Honeywell DT-6360STC Installation Instructions Manual

Model DT-6360STC

Ceiling Mount Motion Sensor

INSTALLATION INSTRUCTIONS

MOUNTING LOCATION

The DUAL TEC® 6360STC motion sensor provides maximum

coverage when mounted on ceilings from 8' (2.4 m) to 16' (4.8 m)

high. Refer to the

passive infrared (PIR) mirror assembly to use at different ceiling

heights.

Choose a mounting location in the center of the protected area.

The protected area should be free of objects that might prevent

the PIR sensor from detecting an intruder: large pieces of

furniture, room dividers, etc.

Remember, infrared energy cannot penetrate solid objects. If the

PIR detector is blocked, the DT-6360STC will not trigger an alarm.

Note: If you plan to use the DT-6360STC's tamper switches,

read the

MOUNTING PROCEDURE

To remove the front cover, orient the DT-6360STC so that one of

the sides with the small rectangular slot in the center is visible.

Using a small flathead screwdriver, gently push down on the slot

while separating the housing parts. Set the front cover aside.

Remove the printed circuit board (PCB) by depressing one of

the retaining brackets at its sides. Use the microwave antenna

to carefully pull the PCB out.

Surface Mounting

If mounting the DT-6360STC directly on a ceiling, use the back

cover as a template to mark holes for the mounting screws and

wiring. Drill the holes. Then pull several inches of wiring from

the ceiling through the center hole in the back housing.

Attach the back housing to the ceiling with the mounting screws.

Recommended mounting screws: #6 (M3.5) pan head.

Note: If surface wiring, use the knockout hole on the side of the

housing.

System Set-up section to determine which

Tamper Installation section on page 1.

