherNet IP User's Guide_EPDOC-X399-en-

511A.pdf.

Studio 5000

Logix

Designer

Software

Studio 5000 Logix Designer Software from Rockwell Allen

Bradley is used in conjunction with UOC configurations to

configure IP addresses of Rockwell Allen Bradley EtherNet/IP

devices. It can also be used to export a file which defines

ControlLogix tag names so that they can be used in Control

Builder to construct UDT data references from UOC. For

further information, see EtherNet IP User's Guide_EPDOC-

X399-en-511A.pdf.

Chapter 3 - Networking

3.2.4 Non-Redundant Star to 900 I/O and EIP Devices

ATTENTION

While using DLR (Device Level Ring) on Stratix 5700 Switch, DO NOT CONNECT a DLR

network to a Non-DLR port on the Switch. DLR should be connected only to the DLR ports

on the switch. Doing this will result in the entire downlink network going down. The recovery

is to only remove the DLR connection from the switch.

In addition to the DLR ring topology, the UOC can also connect to a non-redundant star

EtherNet/IP network through its ETH3 downlink port. This allows it to communicate

simultaneously with ControlEdge 900 I/O as well as EtherNet/IP-capable I/O, devices and PLCs.

Installation and maintenance of a downlink EtherNet/IP network must be done in accordance with

the best practices of Ethernet networking in general and EtherNet/IP in particular.

In this topology, CPMs connect through their ETH3 downlink port with ETH4 port disconnected.

EPMs connect through their ETH1 port with ETH2 port disconnected. An example is shown in the

diagram below.

- 38 -

Page 39

Chapter 3 - Networking

Figure 3.5 UOC CPM to 900 I/O and EIP Devices

Installation and maintenance practices for the UOC’s downlink EtherNet/IP network generally

follow those described in EtherNet IP User's Guide_EPDOC-X399-en-510A.pdf for topology 2, “C300

Through EtherNet/IP”. Additional considerations for components that connect to the EtherNet/IP

network are summarized in the following table. ControlLogix PLCs and EtherNet/IP I/O and Devices

are equivalent to those for DLR ring networks.

- 39 -

Page 40

Component

Type

Comments

ControlEdge

UOC CPM

The UOC CPM connects to a downlink EtherNet/IP network

through its ETH3 and ETH4port. Important properties of UOC

CPM communications on the downlink network are configured

on the UOC Platform Block in Control Builder. This includes

configuration of the UOC DHCP server for assigning EPM IP

addresses. It also includes Downlink Network Configuration to

Non-redundant.

ControlEdge

900 I/O

Racks with

EPMs

When 900 I/O is used, the EPM in the I/O rack serves the role

of communication gateway into the I/O rack. When an EPM is

connected to an EtherNet/IP network, its ETH1 port is

connected to the switch while its ETH2 port is left

disconnected. Before it is inserted into its slot, the 100x rotary

switch on the EPM board must be set to indicate the type of

network connectivity in use. This is done by setting it to position

4. The IP address of the EPM is assigned by the UOC CPM

based on the module number set on the 10X and 1x rotary

switches. These switches must also be set before the EPM is

inserted into its slot. For complete information on the use of

ControlEdge EPM and 900 I/O, see ControlEdge 900 I/O

Device Connectivity section.

Unmanaged

Switches

900 I/O racks with EPM gateways have been qualified to

communicate with UOC through unmanaged switches. EPMs

may not be connected through managed switches. For

information on qualified switches see ControlEdge 900 Platform

Hardware Planning and Installation Guide_ HWDOC-X430.pdf.

Stratix

Switches

EIP I/O, devices and PLCs may be connected to UOC through

qualified, Stratix managed switches. For further information on

how to deploy and configure Stratix switches, see EtherNet IP

User's Guide_EPDOC-X399-en-511A.pdf.

Chapter 3 - Networking

3.2.5 EtherNet/IP in Experion

Experion as a whole supports a variety of topologies for connecting to EtherNet/IP networks. For

additional information see EtherNet IP User's Guide_EPDOC-X399-en-511A.pdf.

To put UOC topologies into context, supported variations, including that of UOC, are summarized in

the following table.

- 40 -

Page 41

#

Summary

Name

Connectivity Description

1 SCADA

Server To

EtherNet/IP

SCADA

Server

|

FTE Network

|

L2.5 or L3

Router

|

Ethernet

Link

|

EtherNet/IP-

capable

Switch

|

EtherNet/IP

Network

|

PLCs

The Experion SCADA Server supports

connectivity to Rockwell Allen Bradley

ControlLogix PLCs which are attached to

an EtherNet/IP network. The SCADA

Server connects to the L2 FTE network

which provides a path through an L2.5

or L3 Router and through nonredundant Ethernet links, to an

EtherNet/IP-capable, Stratix switch.

Access Lists of the router must be

configured as a security boundary

between the FTE and EtherNet/IP

networks.

2 UOC Direct

To

EtherNet/IP

UOC

|

EtherNet/IP-

capable

Switch

|

EtherNet/IP

Network

|

I/O, Devices

and PLCs

The UOC controller supports

connectivity to I/O, devices and Rockwell

Allen Bradley ControlLogix PLCs which

are attached to an EtherNet/IP network.

The UOC connects to a DLR ring

through its ETH3 (with ETH4 left

disconnected) downlink port.

Alternatively, it connects to a nonredundant star network. The IP subnet of

the UOC on its uplink FTE ports is

isolated from the IP subnet of the UOC

on its downlink EtherNet/IP port.

Honeywell ControlEdge 900 I/O can be

connected to the downlink EtherNet/IP

network along with third party I/O and

devices.

