Page 1

DR4300

Circular Chart Recorder

Product Manual

44-01-25-14E

4/00

Sensing and Control

Page 2

DR4300 Circular Chart Recorder

Copyright, Notices, and Trademark

Printed in U.S.A. – © Copyright 2000 by Honeywell

WARRANTY/REMEDY

Honeywell warrants goods of its manufacture as being free of defective materials and faulty

workmanship. Contact your local sales office for warranty information. If warranted goods are

returned to Honeywell during the period of coverage, Honeywell will repair or replace without

charge those items it finds defective. The foregoing is Buyer’s sole remedy and is in lieu of all

other warranties, expressed or implied, including those of merchantability and fitness for a

particular purpose. Specifications may change without notice. The information we supply is

believed to be accurate and reliable as of this printing. However, we assume no responsibility for

its use.

While we provide application assistance personally, through our literature and the Honeywell web

site, it is up to the customer to determine the suitability of the product in the application.

Revision E – April 5, 2000

Sensing and Control

Honeywell

11 West Spring Street

Freeport, Illinois 61032

DR4300 and Accutune II are U.S. trademarks of Honeywell

Information Mapping is a trademark of Informati on Mapping Inc.

Modbus is a trademark of Modicon, Inc.

Other brands or product names are t rademarks of their respective owners.

DR4300 Circular Chart Recorder Product Manual 4/00ii

Page 3

About This Document

Abstract

This manual contains instructions for installation, operation, and troubleshooting of the DR4300 Circular Chart Recorder.

References

The following list identifies all documents that may be sources of reference for material discussed in this publication.

Document Title Doc ID

How to Apply Digital Instrumentation in Severe

Electrical Noise Environments

Modbus® RTU Serial Communications User Manual 51-52-25-66

Modbus® RTU Serial Communications User Manual

Configuration Interface for DR4300

51-52-05-01

51-52-25-71

Contacts

World Wide Web

The following lists Honeywell’s World Wide Web sites that will be of interest to our customers.

Honeywell Organization WWW Address (URL)

Corporate http://www.honeywell.com

Sensing and Control http://www.honeywell.com/sensing

International http://www.honeywell.com/Business/global.asp

Telephone

Contact us by telephone at the numbers listed below.

Organization Phone Number

United States and Canada Honeywell 1-800-423-9883 Tech. Support

1-888-423-9883 Q&A Faxback

(TACFACS)

1-800-525-7439 Service

Asia Pacific Honeywell Asia Pacific

Hong Kong

Europe Honeywell PACE, Brussels, Belgium [32-2] 728-2111

Latin America Honeywell, Sunrise, Florida U.S.A. (854) 845-2600

4/00 DR4300 Circular Chart Recorder Product Manual iii

(852) 2829-8298

Page 4

DR4300 Circular Chart Recorder

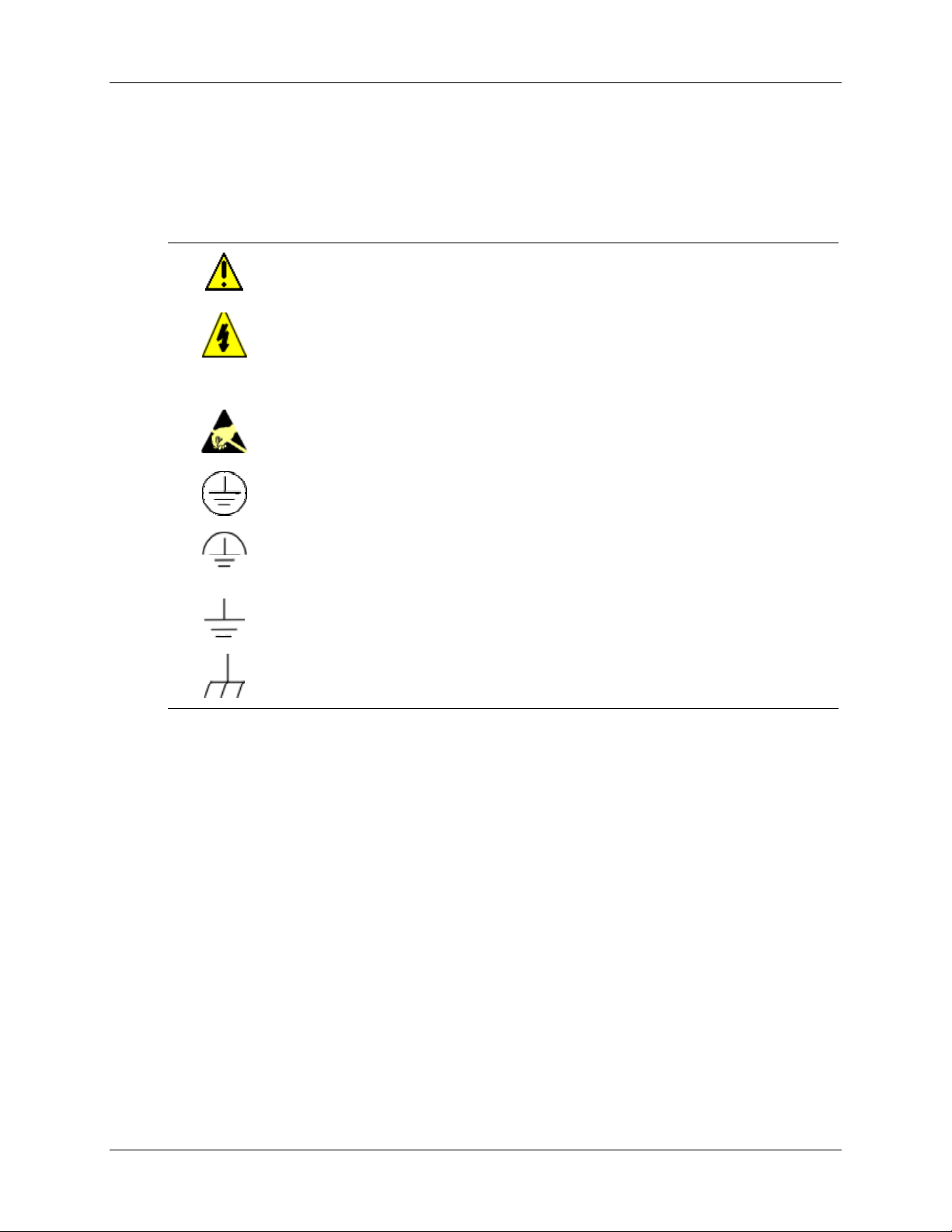

Symbol Definitions

The following table lists those symbols used in this document to denote certain conditions.

Symbol Definition

This CAUTION symbol on the equipment refers the user to the Product Manual for

additional information. This symbol appears next to required information in the

manual.

WARNING

PERSONAL INJURY: Risk of electrical shock. This symbol warns the user of a

potential shock hazard where HAZARDOUS LIVE voltages greater than 30 Vrms,

42.4 Vpeak, or 60 Vdc may be accessible. Failure to comply with these

instructions could result in death or serious injury.

ATTENTION, Electrostatic Discharge (ESD) hazards. Observe precautions for

handling electrostatic sensitive devices

Protective Earth (PE) terminal. Provided for connection of the protective earth (green

or green/yellow) supply system conductor.

Functional earth terminal. Used for non-safety purposes such as noise immunity

improvement. NOTE: This connection shall be bonded to protective earth at the

source of supply in accordance with national local electrical code requirements.

Earth Ground. Functional earth connection. NOTE: This connection shall be bonded

to Protective earth at the source of supply in accordance with national and local

electrical code requirements.

Chassis Ground. Identifies a connection to the chassis or frame of the equipment

shall be bonded to Protective Earth at the source of supply in accordance with

national and local electrical code requirements.

DR4300 Circular Chart Recorder Product Manual 4/00iv

Page 5

Contents

1. OVERVIEW...............................................................................................................1

1.1 Introduction...................................................................................................................................1

1.2 Model Number Breakdown...........................................................................................................4

1.3 About This Manual .......................................................................................................................9

2. INSTALLATION......................................................................................................11

2.1 Overview.....................................................................................................................................11

2.2 Mounting Considerations and Overall Dimensions....................................................................15

2.3 Mounting Methods......................................................................................................................16

2.3.1 Introduction....................................................................................................................16

2.3.2 Mounting Flush in Panel (New Panel Cutout)...............................................................17

2.3.3 Panel Mounting Recorder with NEMA4 or Heavy Duty door......................................18

2.3.4 Mounting on a 2-inch pipe.............................................................................................20

2.3.5 Mounting on Surface (of Panel or Wall) .......................................................................21

2.4 Wiring Prerequisites....................................................................................................................22

2.5 Input Wiring................................................................................................................................27

2.5.1 Power Wiring.................................................................................................................27

2.5.2 Analog Input Wiring......................................................................................................31

2.5.3 Digital Inputs (Optional)................................................................................................33

2.5.4 Communication (Optional)............................................................................................35

2.6 Output Wiring.............................................................................................................................37

2.6.1 Discrete Outputs.............................................................................................................37

2.6.2 Current Output...............................................................................................................41

2.6.3 Transmitter Power Out...................................................................................................43

3. CONFIGURATION, STARTUP, AND OPERATION OF BASIC RECORDER

WITHOUT DISPLAY...............................................................................................45

3.1 Overview.....................................................................................................................................45

3.2 Configuration (Recording Set Up)..............................................................................................46

3.2.1 Setting Configuration and Input Switches.....................................................................46

3.2.2 Setting SW6 Switch 2....................................................................................................64

3.3 Startup and Operation of Recorder without Display ..................................................................65

3.3.1 Overview........................................................................................................................65

3.3.2 Preparing the Recorder for Operation............................................................................66

3.3.3 Running the Optional Step Test.....................................................................................67

3.3.4 Startup............................................................................................................................69

4/00 DR4300 Circular Chart Recorder Product Manual v

Page 6

DR4300 Circular Chart Recorder

4. CONFIGURATION, STARTUP AND OPERATION OF RECORDER WITH

DISPLAY.................................................................................................................71

4.1 Overview.....................................................................................................................................71

4.2 Operator Interface on Recorder with Display and Keypad.........................................................72

4.3 Configuration (Recording and Output Set Up)...........................................................................74

4.3.1 Overview........................................................................................................................74

4.3.2 Configuration Prompts...................................................................................................75

4.3.3 How to Get Started.........................................................................................................77

4.3.4 Configuration Tips.........................................................................................................78

4.1.5 Switch Settings...............................................................................................................79

4.1.6 Configuration Procedure................................................................................................83

4.1.7 Input Parameters Set Up Group.....................................................................................85

4.1.8 Pen Parameters Set Up Group........................................................................................89

4.1.9 Chart Parameters Set Up Group.....................................................................................90

4.1.10 Totalizer Parameters Set Up Group...............................................................................91

4.1.11 Control Parameters Set Up Group.................................................................................94

4.1.12 Tuning Parameters Set Up Group................................................................................100

4.1.13 Setpoint Ramp/Program Set Up Group........................................................................104

4.1.14 Timer Set Up Group.....................................................................................................105

4.1.15 Alarms Set Up Group...................................................................................................106

4.1.16 Auxiliary Output Set Up Group...................................................................................109

4.1.17 Communication Set Up Group.....................................................................................111

4.1.18 Remote Switch (Digital Inputs) Set Up Group............................................................112

4.1.19 Display Parameter Set Up Group.................................................................................114

4.1.20 Lock Out Parameter Set Up Group..............................................................................115

4.1.21 Configuration Record Sheet.........................................................................................116

4.1.22 Limit Control Configuration........................................................................................118

4.4 Startup of Recorder with Display and Keypad.........................................................................119

4.4.1 Overview......................................................................................................................119

4.4.2 Preparing the Recorder for Startup..............................................................................120

4.4.3 Running the Optional Step Test...................................................................................121

4.4.4 Completing Preparation and Startup............................................................................123

4.5 Operation of Recorder with Display and Keypad.....................................................................128

4.5.1 Monitoring Your Recorder ..........................................................................................128

4.1.2 Operator Functions.......................................................................................................132

5. INPUT AND OUTPUT CALIBRATION FOR RECORDER WITH DISPLAY.........141

5.1 Overview...................................................................................................................................141

5.2 Input Calibration Minimum and Maximum Range Values.......................................................142

5.3 Input Calibration Preliminary Information...............................................................................144

5.4 Input Calibration Set Up and Wiring........................................................................................146

5.4.1 General Calibration Set Up..........................................................................................146

5.4.2 Thermocouple Inputs Using a Compensated Calibrator..............................................147

5.4.3 Thermocouple Inputs Using an Ice Bath or Ice Point Reference.................................148

5.4.4 RTD (Resistance Temperature Detector) Inputs .........................................................149

DR4300 Circular Chart Recorder Product Manual 4/00vi

Page 7

5.5 Input Calibration Procedure......................................................................................................151

