Page 1

USA

CAN

MEX

D

03251549

USA CAN MEX

➔ www.docuthek.com

Operating instructions

Pressure switches for gas DG..T

© 2018 Elster GmbH · Edition 09.18

Cert. version 05.18

Translation from the German

Safety

Please read and keep in a safe place

Please read through these instructions

carefully before installing or operating. Following the

installation, pass the instructions on to the operator. This unit must be installed and commissioned

in accordance with the regulations and standards

in force. These instructions can also be found at

www.docuthek.com.

Explanation of symbols

• , 1 , 2 , 3 ... = Action

▷ = Instruction

Liability

We will not be held liable for damage resulting from

non-observance of the instructions and non-compliant use.

Safety instructions

Information that is relevant for safety is indicated in

the instructions as follows:

DANGER

Indicates potentially fatal situations.

WARNING

Indicates possible danger to life and limb.

CAUTION

Indicates possible material damage.

All interventions may only be carried out by qualified

gas technicians. Electrical interventions may only be

carried out by qualified electricians.

Conversion, spare parts

All technical changes are prohibited. Only use OEM

spare parts.

Checking the usage

Gas pressure switches DG..T for monitoring increasing and decreasing gas or air pressure.

DG..T,

DG..FT

DG..HT,

DG..NT

DG..ST NH

DG..NT and DG..HT lock off after switching. They

can be unlocked using the manual reset.

This function is only guaranteed when used within the

specified limits– see page5 (Technical data). Any

other use is considered as non-compliant.

Type code

Code Description

DG Gas pressure switch

6 – 500 Max. setting in mbar

F*

H*

N*

S*

T T-product

G With gold-plated contacts

-2

-4

-9

1

2

K2

T2

Red/green pilot LED for 110 to 230 V AC

N

A External adjustment

* If “none”, this specification is omitted; DG..T

switches with rising pressure.

Part designations

1 Upper housing section with cover

2 Lower housing section

3 Hand wheel

4 ½" NPT conduit coupling

5 Manual reset

(DG..NT and DG..HT only)

Positive

pressure

Gas, air, flue gas,

biogas

Gas, air, flue gas,

biogas

, O2, air –

3

Negative

pressure

Air, flue gas

Air, flue gas

Switches with falling pressure

Locks off with rising pressure

Locks off with falling pressure

Switches with rising and falling pressure;

for NH

, O2 (without approval)

3

Electrical connection

via screw terminals

via screw terminals, IP65

4-pin plug, with socket, IP65

1x ¼" NPT connection

2x ¼" NPT connections

Red/green pilot LED for 24 V DC/AC

Blue pilot lamp for 120 V AC

2

1

5

3

4

USA-1

Page 2

CAN

MEX

D

Type label

4

USA

Approval and type: see

DG T

type label.

CAUTION

If port 4 is at the top, IP65 will not be satisfied.

IP 65

For detailed information on the adjusting range, mean

switching differential, max. inlet pressure, lock-off,

medium and switching properties, see page 5

(Technical data) and the table on page 3 (Ad-

justment).

Installation

CAUTION

Please observe the following to ensure that the

DG..T is not damaged during installation and op

eration:

– Continuous operation with gases containing

more than 0.1%-by-vol. H2S or ozone concentrations exceeding 200µg/m3 accelerate

the ageing of elastomer materials and reduce

the service life.

– Use approved sealing material only.

– Dropping the device can cause permanent dam-

age. In this event, replace the entire device and

associated modules before use.

– Check max. ambient temperature – see

page5 (Technical data).

– When using silicone tubes, only use silicone

tubes which have been sufficiently cured.

– Vapours containing silicone can adversely affect

the functioning of electrical contacts.

– Condensation or vapours containing silicone

must not be allowed to get into the housing.

At subzero temperatures, malfunctions/failures

due to icing can occur.

– When installing outdoors, place the DG..T in

a roofed area and protect from direct sunlight

(even IP65 version).

– Avoid strong impact on the unit.

▷ Installation position as required, preferably with

vertical diaphragm. Then the switching point p

corresponds to the scale value SK set on the

hand wheel. In other installation positions, the

switching pointpS will change and no longer

correspond to the scale valueSK set on the

hand wheel. Check the switching point.

▷ The DG..T must not be in contact with masonry.

Minimum clearance 1" (25 mm).