Chapter 3 - Networking

- 41 -

Page 42

Chapter 3 - Networking

NOTE

Users who wish to use UOC with secure communications should be aware that considerable

planning and configuration is required in its setup. For further information, see section

Configuring a Secure Connection for Experion Integration.

- 42 -

Page 43

CHAPTER

4

INSTALLATION

4.1 Hardware Considerations

The ControlEdge CPM (model # 900CP1-0200) can be used as a ControlEdge PLC or ControlEdge

UOC by programming in the corresponding firmware image.

To convert ControlEdge CPM (model # 900CP1-0200) to ControlEdge UOC, install the UOC

firmware image into the module.

The CPM Mode switch is not used by the ControlEdge UOC after initial firmware programming.

Therefore, once the module is programmed as ControlEdge UOC, the UOC label (see below) is

affixed over the CPM Mode Switch.

The odd device index UOC (default primary) must be inserted in the left-hand slot (slot 0). If there

is a backup module, it must be set to odd+1 and placed in the right-hand slot (slot 1). A nonredundant controller must not be placed in slot 1. For more information on how to set the FTE

device index, see the FTE Device Index section on page 52.

For more information, see ControlEdge 900 Platform Hardware Planning and Installation Guide_

HWDOC-X430.pdf.

4.2 Firmware Considerations

Installation and maintenance of UOC firmware entails several types of activities as follows:

l Converting a PLC CPM into a UOC CPM

l Upgrading a UOC CPM to a new firmware version

l Upgrading a UOC EPM to a new firmware version

l Upgrading a UOC UI/OM to a new firmware version

- 43 -

Page 44

Chapter 4 - Installation

Firmware update and CPM conversion are done using an application called Firmware Manager.

For detailed information on using Firmware manager, see Firmware Manager User Guide_EPDOC-

X470.pdf.

4.2.1 Converting PLC CPM to UOC CPM

ControlEdge UOC and PLC are distinct controllers that can be deployed using a common family of

HW. For information on ControlEdge HW components see ControlEdge 900 Platform Hardware

Planning and Installation Guide_HWDOC-X430.pdf.

The ControlEdge Control Processor Module (CPM) is the central component which communicates

on its uplink ports with the Experion PKS system and on its downlink ports with I/O and devices.

The UOC'shardware and model number are identical to that of the ControlEdge PLC but its

firmware is different. The CPM is always shipped from the factory preloaded with PLC firmware. To

use a CPM in an Experion PKS system, it must first be converted into a UOC CPM by loading

firmware over a network connection.

Network connectivity is established by using an Ethernet port and IP address that conform to the

PLC’s communication methodology. The handling of Ethernet ports and IP addresses in a

ControlEdge PLC is different from that of Experion PKS. As a result, the PLC to be converted must

be placed in a system where it can communicate without needing to be a member of an FTE

community.

There are two possible ways of doing this as follows:

l Use a Bench system with a ControlEdge power supply and rack that can host a CPM.

l Use an Experion system with a ControlEdge power supply and rack or rack slot that can host a

CPM and is not being used for on-process control.

ATTENTION

l Once the PLC is converted into a UOC, it should not be reconnected to a PLC system

as it requires Experion PKS infrastructure to operate.

l The PLC’s ControlEdge Builder is not used to perform PLC-to-UOC conversion.

Manually attempting to load UOC firmware to a PLC-CPM with the PLC’s Control

Edge Builder may result in controller firmware corruption.

l UOC-to-PLC conversion is currently not supported. Manually attempting to load PLC

firmware to a UOC-CPM may result in controller firmware corruption.

l Do not install the PLC’s ControlEdge Builder software on either an Experion node

type or a Bench laptop or PC that has Firmware Manager installed. These

applications have similar controller communication infrastructure that are not

designed to co-exist resulting in Firmware Manager to module communication

breakage.

Converting Using Bench System

The main distinction of a Bench System it that it uses a laptop or PC that is not an Experion PKS

node type. The Bench laptop or PC requires a one-time install of Bench System Firmware Manager

from Experion PKS installation media. The special nature of this install is that it also installs the

UOC firmware in addition to the Firmware Manager application used to load the UOC firmware to

the PLC-CPM. Refer to Firmware Manager User Guide_EPDOC-X470.pdf for how to create a Bench

System laptop or PC.

To complete the Bench System, a ControlEdge controller rack with a power supply must be

procured. Either a redundant or non-redundant rack may be used. For information on rack types,

see ControlEdge 900 Platform Hardware Planning and Installation Guide_HWDOC-X430.pdf.

After the Bench system has been set up, it includes the components as shown here.

- 44 -

Page 45

Figure 4.1 PLC CPM to UOC CPM Conversion using Bench System

Refer to Firmware Manager User Guide_EPDOC-X470.pdf for information on:

l How to create the Bench System laptop or PC.

l How to setup the Bench System PC and the PLC-CPM for conversion.

l How to perform the PLC-to-UOC conversion.

Convert PLC to UOC Using Experion System

Chapter 4 - Installation

Using Experion Equipment

When converting PLC to UOC within an Experion PKS system that is undergoing deployment, it is

not required create a Bench system laptop or PC. It is also not required to designate a specific rack

for use in a bench system. Instead, a controller rack with power supply that is being deployed

within the new system can be identified as a temporary host of the CPM(s) under conversion.

Careful consideration must be given to the creation of spare UOC CPMs before a temporary

conversion rack is put on-line. For further comments on spares, see section Spare UOC CPMs on

page 48.

Conversion using on Experion PKS Node and Experion PKS Rack

A PLC-CPM can be converted using an Experion PKS node that has an installation of Firmware

Manager together with an off-process ControlEdge controller rack that is part of the Experion

system. The necessary system components are summarized in the following diagram.