Page 1

Experion LX

Series 8 Cabinet Installation Instruction

EXDOC-X290-en-500A

April 2017

Release 500

Page 2

Disclaimer

Document Release Issue Date

EXDOC-X290-en-500A 500 0 April 2017

This document contains Honeywell proprietary information. Information contained herein is to be used solely

for the purpose submitted, and no part of this document or its contents shall be reproduced, published, or

disclosed to a third party without the express permission of Honeywell International Sàrl.

While this information is presented in good faith and believed to be accurate, Honeywell disclaims the implied

warranties of merchantability and fitness for a purpose and makes no express warranties except as may be stated

in its written agreement with and for its customer.

In no event is Honeywell liable to anyone for any direct, special, or consequential damages. The information

and specifications in this document are subject to change without notice.

Copyright 2017 - Honeywell International Sàrl

2 www.honeywell.com

Page 3

Contents

1 About this document ............................................................................................................................. 5

2 Overview of CE Compliance .................................................................................................................. 7

3 Mounting and segregation of wiring .................................................................................................. 13

4 Bonding and grounding ....................................................................................................................... 17

5 Power supply selection and distribution ........................................................................................... 21

6 CE Limitations ...................................................................................................................................... 25

2.1 Related products and modules ............................................................................................................................ 8

2.2 Compliance statement and standards used ....................................................................................................... 10

2.3 Reference to original tested configuration (in cabinet) .................................................................................... 11

3.1 Cabling and wiring ........................................................................................................................................... 14

3.2 Mounting limitations within a cabinet .............................................................................................................. 16

4.1 Cabinet safety ground connections ................................................................................................................... 18

4.2 Power supply grounding considerations ........................................................................................................... 20

5.1 Selecting the Power System .............................................................................................................................. 22

5.2 Power Distribution System ............................................................................................................................... 23

6.1 Operation environment and shielded wiring ..................................................................................................... 26

6.2 ESD issues ........................................................................................................................................................ 27

6.3 Transient protection required ............................................................................................................................ 28

7 Maintenance .......................................................................................................................................... 29

7.1 C300 controller module and IOTA replacement ............................................................................................... 30

7.2 PGM Replacement ............................................................................................................................................ 32

7.3 Series 8 IOTA and I/O module Replacement ................................................................................................... 34

8 Declaration of conformity .................................................................................................................... 37

9 Conclusions .......................................................................................................................................... 41

9.1 Conclusions ....................................................................................................................................................... 42

10 Notices ................................................................................................................................................ 43

3

Page 4

CONTENTS

4 www.honeywell.com

Page 5

1 About this document

This document describes how to install and configure the Series 8 cabinet and other important instructions.