5.6 Current Output Calibration.......................................................................................................153

6. ROUTINE MAINTENANCE...................................................................................157

6.1 Overview...................................................................................................................................157

6.2 Replacing the Chart...................................................................................................................158

6.3 Replacing the Ink Cartridge......................................................................................................159

6.4 Maximizing Pen Life ................................................................................................................160

7. TROUBLESHOOTING AND PEN ALIGNMENT OF BASIC RECORDER

WITHOUT DISPLAY.............................................................................................161

7.1 Overview...................................................................................................................................161

7.2 Observable Symptoms of Failure..............................................................................................163

7.3 Troubleshooting Procedures .....................................................................................................164

7.3.1 Overview......................................................................................................................164

7.3.2 Recorder Failure Troubleshooting...............................................................................165

7.3.3 Pen Trace Troubleshooting..........................................................................................166

7.3.4 Chart Rotation Troubleshooting ..................................................................................167

7.3.5 Troubleshooting Erratic Pen Movement......................................................................168

7.4 Alignment of Pen at Zero and 100 %........................................................................................169

8. TROUBLESHOOTING AND PEN ALIGNMENT OF RECORDER WITH

DISPLAY...............................................................................................................171

8.1 Overview...................................................................................................................................171

8.2 Troubleshooting Aids................................................................................................................173

8.3 Self Diagnostics........................................................................................................................174

8.3.1 Power up tests..............................................................................................................174

8.3.2 View Status of Tests ....................................................................................................175

8.3.3 Background Tests.........................................................................................................176

8.3.4 Error Messages.............................................................................................................176

8.4 Observable Symptoms of Failure..............................................................................................179

8.5 Troubleshooting Procedures .....................................................................................................180

8.5.1 Overview......................................................................................................................180

8.5.2 Recorder Failure Troubleshooting...............................................................................181

8.5.3 Pen Trace Troubleshooting..........................................................................................182

8.5.4 Chart Rotation Troubleshooting ..................................................................................183

8.5.5 Troubleshooting Erratic Pen Movement......................................................................184

8.5.6 Troubleshooting the Keypad and Display....................................................................184

8.5.7 Troubleshooting Relay Output.....................................................................................185

8.5.8 Troubleshooting External Alarm Function..................................................................186

8.5.9 Troubleshooting Remote Switch (Digital Input) Function..........................................186

8.5.10 Troubleshooting Modbus Communications.................................................................187

8.6 Alignment of Pen at Zero and Span..........................................................................................188

4/00 DR4300 Circular Chart Recorder Product Manual vii

Page 8

DR4300 Circular Chart Recorder

9. PARTS LIST.........................................................................................................191

9.1 Overview...................................................................................................................................191

9.2 Exploded Views........................................................................................................................192

A. ACCURACY..........................................................................................................199

A.1 Overview...................................................................................................................................199

A.2 Typical Reference Accuracy.....................................................................................................200

B. AVAILABLE 10-INCH CHARTS ...........................................................................203

B.1 Single Range Charts..................................................................................................................203

B.2 Dual Range Charts ....................................................................................................................209

C. SETPOINT RAMP/SOAK PROGRAMMING AND OPERATION..........................213

C.1 Overview...................................................................................................................................213

C.2 Program Contents..................................................................................................................214

C.3 Drawing a Ramp/Soak Profile ..................................................................................................216

C.4 Setpoint Program Prompt Hierarchy.........................................................................................220

C.5 Run/Monitor the Program.........................................................................................................223

D. USING ACCUTUNE II...........................................................................................227

D.1 Overview...................................................................................................................................227

D.2 Starting and Stopping Tuning with Accutune II.......................................................................228

D.3 Using Accutune with Duplex (Heat/Cool) Control ..................................................................229

E. FOREIGN LANGUAGE SAFETY INSTRUCTIONS..............................................231

F. HONEYWELL SERVICE CENTERS ....................................................................243

DR4300 Circular Chart Recorder Product Manual 4/00viii

Page 9

Tables

Table 2-1 Operating Limits and Condensed Specifications........................................................................................12

Table 2-2 Mounting Flush in a New Panel Cutout......................................................................................................17

Table 2-3 Procedure for Mounting Recorder with NEMA4 or Heavy Duty Door......................................................18

Table 2-4 Pipe Mounting Procedure...........................................................................................................................20

Table 2-5 Mounting Flush on a Surface (of Panel or Wall)........................................................................................21

Table 2-6 Wiring Bundling Categories.......................................................................................................................26

Table 2-7 Wiring Illustrations ....................................................................................................................................26

Table 2-8 Procedure for Power Wiring Models..........................................................................................................28

Table 2-9 Analog Input Wiring..................................................................................................................................31

Table 2-10 Digital Input Wiring.................................................................................................................................33

Table 2-11 Communication Wiring............................................................................................................................35

Table 2-12 Output Terminal Use for Output Algorithm and Option Combinations...................................................37

Table 2-13 Relay Output Wiring - 1 or 2 Pen Models................................................................................................38

Table 2-14 Current Output Wiring.............................................................................................................................41

Table 2-15 Transmitter Power Out Wiring.................................................................................................................43

Table 3-1 Procedure for Configuring Model without Display....................................................................................46

Table 3-2 Configuration and Input Switch Settings for Models without Display.......................................................49

Table 3-3 Preparing the Recorder for Operation........................................................................................................66

Table 3-4 Procedure for Running the Step Test..........................................................................................................67

Table 3-5 Startup Procedure.......................................................................................................................................69

Table 4-1 Key Functions ............................................................................................................................................73

Table 4-2 Configuration Tips.....................................................................................................................................78

Table 4-3 SW6 Input Switch Settings for Models Having Display and Keypad .......................................................80

Table 4-4 Configuration Procedure............................................................................................................................83

Table 4-5 Input Parameter Definitions .......................................................................................................................85

Table 4-6 Pen Parameter Definitions..........................................................................................................................89

Table 4-7 Chart Parameter Definitions.......................................................................................................................90

Table 4-8 Totalizer Function Definitions...................................................................................................................91

Table 4-9 Control Parameter Definitions....................................................................................................................94

Table 4-10 Tuning Parameter Definitions ................................................................................................................101

Table 4-11 Setpoint Ramp Parameter Definitions....................................................................................................104

Table 4-12 Timer Parameter Definitions..................................................................................................................105

Table 4-13 Alarm Parameter Definitions..................................................................................................................106

Table 4-14 Auxiliary Output Parameter Definitions.................................................................................................109

Table 4-15 Communication Parameter Definitions..................................................................................................111

Table 4-16 Remote Switch Parameter Definitions....................................................................................................113

Table 4-17 Display Parameter Definitions................................................................................................................114

Table 4-18 Lockout Parameter Definitions...............................................................................................................115

Table 4-19 Limit Control Parameter Definitions......................................................................................................118

Table 4-20 Preparing the Recorder for Operation............................................................................... .....................120

Table 4-21 Procedure for Running the Step Test......................................................................................................121

Table 4-22 Procedure for Setting Chart Time and Applying Power.........................................................................123

Table 4-23 Power-Up Diagnostic Tests....................................................................................................................124

Table 4-24 Procedure for Testing the Displays and Keys.........................................................................................125

Table 4-25 Procedure for Starting the Recorder.......................................................................................................126

Table 4-26 Meaning of Indicators............................................................................................................................129

Table 4-27 Lower Display Operating Parameter Labels...........................................................................................130

Table 4-28 Error Messages.......................................................................................................................................131

Table 4-29 Procedure for Selecting Automatic or Manual Mode .............................................................................133

Table 4-30 Procedure for Changing the Control Setpoints.......................................................................................134

Table 4-31 Procedure for Displaying or Changing the Alarm Setpoints ..................................................................135

Table 4-32 Procedure for Selecting Factory or Field Calibration Values.................................................................136

4/00 DR4300 Circular Chart Recorder Product Manual ix

Page 10

DR4300 Circular Chart Recorder

Table 4-33 Procedure for Resetting Totalizer...........................................................................................................137

Table 4-34 Procedure for Starting Timer..................................................................................................................138

Table 4-35 Procedure for Resetting Limit Controller...............................................................................................139

Table 5-1 Voltage and Resistance Equivalents for 0 % and 100 % Range Values...................................................143

Table 5-2 Equipment Needed for Calibration...........................................................................................................144

Table 5-3 Disconnect the Field Wiring.....................................................................................................................145

Table 5-4 General Calibration Set Up Procedure.....................................................................................................146

Table 5-5 Set Up Wiring Procedure for Thermocouple Inputs Using a Compensated Calibrator...........................147

Table 5-6 Set Up Wiring Procedure for Thermocouple Inputs Using an Ice Bath...................................................148

Table 5-7 Set Up Wiring Procedure for Calibrating RTD Inputs.............................................................................149

Table 5-8 Set Up Wiring Procedure for Calibrating Millivolts, Volts, and Milliamps Inputs..................................150

Table 5-9 Input Calibration Procedure Sequence.....................................................................................................151

Table 5-10 Set Up Wiring Procedure for Current Proportional Output....................................................................153

Table 5-11 Procedure for Calibrating Current Output..............................................................................................154

Table 6-1 Procedure for Replacing the Chart...........................................................................................................158

Table 6-2 Procedure for Replacing the Ink Cartridge...............................................................................................159

Table 6-3 Maximizing Pen Life................................................................................................................................160

Table 7-1 Observable Symptoms of Failure.............................................................................................................163

Table 7-2 Troubleshooting Recorder Failure Symptoms..........................................................................................165

Table 7-3 Troubleshooting Pen Trace Failure Symptoms ........................................................................................166

Table 7-4 Troubleshooting Chart Rotation Failure Symptoms.................................................................................167

Table 7-5 Troubleshooting Erratic Pen Movement Symptoms.................................................................................168

Table 7-6 Procedure for Pen Alignment...................................................................................................................169

Table 8-1 Procedure for Identifying the Software Version.......................................................................................173

Table 8-2 Power-Up Diagnostic Tests......................................................................................................................174

Table 8-3 Procedure for Displaying the Results of Self-Diagnostics........................................................................175

Table 8-4 Error Messages.........................................................................................................................................177

Table 8-5 Observable Symptoms of Failure.............................................................................................................179

Table 8-6 Troubleshooting Recorder Failure Symptoms..........................................................................................181

Table 8-7 Troubleshooting Pen Trace Failure Symptoms ........................................................................................182

Table 8-8 Troubleshooting Chart Rotation Failure Symptoms.................................................................................183

Table 8-9 Troubleshooting Erratic Pen Movement Symptoms.................................................................................184

Table 8-10 Troubleshooting Keypad and/or Display Failure Symptoms..................................................................184

Table 8-11 Troubleshooting Relay Output Failure Symptoms .................................................................................185

Table 8-12 Troubleshooting External Alarm Function Failure Symptoms...............................................................186

Table 8-13 Troubleshooting Remote Switch (Digital Input) Function Failure Symptoms.......................................186

Table 8-14 Troubleshooting Modbus Communications............................................................................................187

Table 8-15 Procedure for Aligning Pen at Zero and Span........................................................................................188

Table 9-1 Door Assembly Parts................................................................................................. ...............................192

Table 9-2 Chart Plate Assembly Parts......................................................................................................................193

Table 9-3 Basic Recorder Parts................................................................................................................................195

Table A-1 Typical Reference Accuracy....................................................................................................................200

Table B-1 10-inch Single Range Chart Part Numbers..............................................................................................203

Table B-2 10-inch Dual Range Chart Part Numbers ............................................................................... .................209

Table C-1 Prompt Hierarchy and Available Selections............................................................................................220

Table C-2 Run/Monitor Functions............................................................................................................................223

Table D-1 Procedure for Starting Accutune II..........................................................................................................228

Table D-2 Procedure for Using Accutune for Duplex Control.................................................................................229

DR4300 Circular Chart Recorder Product Manual 4/00x

Page 11

Figures

Figure 1-1 Guide to Manual’s Organization...............................................................................................................10

Figure 2-1 Overall Dimensions...................................................................................................................................15

Figure 2-2 Plug Locations...........................................................................................................................................16

Figure 2-3 Mounting Flush in a New Panel Cutout (Rear View)................................................................................17

Figure 2-4 Panel Mounting Recorder with NEMA4 or Heavy Duty Door.................................................................19

Figure 2-5 Pipe Mounting Brackets............................................................................................................................20

Figure 2-6 Mounting Flush on a Surface of Panel or Wall (Rear View).....................................................................22

Figure 2-7 Recommended Wiring Routing - Models Without CE Mark....................................................................24

Figure 2-8 Recommended Wiring Routing - Models With CE Mark.........................................................................25

Figure 2-9 Power Wiring – Models Without CE Mark...............................................................................................29

Figure 2-10 Power Wiring – Models With CE Mark..................................................................................................30

Figure 2-11 Analog Input Wiring...............................................................................................................................32

