Page 1

GR Series and DR Graphic Recorders

DR Graphic, Multitrend GR, Minitrend GR and eZtrend GR

See, Store and Send Data Securely

For the best in Display Versatility, Analysis and

Communications ..

choose

Page 2

ii 43-TV-25-41 Iss.4 GLO May 2015 UK

User manual

Page 3

Table of Contents

Section 1: Preface .............................................................................. 1

Preface ...........................................................................................................1

Thank you for choosing a Honeywell GR Series recorder ....................................... 1

Documentation.......................................................................................................... 1

Notes......................................................................................................................... 1

Trademarks............................................................................................................... 1

Safety ............................................................................................................. 2

Symbols..................................................................................................................... 2

Static Electricity........................................................................................................ 3

Protocols used in this manual ........................................................................ 3

Safety and Symbol Identification .............................................................................. 3

Warnings and Safety Precautions .................................................................. 3

Do’s and Don’ts......................................................................................................... 3

Hazardous Voltage.................................................................................................... 4

For use in hazardous locations................................................................................. 5

Section 2: Installation .........................................................................................7

Environment and Location ............................................................................ 7

Mechanical Installation .................................................................................. 8

Installation Instructions........................................................................................... 11

Electrical Installation ................................................................................... 22

Installation Category.............................................................................................. 22

Analogue Input Card.............................................................................................. 29

eZtrend GR Analogue Input (Standard) card.................................................. 32

Analogue Output Card............................................................................................ 33

Pulse Input Card..................................................................................................... 35

Transmitter Power Supply Card............................................................................. 37

Alarm Relay Cards & Digital Input/Output Cards................................................. 38

Communications Connections .............................. ... ............................. .. ................ 42

USB Devices ........................................................................................................... 44

Section 3: Overview ..........................................................................................45

Functions and Features ................................................................................ 45

Recorder Functionality........................................................................................... 47

Features.................................................................................................................. 49

Options - Hardware................................................................................................ 55

Section 4: Recorder Setup ................................................................................63

Power up ...................................................................................................... 63

1. Menu Access ....................................................................................................... 63

2. Log On/Off.......................................................................................................... 64

4. Time and Date Settings...................... .......................................................... .. ..... 65

5. Firmware Options.............. .......................................................... .. ..................... 65

Menu Path................. .......................................................... .................................... 65

Help ........................................................................................................................ 66

Configure Menu...................................................................................................... 67

Setup Menu ............................................................................................................. 68

Edit Recording...................................................................................................... 148

43-TV-25-41 Iss.4 GLO May 2015 UK iii

Page 4

Reports Menu........................................................................................................ 153

Layout .................... ............................. .................................................................. 157

Passwords.................................... ... ............................ .......................................... 164

Settings................. ................................................................................................. 173

Alarms Menu....................... ............................. ... ............................. .. ................... 175

Screen Menu.......................................................................................................... 176

Batch Setup/Batch Groups.................................................................................... 180

Recording Menu.................................................................................................... 184

Messages Menu..................................................................................................... 187

Process Menu.. ...................................................................................................... 190

Status Menu........................................................................................................... 194

Finish ..................... ............................................................................................... 206

Section 5:Security .......................................................................................... 207

Password Security................................................................................................. 207

Users and Groups................................................................................................. 207

Administrator............................................. ............................. .............................. 208

Password Policy.................................................................................................... 210

User Interface requirements ................................................................................. 210

Audit Trail..................... ....................................................................................... . 210

Level Permissions ................................................................................................. 211

Default Password Access...................................................................................... 214

Hardware Configuration Lock.............................................................................. 224

Section 6: Screen Configuration ................................................................... 225

Process Screen Overview................................. ..................................................... 225

Menu Bar .............................................................................................................. 226

Screen Menu Bar..................................................... .............................................. 227

Replay ............. ...................................................................................................... 228

Chart Speeds............................ ............................................................................. 235

Hot Button....................... .......................................................... .. .......................... 235

Screen Activity....................................................................................................... 236

Section 7: Firmware Options ......................................................................... 241

Firmware Credit System .............................................................................241

Firmware Options................................................................................ ................. 243

Section 8: Communication ............................................................................245

Comms Configuration ................................................................................245

Standard Communication Interfaces ..........................................................245

Protocols..................................................................... .......................................... 246

Hardware Installation .................................................................................247

Getting connected - IP Address ............................................................................ 248

Local Area Network setup..................................................................................... 249

Links to Remote Networks..................................... ................................................ 249

Data Logging and Transfer................................................................................... 249

Comms and Trend Manager Suite ..............................................................251

System Requirements........................................................ ..................................... 252

Software Installation............................................................................................. 253

Start Up................................................................................................................. 254

iv 43-TV-25-41 Iss.4 GLO May 2015 UK

Page 5

Communications Server .............................................................................258

Comms Server Overview ....................................................................................... 258

Comms Server Start up.......................................................................................... 258

Comms Server Setup.............................................................................................. 261

Comms Server Logging ......................................................................................... 266

Comms Server Database ............................................................................ 274

System Setup.......................................................................................................... 274

Shutdown Server ........................................................................................274

.Modbus Capabilities:.......... ................................................................................. 275

Web Browser ..............................................................................................276

Internet Security Settings ...........................................................................277

Section 9: PC Software Suite .........................................................................279

The TrendManager Pro Software Suite................................................................. 279

X Series & GR Recorder Screen Designer.......... .................................................. 279

Database Management Tool.................................................................................. 280

Report Generation Tool - AMS2750...................................................................... 280

System Requirements............................................................................................. 280

Section 10: Spares List ..................................................................................281

Minitrend GR Recorder......................................................................................... 281

Multitrend

eZtrend GR Recorder............................................................................................. 291

DR Graphic Recorder........................................................................................... 295

GR Recorder...................................................................................... 285

Section 11: Instrument Care and Maintenance ............................................ 301

Instrument Care and Maintenance .............................................................301

Cleaning Instructions................................. ... ............................. .. ......................... 301

Backlights.............................................................................................................. 301

Operating T emperature ......................................................................................... 301

Touch Screen.......................................................................................................... 302

Calibration ............................................................................................................ 302

Section 12: Technical Data & Specifications ...............................................303

Field IO Specification ................................................................................303

Analogue Input ...........................................................................................304

Relay Alarm/Digital Input Specification ....................................................304

Relay/Alarm Output Card Options........................................................................ 304

Digital Input Cards ............................................................................................... 305

Specification Tables................................................................................. .............. 307

Input Range Performance Accuracy Table............................................................ 312

Input Actuation

(Linear).................................................................................................................. 312

Input Actuation...................................................................................................... 313

LED Flash Codes .................................................................................................. 317

Appendix A: Quality and Safety ....................................................................319

CE Mark .....................................................................................................319

Safety ..........................................................................................................319

43-TV-25-41 Iss.4 GLO May 2015 UK v

Page 6

Appendix B: Maths Expressions ................................................................... 321

Full Maths & Script Processing .................................................................321

Maths Credit Options............................................................................................ 321

Maths Variable and Function Tables ............................................................ .. ...... 322

Full Maths............................................................................................................. 330

Script Function Application Examples ............ ..................................................... 331

Maths Error Messages................. ......................................................................... 336

Appendix C: Thermocouple Connections ....................................................337

How Thermocouples work .........................................................................337

Thermocouple CJC Compensation ............................................................. 338

Internal Automatic ...................................................................................... .. ........ 338

Ext 0°C Reference................................................................................................. 339

External with a Specified Temperature................................................................. 339

External Input Reference ................ ...................................................................... 340

Appendix D: Alarms .......................................................................................341

Alarms Menu....................... ............................. ... ............................. ..................... 341

Appendix E: Ethernet ..................................................................................... 343

Ethernet..... ............................................................................................................ 343

Email............... ....................................................................................... .. ............. 344

General operation of the e-mail system............................................. ................... 344

Appendix F: Fuzzy Logging ........................................................................... 345

Appendix G: F sub zero Sterilisation ............................................................ 349

The significance of F0........................................................................................... 349

Appendix H: Calibration ................................................................................. 351

AI Calibration and CJC Calibration ...........................................................351

Sensor Compensation .................................................................................351

Appendix I: Battery Data ................................................................................ 353

Location: Processor Board .........................................................................353

Safety Guidelines .................................................................................................. 353

Appendix J: Function Codes and Memory Maps ......................................... 355

Modbus Memory Map Supplement: ..........................................................355

Totalisers.............. ................................................................................................. 360

Input Text message................................................................................................ 360

Analogue Input Value............................................................................................ 360

Communications Input.......................................................................................... 360

Pen Values..................... ........................................................................................ 361

Modbus Function Codes .............................................................................362

Appendix K: Troubleshooting ....................................................................... 363

Error Messages ...........................................................................................363

vi 43-TV-25-41 Iss.4 GLO May 2015 UK

Page 7

Appendix L: GR Series AMS2750 capabilities ..............................................377

AMS2750 and the GR Series Recorders ................................................... 377

AMS2750 Process mode ............................................................................ 378

AMS2750 Credit Option....................................................................................... 378

AMS2750 Process Menu....................................................................................... 379

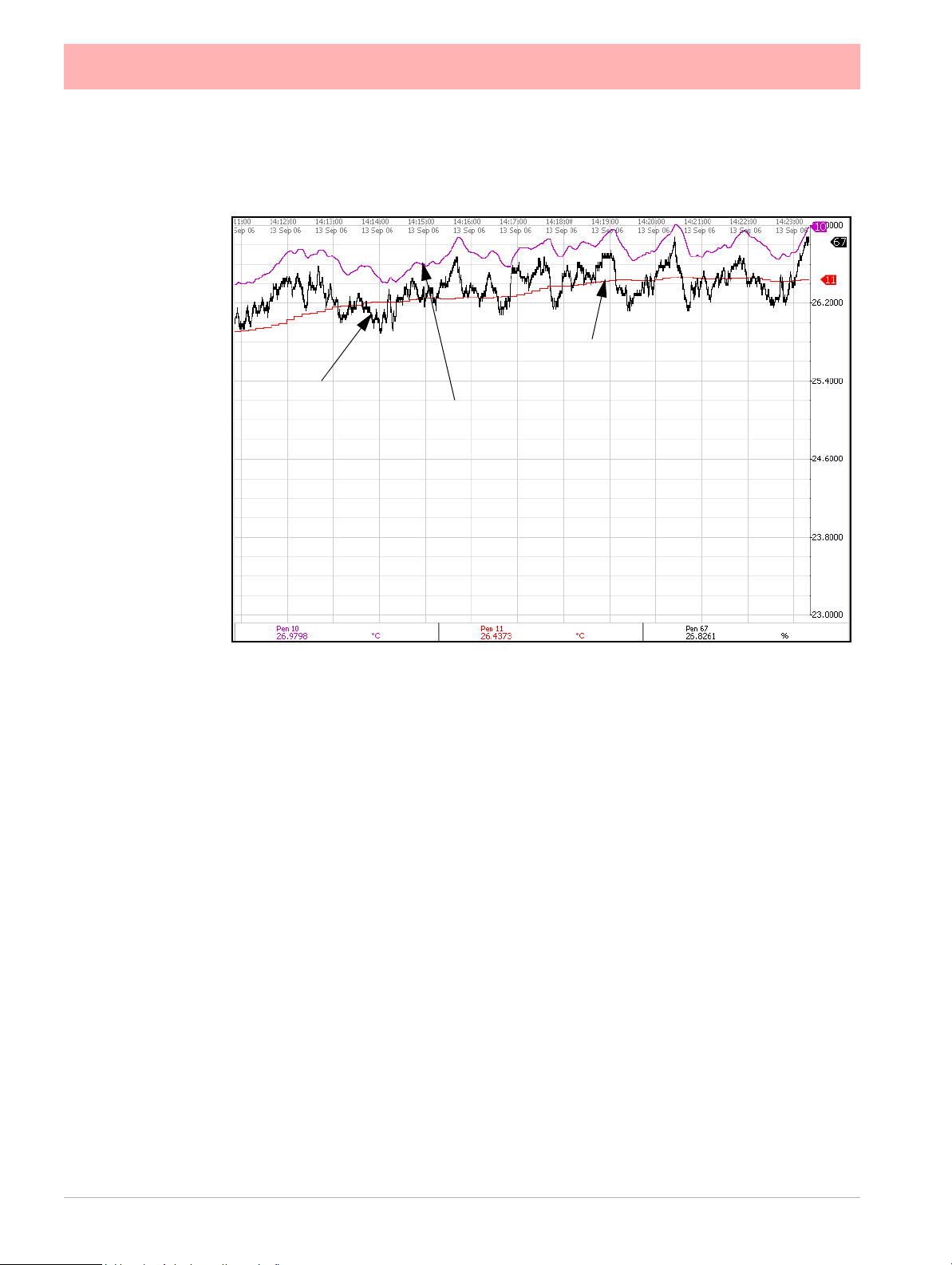

AMS2750 Process Screen..................................................................................... 379

SAT........................................................................................................................ 383

I/O + AMS2750 (Process Mode).......................................................................... 383

AMS2750 Button (Process Mode)......................................................................... 385

Pens for TC’s (Process Mode).............................................................................. 389

Thermocouple Usage Tracking (AMS2750)......................................................... 390

TUS mode ..................................................................................................392

Temperature Uniformity Survey (TUS) Mode....................................................... 392

AMS2750 (TUS) - Credit Option.......................................................................... 393

AMS2750 (TUS) Screen........................................................................................ 394

I/O + AMS2750 (TUS).......................................................................................... 394

AMS2750 Menu (TUS).......................................................................................... 395

Pens for TC’s (TUS Mode).................................................................................... 401

TUS survey process screen................................................................................... 402

Start a Survey........................................................................................................ 410

During survey ....................................................................................................... 410

Events (AMS2750)................................................................................................ 416

Audit Trail (AMS2750)......................................................................................... 417

TUS Data file........................................................................................ ................ 417

TUS Logged data.................................................................................................. 418

Passwords (AMS2750) .............................................................................. 419

TrendManager SuiteSoftware (AMS2750) ................................................ 420

Screen Designer (AMS2750) .....................................................................420

AMS2750 Report Generation Tool ............................................................ 421

Installation............................................................................................................ 421

Introduction .......................................................................................................... 423

Report T ool User Interface................................................................................... 423

Browse Logo......................................................................................................... 424

SAT Report Wizard.................... ............................ ... ............................. ................ 425

TUS Report Wizard............................................................................................... 428

Index .................................................................................................................449

43-TV-25-41 Iss.4 GLO May 2015 UK vii

Page 8

viii 43-TV-25-41 Iss.4 GLO May 2015 UK

Page 9

Section 1: Preface

Preface

Thank you for choosing a Honeywell GR Series recorder

Thank you for purchasing the newest in our range of electronic data recording for GR Ad-

vanced Graphic Recorders.

The Minitrend GR, Multitrend GR eZtrend GR and DR Graphic paperless chart recorders are the latest development of the solid-state replacement for traditional paper recorders.

