Page 1

DS05C,D,G

DIAL-SET® PRESSURE REGULATING VALVES

FEATURES

• Built-in, factory calibrated outlet pressure adjustment

dial.

• Noncorroding unitized cartridge contains all working

parts and is easily replaceable.

• Includes built-in strainer and thermal bypass.

• Balanced seat construction provides superior

pressure regulation.

• Inlet and outlet are internally threaded female NPT, and

externally threaded for use with union assemblies.

• Stand-In Pipe available for temporary installation

during construction or system flushing.

PRODUCT DATA

APPLICATION

The Honeywell DS05C,D,G Dial-Set® Pressure Regulating

Valve is a high quality pressure regulating valve that maintains

a constant outlet pressure over a wide range of inlet supply

pressures. It is suitable for potable water and irrigation

applications. The downstream pressure adjustment dial

eliminates the need for a pressure gauge when adjusting the

pressure setting (static pressure only).

SPECIFICATIONS

Model: DS05 Dial-Set Pressure Regulating Valves.

Construction Materials:

Body: Bronze.

Internal Parts: Stainless steel and engineered plastics.

Regulator Mechanism: Fabric-reinforced diaphragm.

Seat Design: Balanced single seat construction.

Inlet Pressure (Maximum): 400 psi maximum.

Reduced Pressure Range:

5 to 75 psi (1/2 in. to 1 in.).

15 to 130 psi (1-1/4 in.).

Outlet Pressure: Factory set at 60 psi.

Dial Calibration: ±4 psi.

Contents

Applications/Features/Specifications.................................1

Ordering Information .........................................................2

Installation/Maintenance....................................................4

Troubleshooting.................................................................6

Operation...........................................................................7

DS05 Parts and Accessories.............................................8

62-3041—4

Page 2

DS05C,D,G

Differential: 14 psi minimum (inlet to outlet).

Reduced Ratio: 10:1 maximum.

Temperature (Maximum):

Air: 158° F (70° C).

Water: 180° F (82° C).

Ambient Temperature Range:

33° F to 140° F (1° C to 60° C).

Pipe Sizes Available:

1/2 in., 3/4 in., 1 in., and 1-1/4 in. available.

Connections:

Can be configured as female thread-by-thread, single-union

or double-union, NPT threaded or sweat.

Strainer Screen Size: 0.032 in. (0.8 mm).

Gauge Tap: 1 1/4 in. model only.

Approvals:

ASSE (Std. 1003) Certified.

IAPMO, CSA, and City of L.A Listed.