▷ Ensure that there is sufficient installation space.

▷ Ensure unobstructed view of the hand wheel.

1 Disconnect the system from the electrical power

supply.

2 Shut off the gas supply.

3 Ensure that the pipeline is clean.

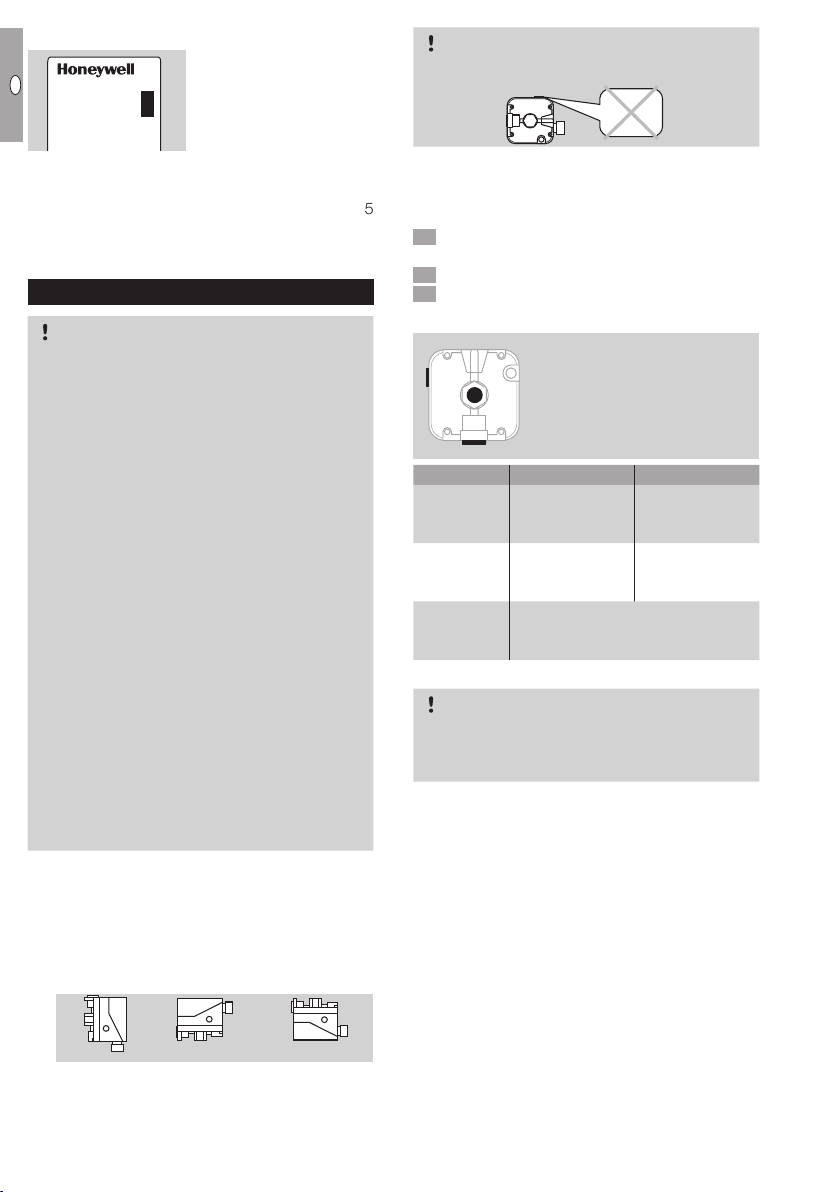

Ports

1 or 2 for

-

4

1

2 *

positive pressure (¼" NPT)

4 for

negative pressure (

Connect Free

Positive

pressure

1 or 2* 4

DG..T

Negative

pressure

4 1 or 2*

DG..T

Differential

pressure

DG..T

1 or 2* for higher absolute pressure.

4 for lower absolute pressure.

* Port 2 only on DG..T..2 with 2x ¼” NPT connections..

CAUTION

Port 4 connects the upper diaphragm chamber

with the micro switch. Do not connect port4 to

pipes carrying gas.

▷ The pressure switches are supplied with an inte-

grated vent limiter. In the event of a diaphragm

tear, the vent limiter limits the escape of gas

to less than 1.0 CFH of natural gas at 2.8psi

S

(DG..6T) or 7 psi (DG..10T – DG..500T). If necessary, port4 (1/8" NPT) can be used to connect

the venting line.