Many options, features and functions are available to meet a wide range of applications and

requirements including: Power, Water Treatment, Therm al Processing, Food and Beverage,

Pharmaceutical/Biotech and Manufacturing industries.

This manual explains the product functionality operati on, configuration and com munication

as well as Safety Precautions, Installation & Wiring, Recorder Setup, Troubleshooting and

Spares List. It is recommended that the user reads the manual before installing and operating the recorder.

Documentation

A full set of manuals for the software and the recorders (including some language versions) are available on the CD provided and from our website

www.honeywellprocess.com

Also Application Notes and Installation Instructions, first time password setup and database tool information.

Supplementary documentation to accompany these recorders are:

TrendManager Pro Software Suite 43-TV-25-11

Screen Designer 43-TV-25-31

.

Table 1.1 : Supplementary documentation

Manual Part number

Notes

• The contents of this manual are correct at the time of issue. The contents may

change at any time without prior notification. This is due to continuous developments to the recorder and it’s functionality.

• Every effort has been made to ensure the accuracy of this document, however

should there be any anomalies found, please contact your nearest

supplier. See back page for contact addresses.

• All rights are reserved. No part of this manual should be copied or reproduced, stored on a retrieval system or transmitted in any form without the

prior permission from Honeywell International Inc.

Honeywell

Trademarks

• Microsoft, MS-DOS, Windows 7, Windows 8, Windows Server 2008 and Windows 2012

Server are all registered trademarks of Microsoft corporation.

43-TV-25-41 Iss.4 GLO May 2015 UK 1

Page 10

Safety

Safety

• *SD, SDHC and SDXC are trademarks or registered trademarks of

SD-3C, LLC in the United States, other countries or both.

• For the purpose of this manual the and symbols will not follow their own trademark names or registered trademark names in every instance.

• Company names and Product names mentioned in this manual are trademarks or

registered trademarks of their individual owners.

The GR Series range of instruments is compliant with the requirements of BS EN 610101:2010 “Safety Requirements for Electrical Equipment for Measurem ent, Control and Laboratory Use” and UL 61010-1 (3rd Edition) and CAN/CSA-C22-2 No.61010-1-12, as options.

If the equipment is used in a manner not specified, the protection provided by the equipment

may be impaired.

The GR Series range of instruments are compliant to the requirements for Class 1, Div.2

Hazardous (Classified) Locations. Refer to the Model Selection Guide.

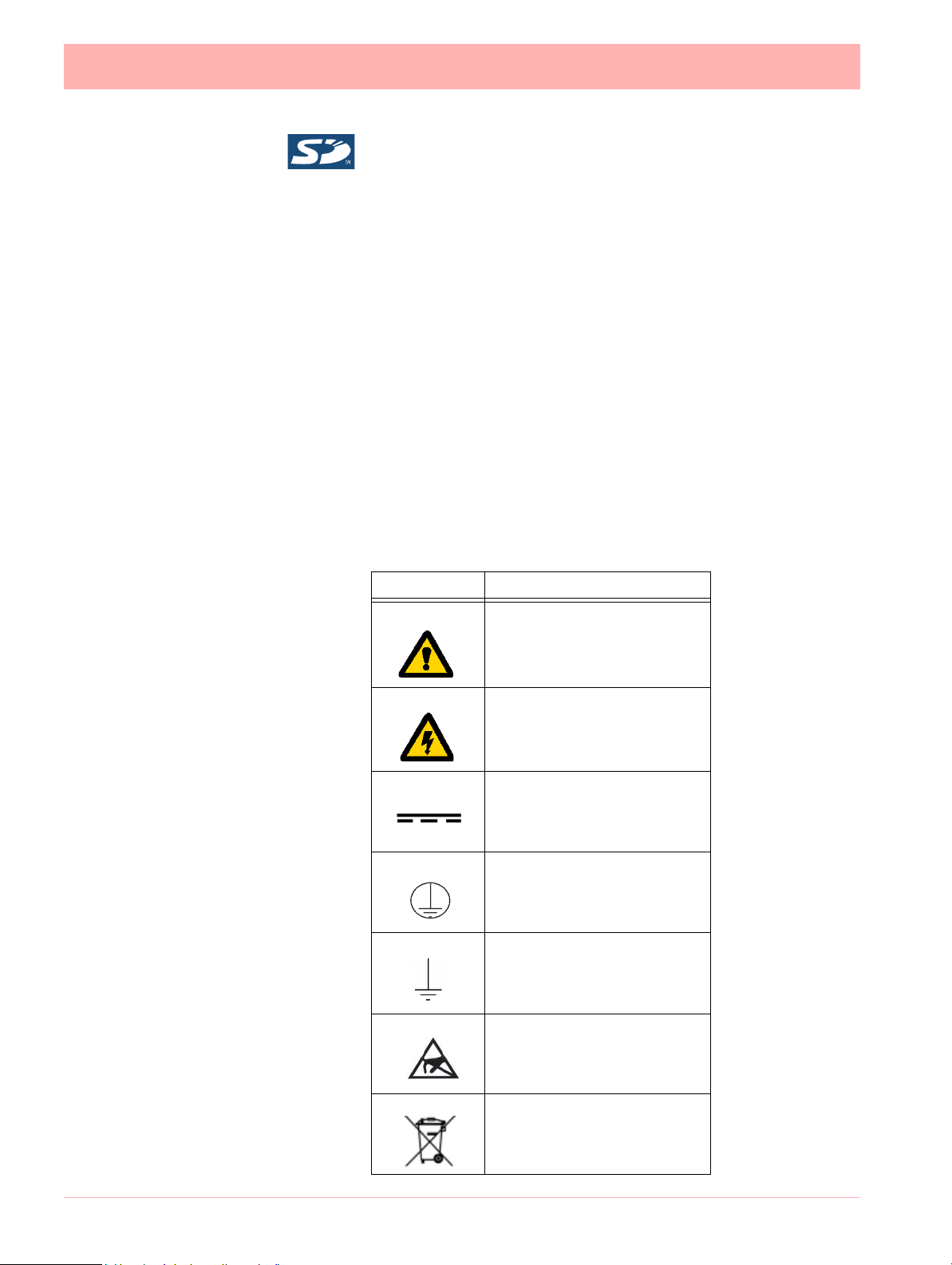

Symbols

One or more of the following symbols may appear on the recorder labelling.

Table 1.2 : Safety Symbols

Symbol Meaning

Caution - refer to manual for

instructions

Caution - risk of electric

shock

Direct Current

Protective conductor terminal

Earth (ground) terminal

Static Electricity

Directive 2002/96/EC

WEEE: Waste Electrical and

Electronic Equipment

2 43-TV-25-41 Iss.4 GLO May 2015 UK

Page 11

Protocols used in this manual

WARNING

IMPROPER INTERRUPTION OF CONNECTIONS

Any interruption of the protective conductor outside the recorder, or disconnection of

the protective earth terminal is likely to make the recorder d angerous under some fault

conditions. Intentional interruption of the protective conductor is dangerous.

Failure to comply with these instructions could result in death or serious injury.

Static Electricity

All circuit boards and electronic modules associated with this recorder contain components

which are susceptible to damage caused by elec trostatic discharge. Should it be necessa ry

to handle such components, appropriate precautions in accordance with ANSI/ESD S20.20

Electrostatic Discharge Control Program Standard, should be observed.

Protocols used in this manual

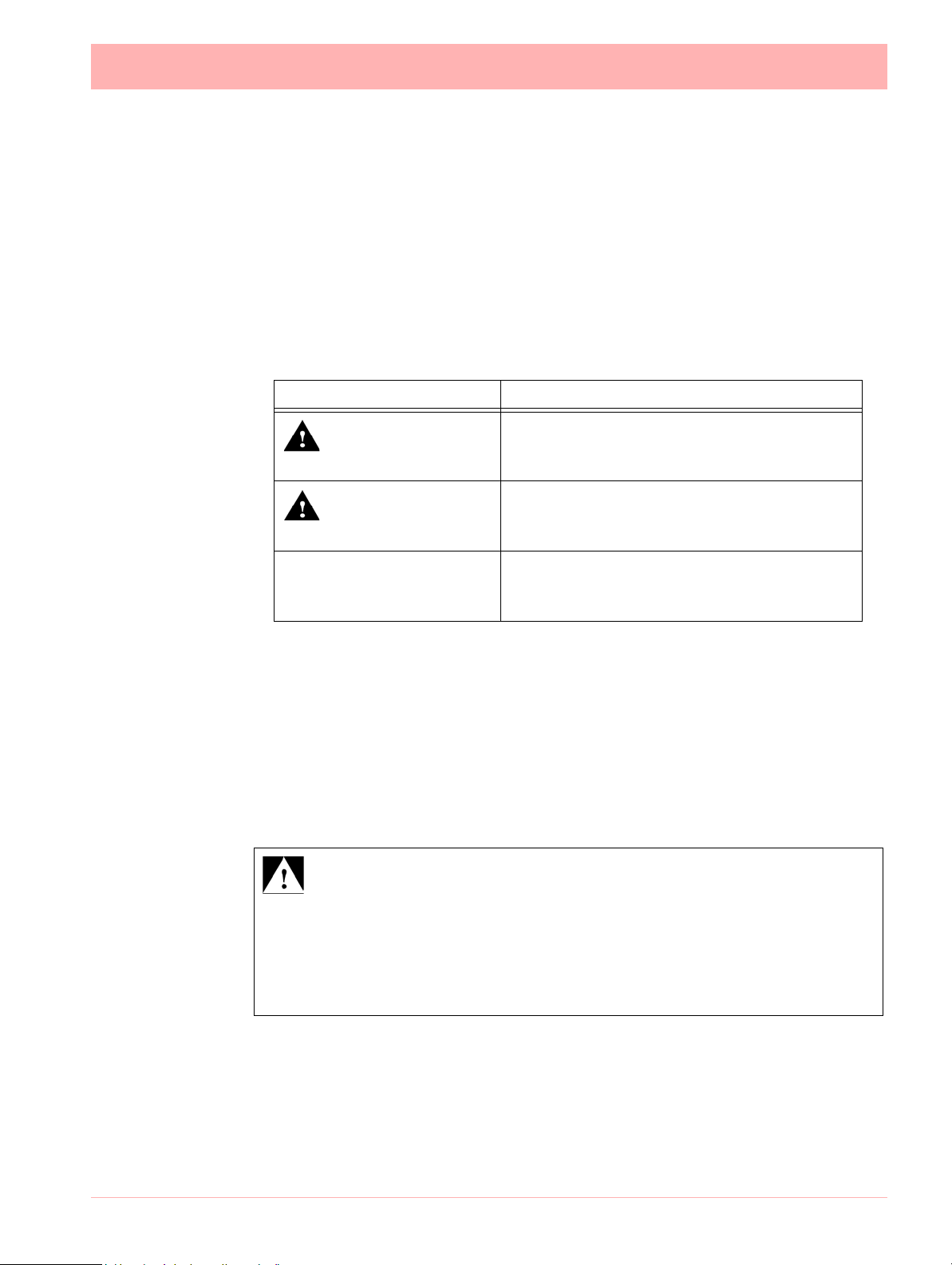

Safety and Symbol Identification

Symbol Description

Table 1.3 :

WARNING

CAUTION

NOTICE

Warnings and Safety Precautions

Do’s and Don’ts

1. DC inputs to the product should be provided by SELV power supply

2. The inputs of the product are supplied from SELV and should not exceed 50V.

3. Before any connections are made to the recorder, ensure the protective earth terminal

is connected to a protective conductor before applying power or any other connections.

The WARNING symbol indicates a potentially

hazardous situation, which, if not avoided, could

result in death or serious injury.

This CAUTION symbol may in dicates a potentially hazardous situation, which, if not avoided, may

result in property damage.

A NOTICE symbol indicates important information that must be remembered and aids in job

performance.

In order to comply with the requirements of safety standard EN 61010-1:2010, the

recorder should have one of the following as a disconnecting device, located within

easy reach of the operator, and be clearly labelled as the disconnecting safety device:

43-TV-25-41 Iss.4 GLO May 2015 UK 3

• A switch or circuit breaker which complies with the requirements of IEC 60947-1 and

IEC 60947-3.

Page 12

Warnings and Safety Precautions

WARNING

IMPROPER SIGNAL AND SUPPLY WIRING

Signal and supply wiring should be kept separate. Where this is impractical, shielded cables should

be used for the signal wiring. Where signal wiring is carrying, or could carry under fault conditions,

hazardous voltage (defined as >30 V rms and 42.4 V peak, or >60 Vd.c.), double insulation must

be used for all signal wiring.

Failure to comply with these instructions could result in death or serious injury.

WARNING

HAZARDOUS VOLTAGE LEVELS

Voltage levels above 30V rms and 42.4V peak or 60V dc are deemed to be

"Hazardous Live". Ensure operators are not exposed to hazardous voltage levels.

Failure to comply with these instructions could result in dea th or serious in jur y.

• A separable coupler which can be disconnected without the use of a tool.

• A separable plug, without a locking device, to mate with a socket outlet in

the building.

4. Whenever it is likely that protection has been impaired, the recorder should be made

inoperative and secured against operation. The manufacturer's service centre should

be contacted.

5. Repair is not to be attempted by a customer. Any adjustment or maintenance expected

of an operator as part of the normal operation of the product is referred to as Operational Maintenance. Any maintenance not expected of the operator is referred to as

Corrective Maintenance and is to be carried out only by authorized service personnel

or returned to an authorized repair centre.

6. Where conductive pollution such as condensation or conductive dust is present, adequate air conditioning, filtering and/or sealing must be installed.

7. This recorder contains one battery on the Processor board which must be treated and

disposed of with care. Batteries must not be short circuited. Batteries should be disposed of in accordance with local regulations, they must not be disposed of with normal

refuse.

Improper signal and supply wiring - WARNING

8.

9. If the equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be inadequate.

10. The protective earth terminal must remain connected (even if the recorder is isolated

from the mains supply) if any of the measuring, communications, or relay terminals are

connected to hazardous voltages.

Hazardous Voltage

Hazardous Voltages are defined by EN61010-1 as follows:

4 43-TV-25-41 Iss.4 GLO May 2015 UK

Page 13

Warnings and Safety Precautions

WARNING

EXPLOSION HAZARD

Do not remove or replace the Connectors, Fuse holders while circuit is live when

Flammable or Combustible atmosphere is present

WARNING

EXPLOSION HAZARD

Do not disconnect equipment when a flammable or combustible atmosphere is

present.

WARNING

EXPLOSION HAZARD

Do not open the enclosure or replace the battery when a flammable or combustibl e

atmosphere is present

WARNING

EXPLOSION HAZARD

Do not connect ro disconnect the equipment or memory card or USB device unless

the power has been swithced off or the area is known to be hazardou s

NOTICE

The Front door is tool secured and do not intende d to op e n du ring live cond itio n or

when flammable or combustible atmosphere is present. Ensure to lock the door for

use in hazardous location.

