Page 1

DRR/HE

THREE-WAY ROTARY VALVE PN10 AND HE25 EXTENSION

PRODUCT DATA

APPLICATION

The DRR25 Three-Way Rotary Valve provides water

temperature control in heating and air-conditioning

applications. These valves are designed for accurate mixing

control of supply water temperature and return-flow

temperature.

The sturdy construction and red brass material ensure long

operating life and high reliability when used in combination

with M6061/VMM and M7061/VRM actuators. The special

inner form of the housing and the all-around changeable

rotary plug allow the valve to be adapted to each possible

application without having to drain the system.

The DRR25 Three-Way Rotary Valve is especially designed

for applications with sludge deposition and for panel heating

(e.g. underfloor and ceiling heating systems) with oxygen

diffusion.

In combination with the distance-adjustable HE25 Extension,

use in a wide range of pre-piped systems is possible.

FEATURES

• Chrome-plated plug for long life-span

• Optimized characteristics for supply water

temperature control

• All around changeable rotary plug

• Reliable and easy mounting of electrical actuators

• Wide range of flow rates in two housing sizes

• Compact design

• Use for manifolds by accessory HE25 Extension

• Thermal insulation package included

SPECIFICATIONS

Nominal static pressure 10 bar; 1000 kPa

Maximum pressure drop dependent on type (see table

on page 3)

Leakage rate < 1% of k

Ports External threads with cap nuts

Angle of rotation 90 °

Packing Double O-ring lined

Material body Red brass

Material inner parts Chrome-plated cast iron

Medium Heating water according to

VDI 2035 (oxygen concentration

less than 0.2 g/m

Water temperatures

in the valve 2...130 °C, non-condensing

Weight dependent on type (see tables in

section "Dimensions" on page 4)

Flow characteristic equal percentage

VS

3

, pH 8...9.5)

® U.S. Registered Trademark EN0B-0611GE51 R1108

Copyright © 2008 Honeywell Inc. • All rights reserved

Page 2

DRR/HE – PRODUCT DATA

OPERATION

The valve controls a mixing water temperature by means of a

rotating plug. The plug adjusts the water flow of two inputs

with two control curves. The required flow water temperature

is achieved by adding a proportion of return water to the

boiler hot water. The DRR has special control characteristics

for optimal control performance.