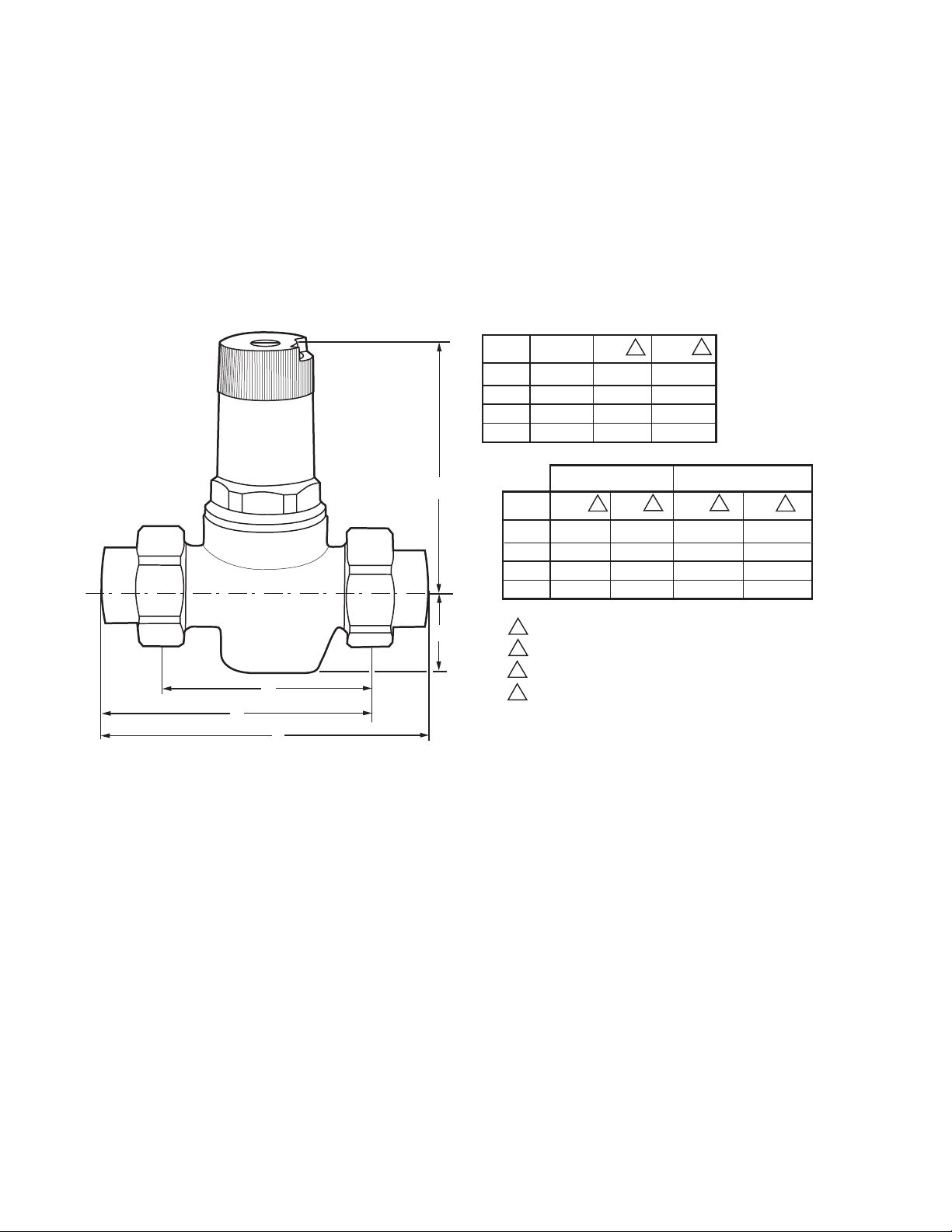

Dimensions: See Figure 1.

SIZE

(INCHES)

1/2

3/4

1

1-1/4

C

(INCHES)

4

4

4

5-9/16

SIZE

1/2

3/4

1

1-1/4

C

(102)

(102)

(102)

(141)

SWEAT TAILPIECE

A

3-7/8

4-5/16

(110)

5-1/4

(133)

6-3/16

(157)

(99)

2

1-3/4

1-3/4

1-3/4

2-5/8

D

(32)

(32)

(32)

(66)

B

4-5/8

5-3/16

6-1/2

7-11/16

4

3

(118)

(132)

(166)

(195)

1

E

(81)

3-3/16

(89)

3-1/2

(100)

3-15/16

(119)

4-11/16

THREADED TAILPIECE

2

AB

(103)

4-1/16

(110)

4-5/16

(127)

5

(152)

6

4-15/16

5-3/16

6-1/16

7-5/16

3

(126)

(132)

(154)

(185)

D

E

A

1 NON-UNION MODEL CONFIGURATION.

2 SINGLE-UNION MODEL CONFIGURATION.

3 DOUBLE-UNION MODEL CONFIGURATION.

4 DIMENSION WITH GAUGE PLUG.

M13748

B

Fig. 1. DS05 Installation dimensions in inches (mm).

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Toronto, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

®

Catalog or price sheets for complete ordering number.

