Page 1

DR65A3000

33-00297EFS-01

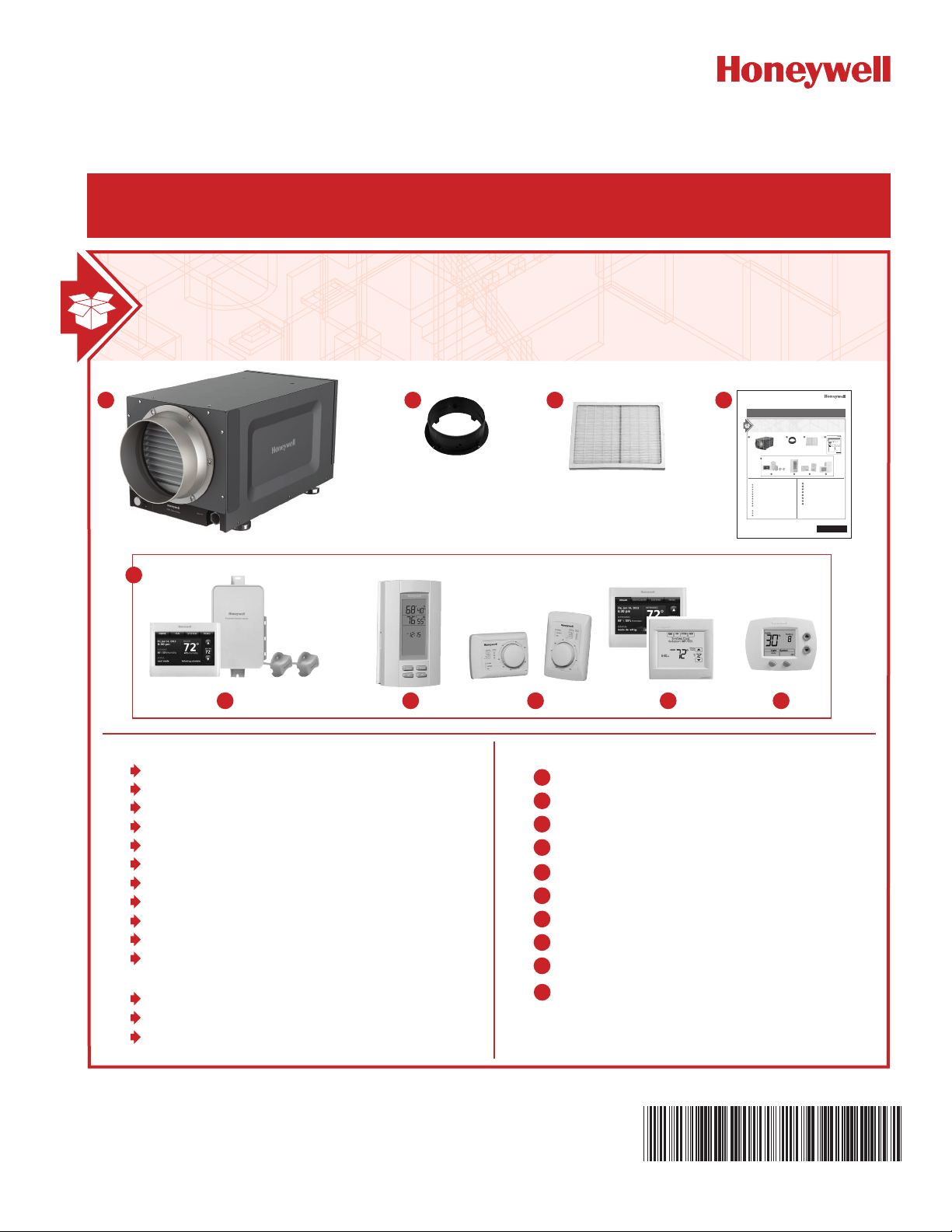

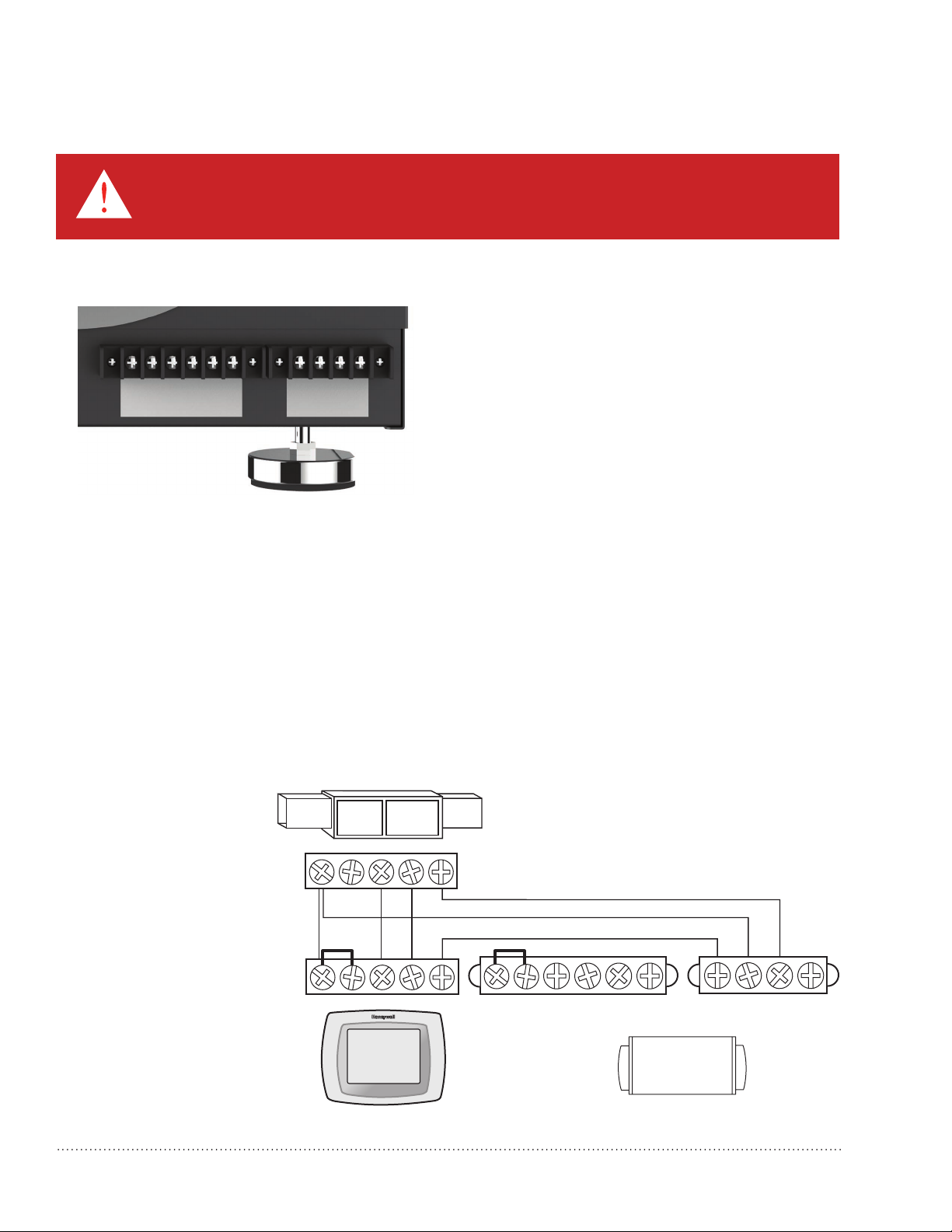

INCLUDED IN THIS BOX

PROFESSIONAL INSTALLATION GUIDE

GUIDE D’INSTALLATION PROFESSIONNELLE

GUÍA DE INSTALACIÓN PROFESIONAL

A B C

F

OPTIONAL CONTROLS SOLD SEPARATELY

F1 F3F2 F4 F5

Tools required to install DR65A3000 dehumidifier

3/8” hex drive

Drill or duct cutting tool

Wire stripper/cutter

Standard screwdriver

T20 Torx screwdriver

Duct tape

8” round duct and starter collar

1822 gauge, 5 conductor thermostat wire

1/2” diameter drain line (8’)

1/2” drain clamps (2)

3/4” male NPT drain outlet

A

B

C

D

E

F1

F2

F3

F4

Options

1/2” drain p-trap (may be required by local code)

Drain pan

Float switch or water sensor (normally closed)

F5

D

DR65A3000

INCLUDED IN THIS BOX

OPTIONAL CONTROLS SOLD SEPARATELY

E

E1 E3E2 E4

Tools required to install TrueDRY DR65

3/8-in. hex drive

Drill or duct cutting tool

Wire stripper/cutter

Standard screwdriver

Duct tape

8-in. round duct and starter collar

18-22 gauge, 5 band thermostat wire

1/2-in. diameter drain line (8 ft.)

1/2-in. drain clamps (2)

3/4-in. male NPT drain outlet

Options

1/2-in. drain p-trap (may be required by local code)

Drain pan

Float switch or water sensor (normally closed)

DR65A3000 (1)

8” duct collar (2)

MERV 11 Filter (1)

Installation Guide

Filter Door (2)

Prestige IAQ Kit

TruelAQ

H8908 Manual Dehumidistat

VisionPRO or Prestige Thermostat

H6062 HumidiPRO Digital Humidity

Control

PROFESSIONAL INSTALLATION GUIDE

GUIDE D’INSTALLATION PROFESSIONNELLE

GUÍA DE INSTALACIÓN PROFESIONAL

DA B C

TrueDRY™ DR65

INCLUDED IN THIS BOX

A B C D

D

E

Tools required to install TrueDRY DR65

3/8-in. hex drive

Drill or duct cutting tool

Wire stripper/cutter

Standard screwdriver

Duct tape

8-in. round duct and starter collar

18-22 gauge, 5 band thermostat wire

1/2-in. diameter drain line (8 ft.)

1/2-in. drain clamps (2)

3/4-in. male NPT drain outlet

Options

1/2-in. drain p-trap (may be required by local code)

Drain pan

Float switch or water sensor (normally closed)

TrueDRY™ DR65 (1)

A

8-in. duct collar (2)

B

MERV 11 Filter (1)

C

Installation Guide

D

Prestige Comfort System (wireless)

E1

TruelAQ

E2

H8908 Manual Dehumidistat

E3

E4

VisionPRO IAQ control

PROFESSIONAL INSTALLATION GUIDE

GUIDE D’INSTALLATION PROFESSIONNELLE

GUÍA DE INSTALACIÓN PROFESIONAL

OPTIONAL CONTROLS SOLD SEPARATELY

E1E3E2E

4

TrueDRY™ DR65 (1)

A

8-in. duct collar (2)

B

MERV 11 Filter (1)

C

Installation Guide

D

Prestige Comfort System (wireless)

E1

TruelAQ

E2

H8908 Manual Dehumidistat

E3

E4

VisionPRO IAQ control

69-2089EFS-12

Page 2

Installation Checklist

Liste de vérification

pour l’installation

Lista de verificación

para la instalación

Included in This Box

A DR65A3000 (1)

B 8” duct collar (2)

C MERV 11 Filter (1)

D Installation Guide

E Filter Door

Control Options (Sold separately)

F1 Prestige IAQ Kit

F2 TrueIAQ

F3 H8908 Manual Dehumidistat

F4 VisionPRO or Prestige

Thermostat

F5 HumidiPRO Digital Control

Tools Required (Not Supplied)

• 3/8” hex drive

• Drill or duct cutting tool

• Wire stripper/cutter

• Standard screwdriver

• T20 Torx screwdriver

• Duct tape

• 8” round duct and starter

collar

• 1822 gauge, 5 conductor

thermostat wire

• 1/2” diameter drain line (8’)

• 1/2” drain clamps (2)

•

3/4” male NPT drain outlet

Options

•

1/2” drain p-trap (may be

required by local code)

•

Drain pan

• Float switch or water sensor

(normally closed)

Inclus dans cette boîte

A DR65A3000 (1)

B Collet de conduite de 8 po (2)

C Filtre MERV 11 (1)

D Guide d’installation

E Porte du filtre

Options de régulateurs (vendus

séparément)

F1 Nécessaire Prestige IAQ

F2 True IAQ

F3 Déshumidistat manuel H8908

F4 Thermostat VisionPRO ou

Prestige

F5 Régulateur d’humidité

numérique HumidiPRO

Outils requis (non fournis)

• Tournevis cruciforme 3/8 po

• Outil de perçage ou de coupe

de conduit

• Dénudeur/coupe-fils

• Tournevis normal

• Tournevis Torx T20

• Ruban adhésif

• Collet de conduit et de départ

rond de 8 po

• Fil de thermostat à 5

conducteurs calibre 1822

• Tuyau de vidange de 1/2 po de

dia. (8 pi)

• Attaches de tuyau de vidange

de ½ po (2)

•

Sortie de vidange ¾ po NPT

mâle

Options

•

SiphonP de vidange d’1/2 po

(peut-être requis par le code

local)

•

Bac de récupération

• Flotteur ou capteur d’eau

(normalement fermé)

Esta caja incluye

A DR65A3000 (1)

B Anillo para conductos de 8

pulgadas (20,3 cm) (2)

C Filtro MERV 11 (1)

D Guía de instalación

E Puerta del filtro

Opciones de control (se venden por

separado)

F1 Kit Prestige IAQ

F2 True IAQ

F3 Deshumidistato manual H8908

F4 Termostato VisionPRO o Prestige

F5 Control de humedad digital

HumidiPRO

Herramientas necesarias (no se

suministran)

• Impulsor de cabeza hexagonal de

3/8 pulgadas

• Taladro o herramienta cortante para

conductos

• Alicates o cortadores de cables

• Destornillador estándar

• Destornillador Torx T20

• Cinta para conductos

• Conducto redondo de 8 pulgadas

(20,3 cm) y collar de arranque

• Cable de termostato calibre 18 a 22,

de 5 conductores

• Línea de desagüe de ½ pulgada

(1,3 cm) de diámetro (8 pies [2,4 m])

• Abrazaderas de desagüe de 1/2

pulgada (1,3 cm) (2)

•

Tubo de desagüe NPT macho de 3/4”

Opciones

•

Trampa en P para desagüe de ½

pulgada (1,3 cm) (es posible que el

código local la exija)

•

Bandeja para drenaje

• Interruptor del flotador o sensor de

agua (normalmente cerrado)

Warning: Installation must be

performed by a qualified service

technician and must comply with

local codes.

Remove power to the device before

installing or servicing the device.

Failure to connect the device

according to these instructions may

result in damage to the device or

the controls.

INSTALLATION INSTRUCTIONS

BEGIN ON PAGE 2

Avertissement : L’installation doit

être effectuée par un technicien

d’entretien qualifié et conformément

aux codes en vigueur.

Couper l’alimentation vers l’appareil

avant d’installer ou de réparer cet

appareil.