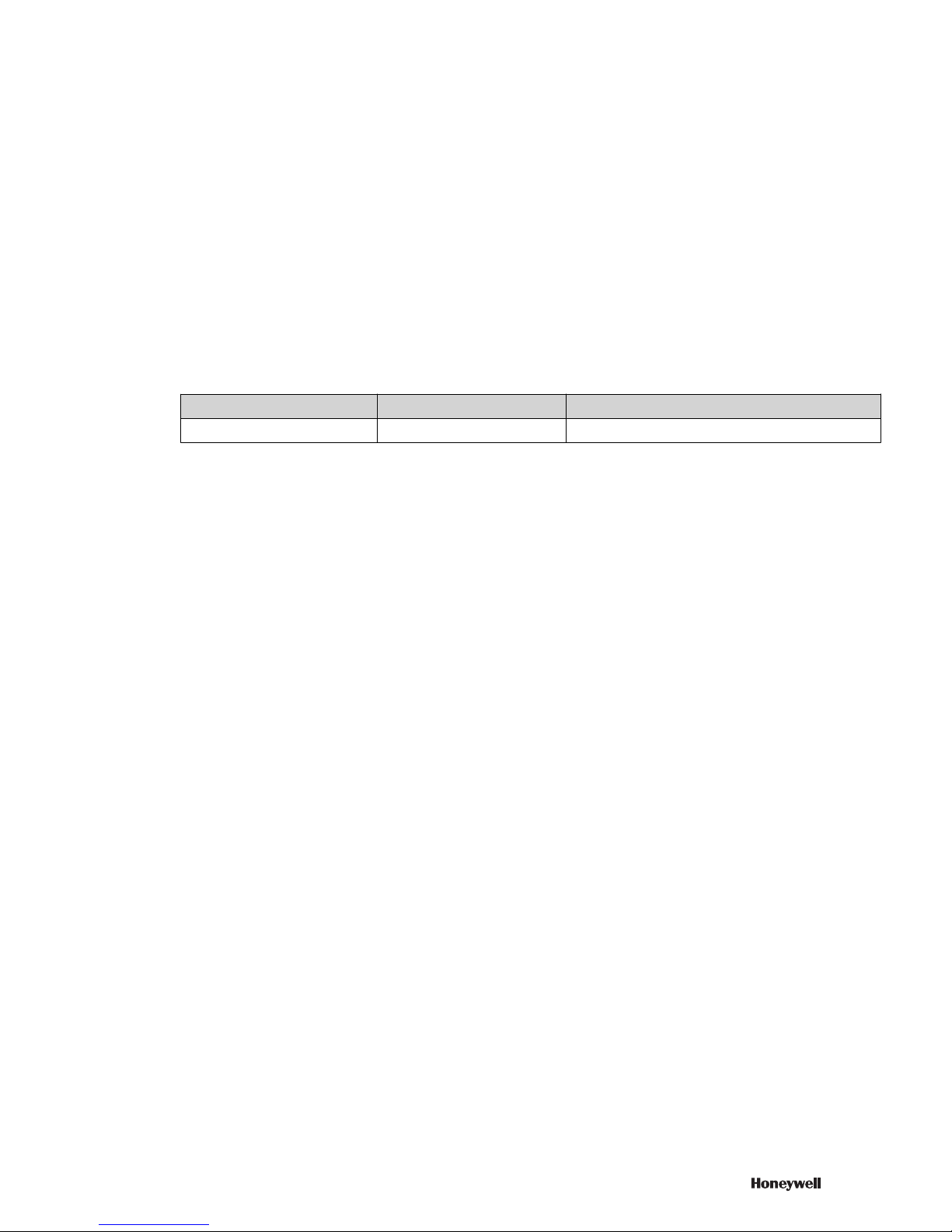

Revision History

Revision Date Description

A April 2017 Initial release of the document

5

Page 6

1 ABOUT THIS DOCUMENT

6 www.honeywell.com

Page 7

2 Overview of CE Compliance

Related topics

“Related products and modules” on page 8

“Compliance statement and standards used” on page 10

“Reference to original tested configuration (in cabinet)” on page 11

7

Page 8

2 OVERVIEW OF CE COMPLIANCE

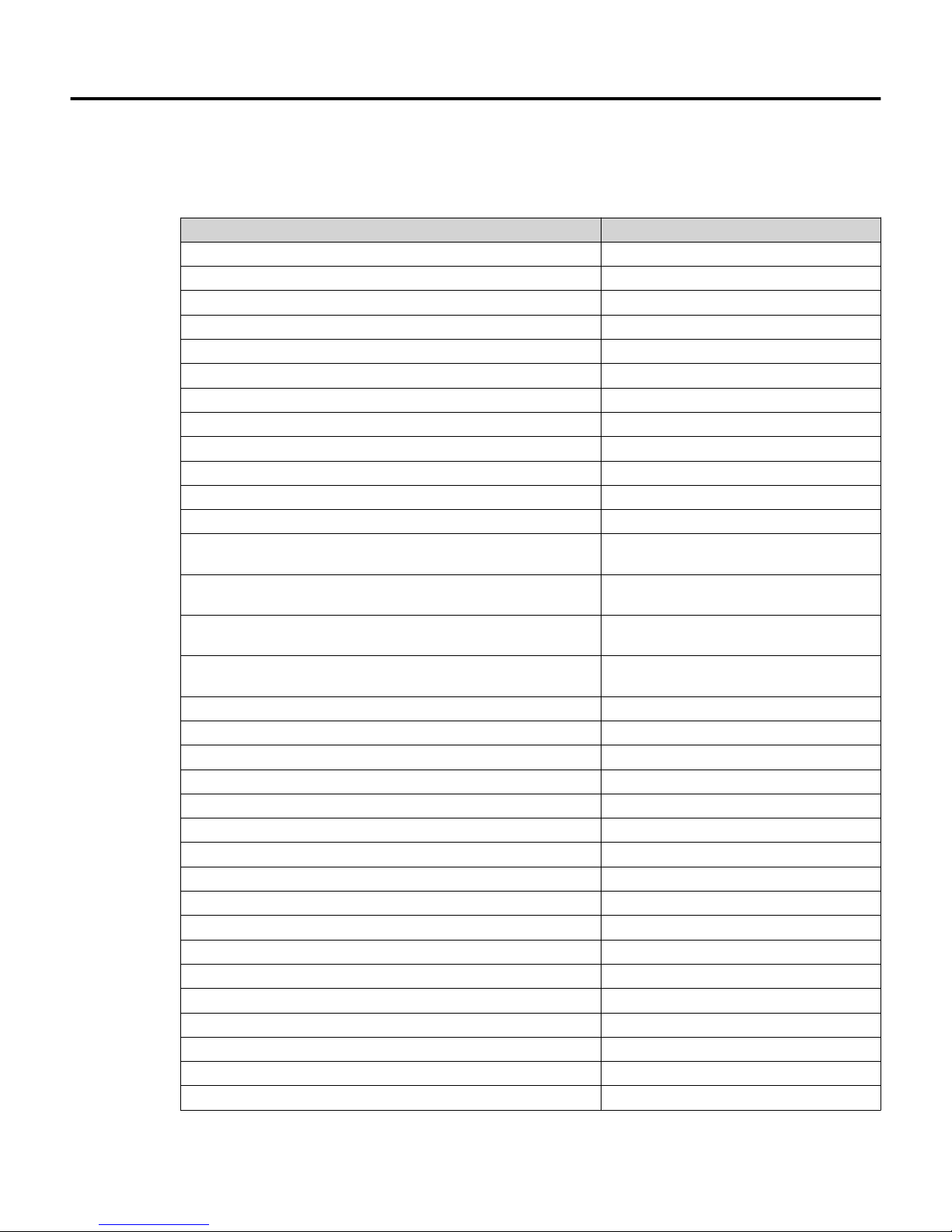

2.1 Related products and modules

Products and modules

Model number Description

8C-PCNT02 C300 Control Processor, coated

8U-PCNT02 C300 Control Processor, uncoated

8C-PAIHA1 HART Analog input module, coated

8U-PAIHA1 HART Analog input module, uncoated

8C-PAINA1 Analog input module, coated

8U-PAINA1 Analog input module, uncoated

8C-PAOHA1 HART Analog output module, coated

8U-PAOHA1 HART Analog output module, uncoated

8C-PAONA1 Analog output module, coated

8U-PAONA1 Analog output module, uncoated

8C-PDILA1 Digital input module, coated

8U-PDILA1 Digital input module, uncoated

8C-PDISA1 Digital input Sequence of Events module,

8U-PDISA1 Digital input Sequence of Events module,

8C-PDIPA1 Digital input Pulse Accumulation module,

8U-PDIPA1 Digital input Pulse Accumulation module,

8C-PDODA1 Digital output module, coated

8U-PDODA1 Digital output module, uncoated

8C-PAIMA1 TC/RTD input module, coated

8U-PAIMA1 TC/RTD input module, uncoated

8C-IP0102 PROFIBUS Gateway module, coated

8U-IP0102 PROFIBUS Gateway module, uncoated

8C-SHEDA1 Header board, coated

8U-SHEDA1 Header board, uncoated

8C-TCNTA1 C300 Controller IOTA, coated

8U-TCNTA1 C300 Controller IOTA, uncoated

8C-TAIXA1 Analog Input IOTA, coated

8U-TAIXA1 Analog Input IOTA, uncoated

8C-TAIXB1 Analog Input redundant IOTA, coated

8U-TAIXB1 Analog Input redundant IOTA, uncoated

8C-TAOXA1 Analog Output IOTA, coated

8U-TAOXA1 Analog Output IOTA, uncoated

