Page 1

UDC3000

L

Versa-Pro

Universal Digital Controller

Overview

The UDC3000 Universal Digital

Controller is Honeywell’s general

purpose microprocessor-based,

stand alone digital controller. It

combines the highest degree of

functionality and operating simplicity offered in a 1/4 DIN size.

The bright dual displays with multilanguage prompts make the

operator interface easy to read,

understand, and operate.

Programmed sequences of displays assure quick and accurate

entry of all configurable parameters. Simple keystrokes let you

select input and range configuration, set the operating parameters

that meet your process control

needs now, and change them later

to meet new ones.

Features

Dual Displays -

cent alphanumeric displays and

indicators with dedicated PV

display.

Deviation Bargraph -

indication or up to ± 10% deviation

display.

Easy Configuration -

language prompts, in programmed

sequence, provide guidance during

configuration. Individual, reliable

tactile keys provide positive

operator feedback. There are no

internal jumpers to set.

Universal Isolated Input -

Input 1 accepts 10 thermocouple

types, RTDs, Radiamatic RHs, mA,

mV or voltage inputs through

keyboard configuration. It is isolated

from Input 2 and all other circuits.

(See Table 1.)

Thermocouple Failsafe -

Configurable upscale or downscale

burnout and failsafe output level.

Decimal Point Location -

Configurable for none, one, or two

places.

Vacuum fluores-

“On Control”

Multi-

Figure 1 - UDC3000 Versa-Pro Controller

Accutune II

truly plug and play tuning algorithm,

which will, at the touch of a button

or through a digital input, accurately

identify and tune any process

including those with deadtime and

integrating processes. This speedsup and simplifies startup plus allows

retuning at any setpoint. Also

included is the original Accutune SP

Adaptive tuning that can

automatically retune whenever a SP

step change is implemented.

Fuzzy Logic -

uses fuzzy logic to suppress

process variable overshoot due to

SP changes or externally induced

process disturbance. It operates

independently from Accutune

tuning. It does not change the PID

constants, but temporarily modifies

the internal controller response to

suppress overshoot. This allows

more aggressive tuning to co-exist

with smooth PV response. It can be

enabled or disabled depending on

the application or the control

criteria.

TM

ALM

DI

RSP

OUT

FUNCTION

SET UP

- Provides a new,

This new feature

F C

1 2

1 2

1 2

SP 3000

LOWER

DISPLAY

L

51-52-03-07

Page 1 of 12

Specification

MAN

3000

MANUAL

AUTO

Manual/Automatic Modes -

Bumpless, balanceless transfer

between control modes.

Two Local Setpoints -

configured to provide two local

setpoints, keyboard or optional

remote switch selectable.

Universal Switching Power -

Operates on any line voltage from

90 to 264 Vac 50/60 Hz without

jumpers. 24V ac/dc instrument

power available as an option.

Limit Control -

relay which is activated whenever

the PV goes above or below a

preset setpoint value. An alarm

indicator will light when the output is

activated. Reset is through a key on

the front of the controller or an

external switch.

Setpoint Rate -

ramp rate to be applied to any local

setpoint change. A separate

upscale or downscale rate is

configurable. A single setpoint ramp

is also available as an alternative.

%

SETPOINT

SELECT

RUN

HOLD

22069

Can be

provides a latching

Lets you define a

2/97

Industrial Automation and Control, 110 Virginia Drive, Fort Washington, PA 19034

Printed in U.S.A. ■ Copyright 1997 Honeywell Inc.

Page 2

51-52-03-07

Page 2

Features, continued

CE

Mark-

73/23/EEC, Low Voltage Directive

and 89/336/EEC, the EMC Directive

Moisture Resistant Front Panel -

Capable of meeting NEMA 3 and

IEC529 IP65 (i.e. hosedown)

requirements.

Timer -

vides a configurable time period of

0 to 99 hours, 59 minutes. Alarm 1

is dedicated to be active at the end

of the timeout period. Timer “start”

is selectable as either the

RUN/HOLD key or Alarm 2. The

optional Digital Input can also be

configured to start the Timer in

addition to either the keyboard or

Alarm 2. The Timer status shown in

the lower display is selectable as

either time remaining or elapsed

time.

Two Sets of Tuning Constants -

Two sets of PID parameters can be

configured for each loop and

automatically selected.

Heat/Cool Capability -

split range control with independent

PID tuning constants - one for

heating, one for cooling, plus mixed

output forms.

Alarm Selection -

two relays to activate external

equipment when preset high/low

setpoints are reached. There is an

indicator for each alarm.

Setpoint Ramp -

programmable setpoint ramp of up

to 255 minutes duration which is

repeatable and activated by the

Run/Hold key.

Output Rate Limiter -

output rate may be configured for

both the upscale and downscale

output directions.

Data Security -

board security protect tuning,

configuration, and calibration data,

accessed by a configurable 4-digit

code. Nonvolatile EEPROM

memory assures data integrity

during loss of power.

Quality/Support -

covered by a 2-year warranty and

backed up by a toll-free phone

number for technical assistance.