Un raccordement de cet appareil

non conforme à ces instructions

peut entraîner des dommages à

l’appareil ou aux commandes.

INSTRUCTIONS D’INSTALLATION

COMMENCER À LA PAGE 18

Advertencia: La instalación la debe

realizar un técnico de reparación

calificado y debe cumplir con los códigos

locales.

Retire la fuente de energía del dispositivo

antes de instalar o reparar el dispositivo.

Si no conecta el dispositivo según

estas instrucciones, el dispositivo o los

controles se pueden dañar.

LAS INSTRUCCIONES DE INSTALACIÓN

COMIENZAN EN LA PÁGINA 34

Page 3

DR65A3000

!

ABOUT YOUR NEW DEHUMIDIFIER

Benefits ....................................... 2

Maintaining Ideal Humidity ....................2

Setting the Controls ............................3

Control Options ................................3

Specifications .................................. 4

INSTALLATION

Install to Fit Your Application ...................5

Plumbing ......................................6

Terminal Description ...........................7

Wiring ....................................... 7

Checkout .....................................10

MAINTENANCE

Cleaning ......................................11

Technical Description .........................12

Parts List ......................................14

5Year Limited Warranty ......................15

• The DR65A3000 is designed to be installed indoors in a space that is protected from rain and flooding.

• Install the unit with space to access the front panel for maintenance and service.

• Avoid directing the discharge air at people, or over the water in pool areas.

• If used near a pool or spa, be certain there is no chance the unit could fall into the water or be splashed,

and that it is plugged into a ground fault interrupt (GFI) outlet.

• To ensure quiet operation, do not place the device directly on the structural supports of the home.

• A drain pan must be placed under the unit if installed above a living area or above an area where water

leakage could cause damage.

1. Never operate a unit with a damaged power cord. If the power cord is damaged it must be

replaced by the manufacturer, its service agent, or similarly qualified person in order to

avoid a hazard.

2. The appliance is not intended for use by persons (including children) with reduced

physical, sensory, or mental capabilities, or lack of experience and knowledge, unless they

have been given supervision or instruction concerning use of the appliance by a person

responsible for their safety. Children should be supervised to ensure that they do not play

with the appliance.

NEED HELP? For assistance with this product please visit http://www.forwardthinking.honeywell.com

or call Honeywell Customer Care toll-free at 18004681502.

?

Read and save these instructions.

® U.S. Registered Trademark. Patents pending. Copyright © 2016 Honeywell International Inc. All rights reserved.

DR65A3000 Dehumidification System 3300297EFS01

Page 4

About the DR65A3000 Dehumidifier

MCR24780

01

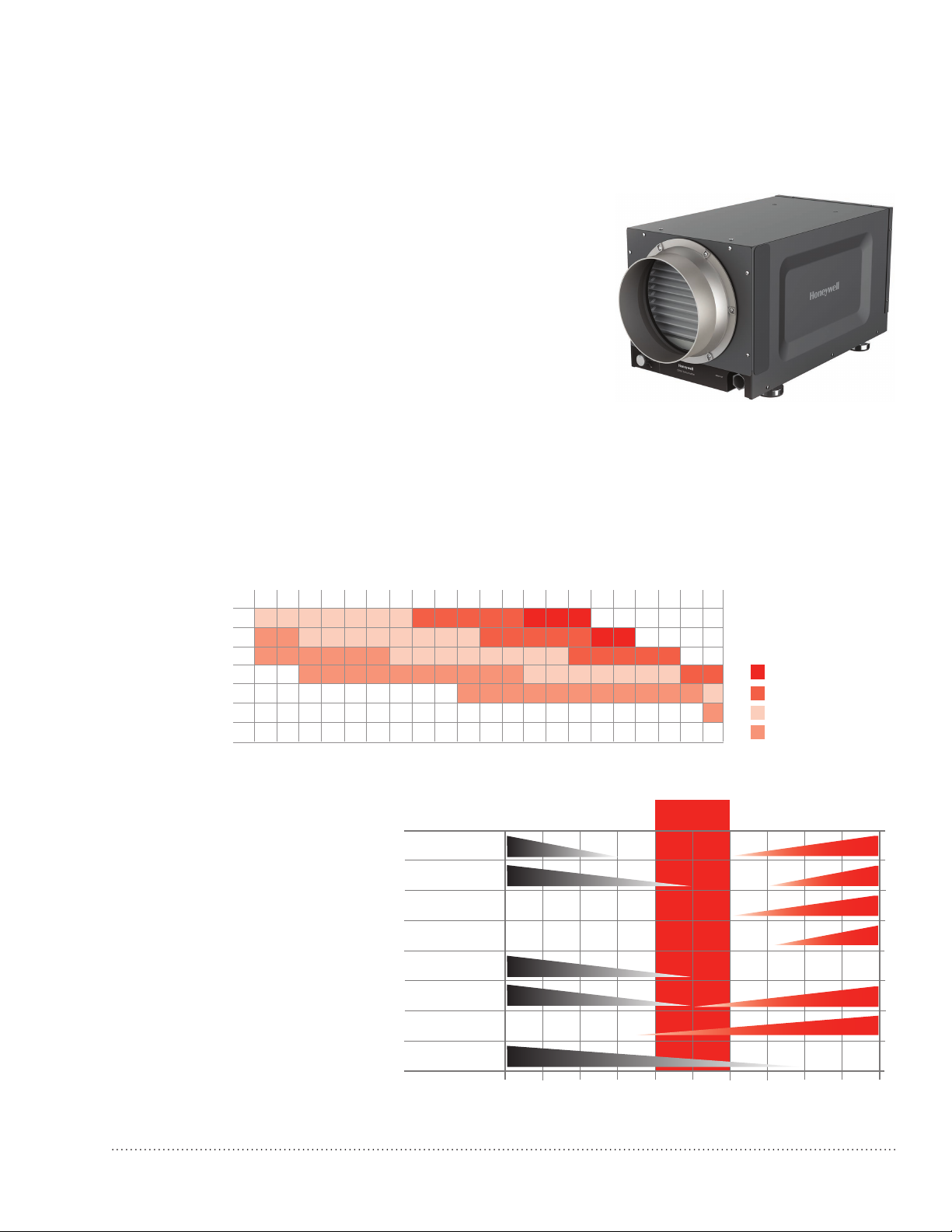

WHAT THE AIR FEELS LIKE

M27328

AIR TEMPERATURE

(DEGREES FAHRENHEIT)

SOURCE: TEMPERATURE - HUMIDIY INDEX WAS DERIVED BY R.G. STEADMAN, JOURNAL OF APPLIED METEOROLOGY, JULY 1979.

The Honeywell DR65A3000 ensures the home is maintained at proper humidity levels through its high

performance and efficiency.

Benefits

• Removes up to 65 pints (30.8 l) of water per day from the indoor

air.

• Built-in humidity control requires no additional wiring to an

external control. Just plug in and go! Choice of external control

options also available for centrally ducted control.

• Energy Star rated.

• Built-in transfromer circuit breaker.

Maintaining Ideal Humidity

Dew points and relative humidity (RH) affect the way your body

senses heat. Higher humidity levels cause the air to feel much hotter than the actual temperature. When

maintained properly, you can run your cooling equipment less because dehumidified air feels cooler.

Ideal humidity is defined by industry experts* as being between 4060% on an average annual basis. When

indoor humidity exceeds 60%, the home is more susceptible to mold and mildew growth. DR65A3000 safeguards against excessive humidity in the home year-round.

HOW HOT THE HEAT-HUMIDITY COMBINATION MAKES IT FEEL.

EXAMPLE: AIR AT 90ºF WITH 50% RH FEELS LIKE 96ºF TO THE HUMAN BODY!

001 4418312316210215110117014011019979593919

59 631031421811411

09 221711311901601201001896959391909887868584838

58 801501201997959391909988

08 199888786868583828181808979787777767574737

57 0897978787777767675757474737372727

07 271717171717070707969686867676666656564646

17079696

*American Society of Heating, Refrigerating

and Air Conditioning Engineers (ASHRAE).

RELATIVE HUMIDITY (PERCENTAGE)

0117014011018969493919098878

878685848382818089787

ASHRAE RECOMMENDED WINTER DESIGN LEVEL

BACTERIA

VIRUSES

FUNGI

MITES

RESPIRATORY

INFECTIONS

ALLERGIC RHINITIS

AND ASTHMA

CHEMICAL

INTERACTIONS

OZONE

PRODUCTION

010203040506070809

00159095808570756065505540453035202510150

EXTREME DANGER

DANGER

EXTREME CAUTION

CAUTION

OPTIMUM

ZONE

00

2

DR65A3000 Dehumidification System 33-00297EFS—01

Page 5

Setting the Controls

BUILTIN HUMIDITY CONTROL: An intuitive ‘set and forget’ humidistat

is built into the DR65A3000 to set the humidity level right on the device.

Optional external control wiring is also available. If an external dehumidistat is used, the on-board dehumidification control must be set to the Off

position.

Control Options

The DR65A3000 may be used with one of the following external controls:

Prestige™ IAQ Kit

• Controls both heating/cooling and ventilation.

• Wireless sensor for displaying outdoor temperature and humidity.

• Advanced ventilation programming includes economizing and extreme

condition shutdown.

• Maintenance and service reminders.

• High definition color display.

• RedLINK™ Wireless technology

VisionPRO™ or Prestige™

• Controls both heating/cooling and ventilation.

• Wireless sensor for displaying outdoor temperature and humidity.

• Ventilation programming for time of day or Ashrae standards.

• Optional ventilation lockouts for high/low temp or humidity conditions

when C7089R1013 wireless outdoor sensor is used.

• WiFi™ or RedLINK™ Wireless technology

HumidiPRO Digital Control

• Manual dehumidification control

• Dehumidifier compressor protection

• RH% and outdoor temperature calibration

• Adjustable high and low range stops (1090%)

TrueIAQ Digital Control

• Automatic adjustments maintain fresh air in home.

• Sensor for displaying outdoor temperature and humidity.

• Advanced ventilation programming includes economizing and extreme

condition shutdown.

• Maintenance and service reminders.

• Controls other indoor air quality equipment.

Manual Dehumidistat and Automatic Ventilation Controls

• Manual humidity control with intuitive comfort settings.

• Automatic W8150 ventilation control to ASHRAE standard, or for

continuous operation.

DR65A3000 Dehumidification System 33-00297EFS—01 3

Page 6

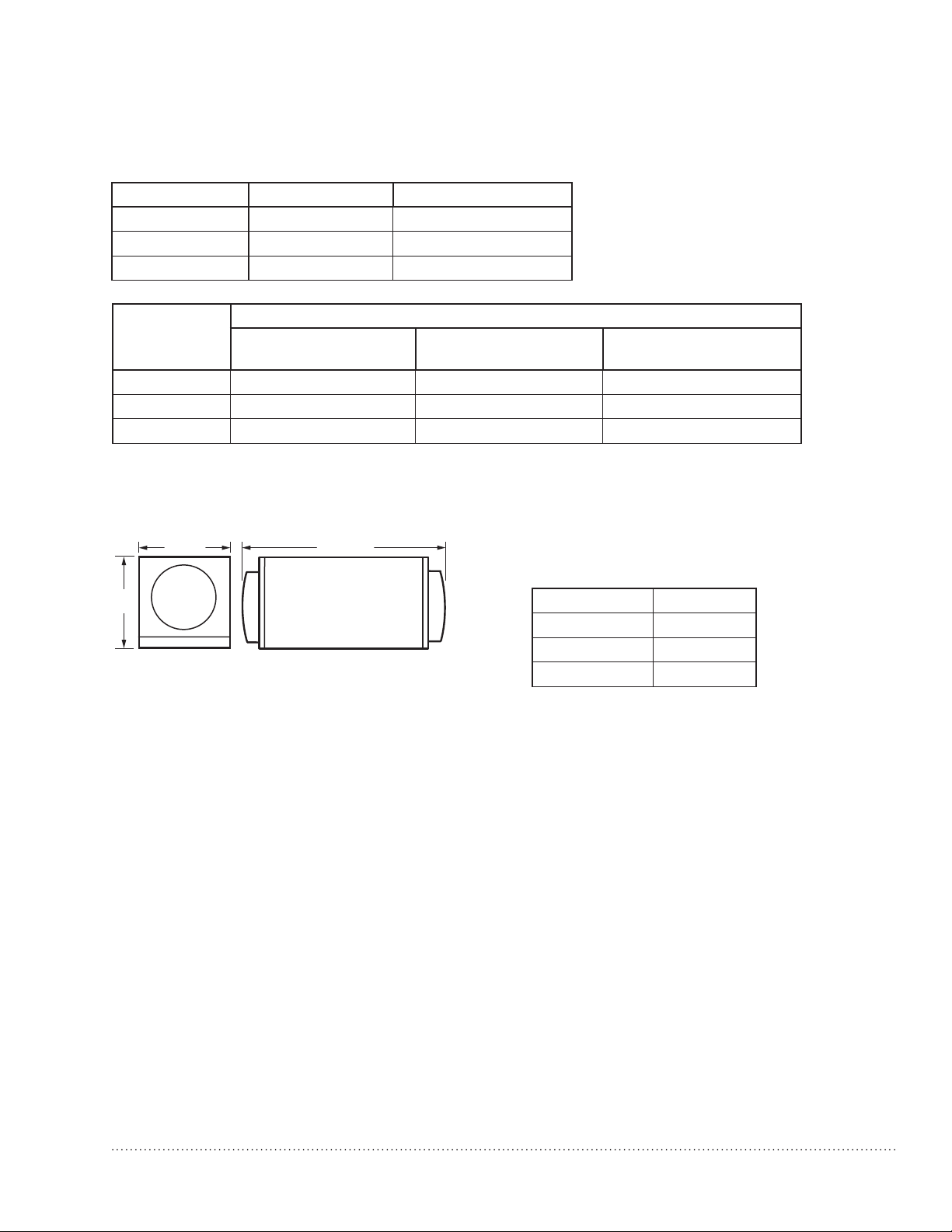

Specifications

28-1/2 (724)

12 (305)

(305)

Install DR65A3000 according to National Electric Codes.

DryBulb Temp Intake Humidity Capacity (Pints/Day)

80°F (26.7°C) 60% RH 65

70°F (21.1°C) 60% RH 47

60°F (15.6°C) 60% RH 34

Home Size

(square ft) @

8 ft ceiling

Dehumidifier Capacity Required to Maintain Desired Indoor RH*

60% RH Indoor

(pints/day)

50% RH Indoor

(pints/day)

40% RH Indoor

(pints/day)

2080 4954 5558 7178

2600 6168 6572 9097

3120 7582 7986 95110

* Based on extreme climates where outdoor humidity is 7090% RH. For less extreme climates, larger

homes can be adequately served with less capacity. Actual requirements may vary.