Figure 2-12 Digital Input Wiring................................................................................................................................34

Figure 2-13 Communication Wiring...........................................................................................................................36

Figure 2-14 Relay Output Wiring...............................................................................................................................39

Figure 2-15 Open Collector Output Wiring................................................................................................................40

Figure 2-16 Current Output Wiring............................................................................................................................42

Figure 2-17 Transmitter Power Out Wiring................................................................................................................44

Figure 3-1 Location of Configuration and Input Switches..........................................................................................47

Figure 3-2 Sample Chart for Single Pen Recorder...................................................................................................... 48

Figure 3-3 Basic Chart Plate Components ....................................................................................... ...........................66

Figure 3-4 Typical Step Test Chart Patterns...............................................................................................................68

Figure 3-5 Setting Chart Time to Time Index.............................................................................................................69

Figure 4-1 Operator Interface.....................................................................................................................................72

Figure 4-2 Prompt Hierarchy......................................................................................................................................75

Figure 4-3 Location of Switches and Relays..............................................................................................................82

Figure 4-4 Basic Chart Plate Components ....................................................................................... .........................120

Figure 4-5 Typical Step Test Chart Patterns.............................................................................................................122

Figure 4-6 Setting Chart Time to Time Index...........................................................................................................123

Figure 4-7 Operator Interface...................................................................................................................................128

Figure 5-1 Location of the Input Connections on the Input Boards..........................................................................145

Figure 5-2 Calibration Set Up Diagram for Thermocouple Inputs Using a Compensated Calibrator......................147

Figure 5-3 Calibration Set Up Diagram for Thermocouple Inputs Using an Ice Bath ..............................................148

Figure 5-4 Calibration Set Up Diagram for RTD Inputs ..........................................................................................149

Figure 5-5 Calibration Set Up Diagram for Millivolts, Volts, and Milliamps Inputs...............................................150

Figure 5-6 Test Equipment Connections for Calibrating Current Output.................................................................153

Figure 6-1 Replacing the Chart and Ink Cartridge....................................................................................................158

Figure 9-1 Door Assembly........................................................................................................................................192

Figure 9-2 Chart Plate Assembly..............................................................................................................................193

Figure 9-3 Recorder Components.............................................................................................................................194

Figure 9-4 DR4300 Recorder (CE Mark) – Internal Cabling Diagram....................................................................196

Figure 9-5 DR4300 Recorder (Non-CE Mark) – Internal Cabling Diagram ............................................................197

Figure C-1 Ramp/Soak Profile Example...................................................................................................................216

4/00 DR4300 Circular Chart Recorder Product Manual xi

Page 12

DR4300 Circular Chart Recorder

DR4300 Circular Chart Recorder Product Manual 4/00xii

Page 13

1.1 Introduction

Function

The DR4300 recorder is a one or two pen microprocessor-based circular chart recorder. The basic DR4301

(one pen) and DR4302 (two pen) recorders provide reliable, convenient pen-drawn analog traces on

preprinted 10 inch (250 mm) charts. Both the chart and the pens are driven by stepper motors controlled by

the microprocessor. Chart speed and range are configurable. The basic recorder is also available in CE

models DR4321 (one pen) and DR4322 (two pen).

In addition to generating pen-drawn chart traces, the DR4311 (one pen) and DR4312 (two pen) models

include a display and keypad. This option lets you display the real time value of the process variable for

each pen channel, as well as other values. The recorder with display and keypad is also available in CE

models DR4331 (one pen) and DR4332 (two pen).

Each pen channel has its own printed circuit assembly (PCA), allowing the channels to operate

independently.

Overview

1. Overview

CE conformity (Europe)

Indicated models of this product are in conformity with the protection requirements of the following

European Council Directives: 73/23/EEC, the Low Voltage Directive, and 89/336/EEC, the EMC

Directive. Conformity of this product with any other “CE Mark” Directive(s) shall not be assumed.

Deviation from the installation conditions specified in this manual, and the special conditions for CE

conformity in Section 2 of this manual, may invalidate this product’s conformity with the Low Voltage and

EMC Directives.

Analog inputs

The input for each pen channel can be one of any standard electrical signal: milliamp, millivolt, voltage,

RTD, or thermocouple. The input type and range are configurable. In the models having display and keypad

the range can be expanded and compressed to meet specific measurement needs. The display and keypad

also permit entry of input bias and filter values. (The input filter for the models without a display is fixed at

one second; their bias is zero.)

Digital inputs

Two digital inputs for each pen channel are available as an option. These inputs can be used to trigger the

switchover to a second control setpoint or a pre-configured constant output if an external event causes

contact closure (sets the digital input to ON). In addition, the digital inputs can be used to remotely reset the

optional totalizer or limit controller.

4/00 DR4300 Circular Chart Recorder Product Manual 1

Page 14

DR4300 Circular Chart Recorder

Communications

The Modbus communication option permits configuration of the unit and monitoring of process variables

over a standard multi-drop serial communications link.

Relay outputs for control and alarms

The models with display and keypad are available with output relays, two for each pen channel. These

relays can be wired for Normally Open (NO) and Normally Closed (NC) terminals. ON-OFF control can be

performed using one relay (relay simplex control) or two relays (relay duplex control).

Any relay not used for control is available for alarming. Two alarm setpoints can be configured for each

alarm relay. An adjustable hysteresis of 0.0 % to 100.0 % is configurable for the alarm setpoint.

Analog output for control or retransmission

Depending on the model ordered, a 4 to 20 mA current output may be available for control or

retransmission of a process variable (“auxiliary output”).

Failsafe operation

The control function can operate in automatic or manual mode. In automatic the control function works to

maintain the process variable at the setpoint entered locally by the operator. During configuration a

“failsafe” value can be specified. This value is used as the output at power up and in case of input failure

during automatic operation. (When the unit goes to failsafe, the control function goes to manual mode.)

In manual mode the operator enters the output locally. If the recorder has gone to failsafe operation, the

operator will be able to change the output value from the failsafe value specified during configuration.

Timer and totalizer options

The recorder is available with timer and totalizer options. The timer can be started locally, remotely, or by

an alarm. The unit can be configured to display elapsed time or time remaining. At the end of the timeout

period Relay 2 is energized, and remains energized until the timer is reset. The totalizer can be reset locally

or remotely; its displayed value can be scaled.

Setpoint Programming Option

The recorder is available with a Setpoint Program option. This feature allows configuration of up to four

setpoint programs using a total of twenty-four ramp and soak segments. A setpoint and time is configured

for each segment. The program can be set up to include guaranteed soak segments. A plus/minus deviation

is configured for all soak segments. Whenever the plus/minus deviation is exceeded, soak timing is frozen.

Display and keypad

In addition to process variables, the display can show output, setpoint, and deviation real time values if the

recorder is equipped with optional outputs. The upper display uses four characters to display the input

value. The lower display shows other parameters using a two- or three-character label and four- or threedigit values. In addition, status and error messages flash on the lower display when necessary.

DR4300 Circular Chart Recorder Product Manual 4/002

Page 15

The six keys are used to select the real time value to be displayed, and to select set up parameters and their

values during configuration. The display and keypad are behind the door, protecting them from dirt.

A supplementary external keypad is also available.

For more information about the operator interface on models having a display and keypad, see Subsection

4.2.

Configuration

The models without a display are configured with two switchbanks: one for configuration, the other for

input definition. Configuration is a simple matter of consulting a table in this manual; selecting the

appropriate combination of range, chart speed, engineering unit, and input type; then setting the switches as

shown in the table.

The display and keypad are used to configure models with these options. When the unit is in configuration

mode, set up parameters are displayed, and grouped by function. Designate site-specific values by selecting

them from a list of choices, or entering them as numeric values. The operator can be locked out from

making configuration changes.

The models with display also use a switchbank to define the type of input to be expected by the hardware.

Input parameters used by the software are configured using the display and keypad.

Overview

Self-diagnostics

All DR4300 recorders run self-diagnostics at power up and in the background during normal operation.

Problems are reported by error messages on the display when present. An LED in the models without a

display lights if the unit fails a self-diagnostic.

Construction

All DR4300 recorders are housed in a rugged molded case which can be panel-, pipe- or surface-mounted.

An acrylic-windowed, gasketed door protects internal components from harsh environments while allowing

easy access to the chart.

4/00 DR4300 Circular Chart Recorder Product Manual 3

Page 16

DR4300 Circular Chart Recorder

1.2 Model Number Breakdown

Introduction

The model number breakdown is presented in the tables that follow. Note that not all options are available

with all recorders. Check the “Availability” column for each model. A star () in the Availability column

means unrestricted availability of the feature for that model. N/A indicates the feature is not available for

that model. A letter in the Availability column denotes restricted availability. The meaning of each letter is

provided at the bottom of this page.

The Notes referred to in the tables are also at the end of this subsection.

Model number format

The basic model number consists of a key number. Appended to this key number are characters that identify

the features in various categories. The meaning of the characters in each category is presented in a table

identified below.

Key Number Table I Table II Table III Table IV Table V Table VI

DR43_ _ - _ _ _ _ - _ _ _ _ _ - _ _ _ _ - _ _ _ _ - _ _ - 000

Key numbers

The base model numbers for the DR4300 Circular Chart Recorder are:

One Pen Recorder (Basic Recorder Without Display) DR4301

Two Pen Recorder (Basic Recorder Without Display) DR4302

One Pen Recorder (With Display) DR4311

Two Pen Recorder (With Display) DR4312

One Pen Recorder (Basic Recorder Without Display, With CE Mark) DR4321

Two Pen Recorder (Basic Recorder Without Display, With CE Mark) DR4322

One Pen Recorder (With Display, With CE Mark) DR4331

Two Pen Recorder (With Display, With CE Mark) DR4332

Restricted availability designations

d = Not available with Table I selection XX0X.

e = Not available with Table I selection XXX0.

f = Not available with Table I selection 0XXX.

g = Not available with Table I selection 0000.

h = Not available with Table I selections FXXX, XFXX, GXXX, XGXX.

j = Not available with Table I selection 0XXX.

k = Not available with Table I selection X0XX.

m = Not available with Table I selections 2XXX, 3XXX, 4XXX, 5XXX, AXXX, XXX0.

n = Not available with Table II selection SXXXX.

p = Not available with Table II selections RXXXX, SXXXX.

q = Not available with Table II selections GXXXX, BXXXX, HXXXX, CXXXX, KXXXX, LXXXX.