1885 Douglas Drive North

Golden Valley, Minnesota 55422-4386

62-3041—4 2

Page 3

DS05C,D,G

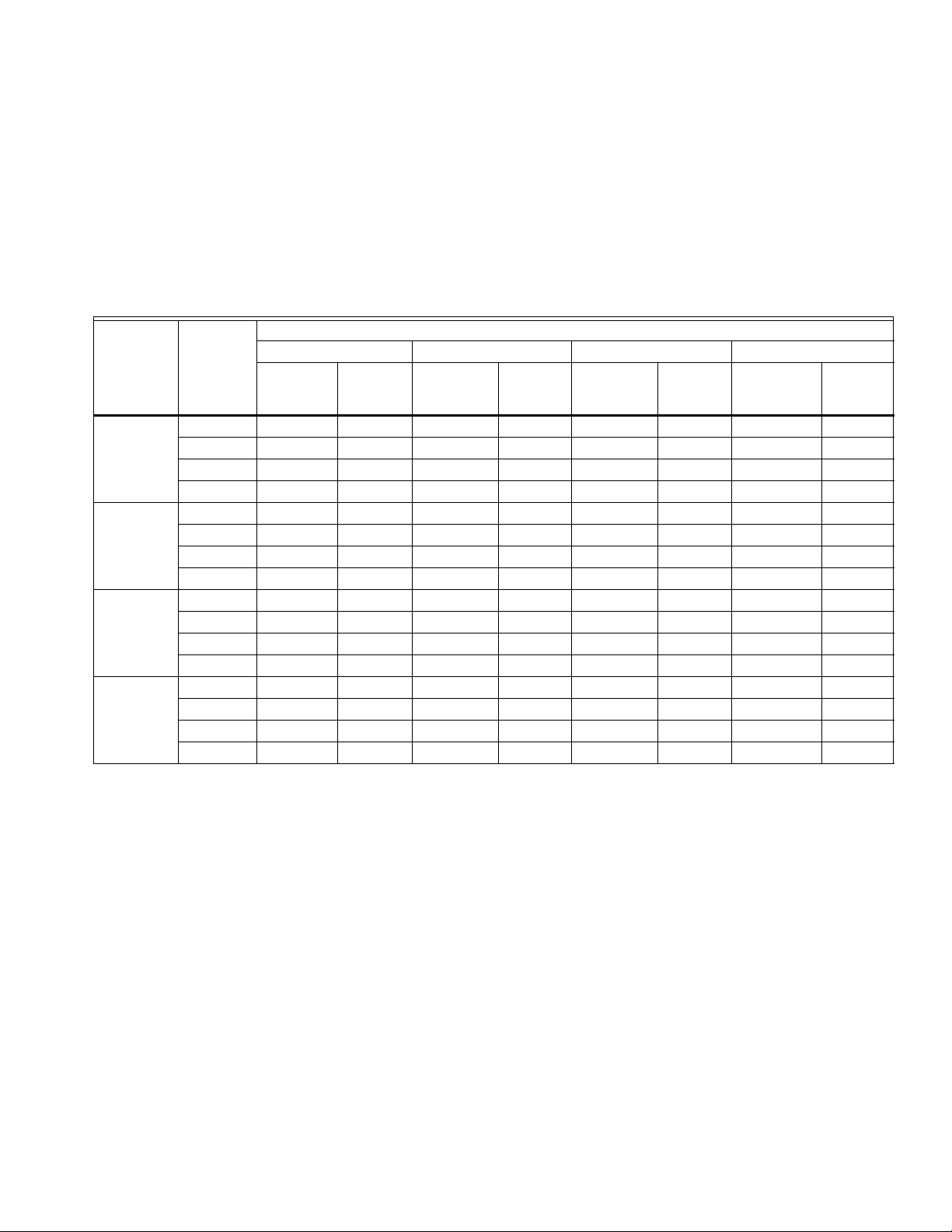

Water Capacities (See Table 1)

The suitability of a given regulator size is dependent on the

pressure requirements where it will operate. For the pressure

regulator valve size required for a specific installation,

determine the following:

1. Pressure differential between inlet and outlet pressure in

pounds per square inch (psi),

2. Capacity in gallons per minute, and

3. Allowable reduced pressure falloff in psi.

Table 1. Water Capacities.