Conformity with

This standard feature pro-

Provides

None, one, or

Provides single

A maximum

Five levels of key-

The UDC3000 is

Optional Features (Fig. 4)

Second Input - Isolated high level

input available for remote setpoint

signal, PV signal via digital inputs,

or motor slidewire input. (Table 1)

Auxiliary Output* - This isolated

Auxiliary Output can be scaled from

4-20 mA for 0 to 100% for any

range. It can be configured to

represent Input 1, Input 2, PV,

active Setpoint, Local SP1,

Deviation, or the Control Output.

Communications* - Provides a link

between the UDC3000 and a

Honeywell supplied interface device

capable of communicating via

RS232 (DMCS), or direct

communication via the RS422/485

communications option to a host

computer.

Approval Body Options - FM

approval, CSA certification and UL

Recognition are available options.

UL Recognition applies to

regulatory use only.

2 Digital Inputs - Allows remote

dry contact closure to select one of

the following for each digital input:

• Manual control mode

• Local setpoint 1

• Local setpoint 2

• Direct controller action

• Reset of Limit Controller

• Hold SP Ramp/Programming

• Select PID set 2

• PV = Input 2

• External program reset

• Disable PID integral action

• To Run - SP Ramp/Program

• To Automatic output value

• Manual mode, failsafe output

• Disable keyboard

• Start Timer

• To Auto/Manual Station

• ToTune

Also allows the following selections

to be combined with the above

selections:

• Select PID set 2

• Direct controller action

• Local setpoint 2

• Disable adaptive tune

Transmitter Power - Provides up

to 30 volts to power a 2 wire

transmitter (requires use of alarm 2

open collector output selection or

auxiliary output.)

* AuxOut and communications are mutually

exclusive (only one may be specified).

Optional Features continued

Auto/Manual Station Plus Backup

Control - You can use a single

UDC3000 to act as both an

Auto/Manual Station PLUS a backup PID Controller, should the

primary loop controller fail. Since

the PID control is sometimes

implemented in the PLC, this

feature provides a very costeffective way to insure the process

does not have to shutdown or

remain in manual mode if the PLC

should fail. Switching from the

Auto/Manual Station to the back-up

control mode is accomplished using

the Digital Input option.

Setpoint Ramp/Soak

Programming - Enables you to

program and store 6 Ramp and 6

Soak segments for setpoint

programming. Run or Hold of

program is keyboard or remote

switch selectable.

Physical Description

The controller is housed in a 5.8

inch deep, black metal case with a

dark gray elastomer bezel, that can

be panel mounted in a 1/4 DIN

cutout, (see Figure 5.) The plug-in

chassis allows easy access to the

controller board and its various

option boards. All power, input, and

output wiring are connected to

screw terminals on the rear panel,

(see Fig 6.) Blue and tan elastomer

bezels are optionally available.

Inputs

Each analog input is sampled 3

times a second, amplified and

then converted to a digital signal

which is isolated and passed to

the microprocessor. The primary

input can be one of various

Thermocouple, Radiamatic, or

Linear actuations, (see Table 1.)

A second input provides a remote

setpoint function and accepts a 4

to 20 mA or 1 to 5 Vdc range that

can be characterized. All ranges

are keyboard selectable. External

cold junction compensation is

provided. You can select upscale

downscale, or failsafe sensor

break protection. A configurable

digital filter of 0 to 120 seconds for

each Input provides input signal

smoothing, if required.

Page 3

51-52-03-07

Page 3

Output Types

The following output types are

available per the model selection

guide:

• Current output

• Electromechanical relays

• Solid state relays

• Open collector output

• Solid state relay (10 amp)

externally mounted (optional)

• Auxiliary current output

(optional)

Output Algorithms

The UDC3000 is available with one

or more of the following output

algorithms:

Time Proportional - provides OnOff or Time Proportional (Relay)

output.

Current Proportional - supplies

proportional direct current output for

final control elements which require

a 4-20 mA signal.

Position Proportional - positions a

reversible motor with a feedback

slidewire in proportion to the output

of the control algorithm. Requires 2

output relays.

Time Proportional Duplex -

depending on which control

algorithm you select, this duplex

output algorithm can provide OnOff Duplex, Time Proportional

Duplex, or 3 Position Step Control.

The time proportional duplex output

provides independent PID tuning

constants and two time proportional

outputs; one for heat zone above

the 50% output, and one for cool

zone below 50% output.

Current Proportional Duplex -

similar to current proportional but

provides a second set of tuning

parameters and a split range

current output or a second current

output via the Auxiliary output

option, for the heat and cool zones.

Output Algorithms, cont

Current/Relay Duplex (Relay =

Heat) - a variation of Duplex with

Current active for 0 to 50% output

(Tuning Set 2) and Relay active 50

to 100% output (Tuning Set 1).

Current/Relay Duplex (Relay =

Cool) - a variation of Duplex with

Current active for 50 to 100%

output and Relay is active for 0 to

50% output.

“Universal” Output Model Flexibility of the Output Algorithms

allows the Current Output Model

with 2 Alarms (DC300K-E) to be

also configured for time simplex,

time duplex, or three position step

control plus, of course, the original

capability of current simplex and

current/time duplex control. A Relay

Output Model with Auxiliary Output

can also be configured for these

output algorithms.

