Page 1

Experion

C300 Controller

User's Guide

EP-DCX464

R301.1

11/06

Page 2

Notices and Trademarks

Copyright 2006 by Honeywell International Inc.

Release 301.1 November 27, 2006

While this information is presented in good faith and believed to be accurate, Honeywell disclaims

the implied warranties of merchantability and fitness for a particular purpose and makes no

express warranties except as may be stated in its written agreement with and for its customers.

In no event is Honeywell liable to anyone for any indirect, special or consequential damages. The

information and specifications in this document are subject to change without notice.

Honeywell, PlantScape, Experion, and TotalPlant are registered trademarks of Honeywell

International Inc.

Other brand or product names are trademarks of their respective owners.

Honeywell International

Process Solutions

2500 West Union Hills

Phoenix, AZ 85027

1-800 343-0228

ii Experion C300 Controller User's Guide R301.1

Honeywell 11/06

Page 3

About This Document

This guide provides information that will assist you in planning and designing activities, as well as

the installation, operation, and troubleshooting of C300 Process Controllers in an Experion

system.

Release Information

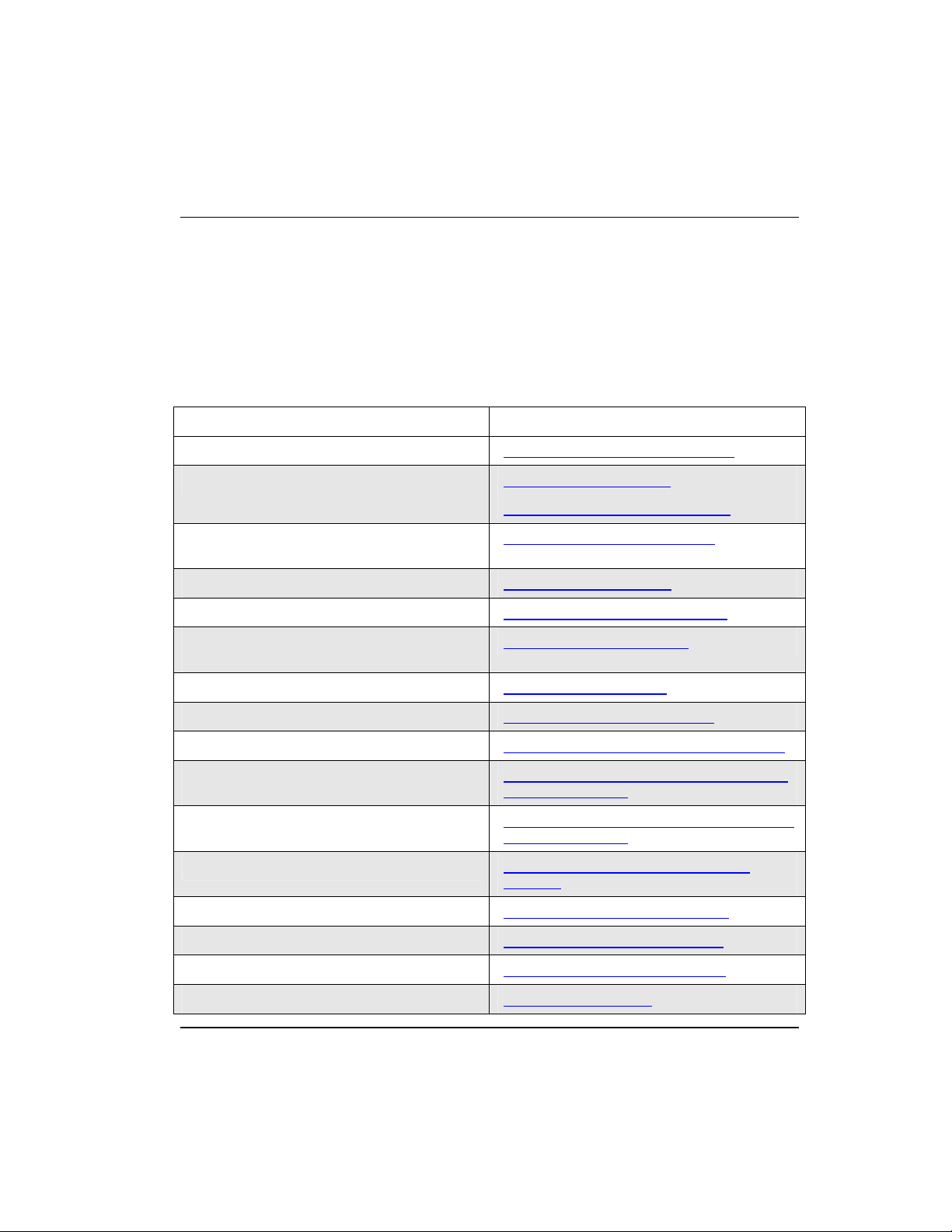

Document Name Document ID

C300 Controller User's Guide - ccig EP-DCX464 301.1 11/06

References

The following list identifies all documents that may be sources of reference for material discussed

in this publication.

Document Title

Release

Number

Publication

Date

Contacts

World Wide Web

The following Honeywell web sites may be of interest to Process Solutions customers.

Honeywell Organization WWW Address (URL)

Corporate

Honeywell Process Solutions

R301.1 Experion C300 Controller User's Guide iii

11/06 Honeywell

http://www.honeywell.com

http://hpsweb.honeywell.com

Page 4

About This Document

Contacts

Telephone

Contact us by telephone at the numbers listed below.

Location Organization Phone

United States

and Canada

Europe Honeywell TAC-EMEA +32-2-728-2704

Pacific

India

Korea

People’s

Republic of

China

Singapore

Taiwan

Japan

Elsewhere

Honeywell IAC Solution

Support Center

Honeywell Global TAC Pacific

Honeywell Global TAC India

Honeywell Global TAC Korea

Honeywell Global TAC China

Honeywell Global TAC South East Asia

Honeywell Global TAC Taiwan

Honeywell Global TAC Japan

Call your nearest

Honeywell office.

1-800-822-7673

1300-300-4822

(toll free within Australia)

+61-8-9362-9559

(outside Australia)