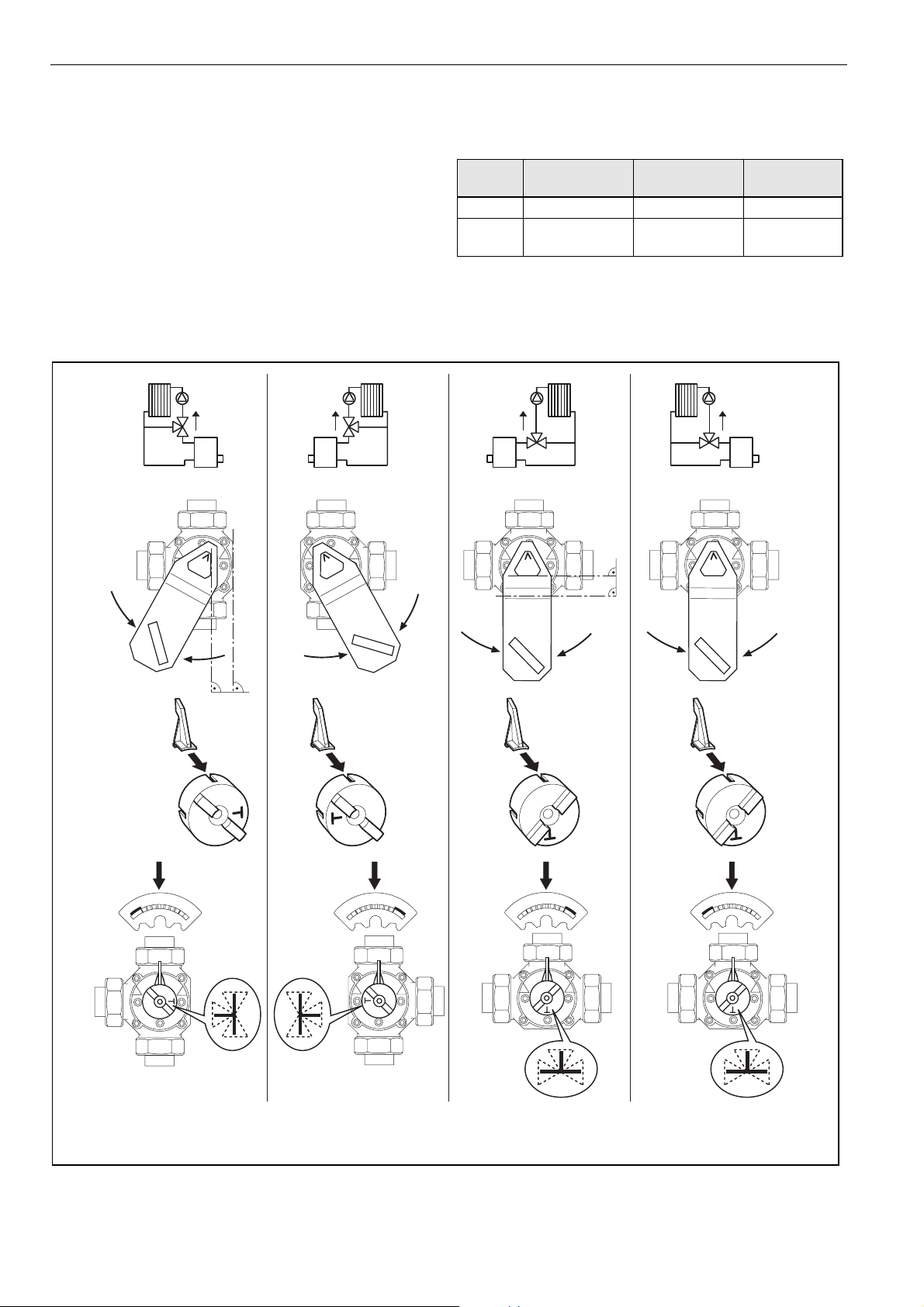

MOUNTING

Adjustments for Mixing Applications

SUITABLE ACTUATORS

torque

[Nm]

10 M6061A1013 M6061L1019 M7061E1012

20

OS no.

24 Vac float.

M6061A1021 /

VMM20-24

OS no.

230 Vac float.

M6061L1027 /

VMM20

OS no.

0/2...10V

M7061E1020

/ VRM20

09 09

EN0B-0611GE51 R1108 2

09 90

Page 3

DRR/HE – PRODUCT DATA

Mounting the Actuator

SPECIFICATION AND ORDER NUMBER PER DN

OS No. DN

DRU25-2.5 25 2.5 7-12 100 10

DRU25-4.0 25 4.0 12-17 100 10

DRU25-6.3 25 6.3 17-30 100 10

DRU25-10 25 10.0 30-50 100 10

DRU25-16 25 16.0 50-70 100 10

HE25 25 - - - - - -

kvs heat flow

[m³/h] [kW] [kPa] [Nm]

nom. torque actuator

∆p

floating

M6061A1013,

M6061A1021 / VMM20-24,

M6061L1019,

M6061L1027 / VMM20

modulating

M7061E1012,

M7061E1020 / VRM20

ACCESSORIES

connection set description DN pipe size [mm] weight [kg] OS No.

Welding sockets with

gasket and cap nut

Soldering sockets with

gasket and cap nut

25 25 0.3 WTU25

25

25

25

18

22

28

0.21

0.21

0.21

LSU25-18

LSU25-22

LSU25-28

Internal threaded sockets

with gasket and cap nut

3 EN0B-0611GE51 R1108

25 25 0.21 STU25

Page 4

DRR/HE – PRODUCT DATA

DIMENSIONS

DRR

type DN a b c d e g h R weight [kg]