In case of GR Mini /Multi the front door is tool secured with cable tie whereas in DR

graphic recorder the front door is tool secured with Hex head Screw.

For use in hazardous locations

(only applicable to recorders with FM approval)

43-TV-25-41 Iss.4 GLO May 2015 UK 5

Page 14

Warnings and Safety Precautions

6 43-TV-25-41 Iss.4 GLO May 2015 UK

Page 15

Section 2: Installation

NOTICE

Should the original packing be destroyed or lost, new packaging can be ordered or as a

last alternative, then ONLY pack the recorder in polystyrene granules if the recorder is

FIRST sealed in a strong plastic bag. Failure to do this will invalidate your warranty.

Damage checks

Any damage caused to the recorder or the contents should be reported immediate ly to your

shipper.

Unpacking

Remove the contents, check the packaging and remove all d ocumentation and ac cessories

supplied. Retain the box and any packaging for future transportation.

Contents

Check that the contents and accessories are correct against the order or Model Selection

Guide using the model number on the recorder. Contact your authorised Honeywell dis-

tributor or Honeywell immediately should there be any query.

The contents are based on Unit Model Number ordered and will vary from unit to unit. The

following list is provided as a general guide and not specific to any single unit.

• Recorder - specification as ordered (check against the Model Selection Guide)

• Mounting fixings - Mounting clamps and panel gasket

• Connector kit - mating half connectors to recorder spec. Including a CJC connector for

Thermocouple operation.

• Quick Start Guide - to get you started

• First time Password system instructions - for ESS recorders only

• CD - Viewer software + documentation

• Plastic stylus x 2 (for use with the touch screen)

• Manual (optional) - Hard copy English, French or German

• Any other items ordered as an option (Model Selection Guide)

Re-packing

Environment and Location

• The recorder is designed to be mounted into a panel. See “Installation Instruc-

tions” on page 11.

• Mounting angle is unlimited. Choose a suitable location with an ideal viewing angle.

See “Mounting and Viewing Angles” on page 8.

• The location should be free from vibration.

• The environment should be of non-condensing humidity.

• The ambient temperature should be between 0C and 50C (32F to 122F).

• The relative humidity should be between 10% to 90%.

• In the presence of sustained strong EM Field (~10V/m or higher), deviation from the

accuracy specifications may occur. To improve performance under such installation

scenarios we recommend using twisted pair cables and/or ferrite cylinders (over

individual wires)

43-TV-25-41 Iss.4 GLO May 2015 UK 7

Page 16

Mechanical Installation

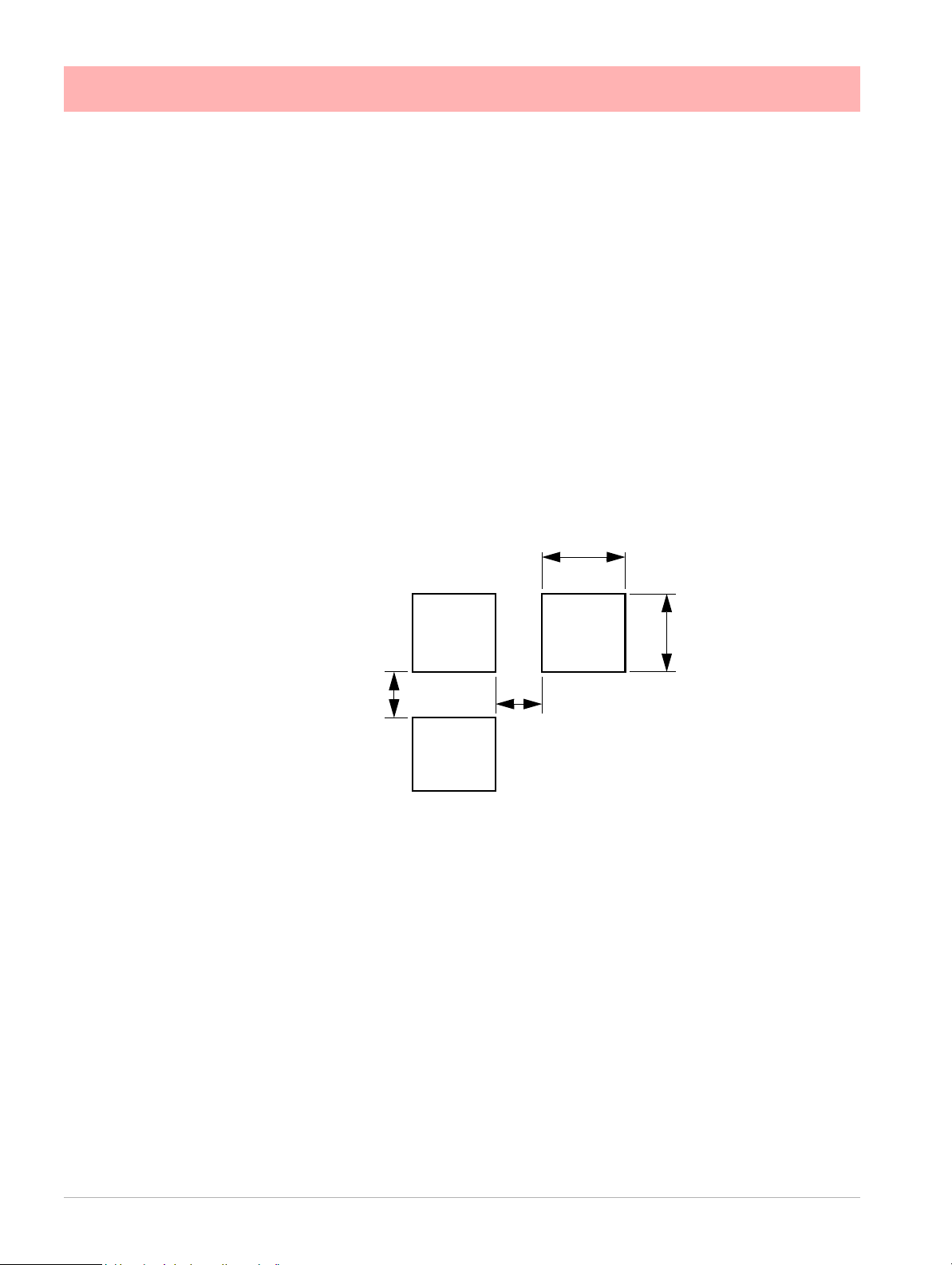

Please note the recommended

spacing for adjacent mounting

Panel

Cut-out

Panel

Cut-out

Panel

Cut-out

138.00

(5.43”)

138.00

(5.43”)

>7.00

(0.28”)

>6.00

(0.237”)

+1

- 0

+1

- 0

Figure 2.1 Minitrend GR and eZtrend GR Panel cut-out

Mounting and Viewing Angles

Mounting - The Minitrend GR, Multitrend GR and eZtrend GR recorders have an unlimited mounting angle.

Mechanical Installation

Viewing - For the best view of the display the v

iewing angle should not exceed:

Minitrend GR 55from the left or right, 40looking down and 50 looking up at the recorder dis-

play.

Multitrend GR and DR Graphic70from the left or right, 45looking down and 55 look-

ing up at the recorder display.

eZtrend GR 45from the left or right, 10looking down and 30 looking up at the recorder display.

Panel cut-out size for the Minitrend GR and eZtrend GR recorders

8 43-TV-25-41 Iss.4 GLO May 2015 UK

Page 17

Mechanical Installation

Panel

Cut-out

Panel

Cut-out

Panel

Cut-out

281.00

(11.06”)

281.00

(11.06”)

>20.00

(0.787”)

>20.00

(0.787”)

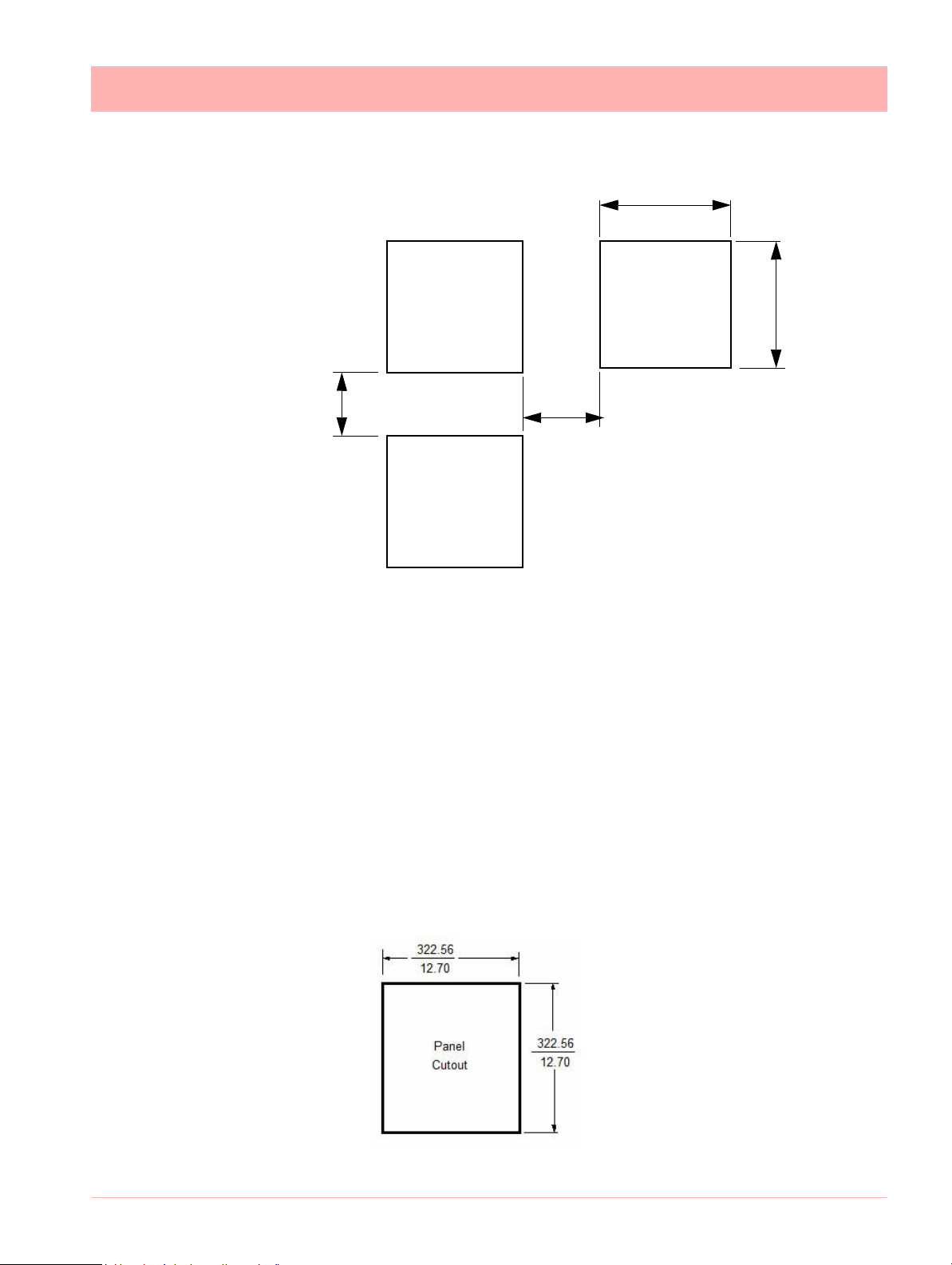

Please note the recommended

spacing for adjacent mounting

Figure 2.2> Multitrend GR Panel cut-out

Figure 2.3>

DR Graphic recorder

Panel cut-out

Panel cut-out size for the Multitrend GR recorder

The Minitrend GR, Multitrend GR and eZtrend GR recorders are DIN Standard sizes

and should be panel mounted.

Panel cut-out size for the D R G r a p h i c recorder

Physical considerations

The recorder can be mounted flush in a panel or on the surface of a p anel or wa ll using th e

mounting kit supplied with the recorder. Adequate access space must be available at the

back of the panel for installation and servicing.

Overall dimensions

The overall dimensions and panel cutout requiremen ts for mounting the recorder are shown

in Figure 2.3

43-TV-25-41 Iss.4 GLO May 2015 UK 9

Page 18

Mechanical Installation

4 Mounting clamp positions for 2 - 20mm panel thickness. For standard units fit

only two brackets on opposite sides of the unit, either top and bottom or left and

right slots. NEMA 4X rated recorders require all four mounting brackets to be fitted.

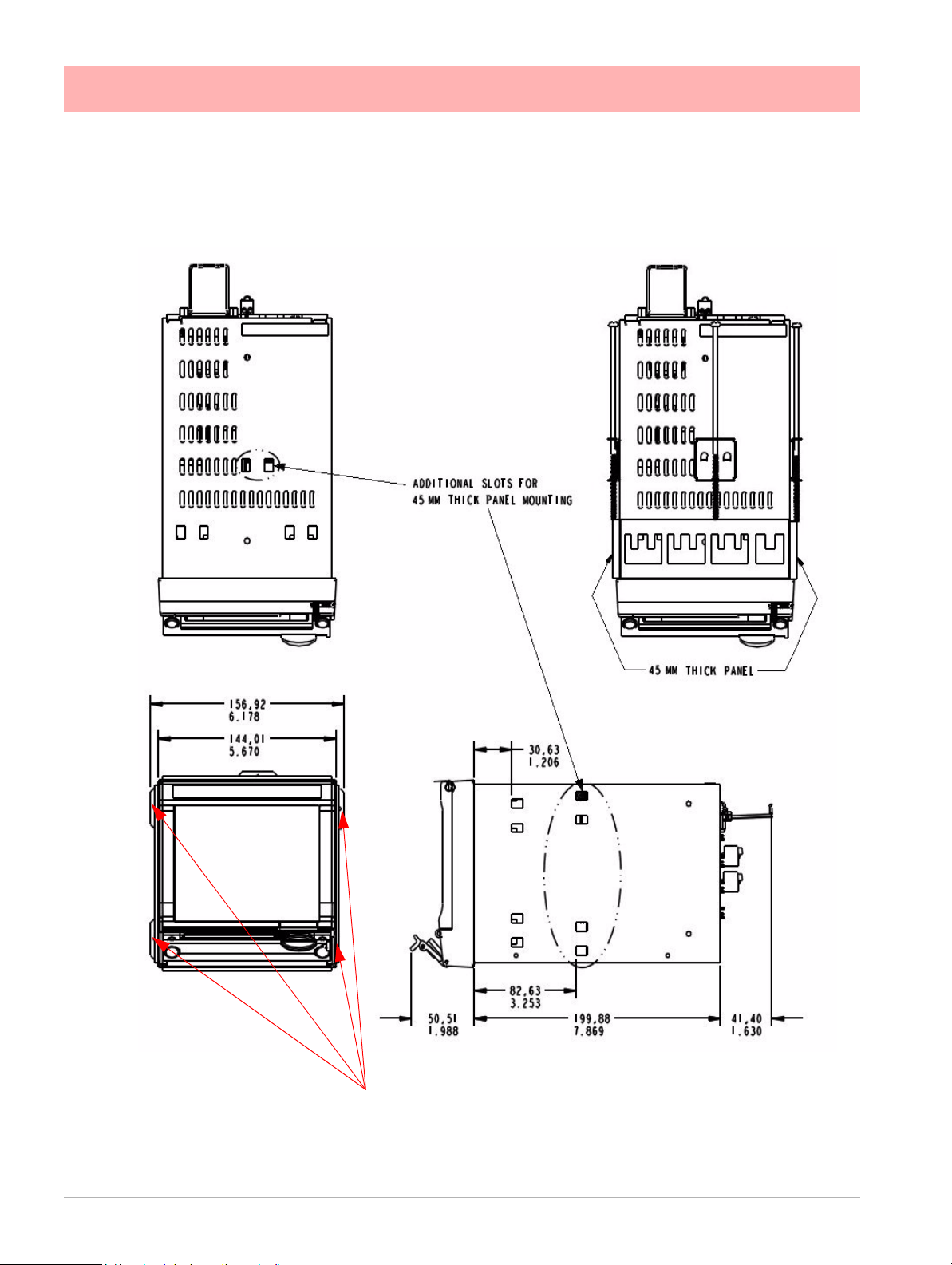

Figure 2.4> Miniitrend GR Recorder Dimensions and Mounting slots (including

45mm panel thickness)

