Page 1

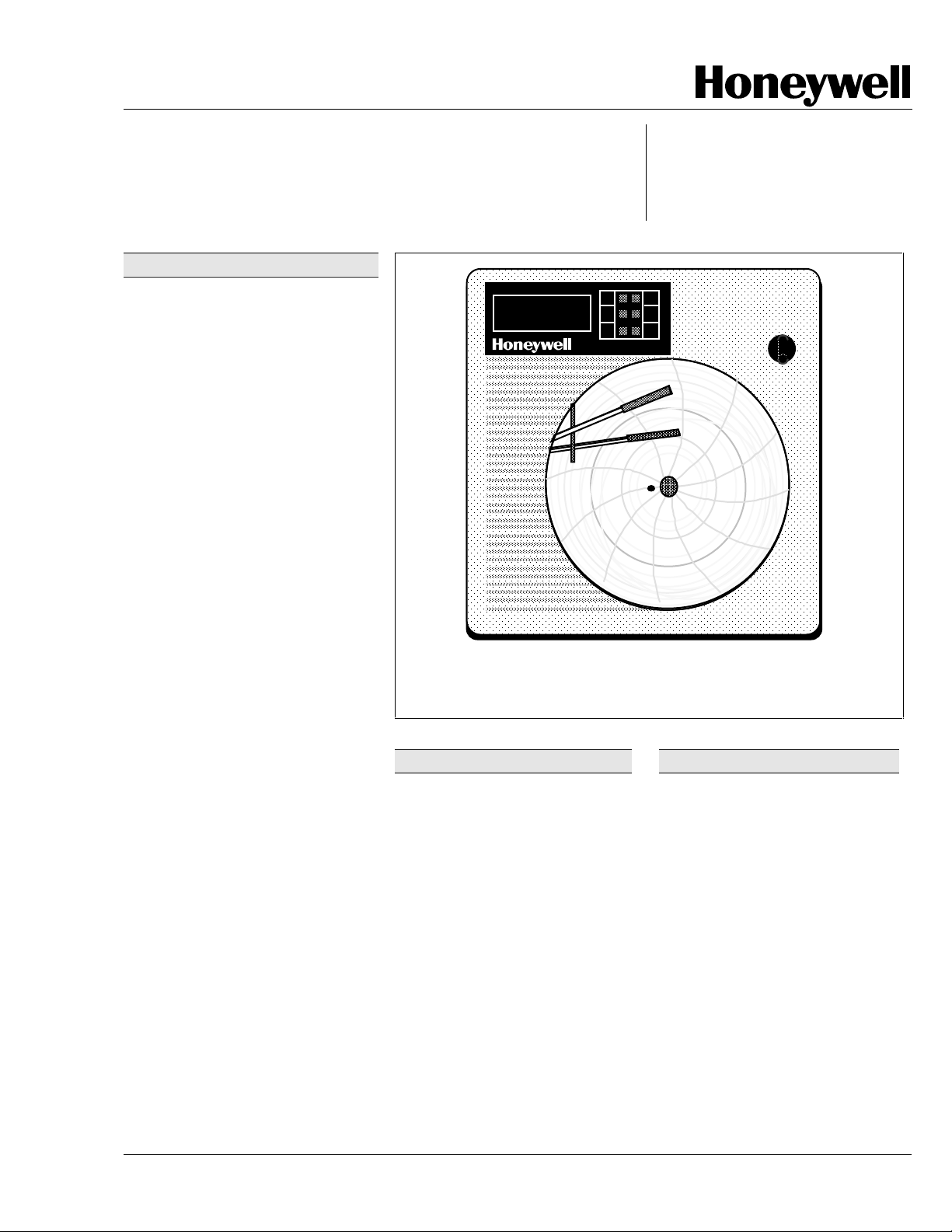

DR4300

Circular Chart Recorder

Function

The DR4300 Circular Chart Recorder

provides one of the most costeffective solutions for dependable

pen drawn analog traces on a 10-inch

(250 mm) chart.

It is easy to set up and configure to

match a wide range of applications

such as food processing,

environmental monitoring, machine

monitoring, flow, water and waste

monitoring, for use on furnaces and

ovens, packaging machines, and

numerous other processes.

The DR4300 Recorder gives you the

flexibility to tailor the recorder to

match any application, from basic

recording to actually doing the

process control, by choosing the

options that are required to

accomplish your application needs.

Both one- and two-pen models

accept inputs from any one of a

variety of sensors or transmitters

within the configurable range limits.

The DR4300 can be specified with

a variety of options such as one or

two digital controllers, a vacuum

fluorescent display for viewing the

process variable or configuration

using English language prompts.