8C-TAOXB1 Analog Output redundant IOTA, coated

coated

uncoated

coated

uncoated

8 www.honeywell.com

Page 9

2 OVERVIEW OF CE COMPLIANCE

Model number Description

8U-TAOXB1 Analog Output redundant IOTA, uncoated

8C-TDILA1 Digital Input IOTA, coated

8U-TDILA1 Digital Input IOTA, uncoated

8C-TDILB1 Digital Input redundant IOTA, coated

8U-TDILB1 Digital Input redundant IOTA, uncoated

8C-TDODA1 Digital Output IOTA, coated

8U-TDODA1 Digital Output IOTA, uncoated

8C-TDODB1 Digital Output redundant IOTA, coated

8U-TDODB1 Digital Output redundant IOTA, uncoated

8C-TAIMA1 TC/RTD IOTA, coated

8U-TAIMA1 TC/RTD IOTA, uncoated

8C-TPOXA1 PROFIBUS GATEWAY IOTA, coated

8U-TPOXA1 PROFIBUS GATEWAY IOTA, uncoated

51202971-112 Combo IOLINK cable

CPS20.241 (PULS) AC/DC power supply module

TRIO-PS/1AC/24DC/20 (Phoenix) AC/DC power supply module

SDR-480P-24 (MEAN WELL) AC/DC power supply module

9

Page 10

2 OVERVIEW OF CE COMPLIANCE

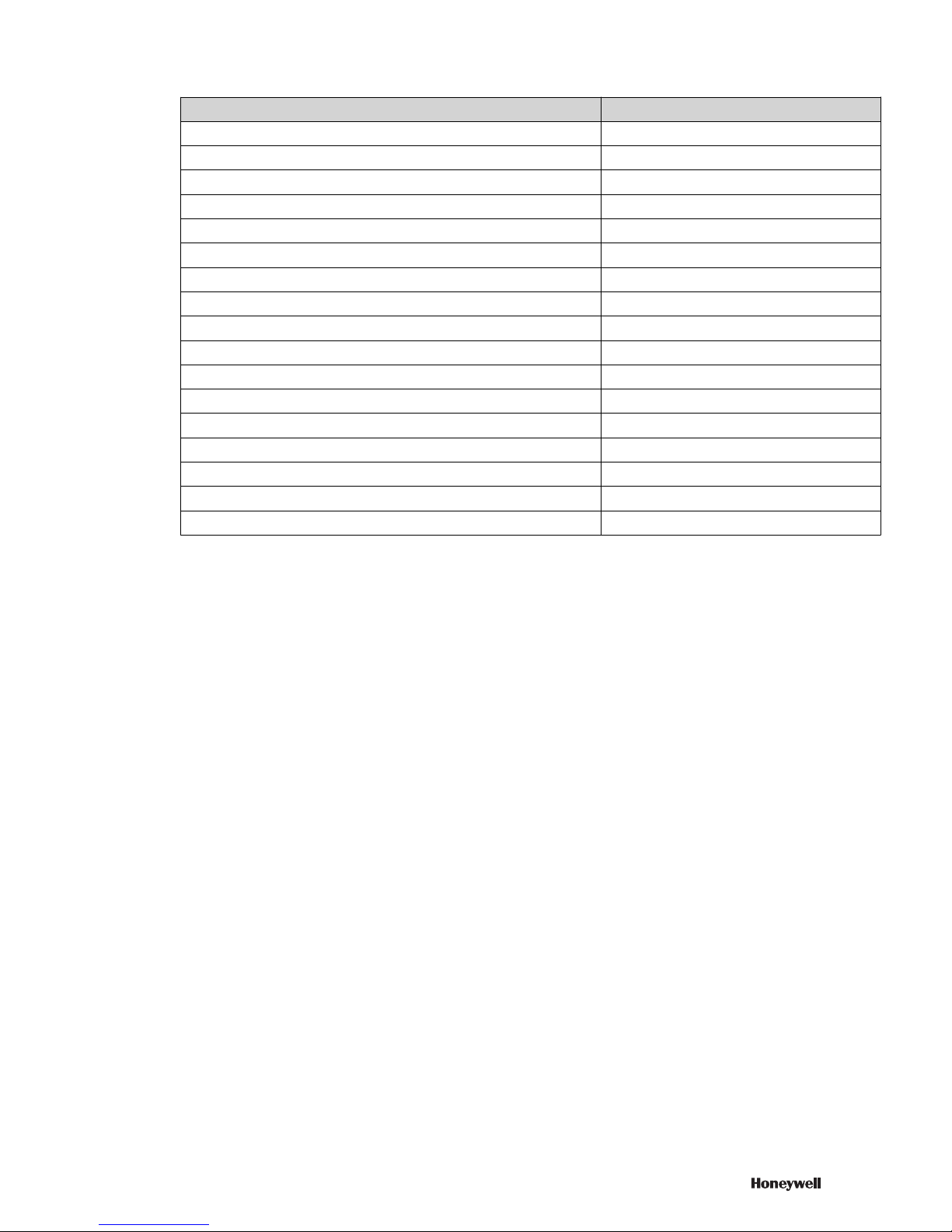

2.2 Compliance statement and standards used

The models specified in the Related Products section conform to the following directives:

• 2004/108/EC Electromagnetic Compatibility (EMC) Directive

• 2006/95/EC Low Voltage (LVD) Directive

The following standards are used for an LVD directive:

Standard Number Standard Name

EN 61010-1:2010 Safety requirements for electrical equipment for

measurement, control, and laboratory use. Part One consists

of general requirements

The following standards are used for an EMC directive:

Standard Number Standard Name

EN 61326-1:2006 Electrical equipment for measurement, control and

laboratory use. EMC requirements are Part One of general

requirements

10 www.honeywell.com

Page 11

2 OVERVIEW OF CE COMPLIANCE

2.3 Reference to original tested configuration (in cabinet)

The C300 controller and PGM modules were tested in cabinet. Other modules were tested independently

without the benefit of cabinet.