Minitrend GR Dimension details

10 43-TV-25-41 Iss.4 GLO May 2015 UK

Page 19

Mechanical Installation

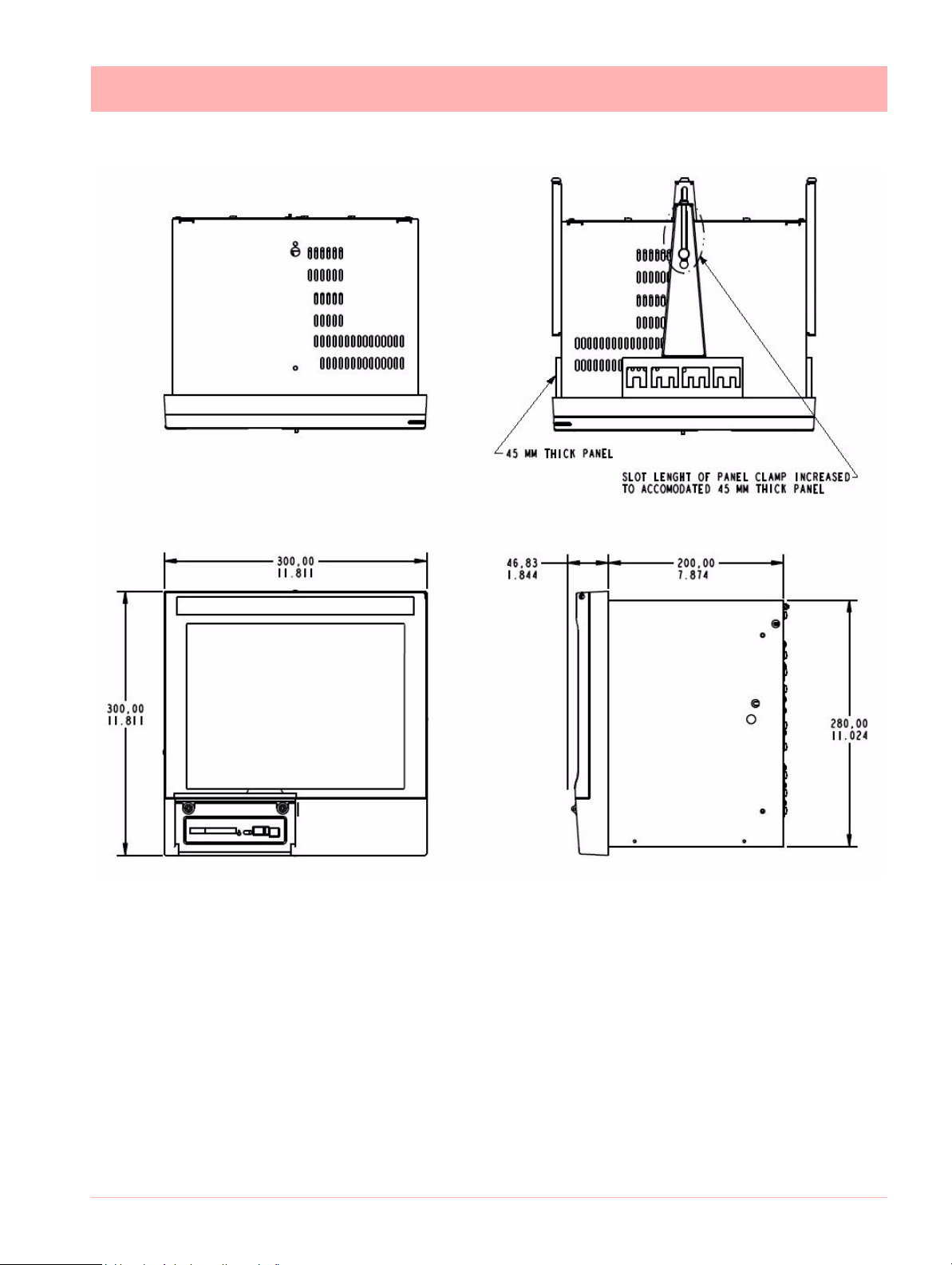

Figure 2.5> Multiitrend GRRecorder Dimensions and Mounting slots

(including 45mm panel thickness)

Mu l t i t r e n d G R Dimension details

Installation Instructions

• Minimum panel thickness = 2mm (0.078”), max = 20mm (0.78”)

• Alternate panel mounting available thickness = 45mm (1.77”)

• Both recorders must be inserted from the front of the panel,

• Two mounting clamps are supplied and can be fixed either on the top and bottom

sides or on the left and right sides of the case.

43-TV-25-41 Iss.4 GLO May 2015 UK 11

Page 20

Mechanical Installation

4 Mounting clamp positions. For standard units fit only two

brackets on opposite sides of the unit, either top an d bo tt om

or left and right slots. NEMA 4X rated recorders require all four

mounting brackets to be fitted.

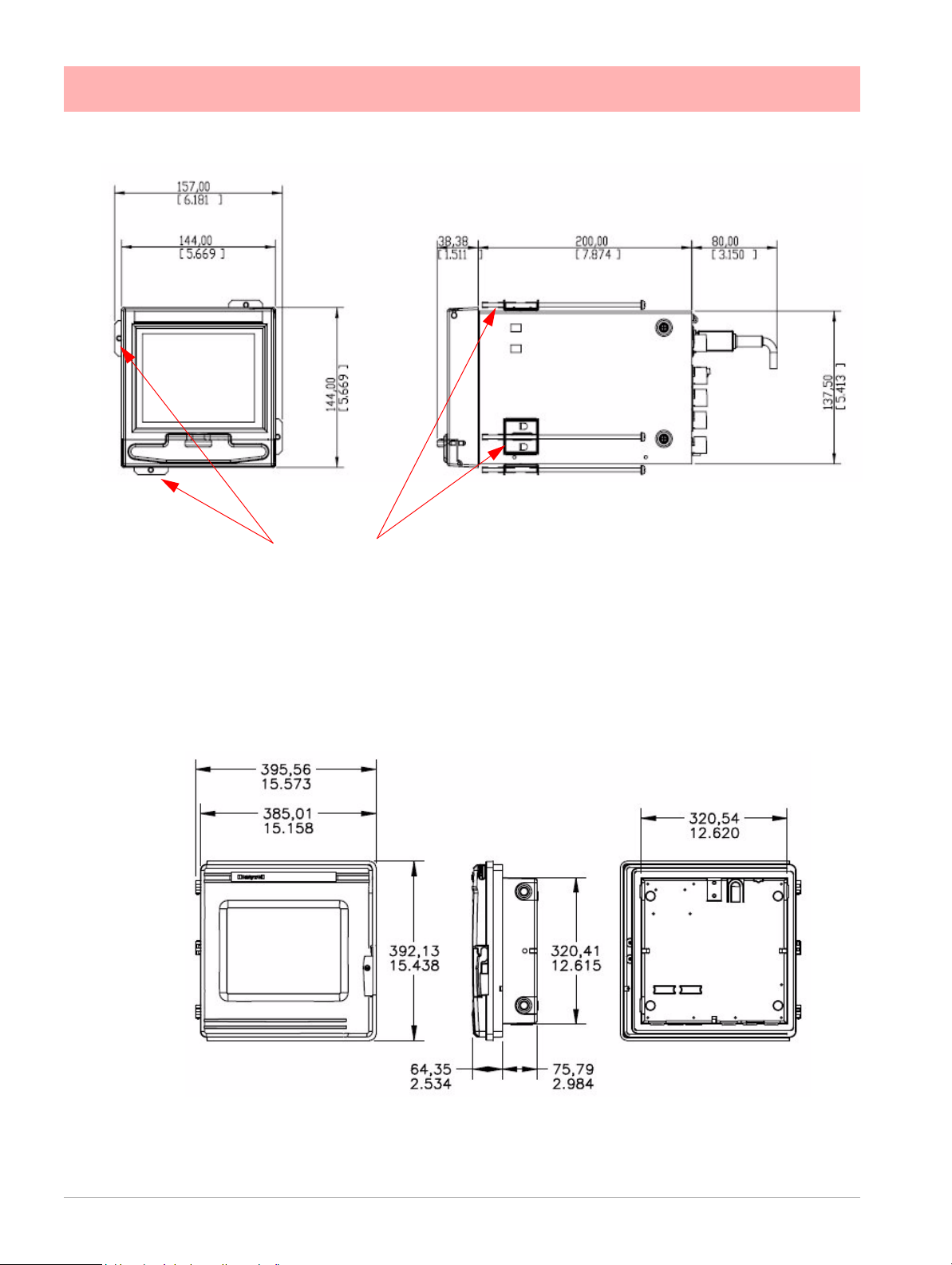

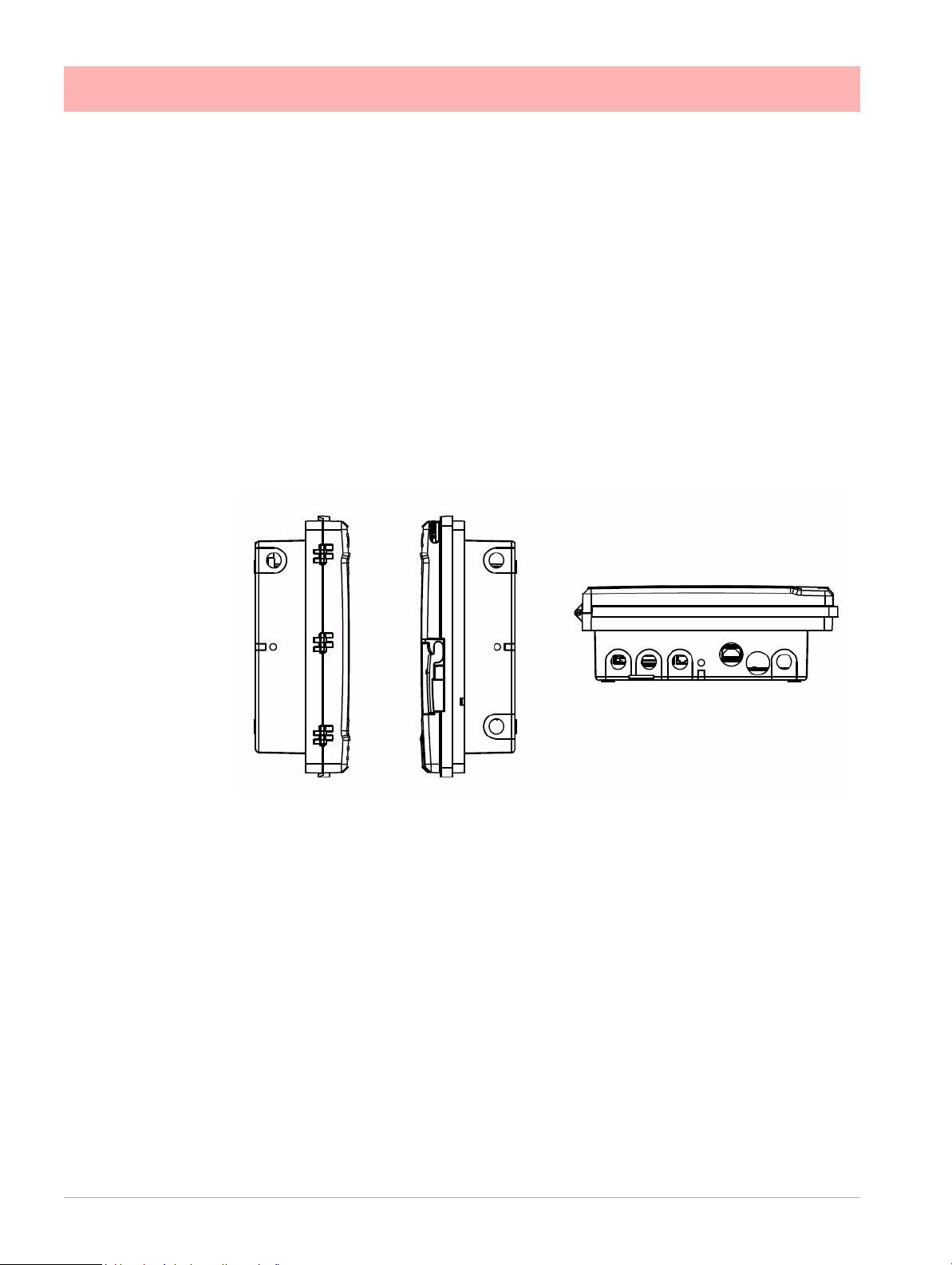

Figure 2.6 eZtrend GRrecorder dimensions

Figure 2.7 DR Graphic recorder dimensions

eZ t r e n d G R Dimension details

DR Graphic recorder Dimension details

12 43-TV-25-41 Iss.4 GLO May 2015 UK

Page 21

Mechanical Installation

CAUTION

CONTROL UNIT DAMAGE

Do not over tighten mounting clamp screws.

Minitrend GR

and eZtrend GR torque setting should be 0.5 - 0.75Nm/4.4 - 6.6lbf-in

Multitrend GR torque setting should be 0.5 - 0.70Nm/4.4 - 6.2lbf-in

Failure to comply with these instructions may result in product damage

Panel Mounting Clamp Installation

The Minitrend GR, Multitrend GR and the eZtrend recorders slide into the panel cut-

out and are held in place by two or four panel clamps (6 clamps for Minitrend GR recorder

with 45mm panel thickness). The panel clamps should be fitted on diagonally opposite sides

of the unit and tightened against the rear of the panel using two fixing screws.