You can also select Modbus

communications, or choose a

number of software options such

as a timer function, setpoint

programming, or advanced fuzzy

tuning/PID control.

™Modbus is a trademark of AEG Modicon

Figure 1—DR4300 Recorder provides clear analog trace and digital

indication of process variable value.

Charts—Over 200 preprinted

charts available to meet specific

recording needs.

Ink Cartridge—Disposable fibertip ink cartridge for dependable

recording with minimum

maintenance.

Universal Power—Eliminates the

concern with matching the local

power requirements.

Universal Inputs—Accepts 10

thermocouple types, RTDs, mA,

mV or voltage inputs through

simple configuration.

Thermocouple Failsafe—

Configurable upscale or downscale burnout.

ALM

F

4300

CHN

1

RSP

OUT

SP 4300

Features

1559

SET

UP

F

DISP

%

▲▼

44-01-03-04

Page 1 of 12

Specification

FUNC

MAN

AUTO

24155

Features, continued

Manual/Automatic Modes—

Bumpless, balanceless transfer

between control modes on

advanced recorders.

User Configurable—Allows you

to set up or alter operating parameters to fit your requirements.

Easily set DIP switch configuration

on basic recorder.

A Vacuum Fluorescent Display/

Keypad with English language

prompts is available for more

advanced recorder set up and

monitoring.

Optional Outputs—Choose from

Alarm, On-Off Control, Limit

Control, or versatile PID digital

controller.

3/01

Sensing and Control, 11 West Spring Street, Freeport, Illinois 61032

Printed in U.S.A. ■ © Copyright 2001—Honeywell

Page 2

44-01-03-04

Page 2

Features, continued

Accutune II™—Provides a new,

truly plug and play tuning

algorithm, which will, at the touch

of a button or through a digital

input, accurately identify and tune

any process including those with

deadtime and integrating

processes. This speeds up and

simplifies start-up plus allows

retuning at any setpoint.

Fuzzy Logic—This new feature

uses fuzzy logic to suppress

process variable overshoot due to

SP changes or externally induced

process disturbances. It operates

independently from Accutune

tuning. It does not change the PID

constants, but temporarily modifies

the internal controller response to

suppress overshoot. This allows

more aggressive tuning to co-exist

with smooth PV response. It can

be enabled or disabled depending

on the application or the control

criteria.

Individual Pen Options—Include

Totalization, a Timer function,

Digital Inputs, Auxiliary Output,

and Setpoint Programming

allowing the most flexibility to meet

the application need.

Quality/Support—The DR4300 is

backed up by a toll-free phone

number for technical assistance.

CE Mark—Conformity with

73/23/EEC, Low Voltage Directive

and 89/336/EEC, the EMC

Directive.

Options

Control Outputs—One or two

control outputs, PID-A, ON-OFF,

or PD with Manual Reset.

Solid State External Control

Relay Outputs—Optional outputs

rated at 2 Amps at 120/240 V or 10

Amps at 120/240 V. Minimum load

is 0.1 Amp.

Options, continued

Auxiliary Output—There is also

a 4 mA to 20 mA current output

available. If not used for control, it

can be used to retransmit a

process variable.

Digital Inputs—Two digital inputs

for each pen channel are

available. These inputs can be

used to trigger the switchover to a

second control setpoint or a preconfigured constant output if an

external event causes contact

closure. In addition, the digital

inputs can be used to remotely

reset the optional tolalizer or Limit

Controller or set up as a trace.

Alarm Selection—None, one, or

two relays to activate external

equipment when preset high/low

setpoints are reached.

Modbus

Allows you to network your

recorders to take advantage of

overall monitoring of the system

using an RS485 network.

Ramp Soak Programming—

Allows configuration of up to four

setpoint programs using a total of

twenty-four ramp and soak

segments. Run or Hold of

program is keyboard or remote

switch selectable.

Totalizer—Totalizes a variable,

such as a flow signal, on one or

both pens. Provides a 6-digit

digital display indication of the

totalized value with reset

capability. Totalizer allows the

units of the totalized value to be

different than the input units. A

low value cutoff value can also be

programmed for the totalizer.

Limit Control—This model

provides a latching relay that

activates whenever the PV goes

above (High Limit) or below (Low

Limit) a preset setpoint value. An

alarm message will be displayed

when the output is activated.

Reset is through a key on the

front of the recorder or an

optional

Communications—

Options, continued

external switch. Only FM

approved limit Control is available.

In addition to this, the second

relay output is available for an

alarm or as a timer output.