11

Page 12

2 OVERVIEW OF CE COMPLIANCE

12 www.honeywell.com

Page 13

3 Mounting and segregation of wiring

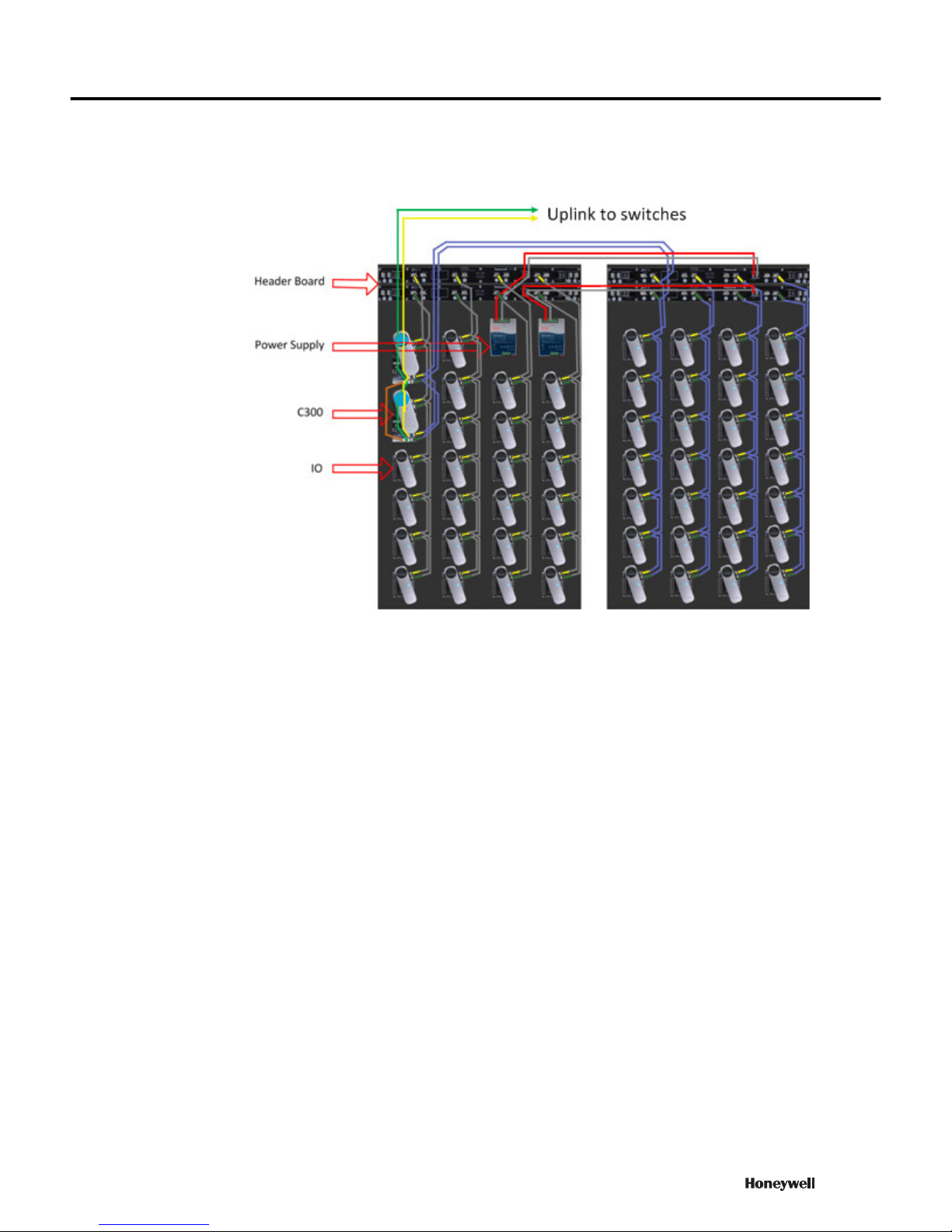

This topic describes the mounting and segregation of wiring. Refer to the illustration below for more

information:

Related topics

“Cabling and wiring” on page 14

“Mounting limitations within a cabinet” on page 16

13

Page 14

3 MOUNTING AND SEGREGATION OF WIRING

3.1 Cabling and wiring

The following table describes the procedure for cabling and wiring.

1

Determine physical installation and routing. See illustration for more information:

2

Consider cable type, cable distance, and redundant cable run paths while laying cables.

3

Avoid installing cables through areas of high human traffic and high EMI/RFI.

4

Determine the maximum cable lengths and the number of drops.

5

Prepare a wiring list.

6

Maintain a blueprint with the location of wiring.

7

Plan for expansion.

8

Plan for diagnostics such as attachment spots for diagnostic tools like a protocol analyzer. See illustration

below for more information:

14 www.honeywell.com

Page 15

3 MOUNTING AND SEGREGATION OF WIRING

15

Page 16

3 MOUNTING AND SEGREGATION OF WIRING

3.2 Mounting limitations within a cabinet

The following mounting limitations within a cabinet exist for Series 8:

• The Power System provides +24 VDC power to compatible assemblies through the header board on top of

one or more cabinets.

• The top connector of the topmost drop cable plugs into a connector on the header board. Use this cable to

connect to all the Series 8 IOTAs. These have three kinds of dimensions: six-inches (152 mm), nine inches

(229 mm) and 12 inches (305 mm).

• An extension cable is used to extend the I/O link to another cabinet side. It can plug into taps on a header

board, at the end of a header board, or at the bottom of a drop cable (although this is not normally done).

Extension cables are normally used to extend a header board to another cabinet side in a complex.

16 www.honeywell.com

Page 17

4 Bonding and grounding

This chapter provides more information about bonding and grounding

Related topics

“Cabinet safety ground connections” on page 18

“Power supply grounding considerations” on page 20

17

Page 18

4 BONDING AND GROUNDING

4.1 Cabinet safety ground connections

Adequate grounding is important for safety considerations and for reducing electromagnetic noise interference.

All earth-ground connections must be permanent and provide a continuous low impedance path to earth ground

for induced noise currents and fault currents. Refer to the following guidelines when considering the grounding

requirements of your system:

Grounding requirements

For safe operations of your equipment, a high-integrity grounding system must be installed as part of the

building's wiring system.

• An equipment ground wire must be enclosed with the circuit conductors (phase and neutral wires).

• The size of the ground conductor must be the same as, or larger, than the circuit conductors supplying the

equipment.

• The ground conductor must be securely bonded to the building-ground electrode.

• Grounding provisions must be in accordance with the NEC, CEC, and any other local codes.

• Ensure that the cabinet enclosure is connected to a protective earth ground using at least a #8 AWG solid

copper wire. There should be metal to metal contact between the grounding bus bar and the enclosure as

well as the channel. See the illustration below for more information:

The following illustration and callout table identifies typical safety ground connections in the cabinet. For

Honeywell assembled cabinets, all power and ground connections within the cabinet are made by Honeywell

manufacturing. The illustration is not to scale nor are component positions representative of actual mounting

locations within the cabinet. See illustration below for more information:

Callout Description

1 The AC safety ground bar is mounted to the cabinet frame.

2 To the cabinet front or rear AC safety ground bar if required.

3 To the cabinet complex front or rear AC safety ground bar as required.

4 To a supplementary ground connection, if required.

5 The local ground bar is mounted to the cabinet frame, if required

See illustration below for more information:

18 www.honeywell.com

Figure 1: Power and ground connections

Page 19

Figure 2: Typical safety ground connections in cabinet

4 BONDING AND GROUNDING

19

Page 20

4 BONDING AND GROUNDING

4.2 Power supply grounding considerations

AC Safety Ground System (mains ground)

The safety ground protects the plant power system, electrical equipment, and personnel from electric shock. All

metal equipment and enclosures are connected to this system through the ground wire. If insulated, the ground

wire color is normally green. The ground wire and neutral wire are connected to the mains ground rods or grid

located where the power enters the building or job area as shown in the following figure. It also describes a

typical AC power source through the mains panel with a safety ground bus and an AC safety (mains) ground

rod.

Termination of any required cable shields

The shield of the cable must be grounded.