The mounting clamp assembly and fitting instructions differ slightly for the two recorders.

Minitrend GR and eZtrend GR See Figure 2.6

1. Insert the panel gasket onto the recorder so it goes between the back of the

recorder bezel and the panel. From the front p anel, place u nit in the pa nel and

push through the panel.

2. To loosen each clamp, unscrew the long screw to accommodate the panel

thickness. Use either a Number 1 Phillips or Straight slot screw driver.

3. From behind the panel, the orientation of the clamp should be with the screw

head towards the rear of the unit.

4. Take the first clamp and locate the two lugs on the clamp into the slots on the

unit.

5. Take the second clamp and do the same but in the diagonal position to the

opposite side. Repeat for all other clamps.

6. Tighten the screw using a Number 1 Phillips or Straight slot screw driver and

the clamp will secure against the panel.

Multitrend GR See Figure 2.7

1. Insert the panel gasket onto the recorder so it goes between the back of the

recorder bezel and the panel. From the front p anel, place u nit in the pa nel and

push through the panel.

2. To loosen each clamp, unscrew the long screw to accommodate the panel

thickness. Use either a Number 1 Phillips or Straight slot screw driver.

3. From behind the panel, the orientation of the clamp should be with the screw

head towards the rear of the unit.

4. Position the circular mounting boss in the hole on one side of the case with the

lip of the boss inside the case. Ensure the front of the clamp is up against the

43-TV-25-41 Iss.4 GLO May 2015 UK 13

panel.

5. Fix the second clamp on the opposite side of the unit.

6. Tighten the screw using a Number 1 Phillips or Straight slot screw driver and

the clamp will secure against the panel.

Page 22

Mechanical Installation

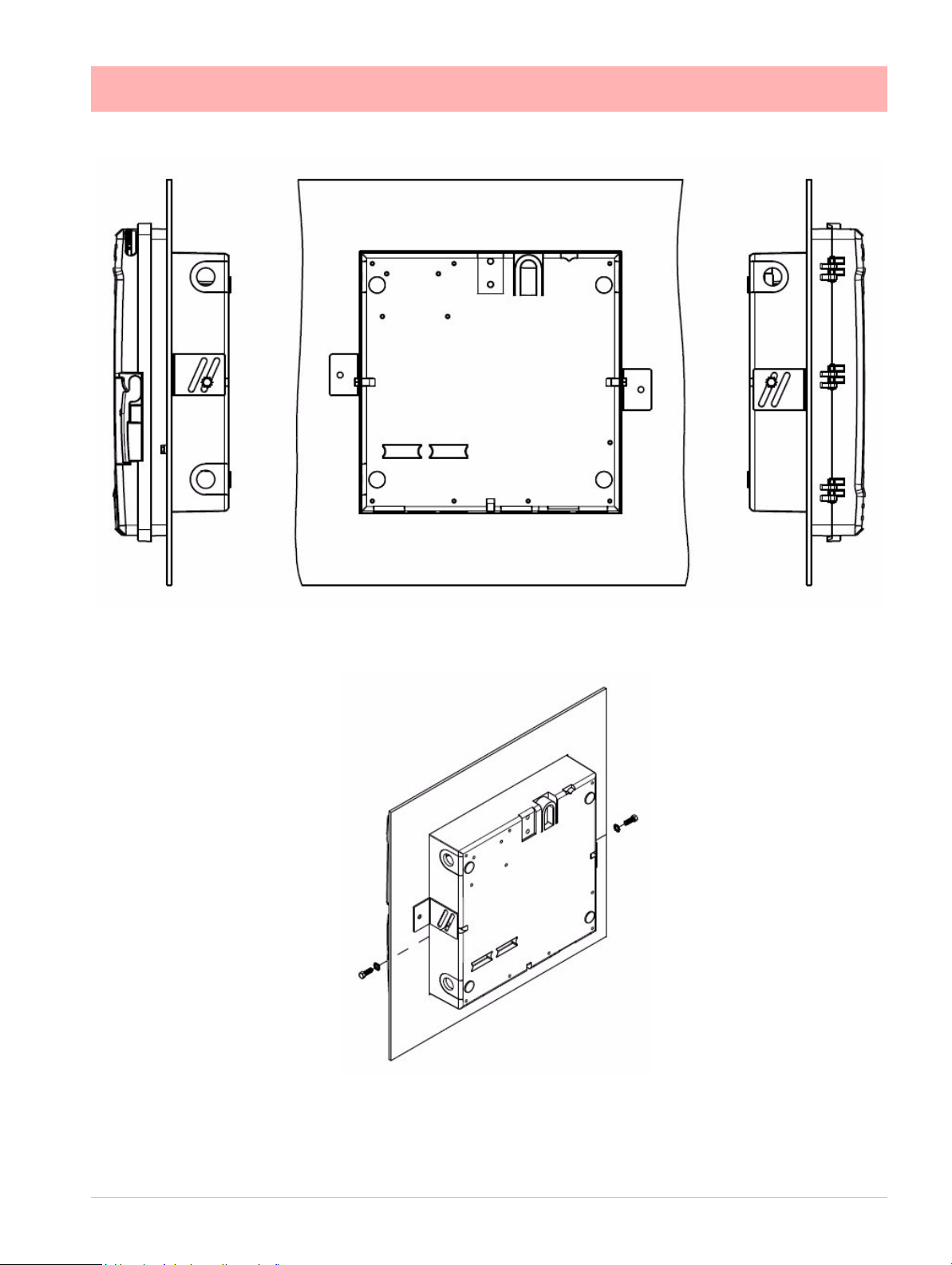

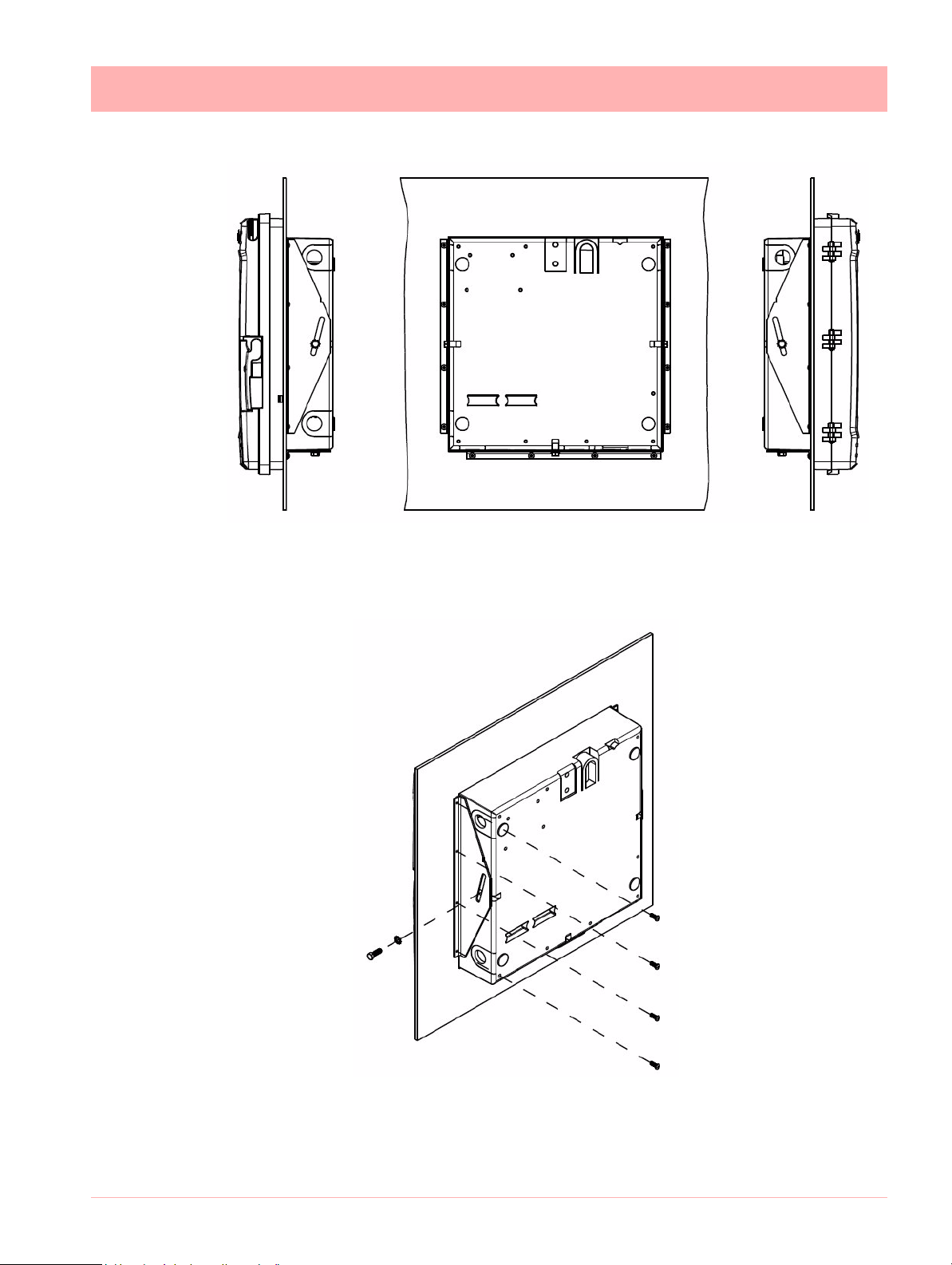

Figure 2.8 DR Graphic recorder dimensions

DR Graphic recorder See Figure 2.8

This section provides instructions for mounting the DR Graphic recorder using one of the

following methods:

• Flush in a panel

• Flush in a panel for recorders with NEMA 4

• On the surface of a wall for panel

Choose the method that meets your mounting requirements. use the associated dimension

drawings for reference.

How to remove knockouts for conduits

Before you mount the recorder, remove the appropriate plugs in the bottom and/or sides of

the recorder case for wire entry via 1/2" (12.7 mm) conduits. Refer to Figure 2.8 for plug

locations. To see recommended use of conduits for various types of wiring, refer to Figure

2.12 and Figure 2.13.

Mounting Flush in panel (new cut-out)

Procedure

1. At the appropriate location, make a square cutout in the panel. Cutout dimensions

should be 12.7 ±0.060 inches by 12.7 ±0.060 inches (322.56 ±1.52 by 322.56 ±1.52

millimeters).

2. Orient the recorder case properly and slide it into the cutout from the front of the panel.

Support the recorder as shown in Steps 3 and 4.

3. Refer to

side of the recorder case using a 1/4-20 x 1/2 inch hex screw for each bracket (mounting hardware supplied with recorder). Leave the screws slightly loose so you can adjust

the brackets.

4. While holding the recorder firmly against the panel, slide each bracket against the back

of the panel and tighten the screws.

14 43-TV-25-41 Iss.4 GLO May 2015 UK

See Figure 2.9.

Figure 2.9. From the back of the panel, attach a mounting bracket to each

Page 23

Mechanical Installation

Figure 2.9 Flush Mounting in a panel cutout

NOTE: Mounting brackets and attaching hardware are included in kit 30755065-501

43-TV-25-41 Iss.4 GLO May 2015 UK 15

Page 24

Mechanical Installation

2 mounting clamp

positions required on

two opposite sides of

the recorder. Nema 4X

requires all 4 clamps to

be fitted.

Mounting clamp slots

Figure 2.10 Minitrend GR Mounting Clamps

4 mounting clamp

positions (2 shown).

2 clamps are required on opposite

sides of the recorder

Figure 2.11 Multitrend GR Mounting Clamps

Mounting Clamp Diagram

16 43-TV-25-41 Iss.4 GLO May 2015 UK

Page 25

Mechanical Installation

Figure 2.12 Minitrend GR 45mm Mounting Clamps

6 mounting clamp positions

(3 shown) for mounting in 45mm

panel thickness. Mounting slots

shown in Figure 2.4 . Only 2

mountimg brackets need to be

fixed, in opposite positions.

Figure 2.13 Multitrend GR - 45mm

Mounting Clamps

4 mounting clamp positions (1 shown)

for mounting in 45mm panel thickness

on opposite sides of the unit. Mounting

slots shown in Figure 2.4 Both mounting clamps are required to be fitted

Mounting Clamp Diagram for 45mm panel thickness

43-TV-25-41 Iss.4 GLO May 2015 UK 17

Page 26

Mechanical Installation

Panel mounting recorder with NEMA4

Refer to Figure 2.14 and follow the procedure below to panel mount your re co rder if it ha s

a NEMA4.

1. Place the panel gasket onto the rear flange of the recorder case.

2. Install four #8-32 screws on each of the three mounting brackets so the ends of the

screw threads are flush with the face of the bracket.

NOTE: Screw heads to be flange side of brackets.

3. Insert the case with gasket into the panel opening.

4. Install one left hand and one right hand bracket with 1/4 x 3/8 long bolts and lockwashers on each side of the case.

NOTE: The notch on each bracket should be facing upward towards the top of the unit.

Do not tighten the hex bolts at this time.

5. Install the remaining right hand bracket on the top with the 1/4 x 3/4 long bolt and lockwasher. Do not tighten the bolt at this time.

6. Place a screwdriver blade on the notch of each bracket and firmly tap so that each

bracket firmly mates the case with gasket to the panel.

NOTE: Keep brackets parallel to case. Tighten the three 1/4 hex bolts to hold the brackets in place.

7. Start to tighten the #8-32 x 1/2 screws on the right side bracket. Alternate screws at

opposite ends until all four screws have a minimum of 10 lb-in of torque applied. Do the

same to both the left side and top brackets.

When completed all twelve screws should have a minimum of 10 lb-in of torque

applied. This assures the case and panel gasket are adequately sealed against the

panel.