Dimensions in inches and (mm):

Airflow versus external static pressure

(01” water pressure) with collars

attached

8 INCH (203)

12

DIAMETER

M29763

Product weight: 60lb (27 Kg)

Shipping weight: 68lb (31 Kg)

Shipping dimensions: 16.7” H × 17” W × 32.9” L

Media Filter: MERV 11, 9” H x 11” W x 0.75” D

Drain connection: 3/4” threaded female NPT

connection.

Duct connections: 8” round inlet and outlet. ABS

plastic, compatible for connection to rigid or

flexible ducting with sheet metal screws and/or

tape.

Cabinet: 20 gauge galvanized steel powder-coat

painted.

Insulation: R value 1

Compressor: Rotary-style, 6.1 KBTU

Refrigerant: R410A, 15 oz.

Operating Temp Range (outside cabinet):

34ºF to 135ºF (1.1ºC to 57.2ºC)

Operating Humidity Range: 099% RH

Input ratings

Output ratings

Standards and approval body

requirements

0” 160 CFM

0.2” 140 CFM

0.4” 120 CFM

0.6” 100 CFM

• Electrical input voltage: 120 VAC, 60 Hz

nominal

• Input current: 5.2 A

• Power transformer to R/C terminals:

24 VAC, 0.85 A

• Energy Performance: 2.22 liters (4.7 pints)

per kilowatt hour (KWH)

• ETL Listed per UL 474 and

CSA C22.2 No 92

• ENERGY STAR rated.

4

DR65A3000 Dehumidification System 33-00297EFS—01

Page 7

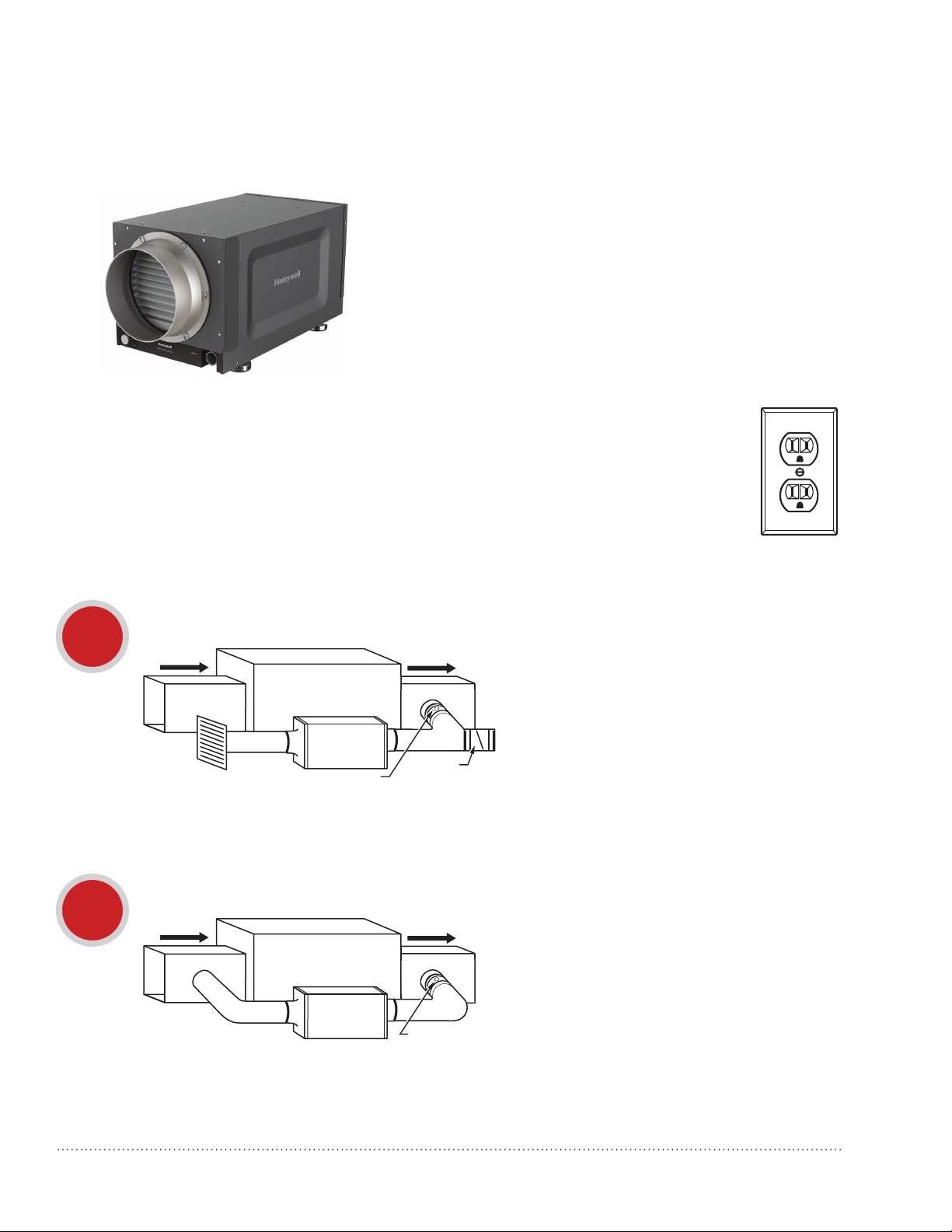

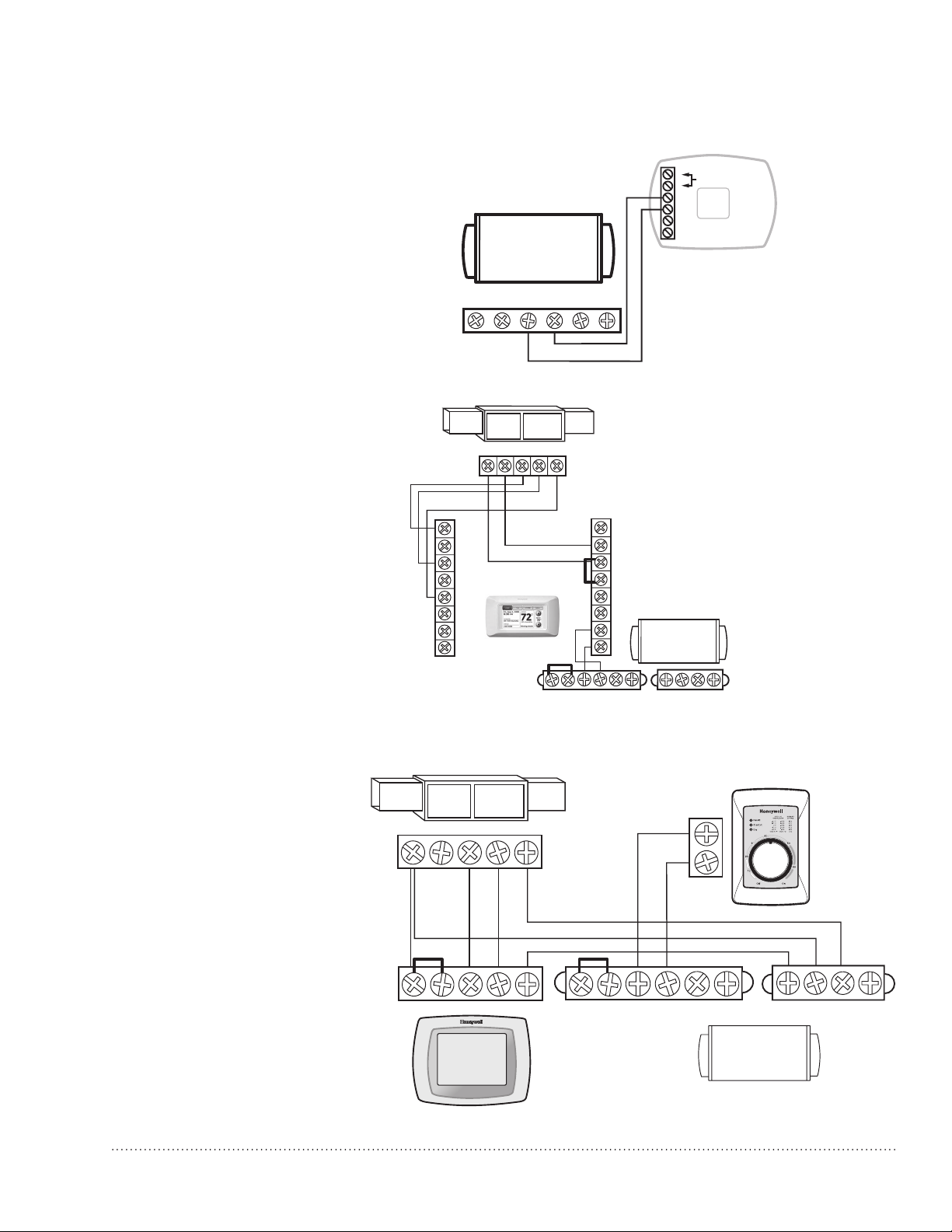

Install to Fit Your Application

AIR HANDLER

M36843

DAMPER

M24745

AIR HANDLER

M36844

Flex duct is recommended in connecting to the DR65A3000 collars to reduce vibration noise.

Duct Sizing: Use minimum 8” diameter round for duct

lengths up to 25’ Minimum 10” required for lengths

longer than 25’ Duct branches from the main inlet/

exhaust should be minimum 8” round for 23 branches, and 8” round or larger for 4 branches or more.

Isolated Areas: Effective dehumidification may

require ducting to isolated or stagnant air flow areas.

Electrical requirements:

115 VAC outlet. Ground fault

interrupter (GFI) recommended.

A

B

Dedicated Return to Main Supply

RETURN

SEPARATE

RETURN

DEHUMIDIFIER

BACKDRAFT

SUPPLY

(OPTIONAL)

GRAVITY DAMPER

Main Return to Main Supply

RETURN

DEHUMIDIFIER

SUPPLY

BACKDRAFT

DAMPER

Ideal when…

• Access to a dedicated central return for

DR65A3000 is available.

• Combined with A/C operation; requires

backdraft damper on the exhaust

port to minimize backdraft when

DR65A3000 is not on but A/C is.

• Providing dry air to a specific area with

an optional 20% open gravity damper

on DR65A3000 supply.

Ideal when…

• Running DR65A3000 when not running

A/C. Requires damper on the exhaust

port to minimize backdraft when

DR65A3000 is not on but A/C is.

• Access to a dedicated central return for

DR65A3000 is not available.

• System fan should run with

dehumidifier for best results.

DR65A3000 Dehumidification System 33-00297EFS—01 5

Page 8

Install to Fit Your Application (continued)

M36846

SEPARATE

AIR HANDLER

M36845

C

D

Main Return to Main Return

RETURN

DEHUMIDIFIER

SUPPLY

Dedicated Return to Dedicated Supply

DEHUMIDIFIER

RETURN

SUPPLY

Ideal when…

• Running DR65A3000 with A/C

operation.

• System fan must run with dehumidifier.

• Minimizing discharge air temperature

(DAT) increase is preferred.

• Access to a dedicated central return for

DR65A3000 is not available.

Ideal when…

• DR65A3000 will not be ducted to a

forced air HVAC system.

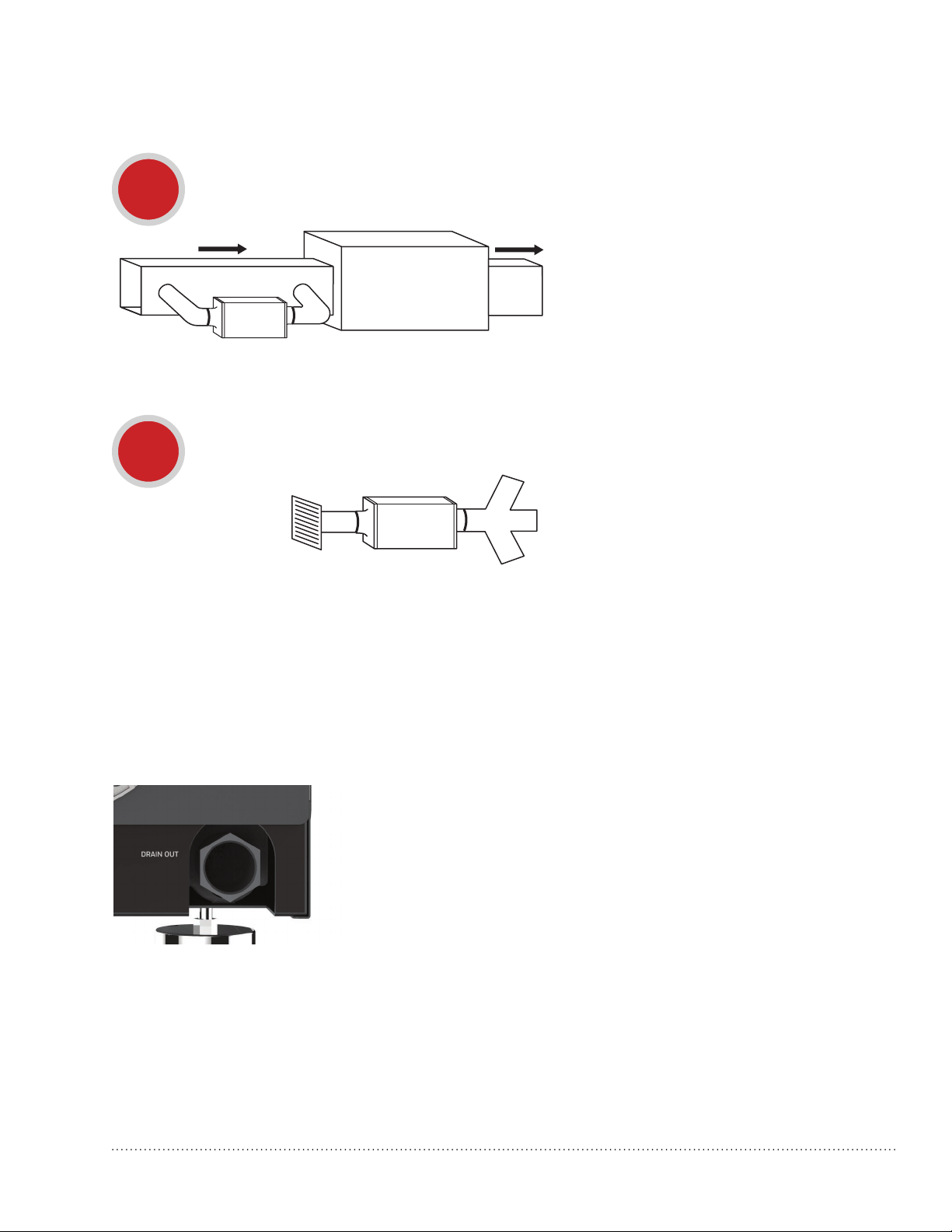

Plumbing

Attach 3/4” male NPT drain nozzle.