DRR25-2.5 25 55 32 110 89 55 51 182 1 ½ 2.48

DRR25-4.0 25 55 32 110 89 55 51 182 1 ½ 2.48

DRR25-6.3 25 55 32 110 89 55 51 182 1 ½ 2.50

DRR25-10 25 55 32 110 89 55 51 182 1 ½ 2.53

DRR25-16 25 55 32 110 89 55 51 182 1 ½ 2.51

a

b d

R

c

e

HE

type DN a b e f g R weight [kg]

HE25 25 110 42 55 0-25 51 1 ½ 1.7

=g

e

a

b

f

gg

h

R

EN0B-0611GE51 R1108 4

Page 5

DRR/HE – PRODUCT DATA

HYDRAULIC FUNCTION

Characteristics

100%

80%

60%

40%

20%

0%

Spare Parts

• O-ring (part no.: 07169 9535)

HE25

3

2

5

4

6 7 8 9

5 EN0B-0611GE51 R1108

Page 6

DRR/HE – PRODUCT DATA

V

/

VALVE DIMENSIONING

Honeywell Rotary Valves are employed mainly in hydraulic systems corresponding to the examples shown on page 2. The

rotary valve can be set quite easily. In order to obtain good control characteristics, the pressure drop in the rotary valve should

be about the same as the pressure drop in the "volume-variable" part of the pipe system, i.e. about 1.5...4.0 kPA or

15...40 mbar. The following dimensioning diagram is based on this interrelationship. The setting is obtained as follows:

1. Find heat flow in the diagram.

2. Move vertically upwards to the intersection with the corresponding ∆ϑ line. On the vertical axis, the volume flow

can be read off on the left in liters per hour.

3. Move horizontally to the right from the intersection with the ∆ϑ line into the shaded section (1.5-4.0 kPa). Here you will find

the nominal rotary valve size to be selected.

4. From this intersection, go vertically downwards. Read off the pressure drop in the rotary valve in kPa (mbar).

VOLUME FLOW (m3/h)

&

Q

&

V

1010

5

2

=

S

V

k

6

1

=

S

V

2

3

N

)

C

°

(

K

0

1

K

=

5

1

ϑ

∆

K

K

0

3

0

2

K

0

K

4

0

5

D

2

3

N

D

/

5

2

N

D

2

N

D

2

3

N

D

/

5

5

N2

D

5

2

N

D

5

N2

D

k

0

1

=

S

V

k

3

.

6

=

S

V

k

4

=

S

V

k

5

.

2

=

S

V

k

77

55

33

OLUME FLOW (m3

22

11

0.70.7

0.50.5

h)

0.30.3

0.20.2

100

10

(mbar)

(kPa)

0.3

5

3

4

0.7

0.5

5

10 100 7

7

30 20

20 200 10

HEAT FLOW (kW)

Example Given: Heat flow = 10 kW, ∆ϑ = 15 K (e.g. 70/55 °C)

70 50

50 30

2

0.2

&

Q

3

1

2

PRESSURE DROP

70

5

7

Required: Nominal rotary valve size and pressure drop

Volume flow:

&

V

Result: According to the diagram, the correct valve size is DN25, k

drop is 2 kPa or 20 mbar or 200 mm water column.

&

Q

=

∆1.163

ϑ∗

10

=

=

151.163

∗

3

/hm 0.57

4.0 (DRR25-4.0). The pressure

vs

(Factor 1.163 contains the water density 1000 kg/m3 and the specific heat capacity 4.19 kJ/kgK.

∆ϑ is the temperature difference between supply and return flow in Kelvin)

Unit Conversion 1 kW = 3600 kJ/h 1 bar = 100 kPa

= 860 kcal/h = 10 m water column

1000 kcal/h = 1.163 kW 1 mbar = 10 mm water column

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Rolle, Z.A. La Pièce 16, Switzerland by its Authorized Representative:

Automation and Control Solutions

Honeywell GmbH

Böblinger Strasse 17

71101 Schönaich

Germany

Phone: (49) 7031 63701

Fax: (49) 7031 637493

http://ecc.emea.honeywell.com

Subject to change without notice. Printed in Germany

EN0B-0611GE51 R1108

Loading...

Loading...