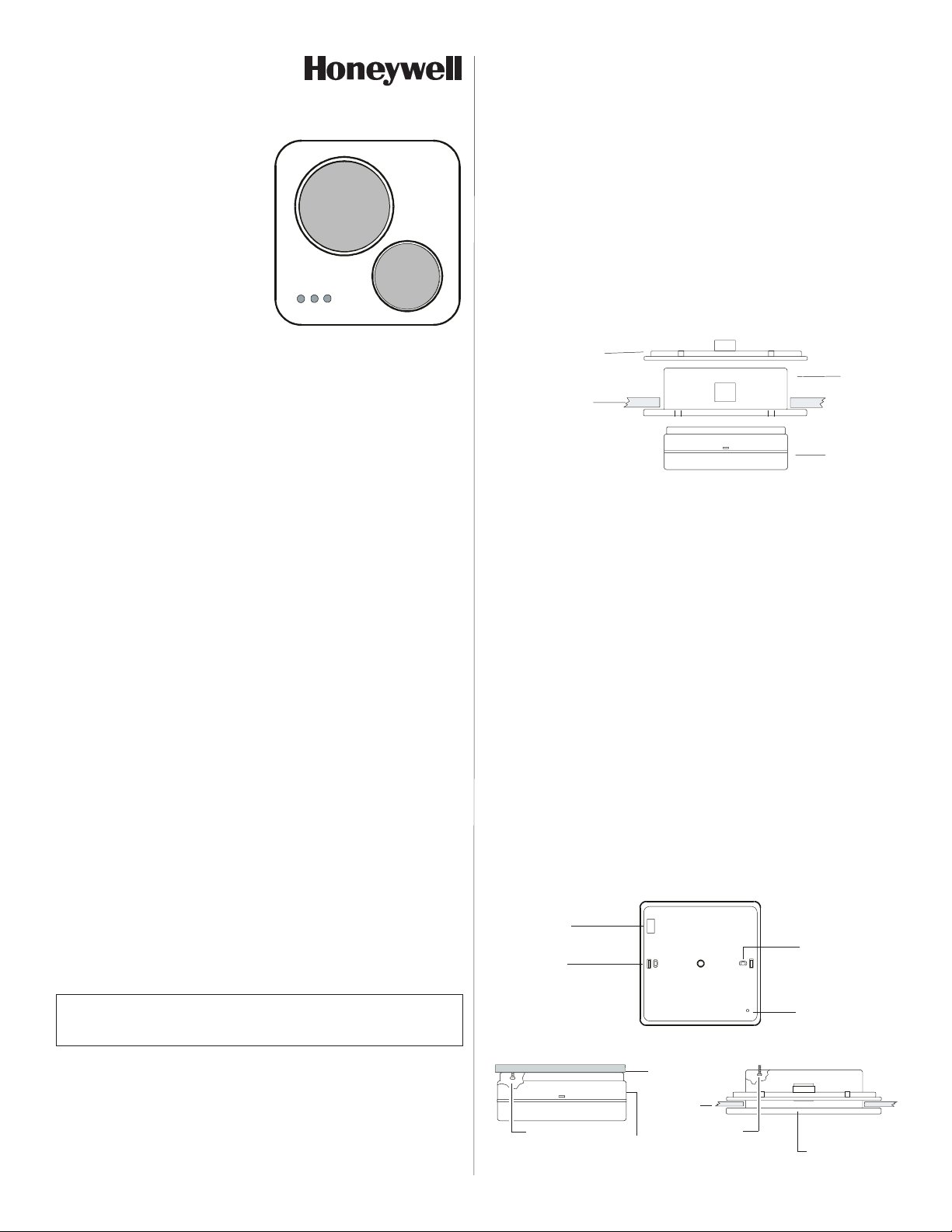

To flush mount the unit, cut a 5.5" x 5.5" (14 cm x 14 cm) hole in

the ceiling. Insert the recess bucket into the hole, using it as a

template to mark drill holes for the four mounting screws.

Remove the bucket and drill the screw holes.

If using the retainer ring, place it through, then directly over, the

hole in the ceiling tile. Make sure to orient the retainer ring

and recess bucket as shown in Figure 1.

Next, attach the back housing of the DT-6360STC to the inside

of the recess bucket, using the same screw holes and screws

used for surface mounting [#6 (M3.5) pan head]. Pull several

inches of wiring from the ceiling through the center hole in the

recess bucket and DT-6360STC back housing.

Insert the recess bucket into the hole in the ceiling, securing it to

the ceiling (and retainer bracket) with four mounting screws.

RETAINER

RING

CEILING

Figure 1

DT-6360STC

Flush Mounting Kit

RECESS

BUCKET

DT-6360STC

Tamper Installation

The DT-6360STC is equipped with two tamper switches: a cover

tamper and ceiling tamper. When the tamper switches are used,

removing the cover from the sensor will activate the cover tamper;

removing the sensor from the ceiling will activate the ceiling

tamper. Both tamper switches are normally closed (NC) and

internally wired in series.

The cover tamper switch can be used without the ceiling tamper

and requires no modifications to the DT-6360STC housing.

To use the ceiling tamper, remove the square knockout in the rear

housing (directly behind the ceiling tamper switch), then install a

screw* in the ceiling. Leave enough of the screw protruding to

depress the tamper switch. Refer to Figure 2.

If the installation is recessed, remove the knockout from the rear

housing, drill a screw hole (behind the knockout) in the recess

bucket, then install the screw* in the recess bucket. Leave

enough of the screw protruding to depress the tamper switch.

Refer to Figure 2.

Figure 2

*Note: #6 (M3.5)

pan head is

recommended.

KNOCKOUT

LATCH

REAR HOUSING

Cover and Ceiling

Tamper Switches

KEYHOLE

IMPORTANT: To ensure insects do not get inside the DT6360STC housing, make sure to seal all holes. (Recommended

sealant: silicone RTV.)

Flush Mounting

The DT-6360STC is shipped with a special kit for flush mounting. The kit contains a recess "bucket" and retainer ring. The

retainer ring is only needed when flush mounting the unit in

ceiling tile. Removing the tile from the ceiling (if possible) will

make the installation process easier.

- 1 -

SURFACE MOUNT

Screw

to depress

tamper

CEILING

DT-6360STC

CEILING

Screw

to depress

tamper

PIN FOR PCB

FLUSH MOUNT

DT-6360STC inside

recess bucket

Removing Front Cover After Installation (flush mount)

After installing and walk-testing the DT-6360STC flush mount, you

may need to make adjustments. Use a screwdriver to reopen the

front cover.

Insert the screwdriver as far as it will go in the grooves inside the

recess bucket. Gently press outward to release the latches

holding the front cover in place.

SYSTEM TESTING

DT-6360STC sensors are equipped with two diagnostic LEDs:

green for PIR and yellow for microwave. The red LED is used to

indicate an alarm condition.

Apply power to the sensor and wait until self-test is completed (90

seconds). Begin walk-testing after all three LEDs have gone out.

WIRING

Observing the proper polarity, wire the sensor as shown below

(use 22 to 14 AWG).