Connect 1/2” drain tube to male connection drain outlet.

Secure drain tube to connector with hose clamp.

Run drain hose continuously downhill to an approved drain

or condensate pump.

The drain line must include a water trap to prevent air from

entering or exiting the dehumidifier.

6

DR65A3000 Dehumidification System 33-00297EFS—01

Page 9

Terminal Description

HVAC

THERMOSTAT

7

CAUTION: Low voltage hazard.

Can cause equipment damage.

Disconnect HVAC equipment before beginning installation.

Two wiring terminal blocks are located on the exhaust end of the dehumidifier.

NOTE: The outer screws on each

terminal block secure the block to the

chassis. They are not used for wiring.

The six terminals for the left hand terminal block are:

FLOAT (2): External low-voltage water sensor or float

switch

DHUM: Compressor and fan operation for

dehumidification

R: 24V output

FAN: Fan activation only for ventilation

C: 24V output

External 24V devices can be powered from R and C

terminals (20VA max.)

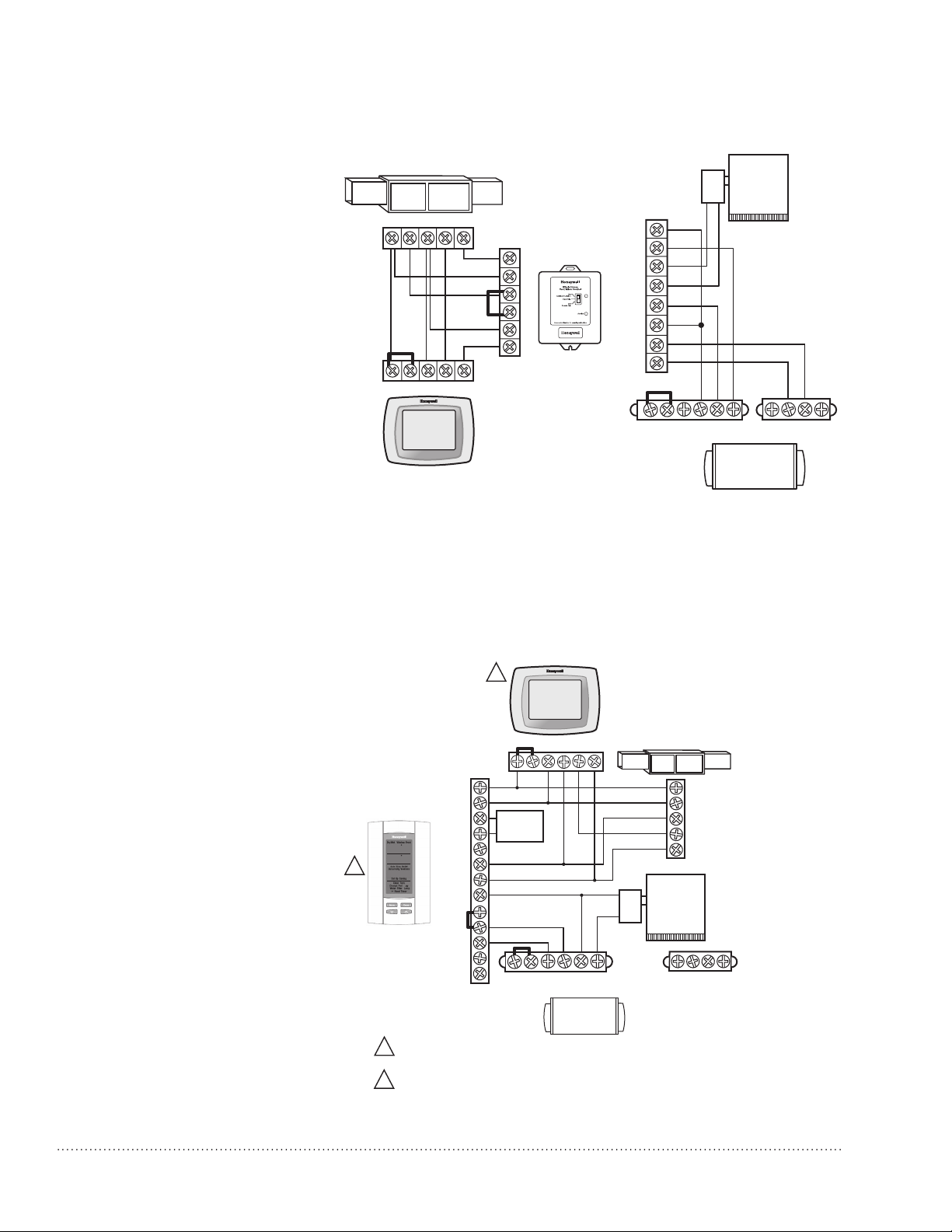

Wiring

Wire the DR65A3000

according to the diagram that applies to

your desired operation.

Follow this diagram for

ducted operation with the

onboard dehumidistat.

GYWR C

GYWRRc

The right hand terminal block in the

above figure is used only for interlocking a

DR65A3000 with an equipment fan. The three

terminals are:

Gt: Fan operation from thermostat

Rf: 24V from equipment fan

Gf: Fan operation from equipment fan

+

+

FLOATFLOAT

DHUM

FAN

R

C

DEHUMIDIFIER

+

Rf

Gt

Gf

+

M3684

DR65A3000 Dehumidification System 33-00297EFS—01 7

Page 10

Wiring (continued)

HVAC

M33154A

+

HVAC

THERMOSTAT

M36848

+

M35602

Follow this diagram if using

the HumidiPro Digital

Humidity Controller.

RFloatDHUM Fan C

GYWR C

24 VAC

C

(CONSTANT)

R

U

U

S

S

Follow this diagram if using

the PrestigeIAQ thermostat.

Follow this diagram if using an

external manual dehumidistat.

W

DHUM

R

FLOAT FLOAT

FAN

C

Rc

R

H

C

DHUM

+

TrueDRY

+

Gt

Rf

R

Gf

DRY

CONTACTS

FAN

H

U_

U_

W2

Y

Y2

G

K

THERMOSTAT

+

FLOAT

NOTE: THERMOSTAT MUST BE CONFIGURED TO DRIVE FURNACE FAN

DURING DEHUMIDIFICATION CALL.

GYWR C

+

GYWRRc

MECHANICAL

DEHUMIDISTAT

+

+

C

DEHUMIDIFIER

Gt

Rf

Gf

8

DR65A3000 Dehumidification System 33-00297EFS—01

Page 11

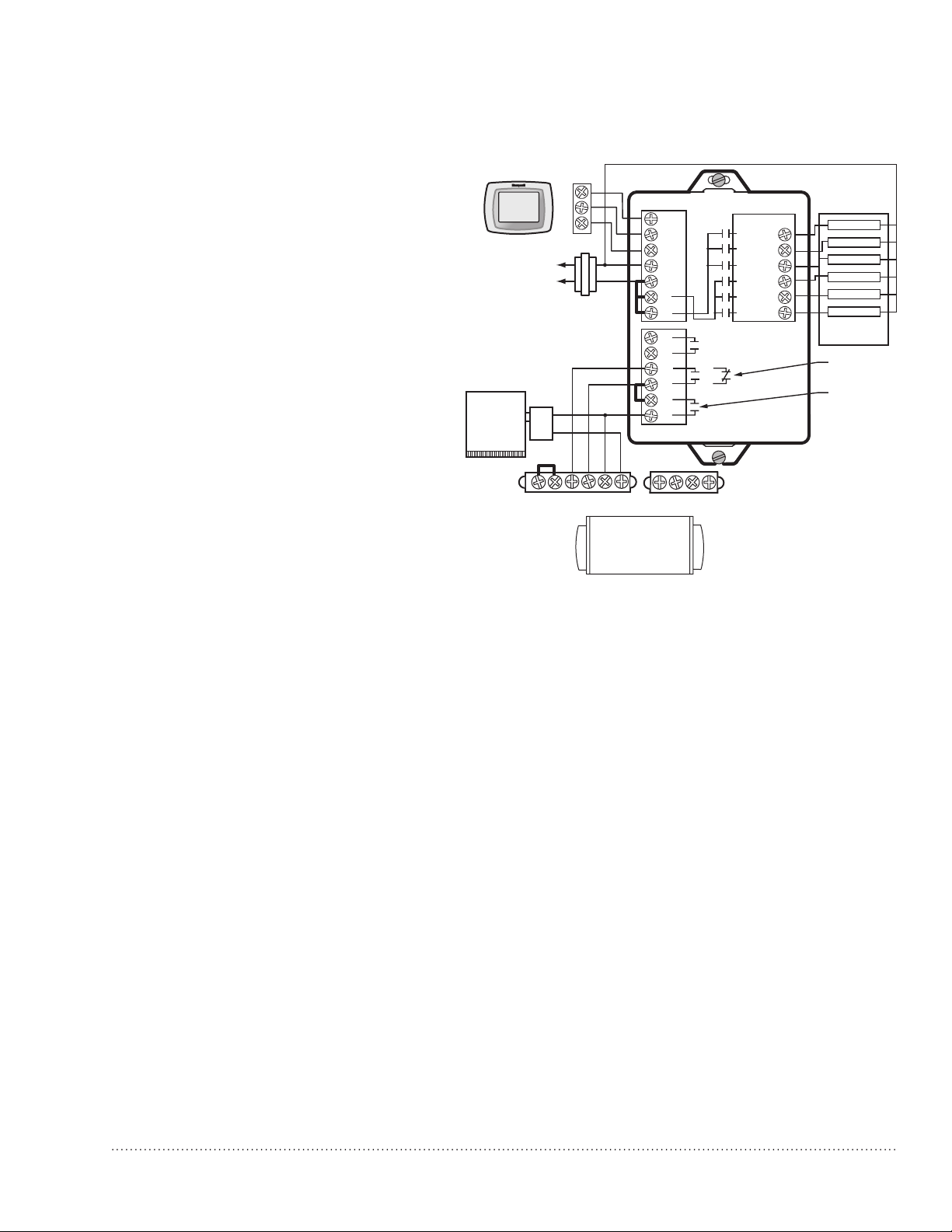

Wiring (continued)

M36849

+

THERMOSTAT

M36850

OTHER THAN A TH5110, TH5220, TH5320, TH6110, TH6220, TH6320, TH8110,

HVAC

EARD8TZ

Follow this diagram for ducted

operation with external ventilation control.

W

Rc

R

THERMOSTAT

GYWR C

W8150A

G

R

C

C

W

G

GY

DAMPER

AUX

REMOTE

R

C

+

+

DHUM

R

FLOAT

FAN

+

C

DEHUMIDIFIER

Gt

Rf

Gf

Follow this diagram if using

DR65A3000 with a powered

dehumidistat such as TrueIAQ

(DG115EZIAQ).

1

GYWRRc

C

R

TrueIAQ

In

%

40

68

Out

%

76

2

55

PM

:

1215

1

IF A THERMOSTAT

TH8320, OR TH8321 IS USED, A RELAY MAY BE REQUIRED TO ISOLATE THE G WIRE.

PROGRAM ISU SETTING 60 TO Ø TO FORCE SYSTEM FAN ON WITH DEHUMIDIFICATION CALL.

2

SENSOR

SENSOR

SWITCH

VENT

VENT

DEHUM

DEHUM

HUM

HUM

C

OUTDOOR

SENSOR

(PROVIDED)

W

G

+

FLOAT

DHUM

DEHUMIDIFIER

+

R

C

FAN

HVAC

EARD8TZ

+

Gt

R

C

W

Y

G

+

Rf

Gf

DR65A3000 Dehumidification System 33-00297EFS—01 9

Page 12

Wiring (continued)

M36851

EQUIPMENT INTERFACE MODULE (EIM)

Follow this diagram if using DR65A3000

with a Prestige IAQ or VisionPro IAQ.

VISIONPRO IAQ

EARD8TZ

D-1

R-2

C-3

+

DHUM

R

FLOAT

FAN

DEHUMIDIFIER

1

2

3

C

R

RC

RH

U1

U1

U2

U2

U3

U3

+

+

C

Gt

Rf

Gf

CONV.HP

O/B

W1

AUX

W2

AUX2

W3

Y

Y

Y2

Y2

G

G

OR

+

FAN

FURNACE BOARD

C

HEAT 1 RELAY

HEAT 2 RELAY

HEAT 3 RELAY

COOL 1 RELAY

COOL 2 RELAY

G

FAN RELAY

CONFIG FOR

DEHUM

CONFIG FOR

VENT

Checkout

Apply power to DR65A3000. Turn the humidity control to a low RH% level to initiate a dehumidification call.

Confirm that the DR65A3000 compressor and fan turn on. The furnace blower will also turn on to circulate

air. This will take up to two minutes. Be sure to turn the control to the desired RH% or to Off when checkout

is complete. Turning the humidity control to Off will turn the DR65A3000 off.

10

DR65A3000 Dehumidification System 33-00297EFS—01

Page 13

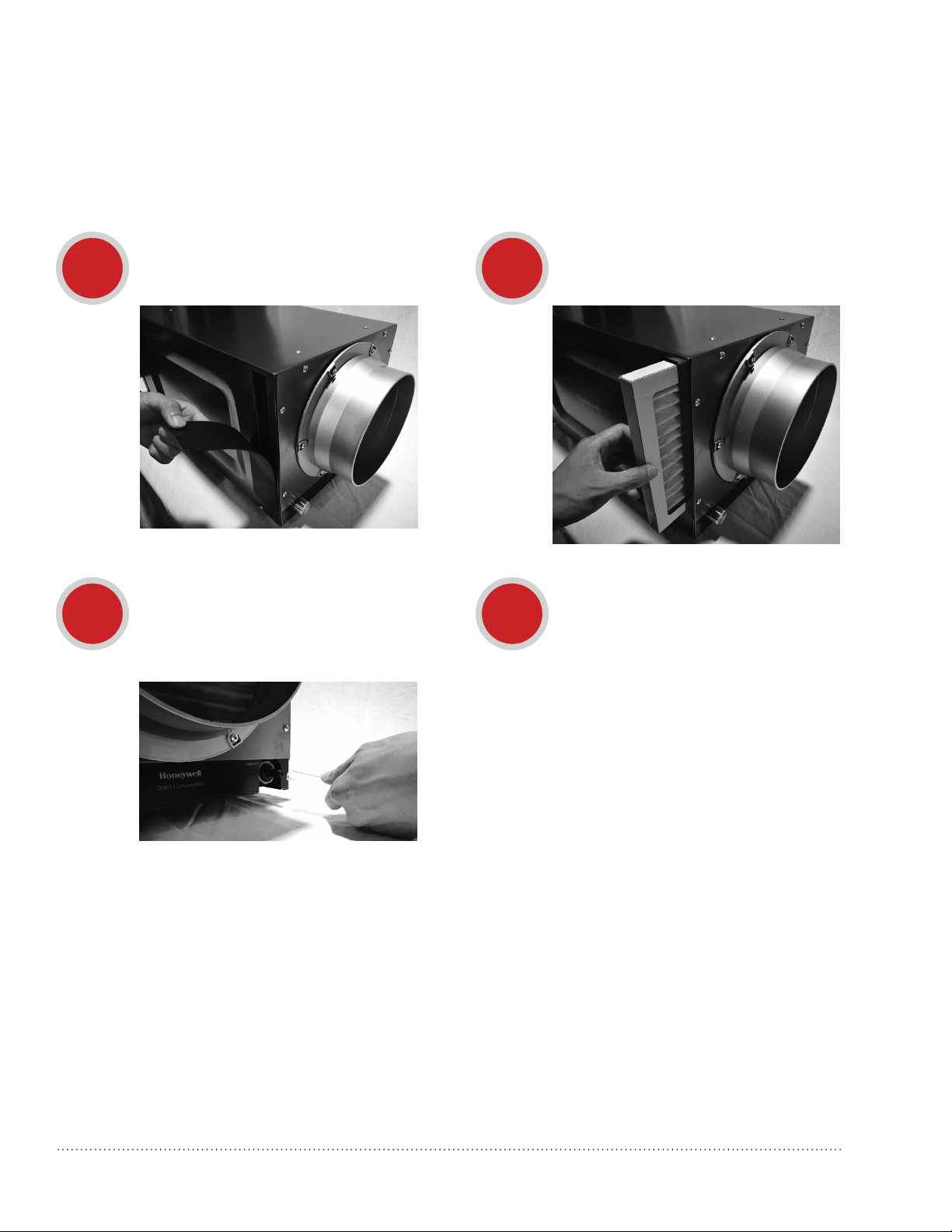

Cleaning

On an annual basis, perform the following maintenance requirement to ensure the dehumidifier runs at peak

efficiency.