Control Algorithms

Depending on the output algorithms

specified, the controller can be

configured for the following control

algorithms:

• On-Off

• PID-A

• PID-B

• PD with Manual Reset

• Three Position Step Control

The Three Position Step

Control algorithm allows the

control of a valve (or other actuator), with an electric motor

driven by two controller output

relays; one to move the motor

upscale, the other downscale

without a feedback slidewire

linked to the motor shaft.

Accutune does not apply to this

algorithm. Features of this

algorithm are:

1. The controller can use all

three modes of control

(PID) instead of PI only.

2. Three Position Step is an

automatic backup mode to

Position Proportional

Control if the feedback

slidewire signal should fail.

Configuration

You decide how the controller is to

interact with the process by selecting, through simple keystrokes, the

functions you want.

Multi-language prompts guide the

operator step-by-step through the

configuration process assuring

quick and accurate entry of all

configurable parameters. There are

no internal jumpers, all configuration is via the keyboard. Five

languages are available via

configuration; English, French,

German, Spanish and Italian.

Control Modes

Manual or Automatic control with

bumpless, balanceless transfer

between modes is a standard

feature. In the manual mode, the

operator directly controls the

controller output level. In the

automatic mode, the controller will

operate from a local setpoint, or a

remote setpoint provided at the

second input or via

communications.

Alarms

Alarm output terminals are located

at the rear terminal panel. One or

two electromechanical alarm relays

are available to activate external

equipment when preset alarm set

points are reached. Each of the two

alarms can be set to monitor two

independent set points. Each alarm

setpoint can be either high or low

alarm. The alarm type can be

selected to be either of the inputs,

the Process Variable, Deviation,

Output, Shed from communications

or to alarm on manual mode. It can

also be used as an On or Off event

at the beginning or end of a

Ramp/Soak segment. The alarm

hysteresis is configurable from 0 to

100% of range.