20 www.honeywell.com

Page 21

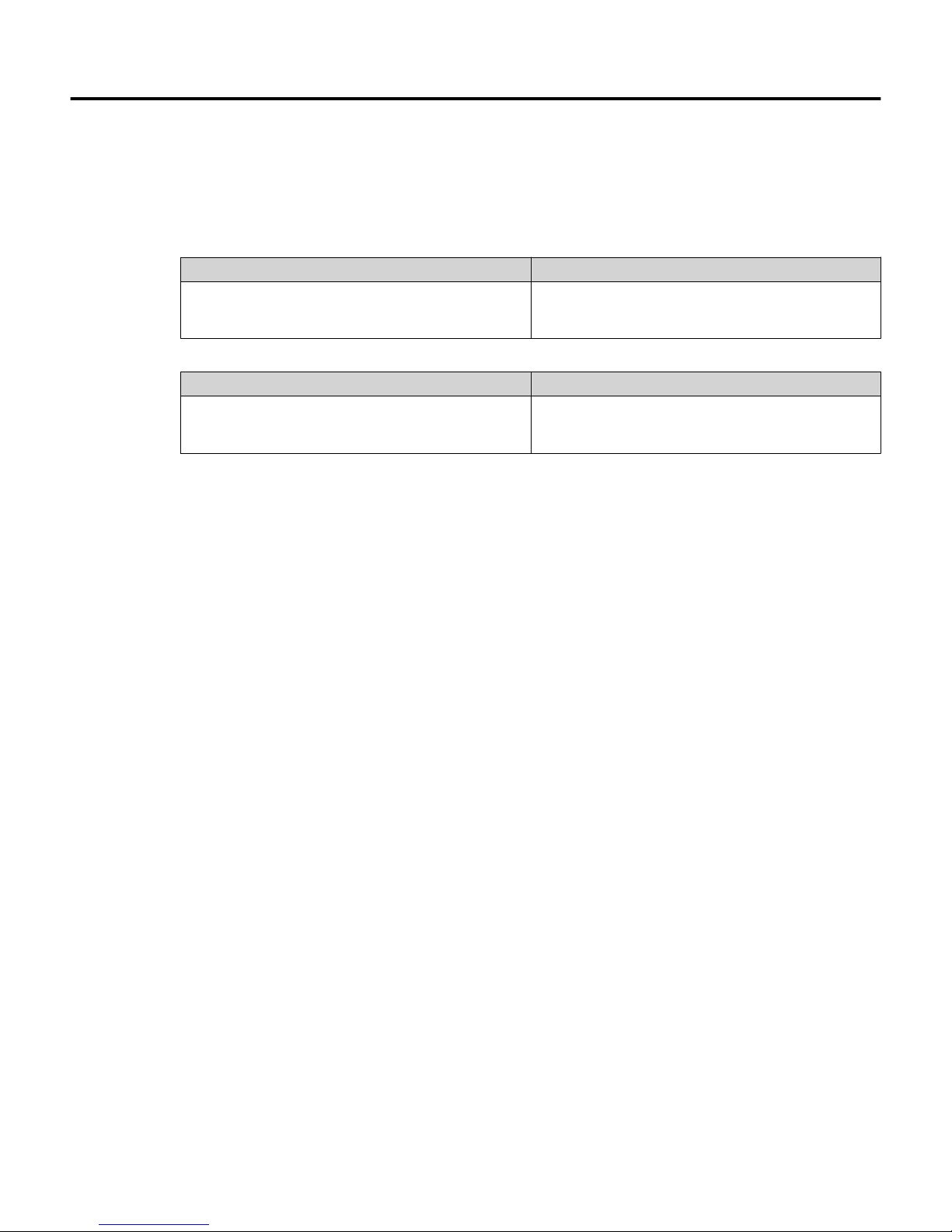

5 Power supply selection and distribution

Series 8 system CE Compliance requires the following manufacturers and model power supplies:

Manufacturer Model number

PULS CPS20.241

MEAN WELL SDR-480P-24

Phoenix TRIO-PS/1AC/24DC/20

Refer to the corresponding manuals of each manufacturer’s for installation limitations.

Related topics

“Selecting the Power System” on page 22

“Power Distribution System” on page 23

21

Page 22

5 POWER SUPPLY SELECTION AND DISTRIBUTION

5.1 Selecting the Power System

The Power System provides +24 VDC power to compatible assemblies through the header board at the top of

one or more cabinet.

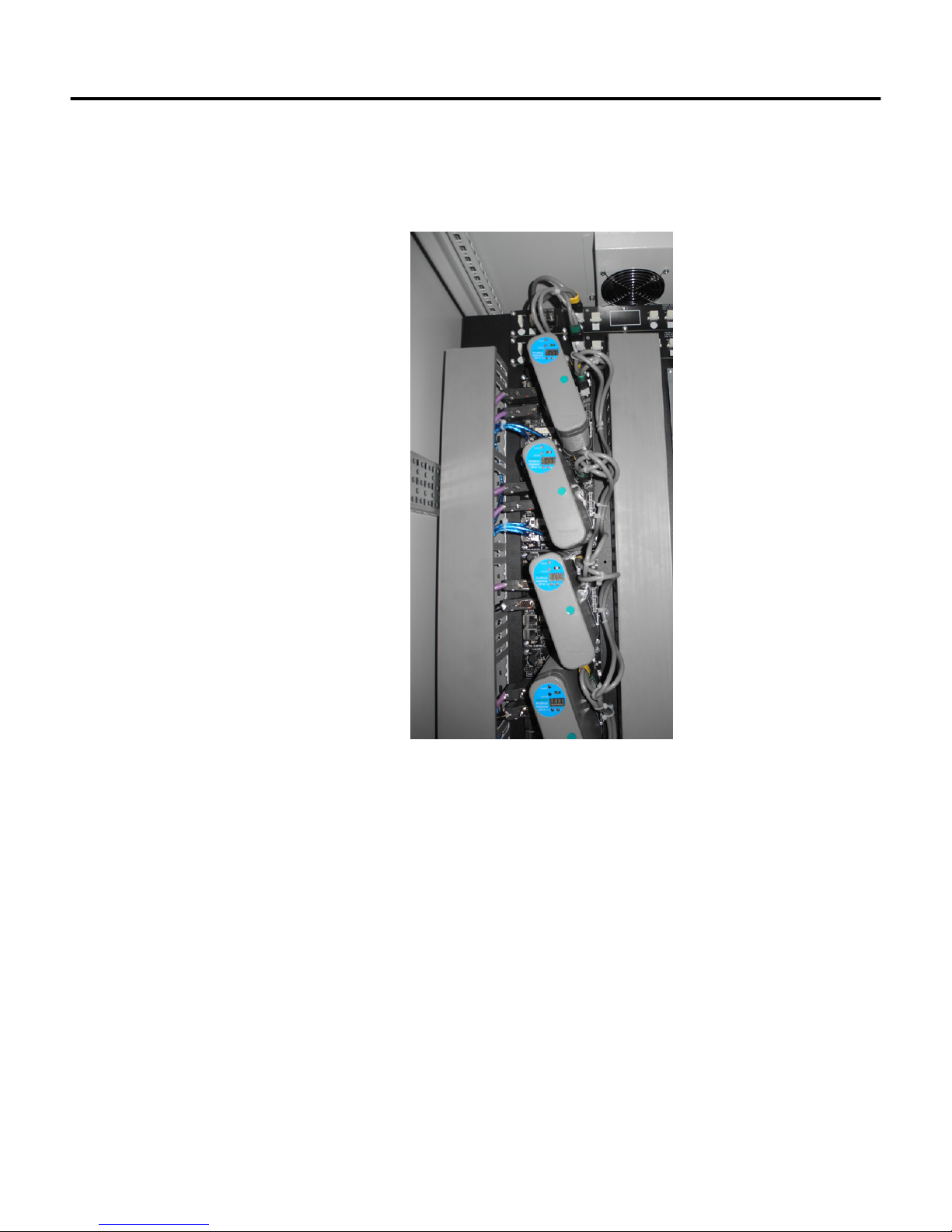

Power system parts

The power systems provide 24 VDC power to assemblies that are compatible in one or more cabinet sides. Each

power system includes the following:

• The metal piece that holds power supplies

• Two 20A Power Supply 120/240 VAC

See illustration below for more information:

22 www.honeywell.com

Page 23

5.2 Power Distribution System

The power distribution subsystem consists of the hardware listed in the following table. It distributes 24 VDC

from a power system to one or more columns of mounting plates in one or both sides of a cabinet that contains

the power system.