Unplug the dehumidifier before begin-

1 2

3 4

ning service. Remove magnetic access

panel to access the filter.

Check the drain connection and drain

line to ensure it is clear of debris and

sludge. Ensure all hose connections

are secure once maintenance of the

drain lines is complete.

Remove filter and replace with new filter. Reinstall magnetic access panel.

When service is complete, initiate a

call for dehumidification and check

that the compressor and fan activate.

If using the VisionPRO IAQ or TrueIAQ

controls, reset maintenance reminders.

DR65A3000 Dehumidification System 33-00297EFS—01 11

Page 14

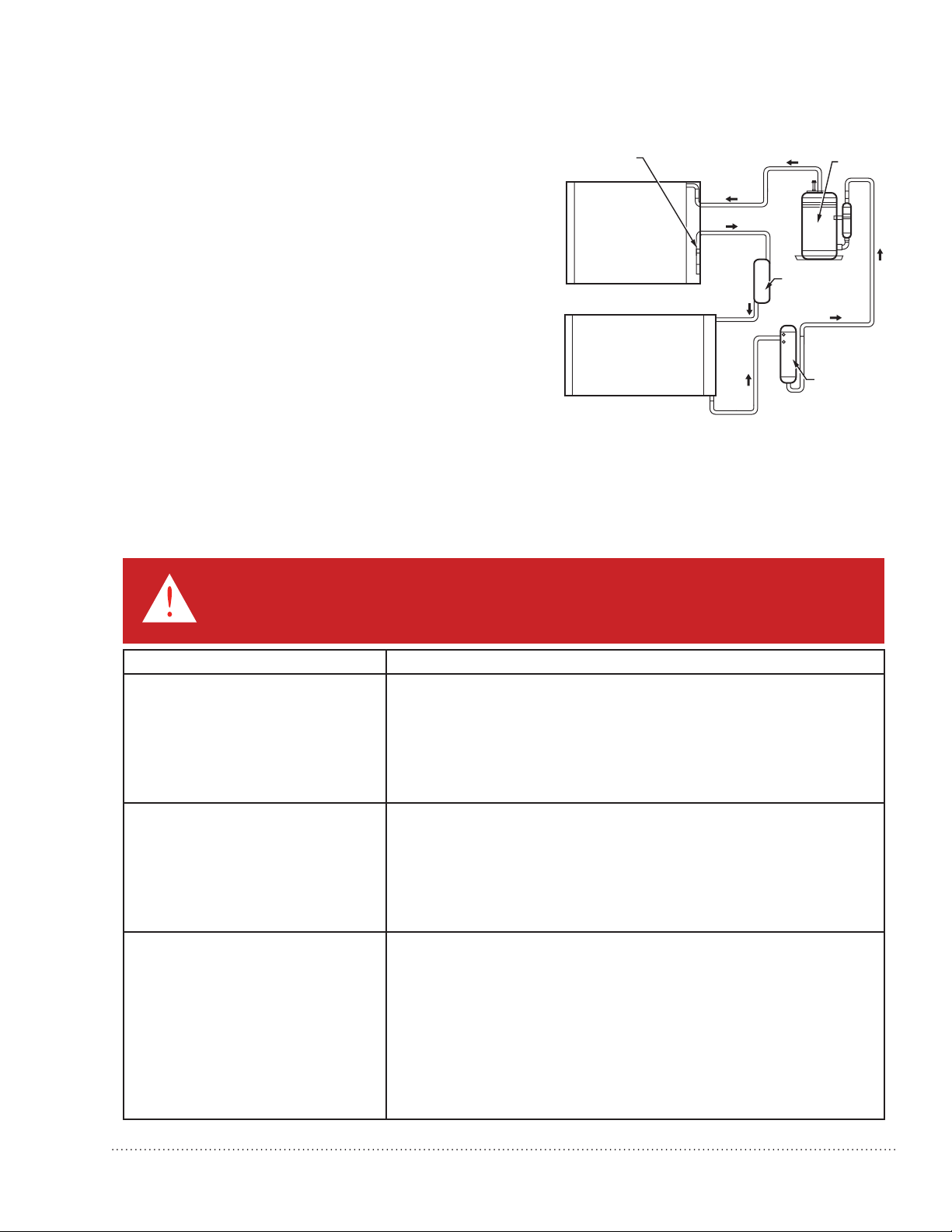

Technical Description

COMPRESSOR

STRAINER/FILTER

M27404

DR65A3000 uses a refrigeration system similar to

an air conditioner to remove heat and moisture from

DRIER

incoming air and add heat to the air that is discharged.

Hot, high-pressure refrigerant gas is routed from the

compressor to the condenser coil. The refrigerant is

CONDENSER

cooled and condensed by giving up its heat to the

air that is about to be discharged from the unit. The

refrigerant liquid then passes through a filter drier and

capillary tubing which causes the refrigerant pressure

and temperature to drop. It next enters the evaporator

coil where it absorbs heat from the incoming air and

evaporates. The evaporator operates in a flooded

EVAPORATOR

condition, which means that all the evaporator tubes

contain liquid refrigerant during normal operation. A

flooded evaporator should maintain nearly constant

pressure and temperature across the entire coil, from

inlet to outlet.

Troubleshooting

Troubleshooting videos are available on Honeywell’s CPRO YouTube channel playlist.

CAUTION: Servicing the DR65A3000 with its high pressure refrigerant system and high

voltage circuitry presents a health hazard which could result in death, serious bodily injury,

and/or property damage. Service should only be performed by a qualified service technician.

CAPILLARY

TUBES

ACCUMULATOR

Problem Recommended Troubleshooting Steps

No dehumidification. Neither

fan nor compressor run and the

ventilation timer is OFF.

1. Unit unplugged or no power to outlet.

2. Humidity control set too high or defective.

3. Loose connection in internal or control wiring.

4. Defective compressor relay.

5. Defective control transformer.

6. Optional Condensate Pump Safety Switch open.

No dehumidification. Compressor

does not run but fan runs when

there is a call for dehumidification

and the ventilation control is OFF.

1. Defective compressor run capacitor.

2. Bad connection in compressor circuit.

3. Defective compressor overload.

4. Defective compressor.

5. Defrost thermostat open.

6. Optional Condensate Pump Safety Switch open.

Fan runs when there is a call

for dehumidification and the

ventilation control is OFF, but the

compressor cycles on and off too

frequently.

1. Low ambient temperature and/or humidity causing unit to cycle

through defrost mode.

2. Defective compressor overload.

3. Defective compressor.

4. Defrost thermostat defective.

5. Dirty air filter(s) or airflow restricted.

6. Low refrigerant charge, causing defrost control to cycle.

7. Bad connection in compressor circuit. Fan does not run with

fan switch in either position.

12

DR65A3000 Dehumidification System 33-00297EFS—01

Page 15

Troubleshooting (continued)

Problem Recommended Troubleshooting Steps

Fan does not run

with ventilation

activated.

Compressor runs

briefly but cycles on

& off with humidity

control turned to

ON.

Evaporator

coil frosted

continuously, low

de-humidifying

capacity.

Unit not providing

ventilation.

Unit removes some

water, but not as

much as expected.

Unit Test to

determine problem:

1. Loose connection in fan circuit.

2. Obstruction prevents fan rotation.

3. Defective fan.

4. Defective fan relay.

5. Defective fan capacitor.

1. Defrost thermostat loose or defective.

2. Low refrigerant charge.

3. Dirty air filter(s) or airflow restricted.

1. Check control wire connections (check connections at fresh air damper also).

2. Defective fresh air damper.

3. Dirty air intake. Clean outside intake hood.

1. Air temperature and/or humidity have dropped.

2. Humidity meter and or thermometer used are out of calibration.

3. Unit has entered defrost cycle.

4. Dirty air filter.

5. Defective defrost thermostat.

6. Low refrigerant charge.

7. Air leak such as loose cover or ducting leaks.

8. Defective compressor.

9. Restrictive ducting.

10. Optional Condensate Pump Safety Switch open.

1. Detach field control wiring connections from main unit.

2. Connect the R and FAN contacts from the main unit together; only the impeller

fan should run. Disconnect the wires.

3. Connect the R and DHUM contacts from the main unit together; the compressor

and impeller fan should run.

4. If these tests work, the main unit is working properly. You should check the

control panel and field control wiring for problems next.

5. Remove the control panel from the mounting box and detach it from the field

installed control wiring. Connect the blue, yellow, and green wires from the

control panel directly to the corresponding colored pigtails on the main unit.

Leave the violet, white, and red wires disconnected!

6. Turn on the humidity control. The compressor and impeller fan should run.

7. If these tests work, the problem is most likely in the field control wiring.

Refrigerant Charging

If the refrigerant charge is lost due to service or a leak, a new charge must be accurately weighed” If any of

the old charge is left in the system, it must be recovered before weighing in the new charge. Refer to the unit

nameplate for the correct charge weight and refrigerant type.

DR65A3000 Dehumidification System 33-00297EFS—01 13

Page 16

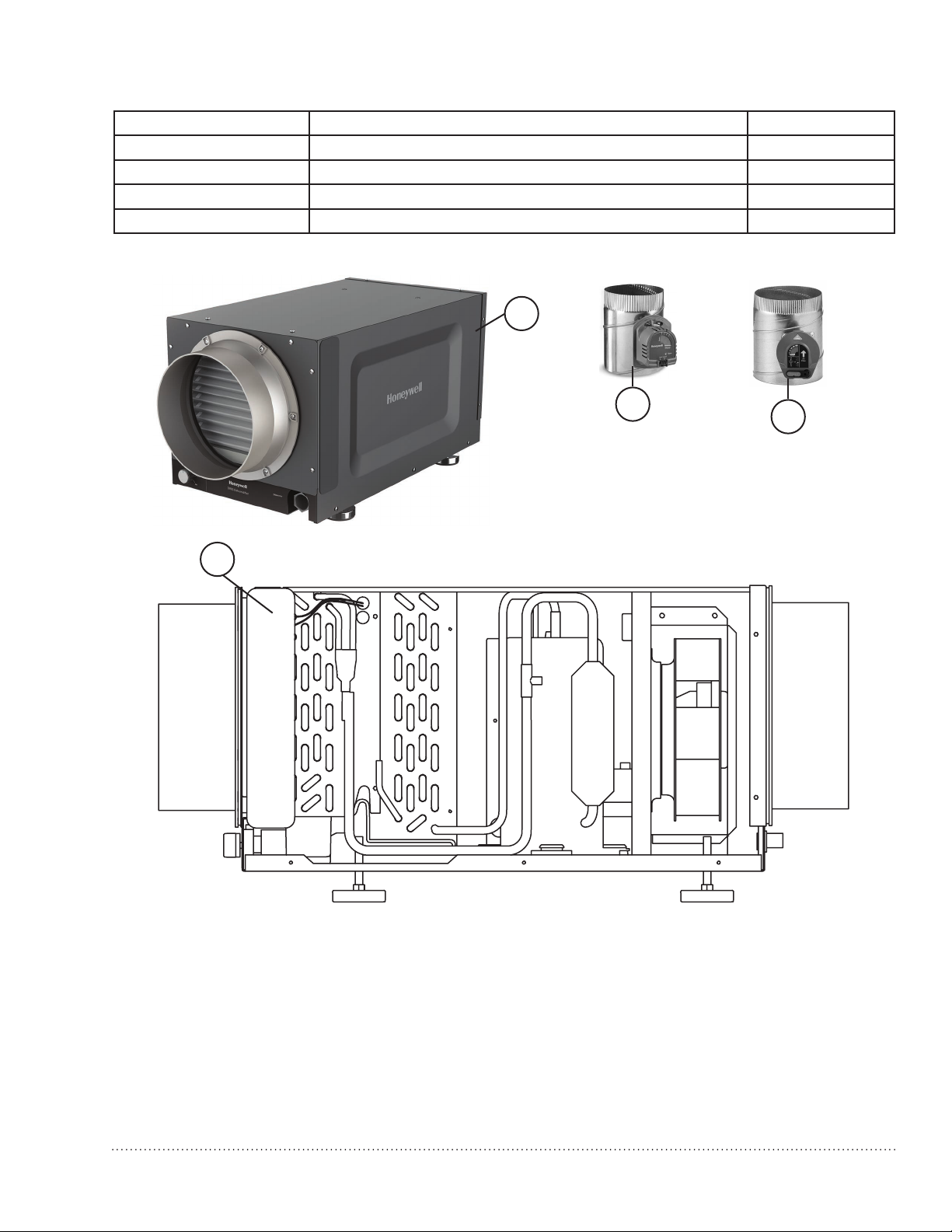

Parts List

Figure Reference Base and Accessory Parts Part Number

1 Dehumidifier DR65A3000/U

2 Motorized Ventilation Damper EARD8TZ

3 8” Bypass Damper CPRD8

4 Filter 50049537005

1

4

2

3

14

M36840

For reference only.