▷ A filter pad at port4 protects the electrical contacts

in the DG..T from dirt particles in the surrounding

air or in the medium.

▷ Filter pad for port4, see PartDetective.

1

/8" NPT)

ps = SK

ps =SK + 0,08 "WC ps = SK - 0,08 "WC

USA-2

Page 3

CAN

MEX

D

3 42

NO

NO

2

NC

1

COM

3

COM

3

NC

1

NO

2

Wiring

CAUTION

To ensure that the DG..T is not damaged during op-

eration, note the switching capacity, see page5

(Technical data).

▷ In the case of low switching capacities, such as

24V, 8mA, for example, we recommend using

an RCmodule (22 Ω, 1μF) in air containing

silicone or oil.

1 Disconnect the system from the electrical power

supply.

5

½" NPT Conduit:

ø 0.4" (10 mm)

2

NO

NC

1

3

COM

2

NO

1

NC

3

COM

½" NPT

▷

DG..FT, DG..NT: the NO-to-COM connection

is interrupted if the pressure drops (contacts 3

and 2 open).

DG..T, DG..HT: the NC-to-COM connection is

interrupted if the pressure rises (contacts 3 and

1 open).

Adjustment

▷

The switching point is adjustable via hand wheel.

1 Disconnect the system from the electrical power

supply.

2 Detach the housing cover.

▷

Tightening torques, see Technical Information

bulletin DG at www.docuthek.com.

3 Connect an ohmmeter.

NO

NC

COM

2

3

1

2

NC

1

3

COM

6 Apply pressure. In doing so, monitor the ohm-

Pressure switches without manual reset

(DG..T, DG..FT, DG..ST)

Pressure switches with manual reset

(DG..HT, DG..NT)

1)

* Adjusting tolerance = ±15% of the scale value.

** Difference between switching pressure and pos-

0

0.4" = 0.4"WC

(1 cm = 1 mbar)

meter and the pressure gauge.

Type

DG 6T

DG 10T

DG 50T

DG 150T

DG 500T

Adjusting

range*

"WC

(mbar)

0.2 – 2.4

(0.5 – 6)

0.4 – 4

(1 – 10)

1 – 20

(2.5 – 50)

12 – 60

(30 – 150)

40 – 200

(100 – 500)

Mean

switching

differential

at min.

and max.

setting

"WC

(mbar)

0.08 – 0.12

(0.2 – 0.3)

0.1 – 0.16

(0.25 – 0.4)

0.4 – 0.8

(1 – 2)

1.2 – 2

(3 – 5)

3.2 – 6.8

(8 – 17)

Max. inlet

pressure p

psi (mbar)

No

venting

line

2.4 psi

(165)

7 psi

(480)

max.

With

venting

line

8.5 psi

(600)

Max. inlet

pressure p

psi (mbar)

No

venting

line

7 psi

(480)

max.

With

venting

line

8.5 psi

(600)

Type

DG 10T

DG 50T

DG 150T

DG 500T

Adjusting

range*

"WC

(mbar)

0.4 – 4

(1 – 10)

1 – 20

(2.5 – 50)

12 – 60

(30 – 150)

40 – 200

(100 – 500)

Reset

pressure**

"WC

(mbar)

0.16 – 0.4

(0.4 – 1)

0.4 – 0.8

(1 – 2)

0.8 – 4.8

(2 – 12)

2 – 7.2

(5 – 18)

Connect the venting line to port 4. Connections,

see page 2 (Installation).

sible reset.

▷ If the DG..T does not trip at the desired switch-

ing point, correct the adjusting range using the

hand wheel. Relieve the pressure and repeat

the process.

USA

1)

1)

4 Set the switching point using the hand wheel.

5 Connect a pressure gauge.

USA-3

Page 4

CAN

MEX

D

Pressure switches with manual

1

reset

USA

▷

DG..NT locks off if the pressure drops to the

value set using the hand wheel.

▷

DG..HT locks off if the pressure rises to the value

set using the hand wheel.

1 Reset the pressure switch using the manual reset.

▷ Requirement for reset:

DG..NT: the pressure must have risen at least

to the set switching point plus the pressure differential between the switching pressure and

possible lock-off.

DG..HT: the pressure must have dropped at least

to the set switching point minus the pressure

differential between the switching pressure and

possible lock-off.