The following hardware requirements are prerequisites for the power distribution subsystem.

• The power system mentioned in the Selecting Power System section.

• Two header boards (51307186)

• Select power cables greater than or equal to 16AWG for AC. Maximum current of the header board is 20 A

See illustration below for more information:

5 POWER SUPPLY SELECTION AND DISTRIBUTION

Figure 3: Cabling for the power distribution subsystem

23

Page 24

5 POWER SUPPLY SELECTION AND DISTRIBUTION

24 www.honeywell.com

Page 25

6 CE Limitations

The following topics provide more information about operating conditions for components, shielded twisted

pair (STP) cables and ESD issues.

Related topics

“Operation environment and shielded wiring” on page 26

“ESD issues” on page 27

“Transient protection required” on page 28

25

Page 26

6 CE LIMITATIONS

6.1 Operation environment and shielded wiring

The operating conditions for components are as follows:

Attributes Values

Storage temperature: -40°C to +85°C (–40°F to +185°F)

Ambient temperature (T4) 0°C to +60°C (32°F to +140°F)

Relative humidity: 5% to 95% (non-condensing)

Vibration (sinosoidal): Excitation: sine-shaped with sliding frequency

Shock 15 G in 3 axes (shock duration: 11 ms)

Shielded wiring required

Ethernet cables are used in cabinets to interconnect C300 Controller IOTAs. Only a shielded twisted pair (STP)

type cable is used. The use of unshielded twisted pair (UTP) cable is not allowed.

• Frequency range: 10-150 Hz

• Loads: 10 Hz— 57 Hz: 0.075 mm

• Loads: 57 Hz-150 Hz: 1 G

• Number. of axes: 3 (x, y, z)

• Traverse rate: 1 oct/min.

26 www.honeywell.com

Page 27

6.2 ESD issues

Static electrical charges

Static electricity can influence electronic equipment, and cause equipment malfunctions or damage. The effects

may range from momentary glitches to outright failures, data loss, and intermittent failures that are difficult to

locate and correct. The situation becomes even more acute with high-resistance materials, such as carpets and

plastic seat covers, in work areas that are not environmentally controlled. Devices and techniques that can be

used to reduce electrostatic discharge include:

• An increase in the relative humidity:This may be practical in only relatively small, closed work areas.

• Conductive over-covering for shoes

• Antistatic floor surfaces: These floor surfaces have all the attributes of conventional floor surfaces, except

they are conductive to suppress static electrical build-up.

• Low-pile antistatic carpets: These carpets are conductive to suppress static electricity. Carpets are available

in a wide variety of patterns and colors, can be placed over most existing floor surfaces and some carpets.

• Antistatic grounded pads: These pads are for operator work station areas, and can be placed over most

existing floor surfaces and carpets. They are meant primarily for the immediate vicinity of the work area,

and require proper grounding.

• Avoiding synthetic materials: Avoid linoleum and synthetic carpets, and other materials that generate static.

If such floor coverings are already in place, antistatic mats can be installed on the floor near the terminals.

6 CE LIMITATIONS

27

Page 28

6 CE LIMITATIONS

6.3 Transient protection required

Why do they occur?

Transient electromagnetic interference (EMI) can be generated whenever inductive loads (such as relays,

solenoids, motor starters, or motors) are operated by hard contacts (such as pushbutton or selector switches).

The wiring guidelines are based on the assumption that you guard your system against the effects of transient

EMI by using surge-suppressors; these will suppress transient EMI at its source. Inductive loads switched by

solid-state output devices alone do not require surge-suppression. However, inductive loads of ac output

modules (that are in series or parallel with hard contacts) require surge-suppression to protect the module output

circuits as well as to suppress transient EMI.

Surge-suppressors

Surge-suppressors are usually most effective when connected at the inductive loads. They are still usable when

connected at the switching devices; however, this may be less effective, because the wires connecting the

switching devices to the inductive loads act as antennas that radiate EMI. You can see the effectiveness of a

particular suppressor by using an oscilloscope to observe the voltage waveform on the line.

28 www.honeywell.com

Page 29

7 Maintenance

Related topics

“C300 controller module and IOTA replacement” on page 30

“PGM Replacement” on page 32

“Series 8 IOTA and I/O module Replacement” on page 34

29

Page 30

7 MAINTENANCE

7.1 C300 controller module and IOTA replacement

To replace a non-redundant controller module, perform the following steps:

Prerequisites

• These procedures can only be performed while off process.

• We recommend that you proceed with extreme caution whenever replacing any component in a control

system.

• Be sure the system is offline or in a safe operating mode.

• Component replacements may also require corresponding changes in the control strategy configuration

through Control Builder, as well as downloading appropriate data to the replaced component.

• Note that all modules are keyed.

1

Loosen screws at each side of the module cover that secures the controller module to the IOTA board.

2

Carefully remove the Controller module from the IOTA board and connector.

3

Insert the new controller module onto the IOTA board making sure that the controller circuit board mates

properly with the IOTA board connector.

4

Secure the controller module to the IOTA board with two screws located at each side of the plastic cover.

5

The new controller will boot-up to ALIVE or NODB state.

6

Load firmware. Ensure that the version is the same as was running on the old controller.

7

On Control Builder, perform a Load with Contents to the controller.

To replace a non-redundant controller IOTA board, perform the following steps.

1

On the defective IOTA, loosen screws at each side of the module cover that secures the controller module to

the IOTA board.

2

Carefully remove the controller module from the IOTA board and connector.

3

Label and disconnect all cables from the IOTA board connectors, (yellow and green FTE cables, gray and

violet I/OLink cables, and Battery cable).

4

Loosen the four mounting screws only half-way that secure the IOTA board to the channel.

5

Remove completely the four mounting screws securing the IOTA board to the channel and remove the

IOTA.

6

Place screws, washers and spacers aside for reassembly.

7

Assemble screws, washers and spacers on the new IOTA board. Mount new controller IOTA board on the

channel at the same position as the old IOTA board.

8

Insert and thread the four mounting screws only half-way to attach the IOTA board to the channel. Do not

tighten.

9

Tighten the four mounting screws securing the IOTA board to the channel.

10

Set the Device Index address to the same address as the old IOTA using the three rotory FTE DEVICE

INDEX switches.

11

Connect FTE-A and FTE-B Ethernet link cables to the RJ-45 connectors on C300 IOTA board.

12

The yellow Cat5 cable connects to the FTEA connector on the IOTA.

13

The green Cat5 cable connects to the FTEB connector on the IOTA.

14

Connect I/O Link cables to IOTA board, if present.

a

Connect the gray I/O LINK cable to IOL1A and IOL1B for IOLINK 1 interface of the controller.

b

Connect the violet IOLINK cable to IOL2A and IOL2B for IOLINK 2 interface of the controller.

15

Install the two-wire twisted pair battery cables onto the Memory Hold Up connector on the left side of the

IOTA board.