DR65A3000 Dehumidification System 33-00297EFS—01

Page 17

5Year Limited Warranty

Honeywell warrants this product to be free from defects in the workmanship or materials, under normal use

and service, for a period of five (5) years from the date of purchase by the consumer. If at any time during the

warranty period the product is determined to be defective or malfunctions, Honeywell shall repair or replace

it (at Honeywell’s option).

If the product is defective,

(i) return it, with a bill of sale or other dated proof of purchase, to the place from which you purchased it; or

(ii) call Honeywell Customer Care at 18004681502. Customer Care will make the determination whether

the product should be returned to the following address: Honeywell Return Goods, Dock 4 MN103860,

1885 Douglas Dr. N., Golden Valley, MN 55422, or whether a replacement product can be sent to you.

This warranty does not cover removal or reinstallation costs. This warranty shall not apply if it is shown by

Honeywell that the defect or malfunction was caused by damage which occurred while the product was in

the possession of a consumer.

Honeywell’s sole responsibility shall be to repair or replace the product within the terms stated above.

HONEYWELL SHALL NOT BE LIABLE FOR ANY LOSS OR DAMAGE OF ANY KIND, INCLUDING ANY

INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING, DIRECTLY OR INDIRECTLY, FROM ANY BREACH

OF ANY WARRANTY, EXPRESS OR IMPLIED, OR ANY OTHER FAILURE OF THIS PRODUCT. Some states do

not allow the exclusion or limitation of incidental or consequential damages, so this limitation may not apply

to you.

THIS WARRANTY IS THE ONLY EXPRESS WARRANTY HONEYWELL MAKES ON THIS PRODUCT. THE

DURATION OF ANY IMPLIED WARRANTIES, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, IS HEREBY LIMITED TO THE FIVEYEAR DURATION OF THIS

WARRANTY. Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you.

This warranty gives you specific legal rights, and you may have other rights which vary from state to state.

If you have any questions concerning this warranty, please write Honeywell Customer Relations, 1985

Douglas Dr, Golden Valley, MN 55422 or call 18004681502.

DR65A3000 Dehumidification System 33-00297EFS—01 15

Page 18

Home and Building Technologies

In the U.S.:

Honeywell

1985 Douglas Drive North

Golden Valley, MN 55422

http://yourhome.honeywell.com

® U.S. Registered Trademark.

© 2017 Honeywell International Inc.

33-00297EFS—01 M.S. 05-17

Printed in U.S.A.

Page 19

DR65A3000

!

À PROPOS DU NOUVEAU DÉSHUMIDIFICATEUR

Avantages ........................................18

Maintien d’une humidité idéale ...................18

Réglage des commandes .........................19

Options de régulateurs ............................19

Spécifications .....................................20

INSTALLATION

Installation en fonction de l’application ...........21

Raccordement ....................................22

Description des bornes ...........................23

Câblage ..........................................23

Vérification ........................................26

• Le modèle DR65A3000 est destiné à être installé à l’intérieur dans un lieu protégé de la pluie et des

inondations.

• Installer l’unité en assurant le dégagement nécessaire pour l’accès au panneau pour la maintenance et

l’entretien.

• Éviter de diriger l’air d’évacuation vers les personnes ou sur l’eau des piscines.

• Si le produit est utilisé près d’une piscine ou d’un spa, veiller à garantir que l’unité ne peut pas tomber

dans l’eau ou être éclaboussée, et qu’elle est raccordée à un disjoncteur de fuite à la terre.

ENTRETIEN

Nettoyage .........................................27

Description technique ............................28

Liste des pièces ...................................30

Garantie limitée de 5 ans ..........................31

• Pour garantir un fonctionnement silencieux, ne pas placer l’unité directement sur les supports de

structure du bâtiment.

• Un bac de récupération doit être placé sous l’unité si elle est installée au-dessus d’une zone habitée ou

d’une zone où une fuite d’eau pourrait causer des dommages.

1. Ne jamais faire fonctionner l’appareil avec un cordon d’alimentation endommagé. Si le

cordon d’alimentation est endommagé, il doit être remplacé par le fabricant, son agent du

service, ou une personne qualifiée afin d’éviter les situations dangereuses.

2. Cet appareil n’est pas conçu pour une utilisation par des personnes (incluant les

enfants) ayant des capacités physiques, sensorielles ou mentales réduites, ou manquant

d’expérience et de connaissance à moins d’avoir reçu la supervision ou les instructions

concernant l’utilisation de l’appareil par une personne responsable de leur sécurité. Les

enfants devraient être supervisés pour s’assurer qu’ils ne jouent pas avec l’appareil.

BESOIN D’AIDE? Pour obtenir de l’aide sur ce produit, prière de visiter le site

http://www.forwardthinking.honeywell.com ou d’appeler le service d’assistance à la clientèle de

?

Honeywell au 1-800-468-1502.

Lire et conserver ces instructions.

® Marque déposée américaine. Brevets en instance. Copyright © 2016 Honeywell International Inc. Tous droits réservés.

Système de déshumidification DR65A3000 33-00297EFS—01

Page 20

À propos du déshumidificateur DR65A3000

MFCR24780

01

NOTRE PERCEPTION DE LA TEMPÉRATURE DE L’AIR

MF27328

É

(DEGRÉ FAHRENHEIT)

SOURCE : INDICE DE TEMPÉRATURE-HUMIDITÉ DÉRIVÉ PAR R.G. STEADMAN, JOURNAL OF APPLIED METEOROLOGY, JUILLET 1979.

Le DR65A3000 de Honeywell permet de maintenir les niveaux d’humidité adéquats dans toute la maison

grâce à sa haute performance et son efficacité.

Avantages

• Retire jusqu’à 30,8 litres (65 chopines) d’eau par jour de l’air

intérieur.

• La commande d’humidité intégrée ne nécessite aucun câblage

supplémentaire à un régulateur externe. Il suffit de brancher et

c’est parti! Choix d’options de régulateurs externes également

disponible pour une régulation centrale.

• Certifié Energy Star.

• Coupe-circuit du transformateur intégré

Maintien d’une humidité idéale

Les points de rosée et d’humidité relative (HR) affectent la manière dont le corps ressent la chaleur. Des

niveaux d’humidité élevés causent une perception de chaleur accrue par rapport à la température réelle.

S’il est correctement entretenu, l’équipement de refroidissement peut être activé moins souvent car l’air

déshumidifié semble plus frais.

NOTRE PERCEPTION DE LA CHALEUR COMBINÉE À L’HUMIDITÉ

EXEMPLE : À 90 °F ET 50 % D’HUMIDITÉ RELATIVE, LA TEMPÉRATURE PERÇUE PAR NOTRE CORPS ATTEINT 96 °F!

HUMIDITÉ RELATIVE (POURCENTAGE)

001 4418312316210215110117014011019979593919

59 631031421811411

09 221711311901601201001896959391909887868584838

58 801501201997959391909988

RATURE DE L’AIR

08 199888786868583828181808979787777767574737

57 0897978787777767675757474737372727

TEMP

07 271717171717070707969686867676666656564646

L’humidité idéale est définie par les

experts de l’industrie* comme se

situant entre 40 et 60 % sur une

base annuelle moyenne. Lorsque

l’humidité intérieure dépasse 60 %,

l’habitation est plus susceptible à

17079696

TAUX D’HUMIDITÉ TYPE EN HIVER

RECOMMANDÉ PAR L’ASHRAE

BACTÉRIES

VIRUS

CHAMPIGNONS

la moisissure. L’unité DR65A3000

protège de l’humidité excessive tout

au long de l’année.

*Société américaine des ingénieurs en

chauffage, refroidissement et climatisation

(ASHRAE).

ACARIENS

INFECTIONS

RESPIRATOIRES

RHINITES ALLERGIQUES

ET ASTHME

INTERACTIONS

CHIMIQUES

PRODUCTION

D’OZONE

00159095808570756065505540453035202510150

0117014011018969493919098878

878685848382818089787

ZONE

OPTIMALE

010203040506070809

DANGER EXTRÊME

DANGER

PRUDENCE EXTRÊME

PRUDENCE

00

18

Système de déshumidification DR65A3000 33-00297EFS—01

Page 21

Réglage des commandes

COMMANDE D’HUMIDITÉ INTÉGRÉE : Un humidistat

intuitif à programmation sans souci est intégré dans l’unité

DR65A3000 pour régler le niveau d’humidité directement

sur l’appareil. Un câble pour régulateur externe en option

est également disponible. Si un déshumidistat externe est

utilisé, la commande de déshumidification intégrée doit être

réglée sur la position Arrêt.

Options de régulateurs

Le DR65A3000 peut être utilisé avec l’un des régulateurs externes suivants :

Système de confort Prestige™ IAQ

• Règle à la fois le chauffage-refroidissement et la ventilation.

• Capteur sans fil pour l’affichage de la température et du taux d’humidité extérieurs.

• Programme de ventilation évolué qui comprend un cycle économiseur et

l’interruption en cas de conditions extrêmes.

• Rappels de maintenance et de réparation.

• Écran couleur haute définition.

• Technologie sans fil RedLINK™

VisionPRO™ ou Prestige™

• Règle à la fois le chauffage-refroidissement et la ventilation.

• Capteur sans fil pour l’affichage de la température et du taux d’humidité extérieurs.

• Programmation de la ventilation selon l’heure du jour ou les normes Ashrae.

• Verrouillage optionnel de la ventilation pour les températures ou les conditions

d’humidité élevées/basses lorsque le capteur extérieur sans fil C7089R1013 est

utilisé.

• Technologie sans fil WiFi™ ou RedLINK™

Régulateur d’humidité numérique HumidiPRO

• Commande de déshumidification manuelle

• Protection du compresseur du déshumidificateur

• Calibration de la température extérieure et du % HR

• Butées de plage haute et basse réglables (10 à 90 %)

Système de confort total VisionPRO et VisionPRO IAQ

• Règle à la fois le chauffage-refroidissement et la ventilation.

• Capteur inclus pour l’affichage de la température extérieure.

• Interface utilisateur intuitive pour la programmation simple de la température sur

sept jours.

• Grand écran rétroéclairé, facilement lisible.

• Rappels de maintenance et de réparation.

• Peut aussi servir à commander d’autres appareils de régulation de la qualité de l’air

ambiant.

Déshumidistat manuel et régulateur de ventilateur automatique

• Régulation manuelle de l’humidité selon des points de consigne intuitifs.

• Régulateur W8150 assurant la régulation automatique de la ventilation

conformément à la norme ASHRAE ou fonctionnant en continu.

Système de déshumidification DR65A3000 33-00297EFS—01 19

Page 22

Spécifications

MF29763

28-1/2 (724)

(305)

Installer le DR65A3000 conformément au code électrique local en vigueur.

Temp. de bulbe

sec

Humidité de l’air

d’admission

Capacité

(chopines par jour)

26,7 °C (80 °F) 60 % d’HR 65

21,1 °C (70 °F) 60 % d’HR 47

15,6°C (60 °F) 60 % d’HR 34

Dimensions de

l’habitation (pieds carrés)

avec

plafonds de 2,4 m (8 pi)

Capacité requise du déshumidificateur pour maintenir l’HR intérieure désirée*

60 % d’HR intérieure

(chopines/jour)

50 % d’HR intérieure

(chopines/jour)

40 % d’HR intérieure

(chopines/jour)

2080 4954 5558 7178

2600 6168 6572 9097

3120 7582 7986 95110

* Basée sur des climats extrêmes avec une humidité relative extérieure de 7090 %. Pour les climats moins

extrêmes, une capacité moindre peut servir des habitations plus grandes. Les exigences actuelles

peuvent varier.

Dimensions en pouces et (mm)

12 (305)

Rapport débit d’air-pression statique

externe (pression d’eau 01 po) avec

collets attachés

12

8 PO

(203) DIA.

0 po 160 pi3/min

0,2 po 140 pi3/min

0,4 po 120 pi3/min

0,6 po 100 pi3/min

Poids du produit : 27 kg (60 lb)

Poids d’expédition : 31 kg (68 lb)

Dimensions d’expédition : 16,7 po H × 17 po W ×

32,9 po L

Filtre à fibres : MERV 11, 9 po H x 11 po W x

0,75 po D

Raccord d’évacuation : Raccord NPT femelle fileté de

¾ po.

Raccords de conduit : Entrée et sortie rondes de 8 po.

Plastique ABS compatible pour un raccordement à

des conduits rigides ou flexibles avec vis à tôle et/

ou ruban adhésif.

Armoire : Acier galvanisé calibre 20 à revêtement de

peinture par pulvérisation.

Isolation : R valeur 1

Compresseur : rotatif, 6,1 KBtu

Fluide frigorigène : R410A, 15 oz.

Plage de température de fonctionnement (armoire

externe): 1,1 °C à 57,2 °C

(34 °F à 135 °F)

Plage d’humidité de fonctionnement :

099% d’HR

Caractéristiques d’entrée

• Tension d’entrée électrique : 120 V c.a.,

60 Hz nominaux

• Courant d’entrée : 5,2 A

Caractéristiques de sortie

• Transformateur de puissance aux bornes

R/C : 24 V c.a., 0,85 A

• Performance énergétique : 2,22 litres (4,7

chopines) par kilowattheure (KWH)

Normes et exigences

réglementaires

• ETL Listed per UL 474 and

CSA C22.2 No 92

• Certifié ENERGY STAR.

20

Système de déshumidification DR65A3000 33-00297EFS—01

Page 23

Installation en fonction de l’application

SECTION DE TRAITEMENT D’AIR

MF33150

DE REFOULEMENT

M24745

MF27324

DE REFOULEMENT

SECTION DE TRAITEMENT D’AIR

Le conduit flexible est recommandé pour la connexion aux collets DR65A3000 pour réduire le bruit dû

aux vibrations.

Taille de conduit : Utiliser un diamètre rond de 8 po de

diamètre minimum pour des longueurs de conduit allant

jusqu’à 7,6 m (25 pi). 25,4 cm (10 po) minimum sont

requis pour des longueurs supérieures à 7,6 m (25 pi).

Les conduits secondaires partant de l’arrivée principale/

l’échappement principal doivent être de 20,3 cm (8 po)

ronds minimum pour 23 canalisations secondaires, et de

20,3 cm (8 po) ronds ou plus pour 4 canalisations secondaires ou plus.

Zones isolées : Une déshumidification efficace peut nécessiter un acheminement de conduits vers une zone isolée ou

à débit d’air stagnant.

Exigences électriques :

sortie 115 V c.a. Disjoncteur de

fuite à la terre recommandé.

Retour dédié vers alimentation principale

A

RETOUR

RETOUR

SÉPARÉ

Retour principal vers alimentation principale

B

RETOUR

DÉSHUMIDIFICATEUR

REGISTRE

DÉSHUMIDIFICATEUR

ALIMENTATION

(REGISTRE

DE GRAVITÉ

(EN OPTION)

ALIMENTATION

REGISTRE

Idéal dans les cas suivants…

• Un accès à un retour central dédié pour

le DR65A3000 est disponible.