Pressure Differential Between Inlet and Outlet

25 psi 50 psi 75 psi 100 psi or more

Flow

Velocity

(ft/sec)

a

Flow

Capacity

(US gpm)

Pressure

Regulator

Valve Size

Reduced

Pressure

Falloff

(psi)

Capacity

(US gpm)

1/2 inch 6 1.2 1.3 2.3 2.4 3.3 3.5 4.4 4.6

10 8.8 9.3 10.1 10.7 10.6 11.2 10.6 11.2

15 13.2 13.9 15.0 15.8 17.6 18.6 17.6 18.6

20 17.6 18.6 20.7 21.9 22.0 23.2 22.9 24.2

3/4 inch 6 3.6 2.1 4.0 2.4 4.0 2.4 4.0 2.4

10 8.1 4.9 9.3 5.6 9.9 6.0 9.9 6.0

15 14.7 8.8 17.6 10.6 19.8 11.9 20.6 12.4

20 23.0 13.8 27.7 16.7 32.1 19.3 4.1 20.5

1 inch 6 5.7 2.1 5.9 2.2 5.9 2.2 6.3 2.4

10 13.2 4.9 15.4 5.7 15.7 5.8 16.4 6.1

15 19.6 7.3 24.6 9.1 18.6 10.6 31.7 10.8

20 25.7 9.6 32.1 11.9 37.6 14.0 43.6 16.2

1-1/4 inch 6 13.5 2.6 16.0 3.4 20.0 4.3 22.0 4.7

10 22.0 4.7 29.0 6.2 34.0 7.3 38.0 8.1

15 37.0 7.9 56.0 12.0 62.5 13.4 73.0 15.6

20 55.0 11.8 78.0 16.7 87.0 18.6 101.0 21.6

a

Velocity in feet per second is based on schedule 40 pipe size. Recommended pressure falloff for general use is approximately

104 kPa (15 psi). Recommended velocities for the flow of water: residential and general use, 5 to 10 ft/sec; industrial use, 7 to 15

ft/sec; boiler feed, 7 to 15 ft/sec.

Given these variables, use Table 1 to determine the proper

size pressure regulator valve for your application.

Example: An installation has 135 psi inlet pressure, 60 psi

outlet pressure (75 psi pressure differential). If a 12 gpm

capacity is required with only 10 psi falloff allowable, a 1/2 in.

DS05 is required.

Velocity

(ft/sec)

a

Flow

Capacity

(US gpm)

Vel ocit y

(ft/sec)

a

Flow

Capacity

(US gpm)

Vel ocit y

(ft/sec)

a

3 62-3041—4

Page 4

DS05C,D,G

A

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition

2. Check the ratings given in these instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out the product

operation as provided in the instructions.

Procedure

1. Flush the system clear of sediment or debris.

2. Close the supply valve and downstream isolating valve

(if one is installed).

3. Install the DS05 with the arrow on the body pointing in

the direction of water flow. (The DS05 can be mounted in

any position.)

The DS05 can be installed directly onto the pipe by using the

female NPT threads on each end. If space limitations restrict

turning the DS05, install single-unions or double-unions.

NOTE: Heat from soldering can damage internal parts of the

DS05. Always solder the tailpieces separately from

the DS05.

4. Open the supply valve slowly and check for leakage and

proper operation of the DS05.