DR4300 Circular Chart Recorder Product Manual 4/004

Page 17

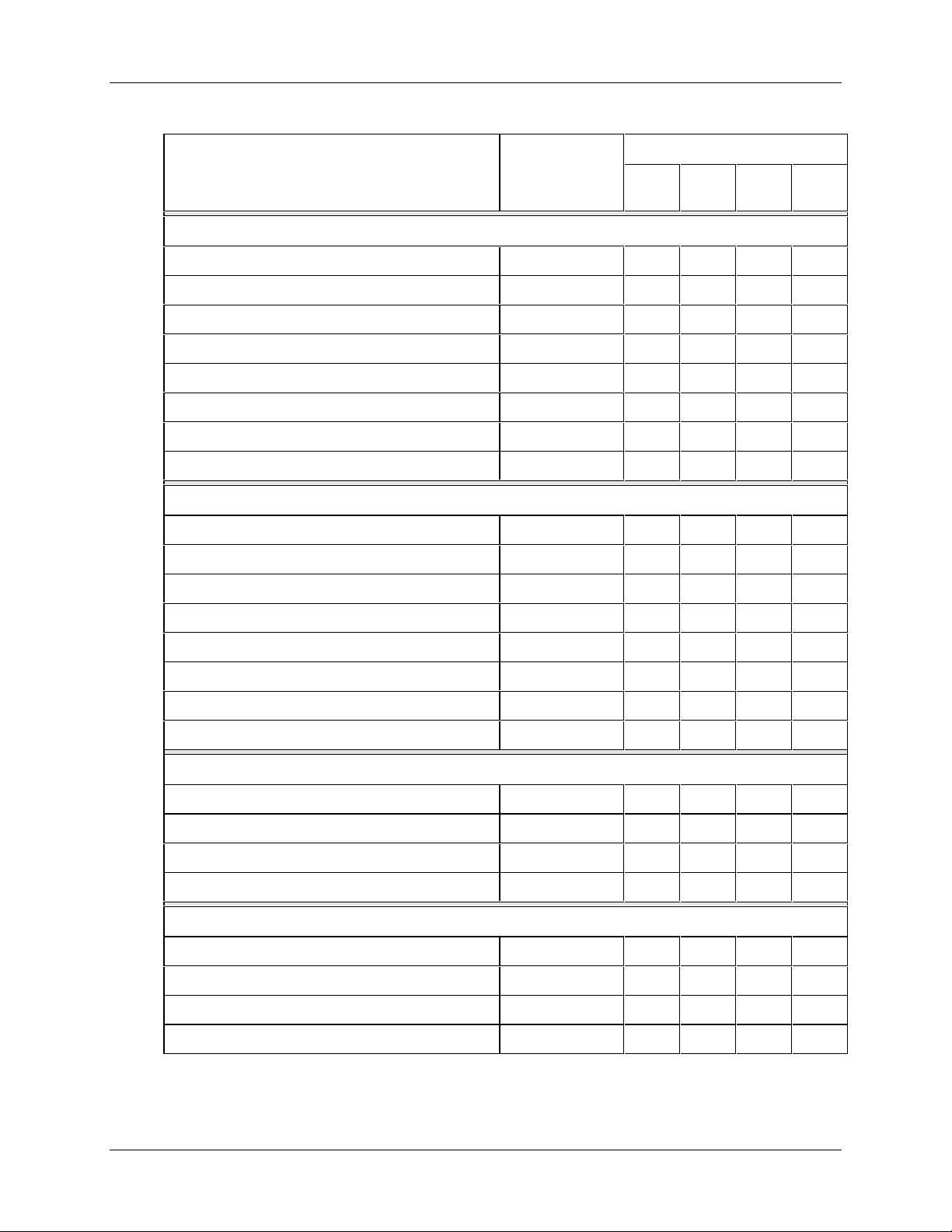

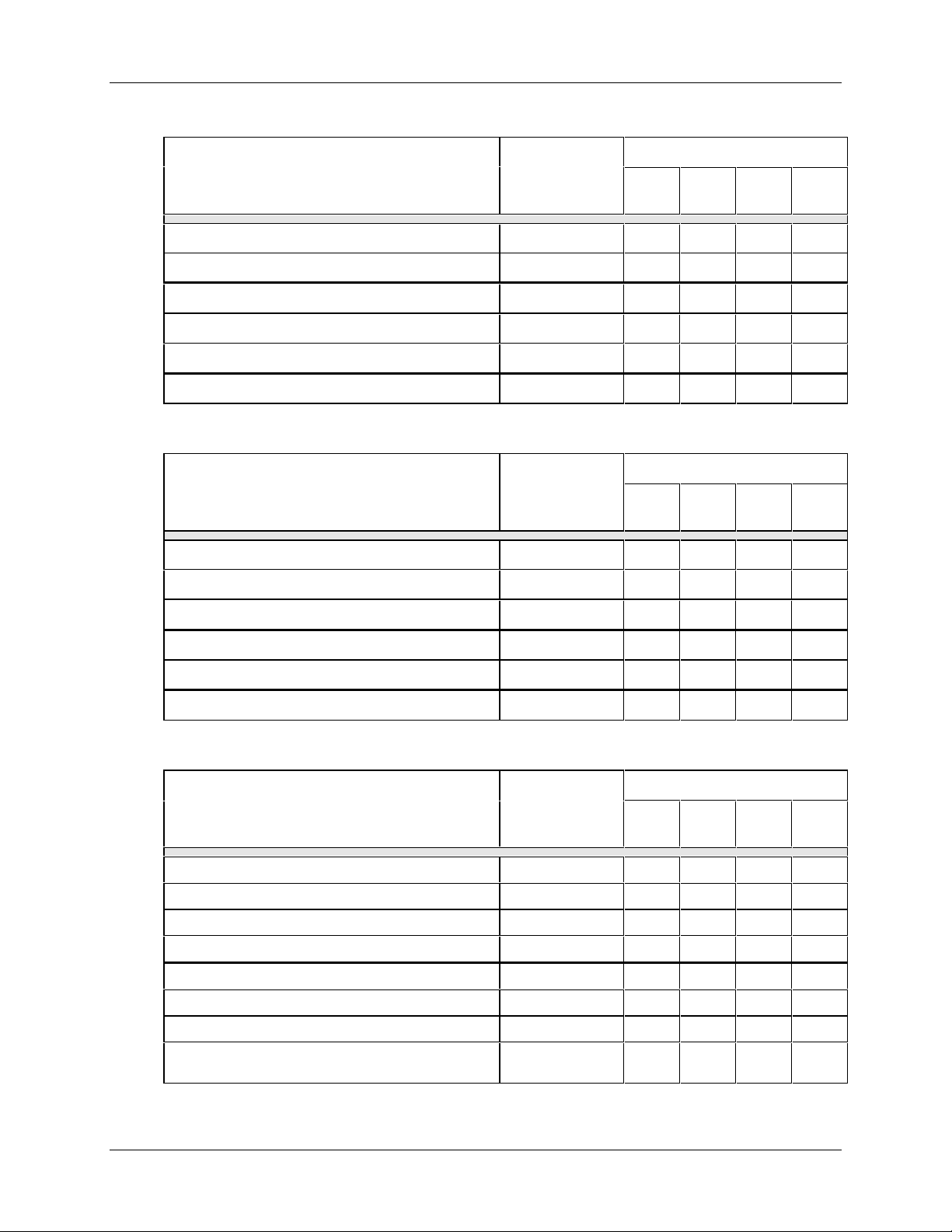

Model Number Table I - OUTPUT

Description Model No. Availability

Overview

4301

4321

Pen One

None 0 _ _ _

2 Outputs (Alarm/On-Off Control) 2 _ _ _ N/A N/A d d

1 PID Control with Accutune II (see Note 1) 3 _ _ _ N/A N/A d d

1 PID Control/Setpoint Program/Timer (see Not e 1) 4 _ _ _ N/A N/A d d

2 Outputs (Alarm 1 and Timer) 5 _ _ _ N/A N/A d d

4 to 20 mA Retransmission Output (see Note 4) A _ _ _ N/A N/A d d

FM Approved Limit Control F _ _ _ N/A N/A d d

FM Approved Limt Control/Timer Output G _ _ _ N/A N/A d d

Pen Two

None _ 0 _ _

2 Outputs (Alarm/On-Off Control) _ 2 _ _ N/A N/A N/A e

1 PID Control with Accutune II (see Note 1) _3 _ _ N/A N/A N/A e

1 PID Control/Setpoint Program/Timer (see Not e 1) _ 4 _ _ N/A N/A N/A e

4302

4322

4311

4331

4312

4332

2 Outputs (Alarm 1 and Timer) _ 5 _ _ N/A N/A N/A e

4 to 20 mA Retransmission Output (see Note 4) _ A _ _ N/A N/A N/A e

FM Approved Limit Control _ F _ _ N/A N/A N/A m

FM Approved Limt Control/Timer Output _ G _ _ N/A N/A N/A m

Output Type Pen 1

None _ _ 0 _

Electromechanical Relay _ _ E _ N/A N/A j j

Solid State Relay _ _ S _ N/A N/A j j

Open Collector _ _ T _ N/A N/A j j

Output Type Pen 2

None _ _ _ 0

Electromechanical Relay _ _ _ E N/A N/A N/A k

Solid State Relay _ _ _ S N/A N/A N/A k

Open Collector _ _ _ T N/A N/A N/A k

4/00 DR4300 Circular Chart Recorder Product Manual 5

Page 18

DR4300 Circular Chart Recorder

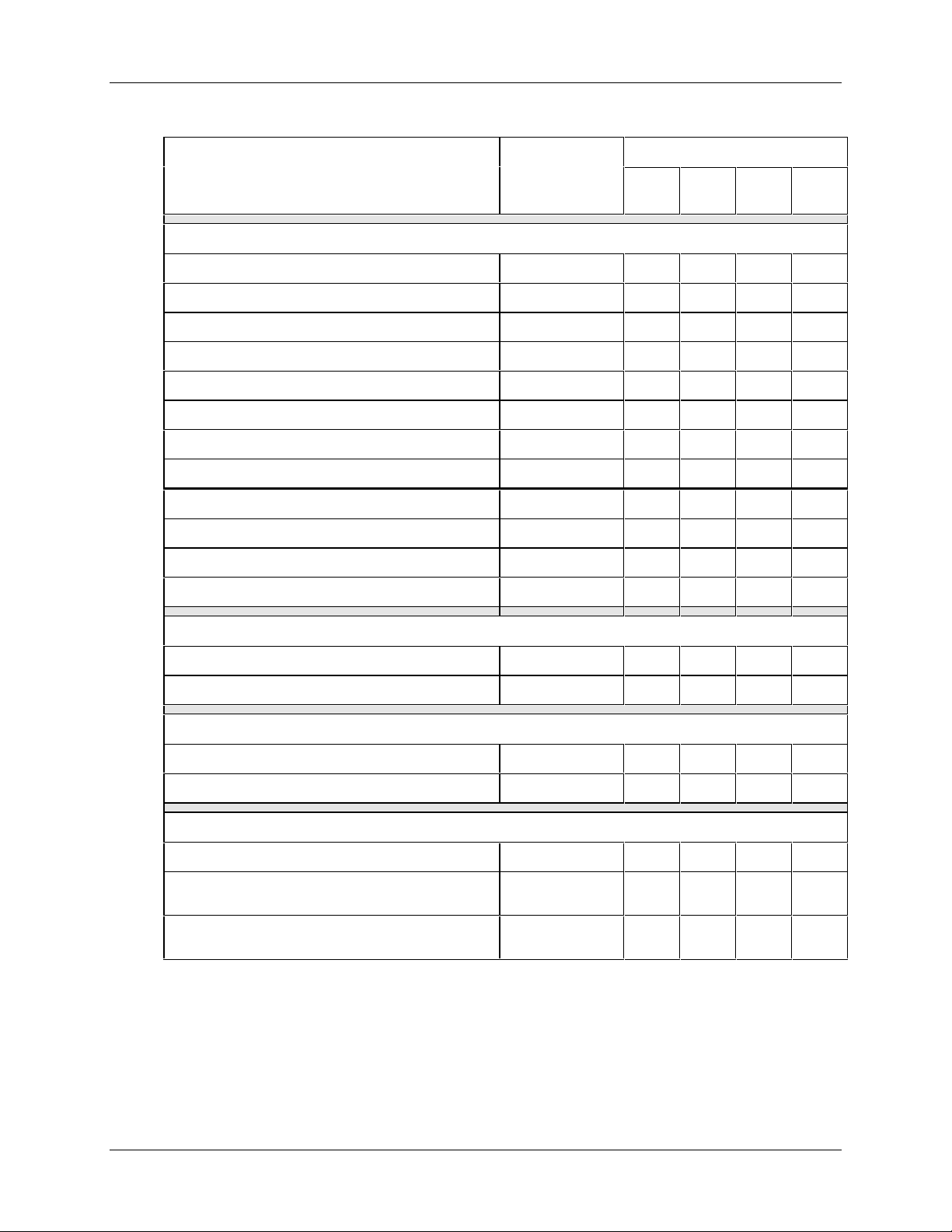

Description Model No. Availability

Model Number Table II - INSTRUMENT OPTIONS

4301

4321

4302

4322

4311

4331

4312

4332

Door Options

Gray Door G _ _ _ _

Blue Door B _ _ _ _

Gray Door with External Keypad H _ _ _ _ N/A N/A

Blue Door with External Keypad C _ _ _ _ N/A N/A

Black Door K _ _ _ _

Black Door with External Keypad L _ _ _ _ N/A N/A

SST Door R _ _ _ _

NEMA 4 SST Door S _ _ _ _

Standard Latch _ 0 _ _ _ nnnn

Keyed Latch _ A _ _ _

Keyed Latch/Chart Plate Seal _ B _ _ _ qqqq

Door Lock _ K _ _ _ pppp

Instrument Power/Transmitter Power

Universal Recorder Power _ _ 1 _ _

Universal Power +24 Vdc Transmitter Power _ _ 3 _ _

Communications

None _ _ _ 0 _

RS485 Modbus RTU Communication (see Note 5) _ _ _ C _

Product Configuration

Standard _ _ _ _ 0

Configuration for Non-Standard Range Settings

(see Note 6)

Configuration for Customer’s Specific Data

(see Note 6)

_ _ _ _ 1

_ _ _ _ 2 N/A N/A

N/A N/A

DR4300 Circular Chart Recorder Product Manual 4/006

Page 19

Model Number Table III - PEN 1 OPTIONS

Description Model No. Availability

Overview

4301

4321

No Digital Inputs 0 _ _ _

Digital Inputs (See Note 3) D _ _ _ N/A N/A f g

None _ 0 _ _

No Totalizer Function _ _ 0 _

Totalizer _ _ T _ N/A N/A h h

Future _ _ _ 0

4302

4322

4311

4331

4312

4332

Model Number Table IV - PEN 2 OPTIONS

Description Model No. Availability

4301

4321

No Digital Inputs 0 _ _ _

Digital Inputs (See Note 3) D _ _ _ N/A N/A N/A g

None _ 0 _ _

4302

4322

4311

4331

4312

4332

No Totalizer Function _ _ 0 _

Totalizer _ _ T _ N/A N/A N/A h

Future _ _ _ 0

Model Number Table V - APPROVALS/CERTIFICATES

Description Model No. Availability

4301

4321

No Approvals 0 _

UL Listing U _ nnnn

CSA Certification C _ nnnn

UL and CSA Approved B _ nnnn

No Certificate _ 0

Certificate of Conformance (F3391) _ 1

Certificate of Calibration (F3399) (See Note 2) _ 2

Certificate of Conformance and Calibration

(See Note 2)

_ 3

4302

4322

4311

4331

4312

4332

4/00 DR4300 Circular Chart Recorder Product Manual 7

Page 20

DR4300 Circular Chart Recorder

NOTE 1: PID control o ptions include current output plus two discrete outputs for alarms. If ON-OFF or

time-proportioned simplex control is used, only one discrete output is available for an alarm.