Timer—Provides a configurable

time period of 0 to 99 hours, 59

minutes. Alarm 1 is dedicated to

be active at the end of the timeout period. Timer “start” is

selectable as either the

RUN/HOLD key or Alarm 2. The

optional Digital Input can also be

configured to start the Timer in

addition to either the keyboard or

Alarm 2. The Timer display is

selectable as either time

remaining or elapsed time.

Transmitter Power—24 Vdc

transmitter output to power up to

two transmitters.

Door Options—Choice of gray,

blue, or black door with standard

latch or optional lock. Standard

acrylic window.

Approvals—UL, CSA, or

combined UL/CSA, FM Approved

Limit Controller.

Digital Controller

The DR4300 Recorder is available

with an integral microprocessorbased single-loop PID controller

for each pen.

A variety of output types—current,

time proportional simplex or

duplex control, with

electromechanical relays, solid

state relays, or open collector

outputs are available.

Depending on the output type,

users can configure the control

action as ON-OFF, PID-A, or PD

with Manual reset.

The recorder’s display and keypad

allows the user to quickly view

what is happening with the

process and to easily make

changes, and with the door

keypad these changes can be

made without opening the

recorder door.

Page 3

44-01-03-04

Page 3

Outputs

The following output types are

available per the model selection

guide:

• Electromechanical Relay

• Solid State Relay

• Open Collector Output

Output Algorithms

The DR4300 is available with the

following output algorithms:

Relay Simplex—Provides On-Off

or Time Proportional (relay)

output. Electromechanical, solidstate or open collector outputs

are standard; 2 amp or 10 amp

externally mounted solid-state

relay outputs are optional. One

output available for alarm.

Relay Duplex (Heat/Cool)—

Depending on which control

algorithm you select, this duplex

output type can provide on-off

duplex or time proportional

duplex. The time proportional

duplex output provides independent PID tuning constants and

two time proportional outputs:

one for heat zone above the

50 % output, and one for cool

zone below 50 % output.

Alarming is not available

Current Simplex—Supplies

proportional direct current output

for final control elements that

require a 4 mA to 20 mA signal.

Both relay outputs are available

for alarm.

Current/Relay Duplex

(Relay = Heat)—Type of output

using one relay for time proportional output for Heat control if PV

is greater than SP and one 4 mA

to 20 mA signal for cooling

control if PV is less than SP.

Relay/Current Duplex

(Relay = Cool)— Type of output

using one 4 mA to 20 mA signal

for Heat control if PV is greater

than SP and one relay for time

proportional output for cooling

control if PV is less than SP.

Control Algorithm

Depending on the output algorithm

you select, the recorder can be

configured for the following control

algorithms:

On-Off—Whenever the controlled

variable deviates a predetermined

amount from the setpoint, the

recorder moves the final control

element to either of two extreme

positions. Hysteresis: 0 % to 100 %

PID-A—The recorder gives full

response to Setpoint and Process

Variable (PV) changes involving

Gain (Proportional), Reset

(Integral), and Rate (Derivative)

effects. There is a fixed relationship

between the value of the controlled

variable and the position of the final

control element. The adjustable

Gain, Rate, and Reset Time tuning

constants let you tailor the

recorder’s response to your

process requirements.

PD with Manual Reset—The

action is similar to the PID-A

algorithm except the reset (Integral)

value is entered as Manual Reset

tuning constant instead of Reset

Time. The manual reset value

eliminates offset by shifting the PD

calculated output upscale or

downscale to return the recorder

variable to the setpoint.

Microprocessor Controlled

Recording

Both the chart and the pen are

driven by stepper motors controlled

by the microprocessor for precise

operation. This allows for

configurable chart speeds without

the need to change motors or

gears. The microprocessor uses

the configured range selection and

input data to determine the proper

pen position and then accurately

positions the pen to the correct

chart position without the need for

slidewire feedback or drive cables.

This provides for accurate and

reliable data recording.

Operator

Interface/Configuration

Since microprocessor control

replaces the previous electromechanical recording

mechanisms, the configuration of

the recorder is determined

primarily by its software.

For the basic recorder the

configuration is easily set up by

selecting the pre-configured

range, actuation, and chart

speed.

An optional display, using English

language prompts, provides

additional flexibility to select other

chart ranges, input actuation,

control or alarm parameters,

chart speeds, plus other software

features.

An upper and lower display

allows the user to view the

process variable (PV) and, by key

selection, the control setpoint,

control output, deviation from

setpoint, totalizer, Setpoint

Programming operation

information, time remaining or

elapsed time on the timer and the

status of Accutune, as desired.