Page 4

51-52-03-07

L

Page 4

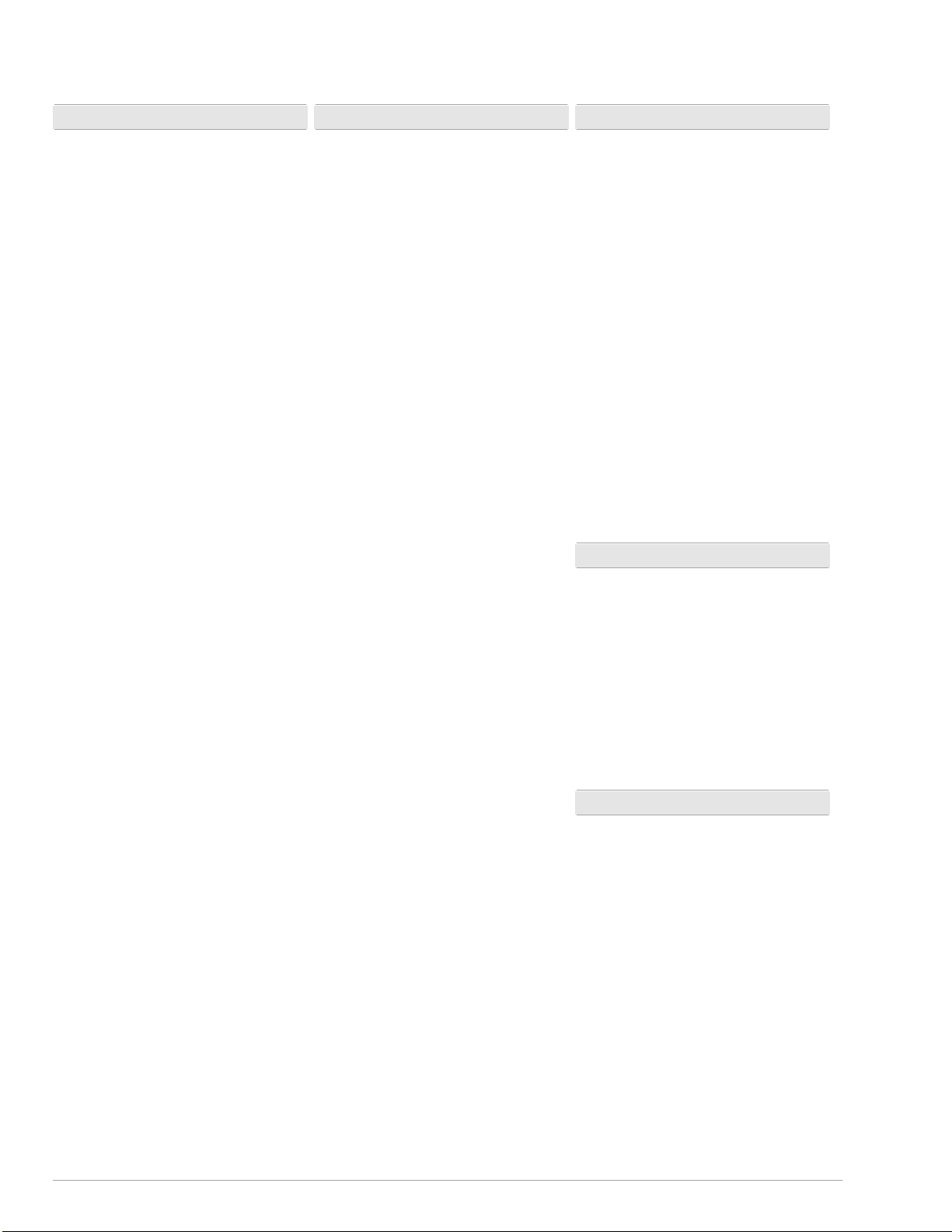

R - Run SP Ramp/Program

H - Hold SP Ramp/Program

Indicator definition when lit

ALM - Alarm conditions exist

DI - Digital Input active

RSP - Remote SP or SP2 active

OUT - Control Relay 1 or 2 on

Keys - See below

Upper Display - Six Characters

• Normal Operation - four digits dedicated to display the process variable

• Configuration Mode - displays parameter value or selection

Lower Display - eight characters

• Normal Operation - displays operating parameters and values

• Configuration Mode - displays function groups and parameters

Indicator definition when lit

F - °Fahrenheit being used

C - °Centigrade being used

ALM

1 2

DI

1 2

RSP

OUT

1 2

SP 3000

FUNCTION

SET UP

LOWER

DISPLAY

F C

R

MAN - controller in manual mode

A - controller in automatic mode

MAN

3000

MANUAL

AUTO

%

SETPOINT

SELECT

RUN

HOLD

Deviation Bargraph

• Center bar indicates PV is

within ± 1% of setpoint.

• Next bar will light if PV is

between ±1% but less than

±2% in deviation.

• If PV is equal to or greater than

±10% deviation, the center bar

plus all ten deviation bars will

light.

MAN and A off —

communications

option active

Figure 2 - Operator Interface

Operator Interface (Fig. 2)

Indicators - They provide alarm,

control mode, and temperature units

indication. There is also indication of

when Remote Setpoint is active, the

status of the control relays, and

whether a setpoint program is in Run

or Hold mode.

A 21-segment bargraph displays

deviation to ±10% of span and an

“On-Control” indicator.

Displays - A 4-digit upper display

is dedicated to the process variable during normal operation with

alternate 6-character information

displayed when in the configure

mode.

During normal operation, the lower

display shows key-selected operating parameters such as Output,

Setpoints, Inputs, Deviation, active

Tuning Parameter Set, Timer Status,

or minutes remaining in a setpoint

ramp (4 digits). It also provides

guidance, through prompts, for the

operator during controller

configuration

(8-characters).