+91-20-2682-2458

+82-2-799-6317

+86-10-8458-3280 ext. 361

+65-6580-3500

+886-7-323-5900

+81-3-5440-1303

iv Experion C300 Controller User's Guide R301.1

Honeywell 11/06

Page 5

About This Document

Symbol Definitions

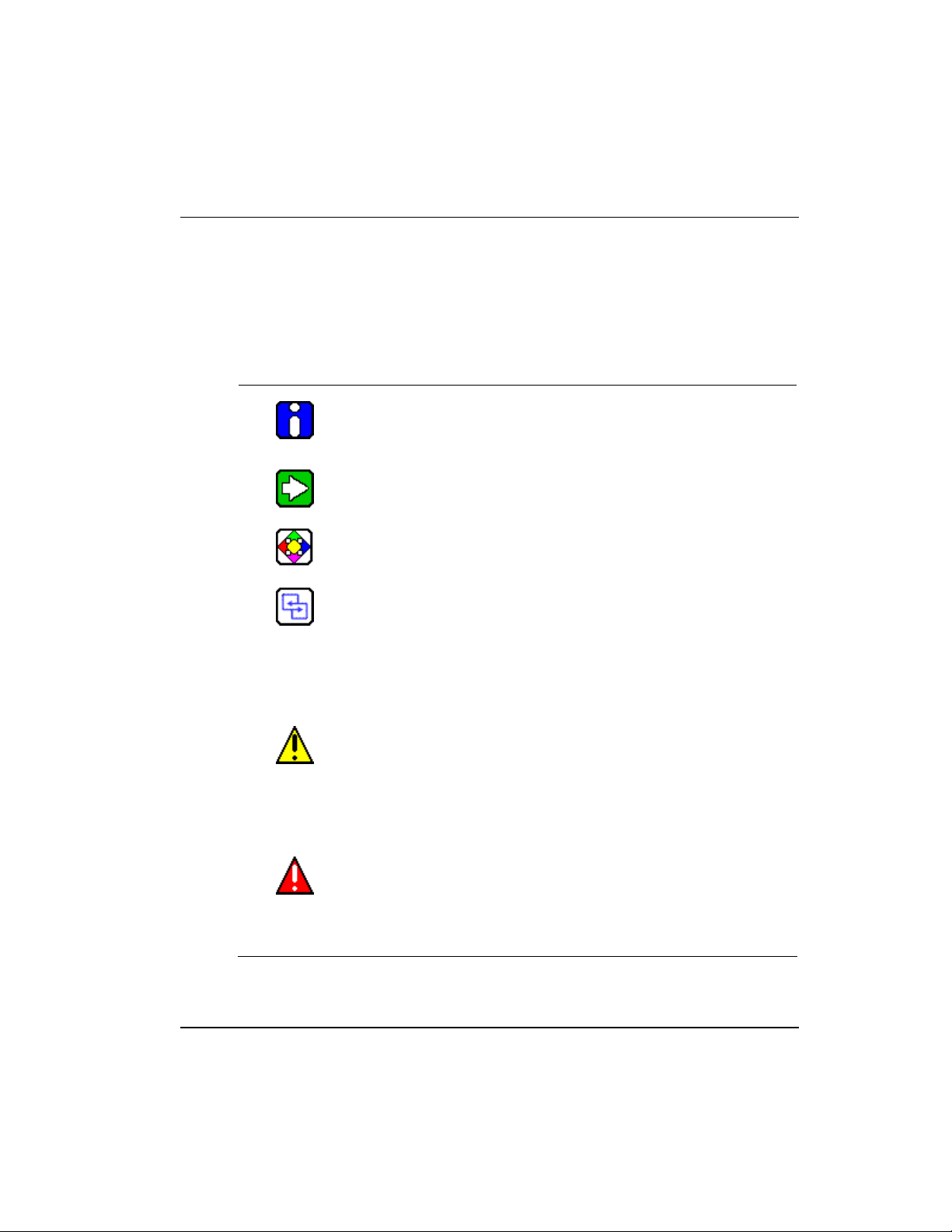

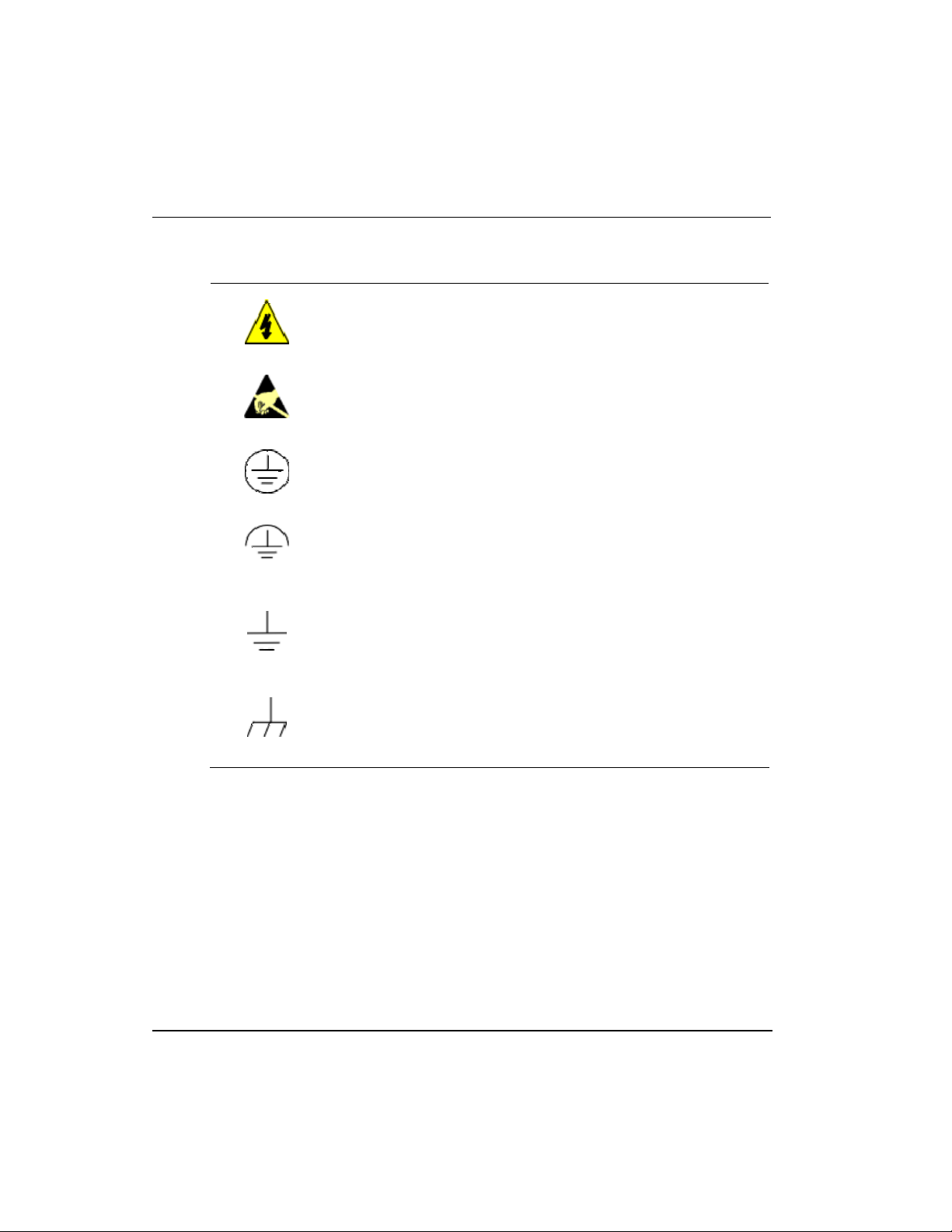

Symbol Definitions

The following table lists those symbols used in this document to denote certain conditions.

Symbol Definition

CAUTION

ATTENTION: Identifies information that requires special

consideration.

TIP: Identifies advice or hints for the user, often in terms of

performing a task.

REFERENCE -EXTERNAL: Identifies an additional source of

information outside of the bookset.

REFERENCE - INTERNAL: Identifies an additional source of

information within the bookset.

Indicates a situation which, if not avoided, may result in equipment

or work (data) on the system being damaged or lost, or may result in

the inability to properly operate the process.

CAUTION: Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also be used

to alert against unsafe practices.

CAUTION symbol on the equipment refers the user to the product

manual for additional information. The symbol appears next to

required information in the manual.

WARNING: Indicates a potentially hazardous situation, which, if not

avoided, could result in serious injury or death.

WARNING symbol on the equipment refers the user to the product

manual for additional information. The symbol appears next to

required information in the manual.

R301.1 Experion C300 Controller User's Guide v

11/06 Honeywell

Page 6

About This Document

Symbol Definitions

Symbol Definition

WARNING, Risk of electrical shock: Potential shock hazard where

HAZARDOUS LIVE voltages greater than 30 Vrms, 42.4 Vpeak, or

60 VDC may be accessible.

ESD HAZARD: Danger of an electro-static discharge to which

equipment may be sensitive. Observe precautions for handling

electrostatic sensitive devices.

Protective Earth (PE) terminal: Provided for connection of the

protective earth (green or green/yellow) supply system conductor.

Functional earth terminal: Used for non-safety purposes such as

noise immunity improvement. NOTE: This connection shall be

bonded to Protective Earth at the source of supply in accordance

with national local electrical code requirements.

Earth Ground: Functional earth connection. NOTE: This

connection shall be bonded to Protective Earth at the source of

supply in accordance with national and local electrical code

requirements.

Chassis Ground: Identifies a connection to the chassis or frame of

the equipment shall be bonded to Protective Earth at the source of

supply in accordance with national and local electrical code

requirements.

vi Experion C300 Controller User's Guide R301.1

Honeywell 11/06

Page 7

Contents

ABOUT THIS GUIDE ..............................................................................1

Introduction ................................................................................................................ 1

Intended audience..................................................................................................................1

Prerequisite skills ...................................................................................................................1

Online documentation reference ............................................................................................1

Locating related documentation .............................................................................................2

C300 CONTROLLER PURPOSE............................................................3

C300 Controller and C200 Controller comparison .................................................3

Getting started............................................................................................................ 5

What task do you want to perform?........................................................................................5

C300 CONTROLLER PLANNING AND DESIGN ...................................7

Review Experion system capabilities ...................................................................... 7

Control Hardware Planning Guide ........................................................................... 7

Series C control hardware ........................................................................................ 8

Series C form factor ...............................................................................................................8

C300 Controller ....................................................................................................................10

C300 Controller execution environments .............................................................................11

I/O modules supported by the C300 Controller ....................................................................12

Identify C300 Controller components.................................................................... 13

C300 Controller performance data......................................................................... 15

Control network considerations............................................................................. 16

C300 Interface to C200 Controllers and ControlNet using FTEB .........................................16

C300 Peer communication with Experion nodes..................................................................16

C300 connections with Rockwell PLC devices.....................................................................17

C300 connections to the Control Firewall.............................................................................17

C300 CONTROLLER INSTALLATION AND UPGRADES ...................19

Pre-installation considerations ..............................................................................19

Installation declarations........................................................................................................19

Series C control hardware installation requirements ............................................................20

R301.1 Experion C300 Controller User's Guide vii

11/06 Honeywell

Page 8

Contents

Series C Power System............................................................................................20

Controller Memory Backup.................................................................................................. 21

C300 Controller installation.....................................................................................21

C300 Controller assembly ................................................................................................... 21

To install a C300 Controller ................................................................................................. 24

C300 Secondary Controller Installation ............................................................................... 27

To install a partner secondary C300 Controller ................................................................... 28

CF9 Control Firewall.................................................................................................30

9-Port Control Firewall (CF9)............................................................................................... 30

Series C I/O modules installation ...........................................................................31

Series C FIM installation ..........................................................................................31

Upgrading C300 Controller Firmware.....................................................................31

Using the Controller Migration Wizard................................................................................. 31

C300 Controller behavior during firmware upgrade and timeout ......................................... 31

C300 CONTROLLER CONFIGURATION ............................................ 33

Configuration overview............................................................................................34

Configuration Studio............................................................................................................34

Define and add assets in your enterprise model ................................................................. 34

FTE system configuration.................................................................................................... 34

Specifying a Time Server .................................................................................................... 35

C300 Controller Device Index ............................................................................................. 35

Create C300 Controller and CEE function blocks.................................................36

To configure a C300 Controller block .................................................................................. 36

Configure CEEC300 block .......................................................................................42

To configure a CEEC300 function block.............................................................................. 42

Configure a Secondary C300 Controller block......................................................46

To configure a Secondary C300 Controller block ................................................................ 47

Convert a non-redundant C300 Controller to a redundant controller.................49

To convert a non-redundant C300 Controller to a Redundant controller ............................. 49

Convert a redundant C300 Controller to a non-redundant controller.................51

To convert a redundant C300 Controller to a non-redundant controller .............................. 51

Configure IOLINK function blocks..........................................................................52

To configure IOLINK blocks ................................................................................................ 53

Import/export C300 Controller configuration ........................................................55

Reset Device Index and IP address of a controller...............................................55

viii Experion C300 Controller User's Guide R301.1

Honeywell 11/06

Page 9

Contents

Create a Control Module ......................................................................................... 57

To create and save a Control Module. .................................................................................58

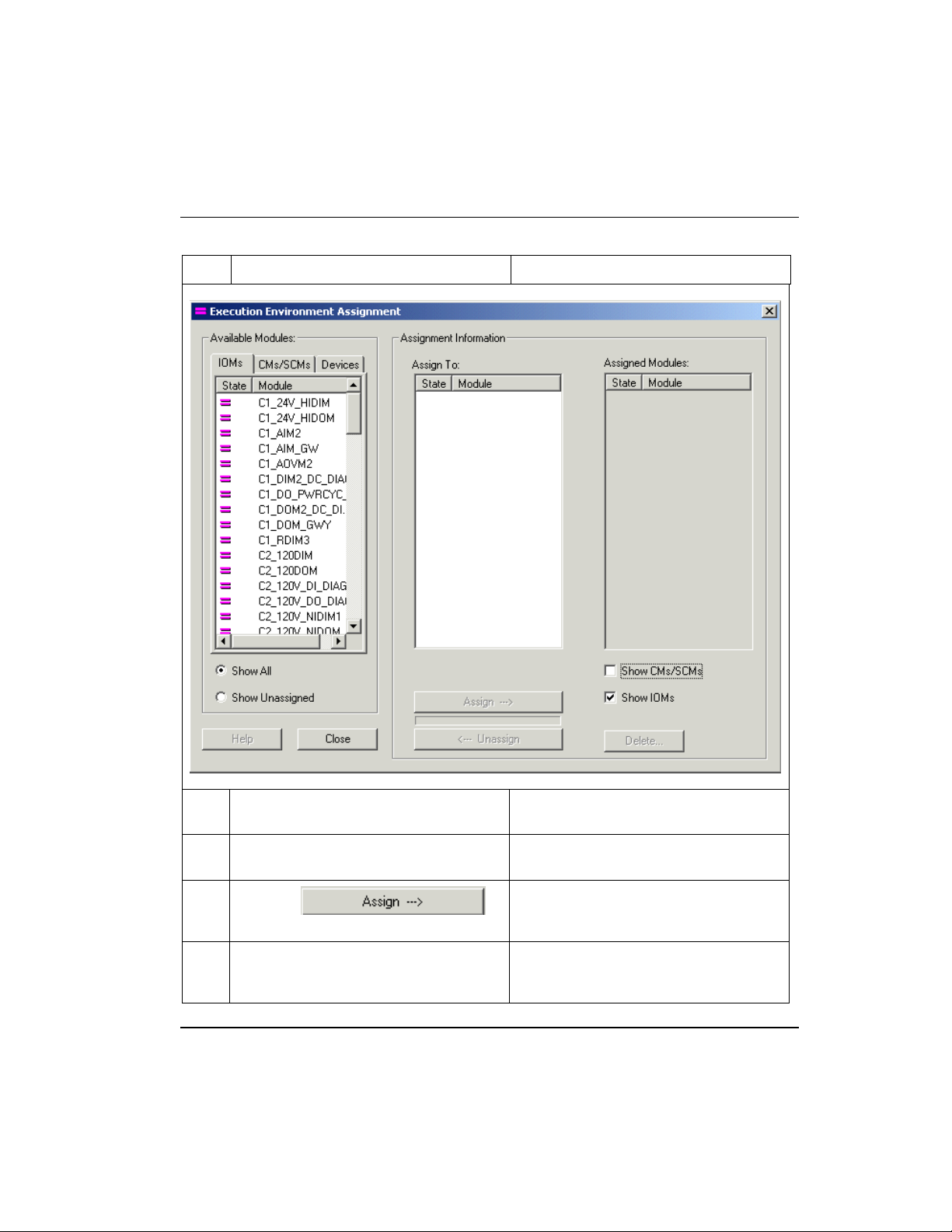

Assign Control Modules and IOMs to a CEEC300 block ..................................... 60

To assign Control Modules and IOMs to a CEE...................................................................61

Copy Control Modules............................................................................................. 66

To copy an existing Control Module .....................................................................................66