In the Setup mode, digital

displays are preempted by

prompts and values for entering

the configur-ation data. Indicators

light to show which input channel

PV is being displayed, which

output relay is active, the

selected temperature unit, and

the recorder’s mode of operation.

The configuration data and

display actions are selected using

an integral keypad.

An optional keypad on the door

allows changes without the need

to open the door of the recorder.

The display can also be set to

toggle between Input 1 and Input

2. The display can also be set to

blank (turn off) if the operator

does not want to see a displayed

value.

Page 4

44-01-03-04

Page 4

Input Processing

The input can be one of any

standard low-level electrical

signals which can be selected by

the user.

Ranges are either pre-configured

or, by using the display/keypad,

expanded and compressed within

the range limits to meet the

specific measurement needs.

Users can select upscale or

downscale break protection for

most actuations.

Input samples are taken at a rate

of once every 0.33 seconds. Each

input is isolated from the other to

insure that the signals do not affect

the other inputs.

A digital filter value of 1 second on

the basic recorder provides input

signal smoothing or with the

display, this can be changed from

0 seconds to 120 seconds of

filtering to match the application

need.

The basic recorder provides a

wide selection of linear and nonlinear inputs for the user to select

which one best meets the need.

By adding the display, a full range

of selections is available to the

user. The non-linear inputs can be

set so the microprocessor

linearizes the input, thus allowing

mixed input actuations for two pen

models to record the process

variable on a linear chart. This can

be bypassed by recording on a

non-linear chart.

Control Modes

The recorder can operate in the

following modes:

Manual Mode—when switched to

manual mode, the recorder holds

its output at the last value used

during automatic operation and

stops adjusting the output for

changes in process variable.

Local Automatic Mode—The

recorder uses the local setpoint

and automatically adjusts the

output to maintain the setpoint at

the desired value.

Diagnostics

Each DR4300 has built-in

diagnostics that check critical

recorder operations and provide

error detection or messages to

alert the user of potential faults.

This self test is run each time the

recorder is powered up.

In addition to this, a built-in step

pattern test can be run on

demand to insure proper pen and

chart drive motor operation; this

draws a special test pattern on

the chart thus providing a record

of the recorder’s proper

operation.

Construction

All DR4300 recorders are

manufactured with a rugged,

durable, molded case designed to

withstand most industrial

environments. This case and the

standard NEMA 3 door are

designed to protect the internal

electrical components from harsh

industrial environments. The

recorder comes standard with an

acrylic window.

Knockouts in the side and bottom

of the case accept conduit

connections for convenient wire

entry of power, inputs, and

outputs. Individual boards for each

input allow the user to easily

service each input separately, add

an additional input to a single pen

recorder and to avoid problems

with isolation of each signal.

The removable connectors also

allow for easier servicing without

having to disconnect the field

wiring.