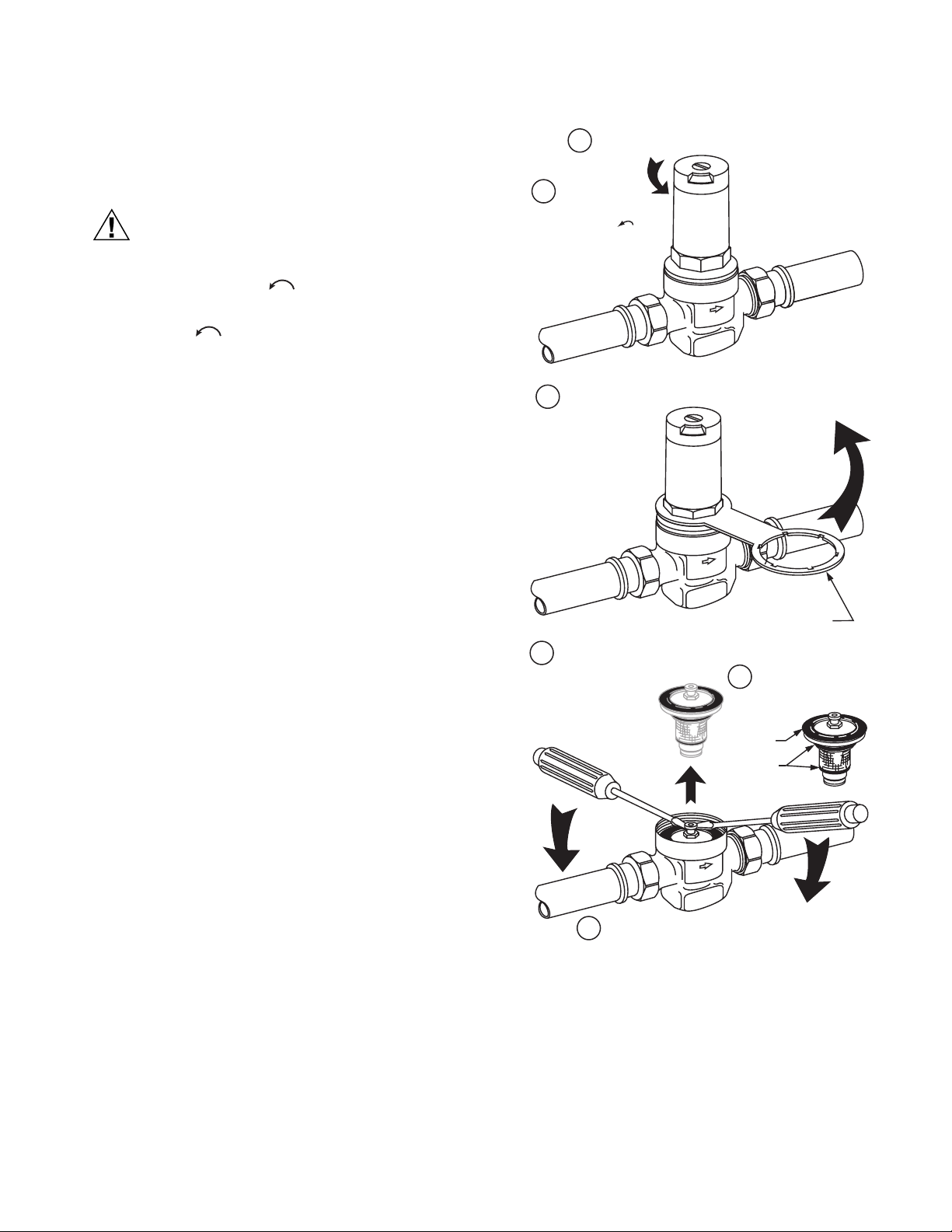

Changing the Downstream Pressure (See Fig. 2)

Remove the dust cap from the DS05. The DS05 is factory set

to 60 psi.

MAINTENANCE

Replacing the Cartridge (See Fig. 3)

The working parts of the DS05 including diaphragm, valve

seat, strainer and disk are all contained in a replaceable

cartridge. To replace the cartridge:

1. Shut off the supply valve and open a downstream faucet

to relieve the system pressure.

2. Loosen the setpoint screw by turning it counterclockwise (Do not remove this screw).

LOOSEN LOCKING

SCREW ONE TURN

DJUST SETPOINT AT THE DESIRED VALUE BY ACTUATING SELECTOR.

60

INLET PRESSURE (MAXIMUM): 400 PSI

REDUCED PRESSURE RANGE:

15 TO 75 PSI 1/2 IN. –1 IN. SIZE

15 TO 130 PSI 1 1/4 IN. SIZE

NOTE: DO NOT DISMANTLE KNOB

SET-POINT READOUT HAS BEEN CALIBRATED

IN THE FACTORY AND SET AT 60 PSI.

DISMANTLING THE SELECTOR KNOB WILL

CANCEL THIS CALIBRATION. RECALIBRATE

USING A PRESSURE GAUGE. SEE RECALIBRATION.

Fig. 2. Changing outlet pressure.