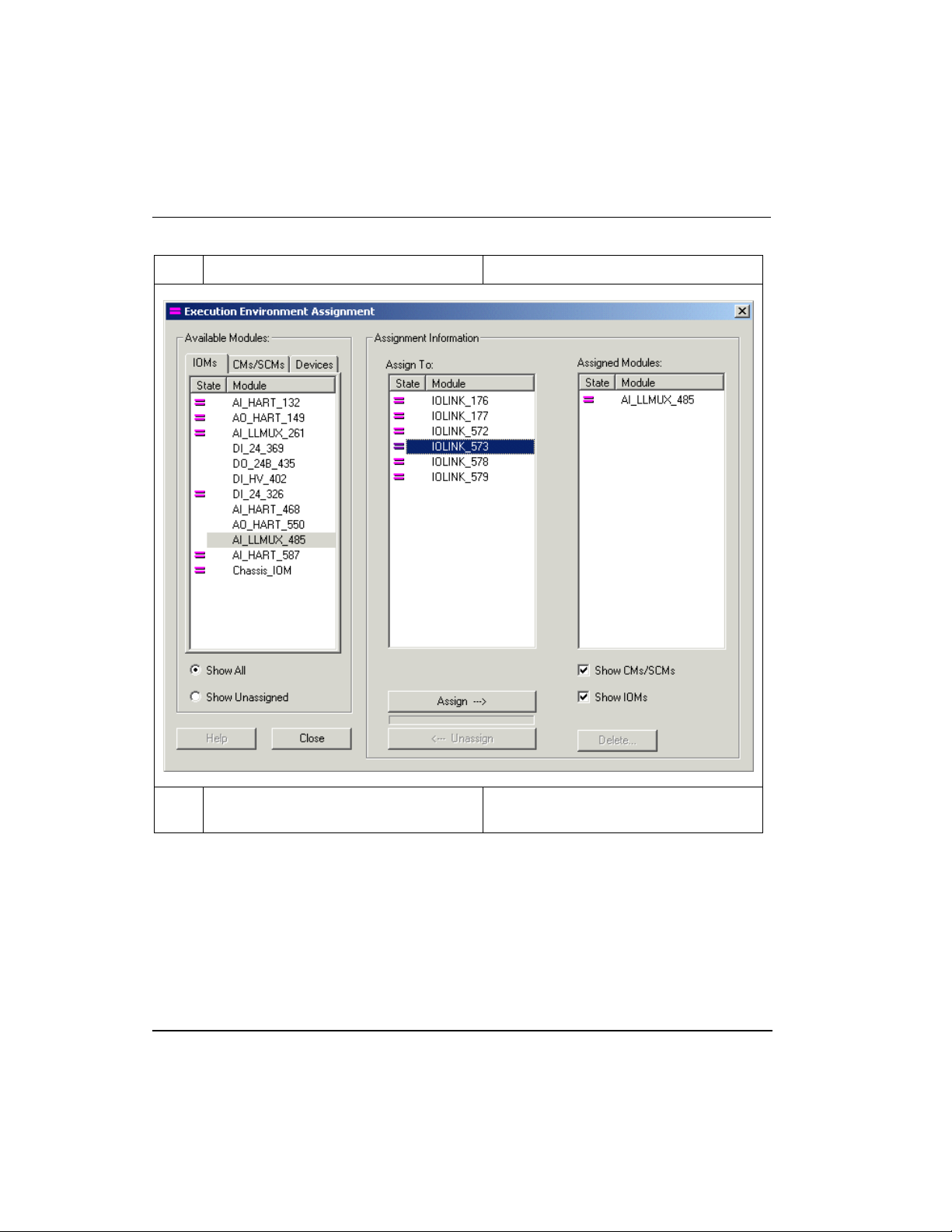

Assign I/O Modules to C300 IOLINK blocks.......................................................... 68

To assign Series C IO Modules and Process Manager IOMs to IOLINK blocks ..................68

Add an I/O Channel to a Control Module............................................................... 73

To add IO Channel blocks to a Control Module chart...........................................................74

C300 CONFIGURATION FORM REFERENCE ....................................77

C300 Controller Block ............................................................................................. 77

Main tab ...............................................................................................................................77

Redundancy tab ...................................................................................................................79

System Time tab ..................................................................................................................82

Statistics tab.........................................................................................................................84

Peer Connections tab...........................................................................................................86

Hardware Information tab.....................................................................................................87

FTE tab ................................................................................................................................88

UTP/TCP tab........................................................................................................................92

IP/ICMP tab..........................................................................................................................95

Soft Failures tab ...................................................................................................................98

QVCS tab...........................................................................................................................100

Server History tab ..............................................................................................................100

Server Displays tab ............................................................................................................102

Control Confirmation tab ....................................................................................................104

Identification tab .................................................................................................................104

Secondary C300 Block .......................................................................................... 106

Main Tab ............................................................................................................................106

Redundancy Tab................................................................................................................106

CEEC300 Function Block ......................................................................................106

Main Tab ............................................................................................................................106

Peer Configuration tab .......................................................................................................109

Statistics tab.......................................................................................................................110

CPU Loading Tab...............................................................................................................114

CPU Overruns tab..............................................................................................................114

Memory tab ........................................................................................................................115

Peer Communications tab..................................................................................................117

Display Communications tab..............................................................................................118

Block Types Info tab...........................................................................................................119

R301.1 Experion C300 Controller User's Guide ix

11/06 Honeywell

Page 10

Contents

Custom Types Info tab ...................................................................................................... 120

QVCS tab .......................................................................................................................... 121

Server History tab.............................................................................................................. 121

Server Displays tab ........................................................................................................... 121

Control Confirmation tab ................................................................................................... 121

Identification tab ................................................................................................................ 121

IOLINK Block...........................................................................................................122

Main Tab ........................................................................................................................... 122

Memory Stats tab .............................................................................................................. 124

Statistics tab...................................................................................................................... 125

I/O Link Status tab............................................................................................................. 133

I/O Status Summary tab .................................................................................................... 136

IOTA Summary tabs.......................................................................................................... 137

QVCS tab .......................................................................................................................... 139

Server History tab.............................................................................................................. 139

Server Displays tab ........................................................................................................... 140

Control Confirmation tab ................................................................................................... 140

Identification tab ................................................................................................................ 140

LOAD C300 CONTROLLER CONFIGURATION ............................... 141

About load operations ...........................................................................................141

Loaded versus project database versions ......................................................................... 141

Load initiation and load dialog box .................................................................................... 142

Load action with compare parameters function ................................................................. 143

Load options for server history and server displays configuration..................................... 143

Initial load order guidelines...................................................................................144

Component deletion considerations .................................................................................. 145

Load components from Project ............................................................................145

Loading C300 Controller ................................................................................................... 145

To load a C300 Controller block and its associated blocks ............................................... 145

Loading IOLINK................................................................................................................. 148

To load a IOLINK block ..................................................................................................... 149

Loading CEEC300............................................................................................................. 151

To load a CEEC300 block ................................................................................................. 151

Loading IOMs and CMs..................................................................................................... 153

Load With Contents command..............................................................................154

Reloading components from project....................................................................154

Upload to the Monitoring database ......................................................................156

C300 CONTROLLER OPERATION ................................................... 157

x Experion C300 Controller User's Guide R301.1

Honeywell 11/06

Page 11

Contents

C300 Controller start up ........................................................................................157

C300 Controller states in boot mode..................................................................................160

C300 Controller states in application mode........................................................................161

C300 faceplate indicators/displays ...................................................................... 162

Power and Status LEDs .....................................................................................................163

Faceplate display information.............................................................................................164

FTE activity LEDs...............................................................................................................166

C300 faceplate display indications ......................................................................167

Control Builder block icon descriptions.............................................................. 168

Activate C300 Controller’s CEE............................................................................ 172

Initial activation order guidelines ........................................................................................172

Activating the CEE .............................................................................................................172

Setting the CEE inactive.....................................................................................................174

CEE Icon states in the Monitoring tab ................................................................................176

Initiating C300 Controller Shutdown.................................................................... 176

Initiating Synchronization command................................................................... 177

Prerequisites ......................................................................................................................177

Commanding synchronization............................................................................................177

Disable Synchronization command ..................................................................... 178

Prerequisites ......................................................................................................................178

To Disable Synchronization................................................................................................178

Initiating Become Primary command................................................................... 178

Prerequisites ......................................................................................................................178

Commanding Become Primary ..........................................................................................179

Initiating Switchover command............................................................................ 179

Prerequisites ......................................................................................................................179

Commanding a switchover.................................................................................................179

Using Station displays .......................................................................................... 180

C300 Controller Point Detail displays.................................................................................180

Controller Detail displays....................................................................................................180

Event and Alarm summary displays ...................................................................................180

FTE Status display .............................................................................................................180

Viewing controller operation and status in Control Builder.............................. 181

C300 operating behaviors ..................................................................................... 183

Time management in the C300 Controller..........................................................................183

Hardware Watchdog Timer ................................................................................................184

Critical Task Health Monitor ...............................................................................................184

C300 Controller overload conditions ..................................................................................185

R301.1 Experion C300 Controller User's Guide xi

11/06 Honeywell

Page 12

Contents

C300 REDUNDANCY OPERATION................................................... 187

Description..............................................................................................................187

Redundancy configuration restrictions ...............................................................188

C300 Controller Device Index ........................................................................................... 188

IOLINK interface considerations........................................................................................ 188

Series C FIM restrictions ................................................................................................... 188

Partner (controller) compatibility..........................................................................189

Redundancy compatibility parameter - RDNCMPT ........................................................... 190

Synchronization states ..........................................................................................191

Standby state .................................................................................................................... 192

Redundancy parameters........................................................................................193

Enable Synchronization – ENBLSYNCCMD ..................................................................... 194

Disable Synchronization – DSBLSYNCCMD .................................................................... 194

Enable Standby – ENBLSTBYCMD .................................................................................. 194

Auto-Synchronization State – RDNAUTOSYNC ............................................................... 194

Inhibit Sync Reason – RDNINHIBITSYNC ........................................................................ 195

Initial Sync Progress – RDNSYNCPROG ......................................................................... 196

Maximum Initial Synchronization Time – RDNISTIMEMAX............................................... 196

Last Synchronization Time – SYNCTIMEBEG .................................................................. 197

Last Lost of Sync Time – SYNCTIMEEND........................................................................ 197

Redundancy Traffic ........................................................................................................... 197

Redundancy Delay ............................................................................................................ 197

Conditions that result in loss of sync ................................................................................. 197

Conditions that do not result in loss of sync ...................................................................... 198

Switchover...............................................................................................................198

Initiate Switchover – SWITCHCMD ................................................................................... 198

Max Switchover Time – RDNSOTIMEMAX ....................................................................... 198

Conditions that result in switchover ................................................................................... 199

Conditions that do not result in a switchover ..................................................................... 199

Become Primary command – BECMPRICMD................................................................... 200

Redundancy history ...............................................................................................200

C300 Redundancy-related notifications...............................................................200

Redundancy Link Status – RDNLINKFAILED ................................................................... 204

OPM Status – RDNOPMSTATUS ..................................................................................... 204

On-process Migration of C300 Controller ............................................................208

‘Go-Back to Idle’ option ..................................................................................................... 208

Controller redundancy specifications..................................................................209

C300 CONTROLLER MAINTENANCE .............................................. 211

xii Experion C300 Controller User's Guide R301.1

Honeywell 11/06

Page 13

Contents

C300 Controller module and IOTA replacement ................................................. 211

To replace a non-redundant controller module...................................................................211

To replace a redundant or secondary controller module ....................................................212

To replace a non-redundant controller IOTA board............................................................213

To replace a redundant or secondary controller IOTA .......................................................214