Page 5

Specifications

Performance

44-01-03-04

Page 5

Number of Inputs

One pen model: One input

Two pen model: Two inputs

REFERENCE ACCURACY

Types of Input

Actuations

Thermocouples

B 105 to 3300

E –454 to 1832

E (low) –200 to 1100 –129 to 593 1.0 0.6 11 6 0.40

J 0 to 1600 –18 to 871 1.6 0.9 7 4 0.15

J (low) 20 to 770 –7 to 410 0.8 0.5 6 3 0.08

K –320 to 2500 –196 to 1371 2.4 1.4 9 5 0.15

K (low) –20 to 1000` –29 to 538 1.0 0.6 7 4 0.10

Ni-Ni Moly 32 to 2500

Nicrosil-Nisil 0 to 2372 –18 to 1200 2.1 1.2 11 6 0.20

R 0 to 3100

S 0 to 3100

T –420 to 700 –251 to 371 1.6 0.9 13 7 0.15

T (low) –200 to 600 –129 to 316 0.8 0.5 7 4 0.15

W5W26 0 to 4200

RTD

Platinum

100 ohms**

100 ohms

(low)**

100 ohms (T)***

150 to 500

500 to 1000

1000 to 3300

–454 to –202

–202 to 1832

32 to 500

500 to 2500

0 to 500

500 to 3100

0 to 500

500 to 3100

0 to 600

600 to 3600

3600 to 4200

–300 to 900

–130 to 392

–238 to 482

Range Reference Accuracy*

with

Field Calibration

°F °C± °F± °C± °F± °C Per 1 Degree •T

41 to 1816

66 to 260

260 to 538

538 to 1815

–270 to 1000

–270 to –130

–130 to 1000

0 to 1317

0 to 260

260 to 1371

–18 to 1704

–18 to 260

260 to 1704

–18 to 1704

–18 to 260

260 to 1704

–18 to 2316

–18 to 316

316 to 1982

1982 to 2316

–184 to 482

–90 to 200

–150 to 250

28.0

6.0

3.0

36.0

2.0

1.5

1.0

4.0

2.0

4.0

2.0

2.8

2.6

3.2

0.8

0.6

0.6

16.0

3.3

1.7

20.0

1.1

0.8

0.6

2.2

1.1

2.2

1.1

1.6

1.5

1.8

0.5

0.3

0.3

Reference Accuracy*

with

Factory Calibration

37

18

79

14

12

9

26

13

23

13

19

13

27

4

3

3

21

10

44

8

7

5

14

7

13

7

11

7

15

2

2

2

Temp Stability

± Degrees

Error

4.00

1.00

0.40

1.40

0.70

0.21

0.14

0.50

0.21

0.50

0.21

1.00

0.50

0.20

0.15

0.15

0.15

*Includes reference junction calibration of ± 0.01 degrees using the standard "ice bath" method of calibration. Factory

calibration at reference ± 1.2 °F. Note that factory calibration may have typical variations of ± 150 microvolts or ± 0.6 ohms

for RTDs which means recalibration may be required to achieve stated accuracy.

**IEC Alpha = 0.00385

***Alpha = 0.00391

NOTE: Field Calibration requires model with display.

Page 6

44-01-03-04

Page 6

Specifications, continued

Performance, continued

REFERENCE ACCURACY

Types of Input

Actuations

Linear

Milliamperes dc

Millivolts dc 0 to 10

Volts dc 0 to 1

Range Reference Accuracy*

with

Field Calibration

0 to 20

4 to 20

0 to 100

0 to 200

0 to 2

0 to 5

1 to 5

0 to 10

16 µA

16 µA

10 µV

100 µV

200 µV

1 mV

2 mV

5 mV

4 mV

10 mV

Reference Accuracy*

with

Factory Calibration

80 µA

80 µA

50 µA

500 µA

1.0 mV

5 mV

10 mV

25 mV

20 mV

50 mV

Design

Minimum Input Span Range is fully configurable within span limitation of the sensing element.

Input Impedance mA dc: 250 ohms

Vdc: 200 K ohms

RTD: 13.3 K ohms

All Others: 10 Megohms

Temp Stability

± Degrees

Error

Per 1 Degree

0.011 %/°F

0.011 %/°F

0.011 %/°F

0.011 %/°F

0.011 %/°F

0.011 %/°F

0.011 %/°F

0.011 %/°F

0.011 %/°F

0.011 %/°F

•T

Span Step Response

Time

Reproducibility 0.1 percent of span

Sampling Rate Input sampled every 1/3 seconds

Input Filter Without Display: Analog with time constant of 3 seconds and digital with time constant of 1

Digital Displays

(Optional)

Modes of Operation Manual

*Includes reference junction calibration of ± 0.01 degrees using the standard "ice bath" method of calibration. Factory

calibration at reference ± 1.2 °F. Note that factory calibration may have typical variations of ± 150 microvolts or ± 0.6 ohms for

RTDs which means recalibration may be required to achieve stated accuracy.

7 seconds maximum

second.

With Display: Analog with time constant of 3 seconds and digital adjustable 0 seconds to 120

seconds.

Vacuum fluorescent, alphanumeric

An upper four-digit display dedicated to the process variable or setpoint.

Alternate information displayed during configuration.

A six-digit lower display shows key selected operating parameters. Also provides guidance

during configuration.

Automatic with local set point

Page 7

Specifications, continued

Design, continued

Indicators Channel PV display (INP 1 or 2)

Controller output (OUT 1 or 2)

Temperature unit (F or C)

Controller’s mode (A or M)

Active Setpoint [L = SP1 active; R = SP2(S2) active]

Controller Output On-Off or Time Proportional

One SPDT electromechanical relay. Control action can be set for direct or reverse.

For Limit Controller: SPDT electromechanical output.

Electromechanical Relay Contact Ratings:

Resistive Load: 5 A @ 120 Vac, 2.5 A @ 240 Vac

Inductive Load: 50 VA @ 120 Vac or 240 Vac

Solid State Relay Contact Rating: 0.8 A @ 120 Vac

Open Collector Output Contact Rating: 12 mA @ 24 Vdc

Time Proportional Relay Resolution: 3.33 mSec.

Cycle Time: 1 second to 120 seconds

Current Proportional

21 mA dc maximum into a negative or positive grounded or non-grounded load of 0

ohms to 600 ohms. Output range can be set between 4 mA and 20 mA, and as direct or

reverse action.