▷ For details of the pressure differential between

the switching pressure and possible reset, see

table on page3 (Adjustment).

Accessories

LED set, red/green

2

+

NO

2

3 COM

1 NC

NO

3

1

2

NC

4

3

COM

Tightness test

1 Shut off the downstream gas pipeline close to

the valve.

2 Open the valve and the gas supply.

▷ Check all used ports for tightness.

3 4

N

2

13 psi

max. 29 psi

< 15 min

Maintenance

In order to ensure smooth operation, check the tightness and function of the DG..T every year, or every

six months if operated with biogas

.

–

N

24 V DC, I = 16 mA; 24 V AC, I = 8 mA,

Order No.: 74921089.

110 to 230 V AC,

Order No.: 74923275.

USA-4

Page 5

CAN

MEX

D

Pilot lamp set, blue

1

2

COM

N

NO

NO

2

3

L1

3

2

1

NC

L1

3

COM

1

NC

N

NO

NC

NO

NO

1

2

NC

1

2

NC

4

3

COM

N

3

COM

N

110/120 V AC, I = 1.2 mA,

Order No.: 74916121.

Further information about accessories can be found

in Technical Information bulletin DG (identical to

DG..T)– www.docuthek.com

Technical data

Gas type: natural gas, town gas, LPG (gaseous),

flue gas, biogas (max. 0.1%-by-vol. H

Max. inlet pressure p

see page 3 (Adjustment).

= withstand pressure,

max.

Max. test pressure for testing the entire system: temporarily (<15minutes) 29psi (2bar).

Switching capacity:

DG..T

U I (

max. 240 V AC max. 5 A max. 0.5 A

cos φ = 1)

DG..TG* < 30 V AC/DC max. 0.1 A max. 0.05 A

*

With gold contacts

Maximum medium and ambient temperatures:

-40 to +140°F (-40 to +60°C).

Long-term use in the upper ambient temperature

range accelerates the ageing of the elastomer materials and reduces the service life (please contact

manufacturer).

The set switching point may palpably change in me-

dia and ambient temperatures below -22°F (-30°C).

Storage temperature: -4 to +104°F

(-20 to +40°C).

Diaphragm pressure switch, silicone-free.

Diaphragm: NBR.

Housing: glass fibre reinforced PBT plastic with

low gas release.

Lower housing section: AlSi 12.

Enclosure: IP65. Safety class: 1.

Cable diameter: AWG24 to AWG13

(0.02 to 0.07" (0.5 to 1.8mm)).

Line entrance: ½" NPT conduit.

Electrical connection type: screw terminals.

Max. tightening torque, see Technical Information

bulletin DG.

Safety information, see Safety manual DG (identical to DG..T)– www.docuthek.com.

Weight: 9.5 to 11.3 oz (270 to 320 g).

Dimensions

S) and air.

2

I (

cos φ = 0.6)

USA

2.76"

(70 mm)

0.43"

(11 mm)

3"

(76 mm)

1/2" NPT

USA-5

Page 6

CAN

MEX

D

Logistics

Transport

USA

Protect the unit from external forces (blows, shocks,

vibration). On receipt of the product, check that the

delivery is complete, see page1 (Part designations). Report any transport damage immediately.

Storage

Store the product in a dry and clean place.

Storage temperature: see page5 (Technical data).

Packaging

The packaging material is to be disposed of in

accordance with local regulations.

Disposal

Components are to be disposed of separately in

accordance with local regulations.

Certification

Directive on the restriction of the use of

hazardous substances (RoHS) in China

Scan of the Disclosure Table China RoHS2– see

certificates at www.docuthek.com

FM approved

Factory Mutual Research Class: 3510 Flow and pressure safety switches.

Designed for applications pursuant to NFPA 85 and

NFPA 86.

UL listed

UL 353 Limit control.

Underwriters Laboratories

Contact

If you have any technical questions, please contact

your local branch office/agent. The addresses are

available on the Internet or from ElsterGmbH.

We reserve the right to make technical modifications

in the interests of progress.

Strotheweg 1, D-49504 Lotte (Büren)

Elster GmbH

Tel. +49 541 1214-0

Fax +49 541 1214-370

hts.lotte@honeywell.com, www.kromschroeder.com

USA-6

Loading...

Loading...