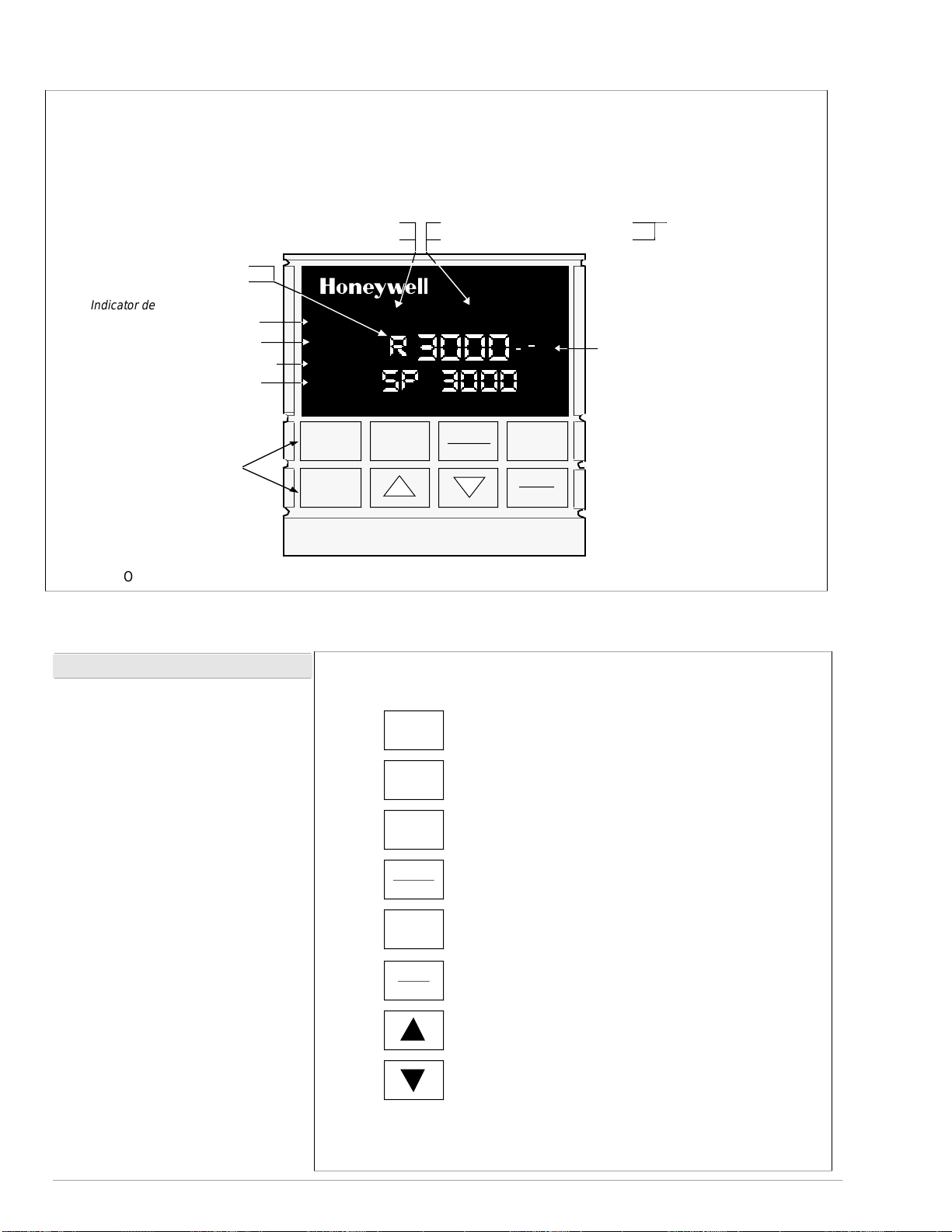

SET UP

FUNCTION

LOWER

DISPLAY

MANUAL

AUTO

SETPOINT

SELECT

RUN

HOLD

Figure 3 - Key Functions

Sequentially displays Set Up groups and allows

Function key to display individual functions.

Selects functions within each Set Up group.

Selects an operating parameter to be shown in

the lower display.

Selects Manual or Automatic control mode.

(may be disabled via configuration)

Alternately selects Local setpoint 1 and Remote

setpoint or between two local setpoints.

(may be disabled via configuration)

Initiates or holds the single setpoint ramp

or Ramp/Soak program.

(may be disabled via configuration)

Increases the setpoint, output, or

configuration values displayed.

Decreases the setpoint, output, or

configuration values displayed.

22816

22071

Page 5

Design

CE Conformity (Europe)

Product Classification:

Enclosure Rating:

Installation Category

(Overvoltage Category):

Pollution Degree:

EMC Classification:

Method of EMC Assessment:

Declaration of Conformity:

Accuracy

51-52-03-07

Page 5

Specifications

This product is in conformity with the protection requirements of the following

European Council Directives: 73/23/EEC, the Low Voltage Directive, and

89/336/EEC, the EMC Directive. Conformity of this product with any other “CE

Mark” Directive(s) shall not be assumed.

Class I: Permanently Connected, Panel Mounted Industrial Control Equipment

with protective earthing (grounding). (EN61010-1)

Panel Mounted Equipment, IP 00, this controller must be panel mounted.

Terminals must be enclosed within the panel. Front panel IP 65 (IEC 529).

Category II: Energy-consuming equipment supplied from the fixed installation.

Local level appliances, and Industrial Control Equipment. (EN 61010-1)

Pollution Degree 2: Normally non-conductive pollution with occasional

conductivity caused by condensation. (Ref. IEC 664-1)

Group 1, Class A, ISM Equipment (EN 55011, emissions), Industrial Equipment

(EN 50082-2, immunity)

Technical File (TF)

51309303-000.

± 0.20% of span typical (± 1 digit for display)

15 bit resolution typical

Temperature Stability

Input Signal Failure Protection

Input Impedance

Stray Rejection

± 0.01% of Full Scale / ˚C change

Thermocouple Inputs:

Burnout Current:

Failsafe Output Level:

4-20 Milliampere Input:

0-10 Volt Input:

All Other:

10 Megohms

Upscale or downscale burnout

0.13 microamps

Configurable 0-100%

250 Ohms

200K Ohms

Common Mode

AC (50 or 60 Hz): 120 dB (with maximum source impedance of 100 Ohms) or ± 1

LSB ((least significant bit) whichever is greater.

Normal Mode

AC (50 or 60 Hz): 60 dB (with 100% span peak-to-peak maximum)

Alarm Output One SPDT electromechanical relay.

A second alarm is available using the second control relay. This is not available

with Relay Duplex, Position Proportional, or Three Position Step control.

Up to four setpoints are independently set as high or low alarm, two for each

relay. Setpoint can be on either Input, Process Variable, Deviation,

Communication Shed, or Output. A single adjustable hysteresis of 0.0 to 100.0%

is provided. The controller can also be set to alarm on shed from

communications. The alarm can also be set as an on or off event at the

beginning of a setpoint ramp/soak segment.

Alarm Relay Contacts Rating

Resistive Load:

5 ampere at 120 Vac or 30 Vdc, 2.5A at 240 Vac.

Page 6

51-52-03-07

Page 6

Design (continued)

Specifications (continued)

Controller Output Types

Current Output (Isolated)

Range can be set anywhere between 0 to 21 mA, and as direct or reverse

action.