Resolution: 11 bits

Accuracy: 0.5 % Full Scale

44-01-03-04

Page 7

Time Proportional Duplex

Variation of time proportional for Heat/Cool applications. Uses two relay contacts with

adjustable deadband that is split at 50 % controller output.

Current Duplex and Time/Current Duplex

Variation of time proportional duplex for Heat/Cool applications. Time proportional

output (heat or cool) is a SPST relay. Current proportional output (heat or cool) is a 4

mA to 20 mA signal that can be fed into a negative or positive grounded load of 0 ohms

to 600 ohms and is operational over 50 % of range or the entire range.

Time Proportional Relay Resolution: 3.33 mSec.

Relay Contact Ratings:

Resistive Load: 5 A @ 120 Vac, 2.5 A @ 240 Vac

Inductive Load: 50 VA @ 120 Vac or 240 Vac

Cycle Time: 1 second to 120 seconds

Current Proportional:

Resolution: 11 bits

Accuracy: 0.5 % full scale

Action

Direct or Reverse

Output Limits

0 % to 100 % Relay Output

–5 % to 105 % Current

Deadband

–5 % to 25 % Time Relay

0 % to 25 % On-Off Duplex

Hysteresis

0 % to 100 % of PV span

Case Molded, foamed-Noryl* with gasketed door to meet NEMA 3 enclosure requirements.

*Registered Trademark — General Electric Co.

Page 8

44-01-03-04

Page 8

Specifications, continued

Design, continued

Pen Disposable fiber-tip ink cartridge, line length per cartridge more than 1000 ft (305 m)

One Pen: Purple

Two Pen: Purple (pen one) and red (pen two)

NOTE: Only pen 1 (purple) is referenced to the chart time line.

Chart 10.24-inch (260 mm) diameter chart with standard preprinted markings and a calibrated

width of 4 inches (100 mm).

Wiring Connections Two piece wiring connectors inside case.

Color Case: Black

Door: Gray (standard); Caribbean blue (optional)