• Pour un fonctionnement avec la

climatisation; nécessite un registre de

refoulement sur l’orifice d’échappement

pour réduire le refoulement lorsque le

DR65A3000 n’est pas en marche mais

que la climatisation fonctionne.

• Pour fournir de l’air sec à une zone

spécifique avec un registre de

gravité en option ouvert à 20 % sur

l’alimentation du DR65A3000.

Idéal dans les cas suivants…

• Pour le fonctionnement du DR65A3000

lorsque la climatisation n’est pas en

marche. Nécessite un registre sur

l’orifice d’échappement pour réduire

le refoulement lorsque le DR65A3000

n’est pas en marche mais que la

climatisation fonctionne.

• Un accès à un retour central dédié pour

le DR65A3000 n’est pas disponible.

• Pour de meilleurs résultats, le

ventilateur du système doit fonctionner

avec le déshumidificateur.

Système de déshumidification DR65A3000 33-00297EFS—01 21

Page 24

Installation en fonction de l’application (suite)

ALIMENTATION

SECTION DE TRAITEMENT D’AIR

MF27325

MF33152

RETOU

Retour principal vers retour principal

C

Idéal dans les cas suivants…

• Le DR65A3000 fonctionne avec la

climatisation.

• Le ventilateur du système doit

fonctionner avec le déshumidificateur.

• Il est préférable de réduire

l’augmentation de la température de

l’air de soufflage.

• Un accès à un retour central dédié pour

le DR65A3000 n’est pas disponible.

Idéal dans les cas suivants…

• Le DR65A3000 ne sera pas relié en

conduit à un système de climatisation à

air pulsé.

D

RETOUR

DÉSHUMIDIFICATEUR

Retour dédié vers alimentation dédiée

DÉSHUMIDIFICATEUR

R

SÉPARÉ

ALIMENTATION

22

Raccordement

Attacher la buse de vidange 3/4 po NPT mâle.

Brancher un tube de vidange de 1/2 po à la sortie de

vidange de connexion mâle.

Attacher un tube de vidange au connecteur avec un col-

lier de serrage Run drain hose continuously downhill to an

approved drain or condensate pump.

Acheminer la conduite de vidange en aval de façon continue vers une pompe de vidange ou de récupération des

eaux condensées.

La conduite de vidange doit comprendre un séparateur

d’eau pour empêcher à l’air d’entrer ou de sortir du

déshumidificateur.

Système de déshumidification DR65A3000 33-00297EFS—01

Page 25

Description des bornes

CVCA

THERMOSTAT

MISE EN GARDE : Risque de basse tension.

Peut endommager l’équipement.

Débrancher l’équipement de CVCA avant de commencer l’installation.

Deux bornes pour fils électriques sont situées sur l’extrémité du système d’échappement du

déshumidificateur.

REMARQUE : Les vis externes sur chaque

bloc de connexion fixent le bloc au châssis.

Elles ne sont pas destinées au câblage.

Les six bornes du bloc de connexion gauche sont :

FLOAT (2): Capteur d’eau basse tension externe ou

flotteur

DHUM: Fonctionnement du compresseur et du

ventilateur pour la déshumidification

R: Sortie 24 V

FAN: Activation du ventilateur uniquement pour la

ventilation

C: Sortie 24 V

Des appareils de 24 V externes peuvent être alimentés

avec les bornes R et C (20 VA max.).

Câblage

Câbler le DR65A3000

conformément au schéma

s’appliquant au

fonctionnement désiré.

Respecter le schéma pour le

fonctionnement avec conduit

avec le déshumidistat intégré

Le bloc de connexion droit dans la figure

ci-dessus n’est utilisé que pour attacher le

DR65A3000 à un ventilateur d’équipement.

Les trois bornes sont :

Gt: Fonctionnement du ventilateur par

le thermostat

Rf: 24 V par le ventilateur d’équipement

Gf: Fonctionnement du ventilateur par

le ventilateur d’équipement

GYWR C

+

+

FLOAT FLOAT

GYWRRc

DHUM

FAN

R

C

(VENT.)

DÉSHUMIDIFICATEUR

+

Gt

+

Rf

Gf

MF33153

Système de déshumidification DR65A3000 33-00297EFS—01 23

Page 26

Câblage (suite)

CVCA

THERMOSTAT

CVCA

MF33154A

MF35602

Respecter le schéma si vous utilisez

le régulateur d’humidité numérique

HumidiPro.

GYWR C

RFloatDHUM Fan C

24 V C.A.

C

(CONSTANTS)

R

U

U

S

S

Respecter ce schéma si un

thermostat PrestigeIAQ est utilisé.

Respecter ce schéma si

un déshumidistat manuel

externe est utilisé.

W

DHUM

R

(VENT.)

C

Rc

R

H

H

U_

U_

FAN

TrueDRY

+

+

C

Gt

Rf

Gf

CONTACTS

SECS

W2

Y

Y2

G

K

THERMOSTAT

+

FLOAT

REMARQUE : LE THERMOSTAT DOIT ÊTRE CONFIGURÉ POUR ALIMENTER

LE VENTILATEUR DE L’APPAREIL DE CHAUFFAGE LORS DE L’APPEL DE

DÉSHUMIDIFICATION.

GYWR C

+

DÉSHUMIDISTAT

MÉCANIQUE

24

+

FLOAT FLOAT

GYWRRc

DHUM

FAN

R

(VENT.)

+

+

C

DÉSHUMIDIFICATEUR

Gt

Rf

Gf

MF33155

Système de déshumidification DR65A3000 33-00297EFS—01

+

Page 27

Câblage (suite)

MF33156A

THERMOSTAT

MF33157A

AUTRE QU’UN TH5110, TH5220, TH5320, TH6110, TH6220, TH6320, TH8110,

T

DE DÉSHUMIDIFICATION.

CVCA

EARD8TZ

Respecter le schéma pour le fonctionnement avec conduit avec

régulateur de ventilation externe.

W

Rc

R

THERMOSTAT

GYWR C

W8150A

G

R

C

C

W

G

GY

R

C

REGISTRE

AUX

À DISTANCE

+

FLOAT

DHUM

R

FAN

(VENT.)

+

+

C

Gt

Rf

DÉSHUMIDIFICATEUR

+

Gf

1

Respecter ce schéma si le

DR65A3000 est utilisé avec un

déshumidistat électrique tel que le

TrueIAQ (DG115EZIAQ).

GYWRRc

C

R

TrueIAQ

In

%

40

68

Out

%

76

PM

1215

55

:

2

C

CAPTEUR

CAPTEUR

CONT.

W

G

CAPTEUR

D’EXTÉRIEUR

(FOURNI)

VENT

VENT

CVCA

R

C

W

Y

G

EARD8TZ

DÉSHUM.

DÉSHUM.

HUM

HUM

+

DHUM

FLOATFAN

R

(VENT.)

+

C

+

Gt

Rf

DÉSHUMIDIFICATEUR

1

SI UN THERMOSTAT

H8320 OU TH8321 EST UTILISÉ, UN RELAIS PEUT ÊTRE REQUIS POUR ISOLER LE FIL G.

LE RÉGLAGE ISU 60 À Ø FORCE LE VENTILATEUR DU SYSTÈME SANS APPEL

2

+

Gf

Système de déshumidification DR65A3000 33-00297EFS—01 25

Page 28

Câblage (suite)

MF33158A

MODULE D’INTERFACE D’ÉQUIPMENT (EIM)

Respecter le schéma si le DR65A3000

est utilisé avec un Prestige IAQ ou

VisionPro IAQ.

VISIONPRO IAQ

EARD8TZ

D-1

R-2

C-3

1

C

R

RC

RH

2

3

H1

U

M2

D1

H

M2

V1

N

T2

PLAQUE

DE RELAIS

D’APPAREIL

DE CHAUFFAGE

ÀVENTILATEUR

CONV.HP

O/B

W1

AUX

W2

AUX2

W3

Y

Y

Y2

Y2

G

G

OU

C

RELAIS CHAUFFAGE 1

RELAIS CHAUFFAGE 2

RELAIS CHAUFFAGE 3

RELAIS REFROIDISSEMENT 1

RELAIS REFROIDISSEMENT 2

G

RELAIS VENTILATEUR

R

C

FAN

(VENT.)

DÉSHUMIDIFICATEUR

+

+

Gt

Rf

+

DHUM

FLOAT

+

Gf

Vérification

Mettre le DR65A3000 sous tension. Mettre la commande d’humidité à un pourcentage d’HR faible pour

lancer l’appel de déshumidification. Confirmer que le compresseur et le ventilateur du DR65A3000 sont en

marche. La soufflante de l’appareil de chauffage tourne aussi pour faire circuler l’air. Ceci prend environ deux

minutes. Veiller à tourner la commande sur le pourcentage d’HR désiré ou sur Arrêt une fois la vérification

effectuée. Le fait de mettre la commande d’humidité sur Arrêt désactive le DR65A3000.

26

Système de déshumidification DR65A3000 33-00297EFS—01

Page 29

Nettoyage

Effectuez les mesures d’entretien suivantes chaque année pour assurer le fonctionnement optimal du

déshumidificateur.

Débranchez le déshumidificateur avant

1 2

3

de commencer le service. Retirez le

panneau d’accès magnétique pour

accéder au filtre.

Vérifier le raccordement de la vidange

et du tuyau de vidange pour s’assurer

qu’il n’y a pas de débris et de saletés.

S’assurer que tous les raccords de

conduite sont bien serrés une fois

l’entretien des lignes de vidange terminé.

4

Retirez le filtre et remplacez-le par un

nouveau. Remettez le panneau d’accès

magnétique en place.

Une fois l’entretien terminé, lancer un

appel de déshumidification et vérifier

que le compresseur et le ventilateur se

mettent en marche.

Si un régulateur VisionPRO IAQ ou

TrueIAQ est utilisé, réinitialiser les rappels pour l’entretien.

Système de déshumidification DR65A3000 33-00297EFS—01 27

Page 30

Description technique

COMPRESSEUR

DESSICATEUR

DE CRÉPINE/FIL

MF27404

Le DR65A3000 utilise un système de réfrigération

similaire à celui d’un climatiseur pour retirer la chaleur

TRE

et l’humidité de l’air d’arrivée et ajouter de la chaleur à

l’air soufflé. Le gaz frigorigène haute pression chaud

est acheminé du compresseur vers le serpentin. Le

CONDENSEUR

fluide frigorigène est refroidi et condensé en dégageant

sa chaleur dans l’air qui est prêt à être soufflé de

l’unité. Le fluide frigorigène passe ensuite par un

TUBES

CAPILLAIRES

déshydratateur-filtre et un tube capillaire, ce qui

provoque la chute de la température et de la pression

du fluide frigorigène Il pénètre ensuite dans le serpentin

évaporateur où il absorbe la chaleur de l’air d’arrivée

et s’évapore. L’évaporateur fonctionne en condition

ÉVAPORATEUR

ACCUMULATEUR

immergée (noyé), ce qui signifie que tous les tubes

de l’évaporateur contiennent du fluide frigorigène lors

du fonctionnement normal. Un évaporateur noyé doit

maintenir une pression et une température quasiment

constantes sur tout le serpentin, de l’entrée à la sortie.

Dépannage

Des vidéos de dépannage sont disponibles sur la liste de lecture CPRO de Honeywell sur YouTube.

MISE EN GARDE : L’entretien du DR65A3000 avec son système frigorigène haute pression

et son circuit haute tension présente des dangers pouvant entraîner des blessures graves ou

mortelles et des dommages matériels. L’entretien de doit être effectué que par un technicien

d’entretien qualifié.

Problème Étapes de dépannage recommandées

Pas de déshumidification.

Le ventilateur ni le

compresseur ne tournent

et le minuteur de

ventilation est sur Arrêt.

Pas de déshumidification.

Le compresseur ne tourne

pas mais le ventilateur

tourne lorsqu’il y a un

appel de déshumidification et la commande du

ventilateur est sur Arrêt.

Le ventilateur tourne

lorsqu’il y a un appel à la

déshumidification et la

commande de ventilation

est sur Arrêt, mais le

compresseur s’arrête et

se met en marche trop

fréquemment.

1. Unité débranchée ou pas d’alimentation à l’arrivée.

2. Commande d’humidité réglée trop haut ou défectueuse.

3. Raccord desserré dans le câblage de la commande ou le câblage interne.

4. Relais de compresseur défectueux.

5. Transformateur de commande défectueux.

6. Contacteur de sécurité de pompe de condensation en option ouvert.

1. Condensateur du compresseur défectueux.

2. Mauvais raccord dans le circuit du compresseur.

3. Surcharge du compresseur.

4. Compresseur défectueux.

5. Thermostat de dégivrage ouvert.

6. Contacteur de sécurité de pompe de condensation en option ouvert.

1. Température et/ou humidité ambiantes faibles, mettant l’unité en mode de

dégivrage.

2. Surcharge du compresseur.

3. Compresseur défectueux.

4. Thermostat de dégivrage défectueux.

5. Filtre(s) à air sale(s) ou débit d’air obstrué.

6. Faible charge de fluide frigorigène, causant l’activation de la commande de

dégivrage.

7. Mauvais raccord dans le circuit du compresseur. Le ventilateur ne fonctionne pas

avec la commande du ventilateur dans n’importe quelle position.

28

Système de déshumidification DR65A3000 33-00297EFS—01

Page 31

Dépannage (suite)

Problème Étapes de dépannage recommandées

Le ventilateur ne tourne pas

avec la ventilation activée. Le

compresseur tourne brièvement

mais passe sur Marche et Arrêt

avec la commande d’humidité

sur Marche.

Le serpentin évaporateur gèle

en continu, faible capacité de

déshumidification.

L’unité ne fournit pas de

ventilation.

Unit removes some water, but

not as much as expected.

Test de l’unité pour déterminer

le

problème :

1. Raccord desserré dans le circuit du ventilateur.

2. Une obstruction empêche le ventilateur de tourner.

3. Ventilateur défectueux.

4. Relais de ventilateur défectueux.

5. Condensateur de ventilateur défectueux.

1. Thermostat de dégivrage desserré ou défectueux.

2. Faible charge de fluide frigorigène.

3. Filtre(s) à air sale(s) ou débit d’air obstrué.

1. Vérifier les connexions des fils de commande (vérifier les connexions sur le

registre d’air frais également).