C300 CONTROLLER TROUBLESHOOTING .....................................217

Overview ................................................................................................................. 217

What to do when faults occur............................................................................... 217

Initial checks........................................................................................................... 218

Checking Control Builder error code reference ..................................................................218

Checking faceplate display and LEDs................................................................................218

Using CTools to capture diagnostic data............................................................................219

Viewing flash log ................................................................................................................220

Viewing release information log .........................................................................................220

Checking server point build log ..........................................................................................220

Checking server point build error log..................................................................................220

Checking error log..............................................................................................................220

Fixing common problems ..................................................................................... 220

Loss of power.....................................................................................................................221

Power-On Self Test (POST) does not complete.................................................................221

Controller display shows –bp– or –ts– ...............................................................................222

Controller display shows –SF– alternating with OK/BKUP.................................................222

One or both FTE LEDs are RED ........................................................................................223

Controller does not synchronize with backup.....................................................................224

Fatal ECC error ..................................................................................................................225

Display shows FAIL............................................................................................................226

Isolated (lonely) Node ........................................................................................................226

Duplicate Device Index setting ...........................................................................................227

Device Index value is zero upon power up.........................................................................228

C300 Controller soft failures................................................................................. 228

IOLINK block soft failures .....................................................................................232

Additional status and fault messages ................................................................. 235

Redundancy-related notifications .......................................................................................235

OPM-related notifications – RDNOPMSTATUS parmaeter................................................235

Online diagnostics................................................................................................. 235

Fault classifications............................................................................................... 235

Hard/Severe Failures .........................................................................................................237

Soft Failures .......................................................................................................................238

Installation-Startup Failures................................................................................................239

R301.1 Experion C300 Controller User's Guide xiii

11/06 Honeywell

Page 14

Contents

Hardware Watchdog Timer Expired .................................................................................. 239

Communications Faults..................................................................................................... 240

Communication and system time startup fault scenarios .................................240

Non-redundant C300 Controller with no Memory Retention.............................................. 240

Non-redundant C300 Controller with Memory Retention................................................... 242

Redundant Primary C300 Controller with no Memory Retention....................................... 243

Redundant Primary C300 Controller with Memory Retention............................................ 245

Secondary C300 Controller with no Memory Retention..................................................... 246

Secondary C300 Controller with Memory Retention.......................................................... 248

Notes:................................................................................................................................ 249

Gathering information for reporting problems to Honeywell ............................250

Getting further assistance.....................................................................................251

Other troubleshooting sources .......................................................................................... 251

Guidelines for requesting support...................................................................................... 253

xiv Experion C300 Controller User's Guide R301.1

Honeywell 11/06

Page 15

Contents

Tables

Tables

Table 1 Series A I/O Modules supported by C300 Controller ......................................12

Table 2 Series C Hardware components...................................................................... 13

Table 3 C300 Controller IOTA Board Connector Summary ......................................... 23

Table 4 Initial Load Order Guidelines ......................................................................... 144

Table 5 C300 Controller Startup and Power On Self Test routine ............................. 158

Table 6 Controller in Boot mode.................................................................................. 160

Table 7 C300 Controller in Application mode............................................................. 161

Table 8 C300 Controller LED indications ...................................................................163

Table 9 C300 Controller faceplate display indications ............................................... 165

Table 10 FTE Activity LED Indications ....................................................................... 166

Table 11 Display indications when controller is in application mode .........................167

Table 12 Display indications when controller is in boot mode.................................... 168

Table 13 C300 Controller icon indications in Control Builder..................................... 169

Table 14 Redundancy-Related Notifications .............................................................. 201

Table 15 OPM-Related Notifications ........................................................................... 204

Table 16 C300 Controller Soft Failures ...................................................................... 229

Table 17 IOLINK Block Soft Failures.......................................................................... 232

Table 18 C300 Fault Classifications and Possible Causes ........................................236

R301.1 Experion C300 Controller User's Guide xv

11/06 Honeywell

Page 16

Contents

Figures

Figures

Figure 1 Series C form factor example ...........................................................................9

Figure 2 Redundant C300 Controller block in the Project tree .....................................11

Figure 3 C300 Controller IOTA Board Features ...........................................................22

Figure 4 Control Module chart with an AICHANNEL block...........................................75

Figure 5 Sample Load Dialog......................................................................................143

Figure 6 C300 Controller Startup and Boot Mode indications .....................................160

Figure 7 C300 Controller faceplate features ...............................................................163

Figure 8 Control Builder Monitoring tab ......................................................................181

Figure 9 C300 Controller configuration form...............................................................182

Figure 10 C300 Controller synchronization states ......................................................192

Figure 11 C300 Controller Block Redundancy tab.......................................................193

Figure 12 Soft Failures tab in Control Builder .............................................................229

xvi Experion C300 Controller User's Guide R301.1

Honeywell 11/06

Page 17

Introduction

This guide provides information that will assist you in planning and designing activities,

as well as the installation, operation, and troubleshooting of C300 Process Controllers in

an Experion system.

Intended audience

This guide is intended for the following users:

• Persons responsible for system planning, initial hardware installation, and control

strategy configuration

• Operators who help to maintain control system operations on a day-by-day basis

• Service persons responsible for routine maintenance of control hardware and who

also diagnose and repair faults.

Prerequisite skills

It is assumed that you should have some knowledge of Experion control systems and

experience of working in a Microsoft Windows environment.

About this guide

Online documentation reference

Knowledge Builder is the online documentation library for the Experion system. It is

provided on a compact disc and can be installed on a suitable personal computer. If you

are using a printed copy of the C300 Controller Guide, we recommend that you install

Knowledge Builder to take advantage of its online search and reference capabilities.

Other resources and guides in Knowledge Builder provide this same information for

other Experion control hardware, such as Process Manager I/O, Series C I/O, and Series

A Chassis I/O. See Locating related documentation

documents.

R301.1 Experion C300 Controller User's Guide 1

11/06 Honeywell

for a partial listing of these

Page 18

Introduction

Locating related documentation

Locating related documentation

Listed here are Knowledge Builder documents that contain general information for

planning and implementing control hardware and network communications in your

Experion system:

Control Hardware Planning Guide - Provides general information to assist you in

planning and design of control hardware in an Experion system. Control hardware

includes C200 Controllers, Series A Chassis I/O and FIMs, also, all I/O families, (except

Series C I/O). It includes some supervisory network considerations for general reference.

Series C I/O Module User’s Guide - The guide contains planning and implementation

information for Series C I/O modules. Module types include: AI, AO, AIMUX, DI and

DO.

Series C Fieldbus Interface Module User’s Guide - Provides planning and

implementation guide for the Series C Fieldbus Interface Module4.

Control Firewall User’s Guide – A hardware and installation reference about the FTE

switch component for Series C control hardware.

Fault Tolerant Ethernet Overview and Implementation Guide - Provides basic

installation instructions and configuration requirements for a Fault Tolerant Ethernet

(FTE) network and its components.

Fault Tolerant Ethernet Installation and Service Guide - Contains instructions for

installing and configuring a Fault Tolerant Ethernet (FTE) node. The guide includes

troubleshooting and service information for an FTE node.

Fault Tolerant Ethernet Bridge User Guide - Provides information for implementing a

Fault Tolerant Ethernet supervisory network through the FTE Bridge module. It

includes module installation, configuration, operation and service data.

Process Manager I/O Troubleshooting and Maintenance Guide - Guide features

notification messages (soft fail codes and hard fail codes), service procedures and parts

lists for PMIO I/O control hardware.

2 Experion C300 Controller User's Guide R301.1

Honeywell 11/06

Page 19

C300 Controller Purpose

This section provides a quick comparison of C200 and C300 Controller features and

reference to topics in this book for a given task related to using the C300 Controller with

the Experion system. Click on the topic to view it.

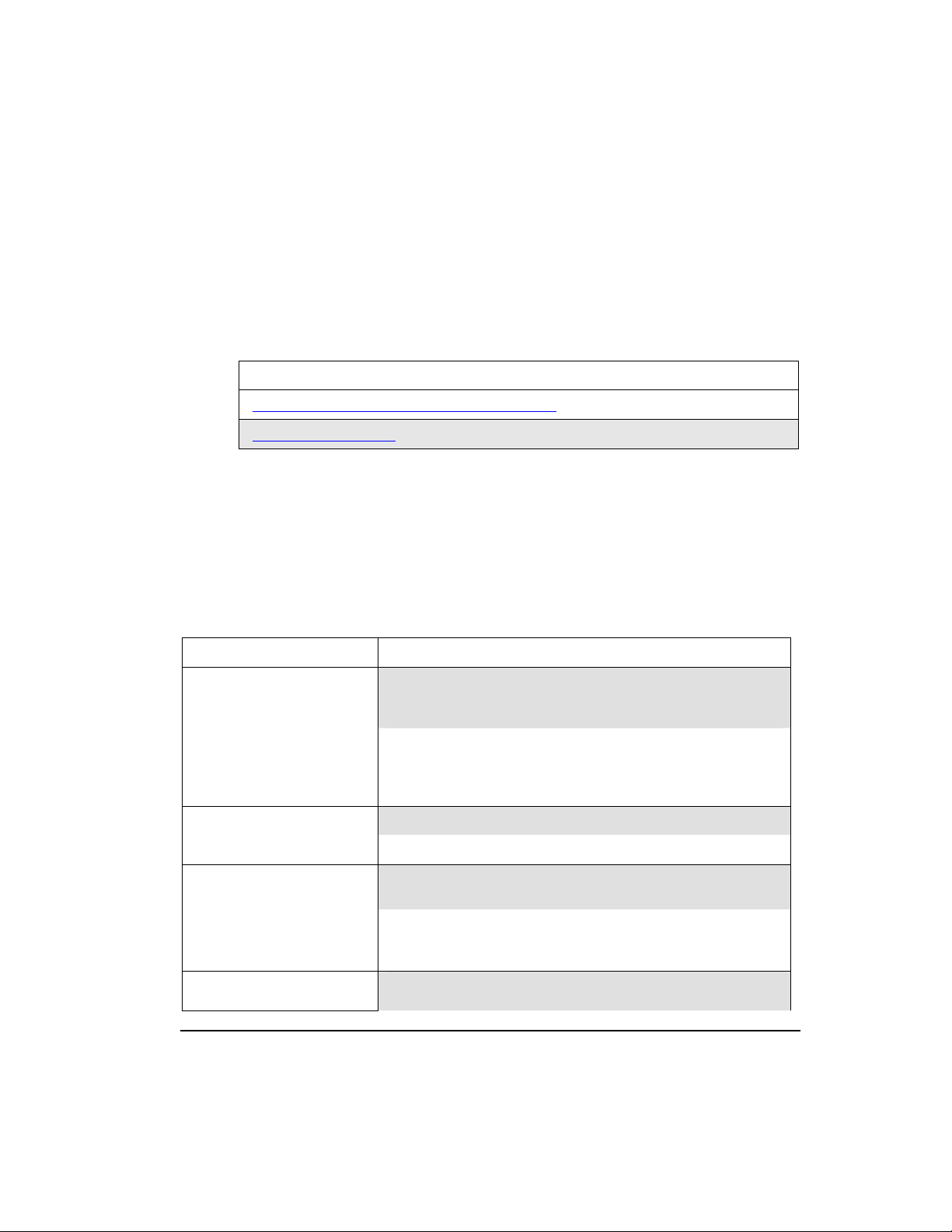

Topic

C300 Controller and C200 Controller comparison

Getting started task list

C300 Controller and C200 Controller comparison

If you are familiar with the operation and capabilities of the C200 chassis-based process

controller, then you can readily appreciate the design improvements and greater

capabilities for process control that the C300 Controller provides. The following table is

a listing that compares design features and operational improvements of the C300

Controller with the C200 controller.