Resolution:

Accuracy:

Temperature Stability:

Load Resistance:

11 bits for 0 to 21 mA

0.5% full scale

0.1% F.S. / ˚C

0 to 1000 ohms

Electromechanical Relays (One or Two)

SPDT contacts. Both Normally Open and Normally Closed contacts are brought

out to the rear terminals.

Internally socketed

Resistive Load:

Inductive Load:

Motor:

1/6 H.P.

5 amps @ 120 Vac, 2.5A at 240 Vac or 30 Vdc

50 VA @ 120 Vac or 240 Vac

Solid State Relays (One or Two)

SPST solid state contacts consisting of a triac N.O. output.

Internally socketed

Resistive Load:

Inductive Load:

1.0 amp @ 25 ˚C and 120 or 240 Vac

0.5 amp @ 55 ˚C and 120 or 240 Vac

50 VA @ 120 Vac or 240 Vac

Open Collector Outputs (One or Two)

Maximum Sink Current:

Overload Protection:

Internally powered @ 30 Vdc

Opto-isolated from all other circuits except current output, but not from each

other.

Socketed jumper assembly replaces relay.

20 mA

100 mA

Solid State Relays (10 amps)

One or two externally mounted triac N.O. outputs for use with open collector

outputs.

Resistive Load:

Inductive Load:

Motor Rating:

15 amps @ 25 ˚C and 120 or 240 Vac

10 amps @ 55 ˚C and 120 or 240 Vac

50 VA @ 120 Vac or 240 Vac

1 HP @ 25 ˚C

0.75 HP @ 55 ˚C

Controller Output Algorithms On-Off or Time Proportional

One relay or open collector output. Control action can be set for direct or reverse.

Time Proportional Relay Resolution:

On-Off Duplex, Three Position Step Control, or Time Proportional Duplex

Two relays or open collector outputs. Control action can be set for direct or

reverse.

Time Proportional Relay Resolution:

Current Proportional

A single 4-20 mA current output signal which can be configured for direct or

reverse action.

Current Proportional Duplex

A single split current output for both heat and cool (4-12 cool, 12-20 heat) or a

combination of current proportional output (Heat = 50 to 100% of range) and

auxiliary current output (Cool = 0 to 50% of range). Both are 4-20 mA signals

which can be set for direct or reverse action.

Position Proportional

Two SPDT electromechanical or solid state relays operate motor having a 100

ohm to 1000 ohm feedback slidewire.

Current/Time Duplex

Variation of time proportional duplex for Heat/Cool applications. Time proportional

output (heat or cool) is a relay. Current proportional output (Heat or Cool) is a 4-20

mA signal that can be fed into a negative or positive grounded load of 0 to 1000

ohms and is operational over 50% of range or the entire range.

Sampling Rate Inputs sampled 3 times a second

3.3 msec

3.3 msec

Page 7

Design (continued)

51-52-03-07

Page 7

Specifications (continued)

Auxiliary Linear Output (Optional)

(Isolated)

Communications Interface (Optional)

DMCS

RS422/485

Digital Inputs (Optional) +15 Vdc source for external dry contacts or isolated solid state contacts. The

Input Filter

21 mA dc maximum into a negative or positive grounded load or non-grounded

load of 0 to 1000 ohms.

Output range can be set anywhere between 0 to 21 mA, and as direct or reverse

action. It can be configured to represent either Input, PV, Setpoint, Deviation, or

Control output. The range of the auxiliary output, as a function of the selected

variable, can be scaled. This output can be used as a second current output for

current duplex outputs.

Resolution:

Accuracy:

Temperature Stability:

Baud Rate:

Length of Link:

Link Characteristics:

Baud Rate:

Parity:

Odd or Even

Length of Link:

Link Characteristics:

drops maximum

Digital Input option detects the state of external contacts for either of the two inputs.

On contact closure the controller will respond according to how each digital input is

configured. Opening contact causes return to previous state.

Software

seconds available on both analog inputs.

12 bits over 0 to 21 mA

0.2% of full scale

0.01% F.S. / ˚C

19200 baud

4000 ft maximum

Two wire, multi-drop proprietary protocol, 31 drops maximum

300, 600, 1200, 2400, 4800, or 19,200 baud

4000 ft maximum

Two wire or four wire, multi-drop RS422 ASCII protocol, 15

: Single pole lowpass section with selectable time constants, off to 120

Digital Displays Vacuum fluorescent, alphanumeric.

Indicators Alarm Relay Status (ALM 1 or 2)

Bargraph 21 segment, vertical Deviation bargraph

Modes of Operation Manual

Dimensions See Figure 5.

Mounting Panel-mounted, 5.82 inch depth

Wiring Connections Screw terminals on the rear of the case. (See Figure 6.)

Power Consumption 18 VA maximum

Power Inrush Current

A six-character upper display dedicated to the process variable (4 digits).

Alternate information displayed during configuration mode.

A eight-character lower display primarily shows key selected operating parameters

(4 digits). Also provides guidance during controller configuration.