60

M7315C

To adjust the outlet pressure to a desired setting:

1. Loosen the locking screw by turning one turn counterclockwise (do not remove this screw).

2. Turn the adjusting knob counter-clockwise

to reduce pressure or clockwise to increase

pressure.

3. Lock the setting by turning the locking screw

clockwise .

4. Replace the dust cap over the dial.

CAUTION

To prevent injury and/or equipment damage,

loosen locking screw and turn adjusting knob

counter-clockwise to remove spring tension.

3. Turn adjusting knob counter-clockwise to remove

spring tension.

4. Remove the bonnet and washer using an MT06A

Service Tool.

5. Remove the cartridge using two screwdrivers as levers.

Attach new O-rings and screen onto the new cartridge.

6. Make sure O-rings are properly installed above and

below the screen.

7. Insert the new cartridges. Do not scratch the sides.

8. Place the washer on top of the cartridge.

NOTE: The inner lip must be pointing up to avoid damaging

the diaphragm.

9. Replace the spring and bonnet.

10. Readjust the outlet pressure to the desired setting by

using the procedure described in Changing the

Downstream Pressure section.

62-3041—4 4

Page 5

Cleaning the Cartridge Screen

To clean the cartridge screen:

1. Shut off the supply valve and open a downstream faucet

to relieve the system pressure.

CAUTION

To prevent injury and/or equipment damage,

loosen locking screw and turn adjusting knob

counter-clockwise to remove spring tension.

Do not remove screw.

2. Loosen locking screw and turn adjusting knob counter-

clockwise to remove spring tension.

3. Remove the bonnet and washer using an MT06A service

tool.

4. Remove the cartridge using two screwdrivers as levers

as shown in Figure 3.

5. Remove and clean the cartridge screen.

6. Replace the cartridge screen and make sure the O-rings

are installed properly.

7. Carefully clean the cartridge seat area.

8. Insert the cartridge. Do not scratch the sides.

9. Place the washer on top of the cartridge.

LOOSEN THE SETPOINT DIAL LOCKING SCREW.

1

UNSTRESS THE

2

PRESSURE SPRING

BY TURNING COUNTERCLOCKWISE .

UNSCREW THE BONNET WITH MT06A SERVICE TOOL.

3

60

60

DS05C,D,G

NOTE: The inner lip must be pointing up to avoid damaging

the diaphragm.

10. Replace the spring and bonnet.

11. Readjust the outlet pressure to the desired setting by

using the procedure described in Changing the Outlet

Pressure section.

Recalibration

If the dial knob assembly has been dismantled, recalibration is

necessary. Recalibrate as follows:

1. Install a good quality pressure gauge at the gauge tap

connection.

2. Open supply pressure and adjust spindle until the gauge

shows 60 psi.

3. Reassemble dial ring and adjustment knob so dial reads

60 psi.

MT06A SERVICE TOOL

(ORDER SEPARATELY)

REMOVE CARTRIDGE USING TWO SCREWDRIVERS AS LEVERS.

4

WHEN REASSEMBLING,

5

ENSURE O-RINGS AND

WASHER ARE PROPERLY

INSTALLED

WASHER

(LIP UP)

O-RINGS

REASSEMBLE BONNET IN REVERSE ORDER.

6

M7313A

Fig. 3. Replacing the DS05 cartridge.

5 62-3041—4

Page 6

DS05C,D,G

TROUBLESHOOTING

Table 2 provides a troubleshooting guide for the DS05 Dial Pressure Regulating Valve.

Table 2. Troubleshooting the DS05 Dial-Set Pressure Regulating Valve.

Problem Solution

Whistling noise. • Slightly increase or decrease the outlet pressure until the noise goes away.

Will not hold pressure. • Clean the filter cartridge as described in the installation section.

Chatters. • Replace screen and O-rings.

• Replace the cartridge as shown in Figure 3.

Freezes up. • Replace bonnet or cartridge if damaged.

• To avoid further freeze up:

— Temporarily (slightly) open a downstream faucet if the DS05 will be exposed to

temperatures below 32° F (0° C). The slight water flow will eliminate freeze-up.