18 43-TV-25-41 Iss.4 GLO May 2015 UK

Page 27

Mechanical Installation

Figure 2.14 Panel Mounting with NEMA4

43-TV-25-41 Iss.4 GLO May 2015 UK 19

Page 28

Mechanical Installation

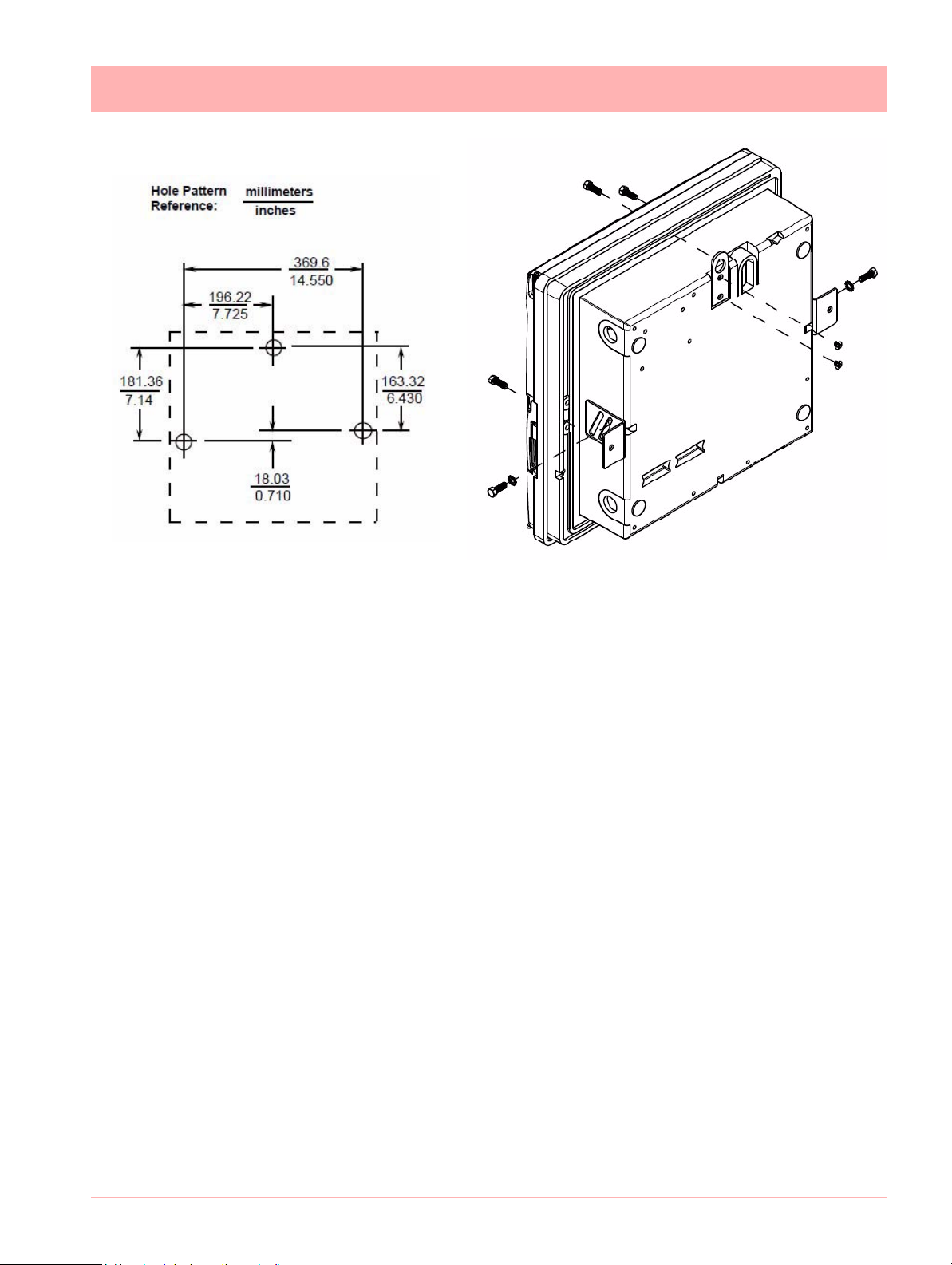

Mounting on Surface of panel or wall

Procedure

Refer to Figure 2-15 and follow the procedure below to mount your recorder on a surface

(panel or wall).

NOTE: Three (3) screws must be supplied by the user for attaching the mounting hardware

(brackets and support hook) to panel or wall.

Using two flat-head 10-32 x 1/4-inch screws supplied with the recorder, fasten the su pport

hook into the recess at the back of the recorder case as shown in Figure 2-15.

1. Using 1/4-20 x 1/2-inch hex screws and lockwashers, attach a mounting bracket to

each side of the case. Leave the screws slightly loose so as to permit some adjustments of the brackets.

2. On the panel, mark the locations for the three holes, as shown by the hole pattern in

Figure 2-15.

3. Using a drill of appropriate size for user-supplied screws, drill a hole in the front of the

panel for the eye of the support hook.

4. Insert the screws for the support hook into the panel, allowing the screw head to protrude approximately 5/16-inch.

5. Hang the recorder support hook on the screw. Make sure that the locations for the other

two holes (marked in Step 3) are correct. If not, make sure that the recorder is aligned

vertically, and use the brackets as templates to mark the proper locations.

6. Remove the recorder from the panel and drill the other two holes.

7. Hang the recorder on the screw by the support hook and insert the other two user-supplied screws through the brackets into the panel. Tighten the two hex screws that

attach the brackets to the case.

20 43-TV-25-41 Iss.4 GLO May 2015 UK

Page 29

Mechanical Installation

Figure 2.15 Surface Mount on wall or panel

43-TV-25-41 Iss.4 GLO May 2015 UK 21

Page 30

Electrical Installation

WARNING

ENSURE SAFETY EARTH CONNECTION

Always ensure the unit is connected to safety earth when connecting to an AC or DC

supply.

Failure to comply with these instructions could result in death or serious injury.

Installation Category

• Installation category - Installation category II, Pollution degree 2

• Follow National and local electrical codes for installation in a Class 1, Div.2 area.

For voltage, frequency and power refer to the appropriate Specification sheet: See “Sec-

tion 12: Technical Data & Specifications” on page 303.

Fuses

There is a fuse situated on the DC input version power supply, type 2A time-delay, this can

be replaced by the user. Replacement of fuse s sho u ld be car rie d ou t by qualified service

personnel.

If the fuse should blow again there is probably a problem elsewhere within the unit and the

recorder should be returned for inspection to your authorised Honeywell distributor or

Honeywell Service department.

Cables

Electrical Installation

To fully comply with the requirements of the CE Mark, all cables connected to the rear of

the unit should use screened cable terminated at both ends. A low impedance earth cable

(<50 m) must be connected to the earthing stud on the rear of the recorder, to ensure

that the recorder is always earthed.

Before performing any installation please read the section on “Safety” on page 2.and

“Warnings and Safety Precautions” on page 3.

All connections to the unit are made via the rear panel, the layout of which is shown in

page 24

Note: The eZtrend GR

to the recorder case using a low impedance bond. Also avoid use of a length of wire between

the cable screen and the recorder case.

Analogue Input card (Slot A). Cable screen must be well conne c te d

Signal Wiring

Your recorder is intended fo r panel- mou nt use, and on ly the fron t face is inte nded to be

exposed to the operator. Disconnection from the supply MUST be made possible by

means of a switch, circuit breaker or other means of supply isolation.

The disconnection device must be included in the panel installation, clearly marked, in

close proximity to the recorder, and within easy reach of the operator. The protective earth

22 43-TV-25-41 Iss.4 GLO May 2015 UK

terminal must remain connected (even if the recorder is isolated from the mains supply) if

any of the analogue or relay terminals are connected to hazardous voltage.

Page 31

AC Power

CAUTION

UNIT DAMAGE CONTROL

To protect against component failures the user should fit an external fuse for the DC

input power supply. The value should be 4A, time delay, high breaking capacity, minimum 60Vdc.rated.

Failure to comply with these instructions may result in product damage

WARNING

HAZARDOUS VOLTAGES

When using the recorder as portable equipment the optional rear cover must be fitted

when hazardous voltages are connected.

Failure to comply with these instructions could result in death or serious injury.

Electrical Installation

AC supply is connected via the standard configuration IEC chassis plug on the power supply, 100 - 240 Vac, 50-60 Hz (40W Minitrend GR, eZtrend GR and 50VA DR Graphic

and 60W Multitrend GR). Absolute limits 90V-132Vac (110V) and 180V-264Vac (240V).

AC/DC Power Suppy

For the Minitrend GR the supply range is 12-30V DC (absolute limits are 12V to 30V DC).

The DR Graphic and Multitrend GR the supply range is 24V DC +/- 10% (absolute limits

are 20V to 55V DC), the AC range is 20 to 30V AC. The Minitrend GR and the eZtrend

GR also has an 18V option with supply range 12VDC -30VDC / 12VAC -20VAC.

DC power rating are as follws Minitrend GR and eZtrend GR: 40W, Multitrend GR:

60W, DR Graphic: 40W.

Power to the D.C.variant is connected via a rectangular 3-way connector as identified in

page 24 for the Minitrend GR and page 24 for the Multitrend GR and page 26 for

the DR Graphic.

Note: Inrush Current = 75A max(High Line, Cold Start) for all recorders.

43-TV-25-41 Iss.4 GLO May 2015 UK 23

Page 32

Electrical Installation

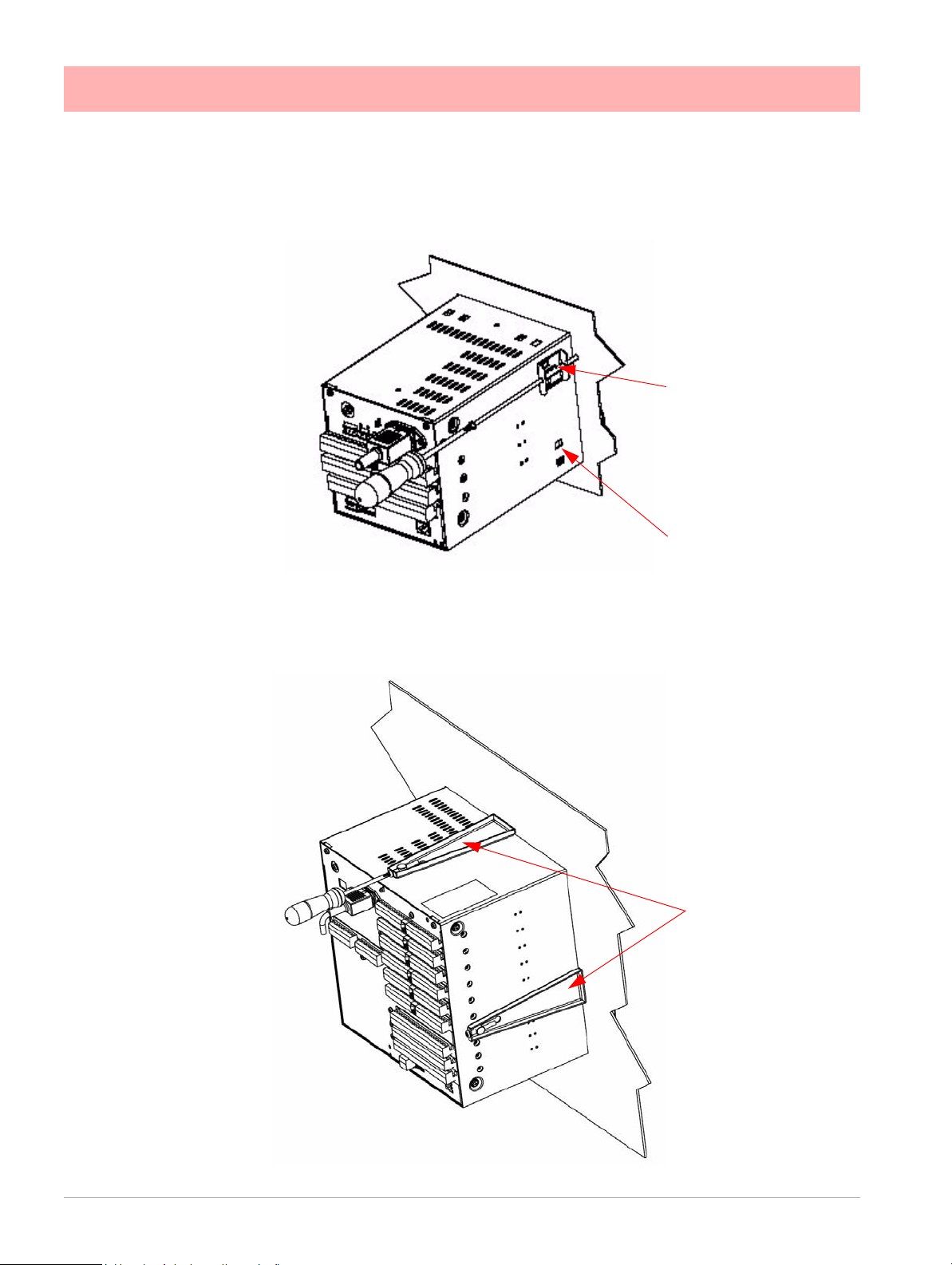

Figure 2.10 Minitr end GR Rear panel

SPNC Relay

Earth screw (ground)

24V TX Power

Supply Output

AC supply

100 - 250 VAC

Analogue Input /

Analogue Output

/ or Pulse Input

Slot A

Slot B

Alarm Relay or

Digital I/O

Slot G

CJC Sensor

24V DC/AC Input

USB Host

Ethernet

Wire seal provision

RS485

Earth screw

(ground)

24V DC/AC Input

SPNC

Relay

24V TX

Power Supply

Output LED

AC supply

100 - 240 VAC

Analogue Input/

Analogue Output/

or Pulse Input

Slot A

Slot B

Slot C

Slot D

Slot E

Slot F

Alarm Relay

or

Digital I/O

Slot G

Slot H

Slot I

Ethernet

USB Host

Figure 2.11 Multitrend GR Rear panel

CJC Sensor

position in the

middle of the

Analogue Input

connector.