30 www.honeywell.com

Page 31

7 MAINTENANCE

16

Insert the controller module onto the IOTA board making sure that the controller circuit board mates

properly with the IOTA board connector.

17

Secure the controller module to the IOTA board with two screws located at each side of the plastic cover.

18

The controller will boot-up into an Alive state or a NODB operating state.

19

In Control Builder, perform a Load with Contents to the controller.

31

Page 32

7 MAINTENANCE

7.2 PGM Replacement

CAUTION

We recommend that you proceed with extreme caution whenever replacing any component in a control system. Be

sure the system is offline or in a safe operating mode. Component replacements may also require corresponding

changes in the control strategy configuration through Control Builder, as well as downloading appropriate data to

the replaced component.

Prerequisites

• This procedure can be performed only while off process. See illustration below for more information:

To replace a non-redundant PGM:

1

Loosen screws at each side of the module cover that secures the PGM to the IOTA board.

2

Loosen the plastic screw on the front of the PGM cover. Be careful not to strip the plastic screw head.

3

Carefully remove the PGM from the IOTA board and connector.

4

Insert the new PGM onto the IOTA board making sure that the PGM circuit board mates properly with the

IOTA board connector.

5

Secure the PGM to the IOTA board with two screws located at each side of the plastic cover.

6

Using a #2 Phillips screwdriver, hand tighten the plastic screw on the front of the module cover. Be careful

not to strip the plastic screw head.

7

The new PGM boots up to Alive or NODB state.

8

Load firmware which is the same version as was running in the old PGM.

9

From Control Builder, perform a Load with Contents to the PGM.

32 www.honeywell.com

Page 33

7 MAINTENANCE

To replace a non-redundant PGM IOTA board

1

On the defective IOTA, loosen the screws at each side of the module cover that secures the PGM to the

IOTA board.

2

Loosen the plastic screw on the front of the module cover. Be careful not to strip the plastic screw head.

3

Carefully remove the PGM from the IOTA board and connector.

4

Label and disconnect all cables from the IOTA board connectors, (yellow and green FTE cables and PBLink

cables).

5

Loosen the four mounting screws only half-way that secure the IOTA board to the channel.

6

Remove the screw from the left side of the IOTA board.

7

Remove the screw from the right side of the IOTA board that connects to the COM bus bar.

8

Remove completely the four mounting screws securing the IOTA board to the channel and remove the

IOTA.

9

Place screws, washers and spacers aside for reassembly.

10

Assemble screws, washers and spacers on the new IOTA board.

11

Mount the new PGM IOTA board on the channel at the same position as the old IOTA board.

12

Insert and thread the four mounting screws only half-way to attach the IOTA board to the channel.

13

Insert and tighten the screw to the left side of the IOTA board.

14

Insert and tighten the screw to the right side of the IOTA board that connects to the COM bus bar.

15

Tighten the four mounting screws securing the IOTA board to the channel.

16

Set the Device Index Address to the same address as the old IOTA using the three rotary FTE Device

Index switches.

17

Connect the FTE-A and FTE-B Ethernet link cables to the RJ-45 connectors on the PGM IOTA board. The

yellow Cat5 cable connects to the FTEA connector on the IOTA. The green Cat5 cable connects to the

FTEB connector on the IOTA.

18

Connect the PBLink cables to the IOTA board.

19

Insert the PGM onto the IOTA board making sure that the PGM circuit board synchronises properly with the

IOTA board connector.

20

Secure the PGM to the IOTA board with two screws located at each side of the plastic cover.

21

Using a #2 Phillips screwdriver, tighten the plastic screw on the front of the module cover. Be careful not to

strip the plastic screw head.

22

The PGM boots up into an Alive state or a NODB operating state.

23

Perform a Load with Contents to the PGM.

Next steps

CAUTION

We recommend that you proceed with extreme caution whenever replacing any component in a control system. Be

sure the system is offline or in a safe operating mode. Component replacements may also require corresponding

changes in the control strategy configuration through the Control Builder; as well as downloading appropriate data

to the replaced component.

33

Page 34

7 MAINTENANCE

7.3 Series 8 IOTA and I/O module Replacement

Prerequisites

• Replacing the Series 8 IOTA, requires that the IOM is in an inactive offprocess state.

To replace a Series 8 IOTA:

1

Label and disconnect all cables from the IOTA board connectors.

2

To remove the IOTA board, it is recommended that you perform the following steps:

a

Remove the IOTA from the panel by loosening the IOTA's mounting screws only half-way one by one.

b

Completely remove the IOTA's mounting screws.

c

Place screws, washers, and spacers in a secure place for potential reuse.

3

Select the mounting location on the carrier and align the mounting holes in the IOTA with screw-hole

locations on the carrier. Ensure that the component side of IOTA is facing up.

a

When mounting either the 9 or 12 inch IOTA board, it is recommended that you secure the three

mounting screws on one side (either left or right) and then secure the other side.

Tip

Securing the four corner screws and the two middle screws may cause bowing of the board and impact the

alignment of the IOTA board to the carrier holes and is not recommended.

4

Insert the I/O module onto the IOTA board making sure that the I/O circuit board mates properly with the

IOTA board connector. Secure the module to the IOTA board with two screws located at each side of the

plastic cover.

5

The I/O module boots-up into Idle state.

6

In Control Builder, perform a Load with Contents procedure.

To replace a Series 8 I/O module:

•

You have logged onto Control Builder with sufficient security level to make control strategy changes. You

can perform the following tasks:

a

You can remove and install the Series 8 IOM under power.

b

Ensure you take ESD hazard precautions when handling the module and IOTA.

CAUTION

We recommend that you proceed with extreme caution whenever replacing any component in a control

system. Ensure the system is offline or in a safe operating mode. Component replacements may also require

corresponding changes in the control strategy configuration through Control Builder, as well as downloading

appropriate data to the replaced component.

To replace an I/O module:

1

Remove the I/O module from the IOTA board and connector.

2

Insert the new I/O module onto IOTA board making sure that the I/O circuit board mates properly with the

IOTA board connector.

3

Secure the module to the:

a

IOTA board using the two metal screws at the plastic cover.

b

Carrier with the long screw that is inserted into the hole on the face of the module's plastic cover.

c

The new I/O module boots-up to the Idle state.

4

Load firmware which is the same version as was running in the old controller.

34 www.honeywell.com

Page 35

5

In the Control Builder, perform a Load with Contents.

Results

<replace with description of results>

7 MAINTENANCE

35

Page 36

7 MAINTENANCE

36 www.honeywell.com

Page 37

8 Declaration of conformity

Please see the attached CE DOC_Series 8 R110.2.