Time-proportioned duplex control requires the use of both outputs and therefore no relay outputs

are available for alarms on that pen channel. Accutune II tuning is a standard feature with PID

control options.

NOTE 2: Customer must supply the input actuation and range information for each input in the Free Form

section of the order to have the unit supplied with a Certificate of Calibration.

NOTE 3: Digital Inputs are only available when ordering outputs in Table I.

NOTE 4: 4 to 20 mA Retransmission Output includes two outputs per pen for alarms. You must specify

the type of alarm outputs required (i.e., Relay, SS Relay, Open Collector Outputs).

NOTE 5: On key numbers DR4301, DR4302, DR4321, and DR4322 the communication address is fixed;

the display assembly is required to change it. Only one DR4301 or DR4321 instrument, or only

one pen of a DR4302 or DR4322 can exist on the network, otherwise communication conflicts

will exist. Pen 1 is the default when communications is specified on these models.

NOTE 6: Recorder is supplied with one box of 30755820-001, 0 to 100 Even "starter" charts. For special

range configuration on the DR4301, DR4302, DR4321, or DR4322 Recorder, provide the Input

Type, Chart Range, Chart Speed, °C or °F, Engineering Units, Linear or Non-Linear Chart Type

when ordering.

For example: Pen 1: "J" Thermocouple, 0-375 °F, 7-Day Linear Chart

Pen 2: 4-20 mA, 0-1000, 7-Day Linear Chart

For configuration on Models DR4311, DR4312, DR4331, and DR4332, the customer must

supply completed "Configuration Worksheets" with order for units to be Factory configured.

DR4300 Circular Chart Recorder Product Manual 4/008

Page 21

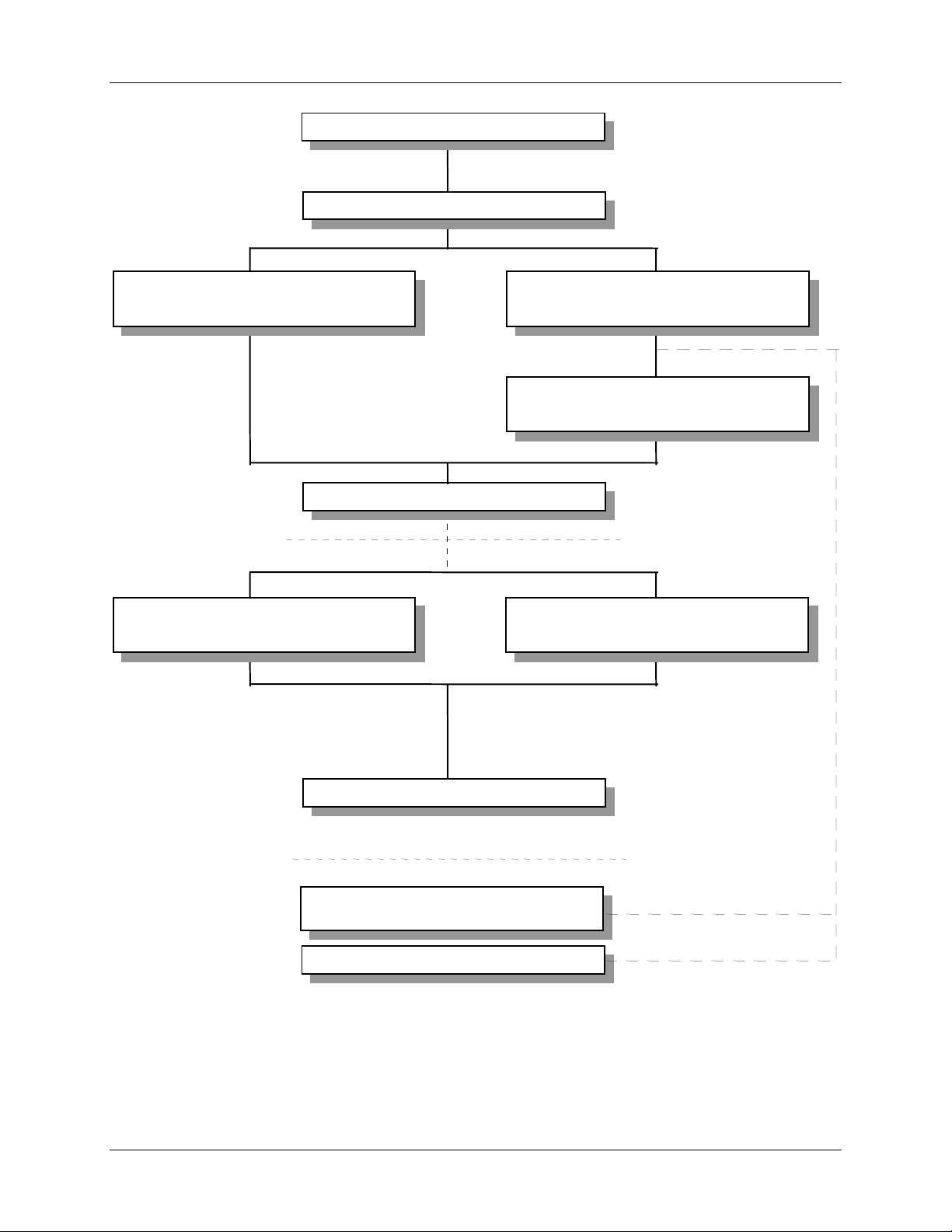

1.3 About This Manual

All models described

This manual contains instructions for installation, set up, startup, operation, troubleshooting, and repair of

all recorder models listed in Subsection 1.2. The models fall into two broad categories:

• basic version without display: DR4301, DR4302, DR4321, and DR4322

• enhanced version with display: DR4311, DR4312, DR4331, and DR4332

Some sections in the manual apply to all models, while others contain information specific to one of these

two categories. Unless a section’s title refers to recorders “without display” or “with display”, the

information in the section applies to all models. To see which sections apply to your recorder, see Figure

1-1.

Overview

4/00 DR4300 Circular Chart Recorder Product Manual 9

Page 22

DR4300 Circular Chart Recorder

SECTION

3 - Configuration, Startup, and

Operation of Recorder

Trouble?

without

SECTION

Display

SECTION

SECTION

1 - Overview

2 - Installation

SECTION

Operation of Recorder

Calibration for Recorder

6 - Routine Maintenance

4 - Configuration, Startup, and

Display

with

SECTION

5 - Input and Output

Display

with

SECTION

7 - Troubleshooting and Pen

Alignment of Recorder

Options

SECTION

without

APPENDIX C -

Display

SECTION

9 - Parts List

Setpoint Ramp/Soak

Alignment of Recorder

Programming and Operation

APPENDIX D -

Using Accutune II

Figure 1-1 Guide to Manual’s Organization

8 - Troubleshooting and Pen

Display

with

24209

DR4300 Circular Chart Recorder Product Manual 4/0010

Page 23

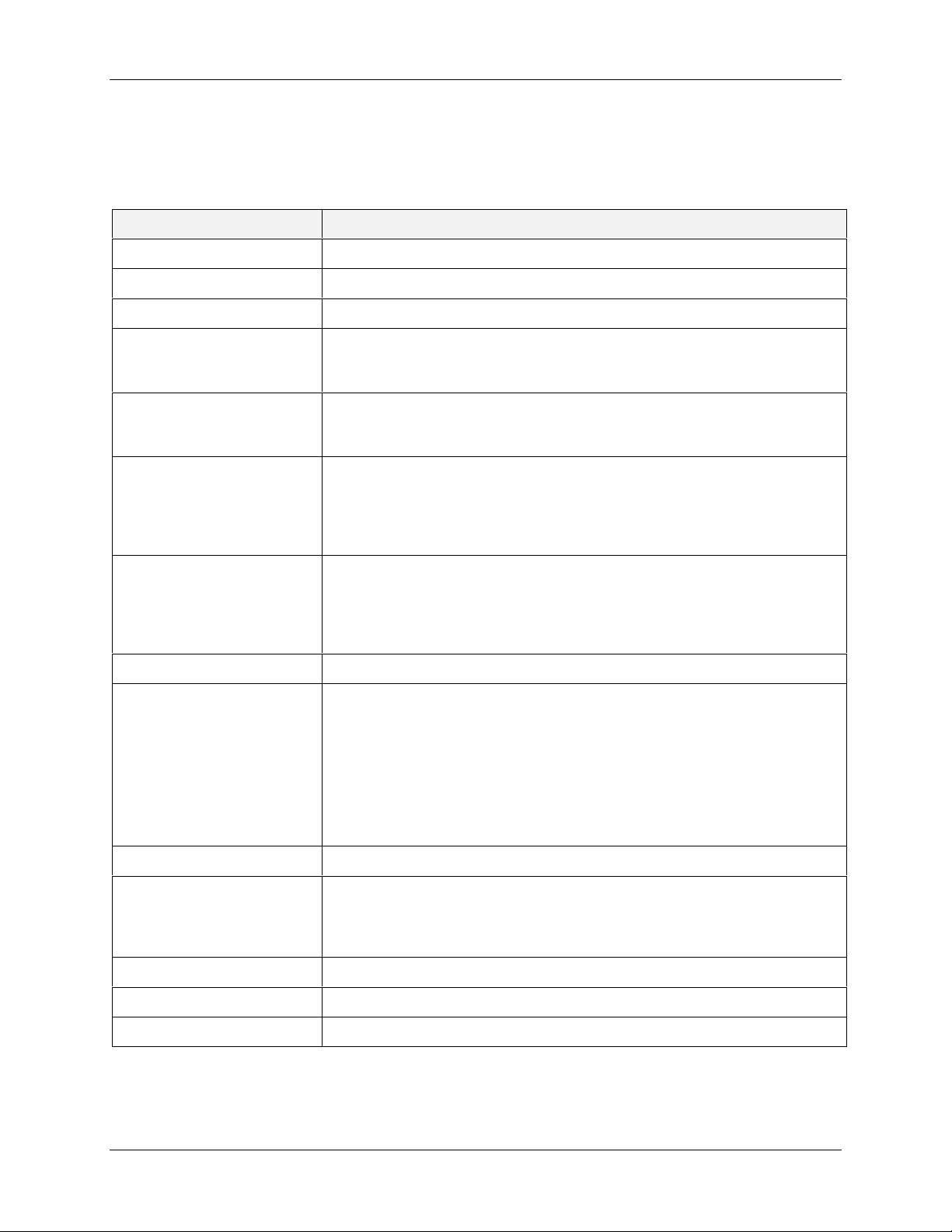

2.1 Overview

Introduction

Installation of the DR4300 recorder consists of mounting and wiring the recorder according to the

instructions given in this section.

Read the pre-installation information below, check the model number interpretation in Section 1, and

become familiar with your model selections, then proceed with installation.

What’s in this section?

The following is a list of topics in this section.

2.1 Overview 11

2.2 Mounting Considerations and Overall Dimensions 15

2.3 Mounting Methods 16

2.4 Wiring Prerequisites 22

2.5 Input Wiring 27

2.6 Output Wiring 37

Installation

2. Installation

Topic See Page

Pre-installation information

If the recorder has not been removed from its shipping carton, inspect the carton for damage and remove the

recorder. Inspect the unit for any obvious shipping damage and report any damage due to transit to the

carrier.

• Make sure a bag c ontaining mounting hardware is included in the carton with the recorder.

• Check that the model number shown on the chart plate agrees with what you have ordered.