Control Mode (A or MAN)

Temperature Units (F or C)

Remote Set Point or SP2 Active (RSP)

Control Relay Status (OUT 1 or 2)

Digital Input Status (DI 1 and 2)

Center bar lit when “on” control

Deviation to ± 10% of PV span in 1% increments

Automatic with local setpoint

Automatic with remote setpoint (2-input units only)

10A Max. for 4 ms (under operating conditions)

CAUTION

sufficient power is supplied. Otherwise, the controllers may not start up normally

due to voltage drop from the inrush current.

When applying power to more than one UDC3000, make sure that

Weight 1.3 kg (3 lbs.)

Page 8

51-52-03-07

Page 8

Specifications (continued)

Environmental and Operating Conditions

Parameter Reference Rated Operative Limits Transportation and storage

Ambient

Temperature

Relative Humidity 10 to 55* 10 to 90* 5 to 90* 5 to 95*

Vibration

Frequency (Hz)

Acceleration (g)

Mechanical Shock

Acceleration (g)

Duration (ms))

Voltage (Vdc) +24 ± 1 20 to 27 20 to 27 - -

Voltage (Vac)

90 to 264Vac

(CSA models rated to 250V max.)

25 ± 3˚C

77 ± 5˚F

0

0

0

0

120 ± 1

240 ± 2

15 to 55

58 to 131

0 to 70

0.1

1

30

90 to 264

˚C

˚F

0 to 55˚C

32 to 131

0 to 200

0.5

5

30

90 to 264

˚F

-40 to 66˚C

-40 to 151

0 to 200

0.5

20

30

- -

- -

˚F

24Vac

Frequency (Hz)

(For Vac)

* The maximum rating only applies up to 40˚C (104˚F). For higher temperatures, the RH specification is derated to maintain constant moisture content.

24 ± 1

50 ± 0.2

60 ± 0.2

20 to 27

49 to 51

59 to 61

20 to 27

48 to 52

58 to 62

- -

- -

- -

Table 1 - Input Actuations

Range

PV Input ˚F ˚C

Thermocouples

B*

E*

E (low)

J

J (low)

K

K (low)

NiNiMoly (NNM)

NiNiMoly (NNM low))

NIC (Nicrosil Nisil)

R

S

T

T (low)

W5W26

W5W26 (low)

RTD

(IEC) ALPHA = 0.00385

100 Ohms

100 Ohms (low)

500 Ohms

Radiamatic RH 1400 to 3400 760 to 1871

Linear**

Milliamps

Millivolts

Volts

0 to 3300

-454 to 1832

-200 to 1100

0 to 1600

20 to 770

0 to 2400

-20 to 1000

32 to 2500

32 to 1260

0 to 2372

0 to 3100

0 to 3100

-300 to 700

-200 to 500

0 to 4200

0 to 2240

-300 to 1200

0 to 300

-300 to 1200

4 to 20 mA

0 to 10 mV

10 to 50 mV

1to5V

0 to 10V

-18 to 1815

-270 to 1000

-129 to 593

-18 to 871

-7 to 410

-18 to 1316

-29 to 538

0 to 1371

0 to 682

-18 to 1300

-18 to 1704

-18 to 1704

-184 to 371

-129 to 260

-18 to 2316

-18 to 1227

-184 to 649

-18 to 149

-184 to 649

Optional 2nd Input

Milliamps

Volts

Slidewire for Position

Proportioning

* May require Field calibration to achieve rated accuracy below 1000 ˚F for type B and below -200 ˚F for type E thermocouple.

** Not available on FM approved Limit models.

4 to 20 mA

1to5V

100 to 1000Ω

Page 9

Data

Isolation

(Functional)

Surge Withstand

Capability (SWC)

Radio Frequency

Interference (RFI)

51-52-03-07

Page 9

General Reference Data

AC Power :

1900Vdc for 2 seconds per Annex K of EN61010-1.

Analog Inputs and Outputs:

Digital Input and Digital Output:

Relay Contacts:

345 Vdc for 2 seconds.

Immunity:

input and relay contact outputs: 2.5 kV, Common Mode and Differential Mode. All other circuits: 1.0 kV,

Common Mode and Differential Mode.

Immunity

meter from the controller.

is electrically isolated from all other inputs and outputs to withstand a HIPOT potential of

are isolated from each other and all other circuits at 850Vdc for 2 seconds.

are isolated from all other circuits at 850Vdc for 2 seconds.

with a working of 115/230 Vac, isolated from each other and all other circuits at

ANSI/IEEE C37.90.1, Surge Withstand Capability (SWC) (Formerly IEEE 472) Mains power

: No effect on performance from a 5 W walkie-talkie operated at 27, 151 or 450 MHz, one

Model Number Interpretation

Table 1 Table 2 Table 3 Table 4 Table 5Key Number

DC3 00

0

Output #1

C = Current 4 – 20mA without Alarms

K = Current 4 – 20mA with Alarm 1

E = Relay, Electromechanical – 5AMP with Alarm 1

A = Relay, Solid State AC – 1AMP with Alarm 1

T = Open Collector Output – 20mA with 1 Alarm

Output #2 or Alarm #2

O = None

E = Relay, Electromechanical – 5AMP (SPDT)