Model Number Description Rating

8C-PCNT02 C300 Control Processor, coated 24Vdc, 320mA

8U-PCNT02 C300 Control Processor,

8C-PAIHA1 HART Analog input module,

8U-PAIHA1 HART Analog input module,

8C-PAINA1 Analog input module, coated 24Vdc, 105mA

8U-PAINA1 Analog input module, uncoated 24Vdc, 105mA

24Vdc, 320mA

uncoated

24Vdc, 110mA

coated

24Vdc, 110mA

uncoated

37

Page 38

8 DECLARATION OF CONFORMITY

Model Number Description Rating

8C-PAOHA1 HART Analog output module,

8U-PAOHA1 HART Analog output module,

8C-PAONA1 Analog output module, coated 24Vdc, 190mA

8U-PAONA1 Analog output module,

8C-PDILA1 Digital input module, coated 24Vdc, 95mA

8U-PDILA1 Digital input module, uncoated 24Vdc, 95mA

8C-PDISA1 Digital input Sequence of

8U-PDISA1 Digital input Sequence of

8C-PDIPA1 Digital input Pulse

8U-PDIPA1 Digital input Pulse

8C-PDODA1 Digital output module, coated 24Vdc,105mA

8U-PDODA1 Digital output module,

8C-PAIMA1 TC/RTD input module, coated 24Vdc, 120mA

8U-PAIMA1 TC/RTD input module,

8C-IP0102 PROFIBUS Gateway module,

R110.1 Series 8 Cabinet

Installation Instruction 35

January 2014 Honeywell

Confidential & Proprietary

8U-IP0102

8C-SHEDA1 Header board, coated 24Vdc, 20A

8U-SHEDA1 Header board, uncoated 24Vdc, 20A

8C-TCNTA1 C300 Controller IOTA, coated 24Vdc, 20A

8U-TCNTA1 C300 Controller IOTA,

8C-TAIXA1 Analog Input IOTA, coated 24Vdc

8U-TAIXA1 Analog Input IOTA, uncoated 24Vdc

8C-TAIXB1 Analog Input redundant IOTA,

8U-TAIXB1 Analog Input redundant IOTA,

8C-TAOXA1 Analog Output IOTA, coated 24Vdc

8U-TAOXA1 Analog Output IOTA, uncoated 24Vdc

8C-TAOXB1 Analog Output redundant

coated

uncoated

uncoated

Events module, coated

Events module, uncoated

Accumulation module, coated

Accumulation module,

uncoated

uncoated

uncoated

coated

PROFIBUS Gateway module,

uncoated

uncoated

coated

uncoated

IOTA, coated

24Vdc, 205mA

24Vdc, 205mA

24Vdc, 190mA

24Vdc, 95mA

24Vdc, 95mA

24Vdc, 105mA

24Vdc, 105mA

24Vdc,105mA

24Vdc, 120mA

24Vdc, 430mA

24Vdc, 430mA

24Vdc

24Vdc

24Vdc

24Vdc

38 www.honeywell.com

Page 39

Model Number Description Rating

8U-TAOXB1 Analog Output redundant

24Vdc

IOTA, uncoated

8C-TDILA1 Digital Input IOTA, coated 24Vdc

8U-TDILA1 Digital Input IOTA, uncoated 24Vdc

8C-TDILB1 Digital Input redundant IOTA,

24Vdc

coated

8U-TDILB1 Digital Input redundant IOTA,

24Vdc

uncoated

8C-TDODA1 Digital Output IOTA, coated 24Vdc

8U-TDODA1 Digital Output IOTA, uncoated 24Vdc

8C-TDODB1 Digital Output redundant

24Vdc

IOTA, coated

8U-TDODB1 Digital Output redundant

24Vdc

IOTA, uncoated

8C-TAIMA1 TC/RTD IOTA, coated 24Vdc

8U-TAIMA1 TC/RTD IOTA, uncoated 24Vdc

8C-TPOXA1 PROFIBUS GATEWAY IOTA,

24Vdc

coated

8U-TPOXA1 PROFIBUS GATEWAY IOTA,

24Vdc

uncoated

51202971-112 Combo IOLINK cable 24Vdc

CPS20.241 (PULS) AC/DC power supply module 100-240V, 6.4-2.7A,

50-60Hz;

TRIO-PS/1AC/24DC/20

AC/DC power supply module 100-240V,6-3A, 50-60Hz

(Phoenix)

SDR-480P-24 (MEAN

AC/DC power supply module 100-240V,5A, 50/60Hz

WELL)

8 DECLARATION OF CONFORMITY

39

Page 40

8 DECLARATION OF CONFORMITY

40 www.honeywell.com

Page 41

9 Conclusions

Related topics

“Conclusions” on page 42

41

Page 42

9 CONCLUSIONS

9.1 Conclusions

Refer to the following statement of Honeywell for the compliance of the CE standard:

• The SI must provide final judgment regarding the CE Conformity of the assembled cabinet

• Honeywell does not take responsibility for the CE Conformity of the assembled cabinet.

• SI responsibility is inclusive of third-party assemblies that are included within the assembled cabinet

42 www.honeywell.com

Page 43

10 Notices

Trademarks

Experion® and SafeBrowse® are registered trademarks of Honeywell International, Inc.

Other trademarks

Microsoft and SQL Server are either registered trademarks or trademarks of Microsoft Corporation in the

United States and/or other countries.

Trademarks that appear in this document are used only to the benefit of the trademark owner, with no intention

of trademark infringement.

Third-party licenses

This product may contain or be derived from materials, including software, of third parties. The third party

materials may be subject to licenses, notices, restrictions and obligations imposed by the licensor. The licenses,

notices, restrictions and obligations, if any, may be found in the materials accompanying the product, in the

documents or files accompanying such third party materials, in a file named third_party_licenses on the media

containing the product, or at http://www.honeywell.com/ps/thirdpartylicenses.

Documentation feedback

You can find the most up-to-date documents on the Honeywell Process Solutions support website at:

http://www.honeywellprocess.com/support

If you have comments about Honeywell Process Solutions documentation, send your feedback to:

hpsdocs@honeywell.com

Use this email address to provide feedback, or to report errors and omissions in the documentation. For

immediate help with a technical problem, contact your local Honeywell Technical Assistance Center (TAC).

How to report a security vulnerability

For the purpose of submission, a security vulnerability is defined as a software defect or weakness that can be

exploited to reduce the operational or security capabilities of the software.

Honeywell investigates all reports of security vulnerabilities affecting Honeywell products and services.

To report a potential security vulnerability against any Honeywell product, please follow the instructions at:

https://honeywell.com/pages/vulnerabilityreporting.aspx

Submit the requested information to Honeywell using one of the following methods:

• Send an email to security@honeywell.com.

or

• Contact your local Honeywell Technical Assistance Center (TAC) listed in the “Support” section of this

document.

43

Page 44

10 NOTICES

Support

For support, contact your local Honeywell Process Solutions Customer Contact Center (CCC). To find your

local CCC visit the website, https://www.honeywellprocess.com/en-US/contact-us/customer-support-contacts/

Pages/default.aspx.

Training classes

Honeywell holds technical training classes about Experion LX. These classes are taught by experts in the field

of process control systems. For more information about these classes, contact your Honeywell representative, or

see http://www.automationcollege.com.

44 www.honeywell.com

Loading...

Loading...