Controller Feature Comparison

Form Factor

Memory (RAM)

Redundancy

I/O Link Interface C200 – An I/O Link Interface plug-in Module (IOLINK) installed

R301.1 Experion C300 Controller User's Guide 3

11/06 Honeywell

C200 – Chassis-based controller with plug-in modules for

Control Processor, I/O Link Interface, Redundancy, FTE

interface, Fieldbus, other I/O and control modules.

C300 – A single control module that plugs into an Input Output

Terminal Assembly (IOTA). Control module functions include

a Control processor, two I/O Link interfaces, Redundancy

functions, and FTE interfaces.

C200 – 4MB User Memory

C300 – 16MB User Memory

C200 –Two identically-equipped controller chassis that contain

two Redundancy Modules (RM) provide controller redundancy.

C300 – Controller redundancy function is built in. A second

C300 Controller and redundancy cable is all that is required for

redundant controller operation. (No RMs)

in the controller chassis is required to connect PMIO I/O to the

Page 20

C300 Controller and C200 Controller comparison

Locating related documentation

Controller Feature Comparison

controller CPM.

C300 – Two I/O Link interfaces are built in to the controller.

Each I/O Link can connect with either PMIO I/O or Series C I/O

modules.

Communications

Interface to supervisory

network

Peer-to-Peer

Connections

Function Blocks C200 and C300 – Both Controllers use the same standard

Engineering Tools C200 and C300 – Both controllers use the same engineering

C200 – Ethernet or Fault Tolerant Ethernet plug-in modules

are needed to connect to respective Ethernet and FTE

communication networks. ControlNet Interface plug-in module

is needed to connect with other ControlNet nodes.

C300 – Ethernet interface is built into the controller and

supports both Ethernet and redundant FTE communications.

No ControlNet interface.

C200 – Ethernet or Fault Tolerant Ethernet Bridge plug-in

modules are needed to connect to respective Ethernet and

FTE networks. ControlNet Interface plug-in module is needed

to connect with other ControlNet nodes.

C300 – Ethernet interface is built into the controller and

supports both Ethernet and redundant FTE communications.

No ControlNet interface. C300 connection to C200 controller

is made through an FTE Bridge module installed in the C200

chassis.

Experion function block types for control strategy execution.

There are some exceptions.

tools utilities and applications for maintenance tasks (except

NTools). C300 uses CTools engineering utility.

4 Experion C300 Controller User's Guide R301.1

Honeywell 11/06

Page 21

Getting started

What task do you want to perform?

Getting started

The following table lists some of the tasks covered in this document that are related to

implementing a C300 Controller in your Experion R300 system or later. If you are

viewing this document online, just click the reference to jump to the topic in this

document.

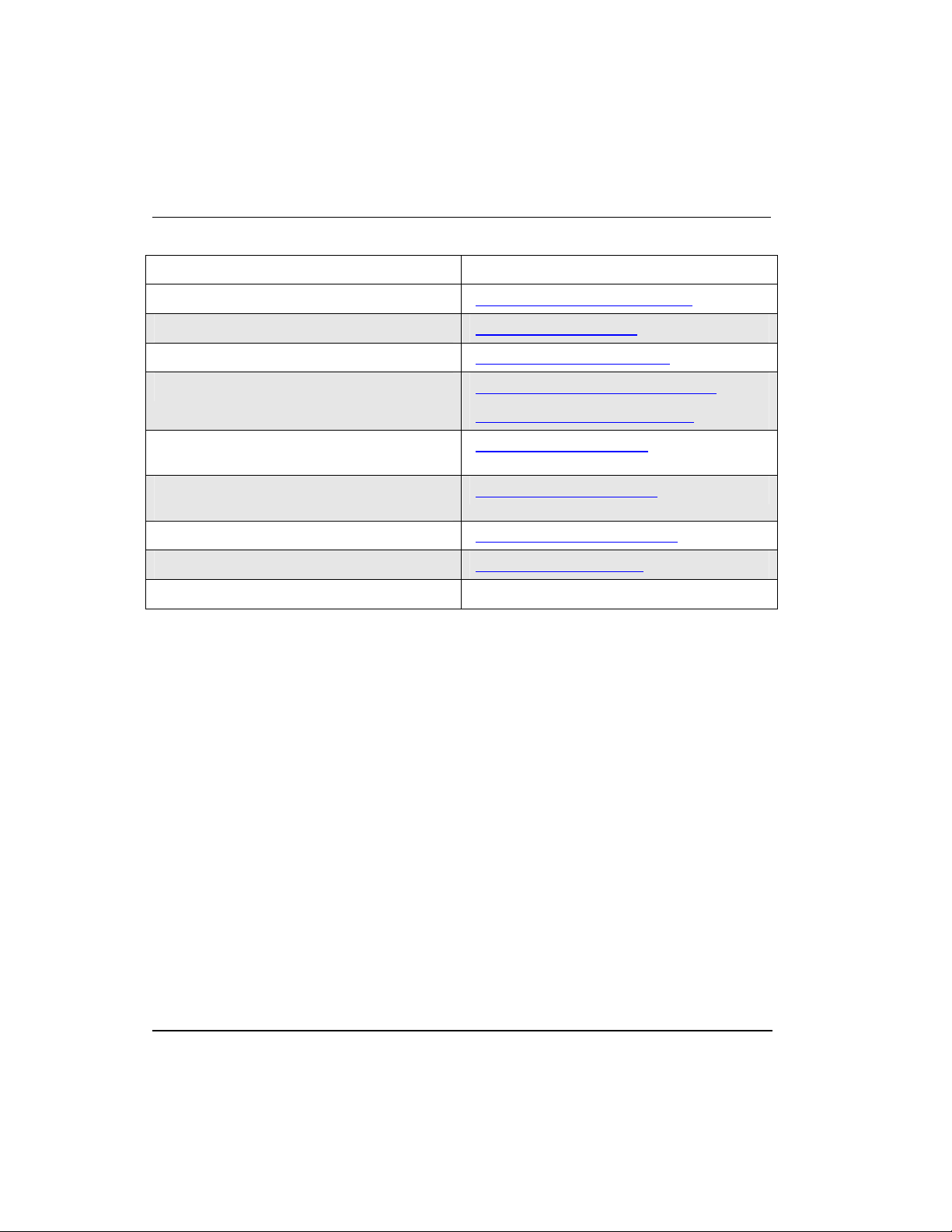

What task do you want to perform?

If You Want to . . . Then, See This Topic . . .

Plan and design a C300 Controller installation C300 Controller Planning and Design

Know more about C300 hardware Series C Control Hardware

Identify C300 Controller components

Know more about C300 Controller

performance

Install and wire C300 Controller hardware C300 Controller installation

Upgrade Controller firmware Upgrading C300 Controller firmware

Create C300 Controller and CEE function

blocks

Configure CEE function blocks Configure CEEC300 block

Configure IOLINK function blocks Configure IOLINK function blocks

Configure a Secondary C300 Controller Configure a Secondary C300 Controller block

Convert a Non-redundant C300 Controller to a

redundant controller

Convert a redundant C300 Controller to a Nonredundant controller

Reset Controller Device Index

View configuration parameter descriptions C300 Configuration Form Reference

Load function blocks to C300 components Load C300 Controller Configuration

Reload components from Project Reloading components from Project

C300 Controller performance data

C300 Controller Configuration

Convert a non-redundant C300 Controller to a

redundant controller

Convert a redundant C300 Controller to a Nonredundant controller

Reset Device Index and IP address of a

controller

Review C300 Controller start up routines C300 Controller start up

R301.1 Experion C300 Controller User's Guide 5

11/06 Honeywell

Page 22

Getting started

What task do you want to perform?

If You Want to . . . Then, See This Topic . . .

Review C300 Controller operating indications C300 Faceplate indicators/displays

Shutdown a C300 Controller C300 Controller shutdown

Activate the Controller’s CEE Activate C300 Controller’s CEE

View Controller operations Viewing controller operation and status

Interacting through Station displays

Review C300 Controller redundancy

functionality

Review C300 Controller maintenance and

replacement procedures

Investigate a cause of a problem C300 Controller Troubleshooting

Install and wire C300 Controller hardware C300 Controller installation

C300 redundancy operation

C300 Controller Maintenance

6 Experion C300 Controller User's Guide R301.1

Honeywell 11/06

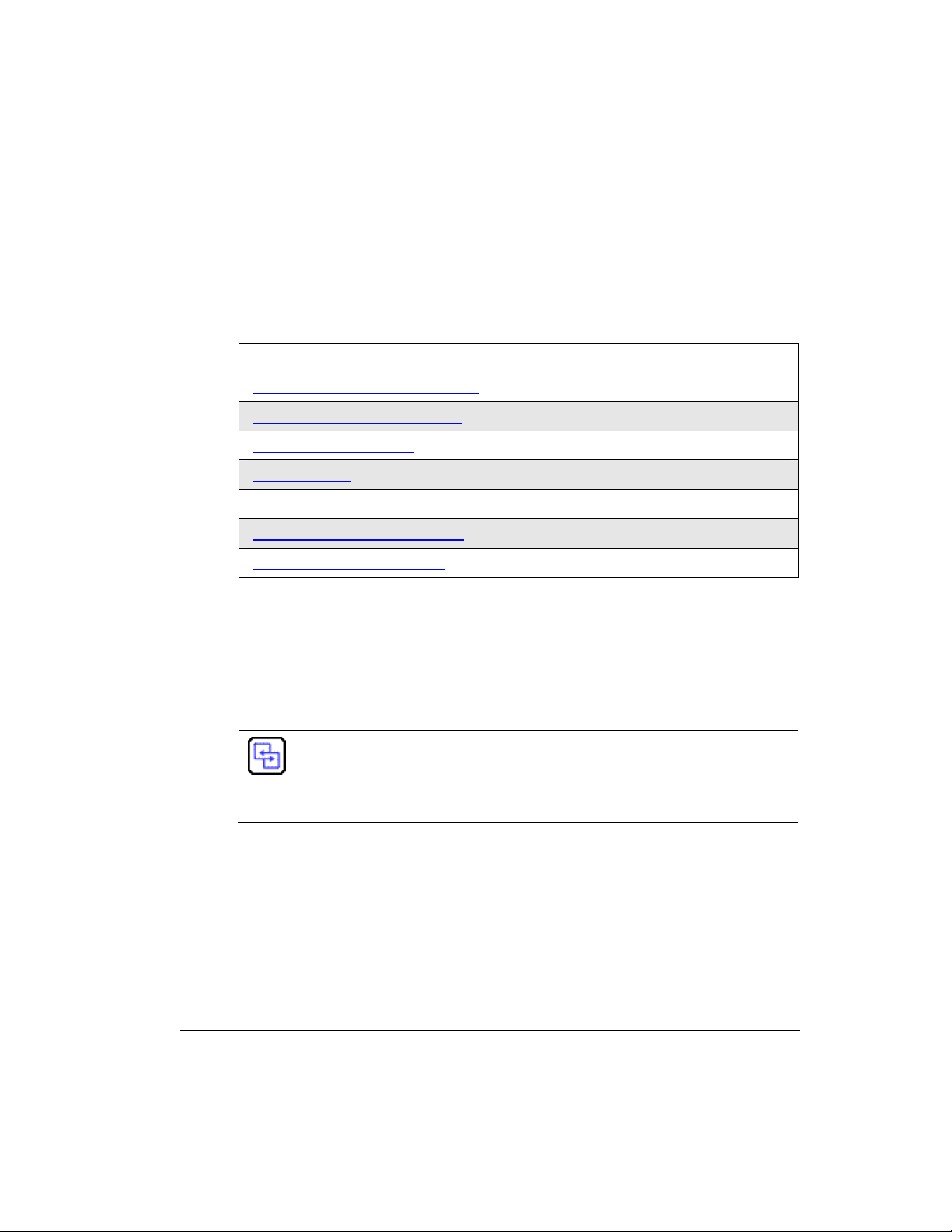

Page 23

C300 Controller Planning and Design

This section includes information about system planning and design of the C300

Controller. The following topics are presented here. Click on the topic to view it.