OPEN COLLECTOR

TROUBLE OUTPUT

Vce .3V max @ 50 mA.

1K series

protection resistor.

Figure 3

Wiring

Diagram

1

The Trouble Output is activated when a self-test failure or an INFORMER® condition occurs.

Refer to THE INFORMER CIRCUIT and the TROUBLESHOOTING sections.

2

EOL = End-of-Line (spare) terminal.

Note: Do not leave excess wire inside the unit. Push as much wire as

possible into the ceiling when returning the PCB to its housing.

Note: For proper wiring methods, refer to National Electrical Code NFPA

70.

Note: Reverse polarity will not damage the unit.

ALARM RELAY

1

EOL

TAMPER SWITCH

Normally Closed

(NC) with cover on

25 mA, 30 VDC.

TBL

125 mA, 25 VDC. 22 ohm

series protection resistor.

122

NC COM

CMD

REMOTE LED ENABLE or

COMMAND INPUT

(Self-Test Initiate) Active

Low 0 to 1.5 V Inactive

High 6 to V+ Input

Impedance 110 Kohms

(minimum).

EOL

NO

V-

V+

POWER

At 12 VDC,

typically

40 mA;

maximum

50 mA

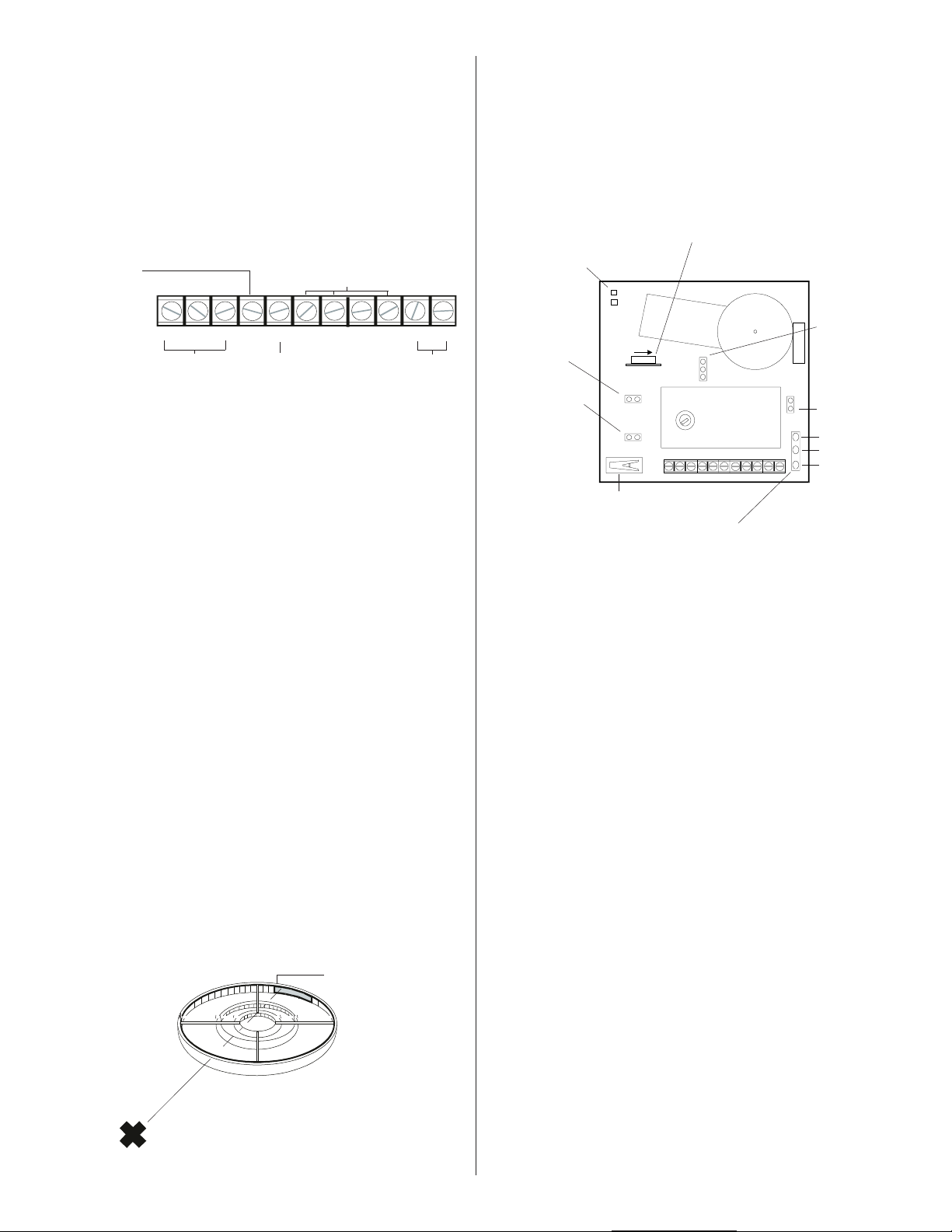

SYSTEM SET-UP

Changing the PIR Mirror Assembly

The DT-6360STC package contains two PIR mirror assemblies:

one for ceilings from 8' (2.4m) to 11' (3.3m) high, another for ceilings

from 12' (3.65m) to 16' (4.8m) high. The unit is shipped with the 8'-

11' (2.4m-3.3m) mirror installed.

To change the mirror assembly, remove the front cover and turn it

over. Next, remove the protective cap and existing mirror assembly

by depressing the four retaining latches at their sides. Store (or

discard) the existing mirror and install the new one. Snap the

protective cap back into place, then replace the front cover.

PIR Masking

To eliminate specific PIR zones from the pattern, mask corresponding segments on the PIR mirror with the adhesive-backed

masking tape provided. Remember, segments to be masked

will be on the side of the mirror OPPOSITE the unwanted zones.

See Figure 4.

Once the tape has been applied, walk-test the sensor to ensure

that the correct mirror segments have been masked.

PIR MASKING

MATERIAL

PLACED HERE

MICROWAVE RANGE

THUMBWHEEL R32 (set to

INSTALLER INITIATED

SELF-TEST

MOMENTARY SHORT

INSTALL JUMPER W3

TO DISABLE TROUBLE

OUTPUT WHEN AN

INFORMER CONDITION

OCCURS (jumper is

factory installed)

REMOTE LED ENABLE

or COMMAND INPUT

Jumper W4 installed:

CMD terminal functions as Remote LED Enable.

Jumper W4 removed:

CMD terminal functions as Command Input.

(Set to Command Input

at factory)

Red - During normal operation LED illuminates when an ALARM condition is triggered.*

Yellow - During normal operation LED flashes ON when a MICROWAVE event is detected.*

Green - During normal operation LED flashes ON when a PIR event is detected.* (PIR Zone Finder)

* If Self-Test fails or an INFORMER condition occurs, LEDs indicates nature of problem (see Tables 1,2 & 3)

maximum at factory)

MAX

R32

W3

W4

TAMPER SWITCH

ALARM & DIAGNOSTIC LEDs:

TOP

W1

BOTTOM

Figure 5

DT-6360STC PCB

PLACE JUMPER W1

TO DETERMINE PIR

SENSITIVITY

(jumper set to

normal at factory;

see page 3)

REMOVE JUMPER

W2 TO DISABLE

DIAGNOSTIC LEDS

AND ALARM LED

W2

(jumper is factory

installed)

RED

YELLOW

GREEN

Microwave Range Adjustment

DT-6360STC sensors are equipped with a microwave range

thumbwheel (R32) for range adjustment. (Refer to Figure 5.)

Set the range at MINIMUM by turning the thumbwheel all the

way to the left.

As you perform the walk-test, gradually turn the thumbwheel to

the right to increase the microwave sensitivity until the desired

ranged is obtained.

Walk-test

Walk across the protected area at the ranges to be covered.

Two to four normal steps make the diagnostic LEDs light, and

the red LED should indicate an alarm condition. When there is

no motion in the protected area, all three LEDs should be off.

COMMAND INPUT / REMOTE LED ENABLE

Position W4 determines what function the Command Input

(CMD) terminal will provide.

Installing a jumper at position W4 makes the CMD terminal

function as a Remote LED Enable terminal. If the signal to the

Remote LED Enable terminal is low, the LEDs are enabled. If

the signal to the terminal is high, the LEDs are disabled.

However, if a self-test error occurs, the LEDs will light regardless

of the state of the signal.

WILL BLOCK ZONES

HITTING HERE

Figure 4

Masking the PIR

Mirrors

The CMD terminal functions as a Command Input terminal when

the jumper is removed from position W4. A momentary low

signal to the terminal (at least .5 seconds) will initiate the selftest.

LED DISABLE (Local)

To disable the diagnostic LEDs and alarm LED, remove the

jumper from position W2 on the PCB. (See Figure 5.)

- 2 -

Loading...

Loading...