— Move the DS05 to a location with an ambient temperature above 32° F (0° C) if it is

currently exposed to prolonged temperature below 32° F (0° C).

Pressure gauge measures a lower

pressure under flow conditions than was

originally set during static conditions.

• DS05 is functioning properly. No action is necessary. The pressure decrease is

characteristic of all direct acting pressure regulating valves and is referred to as

falloff.

62-3041—4 6

Page 7

DS05C,D,G

OPERATION

DUST CAP

(BLACK)

LOCKING SCREW

ADJUSTING

KNOB

60

DIAL RING

BONNET

SPINDLE

SPRING

The Honeywell DS05 Dial-Set Pressure Regulating Valve is a

balanced, direct acting pressure regulating valve. The DS05

provides constant downstream pressure regardless of varying

inlet pressures and downstream flow demands.

The spring force holds the valve in the open position until

downstream pressure sensed by a port, is sufficient to press

on the underside of the diaphragm and close the valve. As

downstream pressure drops due to demand, the force on the

diaphragm is reduced and the valve opens. Adjustment is

made by manually turning the adjustment knob

clockwise to increase the spring force and require a

higher downstream pressure to close the valve. Similarly,

reducing the spring force lowers the outlet set pressure. A

factory-calibrated dial is built into the adjustment mechanism to

allow outlet pressure (no flow) to be set without a gauge. A

locking screw maintains the setting. A black plastic cover is

provided to conceal the setting and protect the Dial-Set from

moisture and debris.

Once the outlet pressure is set, the DS05 automatically

regulates to maintain the downstream pressure. See Figure 5

for the internal construction of the DS05.

Minimum ambient rating is 33° F (1° C).

GASKET

TAILPIECE

NUT

GAUGE TAP PLUG

WASHER

CARTRIDGE

O-RING

SCREEN

O-RING

GASKET

BODY

Fig. 4. DS05 exploded view.

NUT

TAILPIECE

M7314

INLET

60

OUTLET

M7327

Fig. 5. Internal construction of DS05.