A = Relay, Solid State AC – 1AMP (SPST)

T = Open Collector Output – 20mA

External Interface

O – – = None

1 – – = RS422/485

2 – – = Auxiliary Output

4 – – = DMCS

Software Options

– O – = None

– A – = Accutune

– B – = Setpoint Program and Accutune

Digital Inputs

– – O = None

– – 3 = Digital Inputs (2)

Options

0 – – – =

1 – – – =

B – – – =

T – – – =

C – – – =

D – – – =

– 0– – =

– A – – =

– F – – =

– – 0– =

– – T – =

– – – 0 =

– – – D =

Optional Input

– 0 =

– 1 =

– 2 =

PV Input

1 – =

T/C, RTD, mV, 1–5V

2 – =

T/C, RTD, mV, 1–5V,

4–20mA

3 – =

T/C, RTD, mV, 1–5V,

4–20mA,0–10V

90-264Vac Power

24Vac/dc Power

Blue Bezel with

90-264Vac Power

Tan Bezel with

90-264 Vac Power

Blue Bezel with

24Vac/dc Power

Tan Bezel with

24Vac/dc Power

None

Approvals CSA,FM,UL

Approvals - FM,

CSA

None

Customer I.D. Tag

None

DIN Cutout

Adapter

None

4–20mA or 1–5V

Slidewire Input for Position

Proportional or 3 Position

Step with motor position

indication

22603

Figure 4 - Model Number Interpretation

Page 10

51-52-03-07

L

L

L

Page 10

Dimensions

24

.945

96

3.780

Max Panel

Thickness

ALM

ALM

AL

DI

PV

DI

M

RSP

RSP

OUT%1 2

OUT

FUNCTION

SET UP

1 2

1 2

1

1 2 3 4

1 2

1

2

2

1 2

1 2

96

3.780

F C

F

C

LOWER

DISPLAY

F C MAN

MAN

M

A

N

MANUAL

AUTO

%

%

SETPOINT

SELECT

RUN

HOLD

10

.394

Max (2)

92

3.622

+0.008

-0.0

+0.03

-0.0

Panel Cutout

2.4

.093

92

3.622

+0.008

-0.0

+0.03

-0.0

with optional

rear cover

21.6

.850

Figure 5 - UDC3000 Versa-Pro Controller dimensions - not to scale

147.3

5.82

90.7

3.57

22073

Page 11

Wiring Diagram

51-52-03-07

Page 11

L1/H

Instrument Power

L2/N

22

23

24

25

26

27

NOTE:

The product manual should be consulted for specific details and precautions regarding wiring.

Figure 6 - External Wiring Diagram

0

IN 2

IN 1

UDC 3000 EXTERNAL WIRING

10

11

12

13

14

15

16

17

DI 1

DI 2

SHIELD

RX+/TX+

RX-/TX-

TX+ or AUX+

TX- or AUX-

1

2

3

4

5

6

7

8

9

!

CTL 1

4-20 MA

CTL 2

ALM 2

ALM 1

22840

Page 12

51-52-03-07

Page 12

Ordering Information

For the complete ordering information, request Model Selection Guide:

51-51-16-32 for UDC3000 Universal Digital Controller or .

.

Honeywell offers a full Iine of Sensors, Transmitters, and Final Control Devices for use with the UDC3000

Universal Digital Controller. These devices include:

Thermocouples, RTDs

Pressure Transmitters,

Flow Transmitters,

Liquid Level Transmitters.

Valve, Actuators, and Electric Motors.

Specifications are subject to change without notice.

Distributor :

For more information, contact your nearest Honeywell Response Center listed below.

Industrial Automation and Control

Honeywell Inc.

In the U.S.A.:

In Europe:

In Japan:

In Asia:

In the Mediterranean:

Honeywell Pacific Division:

In Canada:

In Latin America:

Honeywell Industrial Automation and Control, 16404 North Black Canyon HWY., Phoenix, AZ 85023, (800) 343-0228

Honeywell S.A., 80084 Amiens Cedex 2, (33) 22.54.56.56

Honeywell Control System Ltd., Honeywell House, Bracknell, UK-RG 12 1 EB, (44) 1344 826000

Yamatake-Honeywell Co. Ltd., Nagai Int’l Bldg., 2 - 12 - 19 Shibuya-Ku, Tokyo 150 Japan, 81-3-3486-2051

Honeywell Asia Pacific Inc., Room 3213-3225, Sun Hung kai Centre, No. 30 Harbor Road, Wanchai, Hong Kong, (852) 829-8298

The Honeywell centre, 155 Gordon Baker Road., Ontario M2H 3N7, 1-800-461-0013

Africa and Middle East Region, Honeywell SpA, Via Vittor Pisani 13, 20124 Milano, Italy (39-2) 67731

Honeywell Pty Ltd., 5 Thomas Holt Drive, North Ryde Sydney, NSW Australia 2113, (61-2) 353 7000

Honeywell Inc.,14505 Commerce Way, Suite 500, Miami Lakes, Florida 33016-1556, (305) 364-2300

Loading...

Loading...