Window: Acrylic

Approval Bodies CE Mark, UL, CSA, FM Approved Limit Controller

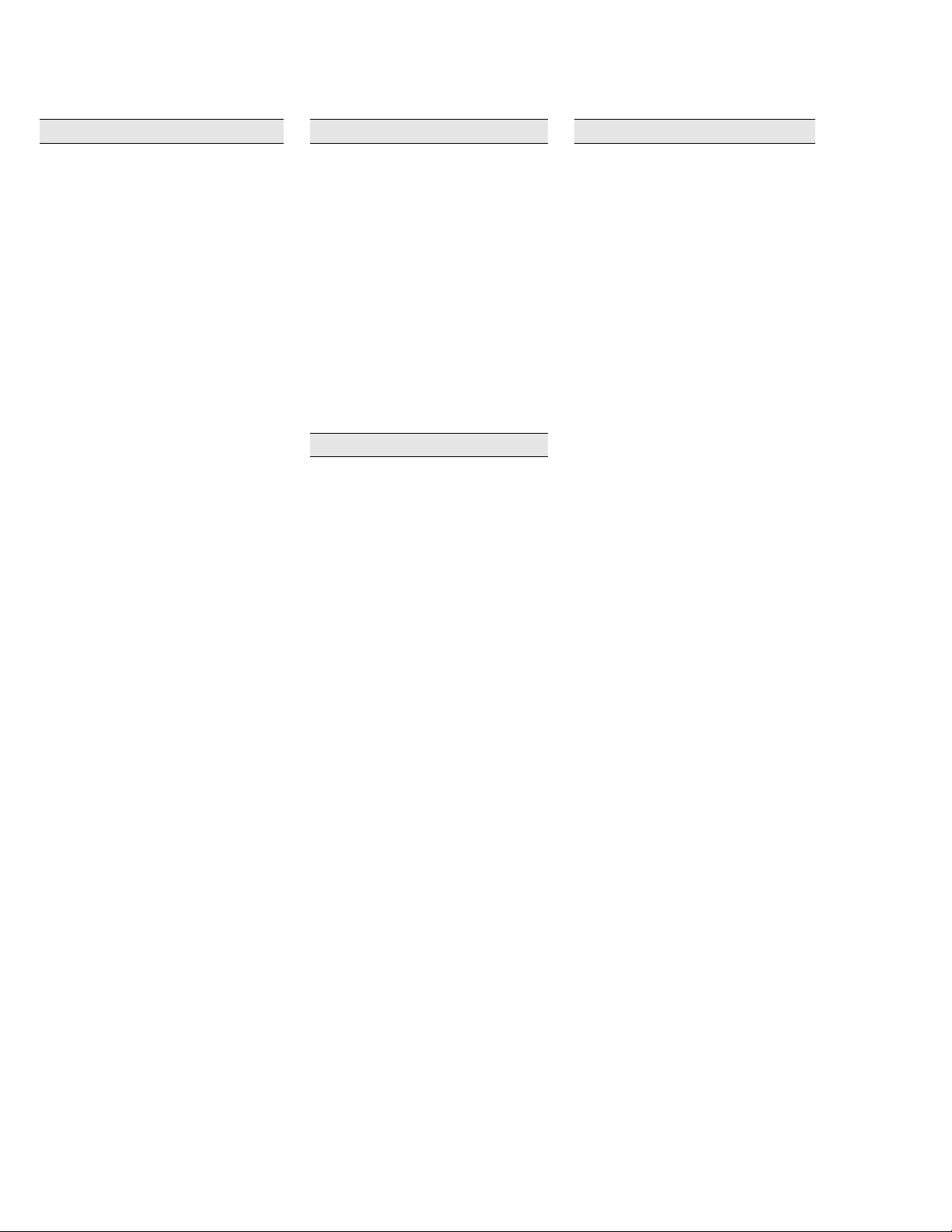

Dimensions See Figure 2.

Weight 12 lb. (5.4 kg)

Mounting Panel, surface, or 2-inch pipe mounting

CE Conformity (Europe)

(Optional)

Product Classification:

Enclosure Rating:

Installation Category (Over-voltage

Category)

Pollution Degree:

EMC Classification

Method of EMC Assessment

Declaration of Conformity

This product is in conformity with the protection requirements of the following European

Council Directives: 73/23/EEC, the Low Voltage Directive, and 89/336/EEC, the EMC

Directive. Conformity of this product with any other “CE Mark” Directive(s) shall not be

assumed.

Class I: Permanently Connected, Panel Mounted Industrial Control Equipment with

protective earthing (grounding). (EN 61010-1)

Panel Mounted Equipment, IP 00, this recorder must be panel mounted.

Terminals must be enclosed within the panel. Front panel IP 65 (IEC 529)

Category II: Energy-consuming equipment supplied from the fixed installation.

Local level appliances, and Industrial Control Equipment. (EN 61010-1)

Pollution Degree 2: Normally non-conductive pollution with occasional conductivity

caused by condensation. (Ref. IEC 664-1)

Group 1,Class A, ISM Equipment (EN 55011, emissions), Industrial Equipment (EN

50082-2, immunity)

Technical File (TF)

51197639-000

Page 9

Specifications, continued

Options

44-01-03-04

Page 9

Alarm Output Two SPDT electromechanical relays, or solid state or open collector outputs for an

Tuning PID tuning parameters of Gain or PB, Rate, Reset.

Chart For Basic Recorder chart speeds set as part of configuration for 8 hours, 12 hours,

Input Display can be set for 0, 1 (XXX.X) or 2 (XX.XX) decimal position with Display/Keypad,

Sensor Burnout Selectable for None, Up, or Down.

Totalizer (Optional) Totalizers (1 per pen); 6 digits displayed; resettable with Keypad or remote (digital)

Alarms Type: Based on PV or deviation, high or low state

Digital Inputs Two digital inputs, dry contact

Through the Door External

Keypad

Modbus Communication Baud Rate: 19,200 maximum

Setpoint Ramp/Soak

Programming (Optional)

alarm.

Relay Contact Ratings:

Resistive Load: 5 A @ 120 Vac or 2.5 A @ 240 Vac

Inductive Load: 50 VA @ 120 Vac or 240 Vac

24 hours or 7 days; with Display/Keypad speeds selectable from 1 hour to 744 hours.

°F or °C units.

Input range can be scaled from –999 to 9999 and bias of –999 to 9999.

input; rate can be set for seconds, minutes, hours, days, or millions per day, scale factor

by 10’s from 1 to 1 x 108; programmable low flow cutoff value.

Hysteresis: 0 % to 100 % of input span

Use for Event Recording, Reset Totalizer, Timer, Switch to Setpoint 2, Switch to Manual

mode.

Six-button keypad to allow operator selections without opening the door.

Protocol: Modbus

Length of Link: 4,000 ft (1,219 m) maximum

Link Characteristics: Two-wire, Multidrop

Allows configuration of up to four setpoint programs using a total of twenty-four

ramp and soak segments.

Run or Hold of program is keyboard or remote switch selectable.

Each ramp segment can be configured to be run in Hours and Minutes or degrees per

minute.

Soak segments can have a guaranteed soak deviation which guarantees the time for

each soak and will not start until the PV is reached.