2. Registre d’air frais défectueux.

3. Admission d’air défectueuse. Nettoyer le capot d’admission extérieur.

1. Chute de la température et/ou de l’humidité de l’air.

2. Hygromètre ou thermomètre utilisés mal étalonnés.

3. L’unité est en mode de dégivrage.

4. Filtre à air sale.

5. Thermostat de dégivrage défectueux.

6. Faible charge de fluide frigorigène.

7. Fuite d’air, telle que couvercle desserré ou fuite au niveau des conduits.

8. Compresseur défectueux.

9. Conduit obstrué.

10. Contacteur de sécurité de pompe de condensation en option ouvert.

1. Détacher les raccords de câblage de commande sur site de l’unité principale.

2. Brancher les contacteurs R et FAN (ventilateur) de l’unité principale ensemble;

seul le ventilateur de turbine doit tourner. Débrancher les fils.

3. Brancher les contacteurs R et DHUM de l’unité principale ensemble; le ventilateur

de compresseur et de turbine doit tourner.

4. Si ces tests fonctionnent, l’unité principale fonctionne correctement. Vérifier

ensuite le panneau de commande et le câblage de commande sur site.

5. Retirer le panneau de commande de la boîte de montage et le détacher du

câblage de commande installé sur site. Brancher les fils bleu, jaune et vert

du panneau de commande directement sur les queues de cochon colorées

correspondantes de l’unité principale. Ne pas brancher les fils violet, blanc et

rouge!

6. Mettre la commande d’humidité sur marche. Le ventilateur du compresseur et de

la turbine doit tourner.

7. Si ces tests fonctionnement, le problème se trouve probablement au niveau du

câblage de commande sur site.

Charge de fluide frigorigène

Si la charge de fluide frigorigène est perdue en raison de l’entretien ou d’une fuite, une nouvelle charge doit

être apportée avec précision. Si toute charge ancienne est laissée dans le système, elle doit être récupérée

avant la mise en place de la nouvelle charge. Consulter la plaque signalétique de l’unité pour connaître le

poids et le type de fluide frigorigène requis.

Système de déshumidification DR65A3000 33-00297EFS—01 29

Page 32

Liste des pièces

M36840

Référence de la figure Pièces de base et accessoires Référence de pièce

1 Déshumidificateur DR65A3000/U

2 Registre de ventilation motorisé EARD8TZ

3 Registre de dérivation de 20,3 cm (8 po) CPRD8

4 Filtre 50049537005

1

4

2

3

30

Pour référence seulement.

Système de déshumidification DR65A3000 33-00297EFS—01

Page 33

Garantie limitée de 5 ans

Honeywell garantit ce produit contre tout vice de fabrication ou de matériau dans la mesure où il en est fait

une utilisation et un entretien convenables, et ce, pour cinq (5) ans à partir de la date d’achat par le consommateur. En cas de défectuosité ou de mauvais fonctionnement pendant la période de garantie, Honeywell

remplacera ou réparera le produit, à sa discrétion, dans un délai raisonnable.

Si le produit est défectueux,

le retourner, accompagné d’une preuve d’achat indiquant la date d’achat, au détaillant auprès de qui il a

été acheté, ou s’adresser au service d’assistance à la clientèle de Honeywell en composant le 1800468

1502. Le service d’assistance à la clientèle déterminera si le produit doit être retourné à l’adresse suivante

: Honeywell Return Goods, Dock 4 MN103860, 1885 Douglas Dr. N., Golden Valley, MN 55422, ou si un

produit de remplacement peut vous être expédié.

La présente garantie ne couvre pas les frais de retrait ou de réinstallation. La présente garantie ne

s’appliquera pas s’il est démontré par Honeywell que la défectuosité ou le mauvais fonctionnement sont dus

à un endommagement du produit alors que le consommateur l’avait en sa possession.

La responsabilité exclusive de Honeywell se limite à réparer ou à remplacer le produit conformément aux

modalités susmentionnées.

HONEYWELL N’EST EN AUCUN CAS RESPONSABLE DES PERTES OU DOMMAGES, Y COMPRIS LES

DOMMAGES INDIRECTS OU ACCESSOIRES DÉCOULANT DIRECTEMENT OU INDIRECTEMENT D’UNE

VIOLATION QUELCONQUE D’UNE GARANTIE, EXPRESSE OU TACITE, APPLICABLE AU PRÉSENT PRODUIT,

OU TOUTE AUTRE DÉFECTUOSITÉ DU PRÉSENT PRODUIT. Certaines provinces ne permettent pas

l’exclusion ou la restriction des dommages indirects ou accessoires et, par conséquent, la présente restriction peut ne pas s’appliquer.

CETTE GARANTIE EST LA SEULE GARANTIE EXPRESSE FAITE PAR HONEYWELL POUR CE PRODUIT.

LA DURÉE DE TOUTE GARANTIE IMPLICITE, INCLUANT LES GARANTIES DE QUALITÉ MARCHANDE OU

D’ADAPTATION À UNE UTILISATION PARTICULIÈRE, EST LIMITÉE PAR LES PRÉSENTES À LA PÉRIODE

DE CINQ ANS DE LA PRÉSENTE GARANTIE. Certaines provinces ne permettent pas de limiter la durée des

garanties tacites et, par conséquent, la présente limitation peut ne pas s’appliquer.

La présente garantie donne au consommateur des droits légaux spécifiques et certains autres droits qui

peuvent varier d’une province à l’autre.

Pour toute question concernant la présente garantie, prière d’écrire aux Services à la clientèle de Honeywell

à l’adresse suivante : Honeywell Customer Relations, 1985 Douglas Dr, Golden Valley, MN 55422 ou composer le 18004681502.

Système de déshumidification DR65A3000 33-00297EFS—01 31

Page 34

Home and Building Technologies

Aux États-Unis:

Honeywell

1985 Douglas Drive North

Golden Valley, MN 55422

http://yourhome.honeywell.com

Marque de commerce déposée aux É.-U.

© 2017 Honeywell International Inc.

33-00297EFS—01 M.S. 05-17

Imprimé aux États-Unis.

Page 35

DR65A3000

!

SOBRE SU NUEVO DESHUMIDIFICADOR

Beneficios .........................................34

Mantenimiento de la humedad ideal ..............34

Configuración de los controles ....................35

Opciones de control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Especificaciones ..................................36

INSTALACIÓN

Realice la instalación según sus necesidades .....37

Plomería ..........................................38

Descripción de las terminales .....................39

Cableado ..........................................39

Revisión ..........................................42

• El DR65A3000 está diseñado para ser instalado en interiores en un espacio protegido de la lluvia y de

inundaciones.

• Instale la unidad de manera tal que quede espacio suficiente para acceder al panel frontal para realizar el

mantenimiento y el servicio técnico.

• Evite que el aire de descarga se dirija en dirección a las personas o sobre el agua de áreas de piscinas.

• Si lo utiliza cerca de una piscina o bañera de hidromasaje, asegúrese de que la unidad no corra el

riesgo de caer en el agua ni de recibir salpicaduras; también asegúrese de que esté enchufada a un

tomacorriente con interruptor de falla a tierra (IFT).

MANTENIMIENTO

Limpieza ..........................................43

Descripción técnica ...............................44

Lista de piezas ....................................46

Garantía limitada de 5 años .......................47

• Para garantizar un funcionamiento silencioso, no coloque el dispositivo directamente sobre los soportes

estructurales de la casa.

• Si la unidad se instala sobre una zona habitable o sobre una zona en la que una pérdida de agua podría

ocasionar daños, se debe colocar una bandeja de desagüe debajo de la unidad.

1. Nunca utilice una unidad con un cable de alimentación dañado. Si el cable de

alimentación está dañado el fabricante, el agente de servicio o una persona con

calificaciones similares debe reemplazarlo para evitar riesgos.

2. La unidad no está destinada para el uso por personas (incluyendo niños) con capacidad

física, sensorial o mental limitada, o con falta de experiencia y conocimiento, a menos que

una persona responsable de su seguridad les haya brindado supervisión o instrucción

relativa al uso de la unidad. Los niños pequeños deben estar supervisados para

garantizar que no jueguen con la unidad.

¿NECESITA AYUDA? Para obtener ayuda sobre este producto, visite

http://www.forwardthinking.honeywell.com, o llame de manera gratuita al Servicio al cliente

?

de Honeywell al 1-800- 468-1502.

Lea y guarde estas instrucciones.

® Marca comercial registrada de los EE. UU. Patentes en trámite. Copyright © 2016 Honeywell International Inc. Todos los derechos reservados.

Sistema de deshumidificación DR65A3000 33-00297EFS—01

Page 36

MSCR24780

01

Acerca del deshumidificador DR65A3000

CÓMO SE SIENTE EL AIRE

MS27328

TEMPERATURA DEL AIRE

(GRADOS FAHRENHEIT)

Debido a su alto rendimiento y eficacia, el DR65A3000 de Honeywell garantiza que la casa se mantenga a

niveles de humedad adecuados.

Beneficios

• Elimina hasta 65 pintas (31 l) de agua por día del aire interior.

• El control de humedad empotrado no necesita un cableado

adicional hacia un control externo. ¡Solo enchúfelo y listo!

También se encuentran disponibles diferentes opciones de

control externo para el control entubado central.

• Calificación Energy Star.

• Disyuntor del circuito del transformador integrado.

Mantenimiento de la humedad ideal

Los puntos de rocío y la humedad relativa (HR) influyen en la

manera en que su cuerpo siente el calor. Los niveles más altos de humedad hacen que el aire se sienta

mucho más caliente que la temperatura real. Si lo mantiene correctamente, puede hacer uso de su equipo

de enfriamiento con menor frecuencia porque el aire deshumidificado se siente más fresco.

Según lo definen los expertos de la

industria*, la humedad ideal es la que

se encuentra entre el 40 y el 60%, en

base a un promedio anual. Cuando la

humedad interior es mayor al 60%,

la casa está mucho más propensa

al crecimiento de moho y hongos.

El DR65A3000 protege la casa del

exceso de humedad durante todo el

año.

* Sociedad Americana de Ingenieros

en Calefacción, Refrigeración y Aire

Acondicionado (American Society of Heating,

Refrigerating and Air Conditioning Engineers,

ASHRAE).

CUÁN CALIENTE SE SIENTE EL AIRE DEBIDO A LA COMBINACIÓN DE CALOR Y HUMEDAD. EJEMPLO: SI EL AIRE

ESTÁ A 90 ºF (32 ºC) CON UN 50% DE HR, ¡EL CUERPO HUMANO LO SIENTE COMO SI FUERAN 96 ºF (36 ºC)!

HUMEDAD RELATIVA (PORCENTAJE)

00159095808570756065505540453035202510150

001 4418312316210215110117014011019979593919

59 631031421811411

09 221711311901601201001896959391909887868584838

58 801501201997959391909988

08 199888786868583828181808979787777767574737

57 0897978787777767675757474737372727

07 271717171717070707969686867676666656564646

FUENTE: EL ÍNDICE DE TEMPERATURA Y HUMEDAD LO DEDUJO R.G. STEADMAN, REVISTA JOURNAL OF APPLIED METEOROLOGY, JULIO DE 1979.

17079696

BACTERIAS

VIRUS

HONGOS

ACAROS

INFECCIONES

RESPIRATORIAS

RINITIS ALÉRGICA

Y ASMA

INTERACCIONES

QUÍMICAS

PRODUCCIÓN

DE OZONO

0117014011018969493919098878

878685848382818089787

NIVEL DE DISEÑO EN INVIERNO

RECOMENDADO POR LA ASHRAE

010203040506070809

PELIGRO EXTREMO

PELIGRO

PRECAUCIÓN EXTREMA

PRECAUCIÓN

ÁREA

ÓPTIMA

00

34

Sistema de deshumidificación DR65A3000 33-00297EFS—01

Page 37

Configuración de los controles

CONTROL DE HUMEDAD EMPOTRADO: Un humidistato

intuitivo para “configurar y olvidarse” está incorporado en el

DR65A3000 para configurar el nivel correcto de humedad

en el dispositivo. También se encuentra disponible el

cableado del control externo opcional. Si se utiliza un

deshumidistato externo, el control de deshumidificación

incorporado deberá colocarse en la posición Off.

Opciones de control

El DR65A3000 puede utilizarse con uno de los siguientes controles externos

Kit Prestige™ IAQ

• Controla la calefacción/refrigeración y la deshumidificación

• Sensor inalámbrico para visualizar la temperatura y la humedad

exteriores

• La programación avanzada de la ventilación cuenta con apagado en

condiciones extremas y para economizar

• Recordatorios de mantenimiento y de servicio técnico

• Pantalla de alta definición a color

• Tecnología inalámbrica RedLINK™

VisionPRO™ o Prestige™

• Controla la calefacción/refrigeración y la deshumidificación

• Sensor inalámbrico para visualizar la temperatura y la humedad

exteriores

• Programación de ventilación para la hora del día o las normas Ashrae.

• Bloqueos de ventilación opcionales para condiciones de temperatura

o humedad alta/baja cuando se utiliza el sensor exterior inalámbrico

C7089R1013.

• Tecnología inalámbrica WiFi™ o RedLINK™

Control digital HumidiPRO

• Control de deshumidificación manual

• Protección del compresor del deshumidificador

• Calibración de la temperatura exterior y del % de HR

• Límites de rango superior e inferior ajustables (1090%)

Control digital TrueIAQ

• Los ajustes automáticos mantienen el aire fresco en la vivienda

• Sensor para visualizar la temperatura y la humedad exterior

• La programación avanzada de la ventilación cuenta con apagado en

condiciones extremas y para economizar

• Recordatorios de mantenimiento y de servicio técnico

• Controla otros equipos de calidad de aire en interiores

Deshumidistato manual y automático controles de ventilación

• Control manual de humedad con configuraciones intuitivas y cómodas

• Control automático de ventilación W8150 conforme al código de la

ASHRAE o para un funcionamiento continuo

Sistema de deshumidificación DR65A3000 33-00297EFS—01 35

Page 38

Especificaciones

MS29763

28-1/2 (724)

(305)

Instale su DR65A3000 según los códigos nacionales de electricidad.

Temperatura de

bulbo seco

Humedad de

entrada

Capacidad

(pintas [l]/día)

80°F (26,7°C) 60% de RH 65 (30,8 l)

70°F (21,1°C) 60% de RH 47 (22,2 l)

60°F (15,6°C) 60% de RH 34 (16,1 l)

Tamaño de la casa

(pies cuadrados) con

techo a 8 pies (2.4 m)

Capacidad del deshumidificador necesaria para mantener la HR* interior

deseada

60% de HR interior

(pintas/día)

50% de HR interior

(pintas/día)

40% de HR interior

(pintas/día)

2080 4954 5558 7178

2600 6168 6572 9097

3120 7582 7986 95110

* En base a climas extremos donde la humedad exterior es del 70 al 90% de HR. En el caso de climas

menos extremos, las casas más grandes pueden aclimatarse correctamente con menos capacidad.

Es posible que los requisitos reales varíen.

Dimensiones en pulgadas y (mm):

12 (305)

Flujo de aire versus presión estática

externa (0 a 1 pulgada [0 a 25,4

mm] de presión de agua) con anillos

DIÁMETRO

12