Topic

Review Experion system capabilities

Control Hardware Planning Guide

Series C control hardware

C300 Controller

Identifying C300 Controller components

C300 Controller performance data

Control network considerations

Review Experion system capabilities

Read the Overview document in Knowledge Builder so that you understand the basic

concepts and terminology, and appreciate the capabilities of Experion.

Complement the information in this document with the data in the Server and Client

Planning Guide to cover all aspects of an Experion installation.

REFERENCE - INTERNAL

For planning and design topics for Experion servers and clients as well as

information about adding third-party controllers, see the Server and Client

Planning Guide.

Control Hardware Planning Guide

Refer to the Control Hardware Planning Guide in Knowledge Builder for a general

discussion of planning activities for Experion Control hardware that covers:

• Initial planning and design

• Control network considerations

• Control hardware configuration

R301.1 Experion C300 Controller User's Guide 7

11/06 Honeywell

Page 24

Series C control hardware

Series C form factor

• Site selection and planning

• Control processing considerations

• Application licensing considerations

Series C control hardware

Series C control hardware consists of the following system components:

• C300 Controller is a distributed process controller and I/O gateway for the

Experion system. With only a few exceptions, the C300 Controller fully supports

configuration, load and execution of the standard function blocks supported in

previous Experion releases, (R210).

• Series C Input/Output Modules that feature HART-capable AI and AO modules,

and a low level Mux AI module. Digital input modules that support high voltage AC

and 24V DC inputs, and a Digital Output module that provides 24 VDC.

• The Series C Fieldbus Interface Module, (Series C FIM) which is designed to

complement the C300 Controller and support Fault Tolerant Ethernet (FTE)

communications within Experion R300 systems or later.

• A 9-port Control Firewall, (CF9) provides eight FTE interface connections for

C300 Controllers and Series C FIMs within a control cabinet and one uplink to the

supervisory FTE communications network.

Series C form factor

All Series C control hardware is constructed using the same form factor; that is, the C300

Controller modules, Series C I/O modules, Control Firewall modules, and Series C FIMs

all mount on their associated Input Output Termination Assemblies (IOTAs), which are

installed on carrier hardware specifically designed to support Series C hardware

installation. The module’s circuit board assemblies are housed in a plastic case with a

round faceplate that identifies the module type and model number along with status

LEDs and a four-character alphanumeric display. The IOTA contains connectors that

accept the associated control module and the various I/O connectors for cables that

connect to other Series C control hardware. Figure 1 shows an example of the design.

8 Experion C300 Controller User's Guide R301.1

Honeywell 11/06

Page 25

Series C control hardware

Series C form factor

Figure 1 Series C form factor example

R301.1 Experion C300 Controller User's Guide 9

11/06 Honeywell

Page 26

Series C control hardware

C300 Controller

REFERENCE - INTERNAL

For more details about Series C I/O and FIM modules refer to the Series C

I/O User’s Guide and the Series C Fieldbus Interface Module User’s Guide.

C300 Controller

The C300 Controller is constructed using the Series C form factor that employs an Input

Output Termination Assembly (IOTA) and an electronics module which mounts and

connects to the IOTA. One C300 Controller contains all of the control functionality and

most of the communications functions that previously required a C200 controller chassis

filled with plug-in modules. This smaller controller footprint and ease of installation,

combined with enhanced functionality that is built upon C200 performance, provides

greater value for Experion users.

The C300 Controller fully supports configuration, load and execution of the standard

function blocks supported in previous Experion releases, (R210). Note that there are a

few exceptions defined below.

Exceptions

The following function blocks are not supported by the C300 Controller in Experion

Release 300.1:

• The LIOM function block set.

• CAB related function blocks other than the Custom Data Block (CDB)

• The REEOUT Function Block – an ACE only function block

• Series A IOM function blocks not listed in Table 1 Series A I/O Modules supported

by C300 Controller.

C300 Controller redundancy

The C300 Controller may operate in both non-redundant and redundant configurations.

Redundant operation requires a second identical controller and connecting cables, which

is the typical configuration.

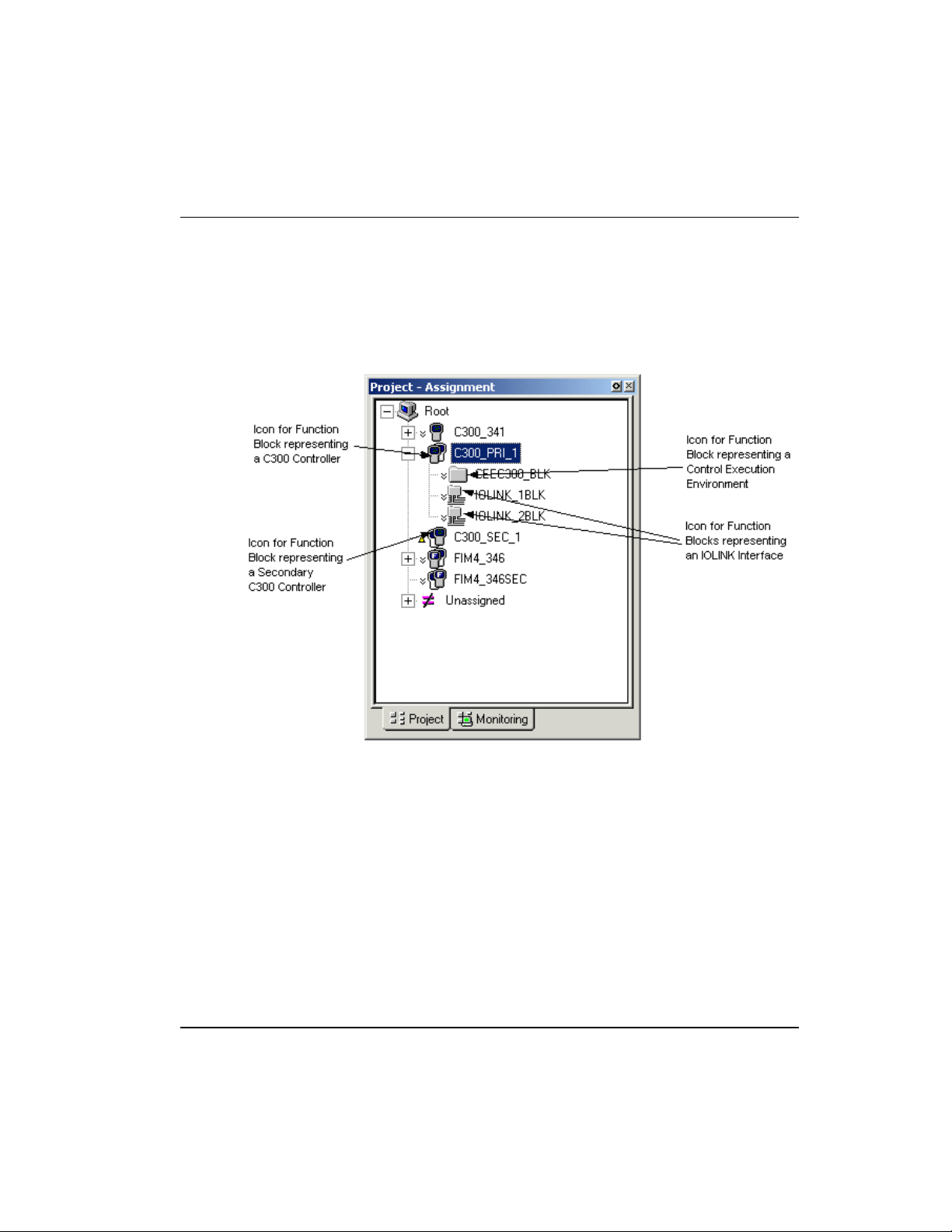

C300 Controller block

When a C300 Controller block is added to the Project tree in Control Builder, a graphic

representation of a controller module and its resident function blocks appears as shown in

Figure 2. The function blocks that are contained in the controller support multiple

execution environments. A Control Execution Environment block (CEEC300) and two

10 Experion C300 Controller User's Guide R301.1

Honeywell 11/06

Page 27

Series C control hardware

C300 Controller execution environments

IOLINK blocks are contained in the controller and appear under the controller. When the

controller block is configured as redundant, the secondary controller block is added in the

Project tree.

Figure 2 Redundant C300 Controller block in the Project tree

C300 Controller execution environments

The C300 Controller supports three Execution Environment (EE) function blocks. One is

the Control EE block, (CEEC300) which is essentially the same block found in the C200

controller. The other two are I/O Link blocks, (IOLINK) similar to the IOLINK block

available with the C200. The IOLINK blocks in the C300 support connection and

communication with PMIO I/O control hardware, (as with the IO Link Interface Module

in C200 controllers), but also support connection and communications with all Series C

I/O modules.

CEE function block

The Control Execution Environment (CEEC300) block is a function block which is

similar to the CEE blocks in the C200 and ACE controllers and uses the same library of

R301.1 Experion C300 Controller User's Guide 11

11/06 Honeywell

Page 28

Series C control hardware

I/O modules supported by the C300 Controller

block types. The CEEC300 block provides an execution and scheduling environment in

which user-configured Control Modules (CMs) and Sequential Control Modules (SCMs)

execute. This block also provides a peer-to-peer communications layer used to

communicate between other controllers. The CEEC300 block supports communication

and containment of Series A I/O module and channel blocks.

IOLink function blocks

Two IOLINK function blocks, which represent the 2 physical IO links on the C300

Controller IOTA, provide the I/O Link interface to support communications with PMIO

I/O module card files and/or Series C I/O modules. Each IOLINK is configured to

support either PMIO I/O or Series C I/O modules, or ‘No Link’ if no I/O control is

required. Each IOLINK supports redundant and non-redundant communications and

contains the same functionality as the IOLINK blocks used in the C200 controller and

IOLIM interface.

I/O modules supported by the C300 Controller

The C300 Controller is connected to the associated I/O hardware by a pair of I/O Link

Interface cables. All Series C I/O modules and all PMIO I/O modules qualified for use in

Experion are supported by the C300 Controller.

For a list of the supported I/O modules, see,

• Planning Your Input/Output Processor (IOP) Cards for a list of supported IO

modules.

• Viewing supported Series C I/O modules for a listing of available Series C IO

modules.

A number of Series A I/O chassis-based modules have been qualified for support with

the C300 Controller. Some of these modules are implemented in a Control Component

Library (CCL). Table 1 lists the I/O modules that are qualified for use with the C300 in

Experion Release 300.