7 62-3041—4

Page 8

DS05C,D,G

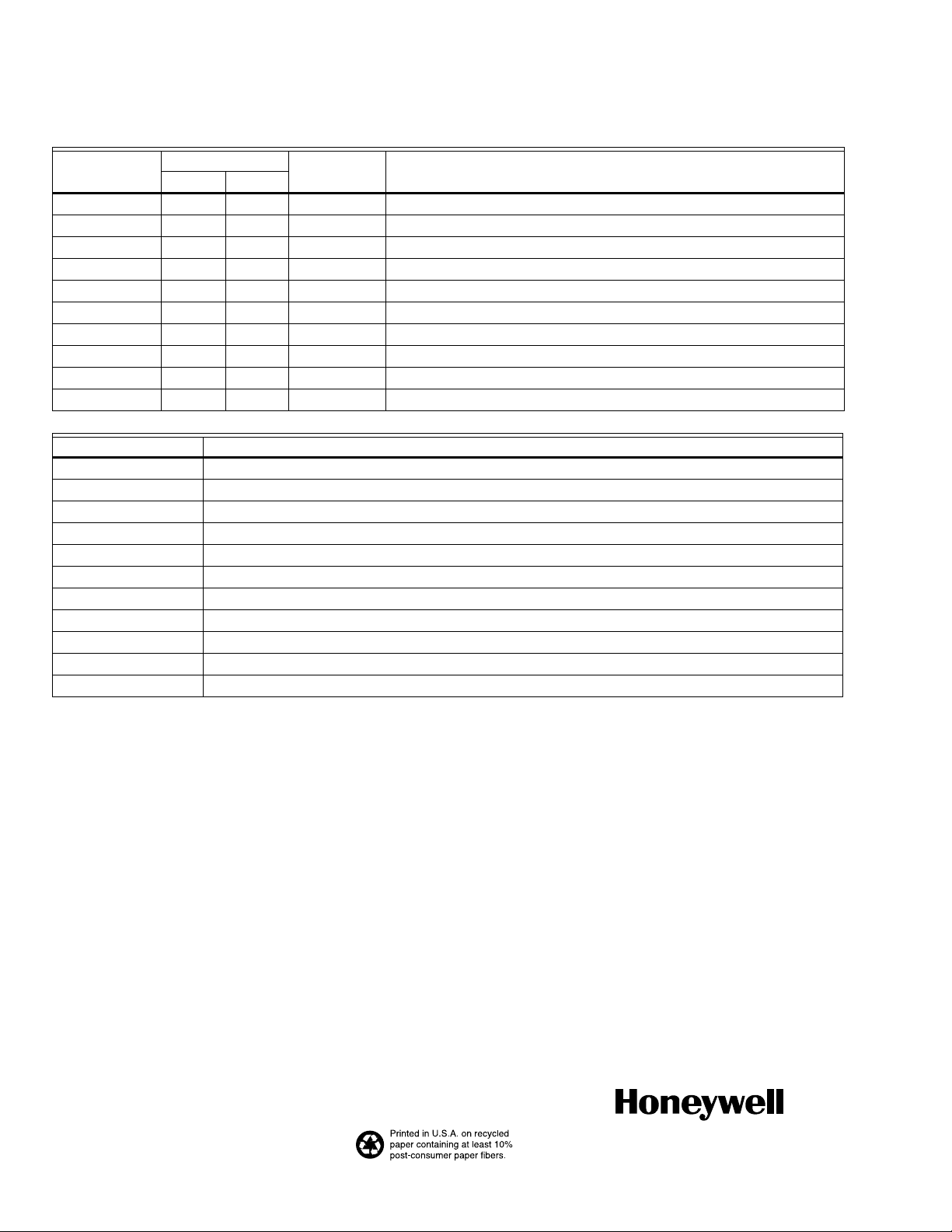

DS05 Parts & Accessories

Product

Number

Pipe Size

Pipe

Connection Description(inch) DN

K06U1135 1-1/4 DN32 - Union kit for 1-1/4 in. NPT D05 and DS05 Series Valves.

K06U1150 3/4 DN20 Sweat 3/4 in. Jumper Kit- 2 Sweat Unions, Gaskets and Nuts.

K06U1168 1 DN25 Sweat 1 in. PRV Jumper Kit- 2 Sweat Unions, Gaskets and Nuts.

K06U1184 3/4 DN20 Female NPT 3/4 in. PRV Jumper Kit- 2 Threaded Unions, Gaskets and Nuts.

K06U1192 1 DN25 Female NPT 1 in. PRV Jumper Kit- 2 Threaded Unions, Gaskets and Nuts.

K06U1200 1-1/4 DN32 Sweat 1-1/4 in. Jumper Kit - 2 Sweat Unions, Gaskets, and Stand-in Pipe.

K06U1218 1-1/4 DN32 Female NPT 1-1/4 in. Jumper Kit- 2 Threaded Unions, Gaskets and Stand-in Pipe.

PRV202-039 3/4 DN20 Male NPT 3/4 in. Stand-in Pipe.

PRV202-040 1 DN25 Male NPT 1 in. PRV Stand-in Pipe.

PRV203-034 1-1/4 DN32 Male NPT 1-1/4 in. PRV Stand-in Pipe.

Product Number Description

272838 Bonnet for 1/2 in. and 3/4 in.

272839 Bonnet for 1 in. and 1-1/4 in.

272840 Union Gaskets for 1/2 in.

272841 Union Gaskets for 3/4 in.

272842 Union Gasket for 1 in.

272843 Union Gasket for 1-1/4 in.

K05A1009 Repair Kit for 1/2 and 3/4 in.

K05A1017 Repair Kit for 1 and 1-1/4 in. (DS05C)

K05A1025 Repair Kit for DS05C/D05T 1/2 in, 3/4 in. & 1 in.

K05B1007 Repair Kit for 1/2 in. and 3/4 in.

K05B1015 Repair Kit for 1 in.

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Toronto, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2006 Honeywell International Inc.

62-3041—4 C.H. Rev. 10-06

Loading...

Loading...