Slots A - F

RS485

Wire Seal

24 43-TV-25-41 Iss.4 GLO May 2015 UK

Page 33

Electrical Installation

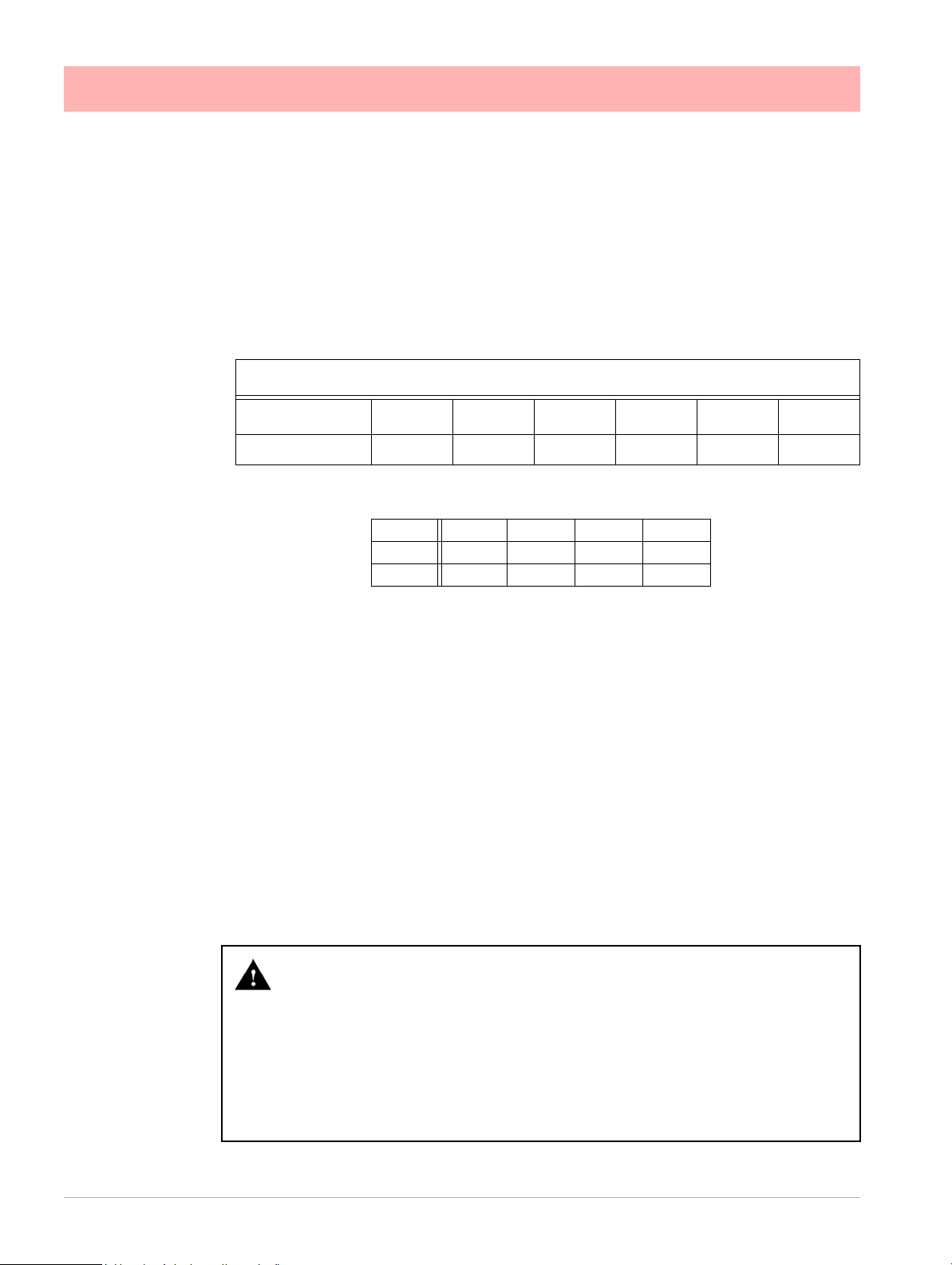

Card and Slot positions

Table 2.1 : Card priority positions

Cards

Analogue Input card A, B A, B, C, D, E, F A*, B (option) A, B

Analogue Output card B E, F - B

Pulse Input card A, B A, B, C, D, E, F - A, B

Alarm Relay or Digital I/O

card

Minitrend GRMultitrend

GR

G G, H, I G B

eZtrend

GR

DR Graphic

43-TV-25-41 Iss.4 GLO May 2015 UK 25

Page 34

Electrical Installation

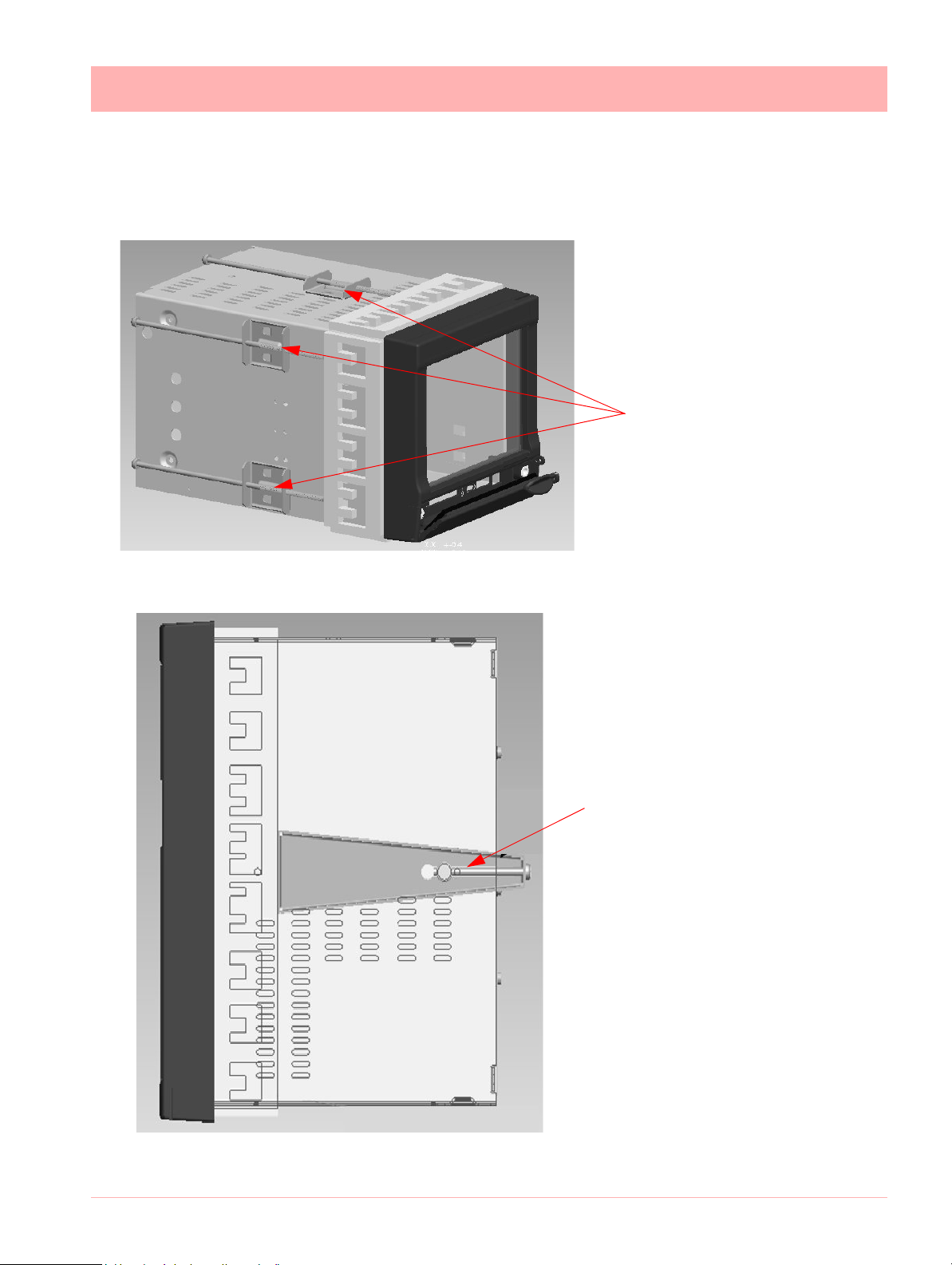

Figure 2.12 DR Graphic slot positions and connections

DR Graphic card positions

26 43-TV-25-41 Iss.4 GLO May 2015 UK

Page 35

Electrical Installation

Figure 2.13 DR Graphic Electrical connections

DR Graphic cards; selection jumper table

Table 2.2 :

AI/AO/Pulse J8 & J9: Link 1 & 2

Slot B

Alarm/DI/DO J8 & J9: Link 2 & 3

NOTE: Do not disturb J4 & J5 jumpers in positions 1 & 2 for Slot A. These are for future

provision.

43-TV-25-41 Iss.4 GLO May 2015 UK 27

Page 36

Electrical Installation

Earth screw

(ground)

12 to 30VDC / 12

to 20VAC Input

Instrument power

(option)

24V TX Power

Supply Output

AC supply

100 - 240 VAC

Analogue Input

card (option)

Slot B

Alarm Relay or

Digital I/O

Slot G (option)

Wire seal provision

CJC Sensor

(not shown)

Analogue Input /

Ethernet connection

card (std) - Slot A

ETHERNET

Figure 2.14 eZtren d GR Rear panel

SPNC Relay

28 43-TV-25-41 Iss.4 GLO May 2015 UK

Page 37

Electrical Installation

WARNING

HAZARDOUS VOLTAGES

Insulation from channel to channel: Normally a cha nnel can b e safe ly conn ected to a

hazardous voltage up to 300V AC common mode* with respect to earth. However,

where a channel is connected to a safety low voltage circuit, an immediately adjacent

channel must be adequately insulated from hazardous voltages between 150V AC

and 300V AC max. This insulation should comprise of at least 1.5mm air gap, or a barrier rated greater than 1400V AC. This is to ensure that protection of the safety low

voltage circuit is fully maintained.

*Common Mode voltage is a voltage applied between the whole channel and earth,

not between pins on a channel. 300V AC is permitted at Measurement Category CAT

ll (Overvoltage Category ll)

Failure to comply with these instructions could result in death or serious injury .

NOTICE

For 12 and 24-way connectors; torque setting 0.4 Nm/3.5lbf-in. Do not over tighten.

Recommended wire size for termination connector is 22-12 AWG (American Wire

gauge) equivalent to 22-14 SWG (Standard Wire Gauge). AWG metric 0.6426-

2.052mm in diameter or SWG metric 0.71 - 2.03mm in diameter.

Analogue Input Card

Each Analogue Input card has up to 8 input channels for the Minitrend GR and the Multitrend GR and up to 6 channels for the eZtrend GR. Connections are made via 2 x 12-

way screw terminal plugs that fit into a PCB header on the rear of the unit. The 2-way CJC

sensor should remain fitted in the central 2-way header.

The Minitrend GR

(2 x 8 channel cards). The slot positions are A & B, these are identified on the rear panel on

the back of the unit. Either slot can be used, it is recommended that slot A is used if only one

card is fitted.

The Multitrend GR can have up to 6 analogu e input cards fitted, up to 48 input channels.

The slot positions A, B, C, D, E or F; these are identified on the rear panel. PC boards are

fitted in order, slot ”A” starts from the top.

can have two analogue input cards fitted giving up to 16 input channels

The eZtrend GR

providing up to 6 more channels. This card would be used after using the 3 or 6 channel

standard eZtrend GR

alogue Input (Standar d) card” on p age 32.The DR Graphic Recorders can have two

analogue input cards fitted giving up to 16 input channels (2 x 8 channel cards). The slot

positions are A & B, these are identified on the IO card chassis inside the unit. Either slot

can be used, it is recommended that slot A is used if only one card is fitted.

Ensure to connect the jumpers on DR Graphic backplane card as per DR Graphic Cards

Selection Jumper Table on page 27 before installing the AI cards. See “eZtrend GR An-

alogue Input (Standard) card” on page 32.

To fit this option card into the eZtrend GR recorder you will require an expansion card to

interface to the recorder.

can use this card as an additional Analogue Input card fitted in Slot B,

Analogue Input card which is fitted in Slot A, see “eZtrend GR An-

43-TV-25-41 Iss.4 GLO May 2015 UK 29

Page 38

Electrical Installation

CAUTION

CONTROL UNIT DAMAGE

Do not apply a hazardous live voltage between + and - pins within a channel. ( eg. 60V

maximum on voltage ranges, 5V maximum on millivolts ranges). Do not apply a voltage

above 1.2V to the * pin.

Failure to comply with these instructions may result in product damage

Rear Covers

Optional rear covers are available for these products (except for the DR Graphic recoder

which does not require a rear cover) and it is recommended to use the rear cover to

protect the wiring and to minimize external effects that could impact the performance of the

CJC. For the rear cover part number, see “Section 10: Spares List” on page 281.

Analogue Input Channel Numbers

Analogue Input cards are either 4, 6 or 8 channels with a full length connector taking up 8

channels even if only 4 or 6 are operational.

Table 2.3 :

Minitrend GR Multitrend GR and DR Graphic Analogue Input card

Card Position

Channel number 1 to 8 9 to 16 17 to 24 25 to 32 33 to 40 41 to 48

Slot A Slot B Slot C Slot D Slot E Slot F

Table 2.4 :

Card 3 CH. 6 CH. 9 CH. 12 CH.

A 1-3 1-6 1-3 1-6

B 9-14 9-14

eZtrend GR Analogue Input cards

Analogue Input Connection Details

Current Input

For Current (mA) Input fit a 10

analogue connector. Figure 2.15 shows a 10

current (mA) input.

Ensure polarity of thermocouple is correct.

Thermocouples

resistor across the + and - pins of the 12-way mating half

(±0.1%) resistor fitted to channel 5 for a

Resistance Thermometers

If using 2 wire R/T the + and - terminals must be linked together. See “Figure 2.16 Input

signal wiring” on page 31..

Analogue Input Signal Wiring

30 43-TV-25-41 Iss.4 GLO May 2015 UK

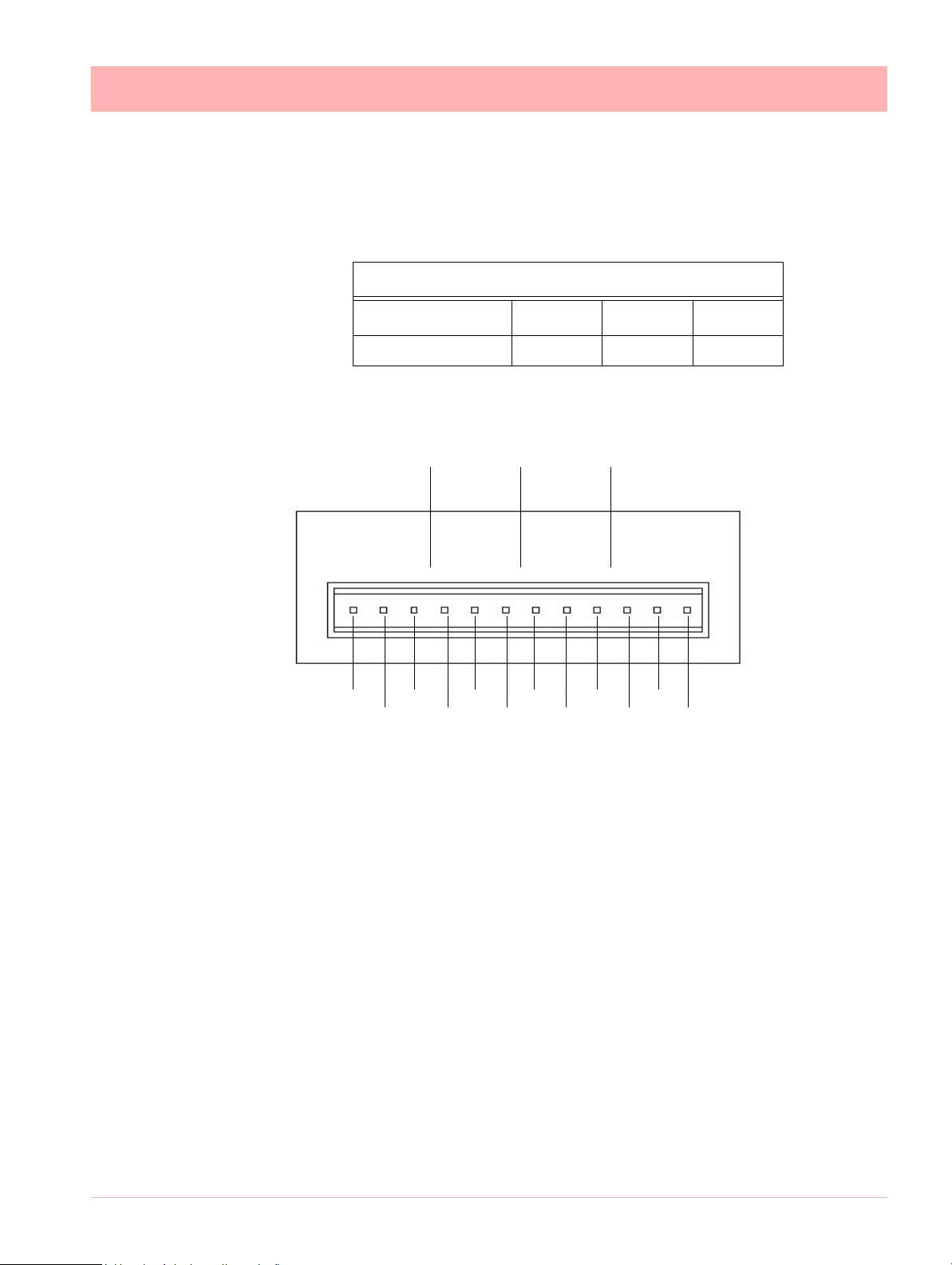

Page 39

Electrical Installation

CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8

CJC

Figure 2.15 Analogue Input connector

-ve

+ve

Current

10R

Ohms

R/T

R/T

2-wire R/T

3-wire R/T

-ve +ve

Figure 2.16 Input signal wiring

Passive Burnout

Thermocouples

Volts/mV

-ve +ve

-ve

+ve

Active Burnout

Thermocouples

R/T

4-wire R/T

This Analogue Input card can be used as an option to add up to 6 more Analogue Input

channels for the eZtrend GR

numbers 9 to 14. The standard fit Analogue Input card is fitted in slot A with up to 6 channels

(channels numbers 1 to 6).