Timer Configurable time period of 0 to 99 hours, 59 minutes.

Alarm 1 is dedicated to be active at the end of the time-out period.

Timer “start” is selectable as either the RUN/HOLD key or Alarm 2.

The optional Digital Input can also be configured to start the Timer in addition to either

the keyboard or Alarm 2.

The Timer display is selectable as either time remaining or elapsed time.

Transmitter Power 24 Vdc with adjustment of ± 6 % (22.6 to 25.4)

100 mA maximum output

Page 10

44-01-03-04

Page 10

Specifications, continued

Environmental and Operation Conditions

Parameter Reference Rated Extreme Transport and

Storage

Ambient Temperature 67 °F to 77 °F

Relative Humidity (% RH) 50 ± 3* 10 to 90* 5 to 90* 5 to 95*

Vibration

Frequency (Hz)

Acceleration (g)

Mechanical Shock

Acceleration (g)

Duration (ms)

Mounting Position from Vertical

Tilted Forward

Tilted Backward

Tilted to Side (±)

Power Requirements

Voltage (VRMS)

Frequency (Hz)

Power Consumption 20 watts maximum

*The maximum rating only applies up to 104 °F (40 °C). For higher temperatures, the RH specification is derated to maintain

constant moisture content.

**122 °F (50 °C) is maximum temperature for recorder with UL Listing.

19 °C to 25 °C

0

0

0

0

5°

5°

5°

120 ±1 or 240 ±1

60 ±0.21 or

50 ±0.21

58 °F to 131 °F

15 °C to 55 °C**

0 to 70

0.1

1

30

5°

30°

10°

100 to 240

60 ±1 or 50 ±1

32 °F to 131 °F

0 °C to 55 °C**

0 to 200

0.5

5

30

5°

90°

20°

90 to 264

48 to 62

–40 °F to 151 °F

–40 °C to 66 °C

0 to 200

0.5

5

30

Any

Any

Any

N/A

N/A

N/A

General Reference Data

Stray Rejection Common Mode Rejection Ratio: 120 dB or 1 LSB (whichever is greater) at 60 Hz with

maximum source impedance of 100 ohms.

Normal Mode Rejection Ratio: 60 dB with 100 % span peak to peak maximum at 60 Hz.

Static Charge Effects Exposed panel surface capable of withstanding a discharge from a 250 pf capacitor

charged to 10 KV through 100 ohms.

RFI Susceptibility Capable of withstanding an EMI-field generated from a 5-watt transmitter being held at

1 meter, and operating at 151.685 and 450 MHz.

Line Noise Effects Field terminals for connecting power line to recorder can withstand the IEEE Surge

Withstanding Capability Test to level of 2.5 KV.

Technical Assistance Toll-free 800 number puts technical assistance only a phone call away.

Page 11

Dimensions

44-01-03-04

Page 11

ALM

F

1

80 .8

CHN

1

RSP

INP 1

L

Front View

F

%

355.6

14.0

322.5

12.70

Panel

Cutout

355.6

14.0

322.5

12.70

Left Side View

23

0.9

320.5

12.6

147.8

5.8

Short wing latch :

Double bit latch :

14.5

.57

5

.19

41.3

1.6

Latch

163.2

6.4

Bottom View

320.5

12.6

Rear View

369.6

14.5

Surface

Mounting

17.5

0.6

196.2

7.7

181.3

7.1

24154

Figure 2—DR4300 Recorder Dimensions—For Reference Only

Page 12

44-01-03-04

Page 12

Ordering Information

For complete ordering information, request Model Selection Guide

44-01-16-04 for DR4300 Circular Chart Recorder.

For more information, contact Honeywell sales at (800) 343-0228.

Specifications are subject to change without notice.

Distributor :

WARRANTY/REMEDY

Honeywell warrants goods of its manufacture as being free of defective materials and faulty workmanship. Contact your local

sales office for warranty information. If warranted goods are returned to Honeywell during the period of coverage, Honeywell

will repair or replace without charge those items it finds defective. The foregoing is Buyer’s sole remedy and is in lieu of all

other warranties, expressed or implied, including those of merchantability and fitness for a particular purpose.

Specifications may change without notice. The information we supply is believed to be accurate and reliable as of this

printing. However, we assume no responsibility for its use.

While we provide application assistance personally, through our literature and the Honeywell web site, it is up to the customer

to determine the suitability of the product in the application.

Sensing and Contr ol

Honeywell

11 West Spring Street

Freeport, IL 61032

44-01-03-04 0301 Printed in USA www.honeywell.com/sensing

Loading...

Loading...