Table 1 Series A I/O Modules supported by C300 Controller

Series A I/O Module Model

Pulse Input Module (supported by CCL) TC-MDP081 TK-MDP081

Serial Interface Module TC-MUX021 TK-MUX021

Profibus interface (supported by CCL) SST-PFBCLX

12 Experion C300 Controller User's Guide R301.1

Honeywell 11/06

Conformally Coated

Model Number

Page 29

Identify C300 Controller components

I/O modules supported by the C300 Controller

Series A I/O Module Model

DeviceNet Interface (supported by CCL) 1756-DNB

Identify C300 Controller components

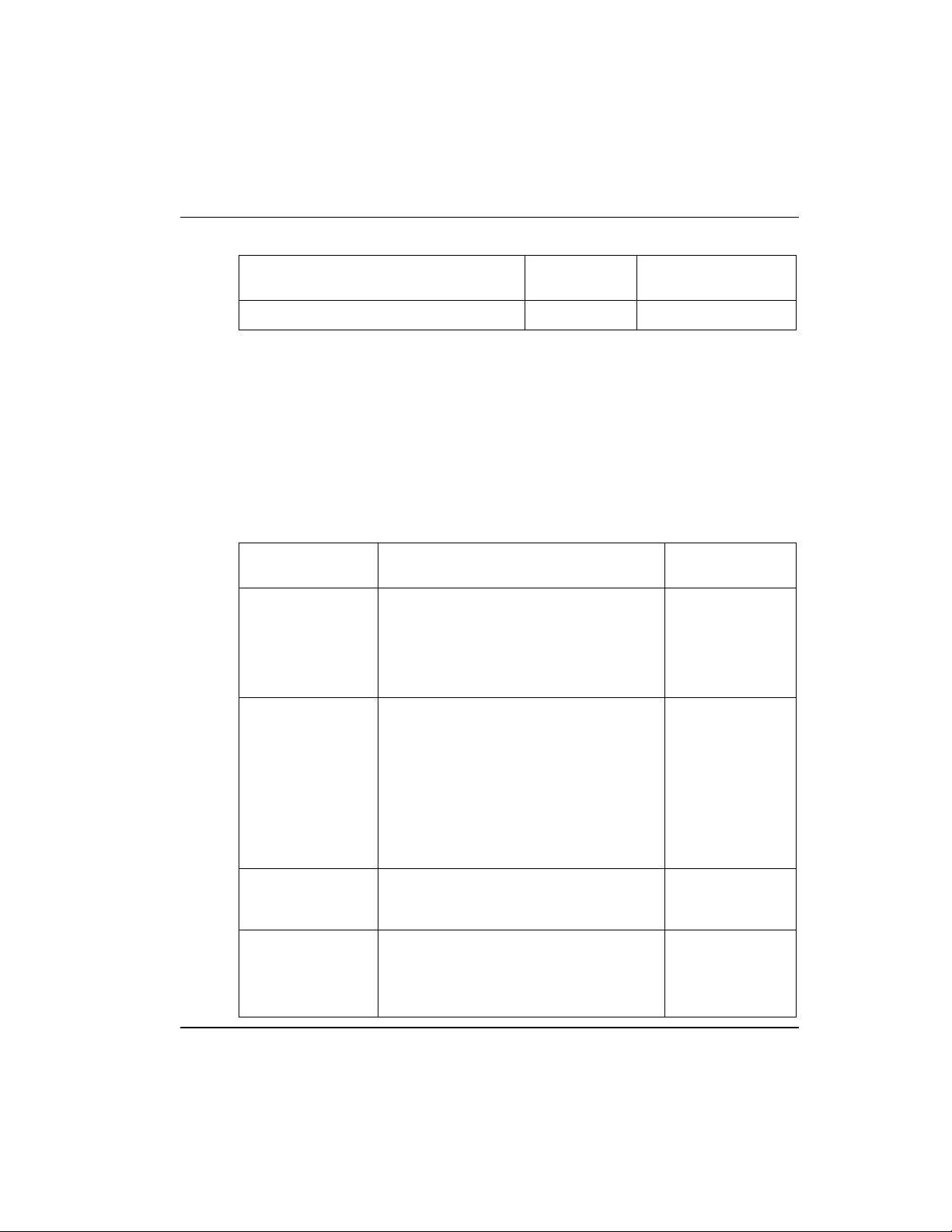

Table 2 identifies the C300 Controller components and its associated components. The

C300 Controller supports non-redundant and fully redundant operation. Redundancy is

built in to the controller, so that just adding another controller and a redundancy cable; a

redundant controller pair is achieved. Note that the ‘CC’ designation on the model

number indicates the printed wiring boards are conformally coated for additional

protection from the environment, (CU = uncoated).

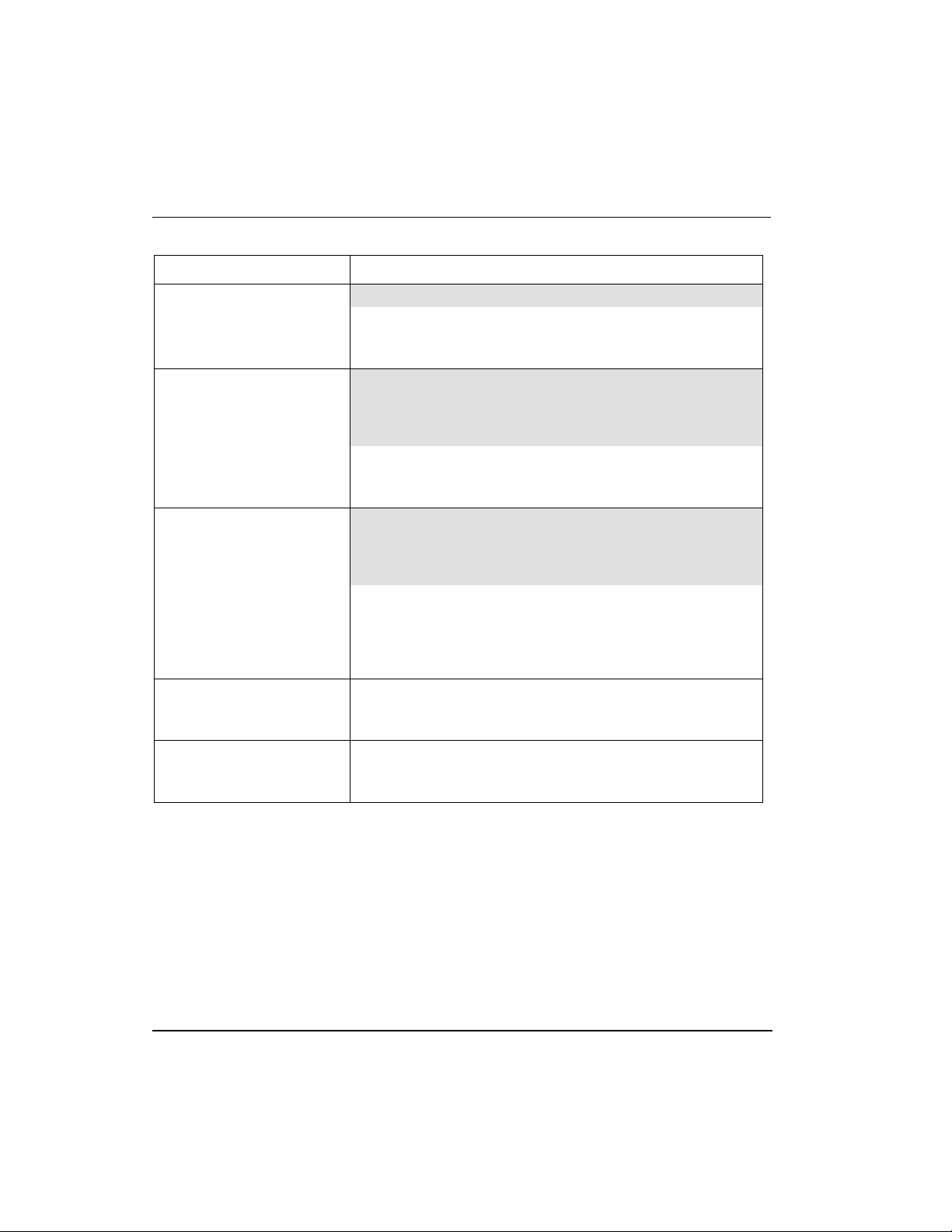

Table 2 Series C Hardware components

Series C

Component

C300 Controller

Module

C300 Controller

Input Output

Termination

Assembly (IOTA)

A distributed process controller and I/O

gateway for the Experion system. Module

contains printed circuit assemblies, status

indicators and a display, inside in a plastic

housing. Module mounts to its Input

Output Termination Assembly (IOTA).

Provides the connection point for the

C300 Controller module and all cable

terminations to the controller, (FTE,

IOLink, Redundancy, Battery and Time

Source cable terminations). Provides 24

Vdc power distribution to the controller

module.

Description Model Number

Conformally Coated

Model Number

CC-PCNT01

CU-PCNT01

CC-TCNT01

CU-TCNT01

Note: The C300 Controller IOTA supports

only one controller module.

9 Port FTE

Control Firewall

Module

9 Port Control

Firewall IOTA

R301.1 Experion C300 Controller User's Guide 13

11/06 Honeywell

Provides FTE distribution to in-cabinet

network nodes, (other C300 Controllers

and Series C FIMs)

Provides connection for eight FTE cables

from in-cabinet controllers and Series C

FIMs. The 9

the FTE supervisory network. Provides 24

Vdc power distribution to the control

th

port provides an uplink to

CC-PCF901

CU-PCF901

CC-TCF901

CU-TCF901

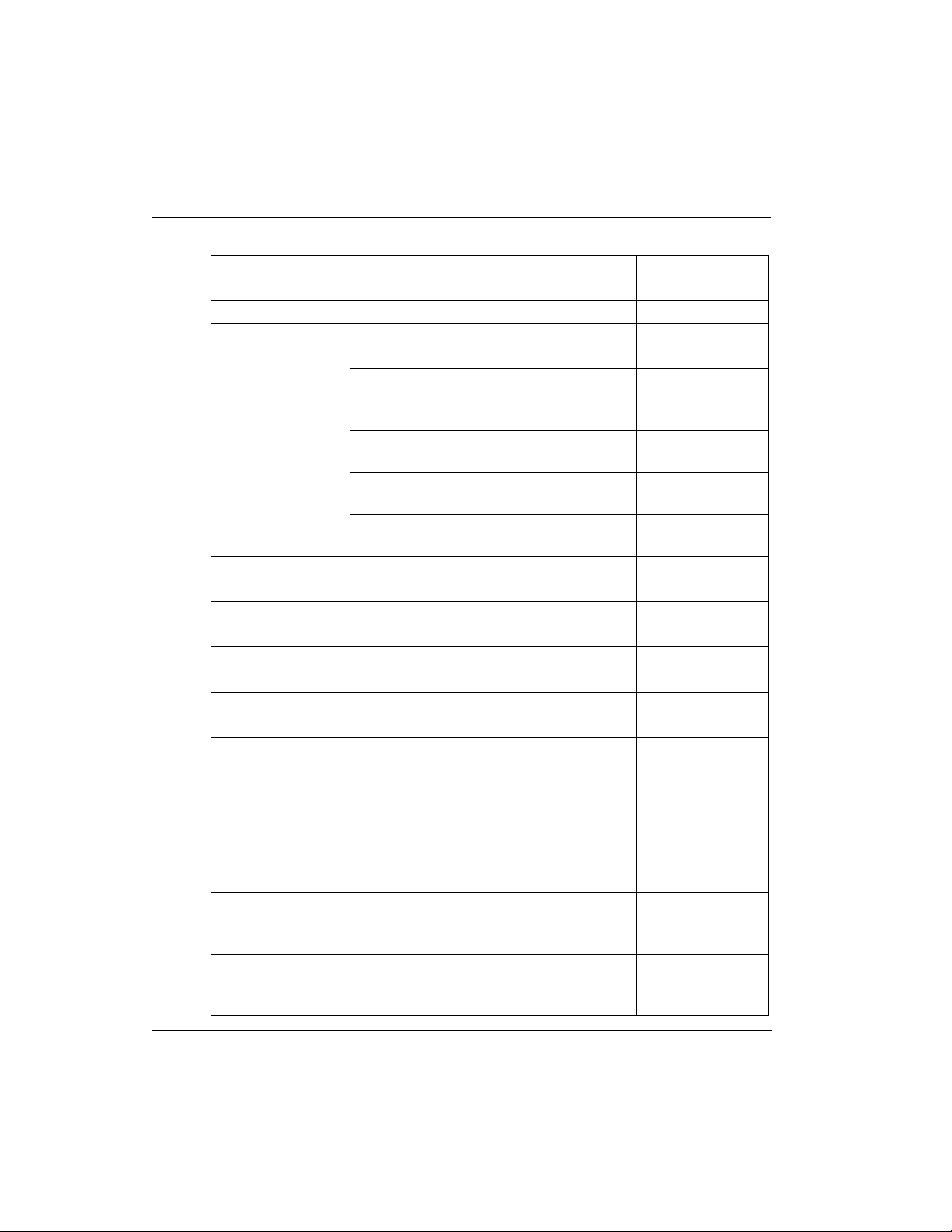

Page 30

Identify C300 Controller components

I/O modules supported by the C300 Controller

Series C

Component

FTE Cable

Redundancy

Cable

IOLink Cable

Battery Cable

IOTA Channel

Supports

Description Model Number

firewall module.