3/00 DR4300 Circular Chart Recorder Product Manual 11

Page 24

DR4300 Circular Chart Recorder

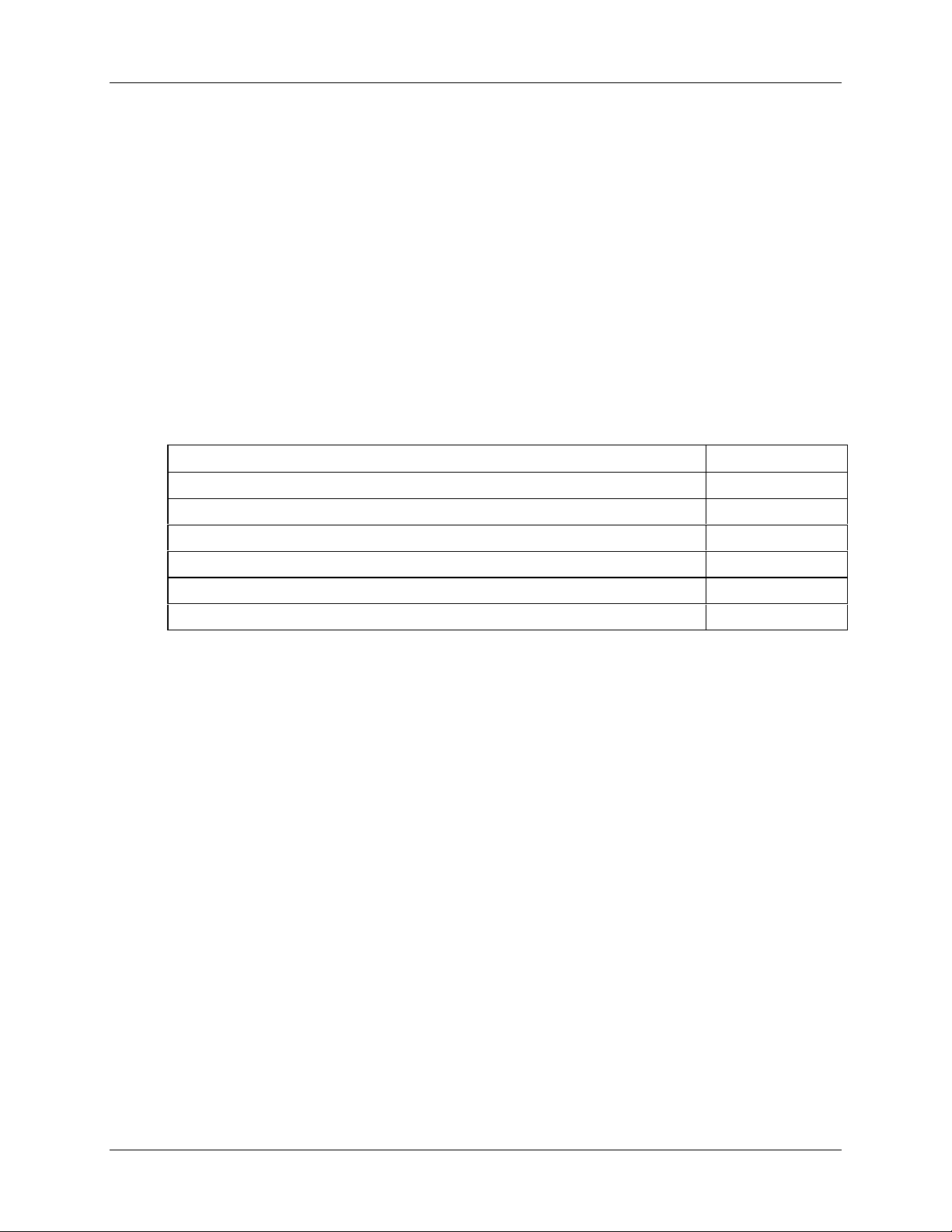

Operating limits

We recommend that you review and adhere to the operating limits listed in Table 2-1 when you install your

recorder.

Table 2-1 Operating Limits and Condensed Specifications

Condition Specifications

Accuracy See Appendix A

Ambient Temperature 0 °C to 55 °C [32 °F to 131 °F]

Relative Humidity 5 % to 90 % RH at 40 °C [104 °F]

Vibration

Frequency

Acceleration

Mechanical Shock

Acceleration

Duration

Mounting Position from

Vertical

Tilted Forward

Tilted Backward

Tilted to side (±)

0 to 200 Hz

0.5 g

5 g

30 ms

5°

90°

20°

Power

Voltage (ac/dc)

Frequency (Hz)

Power Consumption 20 Watts maximum

Type of Actuations Thermocouple: B, E, E (low), J, J (low), K, K (low), Ni-Ni Moly, Nicrosil-Nisil, R, S,

Minimum Input Span Range is fully configurable within span limitation of the sensing element.

Input Impedance mA dc: 250 ohms

Span Step Response Time 7 seconds maximum

Reproducibility 0.1 percent of span

100 Vac to 240 Vac

or

20 Vac/Vdc to 27 Vac/Vdc

49 Hz to 61 Hz

T, T (low), W5 W26

RTD: Platinum 100 ohms*, 100 ohms (low)*, 100 ohms**

Linear: 4-20 mA dc, 0-20 mA dc, 0-10 mV dc, 0-100 mV dc, 0-200 mV dc,

0-1 Vdc, 0-2 Vdc, 0-5 Vdc, 0-10 Vdc, 1-5 Vdc, 2-10 Vdc

Digital: +24 Vdc source for external dry contacts or isolated solid state contacts

*IEC Alpha = 0.00385

**Alpha = 0.00391

Vdc: 200K ohms

RTD: 13.3 K ohms

All others: 10 Megohms

Sampling Rate Input sampled 3 times per second

DR4300 Circular Chart Recorder Product Manual 3/0012

Page 25

Installation

Condition Specifications

Input Filter W ithout Display: Analog with time constant of 3 seconds and digital with time

constant of 1 second.

With Display: Analog with time constant of 3 seconds and digital adjustable 0

seconds to 120 seconds.

Case Molded, foamed-Noryl with gasketed door to meet NEMA 3 enclosure

requirements.

Pen Disposable fiber-tip ink cartridge, line length per cartridge more than 305 m

[1000 ft]

One Pen: Purple

Two Pen: Purple (pen 1) and red (pen 2)

NOTE: Only pen 1 (purple) is referenced to the chart time line.

Chart 262 mm [10.32-inch] diameter chart with standard preprinted markings and a

calibrated width of 100 mm [4 inches].

Wiring Connections Screw terminals (2 piece)

Color Case: Black

Door: Standard—Gray; Optional—Carribean blue or black

Weight 5.4 kg [12 lbs]

Mounting Panel-, pipe- or surface-mounted

Installation Category

(Overvoltage Category)

Pollution Degree Pollution Degree 2: Normally Non-conductive Pollution with Occasional

EMC Classification Group 1, Class A: ISM Equipment (EN55011, emissions), Industrial Equipment

Dielectric Insulation AC Main to Inputs/Outputs 250 Vac

Category II: Energy-consuming Equipment Supplied from the Fixed Installation,

Local Level Appliances, and Industrial Control Equipment (EN61010-1).

Conductivity Caused by Condensation (Ref. IEC 664-1).

(EN50082-2, Immunity).

Input to Input 250 Vac

Input to Output 250 Vac

(except Digital Input to Current Output)

AC Main to Transmitter Power 250 Vac

Options

Current Output (Isolated) Range can be set anywhere between 4 mA and 21 mA, and as direct or reverse

action.

Resolution: 11 bits for 4 mA to 21 mA

Accuracy: 0.5 % full scale

Temperature Stability: 0.1 % F.S./°C

Load Resistance: 0 ohms to 600 ohms

Electromechanical Relay

Output

SPDT contacts. Internally socketed.

Resistive Load: 5 A @ 120 Vac or 2.5 A @ 240 Vac or 30 Vdc.

Inductive Load: 50 VA @ 120 Vac or 240 Vac.

Motor: 1/6 H.P.

3/00 DR4300 Circular Chart Recorder Product Manual 13

Page 26

DR4300 Circular Chart Recorder

Condition Specifications

Solid State Relay Output SPST solid state contacts consisting of a triac NO output.

Internally socketed.

Resistive Load: 1.0 A @ 25 °C for 120 Vac or 240 Vac.

0.5 A @ 55 °C for 120 Vac or 240 Vac.

Inductive Load: 50 VA @ 120 Vac or 240 Vac.

Open Collector Output Maximum Sink Current: 20 mA

Internally powered @ 30 Vdc

Opto-isolated from all other circuits except current output, but not from each other.

Socketed jumper assembly replaces relay.

Modbus Communication Baud Rate: 19,200 maximum, configurable for models with display;

fixed at 9,600 for models without display

Protocol: Modbus

Length of Link: 1,219 m [4,000 ft] maximum

Link Characteristics: Two-wire, multidrop

Digital Inputs

(Supply common with

current output)

Transmitter Power 24 Vdc with adjustment of ± 6 % (22.6 to 25.4)

+24 Vdc source for external dry contacts or isolated solid state contacts for either

of the two inputs.

On contact closure the recorder will respond according to how each digital input is

configured. Opening contact causes return to previous state.

100 mA maximum output

DR4300 Circular Chart Recorder Product Manual 3/0014

Page 27

2.2 Mounting Considerations and Overall Di mensions

Physical considerations

The recorder can be mounted flush in a panel or on the surface of a panel or wall using the mounting kit

supplied with the recorder. Adequate access space must be available at the back of the panel for installation

and servicing.

A kit for mounting the unit on a pipe is available (see Section 9 Parts List).

Overall dimensions

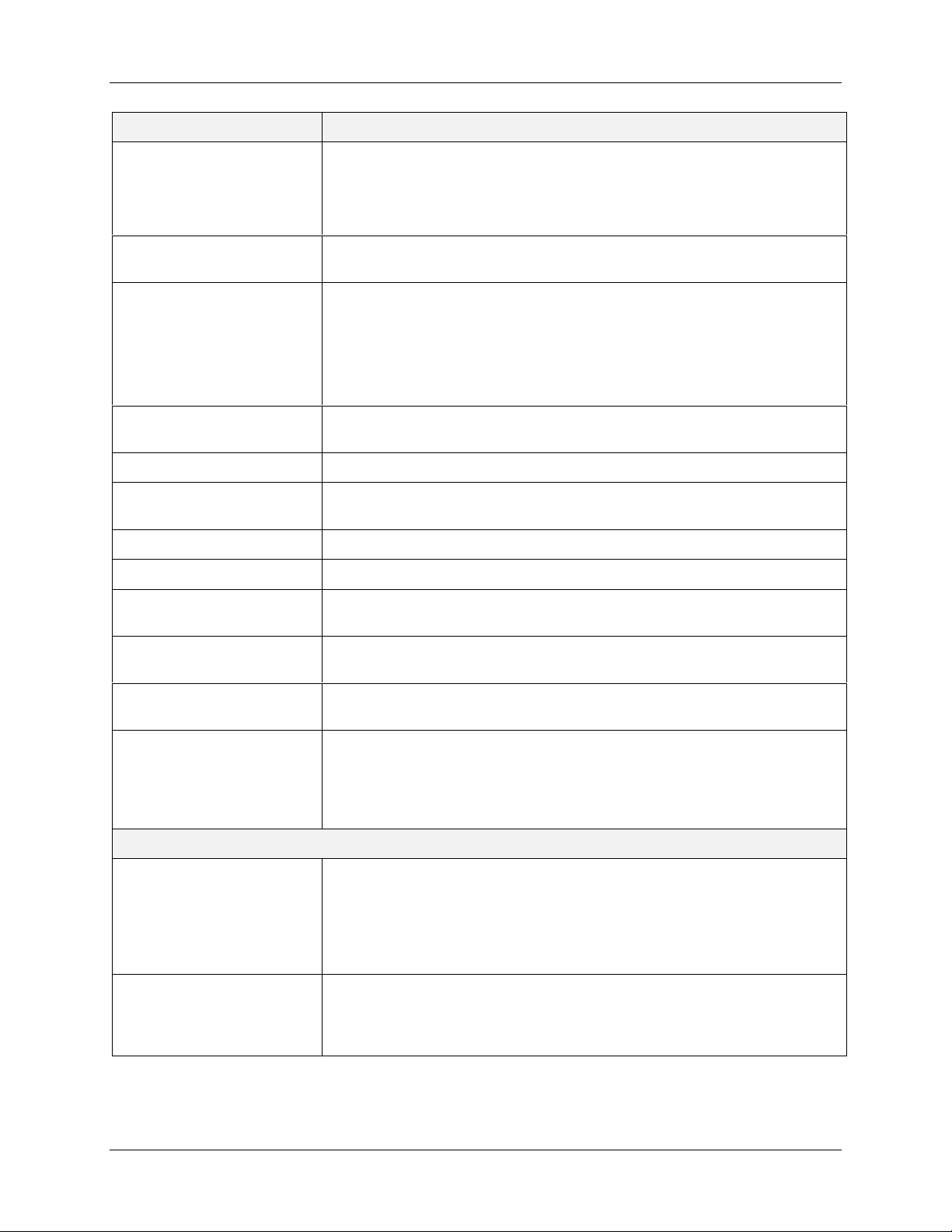

The overall dimensions and panel cutout requirements for mounting the recorder are shown in Figure 2-1.