To fit this option card into the eZtrend GR recorder you will require an expansion card to

interface to the recorder.

recorder. This will fit into Slot B and will display as channel

43-TV-25-41 Iss.4 GLO May 2015 UK 31

Recorder setup will be required if wiring changes are made for Active Burnout Thermocouples. See “*Thermocouple Wiring Changes.” on page 76.

Page 40

Electrical Installation

1 2 3 4 5 6 7 8 9 10 11 12

13 14 15 16 17 18

- +

*

- +

*

- +

*

- +

*

- +

*

- +

*

CH.1 CH.2 CH.3 CH.4 CH.5 CH.6

Figure 2.17 eZtrend GR Analogue Input card (std) - Slot A

Thermocouple Active Burnout status can be viewed in the Main Menu > Status >Diagnostics

> Analogue Input screen, Input column. The Health Watch/Maintenance firmware option

must be active to access the Maintenance and Diagnostic buttons. See “Diagnostics” on

page 200.

For the eZtrend GR

link between positive (+) and negative (-).

recorder Active Burnout is not available. Ohms measurements must have the

CJC Connectors

The CJC connector resides between channel 4 and channel 5 on the Analogue Input card.

For information on connecting the CJC sensor, see “Figure 2.15 Analogue Input connec-

tor” on page 31.

For the

eZtrend GR recorder this is available on the Analogue Input card (option).

e Ztrend GR Analogue Input (Standard) card

The eZtrend GR is fitted with a standar d Ana logue Inpu t card in Slot A, with up to 6 channels. The card is also fitted with an Ethernet port as standard. Connection is made via 1 x

18-way screw terminal plugs that fit into a PCB header on the rear of the unit. To fit up to a

further 6 analogue input channels, see “Analogue Input Card” on page 29

32 43-TV-25-41 Iss.4 GLO May 2015 UK

Page 41

Electrical Installation

WARNING

HAZARDOUS VOLTAGES

Insulation from channel to channel: Normally a channel can be safely connected to a

hazardous voltage up to 150V AC common mode* with respect to earth. However,

where a channel is connected to a safety low voltage circuit (i.e. is accessible for operators to touch), any channel within the same 'input bank' must be limited at all time s

to a maximum of 55Vac or 140Vdc**. This is to ensure that protection of the safety low

voltage circuit is fully maintained.

The inputs are divided into two banks: inputs 1 to 3 are one bank, and inputs 4 to 6 (if

fitted) are another bank. A voltage of up to 150V AC common mode can be applied on

one bank as long as any safety low voltage circuits are on the other bank. The recorder

is protected against accidental connection of a voltage up to 240V AC common mo de

which might occur as a temporary fault condition, provided there are no safety low voltage circuits connected to the same input bank as the channel with the fault.

*Common Mode voltage is a voltage applied between the whole channel and earth,

not between pins on a channel.

** this reduces to 33Vrms or 70Vdc if any channel within the input bank is configured

as an ohms or R/T measurement.

Failure to comply with these instructions could result in death or serious injury .

CAUTION

CONTROL UNIT DAMAGE

Do not apply a hazardous live voltage between + and - pins within a channel (e.g . 60V

maximum on voltage ranges, 5V maximum on millivolts ranges).

The * pin should be connected only as part of ohms or R/T me asurements. Ohm s and

R/T measurements share a common connection (* pin) with all channels in the same

bank (the inputs are divided into two banks: inputs 1 to 3 are one bank, and inputs 4 to

6, if fitted, are another bank). To avoid damage, ensure t hat a channel selected as ohms

or R/T remains floating, i.e. the sensor is not connected to any external voltage.

Alternatively, if an ohms or R/T sensor must be biased to an external voltage, ensure

that the other two channels within the same input bank a re floating or are biased to the

same voltage (i.e. - inputs of all three channels connected to the same voltage).

Failure to comply with these instructions may result in product damage

43-TV-25-41 Iss.4 GLO May 2015 UK 33

Analogue Output Card

Not available on the eZtrend GR recorder.

The Analogue Output card connections are made via 1 x 12- way screw termi nal plu g that

fits into a PCB header on the rear of the unit.

The Analogue Output card position for the Minitrend GR, Multitrend GR and DR

Graphic shown in Table 2.1 on page 25.

Page 42

Electrical Installation

WARNING

HAZARDOUS VOLTAGES

Insulation from channel to channel: Normally a channel can be safely connected to a

hazardous voltage up to 300V AC common mode* with respect to earth. However,

where a channel is connected to a safety low voltage circuit, an immediately adjacent

channel must be adequately insulated from hazardous voltages betwe en 150V AC and

300V AC max. This insulation should comprise of at least 1.5mm air gap, or a barrier

rated greater than 1400V AC. This is to ensure that protectio n of the safety low voltage

circuit is fully maintained.

*Common Mode voltage is a voltage applied between the whole channel and earth, not

between pins on a channel. 300V AC is permitted at Measurement Category CAT ll

(Overvoltage Category ll)

Failure to comply with these instructions could result in death or serious injury.

34 43-TV-25-41 Iss.4 GLO May 2015 UK

Page 43

Electrical Installation

Output 1 Output 2 Output 3

Output 4

Loop -

Loop +NCLoop -

Loop +

NC

Loop -

Loop +NCLoop -

Loop +

NC

1 2 3 4 5 6 7 8 9 10 11 12

NC = Not

connected

Analogue Output Channel Numbers

The Analogue Output cards are either 2 or 4 channels using a connector that only ta kes up

half the length of the connector slot. Looki ng from the rear o f the unit the An alogue Out connector is on the left of the Analogue slot with a blanking plate on the right.

Table 2.5 :

Analogue Output card

Card Position

Channel number 9 to 12 33 to 36 41 to 44

Slot B Slot E Slot F

Analogue Output Connection Details

Pulse Input Card

The Pulse Input card connections are made via 1 x 12-way screw terminal plugs that fits

into a PCB header on the rear of the unit.

The Pulse Input card position for the Minitrend GR

Graphic are shown in Table 2.1 on page 25

The Pulse Input card is not available on the eZtrend GR

option card has 4 channels that can be set as pulse inputs (channels 1 to 4). T he operating

frequency for pulse inputs on the Digital I/O card is 1kHz max.

Input: Low < 1V, High >4V to <50V DC (8V to 50V p-p AC) or Volt free input: Low = short

circuit, High = open circuit.

43-TV-25-41 Iss.4 GLO May 2015 UK 35

and for the Multitrend GR and DR

recorder, however, the 8 Digital I/O

Page 44

Electrical Installation

WARNING

HAZARDOUS VOLTAGES

Insulation from channel to channel: Normally a channel can be safely conne cted to a

hazardous voltage up to 300V AC common mode* with respect to earth. However,

where a channel is connected to a safety low voltage circuit, an immediately adjacent

channel must be adequately insulated from hazardous voltages between 150V AC

and 300V AC max. This insulation should comprise of at least 1.5mm air gap, or a barrier rated greater than 1400V AC. This is to ensure that protection of the safety low

voltage circuit is fully maintained.

*Common Mode” voltage is a voltage applied between the whole channel and earth,

not between pins on a channel. 300V AC is permitted at Measurement Category CAT

ll (Overvoltage Category ll)

Failure to comply with these instructions could result in death or serious injury.

- + NC - + NC - + NC - + NC

Channel 1 Channel 2 Channel 3 Channel 4

Pulse Input Channel Numbers

The Pulse Input card has channels using a connector that only takes up half the length of

the connector slot. Looking from the rear of the unit the Pulse Inp ut connector is on the right

of the slot with a blanking plate on the left.

Table 2.6 :

Pulse Input card

Card Position

Channel number 1 to 4 9 to 12 17 to 20 25 to 28 33 to 36 41 to 44

Slot A Slot B Slot C Slot D Slot E Slot F

Pulse Input Connection Details

Do not connect anything to terminals marked NC (Not Connected). For Frequency and Voltage levels see “Specification Tables” on page 307.

36 43-TV-25-41 Iss.4 GLO May 2015 UK

Page 45

Electrical Installation

Minitrend 24V DC TXP

24V 0V

Figure 2.16 Transmitter Power Supply card for the Multitrend GR recorder

24V

0V

LED

Transmitter Power Supply Card

The Minitrend GRand the eZtrend GR Transmitter

power supply

power supply card within the unit. Connection is made via

a 2-way connector at the rear of the unit, the mating half

is supplied with this option. For connector position see

page 24. The 24V transmitter power supply is not isolat-

ed from the recorder, and is not referenced to ground.

The Multitrend GR

the power supply card within the unit. Connection is made via two 10-way connectors, see

page 24, mating halves supplied with this option. The Multitrend GR transmitter power

supply is isolated from the recorder.

A red LED light will illuminate when there is voltage on the connectors. The LED is situated

between the two connectors at the back of the unit. See page 24.

Recommended wire size for termination connector 22-12 AWG (22-14 SWG).

option is 24V DC 200 mA and is fitted to the

Transmitter power supply option is 24V DC 1 A and is fitted below

43-TV-25-41 Iss.4 GLO May 2015 UK 37

Page 46

Electrical Installation

WARNING

HAZARDOUS VOLTAGES

Digital Input/Output card channels must not be connected to any hazardous live voltages (no higher than 30V AC rms or 60V DC).

Alarm Relay Card channels

Alarm Relay Card channels can be connected to hazardous voltages up to 300V AC,

at Measurement Category CAT II (Overvoltage Category II)

Failure to comply with these instructions could result in death or serious injury.

NOTICE

For 12 and 16-way connectors; torque settin g 0. 4 Nm /3 .5lb - in. Do not over tigh te n.

Recommended wire size for termination connector is 22-12 AWG (22-14 SWG)

Alarm Relay Cards & Digital Input/Output Cards

The Alarm Relay Cards and the Digital Input/Output Cards are both options avai lable for

the Minitrend GR, Multitrend GR, eZtrend GR and the DR Graphic recorders.

To fit these option cards into the eZtrend GR recorder it requires an expansion card to interface to the recorder.

All Alarm Relay card outputs provide 240V AC isolation channel to chann el and channe l to

recorder. Digital Input/Outputs will provide isolation to 100V AC test voltage (not for mains

connection).

All digital inputs have volt free contacts, and are sampled at 10Hz max.

The Minitrend GR, eZtrend GR and the DR Graphic recorders have only one slot avail-

able for digital inputs and relay outputs for eith er a 4 or 8 channel Alarm Relay card or an 8

or 16 channel Digital I/O card fitted in slot G, the position is identified on the rear panel. The

16 channel Digital I/O card is not available on the eZtrend GR recorders.

The Multitrend GR can have up to three Alarm Relay cards fitted in any combination of

Alarm Relay card or Digital I/O cards. The first Alarm Relay card or Digital I/O card is fitted

in slot G, any additional cards will locate in positions H and I.

4 and 8 Alarm Relay Cards

The 24-way connector for the Alarm Relay Card, connects to 3 A, 240 VAC SPCO relays.

The pin-outs for 4 and 8 relay Alarm Relay cards are numbered from left to right and they

read as follows for each channel; NC (normally closed), C (c ommon) , NO ( nor mally ope n) .

Devices driven by the relays are connected via two 12-way screw terminal plugs.

The last two channels, 7&8, 23&24 or 39&40, can be used as digital inputs, conn ect across

Common (C) and Normally Open (NO).

38 43-TV-25-41 Iss.4 GLO May 2015 UK

Page 47

Electrical Installation

CAUTION

IMPROPER MAINS SWITCHING

For 8 channel Alarm Relay cards.

Switching mains on the normally-open contact on channe ls 7 and 8 is not recommended,

as surges and spikes on the mains supply could cause damage to the input circuitry.

The normally-closed contact is unaffected, and can be used like all the other channels.

A Form C dry contact relay is used for this type of card. The inputs are designed to accept

“Dry contact, no volt inputs”. The relays should be used for non-inductive loads only where

a device requires a voltage to operate it, such as a 12 Volt buzzer, connect it to the normally

open (NO) contacts (unless the fail-safe setting is activated).

The maximum voltage which may be used with the alarm relays is 240V

Alarm Relay Channel Numbers

The Alarm Relay cards are either 4 or 8 channels with a full length connector taking up 8

channels even though the cards only operate on 4 channe ls or 8 channe ls. The 8 channels

Alarm Relay card has 2 digital inputs available on the last 2 channels. There are no Digital

Inputs available on the 4 channels Alarm Relay card.

Table 2.7 :

Alarm Relay card 4 channel Alarm Relay card 8 channel

Card

position

Slot G 1 to 4 N/A Slot G 1 to 8 7 & 8

Slot H 17 to 20 N/A Slot H 17 to 24 23 & 24

Slot I 33 to 36 N/A Slot I 33 to 40 39 & 40

Channel

number

Digital

Inputs

Card

position

Channel

number

Digital

Inputs

DR Graphic recorders alarm card slot position and channel number mapping

Table 2.8 :

Alarm Relay card 8

Card position Channel number Digital Input s

Slot B 1 to 8 7 & 8

43-TV-25-41 Iss.4 GLO May 2015 UK 39

Page 48

Electrical Installation