STP CAT5 Cable with RJ 45 connectors

for FTE connections.

2 m (6.5 ft)

(Y) = Yellow coded boots

(G) = Green coded boots

5 m (16 ft)

10 m (33 ft)

20 m (65.5 ft)

STP CAT5 Cable with RJ 45 connectors

joining primary and secondary controllers.

Multidrop cable assemblies to connect the

I/O modules of a controller IOLink.

Multidrop twisted pair cable to connect

battery power to controllers.

Aluminum channels that provide a

mounting medium for the IOTA Carrier.

51305482-102 (Y)

513054820202 (G)

51305482-105 (Y)

513054820205 (G)

51305482-110 (Y)

513054820210 (G)

51305482-120 (Y)

51305482-220 (G)

51305482-xxx

xxxxxxxx-xxx

xxxxxxxx-xxx

CC-MCHN01

IOTA Carrier

Assembly for mounting Series C Hardware

CC-MCAR01

IOTAs. Carriers contain power and

grounding busbars are mounted onto

IOTA channel supports.

Power Supply,

Non-redundant

no Battery Back

24 Vdc, 20 Amp. power supply. Provides

non-redundant power to Carrier busbars

and Series C IOTAs.

CC-PWRN01

Up

Power Supply

Redundant, no

Battery Back Up

Power Supply,

Redundant with

Battery Back Up

24 Vdc, 20 Amp. fully redundant power

supply. Provides redundant power to

Carrier busbars and Series C IOTAs.

24 Vdc, 20 Amp. fully redundant power

supply with battery back up. Provides

redundant power to Carrier busbars and

CC-PWRR01

CC-PWRB01

14 Experion C300 Controller User's Guide R301.1

Honeywell 11/06

Page 31

C300 Controller performance data

I/O modules supported by the C300 Controller

Series C

Component

Series C IOTAs.

Description Model Number

C300 Controller performance data

The following table lists some C3000 Controller performance related data for quick

reference. Note that this information is subject to change without notice.

Performance Capacity

Block Performance 2400 Process Units (PUs) per second

Memory 16 MB user memory

Tagged Objects 4095 Total CMs, SCMs, UCMs, RCMs,

Alarms and Events 10 events per second.

Total I/O Budget 64 I/O units. Total for I/O types.

Number of I/O Links 2

Data Access Performance 2000 points per second.

Data Access Connections 12. Up to two servers and 10 console

Peer to Peer Connections 30 Peer Connection Units.

with full cycle average CPU loading

(CPUCYCLEAVG) of no more than 60%.

IOMs, and other named objects.

See Note 1 for example.

Stations.

Note 1: The C300 Controller supports up to a total of 64 I/O Units which can be

calculated in the following manner:

PMIO I/O Units + Series C I/O Units + Series A I/O Units + Fieldbus IO Units = 64

Where …

• One non-redundant or redundant PMIO IOM = 1 I/O Unit

• One non-redundant or redundant Series C = 1 I/O Unit

• The number of I/O Units assigned to any given Series A I/O device is specified for

that device.

• One non-redundant or redundant Series C Fieldbus Interface Module = 4 I/O Units

R301.1 Experion C300 Controller User's Guide 15

11/06 Honeywell

Page 32

Control network considerations

C300 Interface to C200 Controllers and ControlNet using FTEB

Control network considerations

In an Experion system, the C300 Controller exists as a single node on an FTE network.

The C300 Controller connects to the network and communicates with other FTE nodes

through a Series C Control Firewall (CF9) installed in the same control cabinet. Standard

Ethernet communications also are supported by the C300 Controller, although FTE

should be considered the recommended communications procotol.

The C300 does not contain a ControlNet interface and therefore cannot reside on a

ControlNet supervisory network.

C300 Controllers and C200 controllers can exist on the same server only when FTE is

used as the supervisory network protocol.

C300 Interface to C200 Controllers and ControlNet using FTEB

C300 Controllers can communicate with C200 controllers and associated I/O modules

through a Fault Tolerant Ethernet Bridge (FTEB) module installed in either a C200

controller chassis or a FIM chassis. Pulse Input modules (TC/TK-MDP081) and Serial

Interface modules (TC/TK-MUX021) installed in a non-redundant I/O chassis with an

FTEB are supported by the C300. See the Control Network considerations in the Control

Hardware Planning Guide for control network topologies.

C300 Peer communication with Experion nodes

The C300 supports peer communications with the following nodes in Experion Release

300 and later:

• C300 Controllers

• C200 Controllers – via Fault Tolerant Ethernet Bridge module

• ACE nodes

• Series C FIM nodes

Note that when configuring a peer connection, the C200 controller can be made the

initiator of the connection only when the node is loaded with R300.1 firmware.

Additionally, C200 controllers and ACE nodes should have R300.1 firmware installed

and be running Experion R300.1 software to ensure a reliable peer-to-peer connection.

Although the system topology in Experion Release 300.1 provides for peer

communications between C300 and C200 controllers, (via FTEB module); both

controllers must reside on an FTE supervisory nework. That is, a C300 controller cannot

be added to a server where C200 controllers are resident on a ControlNet supervisory

network.

16 Experion C300 Controller User's Guide R301.1

Honeywell 11/06

Page 33

Currently, C300 controller does not support connection with the following Experion

nodes: Series A (Chassis) FIM, Chassis IOLIM, and OPC servers.

C300 connections with Rockwell PLC devices

You can configure peer connections for the C300 Controller to communicate with

Rockwell PLC devices using the same interfaces as is currently supported for C200

controllers. These interfaces include Exchange function blocks, CIP protocol, and

Programmable Controller Communications Commands (PCCC). See FTE Interoperable

topologies in the Control Hardware Planning Guide for additional information.

The C300 Controller does require the use of an approved Ethernet interface device to

access the ControlNet network on which the PLC devices reside. One of the following

Ethernet interface modules can be used to connect with the Rockwell PLCs:

• FTEB Module (TC/TK-FTEB01)

• Ethernet Interface Module (TC-CEN021)

C300 connections to the Control Firewall

The C300 Controller connects to the control and supervisory communications networks

through the 9-Port Control Firewall. The Control Firewall Module provides connection

to other field Level 1 nodes on the FTE network and an uplink to the supervisory level

FTE network. The module provides message management and protects the Level 1

network from message storms by allowing only messages intended for Level 1 nodes,

and rejecting other unneeded messages.

Control network considerations

C300 connections with Rockwell PLC devices

R301.1 Experion C300 Controller User's Guide 17

11/06 Honeywell

Page 34

Control network considerations

C300 connections to the Control Firewall

18 Experion C300 Controller User's Guide R301.1

Honeywell 11/06

Page 35

C300 Controller Installation and Upgrades

This section includes information about installing various Series C components. Physical

descriptions of the components as well as procedures for installing these components are

provided. The following topics are presented here. Click on the topic to view it.

Pre-installation considerations

Series C Power System

C300 Controller installation

C300 Secondary Controller Installation

CF9 Control Firewall

Upgrading C300 Controller Firmware

Pre-installation considerations

Installation declarations

ATTENTION

This equipment shall be installed in accordance with the requirements of the

National Electrical Code (NEC), ANSI/NFPA 70, or the Canadian Electrical

Code (CEC), C22.1. It is intended to be mounted within an enclosure or

suitable environment acceptable to the local "authority having jurisdiction," as

defined in the NEC, or "authorized person" as defined in the CEC.

Topic

R301.1 Experion C300 Controller User's Guide 19

11/06 Honeywell

Page 36

Series C Power System

Series C control hardware installation requirements

ESD HAZARD

Electrostatic discharge can damage integrated circuits or semiconductors if

you touch connector pins or tracks on a printed wiring board. Follow these

guidelines when you handle any electronic component:

• Touch a grounded object to discharge static potential,

• Wear an approved wrist-strap grounding device,

• Do not touch the wire connector or connector pins,

• Do not touch circuit components inside a component,

• If available, use a static safe workstation,

• When not in use, keep the component in its static shield box or bag.

WARNING

Unless the location is known to be non-hazardous, do not connect or

disconnect cables while the control system is powered.

Series C control hardware installation requirements

See Planning Your Series C Control System in the Control Hardware Planning Guide for

details.

Series C Power System

Power Systems for Series C control hardware provide optional redundant power supplies

with separate mains power feeds. Optional system battery backup is also available and a

memory RAM battery is provided to supply memory retention power for the C300

Controller. The capabilities and options available with the Series-C power system are

very similar to those available with today’s Process Manager Power System.

The Power Supply for the Series C control hardware is mounted on the left hand side of

the enclosure and includes battery backup and battery charger if required. Connection

from the power supply to a power system rail in the IOTA Carriers is made at the top of

the enclosure. Connections from the Power System rail to the IOTA is made with screws

that connect to the rails running down the spine (back of) of the IOTA Carrier. See

Selecting Series C Power System in the Control Hardware Planning Guide for power

system options.

20 Experion C300 Controller User's Guide R301.1

Honeywell 11/06

Page 37

Controller Memory Backup

C300 Controller memory backup provides memory retention power for the C300 should

power be lost to the Series C cabinet. Memory power is rated for 50 hours for a pair of

redundant C300 controllers. See C300 Controller Memory Backup in the Control

Hardware Planning Guide for hardware details.

C300 Controller installation

C300 Controller assembly

The C300 Controller consists of an Input/Output Terminal Assembly (IOTA) board and

the controller module which is housed within a plastic cover and is mounted onto the

IOTA board. The Controller assembly is installed in a control cabinet on verticallymounted carriers specifically for Series C control hardware. The following figure shows

the features of the C300 Controller IOTA board.

C300 Controller installation

Controller Memory Backup

R301.1 Experion C300 Controller User's Guide 21

11/06 Honeywell

Page 38

C300 Controller installation

C300 Controller assembly

Figure 3 C300 Controller IOTA Board Features

22 Experion C300 Controller User's Guide R301.1

Honeywell 11/06

Page 39

C300 Controller installation

C300 Controller assembly

Table 3 C300 Controller IOTA Board Connector Summary

C300 IOTA Board Description

F1 Fuse

IOL1A, IOL1B (BLUE)

IOL2A, IOL2B (GRAY)

FTEA, FTEB

REDUNDANCY Redundant private path cable connector.

MEMORY HOLD-UP Battery Backup cable connector

GPS (Currently not used) GPS cable connector

FTE DEVICE INDEX

100, 10, 1

Prerequisites

Redundant IOLINK connectors for IOLINK 1 and

IOLINK 2

Fault Tolerant Ethernet (FTE) network

connectors

FTE A network cables are Yellow.

FTE B network cables are Green.