Installation

Dimensions:

Front View

322.56

12.70

Millimetres

Inches

355.6

14.0

355.6

14.0

Left Side View

Max. panel

thickness

28.6

1.125

23

0.9

320.5

12.6

147.8

5.8

Short wing latch :

Double bit latch

:

14.5

0.57

5

0.19

41.3

1.6

Latch

369.6

14.5

Bottom View

320.5

12.6

17.5

0.6

196.2

7.7

Panel

Cutout

322.56

12.70

163.2

6.4

Surface

Mounting

Rear View

181.3

7.1

24210

Figure 2-1 Overall Dimensions

3/00 DR4300 Circular Chart Recorder Product Manual 15

Page 28

DR4300 Circular Chart Recorder

2.3 Mounting Methods

2.3.1 Introduction

Overview

This section provides instructions for mounting the recorder using one of the following methods:

• Flush in a panel (Subsection 2.3.2)

• Flush in a panel for recorders with NEMA4 or Heavy Duty door (Subsection 2.3.3)

• On a 2-inch pipe (Subsection 2.3.4)

[A pipe mounting kit is available (see Section 9 Parts List).]

• On the surface of a wall or panel (see Subsection 2.3.5).

Choose the method that meets your mounting requirements. Use the associated dimension drawings for

reference.

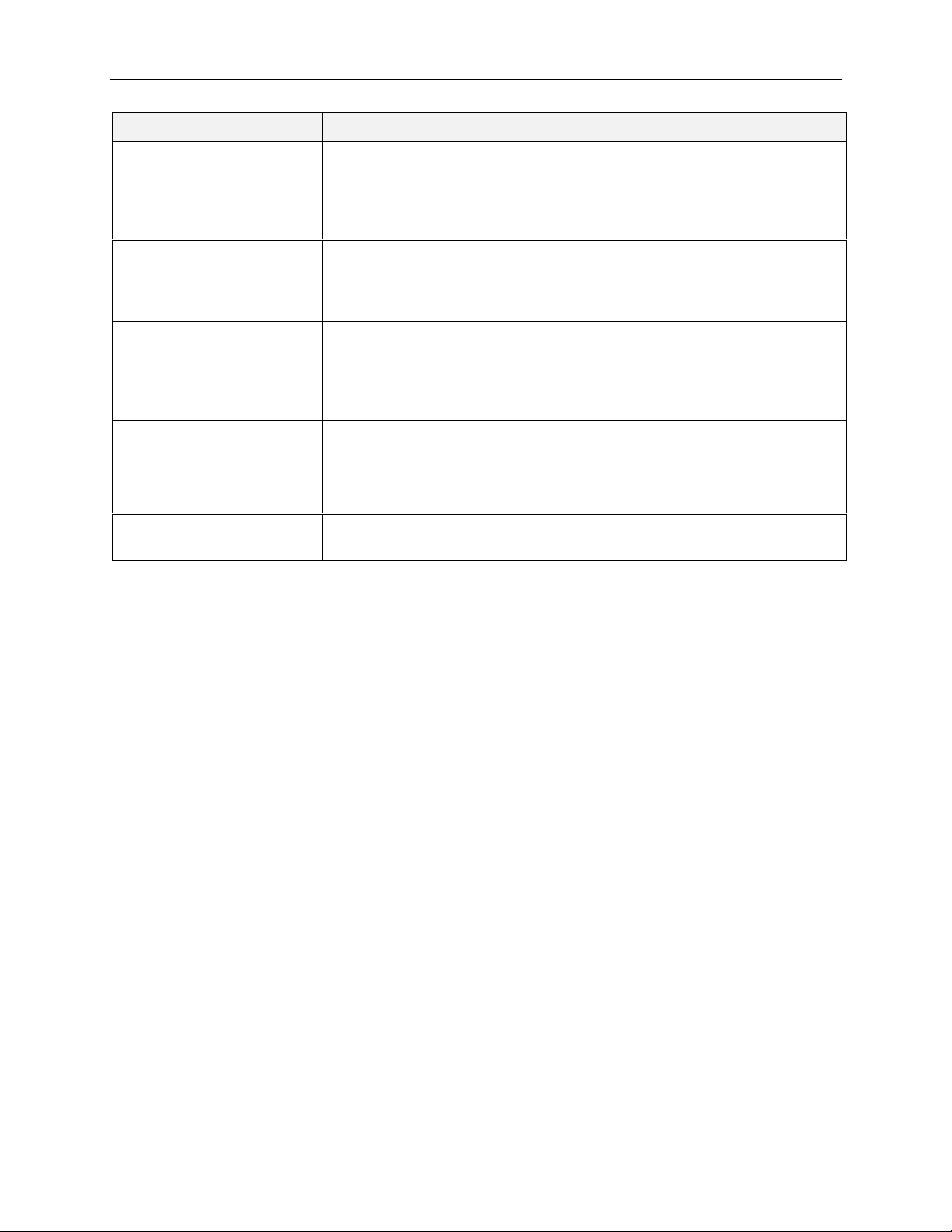

How to remove knockouts for conduits

Before you mount the recorder, remove the appropriate plugs in the bottom and/or sides of the recorder case

for wire entry via 1/2" (12.7 mm) conduits. Refer to Figure 2-2 for plug locations. To see recommended

use of conduits for various types of wiring, refer to Figure 2-7 and Figure 2-8.

Side View

Bottom View

24211

Figure 2-2 Plug Locations

DR4300 Circular Chart Recorder Product Manual 3/0016

Page 29

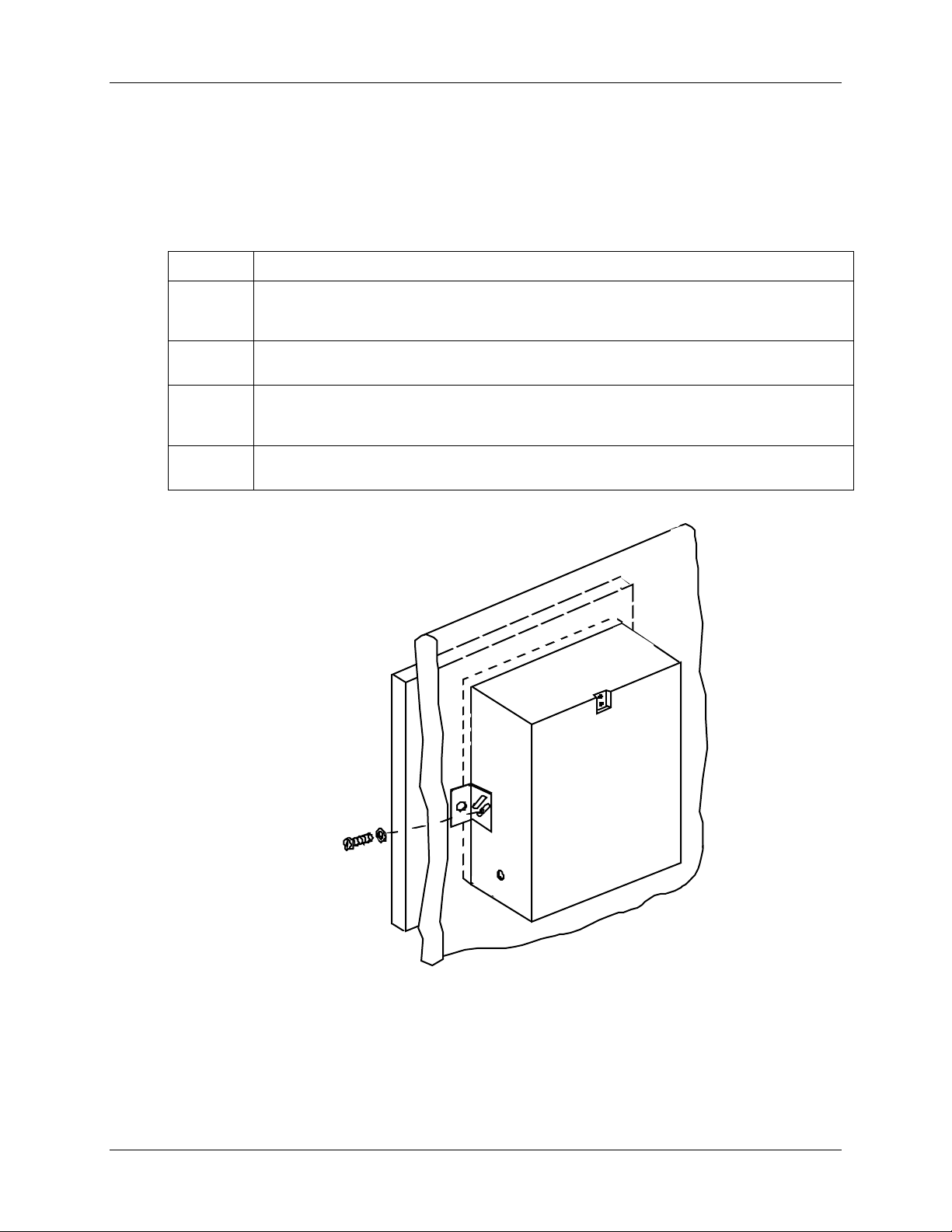

2.3.2 Mounting Flush in Panel (New Panel Cutout)

Procedure

Refer to Figure 2-3 and follow the procedure in Table 2-2 to make a new cutout in a panel and mount your

recorder in the cutout.

Table 2-2 Mounting Flush in a New Panel Cutout

Step Action

Installation

1

2

3

4

At the appropriate location, make a square cutout in the panel. Cutout dimensions should be

322.56 mm ± 1.52 mm x 322.56 mm ± 1.52 mm [12.7 in ± 0.060 in x 12.7 in ± 0.060 in]. See

Figure 2-3.

Orient the recorder case properly and slide it into the cutout from the front of the panel.

Support the recorder as shown in Steps 3 and 4.

Refer to Figure 2-3. From the back of the panel, attach a mounting bracket to each side of the

recorder case using a 1/4-20 x 1/2-inch hex screw for each bracket (mounting hardware

supplied with recorder). Leave the screws slightly loose so you can adjust the brackets.

While holding the recorder firmly against the panel, slide each bracket against the back of the

panel and tighten the screws.

Hex screw,

1/4-20 x

1/2 inch and

washer

21406

Figure 2-3 Mounting Flush in a New Panel Cutout (Rear View)

3/00 DR4300 Circular Chart Recorder Product Manual 17

Page 30

DR4300 Circular Chart Recorder

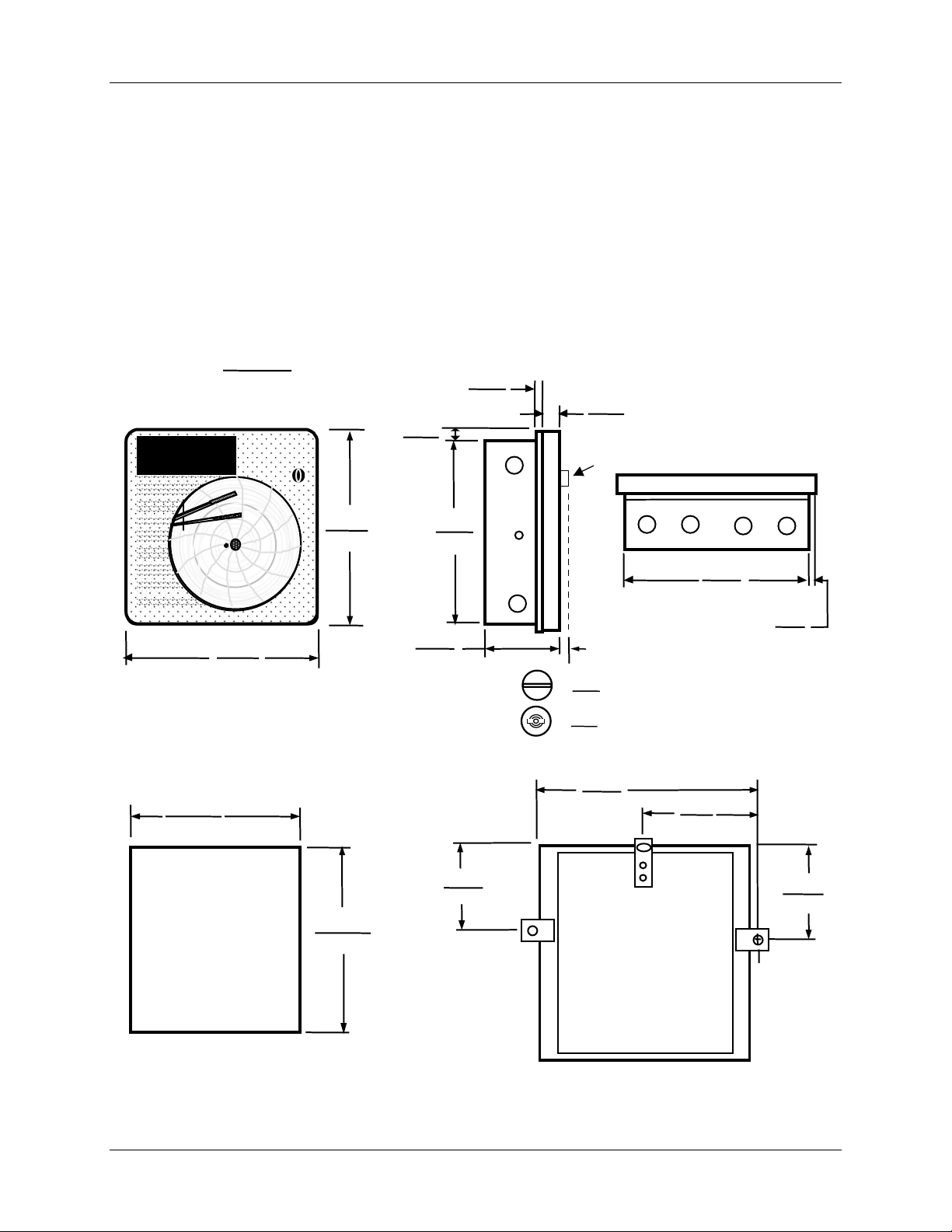

2.3.3 Panel Mounting Recorder with NEMA4 or Heavy Duty door

Refer to Figure 2-4 and follow the procedure in Table 2-3 to panel mount your recorder if it has a NEMA4

or Heavy Duty door.

Table 2-3 Procedure for Mounting Recorder with NEMA4 or Heavy Duty Door

Step Action

Place the panel gasket onto the rear flange of the recorder case.

1

Install four #8-32 screws on each of the three mounting brackets so the ends of the screw

2

threads are flush with the face of the bracket.

NOTE: Screw heads to be flange side of brackets.

Insert the case with gasket into the panel opening.

3

Install one left hand and one right hand bracket with 1/4 x 3/8 long bolts and lockwashers on

4

each side of the case.

NOTE: The notch on each bracket should be facing upward towards the top of the unit.

Do not tighten the hex bolts at this time.

Install the remaining right hand bracket on the top with the 1/4 x 3/4 long bolt and lockwasher.

5

Do not tighten the bolt at this time.

Place a screwdriver blade on the notch of each bracket and firmly tap so that each bracket

6

firmly mates the case with gasket to the panel.

NOTE: Keep brackets parallel to case. Tighten the three 1/4 hex bolts to hold the brackets in

place.

Start to tighten the #8-32 x 1/2 screws on the right side bracket. Alternate screws at opposite

7

ends until all four screws have a minimum of 10 lb-in of torque applied. Do the same to both

the left side and top brackets.

When completed all twelve screws should have a minimum of 10 lb-in of torque applied. This

assures the case and panel gasket are adequately sealed against the panel.

DR4300 Circular Chart Recorder Product Manual 3/0018

Page 31

Installation

Bracket

Hex Head Bolt

1/4-20 x 3/4 inch

Notch

Pan Head Screw

8-32 x 1/2 inch

Hex Head Bolt

1/4-20 x 3/8 inch

NOTE: Mounting brackets and attaching hardware are included in kit 30755065-502;

panel gasket supplied in kit 51197657-501.

Side View

Figure 2-4 Panel Mounting Recorder with NEMA4 or Heavy Duty Door

3/00 DR4300 Circular Chart Recorder Product Manual 19

Page 32

DR4300 Circular Chart Recorder

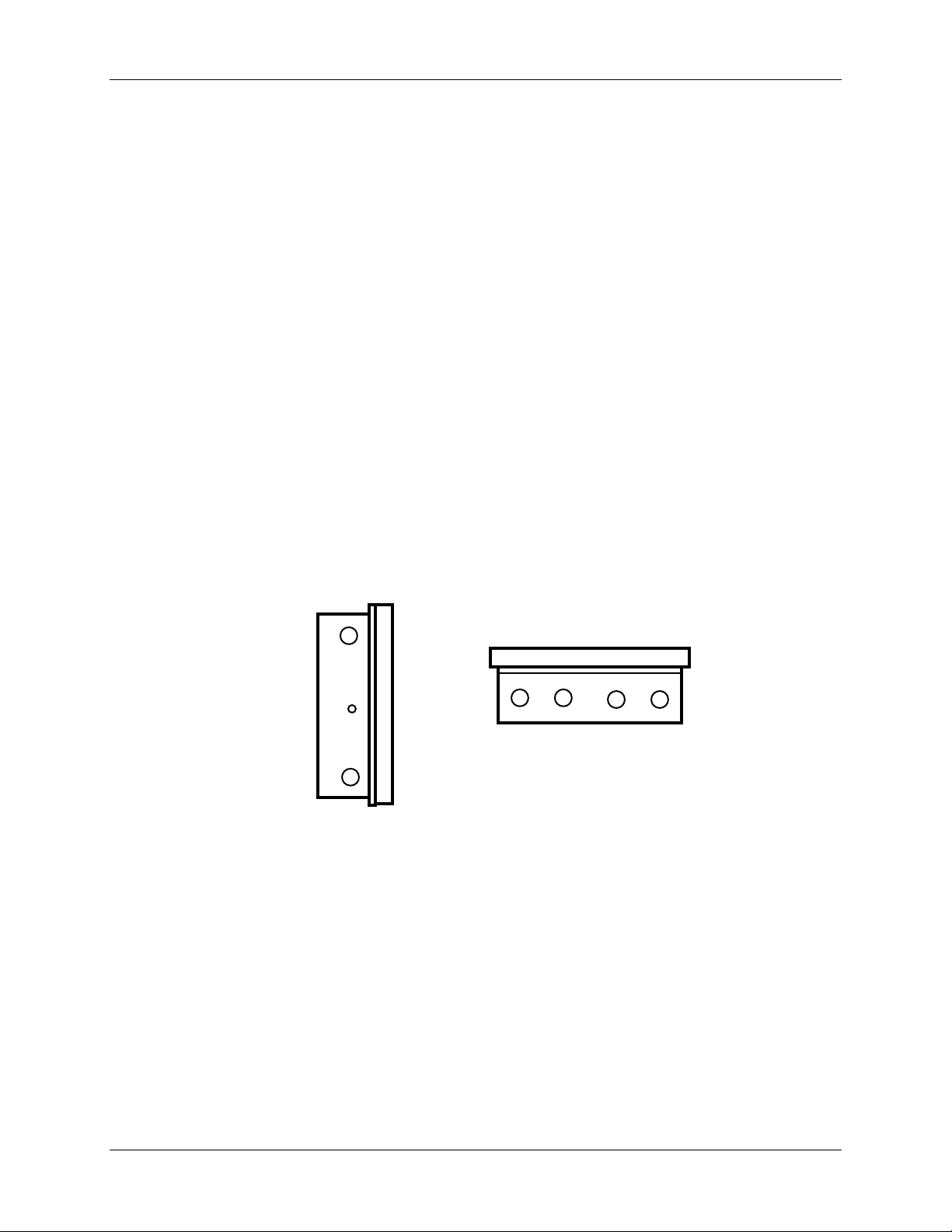

2.3.4 Mounting on a 2-inch pipe

Refer to Figure 2-5 and follow the procedure in Table 2-4 to mount your recorder on a 2-inch pipe.

Table 2-4 Pipe Mounting Procedure

Step Action

Using the eight plastite screws supplied with the pipe mounting bracket kit, attach the two

1

mounting brackets (flat side against the case) to the back of the recorder. Refer to Figure 2-5

for location.

Position the recorder with brackets on the 2-inch pipe.

2

Install the U-bolts around the pipe and through the bracket holes. Secure with lockwashers

3

and hex nuts provided.

Hex Nut

Washer

Rear

of

Case

Figure 2-5 Pipe Mounting Brackets

Pipe Mounting

Bracket

Plastite

Screw

U-bolt

24224

DR4300 Circular Chart Recorder Product Manual 3/0020

Page 33

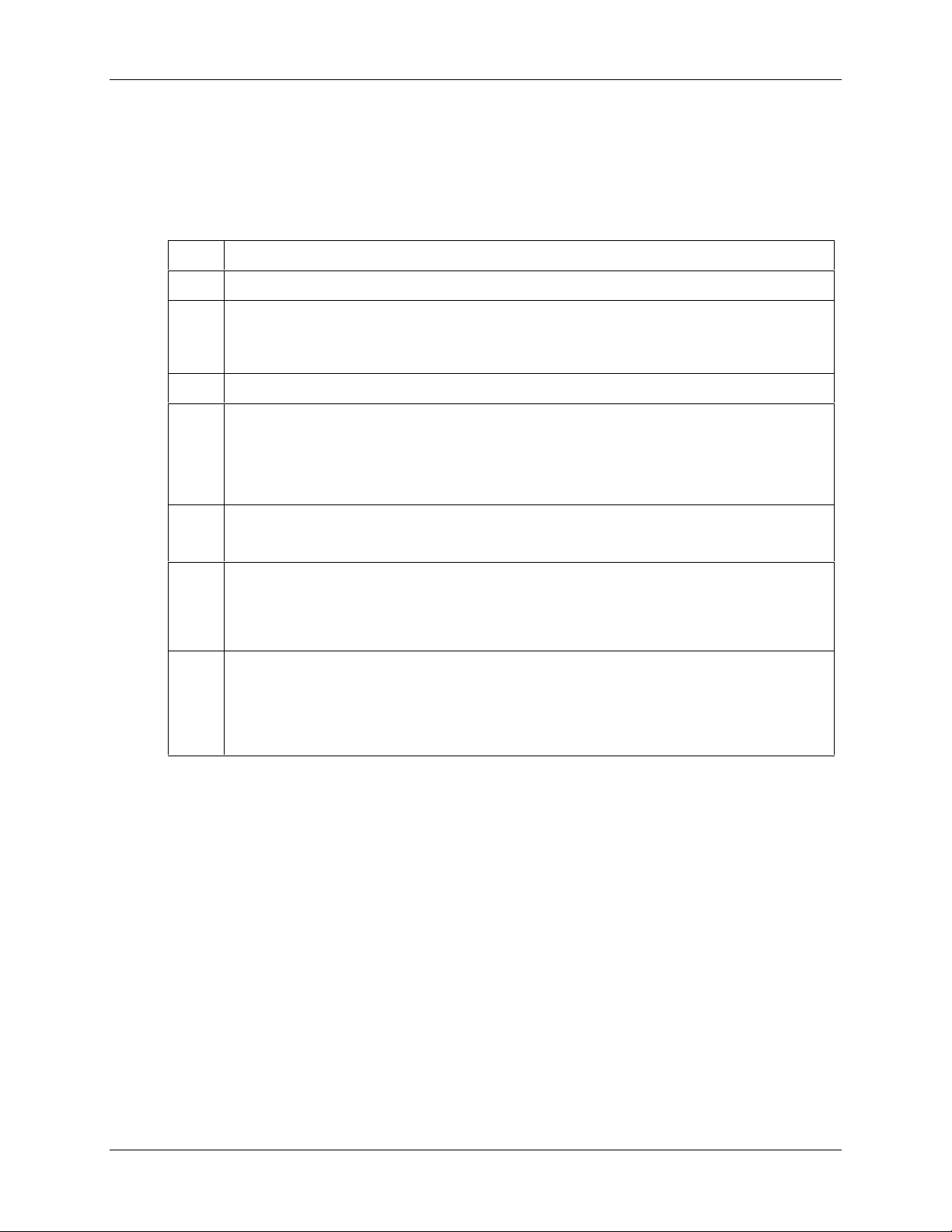

2.3.5 Mounting on Surface (of Panel or Wall)

Procedure

Refer to Figure 2-6 and follow the procedure in Table 2-5 to mount your recorder on a surface (panel or

wall).

ATTENTION

Three (3) screws must be supplied by the user for attaching the mounting hardware (brackets and

support hook) to panel or wall.

Table 2-5 Mounting Flush on a Surface (of Panel or Wall)

Step Action

Installation

1

2

3

4

5

6

7

8

Using two flat-head 10-32 x 1/4-inch screws supplied with the recorder, fasten the support

hook into the recess at the back of the recorder case as shown in Figure 2-6.

Using 1/4-20 x 1/2-inch hex screws and lockwashers, attach a mounting bracket to each side

of the case. Leave the screws slightly loose so as to permit some adjustments of the

brackets.

On the panel, mark the locations for the three holes, as shown by the hole pattern in Figure

2-6.

Using a drill of appropriate size for user-supplied screws, drill a hole in the front of the panel

for the eye of the support hook.

Insert the screws for the support hook into the panel, allowing the screw head to protrude

approximately 5/16-inch.

Hang the recorder support hook on the screw. Make sure that the locations for the other two

holes (marked in Step 3) are correct. If not, make sure that the recorder is aligned vertically,

and use the brackets as templates to mark the proper locations.

Remove the recorder from the panel and drill the other two holes.